在增材制造17-4PH不锈钢的腐蚀性能研究方面,Stoudt等[5]研究表明,通过选区激光熔化技术(SLM)制造的17-4PH不锈钢相比于锻造件表现出更强的耐腐蚀性,电化学测试表明,SLM样品的点蚀电位要明显高于传统锻造样品。增材制造样品雾化过程中保留的氮气可以增强17-4PH不锈钢的耐腐蚀性能,这归因于SLM过程中氮被额外吸收,促进了残余奥氏体的保留并且诱导了Nb(C, N)沉淀相的形成。Barroux等[6]研究表明,通过激光束熔融(LBM)制备的17-4PH不锈钢具有较细的马氏体板条、更细小的NbC沉淀物,含有比锻造样品更多的残余奥氏体和富Cu沉淀物,LBM样品的点蚀电位更低,恒电位极化诱发的亚稳态点蚀数量更少。Wang等[7]研究了固溶+时效处理对激光金属沉积(LMD) 17-4PH不锈钢组织、冲蚀和空泡腐蚀性能的影响,固溶后组织完全转变为马氏体,晶粒发生粗化,NbC大量析出。随后的时效处理能够显著细化组织并产生部分逆转变奥氏体。打印态样品的抗冲蚀和空泡腐蚀性能低于锻件,而经固溶+时效处理后的LMD 17-4PH不锈钢的硬度、抗冲蚀和空泡腐蚀性能均明显优于锻件。Garcia-Cabezon等[8]研究了SLM 17-4PH不锈钢在0.5 mol·L-1 NaCl + 0.5 mol·L-1 H2SO4混合溶液中的电化学腐蚀行为,与锻件相比,SLM样品除了具有更高的腐蚀电位外,其极化曲线阳极段的电流密度也更低,电荷转移电阻更高,并且没有发生明显的局部腐蚀。

与传统成形方法制备的17-4PH不锈钢相比,各种增材制造17-4PH不锈钢的腐蚀性能表现差异较大,性能是否优于传统成形样品未有统一的结论。特别是对于海洋工程17-4PH不锈钢结构的DED再制造技术而言,通常不会对修复结构进行后续热处理,因而亟需探究DED参数对打印态17-4PH不锈钢组织和Cl-环境腐蚀性能的影响规律,通过与常规成形样品的组织性能进行对比,阐明DED 17-4PH不锈钢钝化、点蚀行为与微观组织结构之间的联系。

鉴于此,本文对比了3种热输入条件制备的DED 17-4PH不锈钢与传统挤压件的物相组成与微观组织,和它们在Cl-溶液中的钝化与点蚀行为,分析钝化膜的物相组成、揭示DED 17-4PH不锈钢的微观组织对其腐蚀性能的作用机理。研究结果可为17-4PH不锈钢DED增材制造技术的发展及其结构的安全服役提供参考。

1 实验方法

所用的17-4PH不锈钢粉末的化学成分为(质量分数,%):C 0.089,Cr 15.62,Ni 4.08,Cu 3.02,Nb 0.17,Mn 0.21,余量为Fe。DED 17-4PH不锈钢采用3组不同的热输入(1600,1440和1309 J·cm-1)制备,具体的加工参数见表1,所有打印样品均沿XOY面切取制样。传统挤压件为直径30 mm的商用棒状样品。

表1 同轴送粉DED 17-4PH不锈钢样品的制备参数

Table 1

| Sample | Laser power / W | Scanning speed / mm·min-1 | Layer thickness / mm | Powder feeding rate / g·min-1 | Heat input / J·cm-1 |

|---|---|---|---|---|---|

| 1# | 1200 | 450 | 0.9 | 10.6 | 1600 |

| 2# | 1200 | 500 | 0.9 | 10.6 | 1440 |

| 3# | 1200 | 550 | 0.9 | 10.6 | 1309 |

采用Bruker D8 Advance型X射线衍射仪(XRD)分析不锈钢的物相组成,使用Cu靶,加速电压40 kV,电流40 mA,扫描速度5 (°)·min-1。用于组织观察的样品采用砂纸逐级打磨至2000#,然后用10 g CuSO4 + 50 mL HCl + 50 mL酒精配制成的金相腐蚀液腐蚀10 s,无水乙醇超声清洗后冷风吹干,采用FEI Verios G4型场发射扫描电子显微镜(SEM)对样品的微观组织进行表征。背散射电子衍射(EBSD)样品先经砂纸打磨至5000#,然后使用10%HClO4 + 90%乙醇对其进行电解抛光,采用的直流电压为15 V,电解时间为30~60 s,使用配备EBSD模块的Tescan Clara GMH型SEM对样品的晶粒形态、取向及相组成进行表征。

腐蚀电化学测量采用CS370电化学工作站,使用三电极体系,其中样品为工作电极,铂网为对电极,Ag/AgCl为参比电极,溶液为3.5% (质量分数) NaCl溶液,所有的测量均进行3次以确保实验结果的可重复性。动电位极化曲线从-0.15 V (相对开路电位)开始正向扫描,扫描速率为0.5 mV·s-1,当阳极电流密度达到1 mA·cm-2时终止。电化学阻抗谱(EIS)测试在开路电位状态下进行,选取的频率范围为105~10-2 Hz,交流幅值为10 mV。亚稳态点蚀实验在3.5%NaCl溶液中进行,在-0.05 V (vs. Ag/AgCl)进行恒电位极化2 h,记录电流密度-时间曲线。采用恒电位法测量样品的临界点蚀温度(CPT),具体测试方法参照ASTM G150-2013[9]标准,选择-0.05 V (vs. Ag/AgCl)的测试电位,溶液温度从27 ℃开始记录,以1 ℃·min-1的速率升温。通过Mott-Schottky分析样品钝化膜的半导体特性,所选取的电位扫描范围为-0.2~0.4 V (vs. Ag/AgCl),步长为0.01 V,频率为1 kHz,交流幅值为5 mV。将样品在3.5%NaCl溶液中浸泡4 h后,利用Kratos AXIS Ultra DLD型X射线光电子能谱仪(XPS)研究样品表面钝化膜的物相组成与各元素的化学价态。在6% (质量分数) FeCl3溶液中进行点蚀实验,样品在溶液中室温浸泡8 h后用去离子水和无水乙醇超声清洗2 min并冷风吹干,随后进行SEM/EDS观察。

