腐蚀问题是制约钢铁材料安全长周期服役的关键问题之一[1~3]。近年来,越来越多的研究集中在了耐蚀合金钢的设计开发,从而有望从钢材源头来减缓腐蚀问题,其中耐候钢的开发最为引人注目[4~7]。随着关于合金元素在低合金钢致密锈层形成过程中作用机理研究的深入,总结合金元素的作用规律及机理,认为合金元素Cu、Cr、Ni等对于致密性锈层的形成起到重要作用[8~13]。但是,单靠合金化来提高低合金钢的耐大气腐蚀能力作用有限。而钢的不同组织的耐腐蚀性能不同[14,15],优化钢的组织结构是提高耐蚀性的重要途径[16~18]。近年来耐候钢的主要研究集中于锈层,而忽略了材料本身组织结构的影响。锈层的保护性主要取决于紧邻钢基体内锈层的成分和结构。紧邻基体的内锈层必然受到基体组织的影响,因此,在合金化的同时不能忽略钢的组织结构在大气腐蚀过程中的作用[6,16,19]。

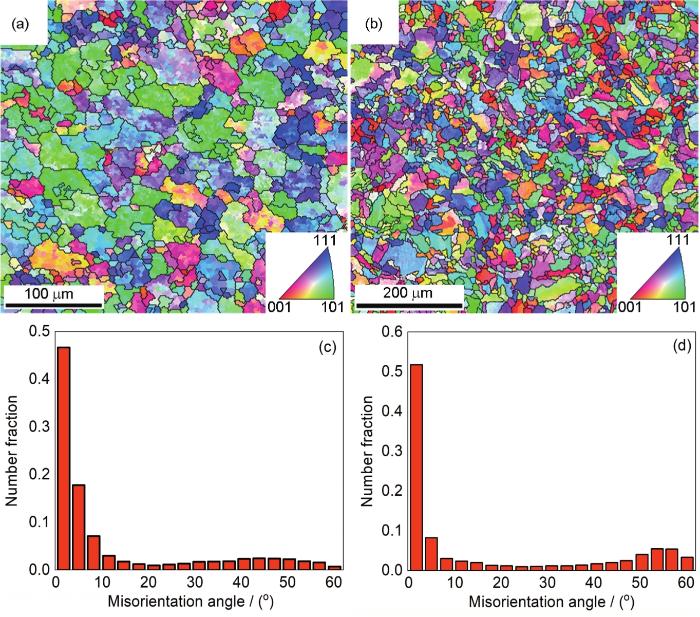

在相同的成分条件下,经过不同热处理的钢的耐腐蚀性能有很大的差别,李少坡等[20]研究表明,钢中C含量较高时,组织为单相贝氏体的钢耐蚀性较优异,而组织为铁素体和珠光体复相组织的钢耐蚀性较差。郭佳等[21]认为,在腐蚀初期,铁素体钢中的大角晶界易于被择优腐蚀,而贝氏体内的小角晶界择优腐蚀趋势较弱;铁素体裸钢具有较强的耐蚀性,但在锈层形成后,其锈层电阻随腐蚀时间的增量较小,而贝氏体锈层电阻随腐蚀时间的增量较大,长期耐腐蚀性能更优,但对于产生的原因未作出合理解释。王志奋等[22]对贝氏体钢用配备电子背散射衍射装置的扫描电镜 (SEM) 进行电子背散射衍射 (EBSD) 观察,表明贝氏体钢试样中晶界均以≤10°的小角晶界为主,≥50°的大角晶界数量较多。王力伟等[23]运用扫描Kelvin探针 (SKP) 技术测量了渗碳后的X80钢试样的Kelvin电位,表明随着材料中Fe3C含量的增加,腐蚀电位降低,退化珠光体在空气中的腐蚀电位低于铁素体。

本工作基于前期研究结果,对3% (质量分数) Cr钢进行了两种不同热处理,获得不同组织结构的3Cr钢,通过宏微观电化学、浸泡实验等方法对不同组织3Cr钢的腐蚀初期的行为及机制进行探究,从而有望进一步对耐蚀钢组织调控设计开发提供新思路。

