通常,Mg在人体内的含量仅次于Ca2+,Na+和K+,排第4位。目前,许多发达国家已将Mg列为人体必需元素,补Mg的重要性并不亚于补Ca。Mg的生理功能主要体现在它能参与多种人体内的新陈代谢过程[1,2],参与蛋白质的合成,能激活体内多种酶,调节神经肌肉和中枢神经系统的活动,保障心肌的正常收缩[3,4,5,6,7,8,9,10]。过量的Mg可以通过肾脏排泄,然后由尿液排出体外,并不会导致血清Mg含量的升高[11]。由于Mg在人体中具有的独特功能性及其与人体良好的生物相容性等优点,国内外研究人员开展了大量关于镁合金在血管支架方面应用的研究工作。通常,镁合金的强化需要在基体中形成一定体积分数的合金相,但合金相和Mg基体之间会存在不同程度的腐蚀电位差,在合金相/基体界面处的微区电偶腐蚀势必会降低镁合金耐蚀能力[12]。然而,稀土元素Nd的标准电位与Mg基体接近,故Nd的添加有利于镁合金耐蚀性的提升[13,14,15]。因此,与其它镁合金相比,Mg-Zn-Y-Nd合金具有较好的力学和耐腐蚀等综合性能,更加适用于在血管支架上的应用。在对冠状动脉支架材料的腐蚀特性和降解过程的研究中,研究人员认为,Mg-Zn-Y-Nd合金在模拟体液中腐蚀较为均匀,且合金腐蚀速率与血液流速和Cl-浓度密切相关[16]。

结合早期报道的研究工作,研究人员主要依赖于合金化和大塑性变形来实现Mg-Zn-Y-Nd合金的组织优化及性能提升。然而,这些调控方法主要是针对合金成分的筛选和优化。当某种特定成分的Mg-Zn-Y-Nd合金被选用后,为获得满足特殊性能要求的微观组织,除了大塑性变形之外,热处理调控也是至关重要的。其中,固溶处理尤为重要,主要归因于其是决定大塑性变形加工后时效效果的关键步骤。然而,早期的研究主要侧重于合金化或大塑性变形后合金在模拟体液中的腐蚀行为,关于固溶处理对Mg-Zn-Y-Nd合金腐蚀行为的影响,却未曾涉及。鉴于此,本工作将以挤压态Mg-6Zn-1.2Y-0.8Nd镁合金为研究对象,对比研究固溶处理前后合金样品在Hank's模拟体液中的腐蚀和析氢行为,揭示两种处理状态样品经不同时间预浸泡后电化学腐蚀性能的变化及其差异情况,并探讨了腐蚀机制。

1 实验方法

本研究工作选取的材料为一种挤压态Mg-Zn-Y-Nd镁合金,其具体化学成分 (质量分数,%) 为:Zn 6,Y 1.2,Nd 0.8,Mg余量。在CO2和SF6混合气氛保护下,将合金在电阻炉中进行熔炼,制备的铸锭直径为130 mm。在温度为400 ℃的空气炉中,对铸锭进行1 h的均匀化处理。均匀化后,将铸锭的外层氧化皮去除。在300 ℃下,将铸锭挤压成截面积为10 mm (厚度方向:ND)×60 mm (宽度方向:TD) 板材,挤压比为15。利用线切割方法,沿合金板材厚度方向上切取截面为8 mm (ND)×8 mm (TD),厚度为5 mm的块状试样。在温度为450 ℃的空气炉中,将块状试样固溶处理2 h (T4态样品)。然后,对固溶处理前后样品表面进行磨抛处理。利用扫描电镜 (SEM,XL30-FEG-ESEM) 对合金微观组织结构进行观察。采用由25 mL乙醇、2 g苦味酸、5 mL乙酸和5 mL去离子水组成的刻蚀剂,对抛光样品进行腐刻。利用光学显微镜 (OM) 对固溶处理前后样品的晶粒结构进行观察。采用Image J软件对SEM像中的合金相和OM像中的晶粒结构进行定量分析,分别测定合金相颗粒的体积分数和未再结晶区的面积分数。值得指出的是,Image J软件仅能测得SEM像中相颗粒的面积分数,故确定的相颗粒体积分数是在假定其面积分数在试样厚度上不发生变化的前提下得到的。为确定出未再结晶区的面积分数,将OM像中未再结晶区定义为在相互垂直方向上宽度的最小尺寸比大于2的区域。