2 结果与讨论

2.1 物相组成与微观组织

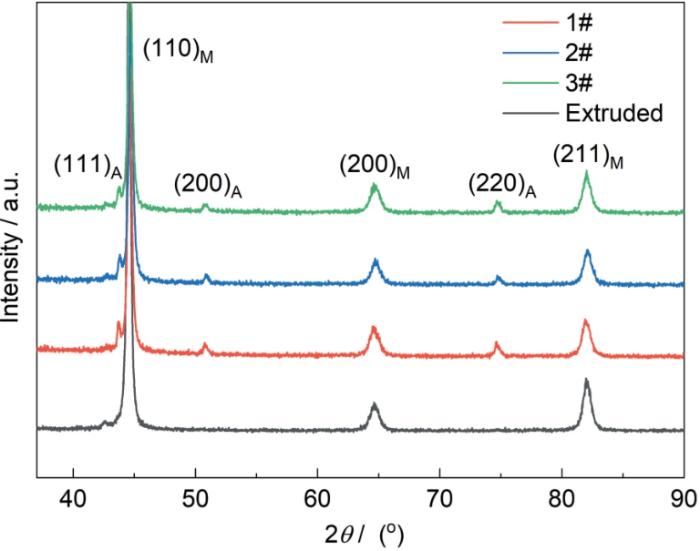

图1为17-4PH不锈钢DED样品和挤压件的XRD图。可以看出,DED样品与传统挤压件的组织主要由体心立方相(BCC)组成,由于合金的碳含量很低,马氏体相与铁素体相的晶体结构十分接近,因此确定DED样品与挤压件组织均以马氏体为主。但是在3种热输入的DED样品中均存在面心立方相(FCC)的特征峰,对应奥氏体晶面(111)A、(200)A和(220)A,说明3种DED样品中含有少量的残余奥氏体相,这可归因于增材制造过程中的高冷速导致组织中留下尚未转变的残余奥氏体[5]。通过XRD图谱中的马氏体和奥氏体特征峰比值计算出3种DED样品中残余奥氏体的体积分数分别为:8.2% (1#DED)、7.8% (2#DED)、7.5% (3#DED),说明DED制备工艺的热输入越大,残余奥氏体含量相对越高。挤压件中未测出残余奥氏体,是由于传统挤压成形工艺冷速较慢,奥氏体向马氏体的转变更加充分,后续将通过EBSD进一步分析挤压件中是否含有残余奥氏体。

图1

图1

17-4PH不锈钢DED样品和挤压件的XRD图谱

Fig.1

XRD spectra of 17-4PH stainless steel DED and extruded samples

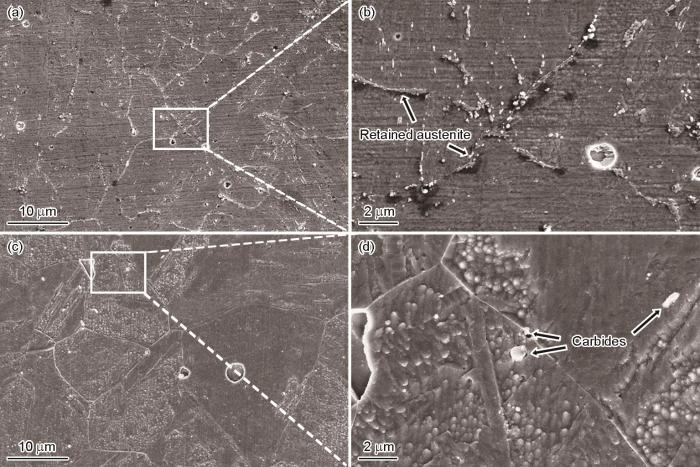

由于2#DED样品的耐腐蚀性能最优(见后续内容),这里采用SEM对比了17-4PH不锈钢2#DED样品和传统挤压件的微观组织,如图2所示,其中图2a、b为2#DED样品,图2c、d为挤压件。可以看出,2#DED样品的原奥氏体晶粒更细,直径约为10 μm,挤压样品的原奥氏体晶粒直径在15~20 μm。晶粒内部为典型的马氏体板条组织,由于SEM对马氏体的分辨效果不佳,后面将采用EBSD进行表征。从图2b中可以看出,2#DED样品的原奥氏体晶界处分布着少量带状凸起相,沿晶界呈断续分布,结合图1的XRD结果推测为残余奥氏体相。与之相比,图2d中的挤压样品的原奥氏体晶界连续且清晰,无明显的局部带状凸起相,说明晶界处无残余奥氏体,但在晶界附近可观察到尺寸约0.5~1 μm的白亮颗粒相,属于17-4PH不锈钢中富Nb碳化物的典型特征[5~7]。

图2

图2

17-4PH不锈钢DED样品和挤压件的SEM图像

Fig.2

SEM images of 17-4PH stainless steel DED and extruded samples: (a, b) 2#DED; (c, d) extruded