1 实验方法

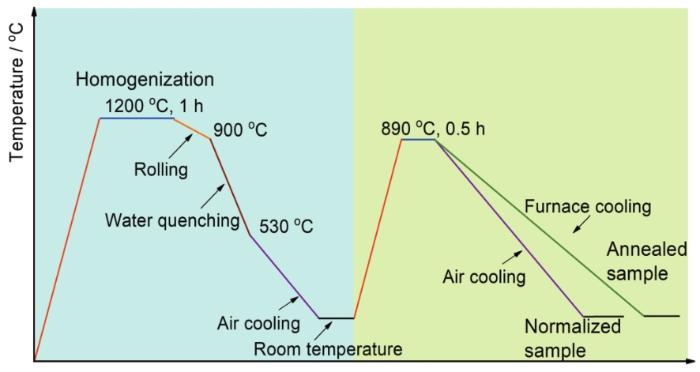

图1

图1

3Cr试验钢的热处理工艺示意图

Fig.1

Schematic diagram of the heat treatment process of the test steel

将热处理后的3Cr钢材料切割成10 mm×10 mm×3 mm样品后,将试样背面焊接导线,用环氧树脂密封后制成电化学试样,保留10 mm×10 mm裸露面打磨后进行机械抛光。电化学测试以两种热处理材料试样为工作电极,饱和甘汞电极为参比电极,洁净的铂片为对电极,采用Princeton VersaSTAT3型电化学工作站进行测试。将试样在0.5%NaCl溶液中分别浸泡3、6和9 h,然后测试电化学阻抗谱 (EIS),其中EIS测试过程中,激励电位为±10 mV,频率范围105~10-2 Hz;采用ZSimpWin软件进行拟合。

将热处理后的样品打磨,抛光,分别浸泡2和20 d后,采用Quanta 250型SEM观察试样表面腐蚀形貌,同时对浸泡20 d的样品去除腐蚀产物后进行观察,其中腐蚀产物去除按标准GB/T 16545-1996执行,除锈剂为500 mL HCl+500 mL H2O+3.5 g C6H12N4混合溶液。对去除腐蚀产物后的样品采用KEYENCE VX-200激光共聚焦显微镜 (CLSM) 测量表面腐蚀形貌变化。

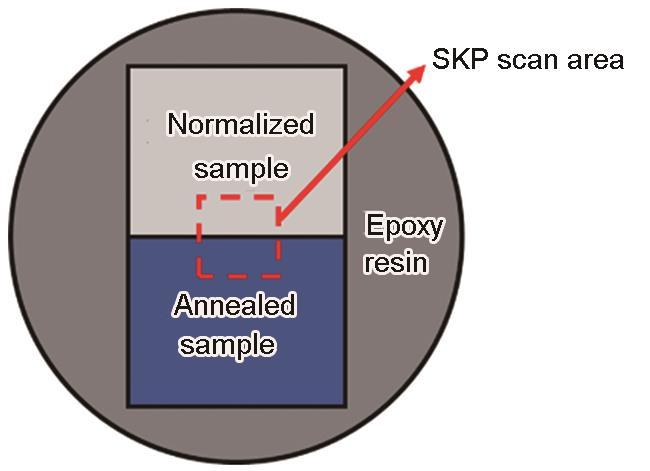

采用M370微区SKP对样品表面腐蚀前后电位信息进行采集,扫描区域示意图见图2。考虑到Kelvin探针测试原理[24~26],实验前将退火与正火试样偶接,并用万用表检查是否导电,然后将SKP样品打磨抛光至1 μm后,使用SiO2悬浮液 (OPS) 抛光至0.05 μm。分别对浸泡前和在pH 3的0.5%NaCl溶液中浸泡30 min后烘干的样品表面进行SKP测试,从而获取其表面电位分布变化情况。SKP测试时保持探针距离试样表面100 μm处,采用Step Scan扫描模式,参数如下:扫描面积500 μm×1400 μm,扫描步长设置为50 μm,其中探针振动频率和振幅分别为80 Hz和30 μm,扫描为二次扫描,其中第一次保持探针高度不变扫描试样表面形貌变化,第二次扫描时探针保持距离试样表面100 μm进行测试。图2中虚框内部位为测试区域,测试时从退火试样向上开始扫描。

