316奥氏体不锈钢因其优异的高温力学性能与耐腐蚀性能,在航空、航天以及航海等领域被广泛应用[1,2]。近年来,随着航空发动机热端部件、船舶燃气轮机以及高温化工装备的不断发展,316不锈钢所面临的服役环境日趋苛刻。工作温度持续升高,并常伴随多种盐类腐蚀介质的沉积(如NaCl、Na2SO4等),对其抗高温氧化与耐热腐蚀能力提出了更高要求[3]。在此类恶劣工况下,若能在材料表面形成连续、致密且结合良好的保护性氧化膜(如Cr2O3),将显著提升其服役寿命与可靠性[4]。然而,传统铸造316(Cast-316)不锈钢在高温含盐环境中表面形成的氧化膜易发生剥落,粘附性较差,导致抗氧化能力不足,成为限制关键部件长期安全运行的主要瓶颈[5]。因此,在维持316不锈钢良好高温力学性能的基础上,进一步提升其高温氧化与腐蚀抗力,已成为当前工程材料研究的重要方向。

增材制造技术,特别是选区激光熔化(SLM),凭借其逐层熔凝、快速冷却的工艺特点,为316不锈钢的组织调控与性能优化提供了全新途径[6,7]。相较于传统铸造工艺,SLM技术能够有效抑制元素偏析、细化显微组织,实现样件的高致密度与成分均匀性,从而为材料性能的提升奠定微观结构基础[8,9]。目前,已有研究大多聚焦于SLM-316不锈钢在常温电化学腐蚀环境中的行为。例如,Sander等[10]报道在3.5% (质量分数) NaCl溶液中,SLM-316不锈钢的点蚀电位较传统铸造材料提高约300 mV,表现出更优的耐点蚀性能。有研究[11]指出,SLM过程中极高的冷却速率显著抑制了MnS等有害夹杂的形成,从而改善了材料的局部腐蚀抗力。此外,Laleh等[12]在SLM成形样品中观察到富Cr、Si的纳米氧化物夹杂,这些细小分散相促进钝化膜的形成,进一步增强了耐蚀性能。

尽管SLM-316不锈钢在常温腐蚀环境下已展现出显著优势,然而,其在高温空气及高温含盐腐蚀环境下的长期服役行为却缺乏系统研究。目前,关于SLM-316不锈钢在高温氧化及热腐蚀条件下的性能数据极为有限,相关氧化膜生长机制、腐蚀产物演变规律尚未明确。这一知识缺口严重制约了该材料在航空发动机、船舶排气系统等高温含盐工况中的推广与应用。因此,系统评估SLM-316不锈钢在高温环境下的氧化与腐蚀行为,不仅具有重要的科学意义,也是推动其走向实际工程应用的关键。

本文系统对比了SLM-316不锈钢与Cast-316不锈钢在700 ℃干燥空气中的氧化以及700 ℃沉积固态NaCl条件下的腐蚀行为,旨在探究SLM-316不锈钢的氧化、腐蚀动力学特征,以及氧化与腐蚀产物演化规律,揭示SLM-316不锈钢微观结构与氧化、腐蚀行为的关系,澄清SLM-316不锈钢的高温氧化与腐蚀机制。为发展面向高温腐蚀环境的高性能增材制造不锈钢提供理论依据与数据支撑。

1 实验方法

实验材料为商用Cast-316不锈钢和SLM-316不锈钢。采用粉末直径为15~45 μm的316不锈钢粉末制备SLM样品,不锈钢粉末的成分详见参考文献[13]。网格间距为100 μm,为防止打印过程中合金发生氧化,实验过程中保护气体为氮气。使用EOS M280 3D打印设备在连续模式下进行试样的制备,激光功率为180 W,扫描速度为600 mm/s,层厚为30 μm,光斑直径为120 μm。使用电火花线切割将两种不锈钢材料切成15 mm × 10 mm × 2 mm的片状试样。依次用120#、240#、400#、600#、800#和1000# SiC砂纸打磨试样表面,去除线切割加工痕迹。然后在酒精中超声清洗30 min,使用冷风将试样吹干,放入真空干燥箱中待用。

