Possible pathways for low carbon transitions: investigating the efforts of oil companies in CCUS technologies

1

2024

... 大力发展碳捕集、利用与封存(CCUS)技术是实现化石能源近零排放、达成国家“双碳”战略目标的重要举措[1~3].随着CCUS技术的发展与应用,超临界CO2输送管道的服役安全受到学术界和工业界越来越多的关注[4,5].通常,管道输送的超临界CO2中存在一定量的H2O、SO2、NO2、O2和H2S等杂质组分[6,7],会明显提升管道的内腐蚀风险.同时,管道运行期间也会受到高内压、自身重力、管道振动、热膨胀等引起的应力作用.高强度管线钢在应力和含杂质的超临界CO2腐蚀环境的共同作用下存在应力腐蚀开裂(SCC)的可能性[8],这是CO2管道工程与完整性管理中需要考虑的内腐蚀风险之一. ...

A proposed global layout of carbon capture and storage in line with a 2 ℃ climate target

0

2021

Construction and innovative practice of new generation oil and gas development technology system

1

2023

... 大力发展碳捕集、利用与封存(CCUS)技术是实现化石能源近零排放、达成国家“双碳”战略目标的重要举措[1~3].随着CCUS技术的发展与应用,超临界CO2输送管道的服役安全受到学术界和工业界越来越多的关注[4,5].通常,管道输送的超临界CO2中存在一定量的H2O、SO2、NO2、O2和H2S等杂质组分[6,7],会明显提升管道的内腐蚀风险.同时,管道运行期间也会受到高内压、自身重力、管道振动、热膨胀等引起的应力作用.高强度管线钢在应力和含杂质的超临界CO2腐蚀环境的共同作用下存在应力腐蚀开裂(SCC)的可能性[8],这是CO2管道工程与完整性管理中需要考虑的内腐蚀风险之一. ...

新一代油气开发技术体系构建与创新实践

1

2023

... 大力发展碳捕集、利用与封存(CCUS)技术是实现化石能源近零排放、达成国家“双碳”战略目标的重要举措[1~3].随着CCUS技术的发展与应用,超临界CO2输送管道的服役安全受到学术界和工业界越来越多的关注[4,5].通常,管道输送的超临界CO2中存在一定量的H2O、SO2、NO2、O2和H2S等杂质组分[6,7],会明显提升管道的内腐蚀风险.同时,管道运行期间也会受到高内压、自身重力、管道振动、热膨胀等引起的应力作用.高强度管线钢在应力和含杂质的超临界CO2腐蚀环境的共同作用下存在应力腐蚀开裂(SCC)的可能性[8],这是CO2管道工程与完整性管理中需要考虑的内腐蚀风险之一. ...

Investigating the effect of salt and acid impurities in supercritical CO2 as relevant to the corrosion of carbon capture and storage pipelines

2

2013

... 大力发展碳捕集、利用与封存(CCUS)技术是实现化石能源近零排放、达成国家“双碳”战略目标的重要举措[1~3].随着CCUS技术的发展与应用,超临界CO2输送管道的服役安全受到学术界和工业界越来越多的关注[4,5].通常,管道输送的超临界CO2中存在一定量的H2O、SO2、NO2、O2和H2S等杂质组分[6,7],会明显提升管道的内腐蚀风险.同时,管道运行期间也会受到高内压、自身重力、管道振动、热膨胀等引起的应力作用.高强度管线钢在应力和含杂质的超临界CO2腐蚀环境的共同作用下存在应力腐蚀开裂(SCC)的可能性[8],这是CO2管道工程与完整性管理中需要考虑的内腐蚀风险之一. ...

... 目前,有关超临界CO2输送管道内腐蚀的研究报道众多,主要关注杂质组分、管输压力及温度等因素对管道腐蚀规律及机理的影响,很少涉及应力的影响.在应力作用下,力学-电化学耦合效应可以导致碳钢的腐蚀电位负移,提高其腐蚀速率,同时更容易造成碳钢表面电化学活性的不均匀性,造成碳钢局部腐蚀甚至SCC[9].考虑到超临界CO2输送环境的特殊性,有些学者讨论和强调CO2输送管道潜在的SCC风险[8~13],但受限于相关实验研究的不足,尚不能完全明晰超临界CO2输送管道的SCC敏感性及机理.从近年研究报道来看,一些研究认为X65管线钢在含SO2/O2的水饱和超临界CO2环境中具有很低的SCC敏感性[14~16].而Wang等[10]研究认为X70管线钢在含SO2的水饱和超临界CO2环境中具有较高的SCC敏感性,尤其是在SO2和O2杂质共存的环境中其SCC敏感性显著增加,主要发生氢致开裂型SCC.Sun等[9]研究表明在含O2、SO2或NO2的水饱和超临界CO2环境中X65管线钢的SCC敏感性与杂质引起的电化学腐蚀程度密切相关;相比O2,NO2和SO2由于其更强的腐蚀作用显著增加X65管线钢的SCC敏感性;在含NO2环境中局部阳极溶解和应力的耦合作用主导X65管线钢的SCC过程.而在含SO2环境中,X65管线钢的SCC过程受局部阳极溶解、氢脆和应力的共同控制[11].显然,对有关含杂质的超临界CO2输送管道的SCC敏感性及机理的认识仍存在争议.此外,上述有限的研究也主要聚焦于杂质组分的影响方面.然而,CO2管道运行参数(例如,压力和温度等)也是影响管道内腐蚀的重要因素[13,17~19],目前尚不清楚其如何影响管线钢的SCC行为.值得注意的是,上述研究主要源于水饱和超临界CO2体系[9~12,14~19],这与低含水(水不饱和)的超临界CO2输送体系的实际腐蚀情形差异很大.由于上述两种体系中水含量的差异,管线钢的腐蚀速率、腐蚀形态及腐蚀机理均存在很大不同[20],这必然造成其SCC敏感性及机理的显著变化.尤其是,随着未来CCUS工程项目由百万吨级向千万吨级发展,来自不同捕集源头的CO2汇入同一条管道输送很可能成为新常态,多碳源汇集的CO2流体中会不可避免地增多杂质的种类,必然导致CO2管道面临多种杂质共存的情况[4,21].因此,有必要研究低含水-多种杂质共存的超临界CO2环境中管线钢的应力腐蚀行为,评估其SCC敏感性,为含杂质的超临界CO2输送管道的内腐蚀控制提供科学依据. ...

Progress and future development trend of CO2 pipeline transportation technology

1

2022

... 大力发展碳捕集、利用与封存(CCUS)技术是实现化石能源近零排放、达成国家“双碳”战略目标的重要举措[1~3].随着CCUS技术的发展与应用,超临界CO2输送管道的服役安全受到学术界和工业界越来越多的关注[4,5].通常,管道输送的超临界CO2中存在一定量的H2O、SO2、NO2、O2和H2S等杂质组分[6,7],会明显提升管道的内腐蚀风险.同时,管道运行期间也会受到高内压、自身重力、管道振动、热膨胀等引起的应力作用.高强度管线钢在应力和含杂质的超临界CO2腐蚀环境的共同作用下存在应力腐蚀开裂(SCC)的可能性[8],这是CO2管道工程与完整性管理中需要考虑的内腐蚀风险之一. ...

CO2管道输送技术进展与未来发展浅析

1

2022

... 大力发展碳捕集、利用与封存(CCUS)技术是实现化石能源近零排放、达成国家“双碳”战略目标的重要举措[1~3].随着CCUS技术的发展与应用,超临界CO2输送管道的服役安全受到学术界和工业界越来越多的关注[4,5].通常,管道输送的超临界CO2中存在一定量的H2O、SO2、NO2、O2和H2S等杂质组分[6,7],会明显提升管道的内腐蚀风险.同时,管道运行期间也会受到高内压、自身重力、管道振动、热膨胀等引起的应力作用.高强度管线钢在应力和含杂质的超临界CO2腐蚀环境的共同作用下存在应力腐蚀开裂(SCC)的可能性[8],这是CO2管道工程与完整性管理中需要考虑的内腐蚀风险之一. ...

Dynamis CO2 quality recommendations

1

2008

... 大力发展碳捕集、利用与封存(CCUS)技术是实现化石能源近零排放、达成国家“双碳”战略目标的重要举措[1~3].随着CCUS技术的发展与应用,超临界CO2输送管道的服役安全受到学术界和工业界越来越多的关注[4,5].通常,管道输送的超临界CO2中存在一定量的H2O、SO2、NO2、O2和H2S等杂质组分[6,7],会明显提升管道的内腐蚀风险.同时,管道运行期间也会受到高内压、自身重力、管道振动、热膨胀等引起的应力作用.高强度管线钢在应力和含杂质的超临界CO2腐蚀环境的共同作用下存在应力腐蚀开裂(SCC)的可能性[8],这是CO2管道工程与完整性管理中需要考虑的内腐蚀风险之一. ...

Materials challenges with CO2 transport and injection for carbon capture and storage

1

2022

... 大力发展碳捕集、利用与封存(CCUS)技术是实现化石能源近零排放、达成国家“双碳”战略目标的重要举措[1~3].随着CCUS技术的发展与应用,超临界CO2输送管道的服役安全受到学术界和工业界越来越多的关注[4,5].通常,管道输送的超临界CO2中存在一定量的H2O、SO2、NO2、O2和H2S等杂质组分[6,7],会明显提升管道的内腐蚀风险.同时,管道运行期间也会受到高内压、自身重力、管道振动、热膨胀等引起的应力作用.高强度管线钢在应力和含杂质的超临界CO2腐蚀环境的共同作用下存在应力腐蚀开裂(SCC)的可能性[8],这是CO2管道工程与完整性管理中需要考虑的内腐蚀风险之一. ...

A systematic review of key challenges of CO2 transport via pipelines

2

2018

... 大力发展碳捕集、利用与封存(CCUS)技术是实现化石能源近零排放、达成国家“双碳”战略目标的重要举措[1~3].随着CCUS技术的发展与应用,超临界CO2输送管道的服役安全受到学术界和工业界越来越多的关注[4,5].通常,管道输送的超临界CO2中存在一定量的H2O、SO2、NO2、O2和H2S等杂质组分[6,7],会明显提升管道的内腐蚀风险.同时,管道运行期间也会受到高内压、自身重力、管道振动、热膨胀等引起的应力作用.高强度管线钢在应力和含杂质的超临界CO2腐蚀环境的共同作用下存在应力腐蚀开裂(SCC)的可能性[8],这是CO2管道工程与完整性管理中需要考虑的内腐蚀风险之一. ...

... 目前,有关超临界CO2输送管道内腐蚀的研究报道众多,主要关注杂质组分、管输压力及温度等因素对管道腐蚀规律及机理的影响,很少涉及应力的影响.在应力作用下,力学-电化学耦合效应可以导致碳钢的腐蚀电位负移,提高其腐蚀速率,同时更容易造成碳钢表面电化学活性的不均匀性,造成碳钢局部腐蚀甚至SCC[9].考虑到超临界CO2输送环境的特殊性,有些学者讨论和强调CO2输送管道潜在的SCC风险[8~13],但受限于相关实验研究的不足,尚不能完全明晰超临界CO2输送管道的SCC敏感性及机理.从近年研究报道来看,一些研究认为X65管线钢在含SO2/O2的水饱和超临界CO2环境中具有很低的SCC敏感性[14~16].而Wang等[10]研究认为X70管线钢在含SO2的水饱和超临界CO2环境中具有较高的SCC敏感性,尤其是在SO2和O2杂质共存的环境中其SCC敏感性显著增加,主要发生氢致开裂型SCC.Sun等[9]研究表明在含O2、SO2或NO2的水饱和超临界CO2环境中X65管线钢的SCC敏感性与杂质引起的电化学腐蚀程度密切相关;相比O2,NO2和SO2由于其更强的腐蚀作用显著增加X65管线钢的SCC敏感性;在含NO2环境中局部阳极溶解和应力的耦合作用主导X65管线钢的SCC过程.而在含SO2环境中,X65管线钢的SCC过程受局部阳极溶解、氢脆和应力的共同控制[11].显然,对有关含杂质的超临界CO2输送管道的SCC敏感性及机理的认识仍存在争议.此外,上述有限的研究也主要聚焦于杂质组分的影响方面.然而,CO2管道运行参数(例如,压力和温度等)也是影响管道内腐蚀的重要因素[13,17~19],目前尚不清楚其如何影响管线钢的SCC行为.值得注意的是,上述研究主要源于水饱和超临界CO2体系[9~12,14~19],这与低含水(水不饱和)的超临界CO2输送体系的实际腐蚀情形差异很大.由于上述两种体系中水含量的差异,管线钢的腐蚀速率、腐蚀形态及腐蚀机理均存在很大不同[20],这必然造成其SCC敏感性及机理的显著变化.尤其是,随着未来CCUS工程项目由百万吨级向千万吨级发展,来自不同捕集源头的CO2汇入同一条管道输送很可能成为新常态,多碳源汇集的CO2流体中会不可避免地增多杂质的种类,必然导致CO2管道面临多种杂质共存的情况[4,21].因此,有必要研究低含水-多种杂质共存的超临界CO2环境中管线钢的应力腐蚀行为,评估其SCC敏感性,为含杂质的超临界CO2输送管道的内腐蚀控制提供科学依据. ...

