CoCrNi中熵合金(Medium-entropy alloys,MEAs)作为新型多组元先进材料体系,突破了传统合金受限于多元相图的设计框架,近年来受到广泛关注[1~5]。通过近等原子比的合金化设计,将高温合金基体元素Co、Ni与抗氧化核心元素Cr相结合,成功制备出具有面心立方(FCC)结构的单相固溶体。研究表明[6,7],其卓越的力学性能源于高熵效应、晶格畸变效应、缓慢扩散效应、“鸡尾酒效应”和中/短程有序的协同作用机制。此外,该合金在抗腐蚀性能方面亦展现出显著优势,这种特性可归因于多重强化效应的协同增效作用。Agustianingrum等[8]对比研究了CoCrNi合金、CoCrFeNiMn合金、304不锈钢的高温氧化行为。在900~1100 ℃下,CoCrNi的氧化速率常数(kp)远低于其他两者,900、1000和1100 ℃下kp分别为4.39 × 10-2、1.58 × 10-1和2.94 mg2·cm-4·h-1;Adomako等[9]对比了轧制CoCrNi、CoCrNiMn和CoCrFeNiMn合金在空气气氛下的高温氧化行为,在900和1000 ℃下,CoCrNi的kp分别为2.52 × 10-13和4.78 × 10-12 g2·cm-4·s-1,较CoCrNiMn和CoCrFeNiMn合金低两个数量级。上述研究表明了CoCrNi MEA具有良好的高温抗氧化性能。

传统的合金制备工艺材料利用率低、设计自由度受限、多工序迭代周期冗长,导致合金部件生产效率低下。相比之下,激光粉末床熔融(Laser powder bed fusion,LPBF)技术凭借其快速成形、高自由度、高相对密度、高材料利用率的优势,能够实现高性能合金的短流程、定制化制造[10]。目前已有许多研究聚焦于增材制造合金微观结构对合金氧化性能的影响,如Guo等[11]研究表明,原子排列高度有序的孪晶界可以通过抑制原子扩散而提升抗氧化性能;Jia和Gu[12]研究表明LPBF Inconel 718合金的细小亚晶粒促使氧化膜孔隙率下降,显著提升膜层致密性和结合力;Huang等[13]揭示了LPBF Inconel 625合金中<100>取向产生的高角度晶界为金属原子扩散提供了短路通道,重合位置点阵晶界延缓了氧的扩散而延迟了晶间氧化。这些研究为理解LPBF技术对合金耐蚀性的调控机制提供了重要依据。

在实际工业环境中,如热力发电过程中,锅炉中高温过热器和锅炉水冷壁等关键构件长期面临燃料烟气沉积形成的熔盐腐蚀问题,显著降低设备服役寿命的同时构成了重大安全隐患[14,15]。与气氛环境不同,高温熔融盐环境中的熔盐介质可通过破坏金属表面保护性氧化膜(如Al2O3、Cr2O3等)削弱其防护能力。同时,熔盐作为离子导体可能诱发微电偶腐蚀,导致合金表面产生局部电位差加剧腐蚀[16]。尽管LPBF CoCrNi MEA已展现优异抗氧化性能,但其在熔盐环境中的热腐蚀行为仍鲜见报道。本文采用电化学阻抗谱测试技术对比研究了LPBF和轧制CoCrNi MEA在650 ℃、50%KCl + 50%Na2SO4 (质量分数,%)盐膜下的电化学腐蚀行为,探索微观组织对于合金熔盐电化学腐蚀行为的影响机制,为LPBF CoCrNi MEA在极端环境中的应用提供关键理论支撑。

