液态铅铋合金(LBE)凭借高安全性、优良的辐射抗性、出色的热传导性能、优异的经济性及稳定的化学惰性,已成为当前铅冷快中子反应堆(LFR)的冷却剂重要候选材料[1~5]。然而,高温和高流速状态的LBE极易对反应堆结构材料产生严重腐蚀作用,严重威胁着铅冷快中子反应堆的安全稳定运行。大量研究证实,溶解氧(DO)浓度是影响液态铅铋合金腐蚀行为的关键因素:当DO浓度过高时,会引发材料严重的氧化腐蚀;当DO浓度过低时,会导致材料出现剧烈的溶解腐蚀。基于这一特性,通过将LBE中的DO浓度控制适宜范围内,不仅能够显著降低结构材料在LBE中的腐蚀速率,还能有效避免PbO的生成,为LFRs的安全运行提供重要保障[6,7]。

值得注意的是,由于增材制造快速凝固的特性,极易导致大量δ-铁素体的析出。研究表明,δ-铁素体有良好的抗含饱和氧的液态铅铋合金腐蚀的性能。Wang等[13]研究了δ-铁素体对316H奥氏体不锈钢在550 ℃、饱和氧的液态铅铋合金中腐蚀行为的影响机制,随着腐蚀时间的增加,δ-铁素体转变为分解态δ-铁素体,虽然其氧化速率加快,但其耐LBE腐蚀能力仍优于奥氏体。Chen等[14]研究了含有δ-铁素体的AISI 316A不锈钢经固溶处理和加速老化处理后在550 ℃、饱和氧的液态铅铋合金中腐蚀行为,在δ-铁素体表面形成的Cr2O3氧化物和Fe-Cr-Si尖晶石氧化物的混合物可以有效阻碍金属转移,从而具有优异的抗氧化侵蚀能力。目前,大部分对δ-铁素体的研究均涉及含氧液态铅铋合金,而对其在贫氧液态铅铋合金中的腐蚀行为研究较少。同样地,对增材制造奥氏体不锈钢的腐蚀行为也仅限于较少地研究。因此,本文研究了存在于电弧增材制造304L不锈钢的δ-铁素体对前者在550 ℃、饱和氧和贫氧的液态铅铋合金中腐蚀性能的影响机理,为增材制造技术在核工业的应用提供参考。

