近年来,随着航空发动机和燃气轮机的发展,涡轮叶片的失效问题日益显著,这对镍基高温合金的承温能力提出了更高的要求。对于叶片材料,除了要具有优异的抗热腐蚀性能,同时要兼备良好的组织稳定性和高温力学性能[7~9]。三者之间往往存在对立的关系,为提高合金的抗热腐蚀性能,须保持高的Cr含量,而高的Cr含量将降低基体Ni的含量,增大基体的过饱和度,降低合金的组织稳定性,高的Cr含量还会在长期时效过程中,促进有害相析出,严重损害合金的强度和塑性。为了提高合金的高温力学性能,需不断降低Cr含量来提高其它强化元素(W、Mo、Ta、Re)的含量来使合金具有更高的强度,而很多强化元素又是TCP相形成元素,它们在合金长期服役过程中会有足够的时间扩散进而形成TCP相,降低了合金的组织稳定性和抗热腐蚀性能。为了保持合金良好的组织稳定性,需要尽量避免γ'相变形、粗化和TCP相析出,这就要求合金在设计过程中应合理的控制Cr含量和强化元素含量[10~14]。本文研究的镍基合金为一种新型高强抗热腐蚀单晶高温合金,该合金中保持了较高Cr含量,通过提高Ta和Co的含量,试图提高合金的高温强度和基体的固溶度,使合金在高温状态长期服役时仍保持优异的抗热腐蚀性能。

本文在前期合金组织稳定性、力学性能研究基础上,进一步研究合金的抗热腐蚀性能,为模拟镍基单晶合金实际的使用状态,对其进行了长期时效处理,研究长期时效后的γ'相粗化和TCP相析出等对合金热腐蚀动力学、热腐蚀产物及其腐蚀机理的影响。

1 实验方法

实验材料为镍基单晶高温合金,其化学成分(质量分数,%)为:Al 3~7、Cr 8~12、Co 6~10、W + Mo + Ta + Re 14.5、Hf 0.1、C 0.015、B 0.005、Ni余量;合金的热处理制度如表1所示。CH样品为完全热处理态,CH-LA样品是在完全热处理态的基础上又进行了1000℃空气中600 h的长期时效。合金经过线切割、研磨、抛光等标准金相制样流程后,使用4 g CuSO4 + 20 mL HCl + 20 mL H2O腐蚀剂进行侵蚀,并对其显微组织进行观察分析。

表1 合金的热处理制度

Table 1

| Heat treatment | CH Sample (completely heat treated) | CH-LA Sample (complete heat treatment + long-term aging) |

|---|---|---|

| Solution | 1270oC/1 h + 1280oC/1 h + 1290oC/2 h + 1300oC/3 h + 1310oC/30 h, AC | 1270oC/1 h + 1280oC/1 h + 1290oC/2 h + 1300oC/3 h + 1310oC/30 h, AC |

| Primary aging | 1100oC/4 h, AC | 1100oC/4 h, AC |

| Secondary aging | 870oC/32 h, AC | 870oC/32 h, AC |

| Long-term aging | - | 1000oC/600 h, AC |

热腐蚀实验采用坩埚实验法,按75%Na2SO4 + 25%NaCl比例配置无水Na2SO4和NaCl混合盐,无水Na2SO4和NaCl的浓度均不低于99.0%。在混合盐中加入少量蒸馏水至糊状,将准备好的合金放入混合盐中,使盐均匀地沉积在合金表面,再将放有合金和混合盐的坩埚放入干燥箱中,在200℃下烘干1 h之后,将装有混合盐和试样的坩埚放入加热到设定温度900℃的箱式电阻炉中。待炉温稳定到900℃后,记录时间即为热腐蚀实验的开始时间,进行100 h的热腐蚀实验,每隔1、3、5、10、20、40、60、80、100 h取一次样,共取9次,每次取样等合金冷却至室温,用沸水洗净合金表面剩余盐,烘干后在干燥器中静置1 h,再称合金质量,然后重新涂盐,开始下一次实验,直至实验结束。

利用精度为0.1 mg的电子分析天平对腐蚀前后合金质量进行测量,以单位面积的质量变化计算腐蚀增重,以腐蚀时间和合金单位面积增重量为横、纵坐标轴绘制腐蚀动力学曲线。同时,测量相应热腐蚀时间后合金腐蚀最严重部位的腐蚀层深度,绘制其腐蚀深度随时间的变化曲线。