图2

采用Kelvin探针原子力显微镜 (KPFM) 对不同热处理条件下组织的微区电化学信息进行分析,使用Multi Mode 8原子力显微镜进行测试,测试模式为KPFM-AM。其中扫描范围是50 μm×50 μm,测试环境为恒温25 ℃,环境相对湿度为20%的洁净室,KPFM测量中的探头是NanoprobeSCM-PIT™导电PtIr涂层硅尖端,力常数为2.8 N/m,谐振频率为75 kHz。除了表面形貌信号外,还使用双扫描模式记录第二个信号。在KPFM测量中,当尖端和样品之间存在电位差时,向尖端施加交流电压以感应悬臂的谐波振荡。然后,将相同幅度的电压施加到尖端以停止振荡并减小电位差。使用这种方法,可以推导出样本的功函数。一些研究表明,功函数与腐蚀电位密切相关。材料的功函数越低,腐蚀电位越低,腐蚀越容易[3,4]。

2 结果与讨论

2.1 组织分析

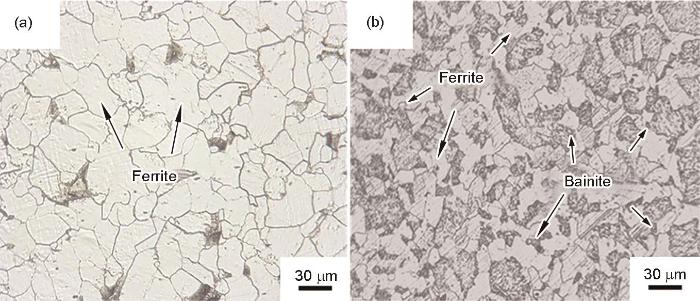

图3

图3

不同热处理条件下3Cr钢的金相组织

Fig.3

Metallographic structures of 3Cr steel under different heat treatment conditions: (a) annealed sample, (b) normalized sample

图4

图4

不同热处理条件下3Cr钢组织EBSD表征

Fig.4

EBSD characterization of 3Cr steel under different heat treatment conditions: (a) annealed microstructure, (b) normalized microstructure, (c) annealed misorientation angle analysis, (d) normalized misorientation angle analysis

2.2 初期浸泡腐蚀形貌

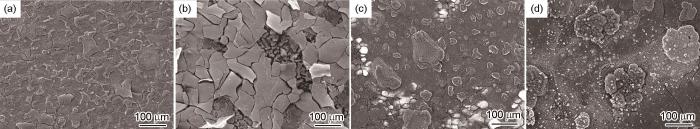

图5

图5

不同热处理条件下3Cr钢试样浸泡2和20 d后的表面腐蚀微观形貌

Fig.5

Surface corrosion micro-morphologies of 3Cr steel samples after immersion for 2 d (a, c) and 20 d (b, d) under annealed (a, b) and normalized (c, d) conditions

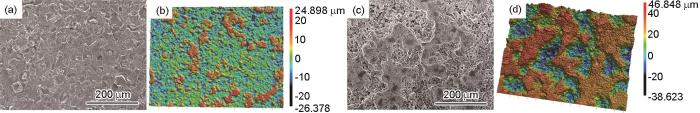

图6

图6

不同热处理条件下3Cr钢浸泡20 d后去除腐蚀产物的微观形貌和3D形貌

Fig.6

Microstructures (a, c) and 3D profile (b, d) of corrosion products removed from 3Cr steel after immersion for 20 d under annealed (a, b) and normalized (c, d) conditions

