奥氏体钢以其良好的抗氧化性能和较高的抗蠕变性能,在锅炉过热器和再热器管道中得到了广泛应用[7]。其中,HR3C与Sanicro25是两种常用奥氏体钢。一些国内外学者对奥氏体钢在不同蒸汽环境中的氧化行为进行了研究。Li等[8]研究了耐热奥氏体钢Super304H和HR3C在1000 MW超超临界锅炉中的抗高温蒸汽氧化行为,认为Super304H钢氧化膜的主要组成是Fe2O3,Cr2O3和FeCr2O4,HR3C钢氧化膜的组成是Fe2O3。且氧化膜均为双层结构,外层富O和Fe,内层富O和Cr。Zhu等[9]研究了TP347HFG和Sanicro25钢在600 ℃、25 MPa无氧超临界水中氧化1000 h后的氧化行为,认为在600~700 ℃下Sanicro25钢的基体/氧化膜界面处生成连续性Cr2O3,而TP347HFG钢只有少量的Cr2O3。Rutkowski等[10]研究了Sanicro25钢在650 ℃下热暴露1000 h后形成的氧化物的微观结构和化学组成,认为Sanicro25钢氧化后的氧化层呈多层结构,最外层富Fe,随着Cr向金属表面扩散,形成了Cr2O3层,且在Cr2O3层下方产生含Si,Cr和Mn的氧化物。贾建文等[11]认为Sanicro25钢在不同的高温氧化和腐蚀条件下,析出相/膜成分/特征也不同。杨珍等[12]研究了HR3C和Super304H钢在750 ℃下静态空气中的循环氧化行为,认为HR3C钢基体表面形成的富Cr氧化物与 (Cr,Mn)2O3膜的起脊开裂有关。并探讨了HR3C钢在750 ℃空气和水蒸气不同种气氛中的氧化机制,认为HR3C钢在水蒸气中的氧化速率远大于其在静态空气中的氧化速率[13]。沈朝等[14]认为HR3C钢在超临界650 ℃/25 MPa水环境中的腐蚀呈幂函数生长规律,而在次临界290 ℃/15.2 MPa水环境中生长规律为先减后增。本课题组[15,16]研究了奥氏体钢HR3C,Super304H和TP347HFG在无氧超临界水中的氧化增重规律,认为氧化增重的顺序为HR3C<TP347HFG<Super304H。还有学者研究了HR3C钢的高温强度和综合性能,彭志方等[17]研究了超超临界火电机组过热器管用钢HR3C的脆化倾向与晶界碳化物M23C6的含量及其尺寸之间的关系,认为管样脆化的根本原因与粗大的奥氏体钢晶粒和宽厚的晶界片有关。由于目前700 ℃超超临界锅炉技术仍未克服材料的抗氧化、抗腐蚀性能问题,因此,700 ℃超临界水环境下HR3C和Sanicro25钢的抗氧化特性的实验研究具有现实意义。

为了更好地了解奥氏体钢的抗氧化性能,本文开展了HR3C和Sanicro25钢在650 ℃/25 MPa和700 ℃/25 MPa超临界水环境中的氧化实验,研究了不同氧化时间、不同温度下HR3C和Sanicro25钢的氧化动力学和生成氧化膜的厚度、表面形貌、横截面形貌以及物相组成,对比HR3C和Sanicro25钢在超临界水中的抗氧化性能,分析了氧化机理,讨论了温度对氧化膜形成过程的影响和结节状氧化物的形成原因。

1 实验方法

HR3C和Sanicro25钢的化学成分如表1所示。先将棒状试样加工成长宽高分别为20 mm×10 mm×2 mm的片状试样,再依次利用200#,400#,600#,800#和1000#的砂纸逐级打磨试样的每个表面。使用游标卡尺精确测量试样尺寸,计算每个试样的表面积。将试样分别放入盛有丙酮的烧杯中,置于装有超纯水的超声波清洗仪中清洗5 min,并用烘干机干燥。最后使用精度为0.01 mg的METTLER TOLEDO电子天平对干燥后的试样称重。

表1 HR3C和Sanicro25钢的化学成分

Table 1

| Steel | C | Si | Mn | Ni | Cr | Cu | Nb | N | W | P | S | Co | Fe |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| HR3C | 0.06 | 0.39 | 1.24 | 20.29 | 24.63 | --- | 0.49 | 0.24 | --- | 0.012 | 0.001 | --- | Bal. |

| Sanicro25 | 0.08 | 0.25 | 0.51 | 25.5 | 22.6 | 2.99 | 0.44 | 0.24 | 3.45 | --- | --- | 1.57 | Bal. |