采用附带Ultimax65能谱仪(EDS)的JSM-IT800场发射扫描电镜(SEM)对腐蚀样品的表面与截面形貌、元素分布等进行观察和分析,采用D8 ADVANCE型X射线衍射仪(XRD)对腐蚀产物物相进行表征。

2 结果与讨论

2.1 合金的显微组织

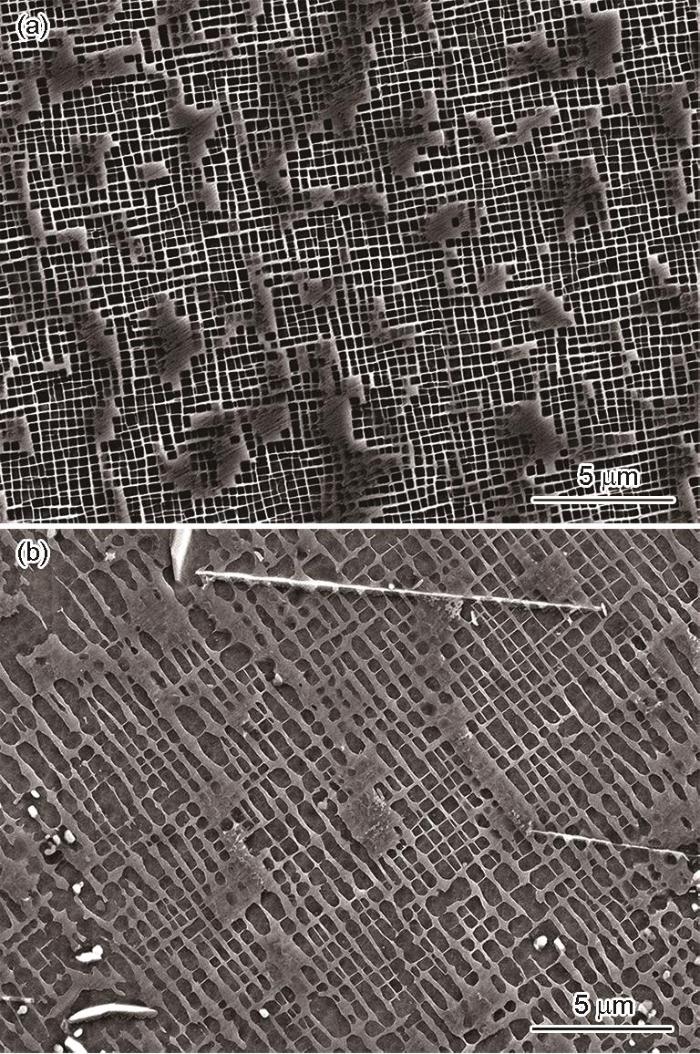

图1是两种热处理状态的镍基单晶高温合金在扫描电镜下的显微组织。铸态镍基单晶高温合金的显微组织是规则排列的立方γ'相以共格方式嵌镶在γ基体相中,突出的格子状是γ基体相,凹下去的部分是γ'相。合金经过完全热处理后,γ基体上均匀分布着具有良好立方度的细小γ'相,如图1a所示。完全热处理后再进行1000℃下600 h的长期时效,合金的显微组织产生明显变化,γ'相产生变形和粗化,而且析出了球状、针状和短棒状的TCP相,即图1b中的白色相,经能谱分析,TCP相富含Re、Cr、Mo、W等难熔元素。对比CH样品和CH-LA样品,长期时效使合金组织退化,γ'相产生了变形和粗化,并且析出了TCP相,势必会对合金的性能带来影响。

图1

图1

CH和CH-LA样品的显微组织

Fig.1

Microscopic structures of CH sample (a) and CH-LA sample (b)

2.2 热腐蚀动力学

图2是两种热处理状态的镍基单晶高温合金在900℃腐蚀100 h的腐蚀增重曲线。可见,CH样品的腐蚀动力学曲线以40 h为边界,近似为两段抛物线,抛物线速率常数分别为0.327和3.147 mg2·cm-4·h-1,40 h前的腐蚀速率小于40 h后。CH-LA样品的腐蚀动力学曲线也以40 h为边界近似为两段抛物线,抛物线速率常数分别为1.047和9.057 mg2·cm-4·h-1,腐蚀速率明显增加。在整个热腐蚀过程中,CH-LA样品的单位面积腐蚀增重一直大于CH样品,CH样品最大增重为14.069 mg·cm-2,CH-LA样品最大增重为24.429 mg·cm-2。