1 实验方法

1.1 实验材料

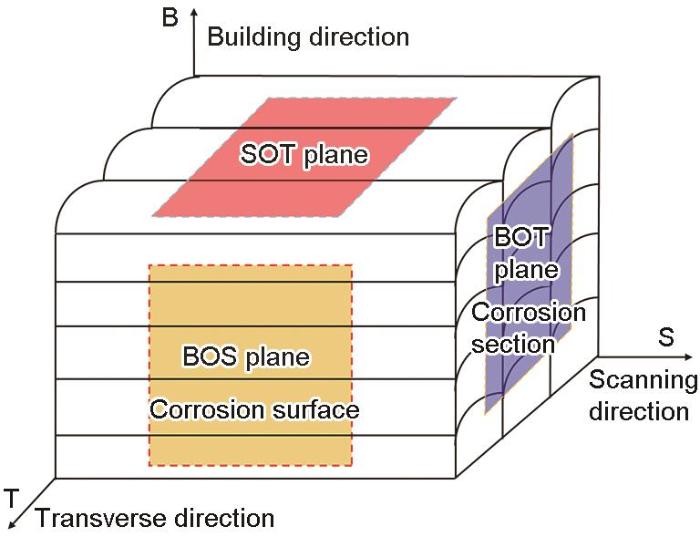

本研究采用的是电弧增材制造的304L不锈钢,选用ϕ1.2 mm的ER308L焊丝作焊接材料,其成分(质量分数)为:C ≤ 0.035,N ≤ 0.07~0.11,Cr ≤ 18.5~21.0,Ni ≤ 9.0~11.0,Mn ≤ 2.0,Si ≤ 0.80,P ≤ 0.030,S ≤ 0.015,Co ≤ 0.04,B ≤ 0.0015,Cu ≤ 0.08,其余为Fe。以直径ϕ1.2 mm的同成分丝材为电极,其工艺参数为:电压20 V,电流140 A,进料速度6 m/min,扫描速度7 m/min,重叠率40%的工艺参数对样品进行加工。样品成型后,在1050 ℃下固溶退火2 h。WAAM 304L不锈钢的化学成分(质量分数,%)为:S 0.0026,P 0.013,C 0.033,Si 0.47,Mn 1.71,Ni 9.70,Cr 20.70。采用电火花线切割将样品切割成一矩形片。图1为切割WAAM 304L不锈钢样品的示意图。其中,OB为堆积方向,OS为扫描方向,OT为与层内扫描方向垂直的横向,黑线为熔合线。腐蚀表面为BOS面,腐蚀截面为BOT面。在本次实验中,先用600#、800#、1000#和2000#的碳化硅砂纸机械研磨试样表面,再用2.5 µm粒度的金刚石磨料进行机械抛光。采用两种溶液对组织进行刻蚀:将样品置入10% (质量分数)草酸进行电刻,电压为10 V,持续时间10 s,用于观察样品的奥氏体组织;第二种刻蚀溶液为5 g氯化铁、50 mL盐酸和100 mL水的混合溶液,进行金相和氧化膜截面刻蚀,用来观察样品的铁素体组织。将用于EBSD表征的样品用碳化硅砂纸机械研磨至2000#,然后用1 μm粒度的金刚石磨料进行机械抛光,最后用0.05 μm粒度的氧化硅悬浮液进行手工抛光。

图1

图1

WAAM 304L不锈钢样品示意图

Fig.1

Schematic diagram of WAAM 304L stainless steel sample

1.2 浸泡腐蚀实验

浸泡实验前,使用去离子水和乙醇将抛光后的样品进行超声清洗。本试验在自建的控氧LBE腐蚀实验装置中进行,实验装置主要由高压釜、热电偶、加热炉和溶解氧传感器组成。试件首先悬挂在液态LBE上方(与液态LBE不接触),然后向液态LBE中引入氢气和氩气的混合气以调整DO浓度。当液态LBE中的DO浓度达到目标值时,将样品浸入液态LBE中开始腐蚀试验。在饱和氧(1.28 × 10-3 %)和贫氧(1.78 × 10-7 %)条件下,WAAM 304L SS腐蚀1000 h。浸泡实验结束后,采用金刚石线切割机切割样品,并将其进行冷镶以备后续实验。

1.3 表征方法

采用FEI XL30型电子背散射衍射仪(EBSD)分析WAAM 304L不锈钢的显微组织结构。采用D8 Advance型X射线衍射仪(XRD)分析氧化膜物相组成。采用NovaNano SEM 450型扫描电子显微镜(SEM)和能量色散光谱仪(EDS)观察样品氧化膜截面形貌和成分。