1 实验方法

1.1 LPBF和轧制CoCrNi中熵合金的制备

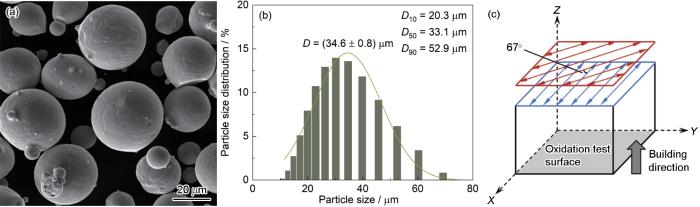

本研究使用的气雾化CoCrNi粉末由北京研邦新材料科技有限公司提供。粉末呈现球型或近球形,有小部分伴有卫星粒子(图1a),粉末平均粒径约为(34.6 ± 0.8) μm (图1b),其化学成分(质量分数,%):Co 34.70,Cr 30.55,Ni 34.54,C 0.0066,S 0.001,N 0.006。采用BLT_S210 LPBF熔化设备制备CoCrNi中熵合金。LPBF过程在高纯度氩气氛中进行(成形室中氧气体积分数小于0.1%),使用316L不锈钢板作为构建基板并预热到373 K。工艺参数为:扫描速度(V)为700 mm/s,层厚(D)为0.03 mm,扫描间距(h)为0.1 mm,激光功率(P)为225 W,扫描策略为在相邻上下两层旋转67°。在试样成形后,采用阿基米德排水法测量得到LPBF CoCrNi MEA的致密度为98.87%,表明成形样品质量较好。研究中用于对比实验的轧制CoCrNi由北京研邦新材料科技有限公司提供,样品通过浇注成型并进行轧制。LPBF成形样品和轧制样品均通过线切割设备制成尺寸为6 mm × 6 mm × 3 mm的样品。

图1

图1

LPBF用CoCrNi MEA粉末的形貌、粒径分布和扫描策略示意图

Fig.1

Morphology of CoCrNi MEA powder for LPBF (a), particle size distribution (b) and schematic illustration of the scanning strategy (c)

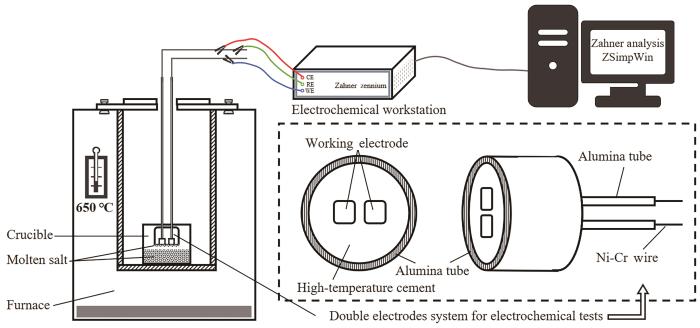

1.2 电化学阻抗谱测试

将试样焊接到Ni-Cr丝一端,使用Al2O3细条状套管对Ni-Cr丝进行保护。选用两个相同样品作为电极,并用高温水泥将电极嵌入Al2O3环形套管中,电极间保持2 mm间距。待高温水泥凝固并与电极结合紧密后,将电极表面用砂纸打磨,清洗后干燥。将KCl和Na2SO4以1∶1质量比混合,共50 g。并将混合盐研磨充分后倒入坩埚,在井式炉中以650 ℃熔融状态稳定后将双电极浸入熔盐,使电极表面被盐膜覆盖后提起并悬空静置。此时合金发生高温热腐蚀现象,整个腐蚀过程持续48 h。采用Zennium系列电化学分析系统对双电极体系进行电化学阻抗谱(EIS)监测。测试时对体系施加10 mV振幅的正弦交流电位扰动,频率扫描范围覆盖104~10-2 Hz宽频域。阻抗谱解析采用ZsimpWin电化学分析软件进行等效电路建模,通过最小二乘法迭代优化实现数据拟合。熔盐电化学测试系统如图2所示,包含Al2O3陶瓷反应腔体、可控气氛环境模块及高温恒电位控制单元,有效保障了实验体系的温度稳定性和测试重复性。

图2

1.3 微观结构表征

采用Bruker D8A A25 型X射线衍射仪(XRD)对实验前的样品进行表征,测试条件设定为Cu靶光源(工作参数40 mA/40 kV),扫描速率为5 (°)/min,扫描范围覆盖30°~80°衍射角。实验数据通过MDI Jade 6.5软件进行解析。为了解LPBF和轧制CoCrNi样品的微观结构和晶体学特征,使用20 mL酒精、20 mL HCl和1 g CuCl2组成的刻蚀液,对样品进行30 s的抛光蚀刻,使用FQ-B3230型光学显微镜观察样品的晶粒形貌。将样品表面用2500#的SiC砂纸进行打磨并抛光,然后通过高氯酸和酒精(配比为1∶4)的电解液,在-20 ℃和30 V电压下电抛光3 s,在SUPRATM55扫描电子显微镜(SEM)上进行了电子背向散射衍射(EBSD)表征,并用取向成像显微镜(OIM)配置软件对所得数据进行分析。