图2

图2

两种热处理状态的镍基单晶高温合金在900℃腐蚀100 h的增重曲线

Fig.2

Mass gain curves of CH and CH-LA alloy samples during hot corrosion in 75%Na2SO4 + 25%NaCl molten salt at 900oC for 100 h

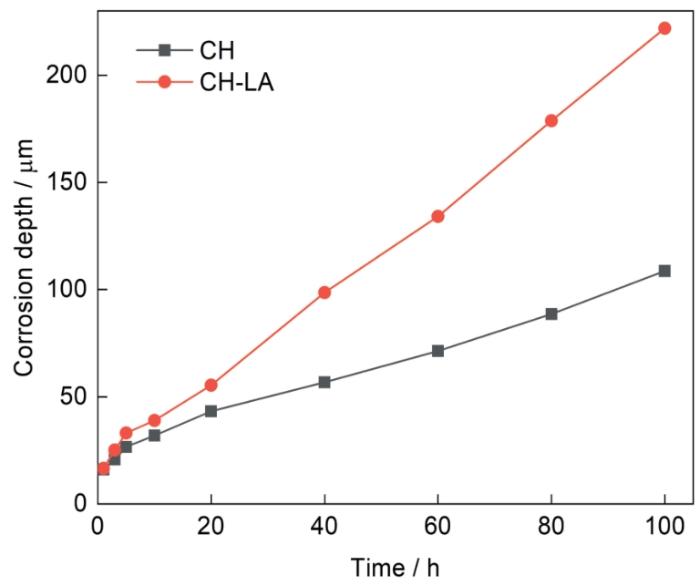

图3是两种热处理状态的镍基单晶高温合金在900℃腐蚀100 h的腐蚀深度曲线。可见,CH样品和CH-LA样品的腐蚀深度曲线均近似服从抛物线规律,且整个热腐蚀过程中CH-LA样品腐蚀深度一直大于CH样品,CH样品最大腐蚀深度为108.7 μm,CH-LA样品最大腐蚀深度为221.91 μm。

图3

图3

两种热处理状态的镍基单晶高温合金在900℃腐蚀100 h的腐蚀深度曲线

Fig.3

Corrosion depth curves of CH and CH-LA alloy samples after hot corrosion in 75%Na2SO4 + 25%NaCl molten salt at 900℃ for 100 h

2.3 腐蚀产物分析

2.3.1 X射线衍射分析

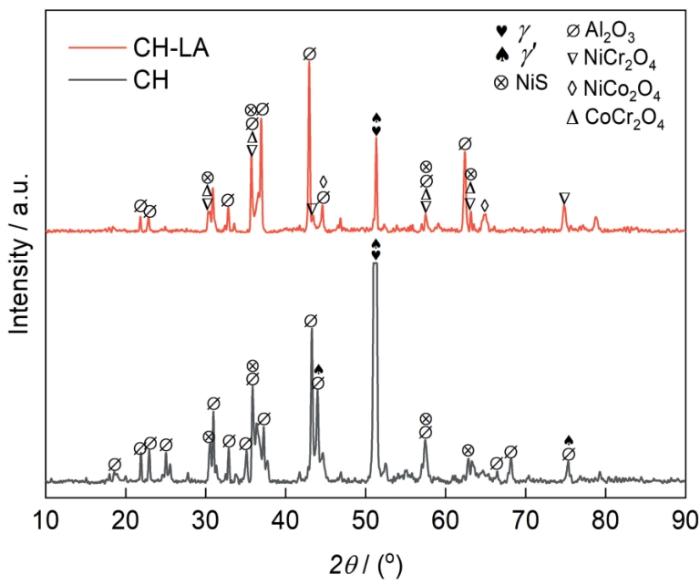

图4

图5

图5

两种热处理状态的镍基单晶高温合金在900℃腐蚀100 h后的表面XRD谱

Fig.5

XRD patterns of the surfaces of CH and CH-LA alloy samples after hot corrosion in 75%Na2SO4 + 25%NaCl molten salt at 900oC for 100 h