对固溶处理前后样品在Hank's溶液中进行了析氢实验,并对不同时间预浸泡样品进行了电化学腐蚀测试。所选用的Hank's溶液主要由8.0 g/L NaCl,0.14 g/L CaCl2,0.35 g/L NaHCO3,0.4 g/L KCl,1.0 g/L葡萄糖,0.06 g/L MgSO4·12H2O,0.06 g/L NaH2PO4·12H2O,0.06 g/L KH2PO4和0.1 g/L MgCl2·6H2O组成。对于电化学极化曲线测试,使用的是Model 273A (Potentiostat/ Galvanostat) 恒电位仪。在 (37±0.5) ℃下,采用三电极体系,镁合金试样作为工作电极,饱和甘汞电极 (SCE) 作参比电极,Pt片为辅助电极。溶液体积 (mL) 与试样暴露面积 (cm2) 之比固定为200∶1。待试样在溶液中腐蚀电位稳定后 (约15 min),进行极化曲线的动电位法测量,扫描速率为0.166 mV/s。对每个处理状态样品,分别进行了3次电化学极化曲线测试。为了反映预浸泡对固溶处理前后样品腐蚀程度的影响,对在开路电位条件下预浸泡2,4,8,24和48 h的样品表面形貌进行了三维光学观察。

2 结果与讨论

2.1 微观组织

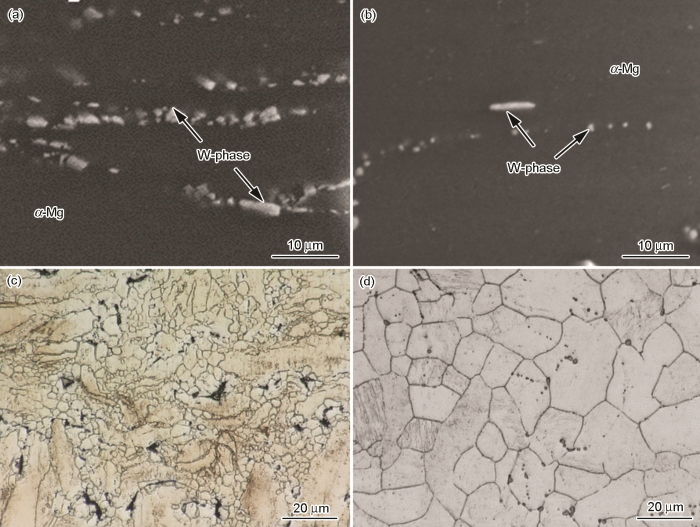

图1

图1

固溶处理前后挤压态Mg-6Zn-1.2Y-0.8Nd合金的微观形貌

Fig.1

SEM (a, b) and OM (c, d) images of as-extruded Mg-6Zn-1.2Y-0.8Nd alloy without (a, c) and with (b, d) solid solution treatment

2.2 析氢和电化学腐蚀行为

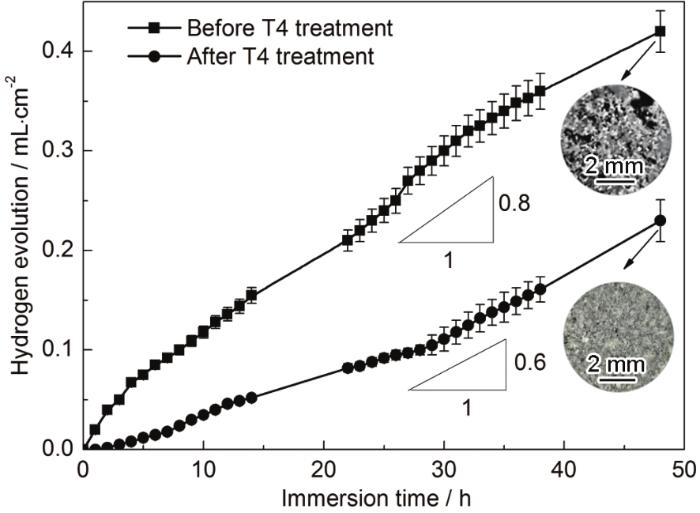

图2

图2

固溶处理前后Mg-6Zn-1.2Y-0.8Nd合金样品在Hank's溶液中的析氢曲线

Fig.2

Hydrogen evolution curves of as-extruded and final T4 treated Mg-6Zn-1.2Y-0.8Nd alloy in Hank's solution