将腐蚀结束后的样品干燥后放入去离子水中煮沸10 min,以去除表面的盐的残留,干燥后进行XRD分析,表征腐蚀后样品的表面物相。采用扫描电子显微镜联用能谱仪(EDS)对样品的截面形貌和元素分布进行表征,确定氧化物的形貌和元素组成。

2 实验结果

2.1 微观组织

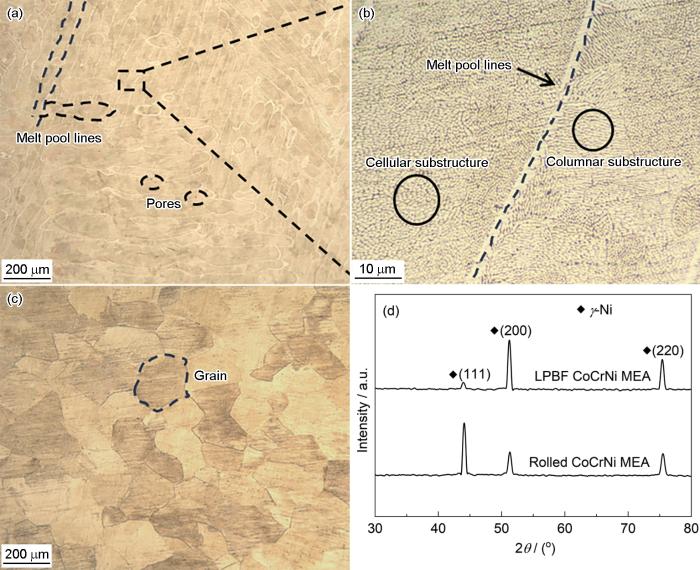

LPBF CoCrNi和轧制CoCrNi的金相组织如图3所示。在试样成形后,采用阿基米德排水法测量了LPBF CoCrNi MEA的致密度,为98.87%,表明成形样品质量较好。图3a显示,LPBF CoCrNi合金显示出明显的熔池线和交叉熔池轨迹,反映了用于样品制备的67°扫描策略特征,熔池线和交叉熔池轨迹是由先沉积层和新粉末同时重熔和快速凝固而沿着构建方向形成[17]。在高倍率下(图3b),LPBF成形合金中存在较多的亚晶粒结构,其中大多数为胞状亚晶粒,少数柱状亚晶粒沿着熔池边界成核,这是LPBF成形镍基高温合金典型的微观特征[18]。而在轧制CoCrNi合金中(图3c),晶粒的平均晶粒尺寸为150 μm左右,晶粒形貌呈近等轴状。XRD衍射图谱表明样品均由面心立方(FCC)结构的γ-Ni相组成,LPBF成形合金中的(200)峰强度最强,而(111)晶面最弱。轧制CoCrNi MEA则呈现出最强的(111)峰,(200)和(220)晶面弱于LPBF合金。在LPBF工艺中,晶体会沿最大热梯度方向(通常为构建方向)在形核基底上外延生长[19]。对于FCC结构的CoCrNi合金,<001>取向因原子排列密度低、固液界面能最小化,因此成为优先生长方向。而轧制作为塑性变形过程,由于合金的滑移系统为{111}<110>。变形时晶粒通过滑移转动,使{111}面平行于轧面(ND方向),<110>方向平行于轧向(RD),最终形成了稳定的<111>//ND纤维织构。

图3

图3

LPBF CoCrNi和轧制CoCrNi合金的金相显微结构和XRD谱图

Fig.3

LPBF CoCrNi MEA at low magnification (a), LPBF CoCrNi MEA at high magnification (b), rolled CoCrNi MEA at low magnification (c) and XRD profiles of LPBF and rolled CoCrNi MEAs (d)