连续式超临界氧化实验平台的示意图见参考文献[18]。反应釜及高温高压蒸汽管路材质为耐高温镍基合金,体积为2 L。实验温度为 (650±4) 和 (700±4) ℃,实验压力为 (25±0.5) MPa。超纯水由超纯水机制备,电导率小于0.1 μs/cm。实验中的水流量为5 mL/min。超纯水未除氧,水中溶解氧量约为8×10-3 g/L。试样用铂丝悬挂于陶瓷架上,放置在反应釜中间段的恒温区,使用高纯氮气吹扫实验台5 min,彻底排除空气。氧化实验最长时间为1000 h,每200 h中断实验,取出全部试样进行称重,留下两个平行试样进行分析,其他试样继续放入釜内完成实验。

采用JSM-6490LV扫描电镜 (SEM) 观察氧化膜的表面和横截面形貌,利用Energy 350能谱仪 (EDS) 对氧化膜进行化学成分分析,用DY2413型X射线衍射仪 (XRD) 及Thermo escalab 250Xi型Raman光谱仪分析氧化膜的物相组成。

2 实验结果

2.1 氧化动力学

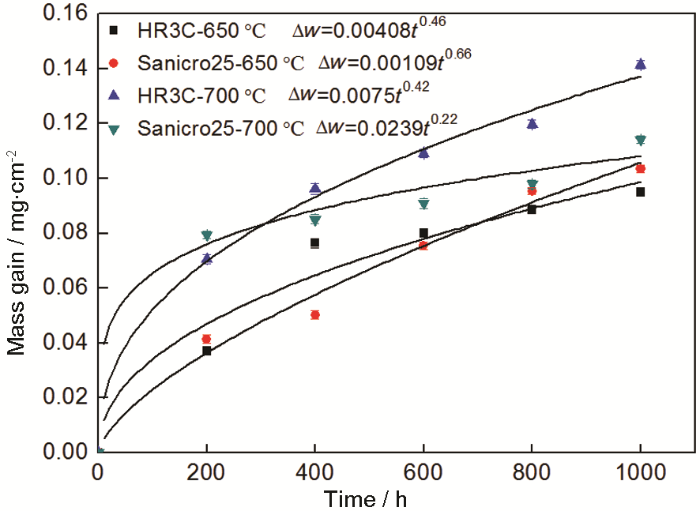

图1为HR3C和Sanicro25钢试样分别在650和700 ℃未除氧超临界水环境中氧化1000 h后的氧化增重曲线,氧化增重 (

式中,

图1

图1

HR3C与Sanicro25钢在650和700 ℃超临界水中的氧化增重曲线

Fig.1

Oxidation mass gain curves of HR3C and Sanicro25 steels in supercritical water at 650 and 700 ℃

2.2 表面形貌及物相组成

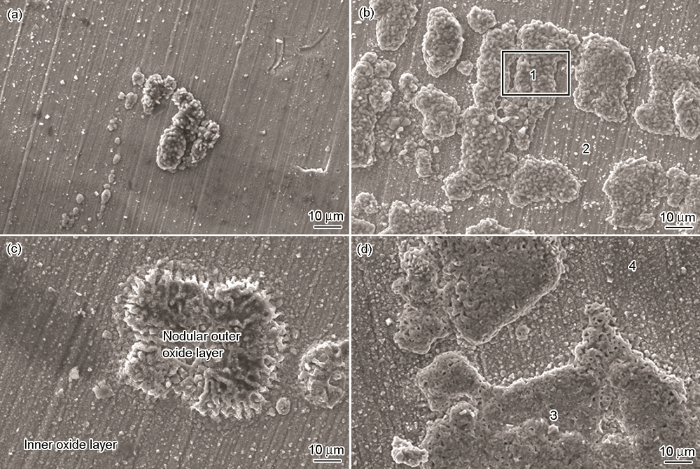

图2

图2

HR3C钢在650和700 ℃超临界水中氧化不同时间后的表面形貌

Fig.2

Surface morphologies of HR3C steel oxidized in supercritical water at 650 ℃ (a, b) and 700 ℃ (c, d) for 200 h (a, c) and 1000 h (b, d)