2.3 电化学结果分析

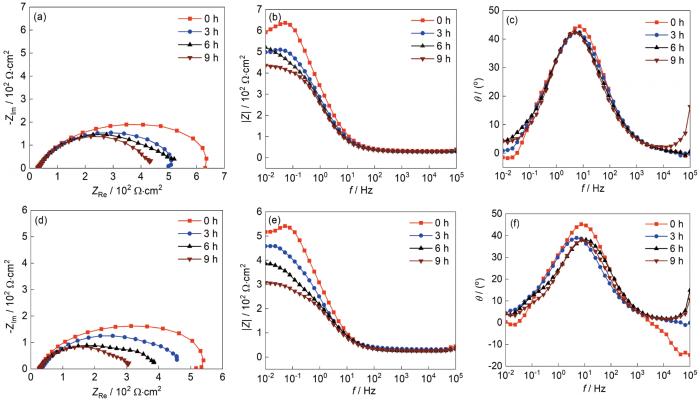

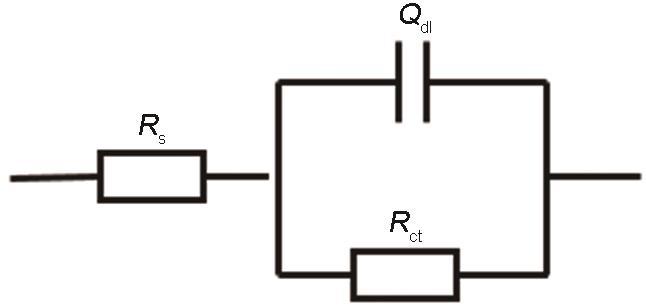

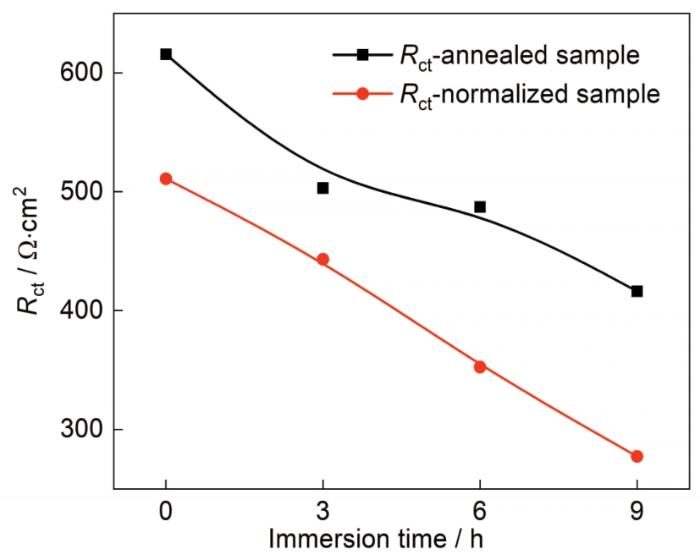

为了研究不同热处理工艺对试样表面的腐蚀初期电化学行为的影响,将试样在0.5%NaCl溶液 (pH 3) 中分别浸泡3、6和9 h,然后测试浸泡前后的电化学阻抗谱。图7a~f分别为退火和正火试样浸泡后的电化学阻抗谱。不同热处理试样在不同浸泡时间后的阻抗谱形状相似,Nyquist图中均表现为一个容抗弧特征,随着浸泡时间延长,容抗弧的半径减小;从Bode图看出,整个电化学体系中只有一个时间常数,由此可以推断出退火和正火试样在pH 3的0.5%NaCl溶液中发生腐蚀反应时,电极表面的电化学体系由一个双电层构成,因此采用图8中的R(QR) 等效电路进行拟合。其中Rs表示溶液电阻,Qdl为界面电容,Rct为电荷转移电阻。由于金属表面的弥散效应,电容C均用常相位角元件Q替换。电化学阻抗谱的拟合结果Rct变化曲线如图9所示,随着浸泡时间的延长,退火和正火试样的Rct均逐渐减小,进一步验证了Nyquist图所显示的特征趋势,说明试样在腐蚀前期,尚未形成致密的腐蚀产物保护膜层;浸泡前退火试样的Rct为615.6 Ω·cm2,而正火试样的Rct为510.9 Ω·cm2,并且在每个浸泡周期,退火试样的Rct均大于正火试样的,说明退火试样的耐蚀性能比正火试样好。

图7

图7

退火试样及正火试样在0.5%NaCl (pH 3) 溶液中浸泡不同时间后的电化学阻抗谱

Fig.7

Nyquist (a, d), impedance module (b, e) and phase angle (c, f) plots of annealed (a-c) and normalized (d-f) samples after soaking in 0.5%NaCl (pH 3) solution for different time