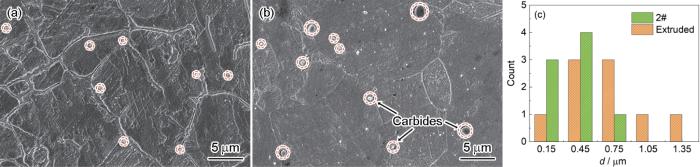

图3

图3

DED样品和挤压件中碳化物数量和尺寸对比

Fig.3

Comparison of the numbers and sizes of carbides in DED and extruded samples: (a) 2#DED; (b) extruded; (c) comparison of carbides features

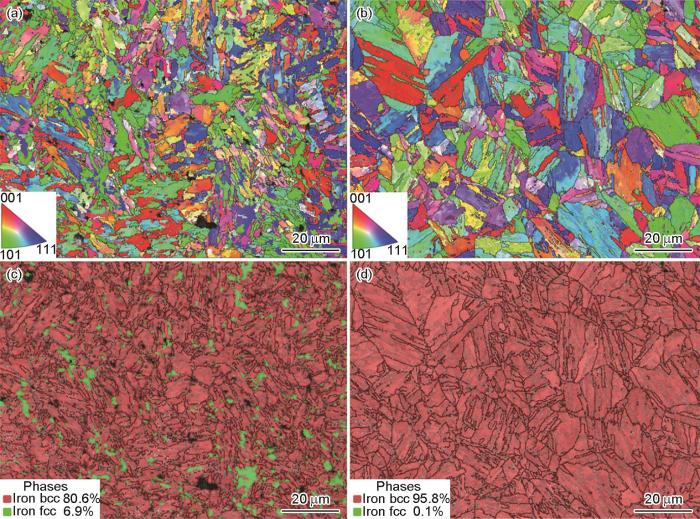

采用EBSD分析DED和挤压样品中马氏体和残余奥氏体的形态、尺寸和占比,得到的反极图(IPF)和相分布图分别见图4a,b和4c,d,其中图4a,c为2#DED样品,图4b,d为传统挤压件。可以看出,2#DED样品的奥氏体晶粒尺寸和晶内马氏体板条明显小于传统挤压样品。采用EBSD软件对马氏体板条的平均面积(用于对比相尺寸)进行分析,得到2#DED样品的平均马氏体板条面积为26 μm2,相较于传统挤压样品的80 μm2减少了67.5%。通过相分布图可知,2#DED样品中含有6.9% (体积分数)的残余奥氏体,大多呈带状和块状,主要分布于奥氏体晶界和马氏体相界处。与之相比,挤压样品的组织中仅含有0.1% (体积分数)的残余奥氏体。需要说明的是,由于样品表面电解抛光过程中产生了一些蚀孔,因此解析出来的两相体积占比之和未达到100%。EBSD的结果表明,DED样品最显著的特征是组织的细化和更高含量的残余奥氏体,这是由于DED的快速冷却作用增加了奥氏体晶粒形核数量并加速了马氏体相变过程,使得组织细化;同时,因为马氏体转变更快发生,晶界和马氏体相界处的高应力和受限空间增加了奥氏体相的稳定性,使部分奥氏体来不及向马氏体转变得以保留,因而残余奥氏体显著增多。

图4

图4

17-4PH不锈钢DED样品和挤压件的EBSD表征结果

Fig.4

EBSD characterization results of 17-4PH stainless steel DED and extruded samples: (a) IPF of 2#DED sample, (b) IPF of extruded sample, (c) phase distribution map of 2#DED sample, (d) phase distribution map of extruded sample

2.2 动电位极化与点蚀行为

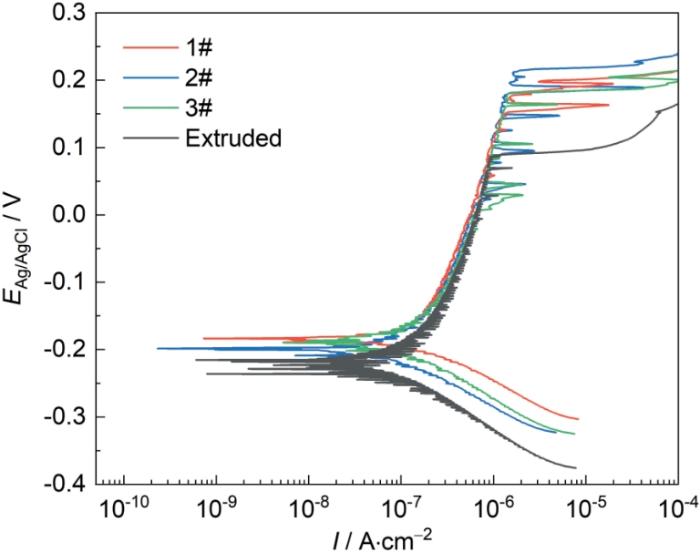

图5为17-4PH不锈钢DED和挤压样品在3.5% NaCl溶液中的动电位极化曲线。4种样品的极化曲线变化趋势基本相同,在该溶液中具有一定的钝化能力,在-0.2 V (vs. Ag/AgCl)附近进入阳极段,随后发生自钝化,钝化区电流密度随着电位的升高缓慢增大,4种样品的钝化区电流密度十分接近。在到达点蚀电位前,样品在钝化区存在明显的亚稳态点蚀,这是马氏体不锈钢在NaCl溶液中发生电化学腐蚀的典型特征。表2为动电位极化曲线Tafel拟合后的自腐蚀电位Ecorr、自腐蚀电流密度Icorr、点蚀电位Ep和钝化区宽度ΔE,每个数据均为3次测试的平均值。DED样品的Ecorr、Ep、ΔE均高于挤压样品,2#DED样品具有最高的Ep (0.218 V (vs. Ag/AgCl))、最宽的ΔE (0.416 V (vs. Ag/AgCl))以及最小的Icorr (8.17 × 10-8 A·cm-2),耐腐蚀性能最优,Ep相较挤压样品提升0.131 V (vs. Ag/AgCl)。4种样品的耐蚀性顺序为2#DED > 1#DED ≈ 3#DED >挤压件,对于DED样品而言,随着热输入的增大,DED样品的耐腐蚀性先升高后降低,但DED样品的耐蚀性均优于传统挤压件。