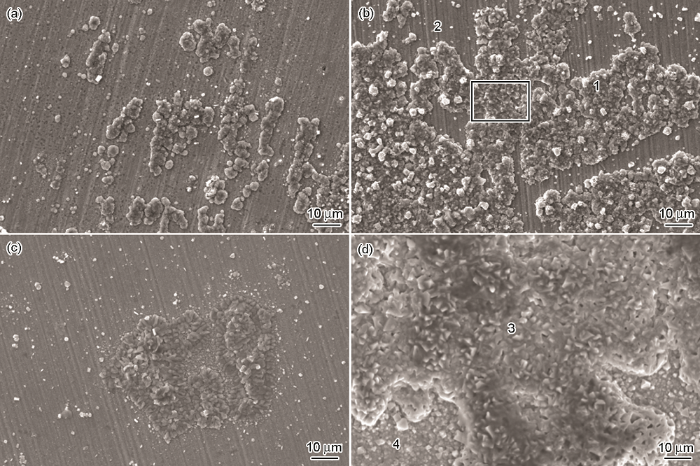

图3

图3

Sanicro25钢在650和700 ℃超临界水中氧化不同时间后的表面形貌

Fig.3

Surface morphologies of Sanicro25 steel oxidized in supercritical water at 650 ℃ (a, b) and 700 ℃ (c, d) for 200 h (a, c) and 1000 h (b, d)

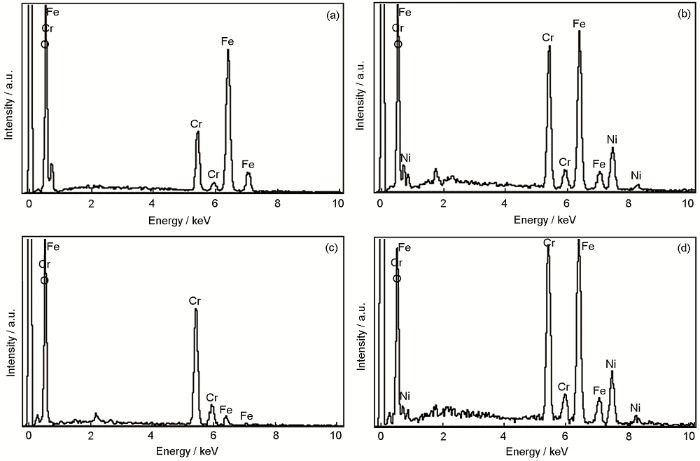

图4

图4

HR3C钢在650和700 ℃的超临界水中氧化1000 h后标记区的EDS结果

Fig.4

EDS results in the marked regions 1 (a), 2 (b), 3 (c) and 4 (d) in Fig.2

表2 HR3C与Sanicro25钢650 ℃下形成的氧化膜组成元素含量

Table2

| Oxide layer | Element | HR3C | Sanicro25 |

|---|---|---|---|

| Nodular outer oxide layer | Fe | 35.16 | 33.21 |

| Cr | 1.51 | 1.21 | |

| Compact inner oxide layer | Fe | 29.02 | 20.73 |

| Cr | 20.26 | 15.26 | |

| Ni | 15.29 | 19.03 |

图5

图5

Sanicro25钢在650和700 ℃的超临界水中氧化1000 h后标记区的EDS结果

Fig.5

EDS results in the marked regions 1 (a), 2 (b), 3 (c) and 4 (d) in Fig.3

图6为HR3C与Sanicro25钢在650和700 ℃超临界水中氧化不同时间后外层氧化物膜的高倍放大形貌图。由图6a和b可知,HR3C钢在650 ℃氧化1000 h后,氧化物呈现颗粒状 (≈2 μm)。Sanicro25钢的氧化物颗粒尺寸比HR3C钢略大。在700 ℃超临界水中氧化200 h后,由图6c和d可知,HR3C钢的外层氧化物呈多面体晶粒状,并观察到孔洞的存在,致密的内层氧化膜表面附着部分大颗粒物 (≈4 μm)。由图6e和f可知,Sanicro25钢的外层氧化物中也存在孔洞,但与HR3C钢相比,可观测程度不明显。内层氧化膜相对光滑,表面颗粒物尺寸介于1~4 μm。在700 ℃超临界水中氧化1000 h后,由图6g~j可知,HR3C与Sanicro25钢的外层氧化物孔洞分布更加密集,内层氧化膜由众多细小颗粒组成,周围伴随大颗粒。