图8

图9

图9

两种热处理试样浸泡不同时间后的Rct变化曲线

Fig.9

Rct change curves of two heat-treated samples after immersion for different time

2.4 微区电化学结果

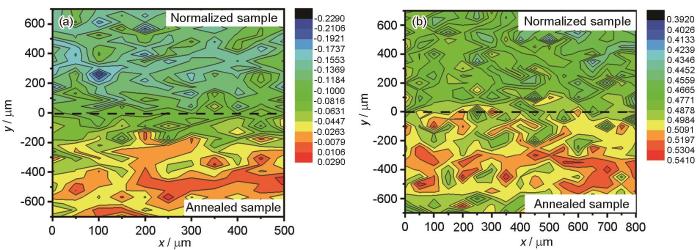

从上述结果中可以看出,微观组织的差异是导致耐腐蚀性能差异的根本原因。因此,进一步采用微区电化学 (SKP,KPFM) 手段对两种试样的微区电化学信息进行分析。图10为浸泡前后样品表面的SKP电位分布结果,二维平面图中上半部分为正火试样。

图10

图10

正火/退火偶接试样在浸泡30 min前后样品表面SKP电位分布

Fig.10

SKP potential distribution of the normalized/annealed coupled sample before (a) and after (b) immersion for 30 min

从图10a可看出,浸泡前,试样表面的电位分布离散,这可能与制样过程中样品表面损伤造成的起伏不平和状态不均匀有关[16]。此外,电位图中正火试样表面电位较低,电位集中在-0.1553 V附近;退火试样表面电位较高,电位集中在0.01057 V附近;从图10b可看出,在浸泡30 min后,正火区域表面的电位仍然较低,电位集中在0.4665 V左右,退火试样表面电位仍然较高,电位集中在0.5304 V左右;浸泡30 min后,偶接试样整个表面的电位均发生正移,说明最初形成的腐蚀产物膜对基体有保护作用。综上所述,局部腐蚀产物的SKP结果表明了浸泡前后,退火试样的电位均高于正火试样,说明在热力学上退火试样的腐蚀倾向性较低。在浸泡30 min后,由于腐蚀产物膜的生成,对基体有保护作用,偶接试样表面电位均发生正移,热力学上说明腐蚀倾向性降低[16,24,25]。

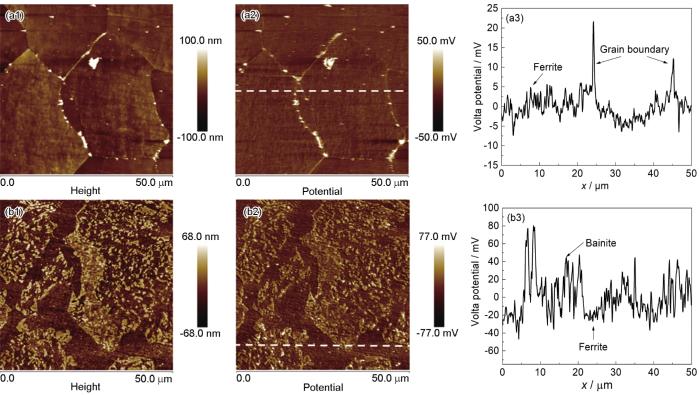

图11

图11

不同热处理条件3Cr钢试样表面形貌图、电势分布图和电势曲线分布图

Fig.11

Morphologies (a1, b1), potentials (a2, b2) and the potential change dagrams of the contour line position (a3, b3) of 3Cr steel samples under annealed (a1-a3) and normalized (b1-b3) conditions

3 结论

(1) 3Cr钢通过正火得到铁素体+贝氏体组织,通过退火得到单一铁素体组织。

(2) 两种热处理导致的组织结构差异是造成两种试样初期腐蚀形貌差异的根本原因。

(3) 相较退火组织,正火组织的微电偶效应导致其耐蚀性能下降,退火组织表现出更好的耐蚀性。

参考文献

The cost of corrosion in China

[J].Corrosion is a ubiquitous and costly problem for a variety of industries. Understanding and reducing the cost of corrosion remain primary interests for corrosion professionals and relevant asset owners. The present study summarises the findings that arose from the landmark “Study of Corrosion Status and Control Strategies in China”, a key consulting project of the Chinese Academy of Engineering in 2015, which sought to determine the national cost of corrosion and costs associated with representative industries in China. The study estimated that the cost of corrosion in China was approximately 2127.8 billion RMB (~ 310 billion USD), representing about 3.34% of the gross domestic product. The transportation and electronics industries were the two that generated the highest costs among all those surveyed. Based on the survey results, corrosion is a major and significant issue, with several key general strategies to reduce the cost of corrosion also outlined.