2.3.2 宏观形貌分析

图6为CH样品和CH-LA样品在900℃不同时间热腐蚀后的表面宏观形貌。可见,CH样品在腐蚀过程中只有微量的腐蚀产物剥落,腐蚀产物膜较为连续完整。CH-LA样品腐蚀过程中腐蚀产物发生了明显的块状剥落,在腐蚀100 h后表面形成较厚的凸凹不平的黑色腐蚀产物,且有较明显的碎裂。

图6

图6

两种热处理状态的镍基单晶高温合金在900℃热腐蚀不同时间后的宏观形貌

Fig.6

Macro morphologies of CH (a-e) and CH-LA (f-j) alloy samples after hot corrosion in mixed molten salt at 900oC for 20 h (a, f), 40 h (b, g), 60 h (c, h), 80 h (d, i) and 100 h (e, j)

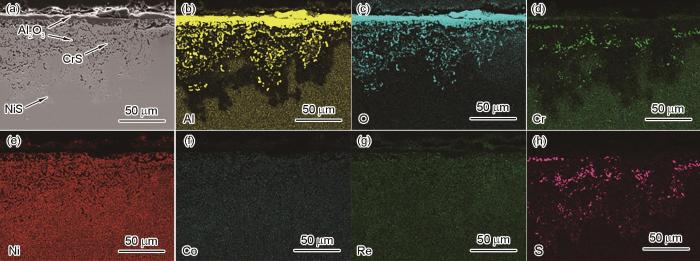

2.3.3 腐蚀层截面分析

图7

图7

CH合金样品在900℃腐蚀100 h后的SEM形貌及EDS图谱

Fig.7

SEM morphology of CH sample after hot corrosion at 900oC for 100 h (a), and corresponding EDS mappings of Al (b), O (c), Cr (d), Ni (e), Co (f), Re (g) and S (h)

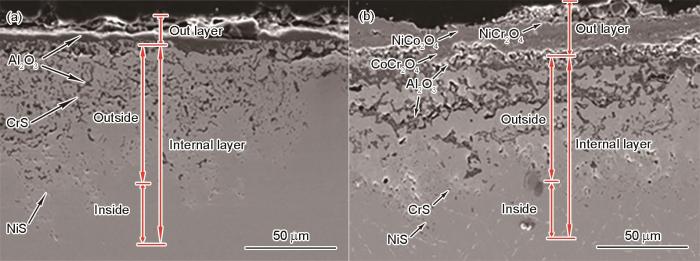

图8

图8

热腐蚀100 h后的CH and CH-LA合金样品的截面形貌

Fig.8

Cross-sectional morphologies of CH (a) and CH-LA (b) alloy samples after hot corrosion at 900oC for 100 h

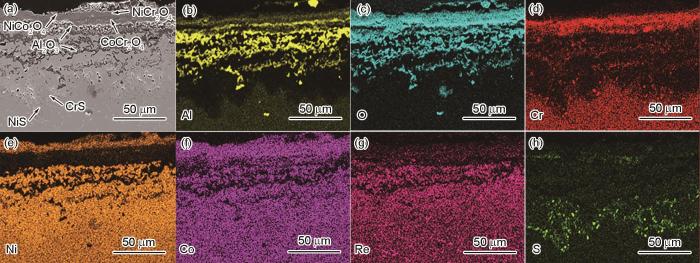

图9

图9

CH-LA样品在900℃腐蚀100 h后的SEM截面形貌及EDS图谱

Fig.9

SEM cross section of CH-LA sample after hot corrosion at 900oC for 100 h (a), and corresponding EDS mappings of Al (b), O (c), Cr (d), Ni (e), Co (f), Re (g) and S (h)

综上所述,CH样品外腐蚀区形成了较为致密连续的Al2O3膜,对合金有很好的保护作用,而CH-LA样品外腐蚀区氧化膜可能通过固相反应已全部转化为尖晶石氧化物,对合金的保护作用下降。

