我国华北、西北和东北地区分布有大量盐碱地,这些地区的建筑大多面临氯盐、镁盐及硫酸盐等多重环境因素的耦合侵蚀影响,导致此地区建筑服役寿命缩短[1]。以矿渣和粉煤灰为胶凝组分的传统地聚物材料在抗Cl-渗透性[2]和抗硫酸盐侵蚀性[3]等方面均优于硅酸盐水泥混凝土材料。Wang等[4]对高钙、低钙、无钙3种类型地聚物与普通硅酸盐混凝土在硫酸盐腐蚀、酸腐蚀、氯化物侵蚀下的耐久性研究表明,3种类型地聚物比普通硅酸盐混凝土具有更好的耐久性。Saptamongkol等[5]研究表明,以高钙粉煤灰与玻璃棉废料为原材料制备的地聚物在抗H2SO4及MgSO4侵蚀方面也有较好的表现。盐碱地中的SO

我国尾矿每年年产量约10亿吨,综合利用率仅仅约为32.5%[6],铁尾矿(Iron tailings,IT)的综合利用率仅为7%左右,相较于发达国家60%的利用率相差巨大[7]。铁尾矿大量堆积不仅占用大量土地,对土壤、水和大气造成污染,而且还会造成资源浪费。将铁尾矿应用到建筑材料中具有一定的经济价值和环保效益。相对于矿渣和粉煤灰的资源化利用,铁尾矿在地聚物中的应用研究并不充分。为了明确盐碱地环境下,钢筋在铁尾矿基地聚物中的锈蚀规律以及铁尾矿基地聚物对钢筋的保护效果,本文通过配置模拟盐碱地环境的溶液,利用恒电流加速锈蚀[8]的方法,通过控制铁尾矿掺量、水胶比、碱激发剂的模数和碱掺量,设计正交试验来研究不同配合比铁尾矿基地聚物中钢筋在盐碱地环境下的锈蚀行为,并分析各因素对铁尾矿基地聚物-钢筋试块的电化学参数的影响规律,得到抗锈蚀性能最好的配合比。