Materials science: Share corrosion data

[J].

A new study for healing pitting defects of 316L stainless steel based on microarc technology

[J].

Synergy of Cu and Sb to enhance the resistance of 3%Ni weathering steel to marine atmospheric corrosion

[J].

Microstructural characterisation and corrosion performance of old railway girder bridge steel and modern weathering structural steel

[J].

Atmospheric corrosion of weathering steels. Overview for engineers. Part I: Basic concepts

[J].The atmospheric corrosion of weathering steel (WS) has been extensively discussed in the scientific literature, but a comprehensive overview of this topic from an engineering viewpoint is currently lacking. The present publication seeks to fill this gap, providing engineers, designers and steel manufacturers with an insight into the current state of knowledge on this important structural material and presenting key research findings in a way that promotes their practical application. The Part I of this review is addressed to various aspects of WS atmospheric corrosion, such as corrosion mechanisms, corrosion products and layers, effect of exposure environment conditions and long term performance. A number of design and metallurgical considerations is also focused. (C) 2019 Elsevier Ltd.

Atmospheric corrosion of weathering steels. Overview for engineers. Part II: Testing, inspection, maintenance

[J].The atmospheric corrosion of weathering steel (WS) has been extensively discussed in the scientific literature, but a comprehensive overview of this topic from an engineering viewpoint is currently lacking. The present publication seeks to fill this gap, providing engineers, designers and steel manufacturers with an insight into the current state of knowledge on this important structural material and presenting key research findings in a way that promotes their practical application. The Part II of this review sets out the methods available to evaluate the protective ability of rust layers and describes testing, inspection and maintenance techniques. The paper ends with a number of examples of corrosion problems in WS structures, an overview of new advanced WS, and considers the painting of WS in highly corrosive atmospheres. (C) 2019 Elsevier Ltd.

The role of chromium content in the long-term atmospheric corrosion process

[J].The corrosion of alloy steels with different amounts of Cr was studied using electrochemical tests, wet–dry cycle corrosion, X-ray diffraction, and Kelvin probe force microscopy. The results show that the content of Cr is positively correlated with the corrosion resistance of bare steel, but the corrosion resistance of atmospheric corrosion does not show the same pattern. The atmospheric corrosion resistance of Cr-containing steel exhibits three different stages with the change of Cr element content. When the Cr content is in the range of 1–4%, the corrosion rate is high and does not change within the Cr content. As the Cr content was further increased from 4 to 7%, the corrosion rate exhibited a linear decrease and then drops rapidly when the Cr content reaches 8%. These three different corrosion rate stages are related to the influence of Cr content on Fe3O4 content in the rust layer.

Fundamental understanding on the effect of Cr on corrosion resistance of weathering steel in simulated tropical marine atmosphere

[J].

Kinetics of atmospheric corrosion of mild steel in marine and rural environments

[J].

Atmospheric corrosion data of weathering steels. A review

[J].

Optimizing the nickel content in weathering steels to enhance their corrosion resistance in acidic atmospheres

[J].

The beneficial galvanic effect of the constituent phases in 2205 duplex stainless steel on the passive films formed in a 3.5% NaCl solution

[J].

Effect of hydrogen charging on SCC of 2205 duplex stainless steel with varying microstructures in simulated deep-sea environment

[J].

In-situ characterization of the electrochemistry of grain and grain boundary of an X70 steel in a near-neutral pH solution

[J].

Insight into the product film formed on Ni-advanced weathering steel in a tropical marine atmosphere

[J].

Characterization of corrosion products formed on Ni 2.4wt%-Cu 0.5wt%-Cr 0.5wt% weathering steel exposed in marine atmospheres

[J].