2.4 分析与讨论

铸态单晶高温合金凝固过程中Al、Ta等γ'相形成元素出现富集,γ相的过饱和浓度变大,增加了γ'相长大驱动力,凝固结束后连续冷却使γ'相从过饱和的γ固溶体中析出,形状呈立方状或蝶状,尺寸较粗大[15~17]。经完全热处理后,元素间的相互扩散降低了元素偏析,提高了合金成分的整体均匀性,使凝固过程中产生的粗大γ'相和γ + γ'共晶完全或者大部分溶解,达到均匀化的目的,在随后的冷却过程中重新析出细小、均匀分布的立方体γ'相[18~20]。长期时效后,由于元素迁移,γ/γ'相界面能和弹性应变能降低,γ/γ'共格弱化,大尺寸的γ'相长大,小尺寸的γ'相溶解,导致γ'变形和粗化,使γ'相形状不规则,分布也不均匀,阻碍位错运动的能力减弱,削弱了γ相沉淀强化作用,使合金的承温能力下降。同时,一些强化元素在化学亲和力作用下发生扩散和聚集,超过一定值时,致使TCP相析出,TCP相的形成消耗了基体中大量的固溶强化元素,减弱了难熔元素对基体的固溶强化,且TCP相属于脆硬相,严重割裂了基体和γ'相,使位错在γ基体中的运动变得容易,进一步减弱了γ'相沉淀强化作用,合金的组织稳定性和抗热腐蚀性能下降[21~24]。

CH样品和CH-LA样品900℃下进行了100 h的热腐蚀后,均发生了明显的热腐蚀现象,腐蚀层外腐蚀区由多层氧化物组成,内腐蚀区由硫化物和氧化物组成,综合判断均发生了“酸碱熔融模型”机制的热腐蚀反应。热腐蚀初期,合金基体中易氧化元素优先扩散至合金表面生成Cr2O3、Al2O3等氧化物。SO

3 结论

(1) CH样品γ基体上均匀分布着具有良好立方度的细小γ'相。CH-LA样品合金γ'相产生变形和粗化,而且析出了富含Re、Cr、Mo、W的球状、针状和短棒状TCP相。

(2)镍基单晶合金900℃下100 h热腐蚀后,CH样品腐蚀膜剥落轻微,合金表面形成了连续的Al2O3外氧化膜,并发生了Al的内氧化、Cr的内硫化及Ni的内硫化。CH-LA样品表面腐蚀产物剥落明显,表面形成了较厚的包含NiCr2O4、NiCo2O4、CoCr2O4的复合氧化物层及其下极薄的Al2O3层,同时也发生了Al的内氧化、Cr的内硫化及Ni的内硫化。

(3) 镍基单晶合金900℃下100 h热腐蚀后,CH样品的腐蚀动力学曲线近似遵循抛物线或分段抛物线规律,腐蚀速率小;而CH-LA样品的腐蚀动力学曲线分段遵循抛物线规律,但腐蚀速率相对大,与长期时效组织粗化并形成TCP相有关。

参考文献

Corrosion behavior of a nickel-based superalloy in molten NaCl at 850oC and 950oC

[J].

一种镍基合金在850℃和950℃熔融NaCl中的热腐蚀行为

[J].

Influence of long-term isothermal aging on microstructure and creep rupture properties of Ni-base superalloy M4706

[J].

Research progress on the influence of hot corrosion on mechanical properties of superalloys and protective measures

[J].

热腐蚀对高温合金力学性能的影响以及防护措施的研究进展

[J].

Internal oxidation and internal sulfuration of Ni-base alloy with high Cr content during hot corrosion in molten sulfate

[J].

高铬镍基合金熔融硫酸盐热腐蚀过程中内氧化和内硫化行为的研究

[J].

Influence of Pt-Al coating on hot corrosion resistance behaviors of a Ni-based single-crystal superalloy

