增材制造(AM)技术,又称3D打印技术,是一种基于离散—堆积原理的先进制造技术,通过高能束(激光/电子束等)逐层熔化粉末、线材或板材等原材料,实现复杂几何零件的制造。与传统工艺相比,AM技术具有材料利用率高、可制造几何形状复杂的零件、适合定制化生产等优势,在航空航天、生物医学及汽车等领域得到了广泛应用[1]。

为了应对上述挑战,热处理工艺被广泛用于改善AM材料的耐腐蚀性能,常见的热处理工艺包括退火、固溶处理、热等静压(HIP)等。这些工艺通过减少孔隙、优化微观结构、释放残余应力等机制,有效改善材料的微观组织与电化学稳定性,提升其抗腐蚀能力。尽管已有研究表明热处理在提升AM构件服役性能方面具有显著成效,但目前的研究主要聚焦于成形过程参数优化,针对不同热处理工艺对腐蚀性能作用机制的系统性探讨尚不充分,特别是在微观组织调控与腐蚀行为演化之间的关系尚缺乏深入理解。

因此,本文旨在系统分析AM零件的腐蚀行为特征,并重点分析退火、固溶处理、热等静压3种热处理工艺的作用机制及其对腐蚀性能的影响。希望通过本综述进一步丰富热处理在AM材料腐蚀防护中的应用研究,填补当前研究空白,为提升AM构件的环境适应性与工程可靠性提供理论依据与研究方向。

1 增材制造零件的腐蚀行为特征

增材制造过程中的快速加热与冷却易引发显著的温度梯度,导致构件产生典型微观缺陷。这些缺陷不仅削弱材料的力学性能,还易成为点蚀、晶间腐蚀与应力腐蚀开裂等局部腐蚀的主要诱因。在严苛服役环境下,其危害尤为突出。因此,深入探究AM构件腐蚀行为特征对于提升其服役稳定性具有重要意义。

1.1 点蚀

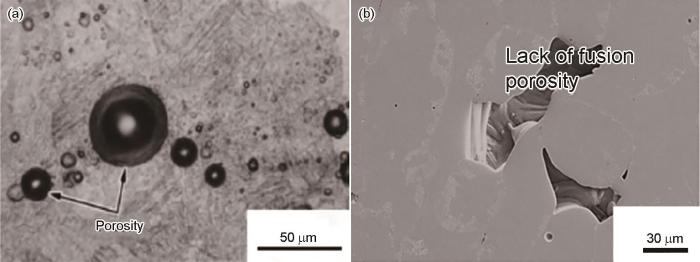

点蚀是一种局部腐蚀形式,通常在金属表面形成小而深的腐蚀坑。增材制造过程中产生的缺陷如孔隙、未熔合缺陷和粗糙表面等,为腐蚀介质提供了渗透通道和滞留区域,加速了点蚀的发生[5]。

图1

综上所述,孔隙、未熔合缺陷以及较高的表面粗糙度是诱发AM金属构件点蚀行为的关键因素。结合热处理工艺优化材料的微观结构,间接缓解表面粗糙度对零件腐蚀性能的影响,同时促进缺陷的部分修复与均匀化,显著降低点蚀的发生概率,从而全面提升AM金属构件在腐蚀环境中的应用性能。

1.2 晶间腐蚀

晶间腐蚀(IGC)是一种沿晶界扩展的腐蚀模式,通常源于晶界化学成分的不均匀性或微观结构的差异[14]。AM零件由于其独特的工艺过程,易发生晶间腐蚀,这对零件的耐腐蚀性能构成显著威胁。

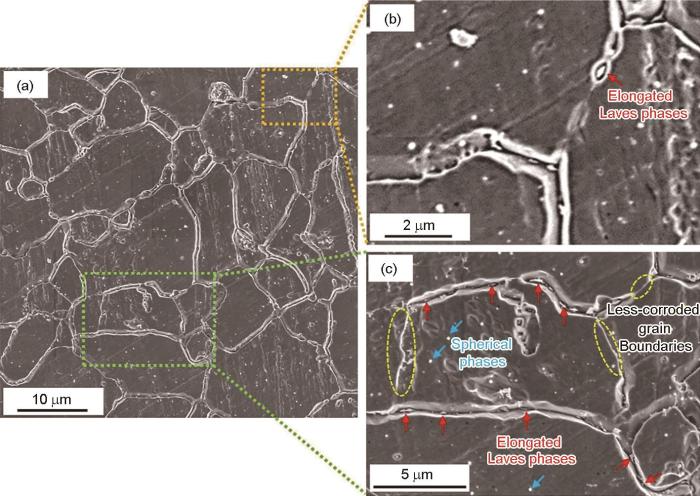

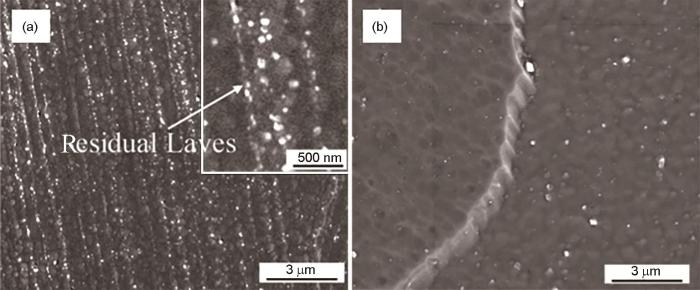

在AM过程中,由于快速冷却抑制了合金元素(如Cr、Mo等)在晶界附近的充分扩散,易在晶界形成富集区域。在特定热处理条件下,这些富集元素可能以碳化物(如Cr23C6)或金属间化合物(如Laves相)的形式在晶界大量析出,从而消耗晶界处的铬元素,导致晶界邻近区域出现贫铬现象,削弱了晶界的耐腐蚀性,使其成为腐蚀的优先发生部位[14]。此外,Laves相的晶界富集和选择性溶解倾向亦会增加晶间腐蚀的风险。研究表明,在深度腐蚀的晶界中,频繁检测到细长的Laves相(红色箭头标记),而在较少或未腐蚀的晶界中则未见其存在(图2c)。Laves相的尺寸和数量与IGC的发生密切相关。具体而言,Laves相的尺寸越大、数量越多,其对IGC的催化效应越显著,从而显著削弱了材料对IGC的抗力(图2b)[15]。