图6

图6

HR3C与Sanicro25钢在650和700 ℃超临界水中氧化不同时间后的形貌图

Fig.6

High magnification views of the square regions marked in Fig.2b (a) and Fig.3b (b), and outer (c, e, g, i) and inner (d, f, h, j) oxide scales formed on HR3C (c, d, g, h) and Sanicro25 (e, f, i, j) at 700 ℃ for 200 h (c~f) and 1000 h (g~j)

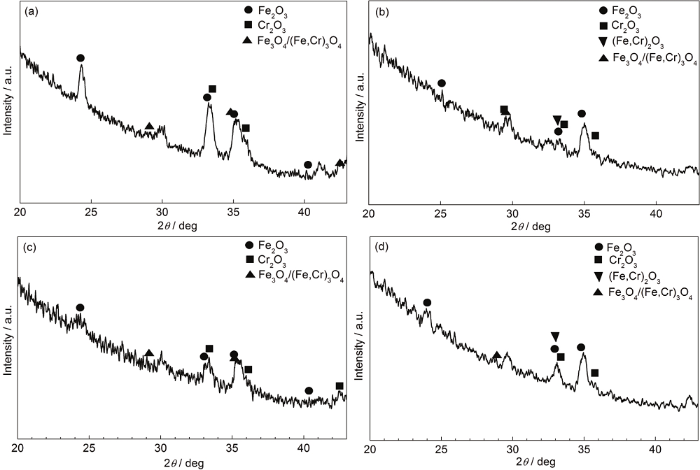

图7为HR3C与Sanicro25钢在650和700 ℃超临界水中氧化1000 h的XRD谱。由图7a和c可知,650 ℃下HR3C和Sanicro25钢的氧化物类型相同,主要为Fe2O3,Cr2O3和尖晶石氧化物Fe3O4/(Fe,Cr)3O4。由图7b和d可知,700 ℃下HR3C和Sanicro25钢的氧化物类型相同,主要为Fe2O3,Cr2O3,(Fe,Cr)2O3以及尖晶石相Fe3O4/(Fe,Cr)3O4。杨华春等[19]还认为Sanicro25钢在27 MPa,700 ℃蒸汽下氧化2000 h后,内、外层的氧化膜中都检测到了氧化物 (Ni,Fe)Cr2O4。可见,氧化物的类型与蒸汽环境有关。

图7

图7

HR3C与Sanicro25钢在650和700 ℃超临界水中氧化1000 h的XRD谱

Fig.7

XRD spectra of HR3C (a, b) and Sanicro25 (c, d) steels oxidized for 1000 h in supercritical water at 650 ℃ (a, c) and 700 ℃ (b, d)

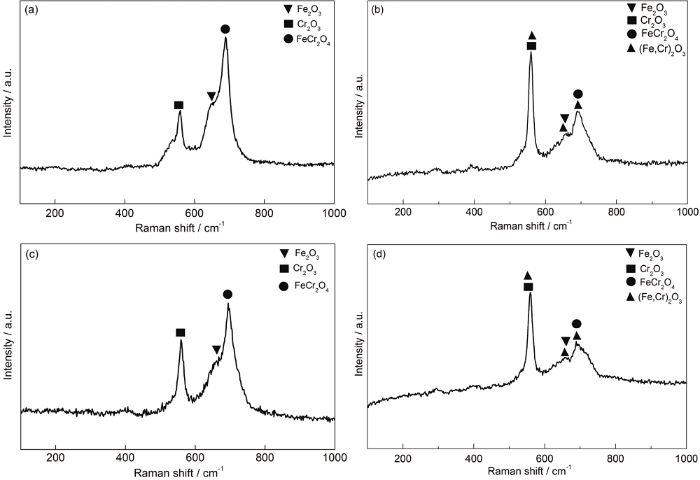

图8为HR3C与Sanicro25钢在650和700 ℃超临界水中氧化1000 h后的Raman图谱。可见,650 ℃下HR3C与Sanicro25钢的氧化物类型主要为Fe2O3,Cr2O3和FeCr2O4。700 ℃下HR3C与Sanicro25钢的氧化物类型主要为Fe2O3,Cr2O3,FeCr2O4和 (Fe,Cr)2O3。Raman光谱与XRD谱测得的氧化物类型基本相同。