[J].Pt-Al coating has been widely used in engine rotor blades because of its ability to improve the oxidation and hot corrosion resistance of Ni-based superalloys. However, the effect exerted by Pt on S and other refractory elements, as well as the rupture mechanisms, is under debate. To investigate the influence of Pt-Al coating on the corrosion resistance of single-crystal superalloy at high temperature, the hot corrosion test utilized Na2SO4 salt coated on the surface of the Pt-Al coating samples and the uncoated ones were carried out at 900oC, respectively. Using several techniques, such as XRD, SEM, EDS, and EPMA, the influence of Pt-Al coating on the hot corrosion behaviors of a Ni-based single-crystal superalloy was analyzed. Moreover, the hot corrosion kinetics, hot corrosion products, and microstructure evolution during the process were analyzed. The results reveal that the hot corrosion resistance of the substrate alloy was enhanced by Pt-Al coating. The hot corrosion rate of the Pt-Al coating sample was lower than that of the uncoated one. Thus, it can be inferred that Pt-Al coating exhibited better hot corrosion resistance. Pt prevented the diffusion of S into the β-(Ni, Pt)Al phase. The S atom was present at the oxide-metal interface, which reduced the hot corrosion rate of the substrate alloy. The presence of Pt in the β-(Ni, Pt)Al obstructed the great mass of Ta in the inter diffusion zone, which led to the diffusion of only a small quantity of Ta atoms into the oxide, and reduced the formation of Ta2O5. Finally, Pt-Al coating was also found to restrain to some extent the void formation at the oxide-metal interface.

Pt-Al涂层对一种镍基单晶高温合金抗热腐蚀行为的影响

[J].

Microstructure and hot corrosion behavior of Al-Ce-Y coatings on DZ125 nickel-based alloy prepared by pack cementation process

[J].

Effect of Co on oxidation and hot corrosion behavior of two nickel-based superalloys under Na2SO4-NaCl at 900oC

[J].

The second generation hot corrosion resistant Ni-based single crystal superalloy DD489 and its typical properties

[J].

第二代耐热腐蚀镍基单晶高温合金DD489及其典型性能

[J].

Study on hot corrosion of Ni-base superalloy with different Ru content

[J].

不同Ru含量的镍基高温合金热腐蚀研究

[J].

Effect of different Cr content on hot corrosion resistance of Ni-base superalloy

[J].

不同Cr含量对镍基高温合金抗热腐蚀性能的影响

[J].

Effect of boron addition on solidification characteristics and TCP phase precipitation behavior of directionally solidified nickel-based superalloy

[J].

B元素对定向凝固镍基合金凝固特性和TCP相析出行为的影响

[J].研究了B元素对定向凝固镍基合金凝固特性和TCP相析出行为的影响规律,并结合热力学计算软件Thermo-Calc和镍基合金数据库,计算分析了B元素对合金在非平衡凝固过程中的Cr、Co和Mo元素偏析行为的影响。结果表明,B元素的加入能够显著降低合金的固/液相温度,加宽凝固范围,增加共晶含量及Co、Cr和Mo元素在枝晶间的偏聚程度,进而加剧TCP相的析出;当B元素含量≤0.012%时,合金在850℃长期时效具有较好的组织稳定性能;当B元素含量增加到0.033%时,合金时效100 h,针状σ相开始析出,合金组织稳定性变差。

Nickel-based single crystal superalloys with different rhenium contents

[J].

铼在镍基单晶高温合金中的作用

[J].

Effect of long-term aging on microstructure evolution and stress rupture properties of Ni-based single crystal superalloy

[J].

长期时效对一种镍基单晶高温合金组织演化及持久性能的影响

[J].

Effects of different elevated temperature and long-term exposure on microstructural evolution and mechanical characteristics of IN617 Ni-based superalloy

[J].

Effect of heat treatment on microstructures and stress rupture properties of hot-corrosion resistant single crystal superalloy

[J].

热处理对一种抗热腐蚀单晶高温合金组织和持久性能的影响

[J].

Precipitation behaviors of γ' phase in cast superalloy K480 and DD407 during heat treatment

[J].

铸造高温合金K480及DD407热处理中γ'相的析出行为

[J].

Microstructural evolution of a kind of nickel base single crystal superalloy with low content of rhenium during long term aging

[J].

一种低铼镍基单晶高温合金在长期时效过程中的组织演化

[J].利用扫描电镜观察了一种低铼镍基单晶高温合金在1 000℃和1 100℃长期时效处理不同时间后的组织演化情况。结果表明:在1 000℃长期时效处理过程中,随着时效时间延长,γ'相逐渐长大,1 000 h后大部分γ'相仍保持一定立方度,γ'相边长达到1μm左右;枝晶内应力的存在导致枝晶干不同区域γ'相呈现不同的形貌;1 100℃长期时效100 h后,γ'相逐渐合并、连接,500 h后γ'相完全形筏,随时效时间延长,γ/γ'界面位错网间距逐渐减小,筏形组织逐渐粗化;1 000℃长期时效1 000 h和1 100℃长期时效500 h后仅有少量μ相析出,该合金具有良好的组织稳定性。

Microstructures and long-term aging stability of nickel-based superalloy DD98M by laser additive manufacturing

[J].