图2

增材制造工艺中形成的微观结构对晶间腐蚀有重要影响。例如,快速冷却可能导致形成细小等轴晶或柱状晶组织,这些组织的晶界特性会影响晶间腐蚀的敏感性。此外,残余应力的存在也会促进晶界腐蚀的萌生和扩展[16]。

晶间腐蚀会导致材料的强度和韧性显著下降,增加裂纹萌生的风险,从而降低零件的整体耐腐蚀性能。在一些关键应用领域,如航空航天和生物医学,这种腐蚀行为可能导致严重的结构失效和安全隐患。适当的热处理可以改善Cr贫化问题,提高抗晶间腐蚀能力。例如,固溶处理通过均匀化分布合金元素,显著降低了晶界腐蚀的风险。

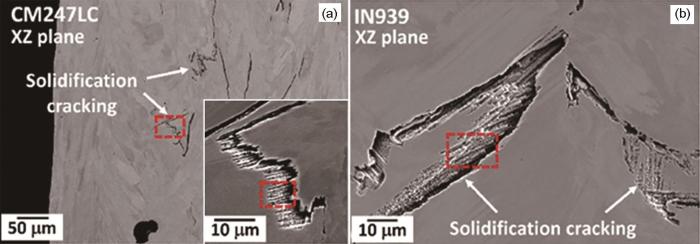

1.3 应力开裂腐蚀

图3

Syed等[23]研究了SLM制造的Ti-6Al-4V合金中的残余应力及其对疲劳裂纹扩展的影响,发现残余应力(尤其是拉应力)会显著增加裂纹扩展速率,而通过热处理可以大幅减少残余拉应力,从而改善材料的疲劳性能。热处理是控制残余应力、提高零件性能的重要手段,使材料内部的残余应力(特别是拉应力)得到释放,降低SCC的风险。

综合来看,增材制造零件的腐蚀行为主要受孔隙、残余应力和表面粗糙度的影响。这些缺陷不仅降低了材料的整体耐蚀性,还可能加速腐蚀行为(如点蚀、晶间腐蚀和应力腐蚀开裂)的发生。为了提高增材制造零件的耐腐蚀性能,热处理手段显得尤为重要。热处理可减少孔隙、释放残余应力,以优化增材制造金属零件的微观结构,是提升其耐腐蚀性的关键方向之一。

2 典型热处理工艺的作用机制

2.1 退火处理——残余应力消除与组织均匀化机制

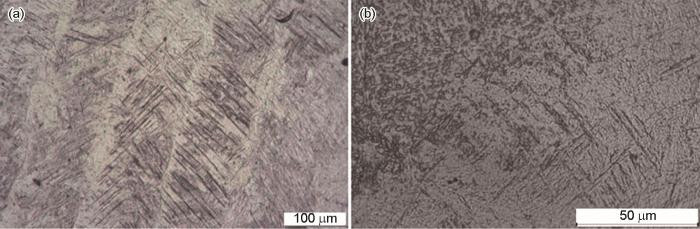

图4

退火处理还对抑制裂纹萌生与扩展起到积极作用。一方面,通过降低材料内部残余应力、提高韧性,材料在外载荷作用下能够更有效地吸收能量。另一方面,退火促进晶粒长大,减少晶界面积,有助于降低晶界应力集中程度,并减轻晶界处元素偏析现象,从而削弱腐蚀介质在晶界的渗透路径,提升材料对裂纹萌生与扩展的抵抗能力[26]。

2.2 固溶处理——元素溶解与晶界调控机制

图5

此外,晶界形貌的调控对腐蚀行为具有积极影响。固溶处理后晶界数量的增加和几何形貌的复杂化增大了晶界扩散和腐蚀裂纹扩展的阻力,有助于抑制晶界型腐蚀的发生。研究表明,部分微细氧化物或碳化物在固溶温度下呈弥散分布,可在晶界处产生钉扎效应,抑制再结晶并稳定微观结构,从而为形成连续致密的钝化膜提供更稳定的组织基础,降低晶界区域的腐蚀敏感性[36]。

2.3 热等静压处理——缺陷闭合机制

热等静压处理(HIP)是一种结合高温与等静压以提升材料致密性和消除内部缺陷的先进热处理工艺,广泛应用于金属铸件、粉末冶金材料及增材制造零件的致密化与缺陷修复过程中。主要用于闭合材料内部的孔隙和未熔合缺陷,从而提高其致密性和微观结构均匀性,增强材料对腐蚀介质的阻隔能力,并提升整体抗腐蚀性能[37]。

图6

3 热处理对AM零件腐蚀行为的影响

热处理作为改善增材制造金属材料微观结构与服役性能的关键工艺,在提升其耐腐蚀能力方面发挥着重要作用。以下将重点探讨退火处理、固溶处理和热等静压处理三种不同热处理对AM零件腐蚀行为的影响,并结合典型材料进行详细分析。