Unraveling the effect of O2, NO2 and SO2 impurities on the stress corrosion behavior of X65 steel in water-saturated supercritical CO2 streams

5

2022

... 目前,有关超临界CO2输送管道内腐蚀的研究报道众多,主要关注杂质组分、管输压力及温度等因素对管道腐蚀规律及机理的影响,很少涉及应力的影响.在应力作用下,力学-电化学耦合效应可以导致碳钢的腐蚀电位负移,提高其腐蚀速率,同时更容易造成碳钢表面电化学活性的不均匀性,造成碳钢局部腐蚀甚至SCC[9].考虑到超临界CO2输送环境的特殊性,有些学者讨论和强调CO2输送管道潜在的SCC风险[8~13],但受限于相关实验研究的不足,尚不能完全明晰超临界CO2输送管道的SCC敏感性及机理.从近年研究报道来看,一些研究认为X65管线钢在含SO2/O2的水饱和超临界CO2环境中具有很低的SCC敏感性[14~16].而Wang等[10]研究认为X70管线钢在含SO2的水饱和超临界CO2环境中具有较高的SCC敏感性,尤其是在SO2和O2杂质共存的环境中其SCC敏感性显著增加,主要发生氢致开裂型SCC.Sun等[9]研究表明在含O2、SO2或NO2的水饱和超临界CO2环境中X65管线钢的SCC敏感性与杂质引起的电化学腐蚀程度密切相关;相比O2,NO2和SO2由于其更强的腐蚀作用显著增加X65管线钢的SCC敏感性;在含NO2环境中局部阳极溶解和应力的耦合作用主导X65管线钢的SCC过程.而在含SO2环境中,X65管线钢的SCC过程受局部阳极溶解、氢脆和应力的共同控制[11].显然,对有关含杂质的超临界CO2输送管道的SCC敏感性及机理的认识仍存在争议.此外,上述有限的研究也主要聚焦于杂质组分的影响方面.然而,CO2管道运行参数(例如,压力和温度等)也是影响管道内腐蚀的重要因素[13,17~19],目前尚不清楚其如何影响管线钢的SCC行为.值得注意的是,上述研究主要源于水饱和超临界CO2体系[9~12,14~19],这与低含水(水不饱和)的超临界CO2输送体系的实际腐蚀情形差异很大.由于上述两种体系中水含量的差异,管线钢的腐蚀速率、腐蚀形态及腐蚀机理均存在很大不同[20],这必然造成其SCC敏感性及机理的显著变化.尤其是,随着未来CCUS工程项目由百万吨级向千万吨级发展,来自不同捕集源头的CO2汇入同一条管道输送很可能成为新常态,多碳源汇集的CO2流体中会不可避免地增多杂质的种类,必然导致CO2管道面临多种杂质共存的情况[4,21].因此,有必要研究低含水-多种杂质共存的超临界CO2环境中管线钢的应力腐蚀行为,评估其SCC敏感性,为含杂质的超临界CO2输送管道的内腐蚀控制提供科学依据. ...

... [9]研究表明在含O2、SO2或NO2的水饱和超临界CO2环境中X65管线钢的SCC敏感性与杂质引起的电化学腐蚀程度密切相关;相比O2,NO2和SO2由于其更强的腐蚀作用显著增加X65管线钢的SCC敏感性;在含NO2环境中局部阳极溶解和应力的耦合作用主导X65管线钢的SCC过程.而在含SO2环境中,X65管线钢的SCC过程受局部阳极溶解、氢脆和应力的共同控制[11].显然,对有关含杂质的超临界CO2输送管道的SCC敏感性及机理的认识仍存在争议.此外,上述有限的研究也主要聚焦于杂质组分的影响方面.然而,CO2管道运行参数(例如,压力和温度等)也是影响管道内腐蚀的重要因素[13,17~19],目前尚不清楚其如何影响管线钢的SCC行为.值得注意的是,上述研究主要源于水饱和超临界CO2体系[9~12,14~19],这与低含水(水不饱和)的超临界CO2输送体系的实际腐蚀情形差异很大.由于上述两种体系中水含量的差异,管线钢的腐蚀速率、腐蚀形态及腐蚀机理均存在很大不同[20],这必然造成其SCC敏感性及机理的显著变化.尤其是,随着未来CCUS工程项目由百万吨级向千万吨级发展,来自不同捕集源头的CO2汇入同一条管道输送很可能成为新常态,多碳源汇集的CO2流体中会不可避免地增多杂质的种类,必然导致CO2管道面临多种杂质共存的情况[4,21].因此,有必要研究低含水-多种杂质共存的超临界CO2环境中管线钢的应力腐蚀行为,评估其SCC敏感性,为含杂质的超临界CO2输送管道的内腐蚀控制提供科学依据. ...

... [9~12,14~19],这与低含水(水不饱和)的超临界CO2输送体系的实际腐蚀情形差异很大.由于上述两种体系中水含量的差异,管线钢的腐蚀速率、腐蚀形态及腐蚀机理均存在很大不同[20],这必然造成其SCC敏感性及机理的显著变化.尤其是,随着未来CCUS工程项目由百万吨级向千万吨级发展,来自不同捕集源头的CO2汇入同一条管道输送很可能成为新常态,多碳源汇集的CO2流体中会不可避免地增多杂质的种类,必然导致CO2管道面临多种杂质共存的情况[4,21].因此,有必要研究低含水-多种杂质共存的超临界CO2环境中管线钢的应力腐蚀行为,评估其SCC敏感性,为含杂质的超临界CO2输送管道的内腐蚀控制提供科学依据. ...

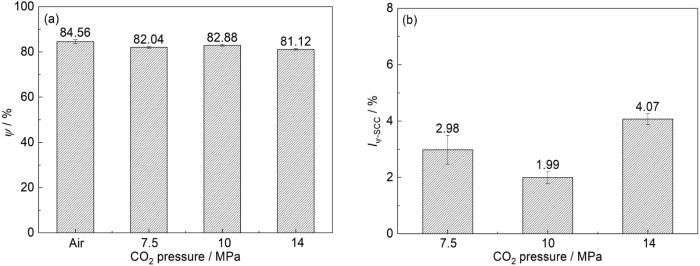

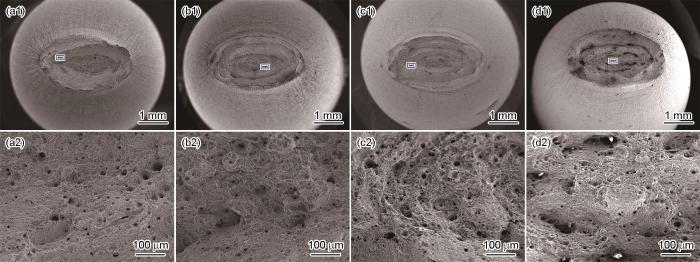

... 图5a为X65管线钢在不同环境中的断面收缩率.据此计算得到其在不同压力的含杂质超临界CO2腐蚀环境中的SCC敏感性因子(IΨ-SCC),如图5b所示.X65管线钢在空气中的断面收缩率为84.56%,其在7.5、10和14 MPa CO2压力环境中分别降低至82.04%、82.88%和81.12% (图5a),对应的IΨ-SCC值分别为2.98%、1.99%和4.07% (图5b).相关研究表明,一般情况下IΨ-SCC值越大,金属发生SCC可能性越高[9,10,26,27].例如,Sun等[9]研究表明在含0.1%O2的水饱和超临界CO2环境(8 MPa CO2和50 ℃)中X65管线钢的IΨ-SCC值仅为0.28%,拉伸断口呈现韧性断裂特征,不发生SCC;而在含0.1%SO2的水饱和超临界CO2环境(8 MPa CO2和50 ℃)中,X65管线钢的IΨ-SCC值高达64.78%,拉伸断口则呈现明显脆性断裂特征,发生SCC.显然,在含0.01%H2O、0.01%O2、0.01%H2S、0.01%SO2和0.01%NO2的超临界CO2环境中,X65管线钢具有一定的SCC敏感性,而且随着CO2压力由7.5 MPa增加至14 MPa,其SCC敏感性呈先降后升的变化趋势.但是,在实验压力范围内X65管线钢的IΨ-SCC均处于非常低的水平,这表明X65管线钢在上述环境中发生SCC的可能性很低. ...

... [9]研究表明在含0.1%O2的水饱和超临界CO2环境(8 MPa CO2和50 ℃)中X65管线钢的IΨ-SCC值仅为0.28%,拉伸断口呈现韧性断裂特征,不发生SCC;而在含0.1%SO2的水饱和超临界CO2环境(8 MPa CO2和50 ℃)中,X65管线钢的IΨ-SCC值高达64.78%,拉伸断口则呈现明显脆性断裂特征,发生SCC.显然,在含0.01%H2O、0.01%O2、0.01%H2S、0.01%SO2和0.01%NO2的超临界CO2环境中,X65管线钢具有一定的SCC敏感性,而且随着CO2压力由7.5 MPa增加至14 MPa,其SCC敏感性呈先降后升的变化趋势.但是,在实验压力范围内X65管线钢的IΨ-SCC均处于非常低的水平,这表明X65管线钢在上述环境中发生SCC的可能性很低. ...

Experimental investigation of stress corrosion on supercritical CO2 transportation pipelines against leakage for CCUS applications

3

2023

... 目前,有关超临界CO2输送管道内腐蚀的研究报道众多,主要关注杂质组分、管输压力及温度等因素对管道腐蚀规律及机理的影响,很少涉及应力的影响.在应力作用下,力学-电化学耦合效应可以导致碳钢的腐蚀电位负移,提高其腐蚀速率,同时更容易造成碳钢表面电化学活性的不均匀性,造成碳钢局部腐蚀甚至SCC[9].考虑到超临界CO2输送环境的特殊性,有些学者讨论和强调CO2输送管道潜在的SCC风险[8~13],但受限于相关实验研究的不足,尚不能完全明晰超临界CO2输送管道的SCC敏感性及机理.从近年研究报道来看,一些研究认为X65管线钢在含SO2/O2的水饱和超临界CO2环境中具有很低的SCC敏感性[14~16].而Wang等[10]研究认为X70管线钢在含SO2的水饱和超临界CO2环境中具有较高的SCC敏感性,尤其是在SO2和O2杂质共存的环境中其SCC敏感性显著增加,主要发生氢致开裂型SCC.Sun等[9]研究表明在含O2、SO2或NO2的水饱和超临界CO2环境中X65管线钢的SCC敏感性与杂质引起的电化学腐蚀程度密切相关;相比O2,NO2和SO2由于其更强的腐蚀作用显著增加X65管线钢的SCC敏感性;在含NO2环境中局部阳极溶解和应力的耦合作用主导X65管线钢的SCC过程.而在含SO2环境中,X65管线钢的SCC过程受局部阳极溶解、氢脆和应力的共同控制[11].显然,对有关含杂质的超临界CO2输送管道的SCC敏感性及机理的认识仍存在争议.此外,上述有限的研究也主要聚焦于杂质组分的影响方面.然而,CO2管道运行参数(例如,压力和温度等)也是影响管道内腐蚀的重要因素[13,17~19],目前尚不清楚其如何影响管线钢的SCC行为.值得注意的是,上述研究主要源于水饱和超临界CO2体系[9~12,14~19],这与低含水(水不饱和)的超临界CO2输送体系的实际腐蚀情形差异很大.由于上述两种体系中水含量的差异,管线钢的腐蚀速率、腐蚀形态及腐蚀机理均存在很大不同[20],这必然造成其SCC敏感性及机理的显著变化.尤其是,随着未来CCUS工程项目由百万吨级向千万吨级发展,来自不同捕集源头的CO2汇入同一条管道输送很可能成为新常态,多碳源汇集的CO2流体中会不可避免地增多杂质的种类,必然导致CO2管道面临多种杂质共存的情况[4,21].因此,有必要研究低含水-多种杂质共存的超临界CO2环境中管线钢的应力腐蚀行为,评估其SCC敏感性,为含杂质的超临界CO2输送管道的内腐蚀控制提供科学依据. ...

... 图5a为X65管线钢在不同环境中的断面收缩率.据此计算得到其在不同压力的含杂质超临界CO2腐蚀环境中的SCC敏感性因子(IΨ-SCC),如图5b所示.X65管线钢在空气中的断面收缩率为84.56%,其在7.5、10和14 MPa CO2压力环境中分别降低至82.04%、82.88%和81.12% (图5a),对应的IΨ-SCC值分别为2.98%、1.99%和4.07% (图5b).相关研究表明,一般情况下IΨ-SCC值越大,金属发生SCC可能性越高[9,10,26,27].例如,Sun等[9]研究表明在含0.1%O2的水饱和超临界CO2环境(8 MPa CO2和50 ℃)中X65管线钢的IΨ-SCC值仅为0.28%,拉伸断口呈现韧性断裂特征,不发生SCC;而在含0.1%SO2的水饱和超临界CO2环境(8 MPa CO2和50 ℃)中,X65管线钢的IΨ-SCC值高达64.78%,拉伸断口则呈现明显脆性断裂特征,发生SCC.显然,在含0.01%H2O、0.01%O2、0.01%H2S、0.01%SO2和0.01%NO2的超临界CO2环境中,X65管线钢具有一定的SCC敏感性,而且随着CO2压力由7.5 MPa增加至14 MPa,其SCC敏感性呈先降后升的变化趋势.但是,在实验压力范围内X65管线钢的IΨ-SCC均处于非常低的水平,这表明X65管线钢在上述环境中发生SCC的可能性很低. ...