图8

图8

HR3C与Sanicro25钢在650和700 ℃超临界水中氧化1000 h后的Raman谱

Fig.8

Raman diagrams of HR3C (a, b) and Sanicro25 (c, d) steels oxidized for 1000 h in supercritical water at 650 ℃ (a, c) and 700 ℃ (b, d)

2.3 截面形貌

由图9可知,HR3C和Sanicro25钢的氧化膜厚度分别约为14和12 μm,氧化膜中主要含有Fe,Cr,O和少量的Ni,且氧化膜外层主要为富铁氧化物,内层主要为富铬氧化物。结合XRD谱及Raman谱可知,650 ℃下,HR3C和Sanicro25钢的外层氧化物主要为Fe3O4和Fe2O3,内层氧化物主要为FeCr2O4和Cr2O3。700 ℃下,HR3C和Sanicro25钢的外层氧化物主要为Fe2O3和 (Fe,Cr)2O3,内层氧化物主要为Cr2O3和尖晶石氧化物Fe3O4/(Fe,Cr)3O4。

图9

图9

HR3C与Sanicro25钢在超临界水中氧化1000 h后的横截面形貌及相应的EDS结果

Fig.9

Cross section morphologies (a~d) and corresponding EDS results (e, f) of HR3C (a, b) and Sanicro25 (c, d) steels oxidized in supercritical water for 1000 h at 650 ℃ (a, c) and 700 ℃ (b, d)

3 分析讨论

Fe2+的扩散速率大于Cr2+的[23,24],Fe2+优先扩散到外层形成Fe3O4,Fe3O4与水分解出来的O2或者加入的溶解氧进一步反应生成Fe2O3。650 ℃时,FeCr2O4物相的形成可能是由于Cr原子由基体向氧化膜扩散,取代了Fe3O4中的铁原子。HR3C和Sanicro25钢的外层氧化膜还存在大量的孔洞,孔洞的数量随着温度的升高而增多。孔洞的存在为O向基体的扩散提供了短程通道,导致内层氧化物的形成。铁基合金在超临界水中腐蚀后氧化膜表面出现的孔洞,与氧化膜表面形成的Fe3O4缺陷类型有关[25]。700 ℃时外层氧化物中存在 (Fe,Cr)2O3物相,并含有少量Cr,这表明在更高温度下,Cr2+扩散到氧化膜外层,在高的氧分压下与Fe形成 (Fe,Cr)2O3。此外,对于HR3C与Sanicro25两种钢,本文中均检测到Cr2O3的存在。Wright等[26]研究了奥氏体钢的氧化行为,并与不同类型的铁素体钢进行对比,认为奥氏体钢生成Cr2O3保护性氧化膜后,氧化速率减慢。高文华等[27]研究了HR3C钢在超临界水中的均匀腐蚀性能,认为高Cr奥氏体合金表面形成的氧化膜能降低离子的扩散速率,对合金基体具有保护性。方圆圆等[28]认为HR3C钢中Cr含量比较高,具有抗蒸汽氧化性,良好的抗蠕变断裂和较高的拉伸强度。张显[29]认为较高Cr含量的Sanicro25钢具有优异的耐高温腐蚀性能。张新等[30]认为Sanicro25钢表面能快速形成一层具有较强抗氧化能力的Cr2O3层,且其抗蒸汽氧化和抗烟气腐蚀能力与HR3C钢的相当。Fulger等[31]和Robertson等[32]也认为氧化膜中形成了Cr2O3和NiCr2O4。Cr2O3能够抑制金属离子的向外扩散,起到降低氧化速率的作用。因此,HR3C与Sanicro25两种钢均表现出较好的抗氧化性能。

4 结论

(1) 在650 ℃/25 MPa和700 ℃/25 MPa超临界水环境中,HR3C和Sanicro25钢的氧化增重均随着温度的升高而升高,随时间的延长而增加。氧化膜均为双层结构,外层主要为富Fe的结节状氧化物,内层主要为富Cr的致密氧化物。

(2) 700 ℃下,HR3C和Sanicro25钢的外层氧化膜上都观测到了孔洞的存在,HR3C钢的氧化膜厚度略大于Sanicro25钢的,HR3C和Sanicro25钢形成的氧化膜的物相组成基本相同,抗高温蒸汽氧化性能相近。

(3) 650和700 ℃下,HR3C和Sanicro25钢的氧化膜中均检测到Cr2O3的存在,其大大提高了奥氏体钢的抗氧化性能。

参考文献

The design and research of a new low cobalt-molybdenum Niobium-containing Ni-base superalloy for 700 ℃ advanced ultra-supercritical power plants

[J].