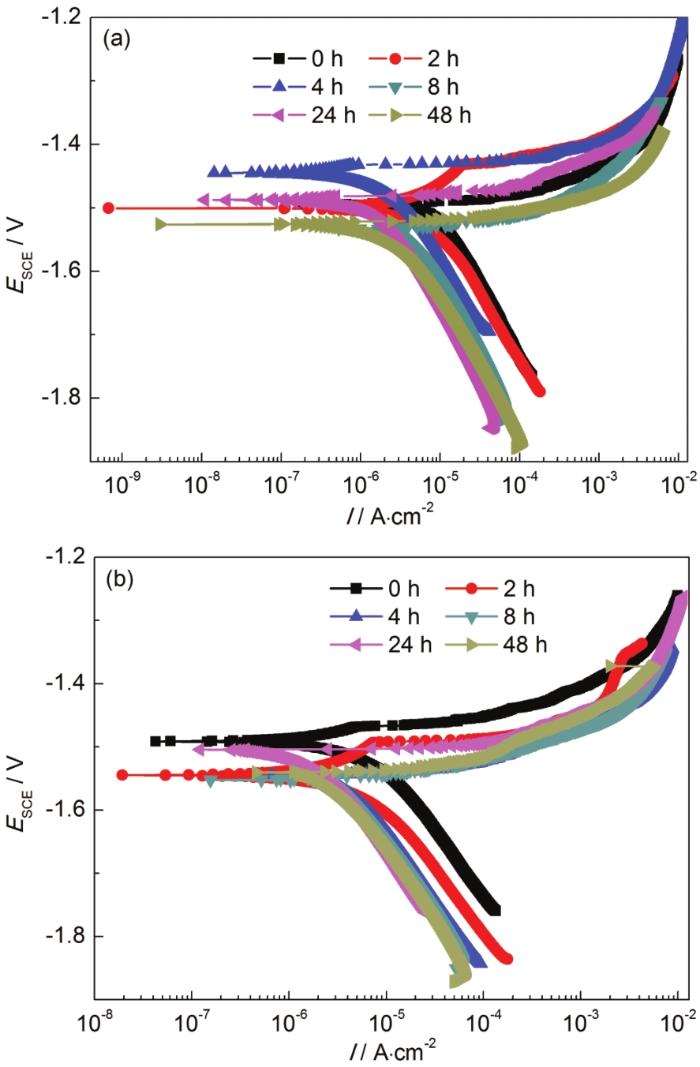

为了揭示出合金在浸泡过程中腐蚀行为的变化情况,对经不同时间预浸泡样品的动电位极化曲线进行了测定,如图3所示。为了便于比较,对固溶处理前后合金样品的电化学曲线进行了拟合,确定的电化学参数列于表1。可以看出,T4态样品在经不同时间预浸泡后的腐蚀电流密度均低于挤压态样品的。由于合金相与Mg基体必然存在一定的电位差,故合金相的固溶可有效弱化微区电偶腐蚀的发生[21,22],从而使T4态样品具有较高的抗腐蚀性能。同时,固溶处理可完全消除能量较高的未再结晶区,将进一步有助于T4态样品抗腐蚀性能的提升。另外,随着浸泡时间的延长,两种处理态样品的腐蚀速率均呈现先降低后增加的趋势。随着浸泡时间延长至24 h,挤压态和T4态样品的腐蚀电流密度分别从7.9×10-3和4.8×10-3 mA/cm2降至2.2×10-3和1.2×10-3 mA/cm2。随着预浸泡时间由24 h增至48 h,挤压态和T4态样品的腐蚀电流密度分别增至2.9×10-3和1.9×10-3 mA/cm2。由于合金的腐蚀电流密度与析氢速率成正比[23],故析氢曲线的斜率应具有不同预浸泡样品腐蚀电流密度先降低后增加的变化趋势。尽管经不同时间预浸泡后样品的腐蚀电流密度存在较大差异,但两种状态样品析氢曲线的斜率总体变化不大。基于阴极极化曲线测得的腐蚀电流密度 (Icorr,mA/cm2) 和析氢速度 (VH,mL/(cm2·d)),可分别获得镁合金平均腐蚀速率 (Pi,mm/a) 和 (PH,mm/a),其换算关系为[24]:

图3

图3

不同时间预浸泡后Mg-6Zn-1.2Y-0.8Nd合金样品在Hank's溶液中的动电位极化曲线

Fig.3

Polarization curves of as-extruded (a) and final T4 treated (b) Mg-6Zn-1.2Y-0.8Nd alloy pre-immersed in Hank's solution for different time

表1 固溶处理前后挤压态Mg-6Zn-1.2Y-0.8Nd合金样品极化曲线的拟合结果

Table 1

| Condition | Pre-immersion time / h | EcorrVSCE | Icorr10-3 mA·cm-2 |

|---|---|---|---|

| Before T4 | 0 | -1.574±0.15 | 7.9±0.5 |

| After T4 | 0 | -1.572±0.15 | 4.8±0.2 |

| Before T4 | 2 | -1.581±0.20 | 5.0±0.3 |

| After T4 | 2 | -1.624±0.15 | 3.6±0.2 |

| Before T4 | 4 | -1.525±0.10 | 4.1±0.3 |

| After T4 | 4 | -1.625±0.15 | 3.1±0.3 |

| Before T4 | 8 | -1.612±0.10 | 3.4±0.3 |

| After T4 | 8 | -1.606±0.15 | 2.0±0.1 |

| Before T4 | 24 | -1.620±0.25 | 2.2±0.2 |

| After T4 | 24 | -1.568±0.15 | 1.2±0.1 |

| Before T4 | 48 | -1.633±0.10 | 2.9±0.1 |

| After T4 | 48 | -1.584±0.15 | 1.9±0.1 |

对比图2和表1中的析氢速率和腐蚀电流密度,可以看出在满足腐蚀速率换算量纲的前提下,腐蚀电流密度的数值要比析氢速率的数值小两个数量级。可见,由腐蚀电流密度推算的腐蚀速率较低,这与Shi等[24]报道的结果相类似。另外,Song等[25]系统归纳和对比了镁合金析氢速率、失重率和极化曲线测得的腐蚀电流密度,认为析氢速率和失重率相互复合,可很好地反映出镁合金的腐蚀速率,但腐蚀电流密度却与析氢速率和失重率的相关性较差,其主要原因在于阴极极化过程中包含了多个反应 (如膜层和无膜层区的析氢反应和Mg的溶解、膜层的动态形成和修复过程等),且这些反应对极化电位的依赖性存在较大差异,致使Tafel外推法测得的腐蚀电流密度难以真正反映出合金样品实际的腐蚀速率。因此,本研究中所测得的腐蚀电流密度难以与析氢速率存在必然的响应关系。然而,测得的腐蚀电流密度反映出T4态样品具有较高的耐蚀性,与析氢实验结果一致,说明极化曲线的测试结果可以较快地反映出合金样品耐蚀性的高低。