采用马弗炉开展高温氧化和高温盐腐蚀实验,实验温度为700 ℃,测试累计时长200 h。为了避免温度差对实验结果造成影响,使用S型热电偶对马弗炉进行温度校准。其中,在高温盐腐蚀测试前需要对样品进行沉积盐处理。具体方法为将不锈钢试片在80 ℃热台上预热,在其表面喷涂过饱和盐水溶液,水分蒸发形成固态盐膜,实现盐沉积。在实验开始前,分别记录试样的尺寸与质量信息,实验过程中使用的电子天平的灵敏度为1 × 10-5 g。

使用配备X-Max型能谱仪(EDS)的扫描电子显微镜(SEM,FEI INSPECT F50)观察高温氧化、腐蚀前、后两种不锈钢试样以及氧化,腐蚀产物的微观组织形貌,并测试不锈钢表面氧化、腐蚀产物的成分。采用X射线衍射仪(XRD,X′Pert Pro)测试氧化、腐蚀前后的相结构信息,测试范围为10°~90°,扫描速度为10 (°)/min。特别注意的是,由于SLM-316不锈钢在700 ℃氧化200 h后,试样表面的氧化产物较薄,其衍射峰并不明显,因此采用掠入式X射线衍射仪(XRD,Rigaku Smartlab 3kW)检测表层氧化产物,掠入角度为1°,扫描步长为10 (°)/min,扫描范围10°~90°。

2 结果和讨论

2.1 原始不锈钢的微观结构特征与相组成

Cast-316与SLM-316不锈钢的XRD谱图如图1所示,Cast-316不锈钢中主要衍射峰分别对应奥氏体面心立方相来自(111)、(200)和(220)晶面,在约44°处出现了铁素体的(110)晶面的衍射峰。与之相比,SLM-316不锈钢则未见铁素体相的衍射峰,说明SLM-316不锈钢的结构为奥氏体结构。SLM制备试样过程中,熔池的冷却速率约104~107 K/s,抑制了铁素体的形成[14~16]。同时,SLM过程中元素偏析效应大大减弱,合金元素分布相对均匀,有利于形成单相奥氏体结构[9]。而在传统铸造工艺中,冷却速度相对较慢,铁素体稳定化元素(如Cr、Mo等)容易发生偏析。这些偏析区域会促使铁素体相的形成,从而导致铸造316不锈钢的组织中除了奥氏体相外,还存在一定量的铁素体相。

图1

图1

原始Cast-316与SLM-316不锈钢的XRD谱图和微观金相组织及SEM照片

Fig.1

XRD patterns (a, b) and microstructures of as-prepared Cast-316 (c) and SLM-316 (d, e) stainless steels

从微观形貌上看(图1c),铸造316不锈钢呈现出典型的等轴晶形貌。而SLM-316不锈钢的显微组织中可以清晰地观察到连续且均匀分布的熔池形貌。在平行于建造方向的截面上,这些熔池呈现典型的鱼鳞状特征,表明在SLM成形过程中,316L不锈钢粉末实现了充分的熔化与致密化,且层间结合状态良好。此外图1d中明显观察到柱状晶结构,其晶粒生长表现出明显的定向性,其生长方向不受单一熔池边界限制,而是沿热流方向(即建造方向)连续延伸,贯穿多个熔池区域。刻蚀后的SLM-316的SEM图如图1e所示,可以看出晶粒内部有大量精细的细胞状亚晶结构。这些细胞状亚晶结构几乎是等轴的,类似于蜂窝状形状。部分范围内可见大量的纤维状亚晶结构。这些纤维状亚晶结构具有较大的长宽比。