图5

图5

17-4PH不锈钢在3.5%NaCl溶液中的动电位极化曲线

Fig.5

Potentiodynamic polarization curves of 17-4PH stainless steel in 3.5%NaCl solution

表2 动电位极化曲线Tafel拟合得到的腐蚀参数

Table 2

| Sample | Ecorr / V (vs. Ag/AgCl) | Icorr / A·cm-2 | Ep / V (vs. Ag/AgCl) | ΔE / V (vs. Ag/AgCl) |

|---|---|---|---|---|

| 1# | -0.178 | 1.67 × 10-7 | 0.199 | 0.377 |

| 2# | -0.198 | 8.17 × 10-8 | 0.218 | 0.416 |

| 3# | -0.188 | 1.42 × 10-7 | 0.180 | 0.368 |

| Extruded | -0.221 | 1.20 × 10-7 | 0.087 | 0.308 |

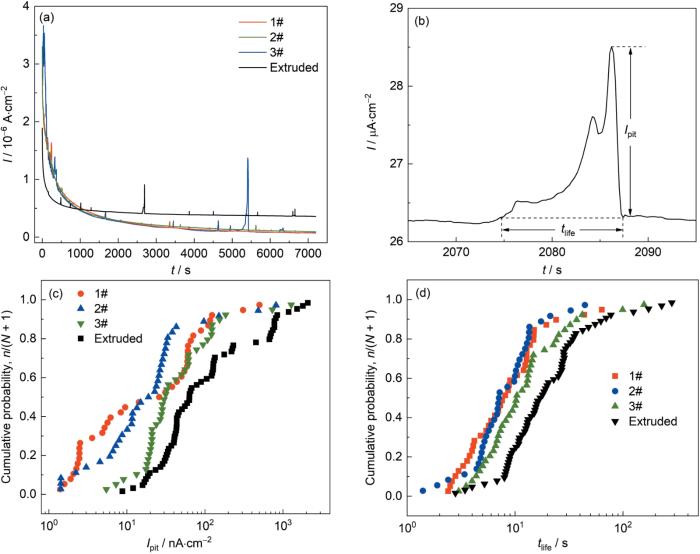

采用恒电位极化方法研究DED和挤压样品在3.5%NaCl溶液中的亚稳态点蚀行为,如图6所示。图6a为-0.05 V (vs. Ag/AgCl)极化2 h的恒电位极化曲线,从电流密度的变化特征可见,挤压样品在更短的时间内达到近稳态,即钝化膜接近生长/溶解的平衡态,而DED样品的极化电流密度在测试时间范围内持续降低,说明钝化膜仍在生长增厚。对比实验结束时刻的电流密度可以看出,DED 3种样品的电流密度十分接近,均小于挤压样品。17-4PH不锈钢样品在该实验条件下均发生了亚稳态点蚀,为了详细分析不同样品的亚稳态点蚀行为差异,采用图6b所示的方法对亚稳态点蚀的峰值电流Ipit和点蚀寿命(点蚀存续时间) tlife的累积概率分布进行统计分析,结果如图6c,d所示。图6c对比了4种样品在不同Ipit区间的概率分布,曲线越靠左代表出现大峰值电流的概率越低。由于大的峰值电流代表点蚀湮灭前的快速溶解反应更显著,即亚稳态点蚀敏感性更高,由此可见,在10~1000 nA·cm-2的电流范围内2#DED样品表现出最低的亚稳态点蚀敏感性,在1~10 nA·cm-2范围内1#DED样品也显示出良好的抗亚稳态点蚀能力,而挤压样品所有的亚稳态点蚀峰值电流都比较高,说明其亚稳态点蚀敏感性最高。图6d对比了各样品亚稳态点蚀的存续时间,曲线越靠左说明点蚀寿命越短,结果表明2#DED样品的亚稳态点蚀抗性最高,挤压样品的点蚀寿命明显高于DED样品。由亚稳态点蚀的结果可以看出,4种样品的亚稳态点蚀敏感性为2#DED < 1#DED < 3#DED < 挤压件,这与动电位极化曲线反映的腐蚀抗性顺序基本吻合。

图6

图6

17-4PH不锈钢在3.5%NaCl溶液中的亚稳态点蚀行为

Fig.6

Metastable pitting behavior of 17-4PH stainless steel in 3.5%NaCl solution: (a) potentiostatic polarization curves at -0.05 V (vs. Ag/AgCl), (b) representative metastable pitting event, (c) cumulative probability distribution vsIpit, (d) cumulative probability distribution vstlife