激光增材制造DD98M高温合金组织及稳定性研究

[J].

Coarsening kinetics of cubic γ' precipitates of a nickel-based single crystal superalloy after long-term aging

[J].

一种镍基单晶高温合金长期时效后γ'相的粗化动力学

[J].研究了第二代镍基单晶高温合金DD5在870~980℃时效150~2000 h后γ'相的粗化动力学。结果表明:长期时效后DD5合金γ'相的形貌和尺寸取决于时效温度和时效时间,可用形貌稳定因子来表征;在870~980℃时效温度下,枝晶中γ'析出相发生粗化,γ'析出相的平均尺寸随时效时间和温度的增加而增大;动力学计算结果表明DD5合金在长期时效后,γ'相的粗化长大受合金元素扩散的控制,γ'析出相依然保持规则立方状,具有较好的组织稳定性。

Effect of long-term aging on microstructure and stress rupture properties of two low-Re nickel based single crystal superalloys

[J].

长期时效对两种低Re镍基单晶高温合金显微组织和持久性能的影响

[J].采用扫描电镜和蠕变试验机研究了长期时效对两种低Re镍基单晶高温合金(1.0Re和1.5Re合金)显微组织和持久性能的影响。结果表明:在980℃/1000 h的长期时效处理过程中,合金的γ'相发生粗化和连接,1.0Re合金粗化速率略大于1.5Re合金。980℃长期时效过程中两种合金均未析出TCP相,均表现出较好的组织稳定性。持久性能测试表明:200 h长期时效后1.0Re和1.5Re合金在1038℃/172 MPa的持久寿命较热处理态分别提高了16.8%和13.3%;随着长期时效时间的延长,持久寿命略有下降,长期时效1000 h后,1.0Re和1.5Re合金的持久寿命较热处理态分别下降了15.8%和14.9%。3种状态下两种合金持久寿命均相近,说明用0.5%W代替0.5%Re后起到相同的强化效果。

Effect of Ru on microstructure evolution of the fourth generation nickel-based single crystal superalloy DD22 during long-term aging

[J].The morphological evolution of γ′ phase, the precipitation of TCP phases and the evolution of the interfacial dislocation networks in DD22 nickel-based single crystal superalloys with different Ru contents (3% and 5%, mass fraction) were investigated by transmission electron microscopy and field emission scanning electron microscopy during long-term aging at 1130 ℃. The results show that γ′ phase of 5Ru alloy are smaller in size and more regular in shape than that of 3Ru alloy. The mismatch of γ/γ′ phases is larger in 5Ru alloy, and the high content of Ru causes the reverse distribution of elements such as Re and Mo. During long-term aging at 1130 ℃, the coarsening rate, dissolution rate and rafting rate of γ′ phase in 5Ru alloy are lower than those of 3Ru alloy. There is still no TCP phase precipitation in 5Ru alloy after long-term aging for 1000 h, while a small amount of TCP phase is precipitated in 3Ru alloy after long-term aging for 50 h. With the prolongation of long-term aging time, the number and size of TCP phases both increase. Compared with 3Ru alloy, the interfacial dislocation networks of 5Ru alloy are denser and more regular after long-term aging for 1000 h. Above all, the reverse distribution of elements and low diffusion coefficient of Ru make 5Ru alloy exhibit higher microstructural stability than 3Ru alloy.

Ru对第四代镍基单晶高温合金DD22长期时效组织演化的影响

[J].利用透射电镜和场发射扫描电镜研究了两种不同Ru含量(3%和5%,质量分数)的第四代镍基单晶高温合金DD22在1130 ℃长期时效过程中γ′相形貌演化、TCP相析出和界面位错网的演化情况。研究结果表明:在完全热处理后5Ru合金比3Ru合金的γ′相尺寸更小,形状更规则,γ/γ′相界面的错配度更大,高Ru含量使合金Re,Mo等元素出现反分配现象;5Ru合金在1130 ℃长期时效过程中γ′相粗化速率、溶解速率和形筏速率均低于3Ru合金;5Ru合金在长期时效1000 h后仍没有TCP相析出,而3Ru合金在时效50 h后便析出TCP相,随着长期时效时间延长,TCP相数量增多,尺寸增大;与3Ru合金相比,长期时效1000 h后5Ru合金γ′/γ界面位错网更加致密和规则;综上所述,Ru的元素反分配作用和低的扩散系数使5Ru合金比3Ru合金表现出更高的组织稳定性。

Effect of long-term aging temperature on the microstructure and tensile properties of a single crystal superalloy

[J].