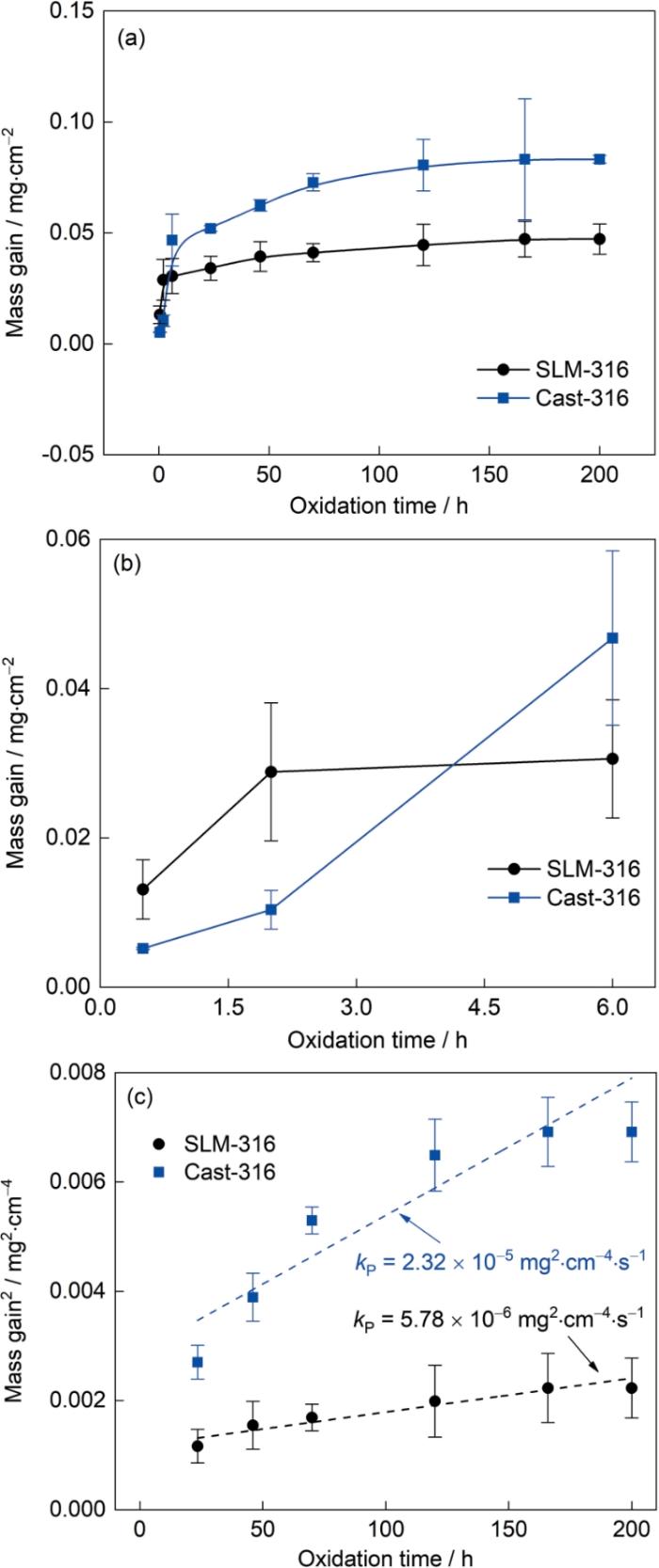

2.2 高温氧化行为

SLM-316与Cast-316不锈钢在700 ℃下氧化200 h的质量变化曲线如图2a和b所示。两种不锈钢试样的质量变化曲线呈现典型的抛物线规律。在氧化初期,两种不锈钢试样的质量快速增长,在氧化6 h后,试样质量的增长速度逐渐减慢,如图2a所示。在氧化初期,试样的质量变化快速增长主要是氧化初期的反应特点决定,试样表面的合金元素将直接参与氧化反应。而在稳态氧化阶段,氧化反应则由元素的扩散行为控制[17]。在700 ℃下氧化200 h后,SLM-316与Cast-316不锈钢试样的增重分别0.047和0.083 mg/cm2。SLM-316不锈钢的增重仅为Cast-316不锈钢增重的一半左右,揭示了选区激光熔化技术制备316不锈钢能改善其氧化抗力。

图2

图2

Cast-316与SLM-316不锈钢在700 ℃的质量变化曲线与氧化速率常数

Fig.2

Mass gain (a, b) and oxidation rate constants (c) of Cast-316 and SLM-316 stainless steels at 700 oC