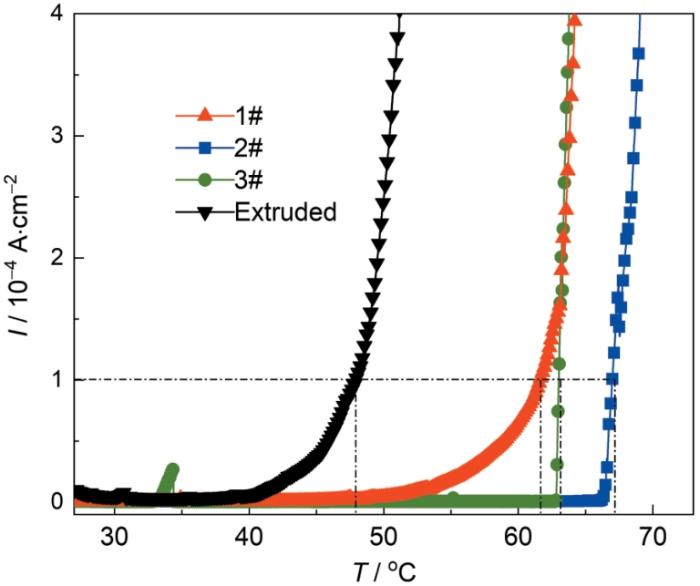

临界点蚀温度(CPT)是衡量钝性金属材料在腐蚀环境中抗点蚀能力的一个重要指标,当环境温度高于CPT时,金属表面发生的亚稳态点蚀会发展为稳态点蚀,它可以量化评价金属的抗点蚀能力[10]。本文采用ASTM G150-2013标准[9]中的恒电位法进行测量,根据动电位极化曲线中的钝化区间选择-0.05 V (vs. Ag/AgCl)作为测试电位,实验结果如图7所示。挤压样品的CPT为47.9 ℃,1#、2#、3#DED样品的CPT分别为61.8、67.2和63.2 ℃,DED样品的CPT要显著高于传统挤压件,性能最优的2#DED样品CPT比挤压样品高19.3 ℃。说明DED样品的耐点蚀性能更好,其钝化膜在较高温度下仍能保持完整的致密结构,钝化膜的自修复能力更强,即使在局部发生亚稳态点蚀后也能迅速修复。CPT实验的结果与动电位极化测试反映的耐蚀性规律基本一致。

图7

图7

17-4PH不锈钢在3.5%NaCl溶液中的临界点蚀温度测试曲线

Fig.7

Critical pitting temperature measuring curves of 17-4PH stainless steel in 3.5%NaCl solution

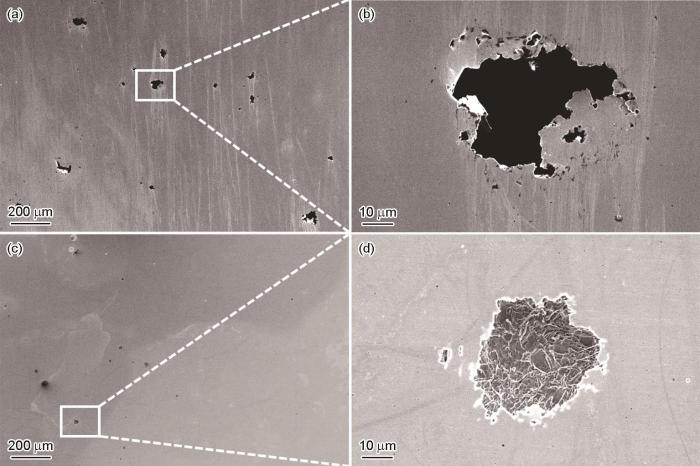

图8

图8

17-4PH不锈钢在6%FeCl3溶液中浸泡8 h后的点蚀形貌

Fig.8

Pitting morphologies of 17-4PH stainless steel after immersion corrosion in 6%FeCl3 solution for 8 h: (a, b) extruded sample, (c, d) 2#DED sample

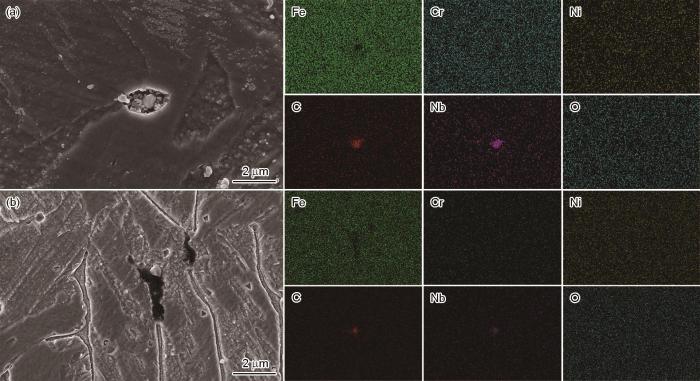

图9

图9

17-4PH不锈钢点蚀萌生部位的SEM形貌和EDS面扫描分析

Fig.9

SEM morphologies and EDS mapping of pitting initiation sites of 17-4PH stainless steel: (a) extruded sample, (b) 2#DED sample

2.3 电化学阻抗与钝化特性

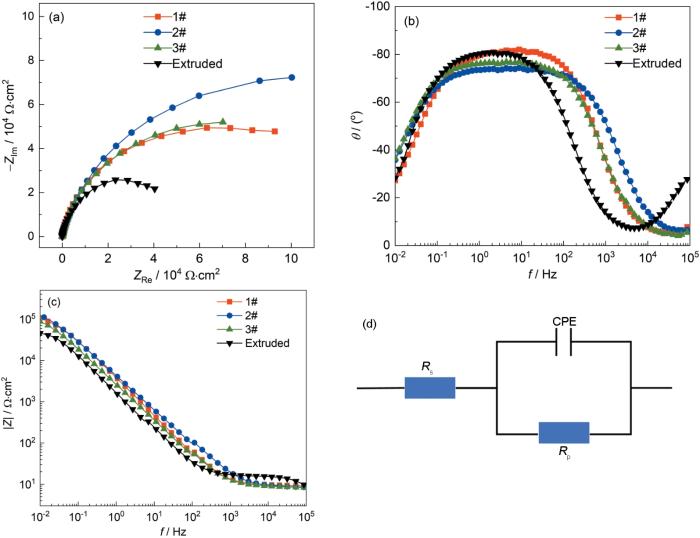

图10

图10

17-4PH不锈钢在3.5%NaCl溶液中的电化学阻抗谱与等效电路

Fig.10

Nyquist plot (a) and Bode plots (b, c) of 17-4PH stainless steel in 3.5%NaCl solution and equivalent electriccircuit (d)