3.1 退火处理对腐蚀行为的影响

图7

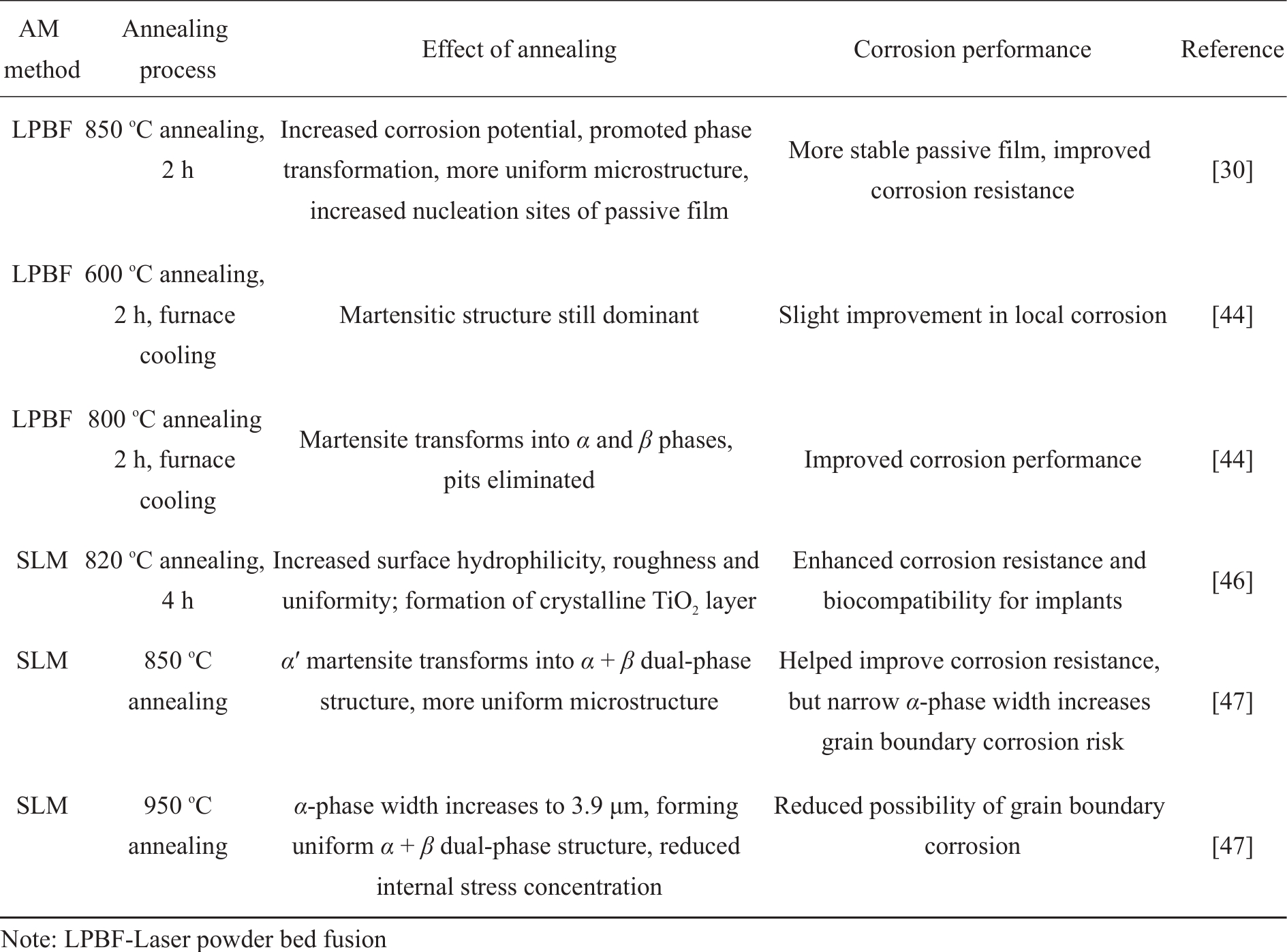

表1显示了不同退火温度对AM Ti-6Al-4V合金腐蚀行为的影响。研究表明,在650 ℃退火2 h时,虽然部分α′相开始分解,但残余应力仍保持较高水平,导致腐蚀电流密度仅下降10%,耐蚀性改善有限,表明低温退火不足以完全消除非平衡相[44]。在750 ℃退火2 h后,α′向α + β相的转变更加充分,微观结构趋于均匀,材料的腐蚀电流密度较未退火样品降低30%,耐蚀性得到提升[45]。经过800 ℃退火处理2 h后,样品表现出与商用热处理样品相当的耐蚀性,点蚀电位提高了0.2 V,表明其抗局部腐蚀能力显著增强[30,44]。然而,当退火温度高于900 ℃后,β相晶粒显著长大,晶界数量减少,易在氯化物环境中引发晶间腐蚀。此外,1000 ℃退火样品在电化学测试中表现出较大的腐蚀电流波动,表明其钝化膜的稳定性较差。综合分析表明,700~850 ℃是改善LPBF Ti-6Al-4V合金腐蚀性能的最优区间,可有效降低腐蚀速率,提升点蚀电位,并保持稳定的钝化膜结构,但还需结合具体工艺参数和环境进行验证。

表1 不同退火温度对增材制造 Ti-6Al-4V合金的影响

Table 1

|

此外,研究还表明,退火处理后的样品在模拟体液中的开路电位更稳定,腐蚀电流密度降低,其耐腐蚀性有所提高。退火处理通过优化微观结构、释放残余应力和促进相变,有效提升了AM Ti-6Al-4V合金的耐腐蚀性能。Chao等[50]研究表明,退火处理后对SLM 316L不锈钢也具有同样的效果,改善了其组织稳定性与耐腐蚀能力。

3.2 固溶处理对腐蚀行为的影响

固溶处理是一种关键的热处理工艺,通常用于镍基高温合金,尤其是Inconel 718合金,以提高材料的耐腐蚀性和力学性能。该工艺能够消除材料中的有害相(如Laves相)和元素偏析现象,改善材料的耐腐蚀性能。

研究表明,SLM Inconel 718合金经980 ℃固溶处理15 min后原有的Laves相网络被消除,取而代之的是均匀分布的针状δ相颗粒,这种微观结构的变化显著提高了材料的腐蚀性能。具体来说,固溶处理后的Inconel 718合金在3.5% (质量分数) NaCl溶液中的腐蚀电流密度从未处理时的0.21 μA/cm2降低至0.08 μA/cm2,腐蚀速率由0.00343 mm/a降至0.00114 mm/a,点蚀电位则提升至330 mV,表明其钝化膜的稳定性增强[51]。电化学阻抗谱分析也显示,固溶处理后的材料钝化膜电阻显著增加,从234 kΩ·cm2增加至407 kΩ·cm2,反映出材料的抗点蚀能力和抗SCC性能均得到改善[51]。

在固溶处理过程中,AM Inconel 718的再结晶行为对其微观结构的均匀性和稳定性有显著影响。研究表明,该合金在固溶处理过程中表现出比传统锻造合金更缓慢的再结晶动力学,再结晶速率明显降低。再结晶行为的减缓使得材料的微观结构更加均匀,减少了元素偏析和局部腐蚀的风险。均匀的微观结构有助于形成稳定的钝化膜,从而提高材料的耐腐蚀性能[36]。