为了进一步揭示SLM-316与Cast-316不锈钢的氧化动力学特征,其在0~6 h时间内的质量变化曲线如图2b所示。与长期氧化的结果不同,在0~2 h时间段内,SLM-316不锈钢试样具有更高的质量增益。氧化时间持续到6 h,SLM-316不锈钢试样的增重才低于Cast-316不锈钢试样。造成SLM-316不锈钢试样在氧化初期其质量快速变化的原因可能是由于其细化的晶粒尺寸导致的[5,18]。细化的晶粒结构为Cr的快速外扩散提供了扩散通道,因此加速了初期的氧化反应,导致产物能够在氧化初期快速的覆盖试样表面,在一定程度上能够减少氧气与不锈钢试样基体的接触,使得不锈钢试样快速进入稳态氧化阶段。图2c为计算的两种不锈钢试样在700 ℃下稳态氧化阶段的氧化速率常数,SLM-316与Cast-316不锈钢试样的氧化速率常数分别为5.78 × 10-6和2.32 × 10-5 mg2/(cm4·s)。Cast-316不锈钢试样的氧化速率约为SLM-316不锈钢的4倍。

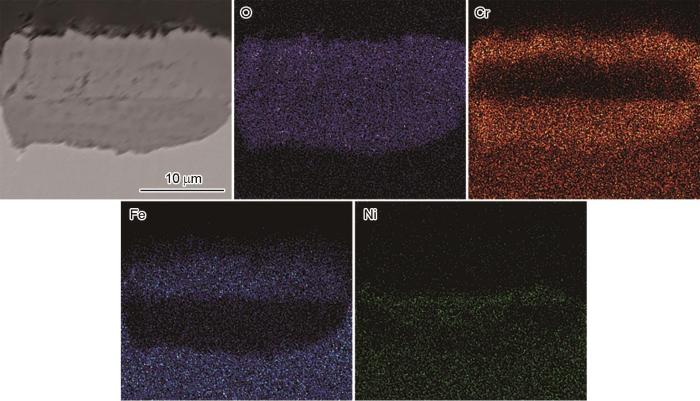

图3为Cast-316与SLM-316不锈钢在700 ℃下氧化200 h的XRD谱图。由于SLM-316不锈钢中氧化膜过薄,采用的是掠入射方式测量。可以看到,两种316不锈钢的谱图中均检测到基体相,同时两种不锈钢的氧化产物具有相似性,均由Cr2O3、Fe2O3与NiCr2O4组成。说明SLM工艺并未改变316不锈钢高温氧化后的产物成分。图4a和d展示了Cast-316与SLM-316不锈钢在700 ℃下氧化200 h后试样的表面形貌。可以看到沿着划痕方向Cast-316与SLM-316不锈钢中均有氧化物生成,其中Cast-316不锈钢表面明暗衬度变化较大,说明表面起伏较大,氧化产物厚度分布不均。而SLM-316不锈钢表面衬度较为一致,说明氧化产物厚度较为均匀。对二者表面进行放大,如图4b和e所示,Cast-316不锈钢表面氧化产物晶粒尺寸较大,与之相比,SLM-316不锈钢表面的氧化产物颗粒更加细小。图4c和f展示了Cast-316与SLM-316不锈钢在700 ℃下氧化200 h后试样的横截面形貌,Cast-316不锈钢试样氧化产物厚度分布不均,最高可约17 μm,而SLM-316不锈钢试样的厚度则较为均匀,氧化膜厚度约1 μm。二者氧化膜的厚度特征与图2中的氧化动力学趋势相吻合。SLM-316不锈钢选区EDS元素分布(图4d虚线部分),Cr和Fe(原子分数)分别占比为22.1%和13.4%,结合XRD结果,表面产物应为Fe2O3/Cr2O3,Cr元素含量相对较高,说明表层Cr2O3占比居多。Cast-316不锈钢氧化200 h后截面元素面分布如图5所示。氧化产物顶部富集有Cr、O元素,结合XRD结果可以判断氧化物顶部为Cr2O3,而在Cr2O3底部有Fe、O元素的富集应为Fe2O3,在Fe2O3的下方观察到Ni、Cr和O元素的富集,应为NiCr2O4。

图3

图3

700 ℃氧化200 h后Cast-316与SLM-316不锈钢的XRD谱图

Fig.3

XRD patterns of Cast-316 (a) and SLM-316 (b) stainless steels after oxidation for 200 h at 700 oC