2 结果与讨论

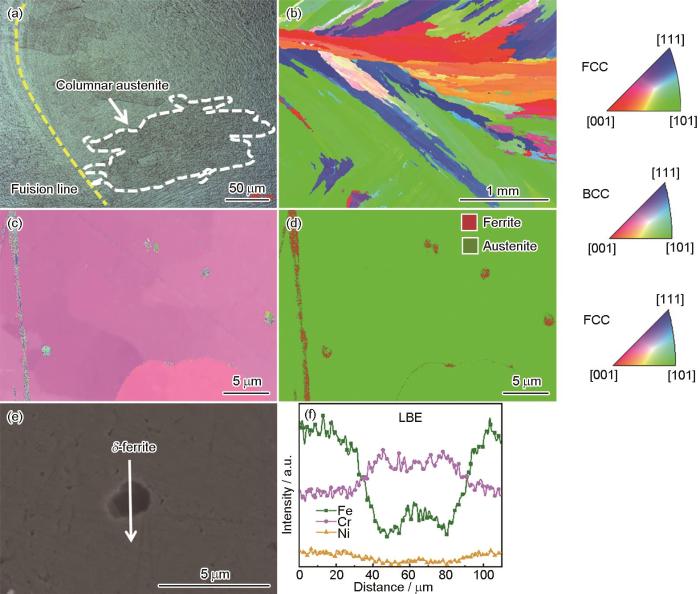

图2

图2

WAAM 304L不锈钢的BOT面的微观结构

Fig.2

Microstructure of BOT surface of WAAM 304L stainless steel: (a) metallographic structure, (b, c) IPF, (d) phase diagram, (e) SEM morphology of δ-ferrite, (f) EDS line scan corresponding to (e)

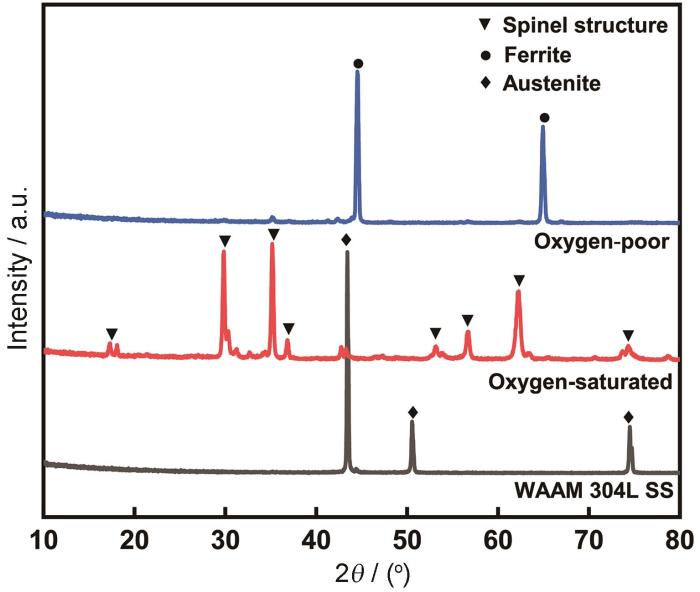

图3为WAAM 304L不锈钢原始样品和浸泡试验后的样品的XRD图谱。原始样品展现出奥氏体的特征峰以及微弱的铁素体特征峰。在饱和氧的LBE中浸泡1000 h后,样品出现大量尖晶石特征峰,表明发生了明显氧化反应。在贫氧的LBE中浸泡1000 h后,样品出现明显的铁素体特征峰,表明奥氏体向铁素体发生转变,发生溶解腐蚀。

图3

图3

WAAM 304L不锈钢的原始样品和在550 ℃、饱和氧/贫氧的液态LBE中浸泡1000 h后的样品的XRD图谱

Fig.3

XRD patterns of as-received WAAM 304L stainless steel sample and samples after 1000 h exposed in liquid LBE under saturated/poor-oxygen and conditions at 550 oC

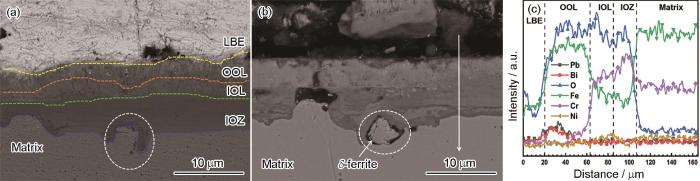

图4

图4

WAAM 304L不锈钢在550 ℃、饱和氧的液态LBE中浸泡1000 h后的氧化膜截面SEM形貌和EDS结果

Fig.4

SEM morphologies of the cross-section of oxide film of WAAM 304L stainless steel after 1000 h exposed in liquid LBE under saturated-oxygen condition at 550 oC: (a) before etching, (b) after etching, and (c) EDS line scan corresponding to (b)