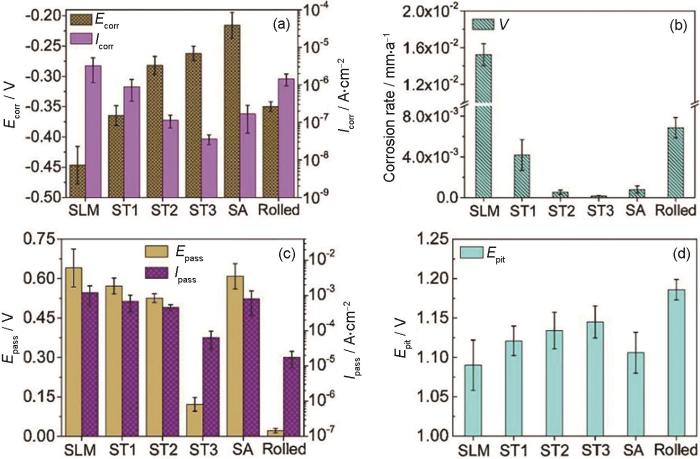

图8

图8

在3.5%NaCl溶液中通过不同工艺制备的Inconel 718试样的电化学腐蚀参数[52]

Fig.8

Comparison of electrochemical corrosion parameters of Inconel 718 samples prepared by different heat treatments in 3.5%NaCl solution: (a) corrosion potential and corrosion current density; (b) corrosion rate; (c) passive potential and passive current density and (d) pitting potential[52]

综上,固溶处理通过消除元素偏析、促进强化相析出和减少残余应力,显著提高了AM Inconel 718合金的力学性能和腐蚀性能。这一研究结果为AM Inconel 718合金在航空航天和能源领域的应用提供了重要的理论依据和技术支持。

3.3 HIP对腐蚀行为的影响

图9

电化学测试结果表明,HIP处理后的增材316L不锈钢样品腐蚀电流密度降低,反映出整体耐腐蚀性的提升。这一改善主要归因于内部缺陷减少、元素分布均匀性以及Cr2O3钝化膜的稳定形成[54]。然而,HIP处理后的样品在晶界和孪晶界处的点蚀频率增加,表明组织演化虽提升了电化学均一性,但也可能引发新的点蚀敏感性,如图10i和j所示[55]。循环动电位极化曲线结果亦显示,在3.5%NaCl溶液中,HIP处理样品的腐蚀电流密度低于未处理样品,结果表明LPBF-316L样品腐蚀性能得到改善。但HIP处理样品的钝化膜击穿次数增多,表明其点蚀发生概率增加。尽管亚晶胞结构的消失削弱了局部钝化膜的完整性,但HIP处理在电化学阻抗和钝化行为方面的改善使其在整体上仍保持较好的耐蚀性[59]。

图10

在高温高氯环境(如288 ℃含氧水环境)下,HIP处理后的增材316L不锈钢表面形成约20 μm厚的Cr2O3氧化层,并伴随碳化物析出和硅富集氧化物颗粒沉积(最大深度可达50 μm)。这类结构变化可能破坏钝化膜的连续性,进而增加SCC发生风险[60]。

综合分析可知,HIP处理对增材316L不锈钢的腐蚀行为呈现“双重效应”:一方面,通过消除孔隙、降低缺陷密度、均匀晶粒结构与促进Cr均匀分布,显著提升其对均匀腐蚀的抵抗能力;另一方面,晶粒粗化及晶界结构变化可能增加局部腐蚀敏感性,尤其在含Cl或高温服役环境中更为显著。因此,在实际应用中需权衡HIP处理带来的腐蚀效应,并通过优化热处理参数实现耐蚀性和力学性能的良好平衡。

4 结论

(1) AM零件在制造过程中普遍存在孔隙、未熔合缺陷、残余应力与表面粗糙等缺陷。在复杂服役环境下,这些缺陷不仅削弱材料的力学性能,更易成为点蚀、晶间腐蚀与应力腐蚀开裂等局部腐蚀行为的诱发源。

(2) 通过调控热处理参数,能够有效释放应力、优化晶粒形貌及调节合金元素分布、提升组织均匀性与致密性,从而增强材料的均匀腐蚀耐受性与局部腐蚀抗力。

(3) 退火处理可促进马氏体α′相向稳定的在α + β两相转变,提升Ti-6Al-4V合金的整体耐蚀性和抗SCC能力;固溶处理通过消除元素偏析与Laves等有害相的溶解,提升Inconel 718等镍基合金的组织均匀性与钝化膜稳定性,从而增强其对点蚀与均匀腐蚀的抵抗能力,适用于镍基合金等耐蚀敏感材料;热等静压处理通过闭合孔隙和促进再结晶,显著提升增材316L等不锈钢的致密性与均匀性,但需关注晶粒粗化带来的局部腐蚀敏感性变化。

(4) 热处理参数与组织演化密切相关,应综合权衡优化。高温或长时间处理虽有助于缺陷消除和晶粒粗化,但可能导致晶界数量减少或成分偏析,应根据具体材料类型与应用环境,合理选择热处理温度、时间及冷却路径,以实现耐腐蚀性与力学性能的协调统一。

参考文献

Post-processing of additively manufactured metallic alloys-a review

[J].

Corrosion performance of additively manufactured stainless steel parts: a review

[J].

Corrosion of additively manufactured alloys: a review

[J].Additive manufacturing (AM), often termed 3D printing, has recently emerged as a mainstream means of producing metallic components from a variety of metallic alloys. The numerous benefits of AM include net shape manufacturing, efficient use of material, suitability to low volume production runs, and the ability to explore alloy compositions not previously accessible to conventional casting. The process of AM, which is nominally performed using laser (or electron) based local melting, has a definitive role in the resultant alloy microstructure. Herein, the corrosion of alloys prepared by AM using laser and electron-based methods, relating the corrosion performance to the microstructural features influenced by AM processing, are reviewed. Such features include unique porosity, grain structures, dislocation networks, residual stress, solute segregation, and surface roughness. Correlations between reported results and deficiencies in present understanding are highlighted.