图4

图4

Cast-316与SLM-316在700 ℃下氧化200 h后的微观表面、截面形貌

Fig.4

Surface and cross-sectional morphologies of Cast-316 (a-c) and SLM-316 (d-f) stainless steels after oxidation for 200 h at 700 oC

图5

图5

Cast-316不锈钢在700 ℃氧化200 h后截面元素面分布图

Fig.5

Elements mapping results of Cast-316 stainless steel after oxidation for 200 h at 700 oC

在两种316不锈钢的氧化过程中均生成了相似的氧化产物,但从氧化物的颗粒尺寸、氧化膜的厚度以及氧化动力学的增重情况来看,SLM-316不锈钢展现出了更优越的抗氧化性。SLM-316不锈钢制备过程中,晶粒内部会产生大量的亚晶结构[19],其亚晶结构的尺寸要远远小于不锈钢板试样的晶粒尺寸。并且亚晶结构的出现伴随着亚晶界的增多[20],为元素的扩散提供的扩散通路。这些晶界是氧化反应的优先形核区域,众多形核点会同时生成氧化产物(如Cr2O3),避免了少数位点集中生长导致的粗大氧化颗粒。同时细小的亚晶界尺寸缩短了Cr、Ni等元素向表面扩散的距离,使其能快速、均匀地参与氧化反应,支撑氧化产物以小尺寸、高密度的形态生长,避免形成粗大的块状或针状氧化物。相比之下,传统铸造的粗晶粒316不锈钢,因晶界数量少,氧化产物更易在少数晶界或表面缺陷处集中生长,最终形成尺寸更大、分布不均的氧化产物。

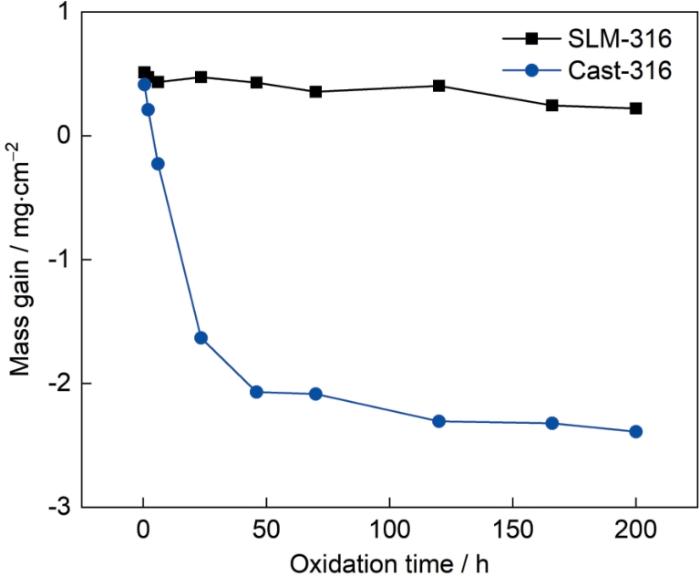

2.3 沉积固态NaCl环境下的高温腐蚀行为

图6展示Cast-316与SLM-316不锈钢试样在700 ℃,沉积固态NaCl环境下的腐蚀动力学曲线。在腐蚀200 h后,Cast-316与SLM-316不锈钢试样的质量变化分别为-2.4与0.23 mg/cm2。Cast-316不锈钢出现了明显的质量负增长情况,而SLM-316不锈钢试样出现了质量的增加。在高温与盐耦合作用下,在不锈钢试样表面快速生成腐蚀产物,但腐蚀产物快速剥落,导致两个试样的质量增长情况逐渐减小,甚至出现氧化物的剥落量显著高于氧化物的生成量,出现氧化物负增长的情况。但是,值得注意的是,SLM-316不锈钢试样的质量变化在整个腐蚀阶段都较为缓慢。然而,在0~20 h的腐蚀时间内,Cast-316不锈钢试样的质量急剧变化,出现显著的质量负增长情况,即氧化物的剥落。而在20 h后,试样的质量变化速度明显减缓。

图6

图6

Cast-316与SLM-316不锈钢试样在700 ℃、沉积固态NaCl环境下的腐蚀动力学曲线

Fig.6

Corrosion kinetic curves of Cast-316 and SLM-316 stainless steel at 700 oC with solid NaCl deposited