图5

图5

WAAM 304L不锈钢在550 ℃、饱和氧的液态LBE中浸泡1000 h下δ-铁素体SEM形貌和EDS结果

Fig.5

SEM morphology and EDS result of δ-ferrite of WAAM 304L stainless steel after 1000 h exposed in liquid LBE under saturated-oxygen condition at 550 oC: (a) SEM morphology of δ-ferritic area, (b) EDS line scan corresponding to (a)

图6

图6

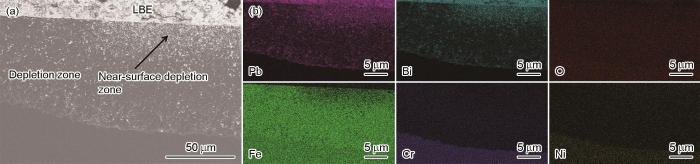

WAAM 304L不锈钢在550 ℃、贫氧的液态LBE中浸泡1000 h下样品腐蚀截面的SEM形貌和EDS面扫描结果

Fig.6

SEM morphology of the cross-section of WAAM 304L stainless steel after 1000 h exposed in liquid LBE under poor-oxygen condition at 550 ℃: (a) SEM morphology of the sample, (b) EDS surface scan corresponding to (a)

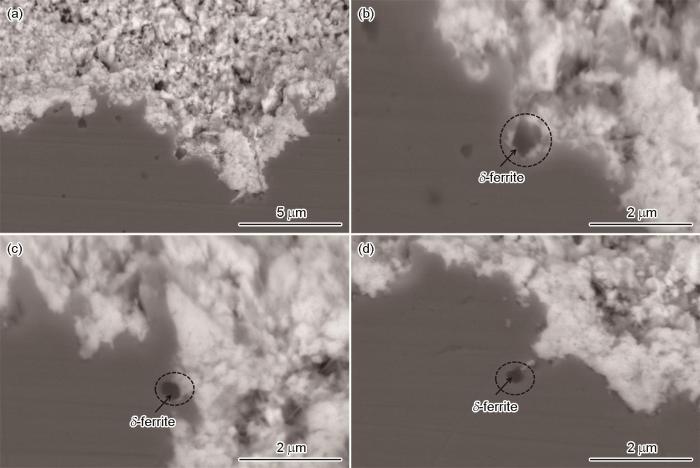

为了研究δ-铁素体在贫氧的LBE中的腐蚀行为,同样采用FeCl3和盐酸混合溶液刻蚀来表征其所在位置。图7为在贫氧的液态LBE中浸泡1000 h后δ-铁素体的SEM形貌。尽管铁素体Cr含量高,但是贫氧环境中Cr无法氧化形成钝化膜,其抗氧化腐蚀的“先天优势”被抵消。虽然δ-铁素体并没有阻碍溶解腐蚀的进程,但是通过观察可见δ-铁素体依然具有良好的耐蚀性,溶解腐蚀趋向于沿其相界进行。而且,贫氧条件下,溶解腐蚀占主导,腐蚀速率由金属元素(Ni、Fe)的溶解动力学控制。δ-铁素体本身Ni含量较低(图2),因此受到溶解腐蚀影响较小。从宏观上来看,由于溶解腐蚀深度较深且范围广,δ-铁素体对WAAM 304L不锈钢在贫氧条件下的腐蚀行为影响非常小。

图7

图7

WAAM 304L不锈钢在550 ℃、贫氧的液态LBE中浸泡1000 h下δ-铁素体的SEM形貌图

Fig.7

SEM morphologies of δ-ferrite of WAAM 304L stainless steel after 1000 h exposed in liquid LBE under poor-oxygen condition at 550 oC: (a) low morphology, (b-d) high morphology