1 实验方法

1.1 原材料

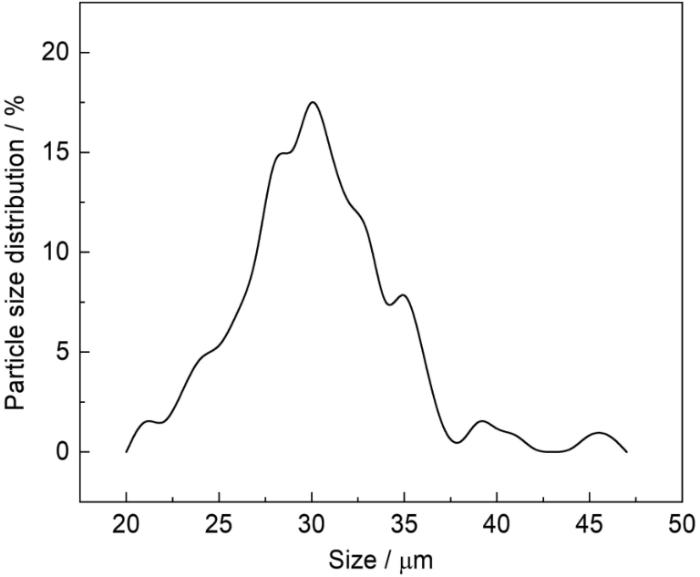

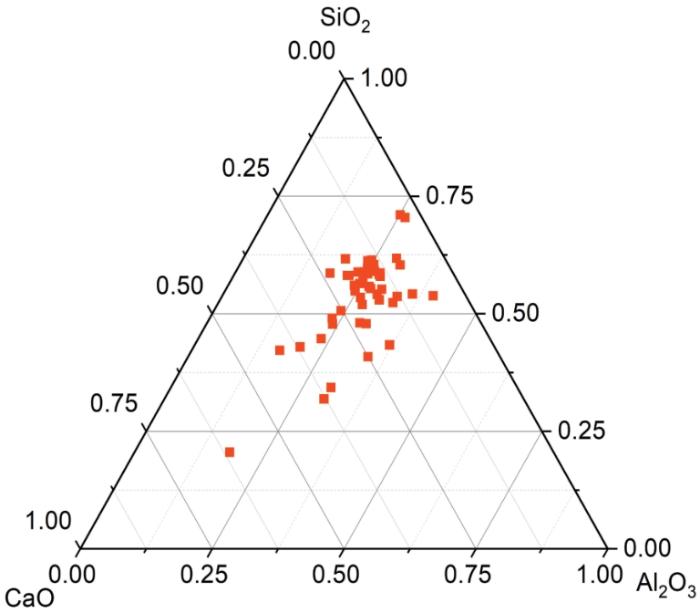

铁尾矿砂取自石家庄市平山县,在使用之前进行过筛及水洗处理,粒径介于0.2~2 mm之间。铁尾矿粉由铁尾矿砂机械研磨而成,粒径不大于47 μm,如图1所示。

图1

表1 铁尾矿及陶瓷粉化学成分

Table 1

| Material | SiO2 | Al2O3 | CaO | Fe2O3 | K2O | MgO | Na2O | K2O | P2O5 |

|---|---|---|---|---|---|---|---|---|---|

| IT | 61.53 | 8.90 | 6.05 | 13.31 | 1.84 | 5.82 | 1..21 | 1.85 | 0.68 |

| Ceramics | 66.63 | 19.01 | 3.57 | 0.94 | 1.84 | 0.85 | 1.01 | 0 | 0 |

1.2 试块制备

选定陶瓷粉掺量、水胶比、水玻璃模数和碱掺量4种因素,通过正交试验设计出9种铁尾矿基地聚物配合比,如表2所示,其中陶瓷粉掺量为30%、40%、50%;水胶比为0.5、0.55、0.6;碱激发剂模数为1.0、1.2、1.4;碱掺量为10%、12%、14%。

表2 铁尾矿基地聚物正交试验配合比

Table 2

| Sample | Water glass | NaOH | Water | IT sand | Ceramic powder | IT powder |

|---|---|---|---|---|---|---|

| A | 231.64 | 57.83 | 173.46 | 1291.37 | 193.71 | 451.98 |

| B | 323.61 | 61.39 | 135.82 | 1252.78 | 187.91 | 438.47 |

| C | 426.94 | 62.71 | 88.95 | 1214.26 | 182.14 | 424.99 |

| D | 380.43 | 55.88 | 70.24 | 1262.31 | 252.46 | 378.69 |

| E | 312.79 | 78.09 | 140.81 | 1245.54 | 249.12 | 373.66 |

| F | 269.46 | 51.12 | 201.76 | 1251.77 | 250.35 | 375.53 |

| G | 377.85 | 71.68 | 69.77 | 1253.79 | 313.44 | 313.44 |

| H | 317.06 | 46.57 | 142.70 | 1262.44 | 315.61 | 315.61 |

| I | 267.65 | 66.82 | 200.42 | 1243.41 | 310.85 | 310.85 |

根据表2配合比,制备尺寸为70.7 mm × 70.7 mm × 70.7 mm的立方体试块用于加速锈蚀测试,每组配合比浇筑两个试块,共计18个试块。钢筋置于试块正中间。

所用钢筋为HPB235热轧光圆钢筋,钢筋底面使用环氧树脂密封,上端预留40 mm钢筋与导线连接,使用环氧树脂将钢筋裸露部分全部密封处理,控制钢筋在每个试块内部的暴露长度均为50 mm。每个配比制备尺寸为40 mm × 40 mm × 40 mm的3个试块,用于强度测试。试块浇筑后置于高温养护箱养护24 h后拆模,之后重新放入高温养护箱养护14 d,养护温度60 ℃,相对湿度大于95%。