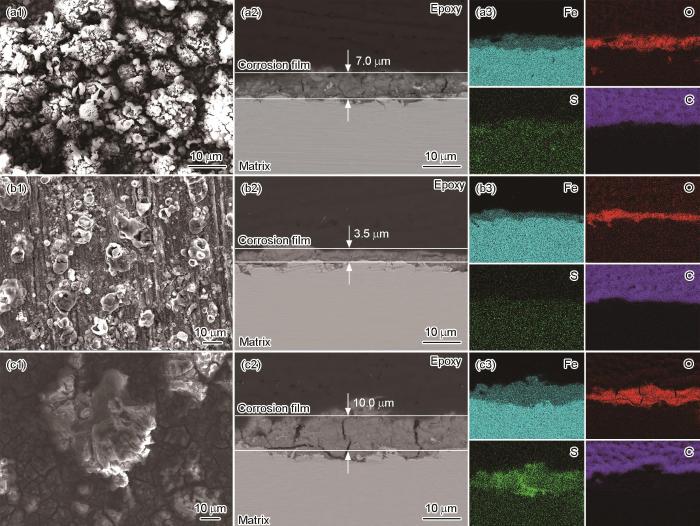

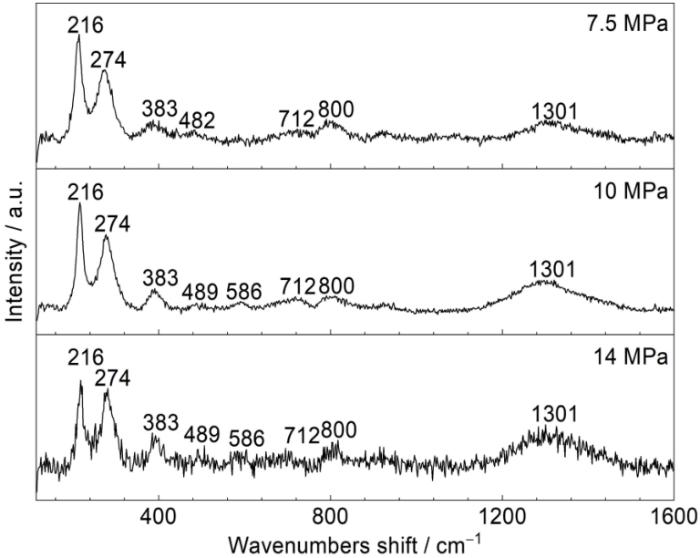

... 由图9a3~c3中EDS分析结果可见,在各CO2压力环境中应力腐蚀204 h后形成的腐蚀产物膜主要由Fe、O和S组成,元素分布均匀.在7.5 MPa和10 MPa CO2压力环境中腐蚀产物膜中S含量较少,说明腐蚀产物以Fe和O的化合物为主;而在14 MPa CO2压力环境中腐蚀产物中S含量明显增多,说明腐蚀产物中含S产物含量增加.为了进一步确定腐蚀产物膜的化学组成及差异,采用Raman光谱对X65管线钢表面腐蚀产物膜进行分析(图10).不同压力的CO2环境中腐蚀产物膜的Raman散射峰基本相同:在波数为216、274、383、482、586、712和1301 cm-1处的Raman散射峰对应于FeOOH[10,28~30],489和800 cm-1对应于FeSO4或FeSO4的水合物[31,32].由此可见,不同CO2压力环境中形成的腐蚀产物膜的主要化学成分相同,均为FeOOH和FeSO4.显然,在含O2、H2S、SO2和NO2的超临界CO2环境中,杂质间可以发生化学反应,生成H2SO4[25,33],进而形成FeSO4产物.FeOOH是含O2或NO2杂质的超临界CO2环境中常见的腐蚀产物[21]:一方面O2和NO2直接参与X65管线钢的腐蚀过程,形成FeOOH;另一方面,在实验环境中X65管线钢表面可能形成的腐蚀产物,如FeSO4、FeCO3和FeS等[34],暴露于含氧的湿气环境中容易被氧化,从而形成FeOOH产物[25]. ...

Hydrogen permeation and SCC susceptibility of X70 pipeline steel in CO2-saturated water environment containing acidic impurity

1

2024

... 目前,有关超临界CO2输送管道内腐蚀的研究报道众多,主要关注杂质组分、管输压力及温度等因素对管道腐蚀规律及机理的影响,很少涉及应力的影响.在应力作用下,力学-电化学耦合效应可以导致碳钢的腐蚀电位负移,提高其腐蚀速率,同时更容易造成碳钢表面电化学活性的不均匀性,造成碳钢局部腐蚀甚至SCC[9].考虑到超临界CO2输送环境的特殊性,有些学者讨论和强调CO2输送管道潜在的SCC风险[8~13],但受限于相关实验研究的不足,尚不能完全明晰超临界CO2输送管道的SCC敏感性及机理.从近年研究报道来看,一些研究认为X65管线钢在含SO2/O2的水饱和超临界CO2环境中具有很低的SCC敏感性[14~16].而Wang等[10]研究认为X70管线钢在含SO2的水饱和超临界CO2环境中具有较高的SCC敏感性,尤其是在SO2和O2杂质共存的环境中其SCC敏感性显著增加,主要发生氢致开裂型SCC.Sun等[9]研究表明在含O2、SO2或NO2的水饱和超临界CO2环境中X65管线钢的SCC敏感性与杂质引起的电化学腐蚀程度密切相关;相比O2,NO2和SO2由于其更强的腐蚀作用显著增加X65管线钢的SCC敏感性;在含NO2环境中局部阳极溶解和应力的耦合作用主导X65管线钢的SCC过程.而在含SO2环境中,X65管线钢的SCC过程受局部阳极溶解、氢脆和应力的共同控制[11].显然,对有关含杂质的超临界CO2输送管道的SCC敏感性及机理的认识仍存在争议.此外,上述有限的研究也主要聚焦于杂质组分的影响方面.然而,CO2管道运行参数(例如,压力和温度等)也是影响管道内腐蚀的重要因素[13,17~19],目前尚不清楚其如何影响管线钢的SCC行为.值得注意的是,上述研究主要源于水饱和超临界CO2体系[9~12,14~19],这与低含水(水不饱和)的超临界CO2输送体系的实际腐蚀情形差异很大.由于上述两种体系中水含量的差异,管线钢的腐蚀速率、腐蚀形态及腐蚀机理均存在很大不同[20],这必然造成其SCC敏感性及机理的显著变化.尤其是,随着未来CCUS工程项目由百万吨级向千万吨级发展,来自不同捕集源头的CO2汇入同一条管道输送很可能成为新常态,多碳源汇集的CO2流体中会不可避免地增多杂质的种类,必然导致CO2管道面临多种杂质共存的情况[4,21].因此,有必要研究低含水-多种杂质共存的超临界CO2环境中管线钢的应力腐蚀行为,评估其SCC敏感性,为含杂质的超临界CO2输送管道的内腐蚀控制提供科学依据. ...

The role of hydrogen in the corrosion and cracking of steels-a review

1

2021

... 目前,有关超临界CO2输送管道内腐蚀的研究报道众多,主要关注杂质组分、管输压力及温度等因素对管道腐蚀规律及机理的影响,很少涉及应力的影响.在应力作用下,力学-电化学耦合效应可以导致碳钢的腐蚀电位负移,提高其腐蚀速率,同时更容易造成碳钢表面电化学活性的不均匀性,造成碳钢局部腐蚀甚至SCC[9].考虑到超临界CO2输送环境的特殊性,有些学者讨论和强调CO2输送管道潜在的SCC风险[8~13],但受限于相关实验研究的不足,尚不能完全明晰超临界CO2输送管道的SCC敏感性及机理.从近年研究报道来看,一些研究认为X65管线钢在含SO2/O2的水饱和超临界CO2环境中具有很低的SCC敏感性[14~16].而Wang等[10]研究认为X70管线钢在含SO2的水饱和超临界CO2环境中具有较高的SCC敏感性,尤其是在SO2和O2杂质共存的环境中其SCC敏感性显著增加,主要发生氢致开裂型SCC.Sun等[9]研究表明在含O2、SO2或NO2的水饱和超临界CO2环境中X65管线钢的SCC敏感性与杂质引起的电化学腐蚀程度密切相关;相比O2,NO2和SO2由于其更强的腐蚀作用显著增加X65管线钢的SCC敏感性;在含NO2环境中局部阳极溶解和应力的耦合作用主导X65管线钢的SCC过程.而在含SO2环境中,X65管线钢的SCC过程受局部阳极溶解、氢脆和应力的共同控制[11].显然,对有关含杂质的超临界CO2输送管道的SCC敏感性及机理的认识仍存在争议.此外,上述有限的研究也主要聚焦于杂质组分的影响方面.然而,CO2管道运行参数(例如,压力和温度等)也是影响管道内腐蚀的重要因素[13,17~19],目前尚不清楚其如何影响管线钢的SCC行为.值得注意的是,上述研究主要源于水饱和超临界CO2体系[9~12,14~19],这与低含水(水不饱和)的超临界CO2输送体系的实际腐蚀情形差异很大.由于上述两种体系中水含量的差异,管线钢的腐蚀速率、腐蚀形态及腐蚀机理均存在很大不同[20],这必然造成其SCC敏感性及机理的显著变化.尤其是,随着未来CCUS工程项目由百万吨级向千万吨级发展,来自不同捕集源头的CO2汇入同一条管道输送很可能成为新常态,多碳源汇集的CO2流体中会不可避免地增多杂质的种类,必然导致CO2管道面临多种杂质共存的情况[4,21].因此,有必要研究低含水-多种杂质共存的超临界CO2环境中管线钢的应力腐蚀行为,评估其SCC敏感性,为含杂质的超临界CO2输送管道的内腐蚀控制提供科学依据. ...

Corrosion of pipeline steel in dense phase CO2 containing impurities: A critical review of test methodologies

2

2023

... 目前,有关超临界CO2输送管道内腐蚀的研究报道众多,主要关注杂质组分、管输压力及温度等因素对管道腐蚀规律及机理的影响,很少涉及应力的影响.在应力作用下,力学-电化学耦合效应可以导致碳钢的腐蚀电位负移,提高其腐蚀速率,同时更容易造成碳钢表面电化学活性的不均匀性,造成碳钢局部腐蚀甚至SCC[9].考虑到超临界CO2输送环境的特殊性,有些学者讨论和强调CO2输送管道潜在的SCC风险[8~13],但受限于相关实验研究的不足,尚不能完全明晰超临界CO2输送管道的SCC敏感性及机理.从近年研究报道来看,一些研究认为X65管线钢在含SO2/O2的水饱和超临界CO2环境中具有很低的SCC敏感性[14~16].而Wang等[10]研究认为X70管线钢在含SO2的水饱和超临界CO2环境中具有较高的SCC敏感性,尤其是在SO2和O2杂质共存的环境中其SCC敏感性显著增加,主要发生氢致开裂型SCC.Sun等[9]研究表明在含O2、SO2或NO2的水饱和超临界CO2环境中X65管线钢的SCC敏感性与杂质引起的电化学腐蚀程度密切相关;相比O2,NO2和SO2由于其更强的腐蚀作用显著增加X65管线钢的SCC敏感性;在含NO2环境中局部阳极溶解和应力的耦合作用主导X65管线钢的SCC过程.而在含SO2环境中,X65管线钢的SCC过程受局部阳极溶解、氢脆和应力的共同控制[11].显然,对有关含杂质的超临界CO2输送管道的SCC敏感性及机理的认识仍存在争议.此外,上述有限的研究也主要聚焦于杂质组分的影响方面.然而,CO2管道运行参数(例如,压力和温度等)也是影响管道内腐蚀的重要因素[13,17~19],目前尚不清楚其如何影响管线钢的SCC行为.值得注意的是,上述研究主要源于水饱和超临界CO2体系[9~12,14~19],这与低含水(水不饱和)的超临界CO2输送体系的实际腐蚀情形差异很大.由于上述两种体系中水含量的差异,管线钢的腐蚀速率、腐蚀形态及腐蚀机理均存在很大不同[20],这必然造成其SCC敏感性及机理的显著变化.尤其是,随着未来CCUS工程项目由百万吨级向千万吨级发展,来自不同捕集源头的CO2汇入同一条管道输送很可能成为新常态,多碳源汇集的CO2流体中会不可避免地增多杂质的种类,必然导致CO2管道面临多种杂质共存的情况[4,21].因此,有必要研究低含水-多种杂质共存的超临界CO2环境中管线钢的应力腐蚀行为,评估其SCC敏感性,为含杂质的超临界CO2输送管道的内腐蚀控制提供科学依据. ...

... [13,17~19],目前尚不清楚其如何影响管线钢的SCC行为.值得注意的是,上述研究主要源于水饱和超临界CO2体系[9~12,14~19],这与低含水(水不饱和)的超临界CO2输送体系的实际腐蚀情形差异很大.由于上述两种体系中水含量的差异,管线钢的腐蚀速率、腐蚀形态及腐蚀机理均存在很大不同[20],这必然造成其SCC敏感性及机理的显著变化.尤其是,随着未来CCUS工程项目由百万吨级向千万吨级发展,来自不同捕集源头的CO2汇入同一条管道输送很可能成为新常态,多碳源汇集的CO2流体中会不可避免地增多杂质的种类,必然导致CO2管道面临多种杂质共存的情况[4,21].因此,有必要研究低含水-多种杂质共存的超临界CO2环境中管线钢的应力腐蚀行为,评估其SCC敏感性,为含杂质的超临界CO2输送管道的内腐蚀控制提供科学依据. ...