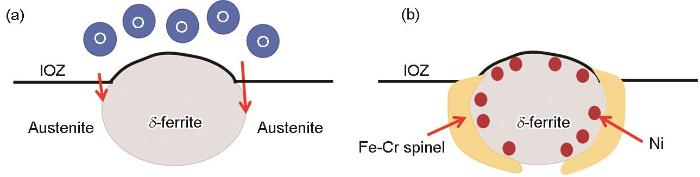

3 讨论

图8

图8

WAAM 304L不锈钢在550 ℃、饱和氧的液态LBE中δ-铁素体的腐蚀机理示意图

Fig.8

Schematic diagram of the corrosion mechanism of δ-ferrite of WAAM 304L stainless steel in liquid LBE under saturated-oxygen condition at 550 oC: (a) before δ-ferrite is corroded, (b) after δ-ferrite is corroded

4 结论

(1) 在饱和氧的液态LBE中,WAAM 304L不锈钢表面形成典型的3层氧化膜。其中,δ-铁素体比奥氏体的抗腐蚀能力更优异,这主要是由于铁素体中的高Cr含量会与O反应形成生成富Cr的保护性氧化膜,从而保护δ-铁素体不被氧化。

(2) 在贫氧的液态LBE中,WAAM 304L不锈钢发生明显的溶解腐蚀。δ-铁素体本身Ni含量较低,受到溶解腐蚀影响较小,表明δ-铁素体具有更好的抗溶解腐蚀性能。然而,δ-铁素体产生的影响并不大。

参考文献

A review of steel corrosion by liquid lead and lead-bismuth

[J].

Effect of relative flow velocity on corrosion behavior of high nitrogen austenitic stainless steel in liquid lead-bismuth eutectic alloy

[J].

相对流速对高氮奥氏体不锈钢在液态铅铋共晶合金中腐蚀行为的影响

[J].对高氮奥氏体不锈钢在400 ℃不同相对流速 (0、0.92、1.27、1.61和2.01 m/s)、氧饱和的液态铅铋合金 (LBE) 中进行1000 h的腐蚀实验。采用扫描电镜 (SEM)、能谱仪 (EDS)、X射线衍射 (XRD) 对腐蚀后的试样表面和截面进行分析。结果表明:相对流速对试样的腐蚀行为有较大影响:静态试样,初始表面的氧化层可有效阻止高氮钢的进一步氧化;动态试样,表面初始氧化层遭到破坏,出现氧化腐蚀和溶解腐蚀共存状态。相对流速从0增至0.92 m/s,初始氧化层的破坏导致表层以下的合金发生扩散氧化,以氧化腐蚀为主;相对流速从0.92 m/s增加到2.01 m/s,较大的相对流速将扩散至表面的合金元素及时带走,溶解腐蚀占比逐渐增多,氧化腐蚀逐渐减少。氧化腐蚀产物为具有双层结构的氧化物颗粒,外层为疏松多孔的Fe<sub>3</sub>O<sub>4</sub>,内层为 (Fe,Cr)<sub>3</sub>O<sub>4</sub>。

Corrosion behavior of Fe34Cr30Mo15Ni15Nb3Al3 high-entropy alloy in molten Pb-Bi eutectic containing 10-6 % oxygen at 500 oC

[J].

Fe34Cr30Mo15Ni15Nb3Al3高熵合金在500 ℃下氧含量为10-6 %的液态铅铋合金中腐蚀行为研究

[J].制备了Fe<sub>34</sub>Cr<sub>30</sub>Mo<sub>15</sub>Ni<sub>15</sub>Nb<sub>3</sub>Al<sub>3</sub>高熵合金,铸态组织包含FCC相、Laves相和B2-NiAl相。随后将高熵合金置于500℃、氧浓度为10<sup>-6</sup>%(质量分数)的液态铅铋合金中进行1000~2000 h的静态腐蚀实验。结果表明:高熵合金未发生明显的元素溶解、铅铋渗透和相变。静态腐蚀1000~2000 h后,Laves相区域表面只生成了Fe-Cr尖晶石。但腐蚀1000 h后,FCC/B2-NiAl相区域表面除了内层生成了Fe-Cr尖晶石,外层还生成了贫Cr的Fe-Cr尖晶石;随着腐蚀时间增加到1500 h,FCC/B2-NiAl相区域外层贫Cr的Fe-Cr尖晶石发生脱落;腐蚀2000 h后,Fe<sub>3</sub>O<sub>4</sub>开始生成,覆盖FCC/B2-NiAl相区域外表面。高熵合金表面的氧化层均较薄,厚度不超过3 µm,表现出较好的耐腐蚀性。高熵合金具有良好耐腐蚀的原因是由于Laves相分布均匀,抑制了金属元素的向外扩散。