Corrosion behavior of selective laser melting-manufactured bio-applicable 316L stainless steel in ionized simulated body fluid

[J].Additive manufacturing (AM) is gaining increasing popularity in various fields, including biomedical engineering. Although AM enables fabrication of tailored components with complex geometries, the manufactured parts typically feature several internal issues, such as unpredictable distribution of residual stress and printing defects. However, these issues can be reduced or eliminated by post-processing via thermomechanical treatment. The study investigated the effects of combinations of AM and post-processing by the intensive plastic deformation method of rotary swaging (variable swaging ratios) on microstructures, residual stress, and corrosion behaviors of AISI 316L stainless steel workpieces; the corrosion tests were performed in an ionized simulated body fluid. The results showed that the gradual swaging process favorably refined the grains and homogenized the grain size. The imposed swaging ratio also directly influenced the development of substructure and dislocations density. A high density of dislocations positively affected the corrosion resistance, whereas annihilation of dislocations and formation of subgrains had a negative effect on the corrosion behavior. The first few swaging passes homogenized the distribution of residual stress within the workpiece and acted toward imparting a predominantly compressive stress state, which also favorably influenced the corrosion behavior. Lastly, the presence of the {111}||swaging direction texture fiber (of a high intensity) increased the resistance to pitting corrosion. Overall, the most favorable corrosion behavior was acquired for the AM sample subjected to the swaging ratio of 0.8, exhibiting a strong fiber texture and a high density of dislocations.

Finite element simulation of pitting corrosion of super 13Cr stainless steel in high-temperature and high-pressured CO2 containing artificial formation waters

[J].

高温高压CO2环境中超级13Cr不锈钢点蚀有限元模拟

[J].

Post-process treatments for additive-manufactured metallic structures: A comprehensive review

[J].

An overview of defects in laser melting deposition forming products and the corresponding controlling methods

[J].

激光熔化沉积成形缺陷及其控制方法综述

[J].

Corrosion of additively manufactured stainless steels—process, structure, performance: a review

[J].The corrosion of additively manufactured (AM) metallic materials, such as stainless steels (SS), is a critical factor for their qualification and reliable use. This review assesses the emerging knowledgebase of powder-based laser AM SS corrosion and environmentally assisted cracking (EAC). The origins of AM-unique material features and their hierarchal impact on corrosion and EAC are addressed relative to conventionally processed SS. The effects of starting material, heat treatment, and surface finishing are substantively discussed. An assessment of the current status of AM corrosion research, scientific gaps, and research needs with greatest impact for AM SS advancement and qualification is provided.

Two and three-dimensional characterisation of localised corrosion affected by lack-of-fusion pores in 316L stainless steel produced by selective laser melting

[J].

Sliding wear characteristics and corrosion behaviour of selective laser melted 316L stainless steel

[J].

Corrosion behaviors of selective laser melted Inconel 718 alloy in NaOH solution

[J].Inconel 718 alloy is a popular material used for additive manufacturing. Corrosion involvement is crucial for its application. The corrosion behaviors of the additive manufacturing Inconel 718 alloy in neutral NaCl solution and acidic solution have been thoroughly investigated and documented. However, information available in the literature regarding the corrosion behaviors of additive manufacturing Inconel 718 alloy in alkaline solution is insufficient. In this paper, the corrosion behavior of Inconel 718 alloy fabricated through selective laser melting (SLM Inconel 718) in NaOH solution was studied using open circuit potential (OCP), potentiodynamic polarization, electrochemical impedance spectroscopy (EIS), potentiostats polarization, Mott-Schottky analysis, and X-ray photoelectron spectroscopy (XPS). The results were compared with a commercial rolled Inconel 718 alloy (R Inconel 718). Pitting corrosion was observed in both SLM Inconel 718 alloy and R Inconel 718 alloy. SLM Inconel 718 alloy has lower activity and corrosion rate compared with R Inconel 718 alloy. Because the passive film formed on the surface of SLM Inconel 718 alloy has a lower content of porous NiO and a higher content of compact Cr2O3, the passive film is more compact; however, the donor/acceptor density is lower in the passive film.

激光选区熔化Inconel 718合金在NaOH溶液中的腐蚀行为

[J].采用开路电位、动电位极化、电化学阻抗、恒电位极化、Mott-Schottky和X射线光电子能谱等测试技术研究了激光选区熔化增材制造Inconel 718合金(SLM Inconel 718)在0.1 mol/L NaOH溶液中的腐蚀行为,并与商用轧制Inconel 718合金(R Inconel 718)进行对比。结果表明,SLM Inconel 718合金与R Inconel 718合金均发生点蚀,SLM Inconel 718合金的点蚀优先发生在熔池边界和孔隙部位。相比R Inconel 718合金,SLM Inconel 718合金的活性更低、腐蚀速率更小、耐蚀性能更优,其主要原因在于:SLM Inconel 718合金表面生成的钝化膜中多孔NiO的含量更低,致密Cr<sub>2</sub>O<sub>3</sub>的含量更高,钝化膜更加致密,并且钝化膜的载流子密度更低,因此,SLM Inconel 718合金的钝化膜保护性能更好,耐蚀性能更优。

Post-processing of Inconel 718 alloy fabricated by additive manufacturing: Selective laser melting

[J].

Effect of surface roughness on corrosion fatigue performance of AlSi10Mg alloy produced by Selective Laser Melting (SLM)

[J].

Mechanism of post-heat treatment on intergranular corrosion behavior of SLM-316L stainless steel with different carbon contents

[J].

后热处理对不同含碳量SLM-316L不锈钢晶间腐蚀行为的作用机制研究

[J].

Effect of heat treatment on the intergranular corrosion of 316L stainless steel fabricated by selective laser melting

[J].

The effect of sub-grain structure on intergranular corrosion of 316L stainless steel fabricated via selective laser melting

[J].

The formation mechanism and effect on mechanical properties of defects of aluminum alloy by selective laser melting: a review

[J].

选区激光熔化铝合金缺陷的形成机制和对力学性能的影响: 综述

[J].

A critical review on residual stress in laser additive manufacturing: formation mechanism, characterization and control method

[J].

激光增材制造中残余应力形成机理、表征及调控方法的研究进展

[J].