Influence of SO2 on the corrosion and stress corrosion cracking susceptibility of supercritical CO2 transportation pipelines

2

2020

... 目前,有关超临界CO2输送管道内腐蚀的研究报道众多,主要关注杂质组分、管输压力及温度等因素对管道腐蚀规律及机理的影响,很少涉及应力的影响.在应力作用下,力学-电化学耦合效应可以导致碳钢的腐蚀电位负移,提高其腐蚀速率,同时更容易造成碳钢表面电化学活性的不均匀性,造成碳钢局部腐蚀甚至SCC[9].考虑到超临界CO2输送环境的特殊性,有些学者讨论和强调CO2输送管道潜在的SCC风险[8~13],但受限于相关实验研究的不足,尚不能完全明晰超临界CO2输送管道的SCC敏感性及机理.从近年研究报道来看,一些研究认为X65管线钢在含SO2/O2的水饱和超临界CO2环境中具有很低的SCC敏感性[14~16].而Wang等[10]研究认为X70管线钢在含SO2的水饱和超临界CO2环境中具有较高的SCC敏感性,尤其是在SO2和O2杂质共存的环境中其SCC敏感性显著增加,主要发生氢致开裂型SCC.Sun等[9]研究表明在含O2、SO2或NO2的水饱和超临界CO2环境中X65管线钢的SCC敏感性与杂质引起的电化学腐蚀程度密切相关;相比O2,NO2和SO2由于其更强的腐蚀作用显著增加X65管线钢的SCC敏感性;在含NO2环境中局部阳极溶解和应力的耦合作用主导X65管线钢的SCC过程.而在含SO2环境中,X65管线钢的SCC过程受局部阳极溶解、氢脆和应力的共同控制[11].显然,对有关含杂质的超临界CO2输送管道的SCC敏感性及机理的认识仍存在争议.此外,上述有限的研究也主要聚焦于杂质组分的影响方面.然而,CO2管道运行参数(例如,压力和温度等)也是影响管道内腐蚀的重要因素[13,17~19],目前尚不清楚其如何影响管线钢的SCC行为.值得注意的是,上述研究主要源于水饱和超临界CO2体系[9~12,14~19],这与低含水(水不饱和)的超临界CO2输送体系的实际腐蚀情形差异很大.由于上述两种体系中水含量的差异,管线钢的腐蚀速率、腐蚀形态及腐蚀机理均存在很大不同[20],这必然造成其SCC敏感性及机理的显著变化.尤其是,随着未来CCUS工程项目由百万吨级向千万吨级发展,来自不同捕集源头的CO2汇入同一条管道输送很可能成为新常态,多碳源汇集的CO2流体中会不可避免地增多杂质的种类,必然导致CO2管道面临多种杂质共存的情况[4,21].因此,有必要研究低含水-多种杂质共存的超临界CO2环境中管线钢的应力腐蚀行为,评估其SCC敏感性,为含杂质的超临界CO2输送管道的内腐蚀控制提供科学依据. ...

... ,14~19],这与低含水(水不饱和)的超临界CO2输送体系的实际腐蚀情形差异很大.由于上述两种体系中水含量的差异,管线钢的腐蚀速率、腐蚀形态及腐蚀机理均存在很大不同[20],这必然造成其SCC敏感性及机理的显著变化.尤其是,随着未来CCUS工程项目由百万吨级向千万吨级发展,来自不同捕集源头的CO2汇入同一条管道输送很可能成为新常态,多碳源汇集的CO2流体中会不可避免地增多杂质的种类,必然导致CO2管道面临多种杂质共存的情况[4,21].因此,有必要研究低含水-多种杂质共存的超临界CO2环境中管线钢的应力腐蚀行为,评估其SCC敏感性,为含杂质的超临界CO2输送管道的内腐蚀控制提供科学依据. ...

Long-term corrosion and stress corrosion cracking of X65 steel in H2O-saturated supercritical CO2 with SO2 and O2 impurities

0

2023

Influence of H2S on the general corrosion and sulfide stress cracking of pipelines steels for supercritical CO2 transportation

1

2021

... 目前,有关超临界CO2输送管道内腐蚀的研究报道众多,主要关注杂质组分、管输压力及温度等因素对管道腐蚀规律及机理的影响,很少涉及应力的影响.在应力作用下,力学-电化学耦合效应可以导致碳钢的腐蚀电位负移,提高其腐蚀速率,同时更容易造成碳钢表面电化学活性的不均匀性,造成碳钢局部腐蚀甚至SCC[9].考虑到超临界CO2输送环境的特殊性,有些学者讨论和强调CO2输送管道潜在的SCC风险[8~13],但受限于相关实验研究的不足,尚不能完全明晰超临界CO2输送管道的SCC敏感性及机理.从近年研究报道来看,一些研究认为X65管线钢在含SO2/O2的水饱和超临界CO2环境中具有很低的SCC敏感性[14~16].而Wang等[10]研究认为X70管线钢在含SO2的水饱和超临界CO2环境中具有较高的SCC敏感性,尤其是在SO2和O2杂质共存的环境中其SCC敏感性显著增加,主要发生氢致开裂型SCC.Sun等[9]研究表明在含O2、SO2或NO2的水饱和超临界CO2环境中X65管线钢的SCC敏感性与杂质引起的电化学腐蚀程度密切相关;相比O2,NO2和SO2由于其更强的腐蚀作用显著增加X65管线钢的SCC敏感性;在含NO2环境中局部阳极溶解和应力的耦合作用主导X65管线钢的SCC过程.而在含SO2环境中,X65管线钢的SCC过程受局部阳极溶解、氢脆和应力的共同控制[11].显然,对有关含杂质的超临界CO2输送管道的SCC敏感性及机理的认识仍存在争议.此外,上述有限的研究也主要聚焦于杂质组分的影响方面.然而,CO2管道运行参数(例如,压力和温度等)也是影响管道内腐蚀的重要因素[13,17~19],目前尚不清楚其如何影响管线钢的SCC行为.值得注意的是,上述研究主要源于水饱和超临界CO2体系[9~12,14~19],这与低含水(水不饱和)的超临界CO2输送体系的实际腐蚀情形差异很大.由于上述两种体系中水含量的差异,管线钢的腐蚀速率、腐蚀形态及腐蚀机理均存在很大不同[20],这必然造成其SCC敏感性及机理的显著变化.尤其是,随着未来CCUS工程项目由百万吨级向千万吨级发展,来自不同捕集源头的CO2汇入同一条管道输送很可能成为新常态,多碳源汇集的CO2流体中会不可避免地增多杂质的种类,必然导致CO2管道面临多种杂质共存的情况[4,21].因此,有必要研究低含水-多种杂质共存的超临界CO2环境中管线钢的应力腐蚀行为,评估其SCC敏感性,为含杂质的超临界CO2输送管道的内腐蚀控制提供科学依据. ...

Effect of temperature and pressure on corrosion behavior of X65 carbon steel in water-saturated CO2 transport environments mixed with H2S

1

2018

... 目前,有关超临界CO2输送管道内腐蚀的研究报道众多,主要关注杂质组分、管输压力及温度等因素对管道腐蚀规律及机理的影响,很少涉及应力的影响.在应力作用下,力学-电化学耦合效应可以导致碳钢的腐蚀电位负移,提高其腐蚀速率,同时更容易造成碳钢表面电化学活性的不均匀性,造成碳钢局部腐蚀甚至SCC[9].考虑到超临界CO2输送环境的特殊性,有些学者讨论和强调CO2输送管道潜在的SCC风险[8~13],但受限于相关实验研究的不足,尚不能完全明晰超临界CO2输送管道的SCC敏感性及机理.从近年研究报道来看,一些研究认为X65管线钢在含SO2/O2的水饱和超临界CO2环境中具有很低的SCC敏感性[14~16].而Wang等[10]研究认为X70管线钢在含SO2的水饱和超临界CO2环境中具有较高的SCC敏感性,尤其是在SO2和O2杂质共存的环境中其SCC敏感性显著增加,主要发生氢致开裂型SCC.Sun等[9]研究表明在含O2、SO2或NO2的水饱和超临界CO2环境中X65管线钢的SCC敏感性与杂质引起的电化学腐蚀程度密切相关;相比O2,NO2和SO2由于其更强的腐蚀作用显著增加X65管线钢的SCC敏感性;在含NO2环境中局部阳极溶解和应力的耦合作用主导X65管线钢的SCC过程.而在含SO2环境中,X65管线钢的SCC过程受局部阳极溶解、氢脆和应力的共同控制[11].显然,对有关含杂质的超临界CO2输送管道的SCC敏感性及机理的认识仍存在争议.此外,上述有限的研究也主要聚焦于杂质组分的影响方面.然而,CO2管道运行参数(例如,压力和温度等)也是影响管道内腐蚀的重要因素[13,17~19],目前尚不清楚其如何影响管线钢的SCC行为.值得注意的是,上述研究主要源于水饱和超临界CO2体系[9~12,14~19],这与低含水(水不饱和)的超临界CO2输送体系的实际腐蚀情形差异很大.由于上述两种体系中水含量的差异,管线钢的腐蚀速率、腐蚀形态及腐蚀机理均存在很大不同[20],这必然造成其SCC敏感性及机理的显著变化.尤其是,随着未来CCUS工程项目由百万吨级向千万吨级发展,来自不同捕集源头的CO2汇入同一条管道输送很可能成为新常态,多碳源汇集的CO2流体中会不可避免地增多杂质的种类,必然导致CO2管道面临多种杂质共存的情况[4,21].因此,有必要研究低含水-多种杂质共存的超临界CO2环境中管线钢的应力腐蚀行为,评估其SCC敏感性,为含杂质的超临界CO2输送管道的内腐蚀控制提供科学依据. ...

Research progress on corrosion of CO2 injection well tubing in CCUS system

0

2024

CCUS系统中CO2注入井管材腐蚀研究进展

0

2024

Research progress on corrosion behavior of gaseous CO2 transportation pipelines containing impurities

3

2021

... 目前,有关超临界CO2输送管道内腐蚀的研究报道众多,主要关注杂质组分、管输压力及温度等因素对管道腐蚀规律及机理的影响,很少涉及应力的影响.在应力作用下,力学-电化学耦合效应可以导致碳钢的腐蚀电位负移,提高其腐蚀速率,同时更容易造成碳钢表面电化学活性的不均匀性,造成碳钢局部腐蚀甚至SCC[9].考虑到超临界CO2输送环境的特殊性,有些学者讨论和强调CO2输送管道潜在的SCC风险[8~13],但受限于相关实验研究的不足,尚不能完全明晰超临界CO2输送管道的SCC敏感性及机理.从近年研究报道来看,一些研究认为X65管线钢在含SO2/O2的水饱和超临界CO2环境中具有很低的SCC敏感性[14~16].而Wang等[10]研究认为X70管线钢在含SO2的水饱和超临界CO2环境中具有较高的SCC敏感性,尤其是在SO2和O2杂质共存的环境中其SCC敏感性显著增加,主要发生氢致开裂型SCC.Sun等[9]研究表明在含O2、SO2或NO2的水饱和超临界CO2环境中X65管线钢的SCC敏感性与杂质引起的电化学腐蚀程度密切相关;相比O2,NO2和SO2由于其更强的腐蚀作用显著增加X65管线钢的SCC敏感性;在含NO2环境中局部阳极溶解和应力的耦合作用主导X65管线钢的SCC过程.而在含SO2环境中,X65管线钢的SCC过程受局部阳极溶解、氢脆和应力的共同控制[11].显然,对有关含杂质的超临界CO2输送管道的SCC敏感性及机理的认识仍存在争议.此外,上述有限的研究也主要聚焦于杂质组分的影响方面.然而,CO2管道运行参数(例如,压力和温度等)也是影响管道内腐蚀的重要因素[13,17~19],目前尚不清楚其如何影响管线钢的SCC行为.值得注意的是,上述研究主要源于水饱和超临界CO2体系[9~12,14~19],这与低含水(水不饱和)的超临界CO2输送体系的实际腐蚀情形差异很大.由于上述两种体系中水含量的差异,管线钢的腐蚀速率、腐蚀形态及腐蚀机理均存在很大不同[20],这必然造成其SCC敏感性及机理的显著变化.尤其是,随着未来CCUS工程项目由百万吨级向千万吨级发展,来自不同捕集源头的CO2汇入同一条管道输送很可能成为新常态,多碳源汇集的CO2流体中会不可避免地增多杂质的种类,必然导致CO2管道面临多种杂质共存的情况[4,21].因此,有必要研究低含水-多种杂质共存的超临界CO2环境中管线钢的应力腐蚀行为,评估其SCC敏感性,为含杂质的超临界CO2输送管道的内腐蚀控制提供科学依据. ...