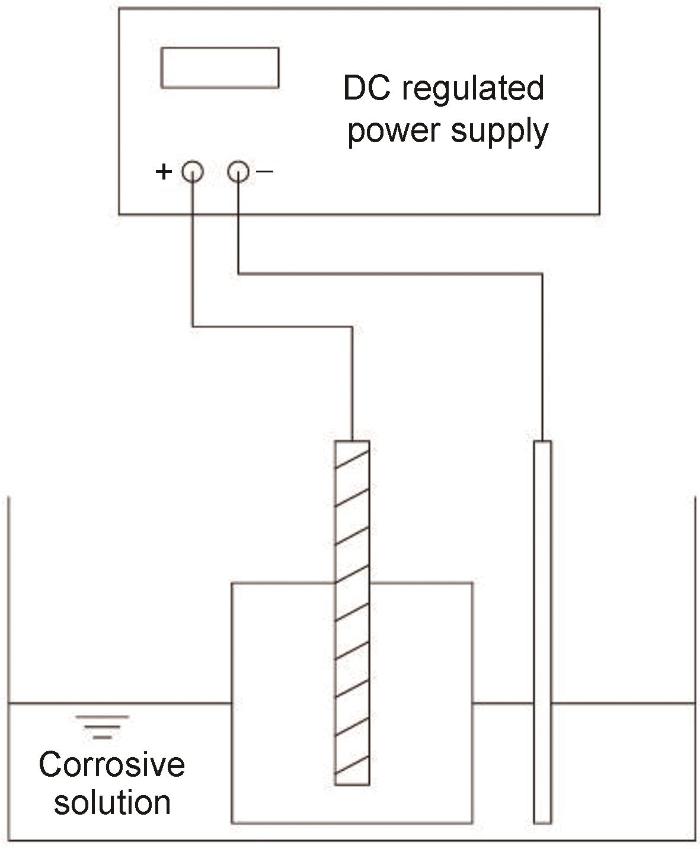

1.3 腐蚀实验

根据黄骅沟渠水质检测结果配置腐蚀溶液。黄骅市浅层地下水水质测试结果为:SO

图2

图2

半浸泡式腐蚀试验装置示意图

Fig.2

Schematic diagram of semi-immersion corrosion testing device

1.4 电化学测试

利用Zahner Zennium Pro电化学工作站测试电化学阻抗谱(EIS),采用三电极体系,其中铁尾矿基地聚物-钢筋试块为工作电极,不锈钢板为辅助电极,饱和甘汞(SCE)电极为参比电极。每通电24 h后中止通电对试块进行EIS谱、腐蚀电位和极化曲线测试。在EIS测试中扰动电压为10 mV的正弦波[14],频率范围为0.5~5 × 106 Hz。

极化曲线数据使用Zahner Analysis软件中的Butler-Volmer公式进行拟合,得到钢筋的腐蚀电流密度Icorr。由Stern-Geary公式Icorr = B/Rp确定极化电阻Rp,其中B为Stern-Geary系数,钢筋处于钝化状态时取52 mV,钢筋处于腐蚀状态时取26 mV[15]。

1.5 性能表征

抗压强度实验采用微机控制电液伺服压力试验机,将尺寸为40 mm × 40 mm × 40 mm的不同配合比铁尾矿基地聚物试块养护14 d后从养护箱中取出,放入抗压夹具中(夹具横截面尺寸为40 mm × 40 mm),抗压夹具中心与压力试验机板的中心对齐,开启油泵使夹具与试块上表面留有适当缝隙。荷载速率设置为500 N/s,直至试块破坏,记录峰值荷载为F,计算抗压强度,精确至0.1 MPa。微观形貌观测采用SU8010型扫描电镜(SEM),首先将养护至14 d龄期的铁尾矿基地聚物试块破碎,取芯部少量块状试样放入异丙醇溶液中浸泡5~7 d终止水化,之后将已停止水化且干燥后的试样压碎,均匀分散在导电胶上并进行喷金处理,放于载物台观察微观形貌并进行能谱测试。将14 d龄期的铁尾矿基地聚物破碎,取芯部块体储存在低湿度、低真空的干燥容器中,研磨至粒径≤ 5 μm,采用D8 Advance型X射线衍射仪(XRD)进行物相分析测试。

2 结果与分析

2.1 力学性能及微观形貌分析

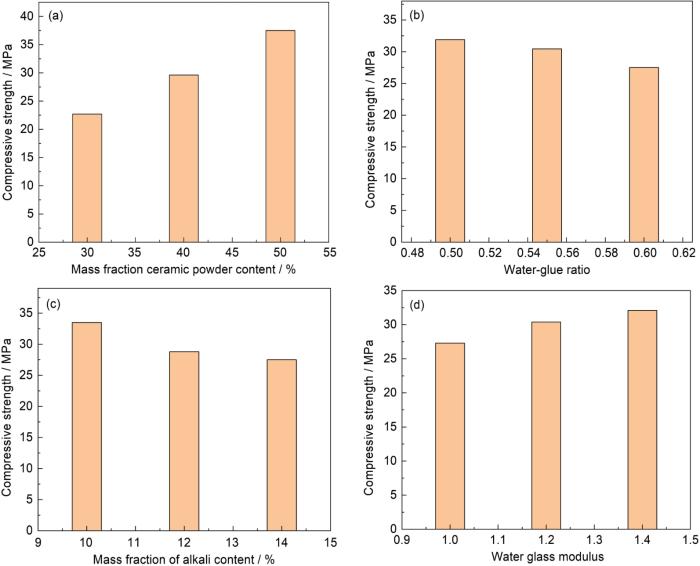

图3

图3

不同陶瓷粉掺量、水胶比、碱掺量及模数试块的抗压强度

Fig.3

Compressive strengths of test blocks with different ceramic powder contents (a), water-binder ratios (b), alkali con-tents (c) and moduli (d)