表3 17-4PH不锈钢的电化学阻抗谱拟合结果

Table 3

| Sample | Rs / Ω·cm2 | Cdl / Ω-1·cm-2·s n | n | Rp / Ω·cm2 |

|---|---|---|---|---|

| 1# | 9.44 | 4.98 × 10-5 | 0.90 | 1.16 × 105 |

| 2# | 8.39 | 5.01 × 10-5 | 0.82 | 1.95 × 105 |

| 3# | 8.58 | 7.75 × 10-5 | 0.85 | 1.30 × 105 |

| Extruded | 14.72 | 1.15 × 10-4 | 0.89 | 0.61 × 105 |

式中,

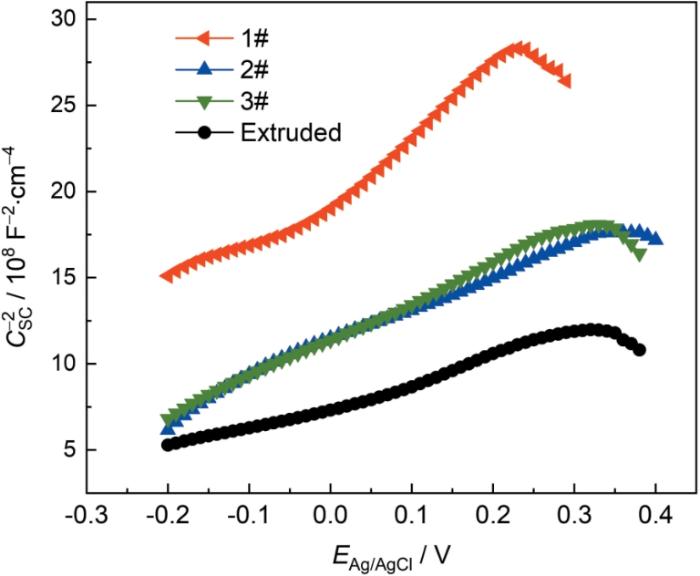

图11

图11

17-4PH不锈钢在3.5%NaCl溶液中的Mott-Schottky曲线

Fig.11

Mott-Schottky curve of 17-4PH stainless steel in 3.5%NaCl solution

表4 Mott-Schottky曲线拟合得到的钝化膜施主密度与平带电位

Table 4

| Sample | ND / cm-3 | EFB / V (vs. Ag/AgCl) |

|---|---|---|

| 1# | 2.09 × 1021 | -0.45 |

| 2# | 4.53 × 1021 | -0.44 |

| 3# | 4.15 × 1021 | -0.51 |

| Extruded | 4.95 × 1021 | -0.56 |

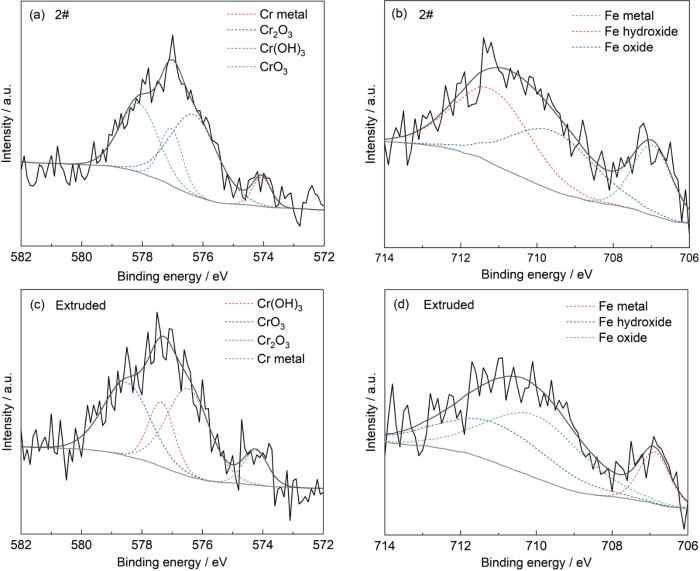

将2#DED和挤压样品在3.5%NaCl溶液中浸泡4 h后进行XPS表征,结果如图12所示,其中图12a,b为2#DED样品,图12c,d为挤压样品。图12a,c为Cr 2p的4个特征峰,分别对应Crmetal (574.24 eV)、Cr2O3 (576.47 eV)、CrO3 (578.51 eV)与Cr(OH)3(577.36 eV);图12b,d为Fe 2p的3个特征峰,分别对应Femetal (706.88 eV)、Fe2O3 (710.03 eV)与Fe(OH)3(711.11 eV),相应的结合能与文献报道一致[18]。可见,钝化膜均由Cr、Fe的氧化物和氢氧化物组成,其中对钝化膜保护作用起主要贡献的是Cr的氧化物。由峰面积计算Cr氧化物在Cr峰中的占比,即Crox/Crall,得到2#DED样品为0.78,挤压样品为0.74;同理计算Crall/Feall得到2#DED样品为0.92,传统挤压样品为0.63,这说明2#DED样品表面钝化膜的Cr氧化物占比更高,这是DED样品表面钝化膜具有更优保护性能的关键[19,20]。