Exploring on development ultra-supercritical pressure power genetration units-development of USC units in China as viewed from the materials

[J].

超级超临界机组开发探讨-从材料的成就看我国超级超临界机组的发展

[J].

Progress of heat-resistant steel for supercritical and ultra-supercritical steam turbine

[J].The research, development, and application of the ultrasupercritical steam turbine heatresistant steel were presented, including development, microstructure, strengthening mechanism, mechanical property, heat treatment and application of the steel. The problems during research process of the steel were also presented. Combined with the future progress of ultrasupercritical steam turbine technology, the prospects for the study of ultrasupercritical steam turbine heatresistant steel are revealed.

超临界与超超临界汽轮机耐热钢的研究进展

[J].:从超临界和超超临界汽轮机耐热钢的发展、组织结构、强化机理、性能、热处理和应用等方面阐述了该耐热钢的研究、发展和应用等方面的概况和发展趋势。指出了超超临界汽轮机耐热钢研究过程中存在的问题,结合未来超超临界汽轮机技术的发展,对超超临界汽轮机耐热钢的研究进行了展望。

Boiler materials for ultra-supercritical coal power plants-stearmside oxidation

[J].

Thermal and performance analysis of a gasification boiler and its energy efficiency optimization

[J].

Analysis and prevention of oxidation peeling of power plant boilers in supercritical units

[J].

超临界机组电站锅炉氧化皮脱落的分析与防治

[J].

Materials for ultrasupercritical coal power plants-boiler materials: Part 1

[J].

Investigation on oxidation behavior of super304H and HR3C steel in high temperature steam from a 1000 MW ultra-supercritical coal-fired boiler

[J].

Oxidation behavior of austenitic steel Sanicro25 and TP347HFG in supercritical water

[J].

Microstructure and chemical composition of the oxide scale formed on the Sanicro 25 steel tubes after fireside corrosion

[J].

Research progress on high temperature oxidation and corrosion behavior of austenitic heat resistant steel Sanicro25

[J].

Sanicro25奥氏体耐热钢的高温氧化和腐蚀行为研究进展

[J].

Oxidation behavior of two austenitic steels used in 600 ℃ supercritical coal-fired power plants

[J].

2种600 ℃超临界锅炉用奥氏体钢的高温氧化行为

[J].

Study on oxidation behaviours of HR3C in air and pure steam at 750 ℃

[J].

HR3C在750 ℃空气和水蒸气中的高温氧化行为研究

[J].

Corrosion behavior of super austenitic stainless steel HR3C in SCW

[J].

超级奥氏体不锈钢HR3C在SCW中的腐蚀行为

[J].

The oxidation behaviour of an austenitic steel in deaerated supercritical water at 600-700℃

[J].

Oxidation and chromia evaporation of austenitic steel TP347HFG in supercritical water

[J].

Relationship between the evolution of phase parameters of grain boundary M23C6 and embrittlement of HR3C super-heater tubes in service

[J].?M23C6 and equivalent width W ) of grain boundary M23C6 plates with the embrittlement of HR3C super-heater tube samples in service was studied. Based on the ASTM E112 standard charts, the total length of two dimensional austenite grain boundaries (Lgb) corresponding to each grain size number (GL) was determined in the observed area of the metallographic images and expressed as Lgb (GL). Making use of the SEM-SE images of the samples, the ?M23C6 and W were determined. The relationships of W with GL and ?M23C6 were established as W(GL, ?M23C6 ). Combined with the result from a Charpy impact test, the function of the impact value (aKV) as the W was obtained. In addition, the grain boundary elastic modulus (Er) was measured by a nano-hardness test. The result shows that intergranular fracture occurred on all the room temperature impact test specimens taken from the super-heater tubes exposed under the operating conditions. The W was increased with the decrease of GL and the increase of Er at a constant ?M23C6, causing a corresponding decrease of aKV, and hence promoting the embrittlement of the HR3C super-heater tubes. The related mechanism for the intergranular fracture caused by the increase of the equivalent width W of grain boundary carbides (carbide coarsening) can be explained through the application of the proposed method.]]>