图4

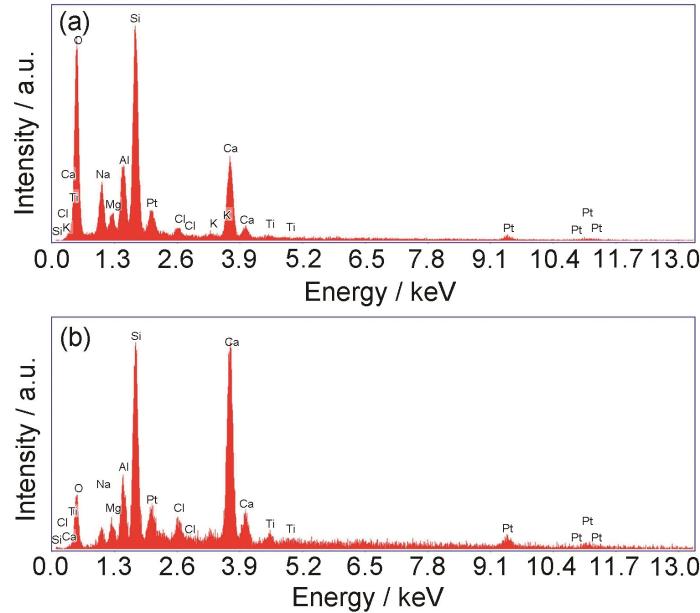

图5

图5

典型测试点的EDS分析结果

Fig.5

EDS results of typical regions marked as spot 30 (a) and spot 32 (b) in Fig.4

图6

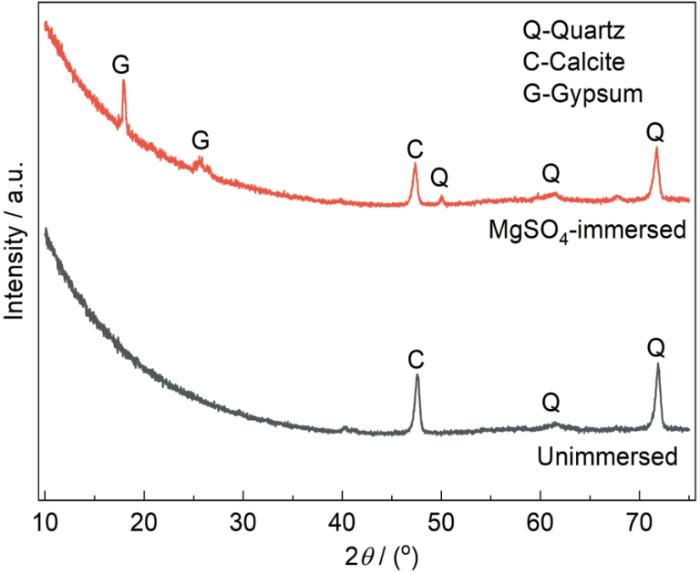

由图7可知,经过硫酸盐的侵蚀,试块内部有石膏生成,并且试块表面出现白色附着物,随着浸泡时间的延长,白色附着物(石膏)增多。

图7

图7

铁尾矿基地聚物盐碱侵蚀前后XRD图谱

Fig.7

XRD patterns of iron tailings-based geopolymers before and after corrosion in saline-alkali simulated solution

2.2 EIS谱

图8为不同陶瓷粉掺量的试块在不同腐蚀时间下的Nyquist图,可见高频区容抗弧半径均随腐蚀时间的增加先变大后变小。随腐蚀时间的增加,低频区半圆弧会变得更加完整,这一特征表明铁尾矿基地聚物中钢筋的锈蚀程度正在加剧。

图8

图8

陶瓷粉掺量30%、40%及50%试块在不同电加速腐蚀时间下的Nyquist曲线

Fig.8

Nyquist curves of test blocks with the ceramic powder contents of 30% (a), 40% (b) and 50% (c) after electrolytic accelerated corrosion for different time