Research progress in stress corrosion of additively manufactured 316L stainless steels

[J].Stress corrosion cracking (SCC), as an important research direction in the interdisciplinary of material mechanics and corrosion electrochemistry, is one of the main failure modes of stainless steel components. Compared with traditional wrought technology, additive manufacturing (AM) 316L stainless steel has complicated microstructure and inherent defects including pores and lack of fusion places (LOF) caused by additive manufacturing process, resulting in more complex SCC behavior. Herein, the basic SCC behavior of 316L stainless steel was discussed in detail on the basis of the researches of AM316L stainless steel at home and abroad. The main contents include two stress corrosion mechanisms of hydrogen induced cracking and anodic dissolution. Two behavior of transgranular cracking and intergranular cracking were described. The effects of microstructure on SCC behavior of AM316L, including twins, different crystal interface, pores, LOF, and element segregation were summarized. The current situation and advantages of three <i>in-situ</i> characterization methods, including electrochemical noise, high-resolution neutron diffraction and three-dimensional morphology characterization were introduced, which are of great significance to explore the SCC behavior of AM316L. Finally, the prospective future of the research directions of SCC behavior of additive manufacturing stainless steel were proposed, including the research of SCC characteristics under high temperature irradiation environment and the principle of stress distribution and restructuration at crack tips.

增材制造316L不锈钢应力腐蚀研究进展

[J].应力腐蚀开裂是不锈钢零部件失效的主要形式之一,是材料力学和腐蚀电化学交叉领域的重要研究方向。与传统工艺制备相比,增材制造技术制备的316L不锈钢内部微观组织复杂,存在增材制造工艺引起的气孔、未熔合区等固有缺陷,导致其应力腐蚀行为更为复杂。本文基于国内外关于增材制造316L不锈钢的研究实例,综述了应力腐蚀行为特征及主控机制,包括氢致开裂和阳极溶解两种应力腐蚀机理、穿晶断裂和沿晶解理两种作用形式,并归纳了孪晶、异种晶相交界处、气孔及未熔合处、元素偏析等组织结构缺陷等对增材制造316L不锈钢应力腐蚀的影响。针对电化学噪声、高分辨中子衍射、三维形貌表征等三种原位测试方法在不锈钢应力腐蚀行为研究方面的现状和技术优势进行了总结。最后提出了高温辐照等严苛环境下的应力腐蚀行为特征研究,以及裂纹尖端应力分配模型及重构准则等增材制造不锈钢应力腐蚀未来的研究方向。

Experimental analysis of residual stresses on AlSi10Mg parts produced by means of Selective Laser Melting (SLM)

[J].

Alloys-by-design: Application to new superalloys for additive manufacturing

[J].

Laser additive manufacturing of FeCrCoMnNi high-entropy alloy: Effect of heat treatment on microstructure, residual stress and mechanical property

[J].

An experimental study of residual stress and direction-dependence of fatigue crack growth behaviour in as-built and stress-relieved selective-laser-melted Ti6Al4V

[J].

Effect of solution heat treatment on the microstructure and mechanical properties of Inconel 625 superalloy fabricated by laser solid forming

[J].

Laser additive manufacturing of titanium alloys: Process, materials and post-processing

[J].Laser additive manufacturing (LAM) of titanium (Ti) alloys has emerged as a transformative technology with vast potential across multiple industries. To recap the state of the art, Ti alloys processed by two essential LAM techniques (i.e., laser powder bed fusion and laser‐directed energy deposition) will be reviewed, covering the aspects of processes, materials and post‐processing. The impacts of process parameters and strategies for optimizing parameters will be elucidated. Various types of Ti alloys processed by LAM, including α‐Ti, (α + β)‐Ti, and β‐Ti alloys, will be overviewed in terms of microstructures and benchmarking properties. Furthermore, the post‐processing methods for improving the performance of LAM‐processed Ti alloys, including conventional and novel heat treatment, hot isostatic pressing, and surface processing (e.g., ultrasonic and laser shot peening), will be systematically reviewed and discussed. The review summarizes the process windows, properties, and performance envelopes and benchmarks the research achievements in LAM of Ti alloys. The outlooks of further trends in LAM of Ti alloys are also highlighted at the end of the review. This comprehensive review could serve as a valuable resource for researchers and practitioners, promoting further advancements in LAM‐built Ti alloys and their applications.

Effect of heat treatment on microstructure and properties of 24CrNiMo alloy steel formed by selective laser melting (SLM)

[J].The 24CrNiMo alloy steel powder was used as experimental material. The microstructure and mechanical properties of as-deposited, quenched and tempered (QT) and stress-relief annealed (SR) specimens were analyzed. The X-ray diffraction (XRD) analysis showed that the specimens in the three states were mainly ferrite (α-Fe), in which the as-deposited samples had puny face-centered cubic (FCC) structure Fe (γ-Fe). The microstructure observation showed that the as-deposited specimens were made up of ferrite, granular bainite, a small amount of cementite and residual austenite. The tensile test results indicated that the tensile strength and yield strength of the as-deposited specimens were 1199 MPa and 1053 MPa respectively, and the elongation at break was 10.7%. The elongation of QT and SR specimens increased to 11.6% and 12.8%, respectively. The electron backscattered scattering detection (EBSD) analysis results showed that the small-angle grain boundary content of the as-deposited samples was 58%, and large-angle grain boundary content was 15%. After QT and SR, small-angle and large-angle grain boundaries were obtained than those in the as-deposited specimens. The high-temperature friction and wear properties and thermal fatigue performances of the QT and SR specimens were improved significantly. The QT specimens had the smallest wear and thermal fatigue crack lengths, excellent resistance to friction and wear performance and prevention of crack growth, with an ideal comprehensive properties.

Research progress of post-processing of stainless steel additive manufacturing parts

[J].

不锈钢增材制造件后处理工艺研究进展

[J].

Fatigue behavior of Ti-6Al-4V cellular structures fabricated by additive manufacturing technique

[J].Porous titanium and its alloys have been considered as promising replacement for dense implants, as they possess low elastic modulus comparable to that of compact human bones and are capable of providing space for in-growth of bony tissues to achieve a better fixation. Recently, the additive manufacturing (AM) method has been successfully applied to the fabrication of Ti-6Al-4V cellular meshes and foams. Comparing to traditional fabrication methods, the AM method offers advantages of accurate control of complex cell shapes and internal pore architectures, thus attracting extensive attention. Considering the long-term safety in the human body, the metallic cellular structures should possess high fatigue strength. In this paper, the recent progress on the fatigue properties of Ti-6Al-4V cellular structures fabricated by the AM technique is reviewed. The various design factors including cell shapes, surface properties, post treatments and graded porosity distribution affecting the fatigue properties of additive manufactured Ti-6Al-4V cellular structures were introduced and future development trends were also discussed.