HR3C钢运行过热器管的脆化与晶界M23C6相参量演化的关系

[J].23C6相参量(面积分数 ?M23C6 和等效宽度W)的变化与脆化的关系. 利用ASTM E112规范奥氏体钢晶粒度评级卡片测算出各级别晶粒度(GL)对应的二维图像晶界总周长(Lgb), 并拟合出两者的关系Lgb(GL); 利用各管样的扫描电镜二次电子(SEM-SE)像, 得到了对应的 ?M23C6 及W, 从而建立了W与GL和 ?M23C6 的关系(W(GL, ?M23C6 )); 再结合Charpy冲击实验, 获得了冲击值(aKV)与W的关系(aKV (W)); 此外, 利用纳米压痕仪测定了晶界的弹性模量(Er). 结果表明, 所有管样冲击断口均呈沿晶断裂形貌; 当 ?M23C6 一定时, GL越小, W越大, 其Er也越大, 对应的aKV越小, 即晶界脆化倾向越大. 揭示了晶界M23C6片等效宽度的增大(粗化)导致脆化的实质.]]>

Oxidation of ferritic and ferritic-martensitic steels in flowing and static supercritical water

[J].

Oxidation behavior of Sanicro25 heat resistant austenitic steel for boiler tube in pressured steam

[J].

锅炉管用Sanicro25奥氏体耐热钢在带压蒸汽中的氧化行为

[J].

Microstructural investigation of the breakdown of the protective oxide scale on a 304 steel in the presence of oxygen and water vapour at 600 ℃

[J].

Indication of chromium oxide hydroxide evaporation during oxidation of 304L at 873 K in the presence of 10% water vapor

[J].

Chromium volatilization rates from Cr2O3 scales into flowing gases containing water Vapor

[J].The mass-transfer coefficient for CrO2(OH)2 volatilization into flowing air-10% H2O or steam was evaluated using classical gas transport theory in the viscous-flow regime. The resulting values were applied to new thermodynamic data for the reaction: 1/2 Cr2O3 + 3/4 O2(g) + H2O(g) = CrO2(OH)2(g) to predict Cr-evaporation fluxes in the temperature range 650–800°C. The calculation was found to predict correctly the Cr-loss rate measured from foil specimens of Fe–20Cr–25Ni+Nb (alloy 709) exposed for up to 10,000 hr under these conditions. In 240 atm (24 MPa) high-purity steam, the calculations suggest that the Cr-evaporation rates will be much lower than in humid air.]]>

Effect of exposure temperature on oxidation of austenitic steel HR3C in supercritical water

[J].

The mechanism of oxide film formation on austenitic stainless steels in high temperature water

[J].

Characterization of the porosity of the oxide scales on ferritic-martensitic steel P91 and P92 exposed in supercritical water

[J].

铁素体-马氏体钢P91和P92在超临界水中腐蚀后氧化膜多孔性分析

[J].

A review of the oxidation behaviour of structural alloys in steam

[J].

Corrosion behavior of HR3C in supercritical water

[J].

HR3C在超临界水中的腐蚀性能研究

[J].

Precipitates in HR3C steel aged at high temperature

[J].M23C6 carbides and NbCrN nitrides. M23C6 carbides precipitated on grain boundaries and in intragranular. Fine and dispersed NbCrN nitrides were found to precipitate in intragranular. The hardness of HR3C steel had been improved through dispersed M23C6 and fine NbCrN precipitates after thermal aging for 500 h at\linebreak 750℃. All the M23C6 carbides, with lattice parameter of three times of the austenite matrix, grown in a cube to cube orientation relationship with the matrix. Some of the M23C6 carbides which precipitated on grain boundaries were transformed into σ phase.]]>

HR3C钢高温时效过程中的析出相

[J].

Properties of austenitic heat-resistant steel Sanicro25 for ultra-supercritical boilers

[J].

超超临界锅炉用奥氏体耐热钢Sanicro25的性能

[J].

Research situation and application prospect of Sanicro 25 heat-resistant steel

[J].

Sanicro25耐热钢的研究现状及应用前景

[J].

Analyses of oxide films grown on AISI 304L stainless steel and Incoloy 800HT exposed to supercritical water environment

[J].

The mechanism of high temperature aqueous corrosion of stainless steels

[J].