Oxide layer stability in lead-bismuth at high temperature

[J].

Low-temperature oxy-nitriding of 316L austenitic stainless steel for improved corrosion resistance in liquid lead-bismuth eutectic

[J].

Structural materials for atomic reactors with liquid metal heat-transfer agents in the form of lead or lead-Bismuth alloy

[J].

Oxidation of steel T91 in flowing lead-bismuth eutectic (LBE) at 550 oC

[J].

Effects of dissolved oxygen on the corrosion-related unidentified deposit formed of 304SS in the flow accelerated zone under the simulated secondary water chemistry

[J].

Precipitated phase distribution and strengthening mechanism of 2319 aluminum alloy deposited by wire arc additive manufacturing

[J].The mechanical properties of wire-arc additive manufactured (WAAM) 2319 aluminum alloy are significantly influenced by the distribution of precipitates. However, the non-equilibrium solidification microstructure under cold metal transfer (CMT) and its evolution mechanism during heat treatment remain unclear. 2319 aluminum alloy specimens are fabricated using CMT-ed WAAM, with some subjected to T6 heat treatment. The distribution of precipitates in the upper, middle, and lower regions of the specimens is systematically investigated before and after heat treatment to elucidate their correlation with mechanical properties and the underlying strengthening mechanisms. The results indicate that the as-deposited specimens exhibit an average tensile strength of 175 MPa. The lower region near the substrate, which contains the highest volume fraction (20.8%) of coarse θ phases, demonstrates the greatest tensile strength (192 MPa). After T6 heat treatment, the volume fraction of θ phases in the upper, middle, and lower positions of the samples decreases by about 80%. Meanwhile, a large number of small needle-like θ′ phases are formed in the matrix, and these dispersed θ′ phases play a major strengthening role, making the average tensile strength of the sample reach 365 MPa. Both as-deposited and heat-treated samples exhibit three strengthening mechanisms: precipitation strengthening, solid solution strengthening, and grain refinement strengthening. The substantial strength improvement in heat-treated samples primarily originates from precipitation strengthening induced by the θ′ phases.

电弧增材制造2319铝合金析出相分布及强化机理

[J].电弧增材制造2319铝合金的力学性能受析出相分布的显著影响,但冷金属过渡(CMT)技术下的非平衡凝固组织及其在热处理中的演变机制尚不明确。采用CMT技术制备2319铝合金试样,并对部分试样进行T6热处理,研究热处理前后试样上、中、下部3个位置的析出相分布规律,阐明析出相分布与力学性能的关系,并揭示热处理前后试样的力学性能强化机理。结果表明:沉积态试样平均抗拉强度为175 MPa,靠近基板的下部位置,θ相体积分数最高(20.8%),其抗拉强度可达192 MPa;经过T6热处理后,试样上、中、下3个位置的θ相体积分数均减少约80%,同时基体中形成大量细小针状θ′相,这些弥散分布的θ′相起到主要的强化作用,使试样平均抗拉强度达到365 MPa;沉积态与热处理态样品均存在沉淀强化、固溶强化和细晶强化三种强化机制,热处理样品的强度增益来源于针状θ′相所引起的沉淀强化。

Comparison of traditional processing and additive manufacturing technologies in various performance aspects: A review

[J].

Microstructure and corrosion evolution of aerospace AA2024 Al-Alloy thin wall structure produced through WAAM

[J].