... ~19],这与低含水(水不饱和)的超临界CO2输送体系的实际腐蚀情形差异很大.由于上述两种体系中水含量的差异,管线钢的腐蚀速率、腐蚀形态及腐蚀机理均存在很大不同[20],这必然造成其SCC敏感性及机理的显著变化.尤其是,随着未来CCUS工程项目由百万吨级向千万吨级发展,来自不同捕集源头的CO2汇入同一条管道输送很可能成为新常态,多碳源汇集的CO2流体中会不可避免地增多杂质的种类,必然导致CO2管道面临多种杂质共存的情况[4,21].因此,有必要研究低含水-多种杂质共存的超临界CO2环境中管线钢的应力腐蚀行为,评估其SCC敏感性,为含杂质的超临界CO2输送管道的内腐蚀控制提供科学依据. ...

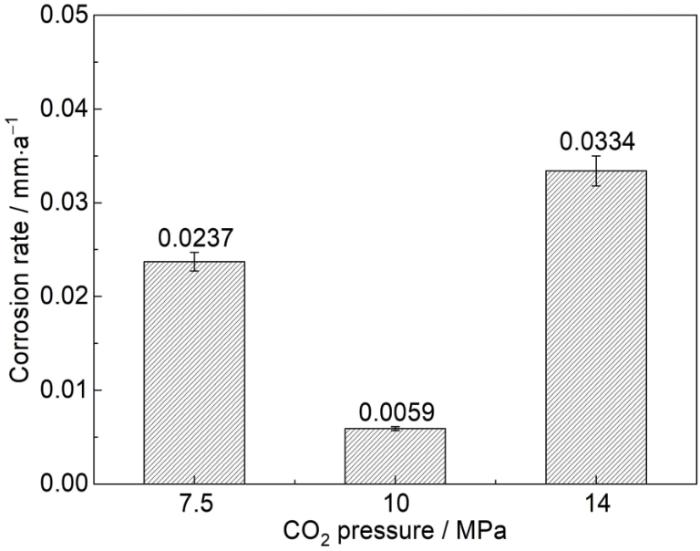

... 对于含杂质的超临界CO2输送环境,管线钢是否发生腐蚀取决于钢表面能否形成自由液相[19].相关研究表明,在相同的含杂质的超临界CO2环境中,随着含水量的提高,由于能够在钢表面形成的腐蚀性液相量增多,管线钢腐蚀速率及腐蚀产物膜厚度也相应增加[35].因此,钢表面形成腐蚀产物膜厚度的不同能够一定程度地反映出其表面腐蚀性液相形成量的差异.不同压力条件下X65管线钢发生不同程度的腐蚀,说明溶解于超临界CO2中H2O析出并沉积在钢表面.相应地,超临界CO2及杂质气体溶解于液相中改变液膜的化学性质,进而影响管线钢的腐蚀.为了明确CO2压力变化对形成液相化学特性的影响,采用OLI Analyzer studio软件的Stream Analyzer模块进行了水化学计算.由图9可见,在7.5、10和14 MPa CO2压力环境中X65管线钢表面腐蚀产物膜厚度分别为7、3.5和10 μm.据此,假设3种CO2压力环境中分别形成7、3.5和10 μm的液膜,即在X65管线钢表面每单位面积(cm2)分别沉积0.0007、0.00035和0.0010 g的H2O.根据表1中实验条件,确定用于水化学计算的CO2及杂质组分量.不同CO2压力环境中液膜的化学分析计算结果如表2所示.随着压力的升高,X65管线钢表面液膜中溶解的CO2、杂质气体及主要离子含量呈先降低后升高的变化趋势,与腐蚀速率变化规律一致.而液膜中杂质气体及主要离子浓度随压力变化趋势与腐蚀速率变化无明显相关性.随着压力的增加,HS-、CO、HCO、CO2的浓度逐渐升高,而HSO、SO、H+、SO2、NO2的浓度逐渐降低.这是因为在水介质环境中裸钢直接与大量液相介质接触而发生腐蚀不同,在低含水超临界CO2环境中,水先在钢表面形成液膜,同时CO2及杂质气体溶解在液膜中,钢表面形成的液膜越厚,液膜中溶解的腐蚀性物质含量也就越高,进而腐蚀也就更严重[25].综上,不同压力环境中X65管线钢腐蚀速率差异与压力变化引起的液相化学环境不同相关. ...

含杂质气态CO2输送管道腐蚀研究进展

3

2021

... 目前,有关超临界CO2输送管道内腐蚀的研究报道众多,主要关注杂质组分、管输压力及温度等因素对管道腐蚀规律及机理的影响,很少涉及应力的影响.在应力作用下,力学-电化学耦合效应可以导致碳钢的腐蚀电位负移,提高其腐蚀速率,同时更容易造成碳钢表面电化学活性的不均匀性,造成碳钢局部腐蚀甚至SCC[9].考虑到超临界CO2输送环境的特殊性,有些学者讨论和强调CO2输送管道潜在的SCC风险[8~13],但受限于相关实验研究的不足,尚不能完全明晰超临界CO2输送管道的SCC敏感性及机理.从近年研究报道来看,一些研究认为X65管线钢在含SO2/O2的水饱和超临界CO2环境中具有很低的SCC敏感性[14~16].而Wang等[10]研究认为X70管线钢在含SO2的水饱和超临界CO2环境中具有较高的SCC敏感性,尤其是在SO2和O2杂质共存的环境中其SCC敏感性显著增加,主要发生氢致开裂型SCC.Sun等[9]研究表明在含O2、SO2或NO2的水饱和超临界CO2环境中X65管线钢的SCC敏感性与杂质引起的电化学腐蚀程度密切相关;相比O2,NO2和SO2由于其更强的腐蚀作用显著增加X65管线钢的SCC敏感性;在含NO2环境中局部阳极溶解和应力的耦合作用主导X65管线钢的SCC过程.而在含SO2环境中,X65管线钢的SCC过程受局部阳极溶解、氢脆和应力的共同控制[11].显然,对有关含杂质的超临界CO2输送管道的SCC敏感性及机理的认识仍存在争议.此外,上述有限的研究也主要聚焦于杂质组分的影响方面.然而,CO2管道运行参数(例如,压力和温度等)也是影响管道内腐蚀的重要因素[13,17~19],目前尚不清楚其如何影响管线钢的SCC行为.值得注意的是,上述研究主要源于水饱和超临界CO2体系[9~12,14~19],这与低含水(水不饱和)的超临界CO2输送体系的实际腐蚀情形差异很大.由于上述两种体系中水含量的差异,管线钢的腐蚀速率、腐蚀形态及腐蚀机理均存在很大不同[20],这必然造成其SCC敏感性及机理的显著变化.尤其是,随着未来CCUS工程项目由百万吨级向千万吨级发展,来自不同捕集源头的CO2汇入同一条管道输送很可能成为新常态,多碳源汇集的CO2流体中会不可避免地增多杂质的种类,必然导致CO2管道面临多种杂质共存的情况[4,21].因此,有必要研究低含水-多种杂质共存的超临界CO2环境中管线钢的应力腐蚀行为,评估其SCC敏感性,为含杂质的超临界CO2输送管道的内腐蚀控制提供科学依据. ...

... ~19],这与低含水(水不饱和)的超临界CO2输送体系的实际腐蚀情形差异很大.由于上述两种体系中水含量的差异,管线钢的腐蚀速率、腐蚀形态及腐蚀机理均存在很大不同[20],这必然造成其SCC敏感性及机理的显著变化.尤其是,随着未来CCUS工程项目由百万吨级向千万吨级发展,来自不同捕集源头的CO2汇入同一条管道输送很可能成为新常态,多碳源汇集的CO2流体中会不可避免地增多杂质的种类,必然导致CO2管道面临多种杂质共存的情况[4,21].因此,有必要研究低含水-多种杂质共存的超临界CO2环境中管线钢的应力腐蚀行为,评估其SCC敏感性,为含杂质的超临界CO2输送管道的内腐蚀控制提供科学依据. ...

... 对于含杂质的超临界CO2输送环境,管线钢是否发生腐蚀取决于钢表面能否形成自由液相[19].相关研究表明,在相同的含杂质的超临界CO2环境中,随着含水量的提高,由于能够在钢表面形成的腐蚀性液相量增多,管线钢腐蚀速率及腐蚀产物膜厚度也相应增加[35].因此,钢表面形成腐蚀产物膜厚度的不同能够一定程度地反映出其表面腐蚀性液相形成量的差异.不同压力条件下X65管线钢发生不同程度的腐蚀,说明溶解于超临界CO2中H2O析出并沉积在钢表面.相应地,超临界CO2及杂质气体溶解于液相中改变液膜的化学性质,进而影响管线钢的腐蚀.为了明确CO2压力变化对形成液相化学特性的影响,采用OLI Analyzer studio软件的Stream Analyzer模块进行了水化学计算.由图9可见,在7.5、10和14 MPa CO2压力环境中X65管线钢表面腐蚀产物膜厚度分别为7、3.5和10 μm.据此,假设3种CO2压力环境中分别形成7、3.5和10 μm的液膜,即在X65管线钢表面每单位面积(cm2)分别沉积0.0007、0.00035和0.0010 g的H2O.根据表1中实验条件,确定用于水化学计算的CO2及杂质组分量.不同CO2压力环境中液膜的化学分析计算结果如表2所示.随着压力的升高,X65管线钢表面液膜中溶解的CO2、杂质气体及主要离子含量呈先降低后升高的变化趋势,与腐蚀速率变化规律一致.而液膜中杂质气体及主要离子浓度随压力变化趋势与腐蚀速率变化无明显相关性.随着压力的增加,HS-、CO、HCO、CO2的浓度逐渐升高,而HSO、SO、H+、SO2、NO2的浓度逐渐降低.这是因为在水介质环境中裸钢直接与大量液相介质接触而发生腐蚀不同,在低含水超临界CO2环境中,水先在钢表面形成液膜,同时CO2及杂质气体溶解在液膜中,钢表面形成的液膜越厚,液膜中溶解的腐蚀性物质含量也就越高,进而腐蚀也就更严重[25].综上,不同压力环境中X65管线钢腐蚀速率差异与压力变化引起的液相化学环境不同相关. ...

Effect of water content on corrosion behavior of X65 pipeline Steel in supercritical CO2 fluids

2

2024

... 目前,有关超临界CO2输送管道内腐蚀的研究报道众多,主要关注杂质组分、管输压力及温度等因素对管道腐蚀规律及机理的影响,很少涉及应力的影响.在应力作用下,力学-电化学耦合效应可以导致碳钢的腐蚀电位负移,提高其腐蚀速率,同时更容易造成碳钢表面电化学活性的不均匀性,造成碳钢局部腐蚀甚至SCC[9].考虑到超临界CO2输送环境的特殊性,有些学者讨论和强调CO2输送管道潜在的SCC风险[8~13],但受限于相关实验研究的不足,尚不能完全明晰超临界CO2输送管道的SCC敏感性及机理.从近年研究报道来看,一些研究认为X65管线钢在含SO2/O2的水饱和超临界CO2环境中具有很低的SCC敏感性[14~16].而Wang等[10]研究认为X70管线钢在含SO2的水饱和超临界CO2环境中具有较高的SCC敏感性,尤其是在SO2和O2杂质共存的环境中其SCC敏感性显著增加,主要发生氢致开裂型SCC.Sun等[9]研究表明在含O2、SO2或NO2的水饱和超临界CO2环境中X65管线钢的SCC敏感性与杂质引起的电化学腐蚀程度密切相关;相比O2,NO2和SO2由于其更强的腐蚀作用显著增加X65管线钢的SCC敏感性;在含NO2环境中局部阳极溶解和应力的耦合作用主导X65管线钢的SCC过程.而在含SO2环境中,X65管线钢的SCC过程受局部阳极溶解、氢脆和应力的共同控制[11].显然,对有关含杂质的超临界CO2输送管道的SCC敏感性及机理的认识仍存在争议.此外,上述有限的研究也主要聚焦于杂质组分的影响方面.然而,CO2管道运行参数(例如,压力和温度等)也是影响管道内腐蚀的重要因素[13,17~19],目前尚不清楚其如何影响管线钢的SCC行为.值得注意的是,上述研究主要源于水饱和超临界CO2体系[9~12,14~19],这与低含水(水不饱和)的超临界CO2输送体系的实际腐蚀情形差异很大.由于上述两种体系中水含量的差异,管线钢的腐蚀速率、腐蚀形态及腐蚀机理均存在很大不同[20],这必然造成其SCC敏感性及机理的显著变化.尤其是,随着未来CCUS工程项目由百万吨级向千万吨级发展,来自不同捕集源头的CO2汇入同一条管道输送很可能成为新常态,多碳源汇集的CO2流体中会不可避免地增多杂质的种类,必然导致CO2管道面临多种杂质共存的情况[4,21].因此,有必要研究低含水-多种杂质共存的超临界CO2环境中管线钢的应力腐蚀行为,评估其SCC敏感性,为含杂质的超临界CO2输送管道的内腐蚀控制提供科学依据. ...

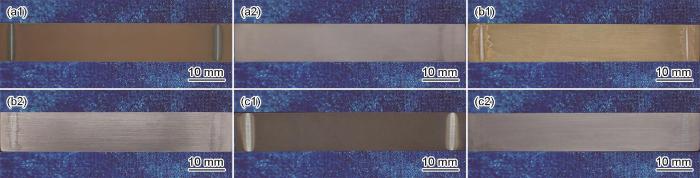

... 应力腐蚀240 h后,取出试样并用数码相机拍照.采用酸洗溶液(组成为5 g六次甲基四胺、0.1 L密度为1.19 g/mL的HCl和0.9 L去离子水)去除3个平行试样表面腐蚀产物[20],充分干燥后分别称重.采用失重法计算X65管线钢的腐蚀速率(CR,mm/a),计算公式如 式(3)[25]: ...