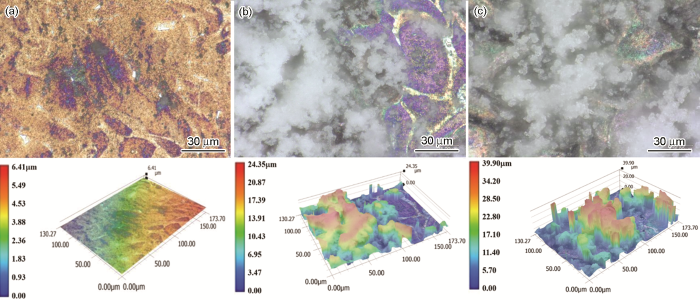

2.3 表面腐蚀形貌观察

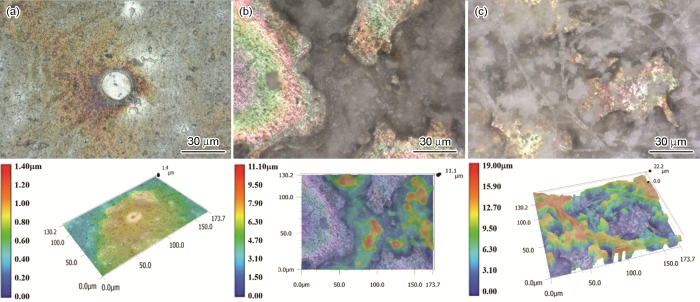

为了揭示出固溶处理对合金抗腐蚀性能提升的作用机制和腐蚀性能随预浸泡时间的变化情况,对不同时间预浸泡样品的表面及三维形貌进行了观察和比较,如图4和5所示。可以看出,挤压态样品表面的腐蚀较为严重。随着浸泡时间从4 h增至48 h,挤压态样品表面的最大高低差可从6.41 μm增至39.90 μm (图4),而T4态样品表面的最大高低差从1.40 μm增至22.20 μm (图5)。因此,在浸泡初始阶段,合金相的固溶对提升合金耐蚀性能的作用较为显著。然而,在预浸泡48 h后,固溶处理对合金抗腐蚀性能的提升作用将有所降低。早期研究[26]表明,Mg-Zn-Y-Nd合金在Hank's溶液中产物膜的成分主要包括Mg,Zn,Ca,P和O,且产物膜可对基体起到一定的防护作用。然而,膜层对基体的防护作用主要取决于其厚度的变化。当膜层较薄时,膜层对基体的防护作用随着膜层完整程度的增加而提升。当膜层增厚到一定程度时,其自身将会发生开裂或在其与基体界面处发生开裂[26],最终降低膜层对基体的防护效果。由于T4态样品腐蚀速度较慢,故表面腐蚀产物膜的增厚速度也较慢。在同样的预浸泡时间处理后,T4态表面产物膜对基体的防护作用也将优于挤压态样品的。因此,与挤压态样品相比,T4态样品的腐蚀速度和析氢速度均较低。

图4

图4

在Hank's溶液中经不同时间预浸泡处理后挤压态Mg-6Zn-1.2Y-0.8Nd合金样品的表面腐蚀形貌及三维高低差照片

Fig.4

Surface corrosion morphologies and 3D images of the as-extruded Mg-6Zn-1.2Y-0.8Nd alloy before and after pre-immersion in Hank's solution for 4 h (a), 24 h (b) and 48 h (c)

图5

图5

在Hank's溶液中经不同时间预浸泡处理后T4态Mg-6Zn-1.2Y-0.8Nd合金样品的表面腐蚀形貌及三维高低差照片

Fig.5

Surface corrosion morphologies and 3D images of the T4-treated Mg-6Zn-1.2Y-0.8Nd alloy before and after pre-immersion in Hank's solution for 4 h (a), 24 h (b) and 48 h (c)

3 结论

(1) 经475 ℃固溶4 h后,挤压态Mg-6Zn-1.2Y-0.8Nd 镁合金样品的抗腐蚀能力得到了提升。随着预浸泡时间从4 h增至48 h,挤压态样品表面的最大高低差可从6.41 μm增至39.90 μm,而经固溶处理样品表面的最大高低差从1.40 μm增至22.20 μm。

(2) 经固溶处理样品的析氢速度是挤压态样品的0.75倍;且经固溶处理样品表面腐蚀变弱,即腐蚀坑数量较少且深度较浅。

参考文献

Research progress in magnesium-based metals for medical applications

[J].

医用镁金属材料的研究进展

[J].

Research on magnesium alloys for bio-medical applications

[J].

镁合金的生物医用研究

[J].

Degradation behaviour of AZ80E magnesium alloy exposed to phosphate buffer saline medium

[J].

Microstructure, mechanical properties and corrosion properties of Mg-Zn-Y alloys with low Zn content

[J].

Study on biocompatility of magnesium and its alloys

[J].

镁及镁合金的生物相容性研究

[J].

Study on biodegradation behavior of AZ31 magnesium alloy

[J].

AZ31镁合金的生物降解行为研究

[J].