图9

图9

试块在不同电加速腐蚀时间下阻抗谱的等效电路图

Fig.9

Equivalent circuit diagram of EIS of test blocks after electrolytic accelerated corrosion for different time

基于试块的Nyquist曲线,利用Zview软件拟合分析得到不同电加速历程下,各配合比的铁尾矿基地聚物的Rc值,如图10所示。由图10a可见,在未通电锈蚀之前,试块的Rc值随陶瓷粉掺量的增加有明显上升的趋势。这表明陶瓷粉掺量越高,试块密实度越高,和试块抗压强度规律相吻合。但试块在电加速腐蚀后,陶瓷粉掺量最低试块的Rc值变化速率快,可能是由于陶瓷粉掺量30%的试块抗压强度低,密实度低,SO

图10

图10

具有不同陶瓷粉掺量、水胶比、模数及碱掺量的试块的Rc值

Fig.10

Rc values of test blocks with different ceramic powder contents (a), water-binder ratios (b), moduli (c) and alkali contents (d)

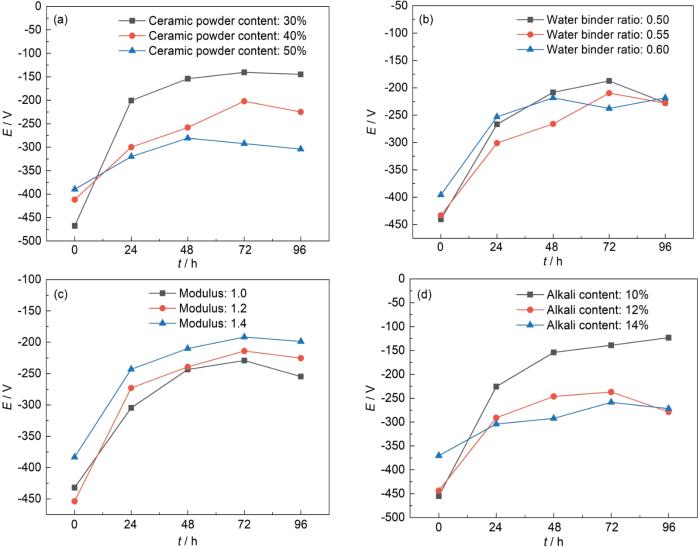

2.3 腐蚀电位

腐蚀电位可以反应出钢筋发生锈蚀的难易程度,图11给出了不同配合比试块中钢筋锈蚀全过程的腐蚀电位随电加速时间的变化情况。

图11

图11

不同陶瓷粉掺量、水胶比、模数及碱掺量试块的腐蚀电位

Fig.11

Corrosion potentials of test blocks with different ceramic powder contents (a), water-binder ratios (b), moduli (c) and alkali contents (d)

由图11c可知,在电加速之后腐蚀电位随着水玻璃模数的增长而增长,原因可能是水玻璃模数提高,试块强度相应增大,使得试块的内部更加密实,Cl-、SO

2.4 极化曲线

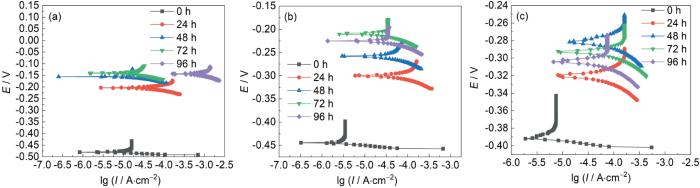

2.4.1 不同陶瓷粉掺量的影响

图12为不同陶瓷粉掺量下试块中钢筋随电加速锈蚀时间变化的极化曲线,不同陶瓷粉掺量的试块在未通电腐蚀之前的极化曲线有着共同特征:阴极极化曲线非常平缓,而阳极极化曲线非常陡峭。阳极Tafel曲线斜率βa非常大,电极阳极溶解过程阻力非常大,表明钢筋此时处于钝化状态。

图12

图12

不同电加速腐蚀时间下陶瓷粉掺量30%、40%及50%试块的Tafel极化曲线

Fig.12

Tafel polarization curves of test blocks with ceramic powder contents of 30% (a), 40% (b) and 50% (c) after electro-lytic accelerated corrosion for different time