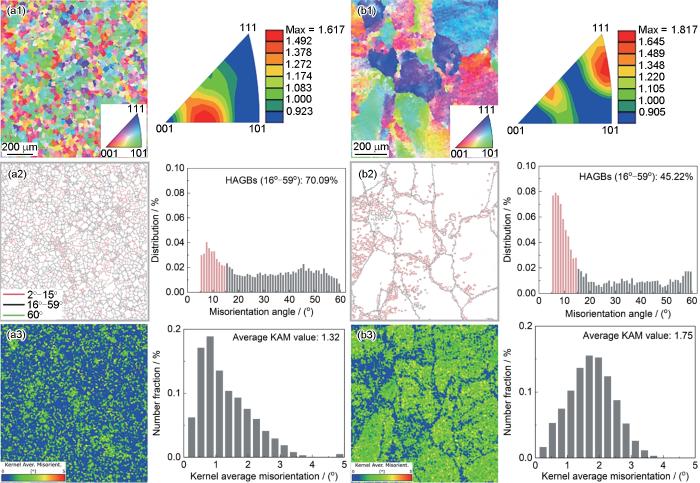

采用EBSD技术对LPBF和轧制CoCrNi MEA进行微观组织结构(图4)。结果显示,LPBF成形合金晶粒沿<001>方向呈现显著择优取向,这与LPBF熔化制造过程中沿构建方向的热梯度诱导外延生长机制密切相关[20]。而轧制CoCrNi MEA平均晶粒尺寸显著增大,数据统计近似为158 μm,且呈现<111>方向择优生长特征。晶界特征分析(图4a2,b2)显示,LPBF成形合金中高角度晶界(HAGB,16°~59°)占比达70.10%,显著高于轧制合金的高角度晶界占比(45.22%)。两种合金中高角度晶界均呈现均匀分布特征,且均未观察到孪晶结构。通过核平均取向差(KAM)图谱及量化分析(图4a3,b3)发现,LPBF成形合金平均KAM值(1.32)明显低于轧制合金的平均KAM值(1.75),表明轧制工艺在材料中引入了更高的位错密度。

图4

图4

LPBF CoCrNi和轧制CoCrNi合金的EBSD结构表征图集

Fig.4

EBSD characterization of LPBF and rolled CoCrNi MEAs: (a1, b1) grain orientation maps and inverse pole figures,(a2, b2) grain boundary misorientation distribution histograms, (a3, b3) Kernel average misorientation (KAM) mappings

2.2 电化学阻抗谱

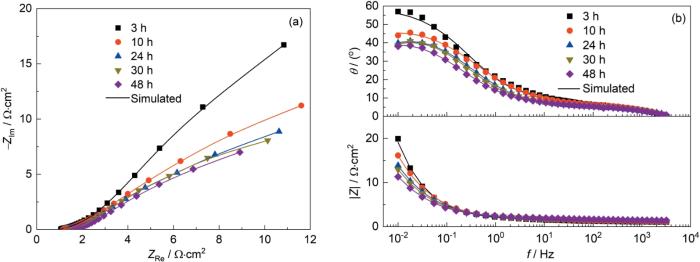

图5

图5

LPBF CoCrNi MEA在高温盐膜腐蚀下的阻抗特征

Fig.5

Nyquist plots (a) and Bode plots (b) of EIS spectrum of LPBF CoCrNi MEAs under salt film corrosion

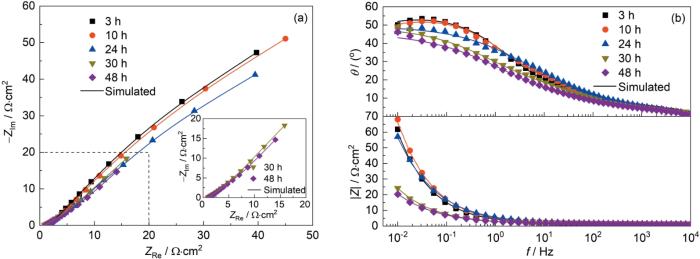

图6

图6

轧制CoCrNi MEA在高温盐膜腐蚀下的阻抗特征

Fig.6

Nyquist plots (a) and Bode plots (b) of EIS spectrum of rolled CoCrNi MEAs under salt film corrosion