Study on high temperature mechanical properties and corrosion behavior of selective laser melted TC4 alloy

[J].

选区激光熔化TC4合金高温力学性能及腐蚀行为研究

[J].

The martensitic transformation and mechanical properties of Ti6Al4V prepared via selective laser melting

[J].This article investigated the microstructure of Ti6Al4V that was fabricated via selective laser melting; specifically, the mechanism of martensitic transformation and relationship among parent β phase, martensite (α’) and newly generated β phase that formed in the present experiments were elucidated. The primary X-ray diffraction (XRD), transmission electron microscopy (TEM) and tensile test were combined to discuss the relationship between α’, β phase and mechanical properties. The average width of each coarse β columnar grain is 80–160 μm, which is in agreement with the width of a laser scanning track. The result revealed a further relationship between β columnar grain and laser scanning track. Additionally, the high dislocation density, stacking faults and the typical ( 10 1 ¯ 1 ) twinning were identified in the as-built sample. The twinning was filled with many dislocation lines that exhibited apparent slip systems of climbing and cross-slip. Moreover, the α + β phase with fine dislocation lines and residual twinning were observed in the stress relieving sample. Furthermore, both as-built and stress-relieved samples had a better homogeneous density and finer grains in the center area than in the edge area, displaying good mechanical properties by Feature-Scan. The α’ phase resulted in the improvement of tensile strength and hardness and decrease of plasticity, while the newly generated β phase resulted in a decrease of strength and enhancement of plasticity. The poor plasticity was ascribed to the different print mode, remained support structures and large thermal stresses.

Additive manufacturing of AlSi10Mg and Ti6Al4V lightweight alloys via laser powder bed fusion: A review of heat treatments effects

[J].Laser powder bed fusion (L-PBF) is an additive manufacturing technology that is gaining increasing interest in aerospace, automotive and biomedical applications due to the possibility of processing lightweight alloys such as AlSi10Mg and Ti6Al4V. Both these alloys have microstructures and mechanical properties that are strictly related to the type of heat treatment applied after the L-PBF process. The present review aimed to summarize the state of the art in terms of the microstructural morphology and consequent mechanical performance of these materials after different heat treatments. While optimization of the post-process heat treatment is key to obtaining excellent mechanical properties, the first requirement is to manufacture high quality and fully dense samples. Therefore, effects induced by the L-PBF process parameters and build platform temperatures were also summarized. In addition, effects induced by stress relief, annealing, solution, artificial and direct aging, hot isostatic pressing, and mixed heat treatments were reviewed for AlSi10Mg and Ti6AlV samples, highlighting variations in microstructure and corrosion resistance and consequent fracture mechanisms.

Heat treatment of Inconel 718 produced by selective laser melting: Microstructure and mechanical properties

[J].

Microstructural evolution & corrosion behavior of Laser-powder-bed-fused Inconel 718 subjected to surface and heat treatments

[J].

Post-processing of Inconel 718 superalloy by Laser-based powder bed fusion: Microstructures and properties evaluation

[J].

Microstructures and tensile properties of GH4099 alloy fabricated by laser additive manufacturing after heat treatment

[J].

激光增材制造GH4099合金热处理后的显微组织及拉伸性能

[J].

Characterization of recrystallization and second-phase particles in solution-treated additively manufactured alloy 718

[J].

The effect of hot isostatic pressure on the corrosion performance of Ti-6Al-4V produced by an electron-beam melting additive manufacturing process

[J].

Fundamental aspects of hot isostatic pressing: an overview

[J].

Effects of hot isostatic pressing on microstructure and mechanical properties of selective laser melted Inconel 718 alloy in different directions

[J].

热等静压处理对选区激光熔化成形Inconel 718合金各向组织及力学性能的影响

[J].

Influence of defects, surface roughness and HIP on the fatigue strength of Ti-6Al-4V manufactured by additive manufacturing

[J].

Fatigue of additive manufactured Ti-6Al-4V, part I: The effects of powder feedstock, manufacturing, and post-process conditions on the resulting microstructure and defects

[J].

Corrosion behaviour of selective laser melted TC4 alloy

[J].

激光选区熔化成形TC4合金腐蚀行为

[J].采用激光选区熔化成形技术(Selective Laser Melting,SLM)制备TC4钛合金试样,观察其显微组织,并用电化学腐蚀实验测试不同成形面以及粗糙度对TC4钛合金耐蚀性能的影响,并与传统轧制态进行对比。结果表明:成形方式、成形面和粗糙度均影响TC4钛合金的耐蚀性能。激光选区熔化成形技术制备的TC4钛合金纵截面由原始柱状β晶粒和与生长方向成±45°针状α'马氏体组成,横截面上的晶粒呈棋盘状。传统轧制态由片状α+β相以及等轴α相组成。传统轧制态的耐腐蚀性要强于SLM成形的试样,且SLM成形的纵截面的耐腐蚀性要强于横截面。表面粗糙度小的试样耐腐蚀性要强于表面粗糙度大的试样。激光选区熔化成形态试样腐蚀表面都出现明显的腐蚀坑,腐蚀形态均为点蚀。

Research progress in heat treatment of laser additively manufactured titanium alloys

[J].

激光增材制造钛合金热处理研究进展

[J].

Corrosion behavior of additively manufactured Ti-6Al-4V parts and the effect of post annealing

[J].This paper evaluates the corrosion behavior of Ti-6Al-4V alloy parts produced by laser-based powder bed fusion additive manufacturing (AM). The effect of post annealing heat treatment on the corrosion resistance of AM parts is studied by comparing the heat treated samples with cold rolled commercial titanium alloy samples. The results obtained via corrosion tests show that the corrosion rate of as-fabricated AM parts is almost sixteen times worse than the commercial grade samples. The accelerated rate was due to the presence of non-equilibrium phases and can be ameliorated by a proper post heat treatment process at 800 degrees C for 2 h. The proposed heat treatment makes the corrosion behavior of AM parts comparable to the commercial grade samples, due to the stress relief of the martensitic phase and formation of BCC phase of beta Ti-6Al-4V which has a higher corrosion resistance. CALculation of PHAse Diagrams (CALPHAD) method was used to identify the equilibrium phases.