Research progress of new type of degradable biomedical magnesium alloys JDBM

[J].

新型可降解生物医用镁合金JDBM的研究进展

[J].

Magnesium intake and incidence of metabolic syndrome among young adults

[J].

Magnesium intake and its relevance with antioxidant capacity in Korean adults

[J].Recently, a study reported that magnesium played a part in the attack of chronic diseases, such as arteriosclerosis, diabetes, metabolic syndrome, and hypertension. However, there are not even enough studies to evaluate magnesium intakes. Therefore, in this study, we evaluated the magnesium intakes of 500 healthy adults. In addition, by selecting 50 targets, we examined the correlation between magnesium intake and antioxidant capacity biomarkers. In the age group of 19-29, the daily magnesium intake was 276.3 mg for males and 232.1 mg for females. In the age group of 30-49, it was 305.1 mg and 246.5 mg, respectively. In the age group of 50-64, the magnesium intake was 294.4 mg for males and 245.7 mg for females. As for the age group of 19-29, the magnesium intake per 4,187 kJ of energy intake was 129.8 mg, which was significantly lower than the 164.6 mg by the age group of 30-49 and 172.4 mg by the age group of 50-64. The ratio of magnesium intake to the recommended intake was 82.1% for those in the age group of 19-29, 87.7% for those in 30-49, and 86.1% for those in 50-64. The rate of the subjects with magnesium intakes lower than the estimated average requirement was 55.3% in the age group of 19-29, 52.4% in 30-49, and 54.2% in 50-64. The magnesium intake from food groups were in the descending order of vegetables, cereals, and fish for the subjects in the age group of 19-29, and vegetables, cereals, and beverages for the subjects in the age groups of 30-49 and 50-64. The source food items of magnesium intake were in the descending order of Kimchi, tofu, rice, and coffee in the age group of 19-29, coffee, Kimchi, tofu, and rice in 30-49, and coffee, Kimchi, rice, and tofu in 50-64. From the 50 targets aged 19-29, significant correlation was not indicated among magnesium intake, serum magnesium, and antioxidant capacity biomarkers. In conclusion, the magnesium intake status of some Korean adults is unsatisfactory. And it is suggested that this low intake of magnesium has no correlation with antioxidant capacity.

Mechanisms of magnesium-stimulated adhesion of osteoblastic cells to commonly used orthopaedic implants

[J].Poor cell adhesion to orthopaedic and dental implants may result in implant failure. Cellular adhesion to biomaterial surfaces primarily is mediated by integrins, which act as signal transduction and adhesion proteins. Because integrin function depends on divalent cations, we investigated the effect of magnesium ions modified bioceramic substrata (Al(2)O(3)-Mg(2+)) on human bone-derived cell (HBDC) adhesion, integrin expression, and activation of intracellular signalling molecules. Immunohistochemistry, flow cytometry, cell adhesion, cell adhesion blocking, and Western blotting assays were used. Our findings demonstrated that adhesion of HBDC to Al(2)O(3)-Mg(2+) was increased compared to on the Mg(2+)-free Al(2)O(3). Furthermore, HBDC adhesion decreased significantly when the fibronectin receptor alpha5beta1- and beta1-integrins were blocked by functional blocking antibodies. HBDC grown on the Mg(2+)-modified bioceramic expressed significantly enhanced levels of beta1-, alpha5beta1-, and alpha3beta1-integrins receptors compared to those grown on the native unmodified Al(2)O(3). Tyrosine phosphorylation of intracellular integrin-dependent signalling proteins as well as the expression of key signalling protein Shc isoforms (p46, p52, p66), focal adhesion kinase, and extracellular matrix protein collagen type I were significantly enhanced when HBDC were grown on Al(2)O(3)-Mg(2+) compared to the native Al(2)O(3). We conclude that cell adhesion to biomaterial surfaces is probably mediated by alpha5beta1- and beta1-integrin. Cation-promoted cell adhesion depends on 5beta1- and beta1-integrins associated signal transduction pathways involving the key signalling protein Shc and results also in enhanced gene expression of extracellular matrix proteins. Therefore, Mg(2+) supplementation of bioceramic substrata may be a promising way to improve integration of implants in orthopaedic and dental surgery.