A study of rust layer of low alloy structural steel containing 0.1%Sb in atmospheric environment of the Yellow Sea in China

[J].

Towards understanding and prediction of atmospheric corrosion of an Fe/Cu corrosion sensor via machine learning

[J].

Effect of carbon content and microstructure on the corrosion resistance of low alloy steels

[J].

碳含量和组织类型对低合金钢耐蚀性的影响

[J].

Incubation and development of atmospheric corrosion in the microstructures of low alloy steels

[J].

大气腐蚀在低合金钢显微组织中的发生与发展

[J].

The Effect of the microstructure on the corrosion resistance of Bainitic steel

[J].

组织结构对贝氏体钢的耐腐蚀性能影响

[J].

Influences of Fe3C and pearlite on the electrochemical corrosion behaviors of low carbon ferrite steel

[J].The microstructure of X80 pipeline steel welding joint, consisted of Fe<sub>3</sub>C and degenerated pearlite, was simulated by carburizing treatment. The effects of Fe<sub>3</sub>C and pearlite on the electrochemical properties of bainitic ferrite steel and localized corrosion occurrence regularity in Yingtan soil simulation solution were investigated by scanning Kelvin probe (SKP), scanning vibrating probe (SVP) and local electrochemical impedance spectroscopy (LEIS), combined with immersion test. It is demonstrated that the corrosion potential of degenerated pearlite is lower than bainitic ferrite, and decreases with increasing Fe<sub>3</sub>C content. Localized corrosion occurs on the surface of the carburized sample in Yingtan soil simulation solution. The anodic oxidation process is observed to be initiated on the carburized degenerated pearlite, whereas the cathodic reaction involving dissolved H<sup>+</sup> is on bainitic ferrite, and the anodic current density increases with increasing Fe<sub>3</sub>C concentration. As the ion contents of the soil simulation solution doubled, the anodic dissolution of degenerated pearlite increases, and the local impedance of the electrode decreases.

Fe3C和珠光体对低碳铁素体钢腐蚀电化学行为的影响

[J].通过对X80管线钢进行固体渗碳模拟焊接接头区域的Fe<sub>3</sub>C和退化珠光体组织,采用扫描Kelvin探针(SKP)、扫描振动参比电极(SVP)和局部电化学交流阻抗谱(LEIS)结合浸泡实验分析了Fe<sub>3</sub>C和珠光体对铁素体钢表面电化学性能以及在鹰潭土壤模拟溶液中的局部腐蚀发生规律的影响. 结果表明, 退化珠光体组织在空气(湿度为40\%, 温度为22 ℃)中的腐蚀电位低于贝氏体铁素体, 并且随着Fe<sub>3</sub>C含量的增加, 腐蚀电位降低; 渗碳试样在鹰潭模拟溶液中发生局部腐蚀,中心铁素体区为整个材料电偶腐蚀的阴极, 退化珠光体和退化珠光体/贝氏体铁素体区为阳极, 随着Fe<sub>3</sub>C含量的增加, 阳极溶解电流密度增大;模拟溶液各离子含量成倍增加后, 退化珠光体的阳极电流密度升高, 电化学交流阻抗值降低, 局部腐蚀效应增大.

SVET, SKP and EIS study of the corrosion behaviour of high strength Al and Al-Li alloys used in aircraft fabrication

[J].

Application of micro area electrochemical scanning technology

[J].

微区电化学扫描技术应用现状

[J].

Review on corrosion test methods and evaluation techniques for materials in atmospheric environment

[J].

材料大气环境腐蚀试验方法与评价技术进展

[J].

Improved stress corrosion cracking resistance of high-strength low-alloy steel in a simulated deep-sea environment via Nb microalloying

[J].

Corrosion behavior of X65 pipeline steel in coastal areas

[J].To study the corrosion behavior of pipeline steel in coastal areas, a tidal seawater macro-cell corrosion device was built using a cycle soaking tank and a macro-cell corrosion facility to simulate the corrosion behavior of pipeline steel in a simulated coastal environment (dry and wet alternations during seawater-soil corrosion macro-cell processes).