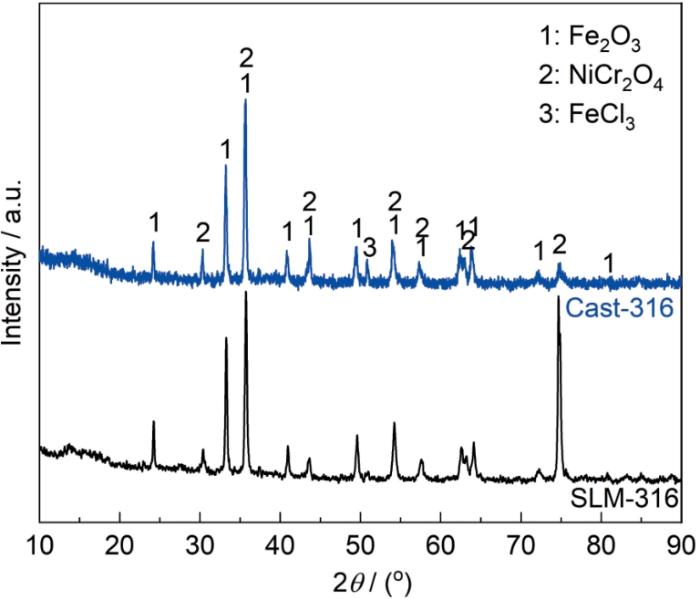

Cast-316与SLM-316不锈钢试样在700 ℃,沉积固态NaCl环境下的腐蚀200 h的XRD试样如图7所示。结果表明,二者腐蚀产物相似,均主要由Fe2O3、NiCr2O4以及少量FeCl3构成。谱图中未检测到NaCl,沉积在样品表面的NaCl应已完全消耗。316不锈钢中元素形成氧化物的倾向为Cr > Fe > Ni,在腐蚀初期O2穿过NaCl盐膜直接与金属基体反应生成保护性Cr2O3[21],一定程度阻碍金属基体和腐蚀介质及O2的接触。随着腐蚀时间的延长,Fe、Ni等元素陆续发生氧化。随后表面盐膜与氧化膜作用释放出Cl2,部分Cl2能够渗透到氧化膜/基体界面,与基体金属发生反应形成氯化物,后者在向外界扩散的过程中又重新被氧化,即发生由Cl2自催化引起的活化氧化[22]。最终形成外层疏松的腐蚀产物。在XRD谱图中并未检测到Cr2O3而是检测出NiCr2O4,应是在这一环境下表面的部分Cr2O3与NiO形成NiCr2O4尖晶石,能够在700℃热腐蚀环境中稳定存在[23]。另一方面,可能是表面的Cr2O3发生了循环反应,生成挥发性的气体CrCl3导致的[24],反应式如下:

图7

图7

Cast-316与SLM-316不锈钢试样在700 ℃、沉积固态NaCl环境下腐蚀200 h后的XRD谱图

Fig.7

XRD patterns of Cast-316 and SLM-316 stainless steels after corrosion for 200 h at 700 oC with solid NaCl deposited

图8a和d为Cast-316与SLM-316不锈钢试样在沉积固态NaCl、700 ℃下的腐蚀200 h后的表面形貌。Cast-316不锈钢试样相对较为平整,氧化物比较完整的覆盖在不锈钢表面,结合腐蚀动力学结果可知,该形貌应为表层疏松腐蚀产物剥落后的状态。表层上局部残留凸起区也证实了Cast-316不锈钢在这一过程中发生严重腐蚀。与之相比,SLM-316不锈钢表面则明显存在多层腐蚀产物,表面腐蚀产物疏松多孔,且存在贯穿性的裂纹。根据动力学数据可知,在这一过程中SLM-316不锈钢中腐蚀产物尚未发生大面积剥落。在700 ℃高温、沉积固态NaCl的严苛腐蚀环境下,Cast-316与SLM-316不锈钢表现出不同的腐蚀行为。Cast-316不锈钢由于晶粒粗大、Cr扩散缓慢,难以形成有效的保护性氧化层,Cl-侵入后引发剧烈的“氯催化活化氧化”循环,不断生成挥发性氯化物并在外部重新氧化,导致形成厚而疏松、附着力极差的多层腐蚀产物;该产物在热应力作用下发生严重剥落,使表面呈现出去除腐蚀产物后相对平整但已严重受损的状态。相反,SLM-316不锈钢中超细的亚晶结构提供了大量短路扩散路径,促进了致密且附着良好的Cr2O3膜早期快速形成,虽在长期腐蚀中Cl-仍在局部缺陷处渗透形成多孔、开裂的氧化物层,但整体腐蚀进程显著延缓,腐蚀产物仍较好地覆盖于表面,未发生大规模剥落,表现出相对较好的高温盐腐蚀抗力。