水含量对超临界CO2输送管道腐蚀的影响

2

2024

... 目前,有关超临界CO2输送管道内腐蚀的研究报道众多,主要关注杂质组分、管输压力及温度等因素对管道腐蚀规律及机理的影响,很少涉及应力的影响.在应力作用下,力学-电化学耦合效应可以导致碳钢的腐蚀电位负移,提高其腐蚀速率,同时更容易造成碳钢表面电化学活性的不均匀性,造成碳钢局部腐蚀甚至SCC[9].考虑到超临界CO2输送环境的特殊性,有些学者讨论和强调CO2输送管道潜在的SCC风险[8~13],但受限于相关实验研究的不足,尚不能完全明晰超临界CO2输送管道的SCC敏感性及机理.从近年研究报道来看,一些研究认为X65管线钢在含SO2/O2的水饱和超临界CO2环境中具有很低的SCC敏感性[14~16].而Wang等[10]研究认为X70管线钢在含SO2的水饱和超临界CO2环境中具有较高的SCC敏感性,尤其是在SO2和O2杂质共存的环境中其SCC敏感性显著增加,主要发生氢致开裂型SCC.Sun等[9]研究表明在含O2、SO2或NO2的水饱和超临界CO2环境中X65管线钢的SCC敏感性与杂质引起的电化学腐蚀程度密切相关;相比O2,NO2和SO2由于其更强的腐蚀作用显著增加X65管线钢的SCC敏感性;在含NO2环境中局部阳极溶解和应力的耦合作用主导X65管线钢的SCC过程.而在含SO2环境中,X65管线钢的SCC过程受局部阳极溶解、氢脆和应力的共同控制[11].显然,对有关含杂质的超临界CO2输送管道的SCC敏感性及机理的认识仍存在争议.此外,上述有限的研究也主要聚焦于杂质组分的影响方面.然而,CO2管道运行参数(例如,压力和温度等)也是影响管道内腐蚀的重要因素[13,17~19],目前尚不清楚其如何影响管线钢的SCC行为.值得注意的是,上述研究主要源于水饱和超临界CO2体系[9~12,14~19],这与低含水(水不饱和)的超临界CO2输送体系的实际腐蚀情形差异很大.由于上述两种体系中水含量的差异,管线钢的腐蚀速率、腐蚀形态及腐蚀机理均存在很大不同[20],这必然造成其SCC敏感性及机理的显著变化.尤其是,随着未来CCUS工程项目由百万吨级向千万吨级发展,来自不同捕集源头的CO2汇入同一条管道输送很可能成为新常态,多碳源汇集的CO2流体中会不可避免地增多杂质的种类,必然导致CO2管道面临多种杂质共存的情况[4,21].因此,有必要研究低含水-多种杂质共存的超临界CO2环境中管线钢的应力腐蚀行为,评估其SCC敏感性,为含杂质的超临界CO2输送管道的内腐蚀控制提供科学依据. ...

... 应力腐蚀240 h后,取出试样并用数码相机拍照.采用酸洗溶液(组成为5 g六次甲基四胺、0.1 L密度为1.19 g/mL的HCl和0.9 L去离子水)去除3个平行试样表面腐蚀产物[20],充分干燥后分别称重.采用失重法计算X65管线钢的腐蚀速率(CR,mm/a),计算公式如 式(3)[25]: ...

Effect of SO2, O2, NO2, and H2O concentrations on chemical reactions and corrosion of carbon steel in dense phase CO2

2

2019

... 目前,有关超临界CO2输送管道内腐蚀的研究报道众多,主要关注杂质组分、管输压力及温度等因素对管道腐蚀规律及机理的影响,很少涉及应力的影响.在应力作用下,力学-电化学耦合效应可以导致碳钢的腐蚀电位负移,提高其腐蚀速率,同时更容易造成碳钢表面电化学活性的不均匀性,造成碳钢局部腐蚀甚至SCC[9].考虑到超临界CO2输送环境的特殊性,有些学者讨论和强调CO2输送管道潜在的SCC风险[8~13],但受限于相关实验研究的不足,尚不能完全明晰超临界CO2输送管道的SCC敏感性及机理.从近年研究报道来看,一些研究认为X65管线钢在含SO2/O2的水饱和超临界CO2环境中具有很低的SCC敏感性[14~16].而Wang等[10]研究认为X70管线钢在含SO2的水饱和超临界CO2环境中具有较高的SCC敏感性,尤其是在SO2和O2杂质共存的环境中其SCC敏感性显著增加,主要发生氢致开裂型SCC.Sun等[9]研究表明在含O2、SO2或NO2的水饱和超临界CO2环境中X65管线钢的SCC敏感性与杂质引起的电化学腐蚀程度密切相关;相比O2,NO2和SO2由于其更强的腐蚀作用显著增加X65管线钢的SCC敏感性;在含NO2环境中局部阳极溶解和应力的耦合作用主导X65管线钢的SCC过程.而在含SO2环境中,X65管线钢的SCC过程受局部阳极溶解、氢脆和应力的共同控制[11].显然,对有关含杂质的超临界CO2输送管道的SCC敏感性及机理的认识仍存在争议.此外,上述有限的研究也主要聚焦于杂质组分的影响方面.然而,CO2管道运行参数(例如,压力和温度等)也是影响管道内腐蚀的重要因素[13,17~19],目前尚不清楚其如何影响管线钢的SCC行为.值得注意的是,上述研究主要源于水饱和超临界CO2体系[9~12,14~19],这与低含水(水不饱和)的超临界CO2输送体系的实际腐蚀情形差异很大.由于上述两种体系中水含量的差异,管线钢的腐蚀速率、腐蚀形态及腐蚀机理均存在很大不同[20],这必然造成其SCC敏感性及机理的显著变化.尤其是,随着未来CCUS工程项目由百万吨级向千万吨级发展,来自不同捕集源头的CO2汇入同一条管道输送很可能成为新常态,多碳源汇集的CO2流体中会不可避免地增多杂质的种类,必然导致CO2管道面临多种杂质共存的情况[4,21].因此,有必要研究低含水-多种杂质共存的超临界CO2环境中管线钢的应力腐蚀行为,评估其SCC敏感性,为含杂质的超临界CO2输送管道的内腐蚀控制提供科学依据. ...

... 由图9a3~c3中EDS分析结果可见,在各CO2压力环境中应力腐蚀204 h后形成的腐蚀产物膜主要由Fe、O和S组成,元素分布均匀.在7.5 MPa和10 MPa CO2压力环境中腐蚀产物膜中S含量较少,说明腐蚀产物以Fe和O的化合物为主;而在14 MPa CO2压力环境中腐蚀产物中S含量明显增多,说明腐蚀产物中含S产物含量增加.为了进一步确定腐蚀产物膜的化学组成及差异,采用Raman光谱对X65管线钢表面腐蚀产物膜进行分析(图10).不同压力的CO2环境中腐蚀产物膜的Raman散射峰基本相同:在波数为216、274、383、482、586、712和1301 cm-1处的Raman散射峰对应于FeOOH[10,28~30],489和800 cm-1对应于FeSO4或FeSO4的水合物[31,32].由此可见,不同CO2压力环境中形成的腐蚀产物膜的主要化学成分相同,均为FeOOH和FeSO4.显然,在含O2、H2S、SO2和NO2的超临界CO2环境中,杂质间可以发生化学反应,生成H2SO4[25,33],进而形成FeSO4产物.FeOOH是含O2或NO2杂质的超临界CO2环境中常见的腐蚀产物[21]:一方面O2和NO2直接参与X65管线钢的腐蚀过程,形成FeOOH;另一方面,在实验环境中X65管线钢表面可能形成的腐蚀产物,如FeSO4、FeCO3和FeS等[34],暴露于含氧的湿气环境中容易被氧化,从而形成FeOOH产物[25]. ...

Effect of temperature on stress corrosion behavior of Ti-alloy Ti80 in sea water

1

2023

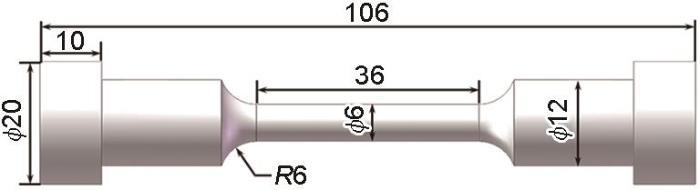

... 利用YYF-50型拉伸实验机在含杂质的超临界CO2环境中开展慢应变速率拉伸(SSRT)实验,实验条件如表1所示.将试样安装在高压釜拉伸台上后,向反应釜内注入实验所需的水量(除氧去离子水),迅速关闭反应釜,并持续通入99.999%纯度的CO2气体至少2 h进行除氧.随后,加热反应釜至实验温度,再分别向反应釜内通入O2/CO2、H2S/CO2、SO2/CO2和NO2/CO2混合气至实验所需杂质气体含量,再使用增压泵将纯CO2泵入反应釜内,直至实验设定压力.将拉伸试样暴露在实验环境中预腐蚀18 h后,进行慢应变速率拉伸实验,应变速率为1 × 10-6 s-1.各条件下的实验至少重复2次,以确保实验结果重复性.实验结束后,利用扫描电子显微镜(SEM,JEOL JSM-7200F)观察拉伸试样断口表面及侧面微观形貌.采用 公式(1)计算拉伸试样的断面收缩率(Ψ)[22]: ...

温度对钛合金应力腐蚀行为的影响

1

2023

... 利用YYF-50型拉伸实验机在含杂质的超临界CO2环境中开展慢应变速率拉伸(SSRT)实验,实验条件如表1所示.将试样安装在高压釜拉伸台上后,向反应釜内注入实验所需的水量(除氧去离子水),迅速关闭反应釜,并持续通入99.999%纯度的CO2气体至少2 h进行除氧.随后,加热反应釜至实验温度,再分别向反应釜内通入O2/CO2、H2S/CO2、SO2/CO2和NO2/CO2混合气至实验所需杂质气体含量,再使用增压泵将纯CO2泵入反应釜内,直至实验设定压力.将拉伸试样暴露在实验环境中预腐蚀18 h后,进行慢应变速率拉伸实验,应变速率为1 × 10-6 s-1.各条件下的实验至少重复2次,以确保实验结果重复性.实验结束后,利用扫描电子显微镜(SEM,JEOL JSM-7200F)观察拉伸试样断口表面及侧面微观形貌.采用 公式(1)计算拉伸试样的断面收缩率(Ψ)[22]: ...

Effects of pre-strain on hydrogen-induced stress corrosion cracking behavior of Q345R steel in hydrofluoric acid vapor environment

1

2024

... 式中,S1为拉伸试样在腐蚀环境中断裂后的断面面积,mm2;S0为拉伸试样标距段的横截面面积,mm2.为了明确CO2压力对X65管线钢SCC敏感性的影响,采用 公式(2)计算X65管线钢的SCC敏感性因子(IΨ-SCC)[23]: ...

Corrosion behaviors of steels under supercritical CO2 conditions

1

2015

... 利用高温高压反应釜在含杂质的超临界CO2腐蚀环境中开展不同压力下的应力腐蚀实验.图3为实验装置示意图.根据ASTM G39标准[24],采用四点弯曲法(FPB)对试样加载应力,应力值为X65管线钢的屈服强度520 MPa.实验前,先将4个加载试样安装在反应釜中的试样夹具上(图3).然后,采用与慢应变速率拉伸实验预腐蚀前相同的操作步骤进行加水、除氧、升温、加混合气和加压,保持实验条件与慢应变速率拉伸实验一致(表1). ...

Corrosion behaviors of X65 steel in gaseous CO2 environment containing impurities

4

2022

... 应力腐蚀240 h后,取出试样并用数码相机拍照.采用酸洗溶液(组成为5 g六次甲基四胺、0.1 L密度为1.19 g/mL的HCl和0.9 L去离子水)去除3个平行试样表面腐蚀产物[20],充分干燥后分别称重.采用失重法计算X65管线钢的腐蚀速率(CR,mm/a),计算公式如 式(3)[25]: ...

... 由图9a3~c3中EDS分析结果可见,在各CO2压力环境中应力腐蚀204 h后形成的腐蚀产物膜主要由Fe、O和S组成,元素分布均匀.在7.5 MPa和10 MPa CO2压力环境中腐蚀产物膜中S含量较少,说明腐蚀产物以Fe和O的化合物为主;而在14 MPa CO2压力环境中腐蚀产物中S含量明显增多,说明腐蚀产物中含S产物含量增加.为了进一步确定腐蚀产物膜的化学组成及差异,采用Raman光谱对X65管线钢表面腐蚀产物膜进行分析(图10).不同压力的CO2环境中腐蚀产物膜的Raman散射峰基本相同:在波数为216、274、383、482、586、712和1301 cm-1处的Raman散射峰对应于FeOOH[10,28~30],489和800 cm-1对应于FeSO4或FeSO4的水合物[31,32].由此可见,不同CO2压力环境中形成的腐蚀产物膜的主要化学成分相同,均为FeOOH和FeSO4.显然,在含O2、H2S、SO2和NO2的超临界CO2环境中,杂质间可以发生化学反应,生成H2SO4[25,33],进而形成FeSO4产物.FeOOH是含O2或NO2杂质的超临界CO2环境中常见的腐蚀产物[21]:一方面O2和NO2直接参与X65管线钢的腐蚀过程,形成FeOOH;另一方面,在实验环境中X65管线钢表面可能形成的腐蚀产物,如FeSO4、FeCO3和FeS等[34],暴露于含氧的湿气环境中容易被氧化,从而形成FeOOH产物[25]. ...