随着电加速腐蚀的延长,极化曲线与未通电腐蚀前出现明显差别,主要表现在阳极极化曲线的坡度明显减缓,即Tafel斜率明显降低,表明钢筋已经锈蚀。

2.4.2 不同配合比的影响

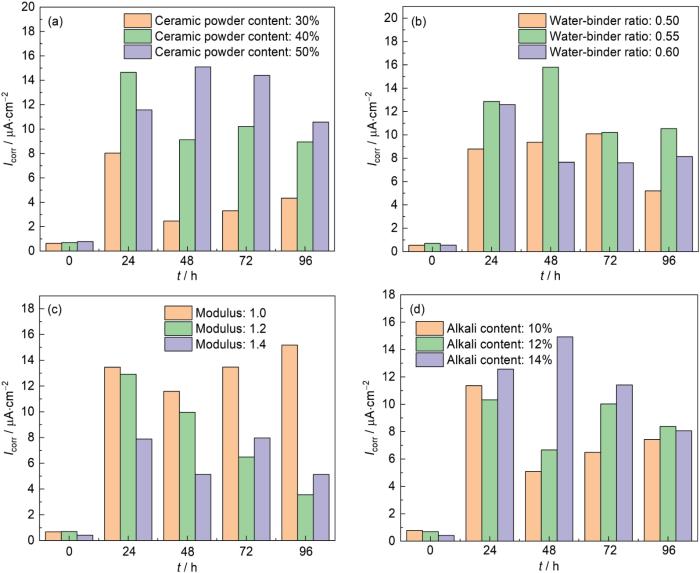

由图13可以看出,在未通电锈蚀前,腐蚀电流密度Icorr都很低,其值均在1 μA/cm2以下,这表明在此阶段钢筋表面的钝化膜并未发生破坏。

图13

图13

不同陶瓷粉掺量、水胶比、模数及碱掺量试块的腐蚀电流密度

Fig.13

Corrosion current densities of test blocks with different ceramic powder contents (a), water-binder ratios (b), moduli (c) and alkali contents (d)

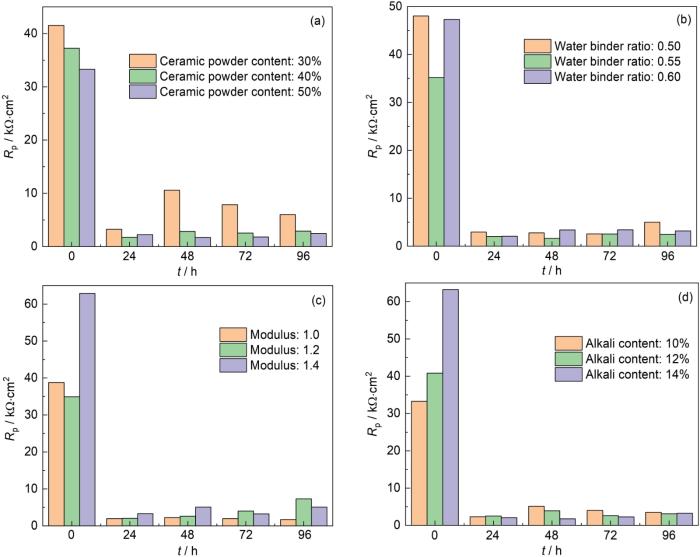

图14示出了不同配合比试块的极化电阻。可知,钢筋极化电阻随腐蚀时间的增加呈现先下降后上升再下降的趋势。

图14

图14

不同陶瓷粉掺量、水胶比、模数及碱掺量试块的极化电阻

Fig.14

Polarization resistances of test blocks with different ceramic powder contents (a), water-binder ratios (b), moduli (c) and alkali contents (d)

在电加速24 h之后钢筋极化电阻急速下降,其原因可能为在侵蚀初期,试块的内部结构松散,各种有害离子可以更容易进入试块内部,大量Cl-在钢筋表面聚集,使得钢筋表面钝化膜被破坏。但随侵蚀时间的延长,SO

3 结论

(1) 电加速腐蚀的整个过程中,试块电阻呈现先上升后下降的趋势,表明SO

(2) 在同一盐碱地模拟溶液和电加速条件下,合理配合比的试块对钢筋的保护效果更好,尤其是陶瓷粉掺量对钢筋的保护效果影响更加明显;陶瓷粉掺量低,初始电阻较低的试块对石膏、铁锈等膨胀产物吸收性更好,在盐碱地复杂侵蚀环境中抗锈蚀性能更好。

(3) 通过试块的Rc值变化规律得出陶瓷粉掺量较低、水玻璃模数较高、碱掺量较低的配合比试块的抗锈蚀能力更好。

(4) 陶瓷粉掺量较高、水玻璃模数较低、碱掺量较高的试块腐蚀电流较大,钢筋的锈蚀程度也较大。

参考文献

Durability of concrete bridge exposed to chloride ion erosion in saline alkali soil

[J].