图12

图12

17-4PH不锈钢表面钝化膜的XPS光谱

Fig.12

XPS spectrum of the passive film on 17-4PH stainless steel's surface: (a, c) Cr 2p; (b, d) Fe 2p

2.4 分析与讨论

本研究表明,在微观组织方面,DED样品相较于传统挤压件最显著的差异是DED样品的原奥氏体晶粒和马氏体明显细化,以及主要分布于晶界和马氏体板条界处的带状残余奥氏体。此外,由于DED的快速冷却作用,富Nb碳化物的析出也受到了抑制。下面从组织特征与钝化行为之间的联系讨论DED样品具有更优钝化能力和耐点蚀性能的机理。

再者,细化的组织对于耐蚀性也有贡献。Ralston等[26]研究表明,金属的晶粒大小(gs)和腐蚀速率(Icorr)之间存在如下关系:

式中,A为与环境有关的常数,B为材料常数。由

上述三方面的综合作用,使得DED样品表面钝化膜的点缺陷密度更低,钝化膜更为完整致密,而且Cr氧化物占比更高;同时,在点蚀行为方面,DED样品点蚀电位更正,亚稳态点蚀敏感性低,临界点蚀温度更高,浸泡后点蚀坑数量更少且尺寸更小,即DED样品具有更为优异的钝化与耐点蚀性能。

此外,虽然3种热输入的DED样品耐蚀性能均优于传统挤压件,但三者的耐蚀性能也有一定的差异,本研究发现适中的热输入样品耐蚀性能最优,这可能是由于不同热输入条件下组织的细化程度、残余奥氏体含量、析出相尺寸和分布等因素综合作用的结果,鉴于篇幅原因,笔者将在后续的论文中进行报道。

3 结论

(1) 与热挤压件相比,DED样品中的原奥氏体晶粒和马氏体更加细小,其中热输入1440 J·cm-1的DED样品组织中马氏体尺寸比热挤压者减小67.5%,且含有6.9%的残余奥氏体(EBSD),主要分布于晶界和马氏体板条界处。而挤压件中仅含有0.1%的残余奥氏体,但在晶界和马氏体相界附近存在较多尺寸为0.15~1.35 μm的碳化物颗粒。

(2) DED样品的耐腐蚀性能优于挤压件,具体表现在:自腐蚀电位和点蚀电位更正、钝化区更宽、极化电阻更高,其中最大高达3.2倍、亚稳态点蚀敏感性更低,临界点蚀温度比挤压样品最多可提高19.3 ℃。浸泡腐蚀后,DED样品表面所形成的点蚀坑数量更少且尺寸更小,点蚀萌生后沿纵深发展更为缓慢。

(3) DED样品的平带电位更正,钝化膜施主密度最大降低58%,对载流子迁移的阻碍能力更强。DED样品和挤压件的钝化膜均由Cr2O3、CrO3、Cr(OH)3、Fe2O3、Fe(OH)3组成,DED的钝化膜中Cr氧化物含量更高,对基体的耐蚀保护作用更优。

参考文献

Predicting microstructure and strength of maraging steels: Elemental optimisation

[J].

The effect of microstructural evolution on hardening behavior of type 17-4PH stainless steel in long-term aging at 350 oC

[J].

Investigating the impact of pre-deformation on age hardening and pitting corrosion resistance of 17-4PH stainless steel

[J].

Effect of retained austenite on subsequent thermal processing and resultant mechanical properties of selective laser melted 17-4PH stainless steel

[J].

Influence of postbuild microstructure on the electrochemical behavior of additively manufactured 17-4 PH stainless steel

[J].The additive manufacturing (AM) build process produces a segregated microstructure with significant variations in composition and phases that are uncommon in traditional wrought materials. As such, the relationship between the post-build microstructure and the corrosion resistance is not well understood. Stainless steel alloy 17-4PH is an industrially-relevant alloy for applications requiring high-strength and good corrosion resistance. A series of potentiodynamic scans conducted in a deaerated 0.5 mol/L NaCl solution evaluated the influence of these microstructural differences on the pitting behavior of SS17-4. The pitting potentials were found to be higher in the samples of additively-processed material than in samples of the alloy in wrought form. This indicates that the additively-processed material is more resistant to localized corrosion and pitting in this environment than the wrought alloy. The results also suggest that after homogenization, the additively-produced SS17-4 could be more resistant to pitting than wrought SS17-4 in an actual service environment.

Pitting corrosion of 17-4PH stainless steel manufactured by laser beam melting

[J].

Effect of solution aging treatment on corrosion resistance and erosion resistance of laser metal deposition 17-4PHss

[J].

Microstructure-hardness-corrosion performance of 17-4 precipitation hardening stainless steels processed by selective laser melting in comparison with commercial alloy

[J].The 17–4 Precipitation Hardening Stainless Steel (PH SS) manufactured by Selective Laser Melting (SLM) has wide application perspectives, but they are limited due to defects and anisotropy. The selection of the appropriate process variables plays a fundamental part in the microstructure and in the determination of the final mechanical and corrosion properties. The main purpose of this study is to analyze the corrosion behavior, hardness and microstructure of 17–4 PH SS manufactured by SLM in comparison to the commercial counterparts. The anisotropic behavior was investigated by analyzing the microstructure–hardness and corrosion interrelationship, both in the surface of the construction platform and in the growth direction of the element. The corrosion behavior of the SLM 17–4PH SS in its natural state was investigated in relation to that of the 17–4 PH SS heat treated in a 0.1 M NaCl + 0.5 M H2SO4 solution, using three electrochemical techniques. The results confirmed that the corrosion resistance of SLM 17–4 PH SS was considerably better than that of the forging, even after 60 days of immersion in the test solution. This was attributed to the absence of important manufacturing defects, to the fine microstructure with an important amount of austenite produced by SLM, and to a small amount of non-metallic inclusions precipitated as a result of the fast cooling and the high speed of solidification associated with the SLM process.