电弧增材制造航空AA2024铝合金的微观结构及其腐蚀行为研究

[J].研究了电弧增材制造 (WAAM) 航空AA2024铝合金的微观组织结构及其腐蚀行为。通过扫描电镜 (SEM)、透射电镜 (TEM) 和能量色散X射线光谱仪 (EDX),研究了该铝合金腐蚀前后的微观组织结构以阐明其腐蚀行为。结果表明,电弧增材制造AA2024铝合金中,存在熔池区 (MPZ)、熔池边界区 (MPB) 和热影响区 (HAZ)。3个区域中均存在以孤立或成簇的形式存在的S相 (Al<sub>2</sub>CuMg)、θ相 (Al<sub>2</sub>Cu) 和α相 (AlFeMnSi) 金属间化合物 (IM)。相对MPZ和HAZ,MPB显示出更高的局部腐蚀敏感性,这与IM的脱合金化行为密切相关。

Corrosion behavior of 304L stainless steel by wire arc additive manufacturing in liquid lead-bismuth eutectic at 550 oC

[J].

Research on the effects of δ-ferrite on properties of nuclear-grade austenitic stainless steels

[D].

核级奥氏体不锈钢中δ-铁素体对相关性能影响的研究

[D].

Corrosion behavior of δ-ferrite in AISI 316 austenitic stainless steel exposed to oxygen-saturated lead-bismuth eutectic at 550 oC

[J].

Study on microstructure and mechanical properties of 304LN fabricated by electric arc additive manufacturing

[J].

电弧增材制造的304LN微观组织与力学性能研究

[J].

Transmission electron microscopy study of complex oxide scales on DIN 1. 4970 steel exposed to liquid Pb-Bi eutectic

[J].The deployment of Gen-IV lead-cooled fast reactors requires a good compatibility between the selected structural/cladding steels and the inherently corrosive heavy liquid metal coolant. An effective liquid metal corrosion mitigation strategy involves the in-situ steel passivation in contact with the oxygen-containing Pb-alloy coolant. Transmission electron microscopy was used in this work to study the multi-layered oxide scales forming on an austenitic stainless steel fuel cladding exposed to oxygen-containing (C-O approximate to 10(-6) mass%) static liquid lead bismuth eutectic (LBE) for 1000 h between 400 and 500 degrees C. The oxide scale constituents were analyzed, including the intertwined phases comprising the innermost biphasic layer.

Transmission electron microscopy (TEM) on oxide layers formed on D9 stainless steel in lead bismuth eutectic (LBE)

[J].

Corrosion behavior of a Cr-Al coating deposited on 304 austenitic stainless steel by multi-arc ion plating in liquid lead-bismuth eutectic

[J].In this paper, a Cr-Al coating was deposited using multi-arc ion plating (MAIP) on 304 austenitic stainless steel. The Cr-Al-coated sample was treated by vacuum annealing at 600 °C for 12 h, and its corrosion behaviors against static LBE were carefully evaluated by SEM, EDS and XPS at a temperature of 600 °C for 1000 h, compared with an uncoated sample. The results showed that the uncoated sample was corroded by the dissolution and oxidation of LBE severely; a duplex-layered oxide layer consisting of an outer Fe3O4 magnetite layer and an inner FeCr2O4 spinel layer was produced on the surface of 304 stainless steel after LBE corrosion. For Cr-Al diffusion coating, an oxide layer was formed that separated the LBE into the 304 matrix. XPS detection showed that the oxide layer primarily included Al2O3. Besides this, the hardness of the coating was tested with a Vickers hardness tester, and the annealed Cr-Al diffusion coating exhibited an average hardness of 260 HV, about five times as high as the Al coating before annealing, of which the average hardness was 48 HV.

Comparison of the corrosion behavior of austenitic and ferritic/martensitic steels exposed to static liquid Pb-Bi at 450 and 550 oC

[J].

Dissolution mechanism of 316L in lead-bismuth eutectic at 500 oC

[J].