混凝土桥梁受盐碱地中氯离子侵蚀的耐久性研究

[J].

Durability and service life analysis of metakaolin-based geopolymer concretes with respect to chloride penetration using chloride migration test and corrosion potential

[J].

Sintered and unsintered pressed fly ash geopolymer: A comprehensive study on structural transformation in nitric and sulfuric acid

[J].

The durability of alkali-activated materials in comparison with ordinary portland cements and concretes: A review

[J].

Hybrid geopolymer paste from high calcium fly ash and glass wool: Mechanical, microstructure, and sulfuric acid and magnesium sulfate resistance characteristics

[J].

Research and application progress of iron tailings sand

[J].With the rapid development of China's mineral industry, the emission of iron tailings sand has increased sharply. At present, the negative storage and landfill are still the main treatment methods, which does not only occupy a large amount of land resources, but also cause serious environmental pollution. Therefore, large-scale consumption of iron tailings sand is imminent. Iron tailings sand is a kind of waste discharged after the ‘useful part' of iron ore is selected by grinding, flotation or magnetic separation under a certain condition. Compared with natural fine aggregate, the particle is finer, angular and more solid, which could be widely used in various practical projects. Among them, the regional differences of iron tailings, raw ore composition, grade, particle size and mining beneficiation refining process have a greater impact on the physical and chemical properties. As an inert material, different activation methods could be conducted to improve the activity of iron tailings sand, whereas, the composite activation is the most effective technology. In this paper, the utilization of building materials of iron tailings sand at home and abroad and its application in other fields are reviewed. The influence of concrete prepared by iron tailings sand on mechanical properties and durability is summarized. The key properties of the application in road functional materials are discussed. The application status of iron tailings sand-based bricks is sorted out. The feasibility of using it to prepare geopolymer is evaluated. Its advantages in the preparation of mesoporous molecular sieves and the improvement of expansive soil are discussed.

铁尾矿砂的研究与应用进展

[J].

Study on corrosion deterioration of reinforced concrete under constant acceleration test based on double stress

[J].

基于双应力的钢筋混凝土恒加试验腐蚀劣化规律研究

[J].

Research status and prospects of geopolymers preparation from tailings

[J].

利用尾矿制备地聚物研究现状及展望

[J].

Current density and corrosion morghology of steel bar corrosion in reinforced concrete

[J].

钢筋混凝土的通电锈蚀电流密度及钢筋锈蚀形貌

[J].

Study on energized corrosion mechanism of reinforced concrete in groundwater environment of Lanzhou metro

[J].

兰州地铁地下水环境中钢筋混凝土通电锈蚀机理研究

[J].

Accelerated corrosion of steel bars in new and old concrete structures

[J].

新老混凝土的钢筋加速锈蚀

[J].

Corrosion process of steel bar in cement pastes under combined action of chloride and sulfate attacks

[J].

氯盐和硫酸盐侵蚀下水泥净浆中钢筋锈蚀过程

[J].

Equivalent electrical circuits fitting of electrochemical impedance spectroscopy for rebar steel corrosion of coral aggregate concrete

[J].

等效电路拟合珊瑚混凝土中钢筋锈蚀行为的电化学阻抗谱研究

[J].

Reinforcement corrosion of coral concrete with different reinforcement types and protective thickness under bending stress

[J].This paper includes handmade equipment to conduct bending stress loading experiments on coral concrete members. And the influence of bending stress on corrosion of various reinforcement types of steel bar in coral concrete with various protective layer thicknesses was investigated. ABAQUS finite element analysis software was used to simulate the stress magnitude and stress state of the reinforced coral concrete member model under bending stress. The corrosion of several types of steel reinforcement under bending stress was also compared and examined using the polarisation curves and electrochemical impedance spectrum analysis. The findings indicate that handmade equipment can better simulate the corrosion of reinforcing steel under the coupling effect of bending stress and marine environment, and the corrosion resistance of reinforcing steel decreases with increasing bending stress. The effect of increasing bending stress on reinforcement corrosion is significant within a range of protective layer thickness (0~30 mm), but as protective layer thickness increases to a certain point (50 mm), the effect of increasing bending stress on reinforcement corrosion gradually decreases. The influence of bending stress on reinforcement from strong to weak is HPB400 steel bar, galvanized steel bar, 304 stainless steel bar.