Synergetic effect of fluoride and chloride on the critical pitting temperature of 316 stainless steel

[J].

F-和Cl-对316不锈钢临界点蚀温度的协同作用

[J].

Initial corrosion behavior of several pure irons and steels in 3.5%NaCl solution

[J].

6种典型商用纯铁和钢材在3.5%NaCl溶液中的初期腐蚀行为

[J].采用电化学和浸泡腐蚀实验,结合扫描电镜、3D光学轮廓仪和显微Raman光谱仪等研究了纯铁3N2、4N2、5N2以及普碳钢Q235B、耐候钢SPA-H、不锈钢304L在3.5%NaCl溶液中的初期腐蚀行为。电化学阻抗谱结果表明样品的腐蚀速率为:304L < 5N2 < 4N2 < 3N2 < SPA-H < Q235B。扫描电镜和3D轮廓仪揭示了纯铁3N2、4N2和5N2发生了局部腐蚀,其中3N2蚀坑最深。各样品表面腐蚀产物的主要成分为Fe<sub>3</sub>O<sub>4</sub>、γ-FeOOH和α-FeOOH。

Improvement on the pitting corrosion resistance of 304 stainless steel via duplex passivation treatment

[J].

The electronic properties of sputtered chromium and iron oxide films

[J].

Electrochemical corrosion behavior of 17-4PH stainless steel with laser surface melting treatment

[J].

激光表面处理17-4PH不锈钢的电化学腐蚀行为

[J].

Electrochemical and microstructural characterization of a precipitation hardened 17-4 steel in different environments

[J].

Effect of high temperature on the corrosion behavior and passive film composition of 316L stainless steel in high H2S-containing environments

[J].

Capacitance behaviour of passive films on ferritic and austenitic stainless steel

[J].

Combined XPS/TEM study of the chemical composition and structure of the passive film formed on additive manufactured 17-4PH stainless steel

[J].

Resolving surface chemical states in XPS analysis of first row transition metals, oxides and hydroxides: Cr, Mn, Fe, Co and Ni

[J].

XPS characterization of Co and Cr pigmented copper solar absorbers

[J].

Impact of reversed austenite on the pitting corrosion behavior of super 13Cr martensitic stainless steel

[J].

Diffusion kinetics of chromium in a novel Super304H stainless steel

[J].Diffusion behavior and diffusion kinetics of chromium (Cr) from the pure chromium coating in the matrix of Super304H and TP304H steels were investigated in a temperature range of 600–900 ℃ by using energy-dispersive spectrum (EDS) quantitative line scanning and Fick’s second law of diffusion. Pure Cr coating was obtained by electroplating. Experimental results show that the diffusion depth and diffusivity of Cr increase gradually with the increase in temperature. The diffusion activation energy of Cr is found to be lower and the diffusion coefficient of Cr to be higher in the Super304H steel than those in the TP304H steel at the same temperature. Furthermore, the diffusion equation of Cr in the Super304H and TP304H steels is \n \n \n \n \n D\n \n \n \n C\n r\n \n /\n \n S\n u\n p\n e\n r\n 304\n H\n \n \n \n \n \n \n \n \n =\n \n 1\n \n \n \n \n.\n 08\n ×\n 1\n \n \n \n \n \n \n 0\n \n \n \n \n \n −\n 15\n \n \n \n \n \n \n \n e\n x\n p\n \n (\n −\n 6\n \n \n \n \n.\n 08\n \n ×\n \n 1\n \n \n \n \n \n \n 0\n \n \n \n \n 4\n \n \n \n \n \n \n \n /\n \n R\n T\n )\n \n \n \n ${D_{{\\rm{Cr/Super304H}}}} \\, {\\rm{=\\, 1}}{\\rm{. 08 \\times 1}}{{\\rm{0}}^{{\\rm{- 15}}}}{\\rm{exp\\ (- 6}}{\\rm{. 08 \\, \\times \\, 1}}{{\\rm{0}}^{\\rm{4}}}{\\rm{/RT)}}$\n \n and \n \n \n \n \n D\n \n \n \n C\n r\n \n /\n \n T\n P\n 304\n H\n \n \n \n \n \n \n \n =\n 2\n \n \n \n \n.\n 29\n ×\n 1\n \n \n \n \n \n \n 0\n \n \n \n \n \n −\n 15\n \n \n \n \n \n \n \n e\n x\n p\n \n (\n −\n 7\n \n \n \n \n.\n 44\n ×\n 1\n \n \n \n \n \n \n 0\n \n \n \n \n 4\n \n \n \n \n \n \n \n /\n \n R\n T\n )\n \n \n \n ${D_{{\\rm{Cr/TP304H}}}}{\\rm{= 2}}{\\rm{. 29 \\times 1}}{{\\rm{0}}^{{\\rm{- 15}}}}{\\rm{exp\\ (- 7}}{\\rm{. 44 \\times 1}}{{\\rm{0}}^{\\rm{4}}}{\\rm{/RT)}}$\n \n, respectively.

Effect of microstructure on corrosion behavior of high strength martensite steel: A literature review

[J].

Microstructure and intergranular corrosion resistance of UNS S17400 (17-4PH) stainless steel

[J].

Stabilisation of retained austenite in laser surface melted tool steels

[J].

Revealing the relationship between grain size and corrosion rate of metals

[J].