图8

图8

Cast-316与SLM-316不锈钢试样在沉积固态NaCl、700 ℃环境下的腐蚀200 h后试样的表面形貌

Fig.8

Surface morphologies of Cast-316 (a, b) and SLM-316 (c, d) stainless steels after corrosion for 200 h at 700 oC with solid NaCl deposited

3 结论

(1) SLM-316不锈钢表现出显著优于Cast-316不锈钢的抗高温氧化性能。经过700 ℃、200 h的高温氧化实验,SLM-316不锈钢的氧化增重仅为Cast-316不锈钢的一半左右,且其氧化膜更薄、更均匀致密。

(2) 在沉积固态NaCl的700 ℃腐蚀实验中,SLM-316不锈钢仅轻微增重,而Cast-316不锈钢则发生严重腐蚀产物剥落,失重高达-2.4 mg/cm2,其腐蚀速率比SLM-316不锈钢高两个数量级。

(3) SLM工艺所引入的超细亚晶结构是性能提升的关键,其通过增加晶界密度促进Cr2O3保护膜快速、均匀形核,形成致密氧化层,有效阻隔氧和腐蚀介质向内扩散。

参考文献

Impact of the allowed compositional range of additively manufactured 316L stainless steel on processability and material properties

[J].This work aims to show the impact of the allowed chemical composition range of AISI 316L stainless steel on its processability in additive manufacturing and on the resulting part properties. ASTM A276 allows the chromium and nickel contents in 316L stainless steel to be set between 16 and 18 mass%, respectively, 10 and 14 mass%. Nevertheless, the allowed compositional range impacts the microstructure formation in additive manufacturing and thus the properties of the manufactured components. Therefore, this influence is analyzed using three different starting powders. Two starting powders are laboratory alloys, one containing the maximum allowed chromium content and the other one containing the maximum nickel content. The third material is a commercial powder with the chemical composition set in the middle ground of the allowed compositional range. The materials were processed by laser-based powder bed fusion (PBF-LB/M). The powder characteristics, the microstructure and defect formation, the corrosion resistance, and the mechanical properties were investigated as a function of the chemical composition of the powders used. As a main result, solid-state cracking could be observed in samples additively manufactured from the starting powder containing the maximum nickel content. This is related to a fully austenitic solidification, which occurs because of the low chromium to nickel equivalent ratio. These cracks reduce the corrosion resistance as well as the elongation at fracture of the additively manufactured material that possesses a low chromium to nickel equivalent ratio of 1.0. A limitation of the nickel equivalent of the 316L type steel is suggested for PBF-LB/M production. Based on the knowledge obtained, a more detailed specification of the chemical composition of the type 316L stainless steel is recommended so that this steel can be PBF-LB/M processed to defect-free components with the desired mechanical and chemical properties.

Hot isostatic pressing of differently sintered binder jetted 316L stainless steel: Microstructure evolution and mechanical properties

[J].