长期时效温度对一种单晶高温合金组织和拉伸性能的影响

[J].

Microstructural stability and stress rupture property of a 6Re/3Ru containing nickel-based single crystal superalloy

[J].The microstructural evolution during long-term aging at 1000℃ and 1130℃ and the stress rupture property at 1100℃/140 MPa of a fourth-generation nickel-based single crystal superalloy with 6Re/3Ru were investigated. The microstructure and dislocation configuration of the alloy were observed by field emission scanning electron microscopy (FE-SEM) and transmission electron microscopy (TEM) in terms of its microstructural stability and stress rupture property. The results showed that the alloy displayed excellent microstructural stability. During long-term aging at 1000℃, γ′ phase grew up gradually, but γ′ phase still remained high cubic degree, however, the TCP phases did not precipitate after aging for 1000 h. After aging at 1130℃ for 500 h, the γ′ phase connected each other and became rafting ed. The TCP phase started to precipitate after long-term aging at 1130℃ for 200 h, however, the content of TCP phase was only 0.04% after aging for 1000 h in the alloy. After aging at 1130℃ for 500 h, dislocation networks formed at γ/γ′ interfaces which became more regular and denser with the increase of aging time. The stress rupture life of the alloy at 1100℃/140 MPa was 676.5 h, which reached the level of the fourth-generation nickel-based single crystal superalloy. The γ′ phase underwent N-type rafting, the needle-like TCP phase (μ phase) precipitated, and dislocation pile-up was found near TCP phase after fracture. During stress rupture test, the formation of γ/γ′ interfacial dislocation networks and a<010> super-dislocations in the alloy was beneficial to the stress rupture property.

一种6Re/3Ru镍基单晶高温合金微观组织的稳定性和高温持久性能

[J].用场发射扫描电镜(FE-SEM)和透射电镜(TEM)观察一种第四代镍基单晶高温合金长期时效和持久断裂后的微观组织和位错组态,研究了这种合金在1000℃和1130℃长期时效过程中的组织演化和在1100℃/140 MPa条件下的持久性能。结果表明:这种合金具有较好的组织稳定性,在1000℃长期时效过程中γ'相逐渐长大,但是在1000 h后仍有较好的立方度且没有TCP相析出。在1130℃长期时效500 h后γ'相发生连接和筏化;时效200 h后开始析出TCP相,时效1000 h后合金中TCP相的面积分数只有0.04%。在1130℃长期时效500 h后,γ/γ'界面形成位错网并随着时效时间的延长变得更加规则致密。这种合金在1100℃/140 MPa条件下的持久寿命为676.5 h,达到第四代镍基单晶高温合金水平。持久断裂后γ'相发生N型筏化,合金中析出针状TCP相(μ相)并在TCP相附近出现位错塞积。在持久试验过程中,合金中生成的γ/γ'界面位错网和a<010>超位错有利于提高其持久性能。

Microstructure and property stability of powder metallurgy nickel-based U720Li superalloy during long-term aging

[J].

Hot corrosion behavior of a Ni-base superalloy containing Ti in molten sulfate at 850oC and 950oC

[J].

含钛镍基合金在850℃和950℃的热腐蚀行为

[J].

Hot corrosion behavior and mechanism of HR3C and HR6W used in advanced ultra-supercritical power plant

[J].

高效超超临界机组用材HR3C和HR6W的热腐蚀行为及机理研究

[J].

High temperature hot corrosion behaviors of directional solidification Ni-base superalloy DZ792 and DZ729G

[J].

定向凝固镍基DZ792及DZ792G合金的高温热腐蚀行为

[J].

Corrosion behavior of Cr, Fe and Ni based superalloy in molten NaCl

[J].