... [25]. ...

... 对于含杂质的超临界CO2输送环境,管线钢是否发生腐蚀取决于钢表面能否形成自由液相[19].相关研究表明,在相同的含杂质的超临界CO2环境中,随着含水量的提高,由于能够在钢表面形成的腐蚀性液相量增多,管线钢腐蚀速率及腐蚀产物膜厚度也相应增加[35].因此,钢表面形成腐蚀产物膜厚度的不同能够一定程度地反映出其表面腐蚀性液相形成量的差异.不同压力条件下X65管线钢发生不同程度的腐蚀,说明溶解于超临界CO2中H2O析出并沉积在钢表面.相应地,超临界CO2及杂质气体溶解于液相中改变液膜的化学性质,进而影响管线钢的腐蚀.为了明确CO2压力变化对形成液相化学特性的影响,采用OLI Analyzer studio软件的Stream Analyzer模块进行了水化学计算.由图9可见,在7.5、10和14 MPa CO2压力环境中X65管线钢表面腐蚀产物膜厚度分别为7、3.5和10 μm.据此,假设3种CO2压力环境中分别形成7、3.5和10 μm的液膜,即在X65管线钢表面每单位面积(cm2)分别沉积0.0007、0.00035和0.0010 g的H2O.根据表1中实验条件,确定用于水化学计算的CO2及杂质组分量.不同CO2压力环境中液膜的化学分析计算结果如表2所示.随着压力的升高,X65管线钢表面液膜中溶解的CO2、杂质气体及主要离子含量呈先降低后升高的变化趋势,与腐蚀速率变化规律一致.而液膜中杂质气体及主要离子浓度随压力变化趋势与腐蚀速率变化无明显相关性.随着压力的增加,HS-、CO、HCO、CO2的浓度逐渐升高,而HSO、SO、H+、SO2、NO2的浓度逐渐降低.这是因为在水介质环境中裸钢直接与大量液相介质接触而发生腐蚀不同,在低含水超临界CO2环境中,水先在钢表面形成液膜,同时CO2及杂质气体溶解在液膜中,钢表面形成的液膜越厚,液膜中溶解的腐蚀性物质含量也就越高,进而腐蚀也就更严重[25].综上,不同压力环境中X65管线钢腐蚀速率差异与压力变化引起的液相化学环境不同相关. ...

含杂质气态CO2环境中X65钢腐蚀行为

4

2022

... 应力腐蚀240 h后,取出试样并用数码相机拍照.采用酸洗溶液(组成为5 g六次甲基四胺、0.1 L密度为1.19 g/mL的HCl和0.9 L去离子水)去除3个平行试样表面腐蚀产物[20],充分干燥后分别称重.采用失重法计算X65管线钢的腐蚀速率(CR,mm/a),计算公式如 式(3)[25]: ...

... 由图9a3~c3中EDS分析结果可见,在各CO2压力环境中应力腐蚀204 h后形成的腐蚀产物膜主要由Fe、O和S组成,元素分布均匀.在7.5 MPa和10 MPa CO2压力环境中腐蚀产物膜中S含量较少,说明腐蚀产物以Fe和O的化合物为主;而在14 MPa CO2压力环境中腐蚀产物中S含量明显增多,说明腐蚀产物中含S产物含量增加.为了进一步确定腐蚀产物膜的化学组成及差异,采用Raman光谱对X65管线钢表面腐蚀产物膜进行分析(图10).不同压力的CO2环境中腐蚀产物膜的Raman散射峰基本相同:在波数为216、274、383、482、586、712和1301 cm-1处的Raman散射峰对应于FeOOH[10,28~30],489和800 cm-1对应于FeSO4或FeSO4的水合物[31,32].由此可见,不同CO2压力环境中形成的腐蚀产物膜的主要化学成分相同,均为FeOOH和FeSO4.显然,在含O2、H2S、SO2和NO2的超临界CO2环境中,杂质间可以发生化学反应,生成H2SO4[25,33],进而形成FeSO4产物.FeOOH是含O2或NO2杂质的超临界CO2环境中常见的腐蚀产物[21]:一方面O2和NO2直接参与X65管线钢的腐蚀过程,形成FeOOH;另一方面,在实验环境中X65管线钢表面可能形成的腐蚀产物,如FeSO4、FeCO3和FeS等[34],暴露于含氧的湿气环境中容易被氧化,从而形成FeOOH产物[25]. ...

... [25]. ...

... 对于含杂质的超临界CO2输送环境,管线钢是否发生腐蚀取决于钢表面能否形成自由液相[19].相关研究表明,在相同的含杂质的超临界CO2环境中,随着含水量的提高,由于能够在钢表面形成的腐蚀性液相量增多,管线钢腐蚀速率及腐蚀产物膜厚度也相应增加[35].因此,钢表面形成腐蚀产物膜厚度的不同能够一定程度地反映出其表面腐蚀性液相形成量的差异.不同压力条件下X65管线钢发生不同程度的腐蚀,说明溶解于超临界CO2中H2O析出并沉积在钢表面.相应地,超临界CO2及杂质气体溶解于液相中改变液膜的化学性质,进而影响管线钢的腐蚀.为了明确CO2压力变化对形成液相化学特性的影响,采用OLI Analyzer studio软件的Stream Analyzer模块进行了水化学计算.由图9可见,在7.5、10和14 MPa CO2压力环境中X65管线钢表面腐蚀产物膜厚度分别为7、3.5和10 μm.据此,假设3种CO2压力环境中分别形成7、3.5和10 μm的液膜,即在X65管线钢表面每单位面积(cm2)分别沉积0.0007、0.00035和0.0010 g的H2O.根据表1中实验条件,确定用于水化学计算的CO2及杂质组分量.不同CO2压力环境中液膜的化学分析计算结果如表2所示.随着压力的升高,X65管线钢表面液膜中溶解的CO2、杂质气体及主要离子含量呈先降低后升高的变化趋势,与腐蚀速率变化规律一致.而液膜中杂质气体及主要离子浓度随压力变化趋势与腐蚀速率变化无明显相关性.随着压力的增加,HS-、CO、HCO、CO2的浓度逐渐升高,而HSO、SO、H+、SO2、NO2的浓度逐渐降低.这是因为在水介质环境中裸钢直接与大量液相介质接触而发生腐蚀不同,在低含水超临界CO2环境中,水先在钢表面形成液膜,同时CO2及杂质气体溶解在液膜中,钢表面形成的液膜越厚,液膜中溶解的腐蚀性物质含量也就越高,进而腐蚀也就更严重[25].综上,不同压力环境中X65管线钢腐蚀速率差异与压力变化引起的液相化学环境不同相关. ...

Stress corrosion of X80 pipeline steel welded joints by slow strain test in NACE H2S solutions

1

2013

... 图5a为X65管线钢在不同环境中的断面收缩率.据此计算得到其在不同压力的含杂质超临界CO2腐蚀环境中的SCC敏感性因子(IΨ-SCC),如图5b所示.X65管线钢在空气中的断面收缩率为84.56%,其在7.5、10和14 MPa CO2压力环境中分别降低至82.04%、82.88%和81.12% (图5a),对应的IΨ-SCC值分别为2.98%、1.99%和4.07% (图5b).相关研究表明,一般情况下IΨ-SCC值越大,金属发生SCC可能性越高[9,10,26,27].例如,Sun等[9]研究表明在含0.1%O2的水饱和超临界CO2环境(8 MPa CO2和50 ℃)中X65管线钢的IΨ-SCC值仅为0.28%,拉伸断口呈现韧性断裂特征,不发生SCC;而在含0.1%SO2的水饱和超临界CO2环境(8 MPa CO2和50 ℃)中,X65管线钢的IΨ-SCC值高达64.78%,拉伸断口则呈现明显脆性断裂特征,发生SCC.显然,在含0.01%H2O、0.01%O2、0.01%H2S、0.01%SO2和0.01%NO2的超临界CO2环境中,X65管线钢具有一定的SCC敏感性,而且随着CO2压力由7.5 MPa增加至14 MPa,其SCC敏感性呈先降后升的变化趋势.但是,在实验压力范围内X65管线钢的IΨ-SCC均处于非常低的水平,这表明X65管线钢在上述环境中发生SCC的可能性很低. ...

High stress corrosion cracking resistance of in-situ nanoparticle strengthened steel

1

2022

... 图5a为X65管线钢在不同环境中的断面收缩率.据此计算得到其在不同压力的含杂质超临界CO2腐蚀环境中的SCC敏感性因子(IΨ-SCC),如图5b所示.X65管线钢在空气中的断面收缩率为84.56%,其在7.5、10和14 MPa CO2压力环境中分别降低至82.04%、82.88%和81.12% (图5a),对应的IΨ-SCC值分别为2.98%、1.99%和4.07% (图5b).相关研究表明,一般情况下IΨ-SCC值越大,金属发生SCC可能性越高[9,10,26,27].例如,Sun等[9]研究表明在含0.1%O2的水饱和超临界CO2环境(8 MPa CO2和50 ℃)中X65管线钢的IΨ-SCC值仅为0.28%,拉伸断口呈现韧性断裂特征,不发生SCC;而在含0.1%SO2的水饱和超临界CO2环境(8 MPa CO2和50 ℃)中,X65管线钢的IΨ-SCC值高达64.78%,拉伸断口则呈现明显脆性断裂特征,发生SCC.显然,在含0.01%H2O、0.01%O2、0.01%H2S、0.01%SO2和0.01%NO2的超临界CO2环境中,X65管线钢具有一定的SCC敏感性,而且随着CO2压力由7.5 MPa增加至14 MPa,其SCC敏感性呈先降后升的变化趋势.但是,在实验压力范围内X65管线钢的IΨ-SCC均处于非常低的水平,这表明X65管线钢在上述环境中发生SCC的可能性很低. ...

In situ Raman spectroscopy study of corrosion products on the surface of carbon steel in solution containing Cl- and SO

1

2011

... 由图9a3~c3中EDS分析结果可见,在各CO2压力环境中应力腐蚀204 h后形成的腐蚀产物膜主要由Fe、O和S组成,元素分布均匀.在7.5 MPa和10 MPa CO2压力环境中腐蚀产物膜中S含量较少,说明腐蚀产物以Fe和O的化合物为主;而在14 MPa CO2压力环境中腐蚀产物中S含量明显增多,说明腐蚀产物中含S产物含量增加.为了进一步确定腐蚀产物膜的化学组成及差异,采用Raman光谱对X65管线钢表面腐蚀产物膜进行分析(图10).不同压力的CO2环境中腐蚀产物膜的Raman散射峰基本相同:在波数为216、274、383、482、586、712和1301 cm-1处的Raman散射峰对应于FeOOH[10,28~30],489和800 cm-1对应于FeSO4或FeSO4的水合物[31,32].由此可见,不同CO2压力环境中形成的腐蚀产物膜的主要化学成分相同,均为FeOOH和FeSO4.显然,在含O2、H2S、SO2和NO2的超临界CO2环境中,杂质间可以发生化学反应,生成H2SO4[25,33],进而形成FeSO4产物.FeOOH是含O2或NO2杂质的超临界CO2环境中常见的腐蚀产物[21]:一方面O2和NO2直接参与X65管线钢的腐蚀过程,形成FeOOH;另一方面,在实验环境中X65管线钢表面可能形成的腐蚀产物,如FeSO4、FeCO3和FeS等[34],暴露于含氧的湿气环境中容易被氧化,从而形成FeOOH产物[25]. ...

Characterization of corrosion products formed on the surface of carbon steel by Raman spectroscopy

0

2009

Insights into the mechanism related to the phase transition from γ-Fe2O3 to α-Fe2O3 nanoparticles induced by thermal treatment and laser irradiation

1

2012

... 由图9a3~c3中EDS分析结果可见,在各CO2压力环境中应力腐蚀204 h后形成的腐蚀产物膜主要由Fe、O和S组成,元素分布均匀.在7.5 MPa和10 MPa CO2压力环境中腐蚀产物膜中S含量较少,说明腐蚀产物以Fe和O的化合物为主;而在14 MPa CO2压力环境中腐蚀产物中S含量明显增多,说明腐蚀产物中含S产物含量增加.为了进一步确定腐蚀产物膜的化学组成及差异,采用Raman光谱对X65管线钢表面腐蚀产物膜进行分析(图10).不同压力的CO2环境中腐蚀产物膜的Raman散射峰基本相同:在波数为216、274、383、482、586、712和1301 cm-1处的Raman散射峰对应于FeOOH[10,28~30],489和800 cm-1对应于FeSO4或FeSO4的水合物[31,32].由此可见,不同CO2压力环境中形成的腐蚀产物膜的主要化学成分相同,均为FeOOH和FeSO4.显然,在含O2、H2S、SO2和NO2的超临界CO2环境中,杂质间可以发生化学反应,生成H2SO4[25,33],进而形成FeSO4产物.FeOOH是含O2或NO2杂质的超临界CO2环境中常见的腐蚀产物[21]:一方面O2和NO2直接参与X65管线钢的腐蚀过程,形成FeOOH;另一方面,在实验环境中X65管线钢表面可能形成的腐蚀产物,如FeSO4、FeCO3和FeS等[34],暴露于含氧的湿气环境中容易被氧化,从而形成FeOOH产物[25]. ...