Magnesium: Nutrition and metabolism

[J].Magnesium is an essential mineral that is needed for a broad variety of physiological functions. The usual daily magnesium uptake with a western diet is sufficient to avoid deficiency but seems not to be high enough to establish high normal serum magnesium concentrations that are protective against various diseases. Changes in magnesium homeostasis mainly concern the extracellular space, as the intracellular magnesium concentration is well regulated and conserved. The extracellular magnesium concentration is primarily regulated by the kidney, the mechanisms of this regulation have been elucidated recently. Due to the growing knowledge about the regulation of extra- and intracellular magnesium concentrations and the effects of changed extracellular magnesium levels the use of magnesium in therapy gains more widespread attention.

Microstructure and corrosion behaviour in simulated body fluid of solution treated Mg-Nd-Gd-Sr-Zn-Zr alloys

[J].

固溶处理态Mg-Nd-Gd-Sr-Zn-Zr镁合金的显微组织及其在模拟体液中的腐蚀行为

[J].

Performances of biodegradable Mg-Nd-Zn-Zr magnesium alloy for cardiovascular stent

[J].

心血管支架用Mg-Nd-Zn-Zr生物可降解镁合金的性能研究

[J].

Effects of extrusion ratio on microstructure, mechanical and corrosion properties of biodegradable Mg-Nd-Zn-Zr alloy

[J].

Optimizing mechanical property and cytocompatibility of the biodegradable Mg-Zn-Y-Nd alloy by hot extrusion and heat treatment

[J].

Simulation for the degradation process of Mg-Zn-Y-Nd alloy coronary stent

[D].

Mg-Zn-Y-Nd合金冠脉支架降解过程的模拟

[D].

Microstructure and modification of Nd and Zn trace elements in a Mg-Zn-Y-Nd vascular alloy stent

[J].

Nd, Zn微量元素在Mg-Zn-Y-Nd血管合金支架中组织学特性和改性的变化

[J].

Research on the microstructure and property of ultrafine-grained Mg-Zn-Y-Nd alloy for vascular stent application

[D].

血管支架用超细晶Mg-Zn-Y-Nd合金组织及性能的研究

[D].

Optimizing mechanical property and cytocompatibility of the biodegradable Mg-Zn-Y-Nd alloy by hot extrusion and heat treatment

[J].

Effect of grain structure on the stress corrosion cracking (SCC) behavior of an as-extruded Mg-Zn-Zr alloy

[J].

Influence of solution treatment on the corrosion fatigue behavior of an as-forged Mg-Zn-Y-Zr alloy

[J].

High corrosion resistance and weak corrosion anisotropy of an as-rolled Mg-3Al-1Zn (in wt.%) alloy with strong crystallographic texture

[J].Combining with electrochemical corrosion measurements, immersion and hydrogen evolution testing performed in 0.9 wt.% NaCl solution at 37 degrees C, the corrosion resistance of an as-rolled Mg-3%Al-1%Zn alloy before and after a 3% compressive strain along the rolling direction was investigated. Results revealed that the corrosion behavior of differently oriented surfaces of the as-rolled samples with a strong basal texture was obviously different. Among them, the corrosion rate of sample surface with the orientation parallel to the normal direction (ND) of the plate was the fastest, the corrosion rate of sample surface with the orientation parallel to the rolling direction (RD) of the plate took the second place and the corrosion rate of sample surface with the orientation parallel to the transverse direction (TD) was the slowest. After being pre-strained, the activation of a high density of {10-12} twins could remarkably reduce the corrosion rate of surrounding alpha-Mg matrix and simultaneously weaken the corrosion anisotropy between differently oriented samples. The main reason was that similar to grain boundaries, twin boundaries acted as physical barriers to the corrosion attack. Moreover, the activated twins increased the protectiveness of surface films and then suppressed the micro corrosion couples occurred in twinned grains.

Corrosion behavior of Mg-Zn-Y-Nd alloy in simulated body fluid

[J].

模拟人体体液中镁合金的腐蚀行为研究

[J].

Measurement of the corrosion rate of magnesium alloys using Tafel extrapolation

[J].

Understanding magnesium corrosion-A framework for improved alloy performance

[J].