Influence of heat treatment parameters on the corrosion resistance of additively manufactured Ti-6Al-4V alloy

[J].

Fabrication and characterization of selective laser melting printed Ti-6Al-4V alloys subjected to heat treatment for customized implants design

[J].

Effect of heat treatment on the microstructure and mechanical properties of selective laser-melted Ti64 and Ti-5Al-5Mo-5V-1Cr-1Fe

[J].Additive manufacturing (AM) has shown the ability in processing titanium alloys. However, due to the unique thermal history in AM, the microstructure of AM-fabricated parts is metastable and non-equilibrium. This work was aiming to tailor the microstructure and to improve the mechanical properties of α+β Ti-6Al-4V alloy and metastable β Ti-5Al-5Mo-5V-1Cr-1Fe alloys by manipulating the post-process heat treatment. The results showed that Ti-6Al-4V exhibited a metastable α’ martensite microstructure in the as-fabricated condition, while a metastable β structure was formed in as-printed Ti-5Al-5Mo-5V-1Cr-1Fe. After post-process heat treatment, both lamellar and bimodal microstructures were obtained in Ti64 and Ti-5Al-5Mo-5V-1Cr-1Fe alloys. Especially, the Ti-6Al-4V alloy subjected to 950 °C annealing showed the lamellar structure with the highest fracture toughness of 90.8 ± 2.1 MPa.m1/2. The one cyclically heat-treated has excellent combined strength, ductility and fracture toughness attributed to the bimodal structure. In addition, similar observations of lamellar and bimodal microstructure appeared in the post-process heat-treated Ti-5Al-5Mo-5V-1Cr-1Fe alloy. This study demonstrated that heat treatment is an effective way to tackle the non-equilibrium microstructure and improve the mechanical properties of selective laser melting (SLM)-fabricated titanium alloys.

Effect of heat treatment on the phase transformation and mechanical properties of Ti6Al4V fabricated by selective laser melting

[J].

Effect of post-processing on the corrosive behaviour of L-DED Ti-6Al-4V

[J].

The effect of post-processing heat treatment on the microstructure, residual stress and mechanical properties of selective laser melted 316L stainless steel

[J].

Corrosion study of selective laser melted IN718 alloy upon post heat treatment and shot peening

[J].Selective laser melted (SLM) IN 718 alloy specimens are subjected to heat treatment and shot peening to assess the effect of post processing on the corrosion performance of the alloy in a 3.5 wt % NaCl solution. The four conditions used in this analysis are as-built material (AB), heat-treated as-built material (HT), shot-peened as-built material (SP), and heat-treated and shot-peened as-built material (HTSP). Microstructural studies revealed the presence of a 500 nm sized cellular structure with a γ matrix surrounded by the Laves phase in the AB material. Shot-peening reduced the surface roughness of the AB and HT samples to almost 80%. The potentiodynamic experiments revealed a highest Icorr value of 0.21 µA/cm2 for the AB material and the lowest Icorr value of 0.04 µA/cm2 for the HTSP material. In the Electrochemical Impedance Spectroscopy (EIS) analysis, the Nyquist plot substantiated the increasing corrosion resistance in the same order of decreasing corrosion rate. The Bode plot exhibited two resistance–capacitance (RC) time constants for all four conditions. The solution resistance measured around 30 Ω, with the HTSP specimen exhibiting the highest passive film resistance of 676 kΩ cm2 and the AB specimen exhibiting the lowest passive film resistance of 234 kΩ cm2. This study has shown that elimination of the network of the Laves phase in SLM material through heat treatment and smooth surface morphology achieved through shot peening improves the corrosion resistance of Inconel 718 alloy.

Microstructural evolution and corrosion behaviors of Inconel 718 alloy produced by selective laser melting following different heat treatments

[J].

Effects of the heat treatment on the microstructure and corrosion behavior of 316L stainless steel manufactured by Laser Powder Bed Fusion

[J].

Additively manufactured 316L stainless steel via laser powder directed energy deposition (LP-DED): Mechanical properties at cryogenic and elevated temperatures

[J].

Microstructure tailoring of laser powder bed fused 316L impellers for enhanced mechanical properties and optimum electrochemical characteristics through hot isostatic pressing

[J].

Effects of hot isostatic pressing on the elastic modulus and tensile properties of 316L parts made by powder bed laser fusion

[J].

Effect of hot isostatic pressing on porosity and mechanical properties of 316 L stainless steel prepared by the selective laser melting method

[J].The manufacturing route primarily determines the properties of materials prepared by additive manufacturing methods. In this work, the microstructural features and mechanical properties of 316 L stainless steel prepared by the selective laser method have been determined. Three types of samples, (i) selective laser melted (SLM), (ii) selective laser melted and hot isostatic pressed (HIP) and (iii) selective laser melted and heat treated (HT), were characterized. Microstructural analysis revealed that SLM samples were formed by melt pool boundaries with fine cellular–dendritic-type microstructure. This type of microstructure disappeared after HT or HIP and material were formed by larger grains and sharply defined grain boundaries. The SLM-prepared samples contained different levels of porosity depending on the preparation conditions. The open interconnected LOF (lack of fusion) pores were observed in the samples, which were prepared with using of scanning speed 1200 mm/s. The blowhole and keyhole type of porosity were observed in the samples prepared by lower scanning speeds. The HIP caused a significant decrease in internal closed porosity to 0.1%, and a higher pressure of 190 MPa was more effective than the usually used pressure of 140 MPa, but for samples with open porosity, HIP was not effective. The relatively high yield strength of 570 MPa, tensile strength of 650 MPa and low ductility of 30–34% were determined for SLM samples with the lower porosity content than 1.3%. The samples after HIP showed lower yield strengths than after SLM (from 290 to 325 MPa) and relatively high ductility of 47.8–48.5%, regardless of the used SLM conditions.

Hydrogen embrittlement susceptibility of additively manufactured 316L stainless steel: Influence of post-processing, printing direction, temperature and pre-straining

[J].

Heat treatment effect on the microstructure, mechanical properties, and wear behaviors of stainless steel 316L prepared via selective laser melting

[J].