Micro-Raman studies of hydrous ferrous sulfates and jarosites

1

2005

... 由图9a3~c3中EDS分析结果可见,在各CO2压力环境中应力腐蚀204 h后形成的腐蚀产物膜主要由Fe、O和S组成,元素分布均匀.在7.5 MPa和10 MPa CO2压力环境中腐蚀产物膜中S含量较少,说明腐蚀产物以Fe和O的化合物为主;而在14 MPa CO2压力环境中腐蚀产物中S含量明显增多,说明腐蚀产物中含S产物含量增加.为了进一步确定腐蚀产物膜的化学组成及差异,采用Raman光谱对X65管线钢表面腐蚀产物膜进行分析(图10).不同压力的CO2环境中腐蚀产物膜的Raman散射峰基本相同:在波数为216、274、383、482、586、712和1301 cm-1处的Raman散射峰对应于FeOOH[10,28~30],489和800 cm-1对应于FeSO4或FeSO4的水合物[31,32].由此可见,不同CO2压力环境中形成的腐蚀产物膜的主要化学成分相同,均为FeOOH和FeSO4.显然,在含O2、H2S、SO2和NO2的超临界CO2环境中,杂质间可以发生化学反应,生成H2SO4[25,33],进而形成FeSO4产物.FeOOH是含O2或NO2杂质的超临界CO2环境中常见的腐蚀产物[21]:一方面O2和NO2直接参与X65管线钢的腐蚀过程,形成FeOOH;另一方面,在实验环境中X65管线钢表面可能形成的腐蚀产物,如FeSO4、FeCO3和FeS等[34],暴露于含氧的湿气环境中容易被氧化,从而形成FeOOH产物[25]. ...

The hydrates and deuterates of ferrous sulfate (FeSO4): A Raman spectroscopic study

1

2007

... 由图9a3~c3中EDS分析结果可见,在各CO2压力环境中应力腐蚀204 h后形成的腐蚀产物膜主要由Fe、O和S组成,元素分布均匀.在7.5 MPa和10 MPa CO2压力环境中腐蚀产物膜中S含量较少,说明腐蚀产物以Fe和O的化合物为主;而在14 MPa CO2压力环境中腐蚀产物中S含量明显增多,说明腐蚀产物中含S产物含量增加.为了进一步确定腐蚀产物膜的化学组成及差异,采用Raman光谱对X65管线钢表面腐蚀产物膜进行分析(图10).不同压力的CO2环境中腐蚀产物膜的Raman散射峰基本相同:在波数为216、274、383、482、586、712和1301 cm-1处的Raman散射峰对应于FeOOH[10,28~30],489和800 cm-1对应于FeSO4或FeSO4的水合物[31,32].由此可见,不同CO2压力环境中形成的腐蚀产物膜的主要化学成分相同,均为FeOOH和FeSO4.显然,在含O2、H2S、SO2和NO2的超临界CO2环境中,杂质间可以发生化学反应,生成H2SO4[25,33],进而形成FeSO4产物.FeOOH是含O2或NO2杂质的超临界CO2环境中常见的腐蚀产物[21]:一方面O2和NO2直接参与X65管线钢的腐蚀过程,形成FeOOH;另一方面,在实验环境中X65管线钢表面可能形成的腐蚀产物,如FeSO4、FeCO3和FeS等[34],暴露于含氧的湿气环境中容易被氧化,从而形成FeOOH产物[25]. ...

Experimental based CO2 transport specification ensuring material integrity

1

2022

... 由图9a3~c3中EDS分析结果可见,在各CO2压力环境中应力腐蚀204 h后形成的腐蚀产物膜主要由Fe、O和S组成,元素分布均匀.在7.5 MPa和10 MPa CO2压力环境中腐蚀产物膜中S含量较少,说明腐蚀产物以Fe和O的化合物为主;而在14 MPa CO2压力环境中腐蚀产物中S含量明显增多,说明腐蚀产物中含S产物含量增加.为了进一步确定腐蚀产物膜的化学组成及差异,采用Raman光谱对X65管线钢表面腐蚀产物膜进行分析(图10).不同压力的CO2环境中腐蚀产物膜的Raman散射峰基本相同:在波数为216、274、383、482、586、712和1301 cm-1处的Raman散射峰对应于FeOOH[10,28~30],489和800 cm-1对应于FeSO4或FeSO4的水合物[31,32].由此可见,不同CO2压力环境中形成的腐蚀产物膜的主要化学成分相同,均为FeOOH和FeSO4.显然,在含O2、H2S、SO2和NO2的超临界CO2环境中,杂质间可以发生化学反应,生成H2SO4[25,33],进而形成FeSO4产物.FeOOH是含O2或NO2杂质的超临界CO2环境中常见的腐蚀产物[21]:一方面O2和NO2直接参与X65管线钢的腐蚀过程,形成FeOOH;另一方面,在实验环境中X65管线钢表面可能形成的腐蚀产物,如FeSO4、FeCO3和FeS等[34],暴露于含氧的湿气环境中容易被氧化,从而形成FeOOH产物[25]. ...

Corrosion behavior of P110 steel in vapor-liquid phase of H2S/CO2 coexistence system

1

2024

... 由图9a3~c3中EDS分析结果可见,在各CO2压力环境中应力腐蚀204 h后形成的腐蚀产物膜主要由Fe、O和S组成,元素分布均匀.在7.5 MPa和10 MPa CO2压力环境中腐蚀产物膜中S含量较少,说明腐蚀产物以Fe和O的化合物为主;而在14 MPa CO2压力环境中腐蚀产物中S含量明显增多,说明腐蚀产物中含S产物含量增加.为了进一步确定腐蚀产物膜的化学组成及差异,采用Raman光谱对X65管线钢表面腐蚀产物膜进行分析(图10).不同压力的CO2环境中腐蚀产物膜的Raman散射峰基本相同:在波数为216、274、383、482、586、712和1301 cm-1处的Raman散射峰对应于FeOOH[10,28~30],489和800 cm-1对应于FeSO4或FeSO4的水合物[31,32].由此可见,不同CO2压力环境中形成的腐蚀产物膜的主要化学成分相同,均为FeOOH和FeSO4.显然,在含O2、H2S、SO2和NO2的超临界CO2环境中,杂质间可以发生化学反应,生成H2SO4[25,33],进而形成FeSO4产物.FeOOH是含O2或NO2杂质的超临界CO2环境中常见的腐蚀产物[21]:一方面O2和NO2直接参与X65管线钢的腐蚀过程,形成FeOOH;另一方面,在实验环境中X65管线钢表面可能形成的腐蚀产物,如FeSO4、FeCO3和FeS等[34],暴露于含氧的湿气环境中容易被氧化,从而形成FeOOH产物[25]. ...

H2S/CO2共存体系气液相中P110钢的腐蚀行为

1

2024

... 由图9a3~c3中EDS分析结果可见,在各CO2压力环境中应力腐蚀204 h后形成的腐蚀产物膜主要由Fe、O和S组成,元素分布均匀.在7.5 MPa和10 MPa CO2压力环境中腐蚀产物膜中S含量较少,说明腐蚀产物以Fe和O的化合物为主;而在14 MPa CO2压力环境中腐蚀产物中S含量明显增多,说明腐蚀产物中含S产物含量增加.为了进一步确定腐蚀产物膜的化学组成及差异,采用Raman光谱对X65管线钢表面腐蚀产物膜进行分析(图10).不同压力的CO2环境中腐蚀产物膜的Raman散射峰基本相同:在波数为216、274、383、482、586、712和1301 cm-1处的Raman散射峰对应于FeOOH[10,28~30],489和800 cm-1对应于FeSO4或FeSO4的水合物[31,32].由此可见,不同CO2压力环境中形成的腐蚀产物膜的主要化学成分相同,均为FeOOH和FeSO4.显然,在含O2、H2S、SO2和NO2的超临界CO2环境中,杂质间可以发生化学反应,生成H2SO4[25,33],进而形成FeSO4产物.FeOOH是含O2或NO2杂质的超临界CO2环境中常见的腐蚀产物[21]:一方面O2和NO2直接参与X65管线钢的腐蚀过程,形成FeOOH;另一方面,在实验环境中X65管线钢表面可能形成的腐蚀产物,如FeSO4、FeCO3和FeS等[34],暴露于含氧的湿气环境中容易被氧化,从而形成FeOOH产物[25]. ...

Effect of water content on the corrosion behavior of X65 pipeline steel in supercritical CO2-H2O-O2-H2S-SO2 environment as relevant to CCS application

1

2018

... 对于含杂质的超临界CO2输送环境,管线钢是否发生腐蚀取决于钢表面能否形成自由液相[19].相关研究表明,在相同的含杂质的超临界CO2环境中,随着含水量的提高,由于能够在钢表面形成的腐蚀性液相量增多,管线钢腐蚀速率及腐蚀产物膜厚度也相应增加[35].因此,钢表面形成腐蚀产物膜厚度的不同能够一定程度地反映出其表面腐蚀性液相形成量的差异.不同压力条件下X65管线钢发生不同程度的腐蚀,说明溶解于超临界CO2中H2O析出并沉积在钢表面.相应地,超临界CO2及杂质气体溶解于液相中改变液膜的化学性质,进而影响管线钢的腐蚀.为了明确CO2压力变化对形成液相化学特性的影响,采用OLI Analyzer studio软件的Stream Analyzer模块进行了水化学计算.由图9可见,在7.5、10和14 MPa CO2压力环境中X65管线钢表面腐蚀产物膜厚度分别为7、3.5和10 μm.据此,假设3种CO2压力环境中分别形成7、3.5和10 μm的液膜,即在X65管线钢表面每单位面积(cm2)分别沉积0.0007、0.00035和0.0010 g的H2O.根据表1中实验条件,确定用于水化学计算的CO2及杂质组分量.不同CO2压力环境中液膜的化学分析计算结果如表2所示.随着压力的升高,X65管线钢表面液膜中溶解的CO2、杂质气体及主要离子含量呈先降低后升高的变化趋势,与腐蚀速率变化规律一致.而液膜中杂质气体及主要离子浓度随压力变化趋势与腐蚀速率变化无明显相关性.随着压力的增加,HS-、CO、HCO、CO2的浓度逐渐升高,而HSO、SO、H+、SO2、NO2的浓度逐渐降低.这是因为在水介质环境中裸钢直接与大量液相介质接触而发生腐蚀不同,在低含水超临界CO2环境中,水先在钢表面形成液膜,同时CO2及杂质气体溶解在液膜中,钢表面形成的液膜越厚,液膜中溶解的腐蚀性物质含量也就越高,进而腐蚀也就更严重[25].综上,不同压力环境中X65管线钢腐蚀速率差异与压力变化引起的液相化学环境不同相关. ...

Influence of CO2 subcritical and supercritical pressures on the protective properties of corrosion product scales formed on X65 steel

1

2024

... 当腐蚀产物膜在X65管线钢表面形成后,其可将钢表面与腐蚀性液相隔离,此时管线钢的腐蚀不再受液相环境直接影响,必须考虑钢基体表面覆盖的腐蚀产物膜的影响.由腐蚀产物膜表面及截面SEM结果(图9)可见,随着CO2压力改变,腐蚀产物膜致密程度相应产生变化,且与腐蚀速率变化规律一致.压力变化可能通过改变腐蚀产物膜保护性来影响管线钢的腐蚀[36].为了验证不同压力环境中X65管线钢表面腐蚀产物膜的保护性,对不同压力的含杂质超临界CO2环境中应力腐蚀后覆盖腐蚀产物膜的X65管线钢进行EIS测试.图11a和b为不同压力条件下X65管线钢表面腐蚀产物膜的EIS图谱.由图11a可见,在不同压力CO2环境中形成的腐蚀产物膜的Nyquist图均呈现单一容抗弧的特征.随着CO2压力的升高,容抗弧直径(图11a)、0.01 Hz处的阻抗模值以及最大相位角(图11b)均先增大后减小.这表明随着CO2压力的增加,X65管线钢表面腐蚀产物膜的耐蚀性先增加后降低,即在10 MPa CO2压力环境中形成的腐蚀产物膜具有最好的保护性.采用图11c中等效电路对图11a和b中的EIS数据进行拟合,其中Rs为溶液电阻,Qdl和Rct分别表示腐蚀产物膜与溶液界面处的双电层电容和电荷转移电阻.腐蚀产物膜的EIS拟合数据如表3所示.随着CO2压力升高,Rct先增加后降低.相比10 MPa,7.5 MPa压力条件下的Rct略有降低,14 MPa压力下Rct降低了约3倍.上述结果表明,10 MPa压力环境中形成的腐蚀产物膜对传质过程具有更高的阻力,其保护性最好.由此可见,不同CO2压力环境中X65管线钢腐蚀速率差异也与压力变化引起的腐蚀产物膜保护性变化密切相关. ...