Effect of molten salts composition on the corrosion behavior of additively manufactured 316L stainless steel for concentrating solar power

[J].The effects of different molten salts on the corrosion resistance of laser powder bed fusion (L-PBF) 316L stainless steel was evaluated at 650 and 700 °C. The samples were characterized via XRD and SEM/EDX after high-temperature corrosion tests to evaluate the corrosion damage to the L-PBF 316L stainless steel caused by the molten salts. The presence of the salts accelerated the corrosion process, the chloride-based salts being the most aggressive ones, followed by the carbonate-based and the nitrate/nitrite-based salts, respectively. The L-PBF 316L did not react strongly with the nitrate/nitrite-based salts, but some corrosion products not found in the samples tested in the absence of salts, such as NaFeO2, were formed. LiFeO2 and LiCrO2 were identified as the main corrosion products in the samples exposed to the carbonate-based molten salts, due to the high activity of Li ions. Their growth produced the depletion of Fe and Cr elements and the formation of vacancies that acted as diffusion paths on the surface of the steel. In the samples exposed to chloride-based molten salts, the attacked area was much deeper, and the corrosion process followed an active oxidation mechanism in which a chlorine cycle is assumed to have been involved.

High temperature oxidation behavior of F55 super duplex stainless steel at 800-1000 oC in 1.013 ×105 Pa O2

[J].

F55双相不锈钢在800~1000 ℃纯氧气中的高温氧化行为

[J].

High temperature oxidation and high temperature tensile properties of 316L stainless steel

[J].

316L不锈钢高温氧化及高温拉伸性能

[J].

Development of individual three-dimensional bone substitutes using “selective laser melting”

[J].

Flexible manufacturing of metallic products by selective laser melting of powder

[J].

Progress on solidification grain morphology and microstructure control of laser additively manufactured large Titanium components

[J].

激光增材制造高性能大型钛合金构件凝固晶粒形态及显微组织控制研究进展

[J].

Additive manufacturing of metallic components-Process, structure and properties

[J].

On the corrosion and metastable pitting characteristics of 316L stainless steel produced by selective laser melting

[J].

Investigation into spatter behavior during selective laser melting of AISI 316L stainless steel powder

[J].

Unanticipated drastic decline in pitting corrosion resistance of additively manufactured 316L stainless steel after high-temperature post-processing

[J].

Corrosion characterization in SLM-manufactured and wrought 316 L Stainless Steel induced by Desulfovibrio desulfuricans

[J].

Particulate migration behavior and its mechanism during selective laser melting of TiC reinforced Al matrix nanocomposites

[J].

Microstructure and yield strength of SLM-fabricated CM247LC Ni-Superalloy

[J].

Superior tensile properties of 1%C-CoCrFeMnNi high-entropy alloy additively manufactured by selective laser melting

[J].

A novel NiCoCrAlPt high-entropy alloy with superb oxidation resistance at 1200 oC

[J].

Study on oxidation behavior of 316L stainless steel in high temperature environment and fluid corrosion of oxide film

[D].

316L不锈钢在高温环境的氧化行为及氧化膜的冲刷腐蚀研究

[D].

Additively manufactured hierarchical stainless steels with high strength and ductility

[J].Many traditional approaches for strengthening steels typically come at the expense of useful ductility, a dilemma known as strength-ductility trade-off. New metallurgical processing might offer the possibility of overcoming this. Here we report that austenitic 316L stainless steels additively manufactured via a laser powder-bed-fusion technique exhibit a combination of yield strength and tensile ductility that surpasses that of conventional 316L steels. High strength is attributed to solidification-enabled cellular structures, low-angle grain boundaries, and dislocations formed during manufacturing, while high uniform elongation correlates to a steady and progressive work-hardening mechanism regulated by a hierarchically heterogeneous microstructure, with length scales spanning nearly six orders of magnitude. In addition, solute segregation along cellular walls and low-angle grain boundaries can enhance dislocation pinning and promote twinning. This work demonstrates the potential of additive manufacturing to create alloys with unique microstructures and high performance for structural applications.

Comparison of microstructure and properties between 316L plate and materials formed by selective laser melting

[J].

316L板材与选区激光熔化成形材料的组织和性能对比

[J].

NaCl induced corrosion of three austenitic stainless steels at high temperature

[J].

新型奥氏体不锈钢高温NaCl腐蚀行为研究

[J].

Thermal corrosion behavior of KCl coating on the surface of pre-oxidized Fe-Cr alloy

[J].

Fe-Cr合金预氧化后涂覆KCl盐膜的热腐蚀行为

[J].

Hot corrosion mechanism and protection of stainless steel in molten chloride salt

[D].

不锈钢在氯化物熔盐中的热腐蚀机理及防护研究

[D].