弯曲应力作用下不同钢筋种类和保护层厚度珊瑚混凝土的钢筋锈蚀研究

[J].

Compatibility studies between N-A-S-H and C-A-S-H gels. Study in the ternary diagram Na2O-CaO-Al2O3-SiO2-H2O

[J].

Sulfate resistance and mechanism analysis of different geopolymer mortars

[J].

不同地聚物砂浆抗硫酸盐侵蚀性能及其机理分析

[J].

Study on influence mechanism of sodium chloride on the strength of alkali-activated geopolymers

[J].

氯化钠对碱激发地聚物强度影响机理研究

[J].为阐明氯化钠掺量对碱激发地聚物强度的影响和机理,以水玻璃碱激发粉煤灰基地聚物为基础,采用UCS、XRD、FTIR、SEM和物理吸附试验研究了氯化钠掺量对碱激发地聚物强度及微观结构的影响。试验结果表明氯化钠掺入碱激发地聚物中总体效果不佳;氯化钠的少量掺入会反应生成方钠石,对强度有一定的促进作用。但随着掺入量的增加,Na<sup>+</sup>离子的钝化效应导致碱激发效果下降,铝硅酸盐原料溶解受到限制,降低了地聚合反应程度;未反应的硫酸钠沉积于地聚物体系中阻碍了体系中离子迁移,并削弱了凝胶的胶结作用,致使试样中孔隙增多、孔径增大,微观结构遭到破坏,从而限制了强度的发展。

Electrochemical characteristics of reinforced concrete with multiple cementitious system in carbonization environment

[J].

碳化环境下多元胶凝体系钢筋混凝土电化学特性

[J].

Mix design and mechanical properties of geopolymer and alkali activated concrete: review of the state-of-the-art and the development of a new unified approach

[J].

Effects of sodium carbonate, sodium hydroxide and water glass composite activation on properties of geopolymer cementitious materials

[J].Composite alkali activator was prepared by using sodium carbonate instead of sodium hydroxide to adjust the modulus of water glass. The effects of different alkali content and sodium carbonate replacement ratio on fluidity, setting time, and compressive strength of geopolymer cementitious materials were studied. The phase composition and microstructure of hydration products of geopolymer cementitious materials were analyzed through FT-IR, XRD, and SEM experiments. The results show that the combined effects of sodium hydroxide and sodium carbonate combined with composite water glass activators are superior to the effects of their individual combined with water glass activators. When alkali content is 6% (mass fraction) and the replacement ratio of sodium carbonate is 40%(mass fraction), the fluidity of geopolymer cementitious materials reaches 185 mm, and 28 d compressive strength reaches 94.4 MPa. The increase of replacement ratio of sodium carbonate can prolong the setting time of geopolymer cementitious materials. When the replacement ratio reaches 100%, the initial setting time and final setting time of geopolymer cementitious materials reach 372 and 420 min. When different alkali components are used as activators, similar hydration products are observed in geopolymer cementitious materials, mainly consist of amorphous aluminosilicate C-(A)-S-H gel.

碳酸钠、氢氧化钠与水玻璃复合激发对地聚物胶凝材料性能的影响

[J].采用碳酸钠替代氢氧化钠调节水玻璃模数制备复合碱激发剂,研究不同碱掺量下碳酸钠掺入比例对地聚物胶凝材料净浆流动度、凝结时间及抗压强度的影响,并通过FT-IR、XRD和SEM试验分析地聚物胶凝材料水化产物的物相组成及微观形貌。结果表明,氢氧化钠与碳酸钠共同复合水玻璃的激发剂激发效果优于二者单独与水玻璃复合的激发剂,当碱掺量为6%(质量分数)、碳酸钠替代比例为40%(质量分数)时,地聚物胶凝材料净浆流动度为185 mm,28 d抗压强度为94.4 MPa。碳酸钠替代比例增加可延长地聚物胶凝材料凝结时间,当替代比例为100%时,地聚物胶凝材料初凝时间、终凝时间可达372和420 min。不同碱组分激发剂作用时,地聚物胶凝材料水化产物相似,均以无定形铝硅酸盐C-(A)-S-H凝胶为主。