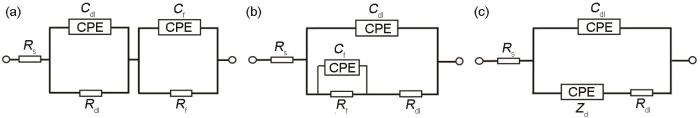

采用如图7所示的等效电路分别对LPBF和轧制CoCrNi MEA在不同时间腐蚀下的电化学阻抗谱进行拟合[23],具体的拟合结果列于表1。LPBF与轧制CoCrNi MEA在熔盐腐蚀第一阶段(0~10 h和0~24 h)由于表面腐蚀层维持了稳定的消耗愈合过程,合金表面存在完整致密的氧化膜[24,30,35],于是均采用(图7a)所示的腐蚀产物层电容与双电层电容串联的等效电路进行拟合。电路模型中各元件物理意义如下:Rs表征熔融盐电阻,反映熔融盐膜的离子导电能力;Cdl表征合金/熔融盐界面双电层电容,其中常用常相位元件(CPE)替代理想电容,用于修正实际双电层电容的非理想特性(受表面粗糙度、化学异质性等因素影响),而与其串联或者并联的Rdl表征电化学反应电荷转移电阻,反映了电化学难易度;Cf表征膜层电容,Rf表征腐蚀产物层电阻,反映了表面钝化膜或腐蚀产物层的离子传输阻力。对于两种合金而言,弥散系数ndl和nf明显偏离1,存在弥散效应,这也是合金发生熔盐腐蚀的一个显著特征[24]。

图7

图7

LPBF CoCrNi和轧制CoCrNi合金的拟合等效电路

Fig.7

Equivalent circuits representing the corrosion of LPBF CoCrNi MEAs and rolled CoCrNi MEAs beneath a molten 50%KCl + 50%Na2SO4 film at 650 oC in air: (a) when the alloy is covered with a complete and dense protective salt layer, (b) when the alloy is covered with a loose, porous and uneven protective salt layer, (c) when the alloy is under charge transfer and diffusion control

表1 LPBF和轧制CoCrNi MEA在高温盐膜腐蚀下的电化学阻抗谱拟合参数

Table 1

| Alloy | Time | Rs | Y0, dl | ndl | Rdl | Y0, d | nd | Y0, f | nf | Rf |

|---|---|---|---|---|---|---|---|---|---|---|

| / h | / Ω·cm2 | / Ω-1·cm-2·s-n | / Ω·cm2 | / Ω-1·cm-2·s-n | / Ω-1·cm-2·s-n | / Ω·cm2 | ||||

| LPBF CoCrNi | 3 | 0.969 | 0.620 | 0.611 | 7.864 | - | - | 0.560 | 0.838 | 114.6 |

| 10 | 1.128 | 0.063 | 0.559 | 0.699 | - | - | 0.268 | 0.609 | 167.3 | |

| 24 | 1.142 | 0.075 | 0.527 | 0.722 | - | - | 0.308 | 0.669 | 63.69 | |

| 30 | 1.126 | 0.088 | 0.509 | 0.817 | - | - | 0.326 | 0.689 | 64.28 | |

| 48 | 1.185 | 0.106 | 0.479 | 0.979 | - | - | 0.360 | 0.707 | 65.82 | |

| Rolled CoCrNi | 3 | 1.059 | 0.237 | 0.800 | 3.467 | - | - | 0.109 | 0.715 | 259.7 |

| 10 | 1.154 | 0.159 | 0.404 | 4.471 | - | - | 0.098 | 0.723 | 244.1 | |

| 24 | 1.190 | 0.155 | 0.409 | 8.789 | - | - | 0.111 | 0.677 | 280.7 | |

| 30 | 0.973 | 0.100 | 0.529 | 2.127 | 0.095 | 0.5601 | - | - | - | |

| 48 | 0.998 | 0.080 | 0.514 | 0.8853 | 0.131 | 0.5054 | - | - | - |

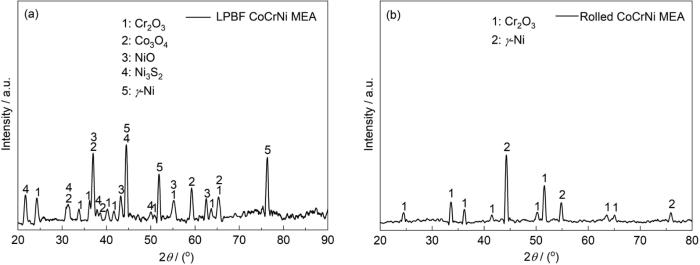

2.3 腐蚀产物成分及结构

LPBF和轧制CoCrNi MEA在50%KCl + 50% Na2SO4盐膜腐蚀48 h后表面的XRD图谱如图8所示。LPBF CoCrNi MEA的腐蚀后的表面主要由Cr2O3、Co3O4、NiO和Ni3S2组成,轧制CoCrNi MEA表面仅有Cr2O3生成。

图8

图8

LPBF和轧制CoCrNi MEA在50%KCl + 50%Na2SO4盐膜腐蚀48 h后的XRD图谱

Fig.8

XRD pattern of LPBF CoCrNi MEA (a) and rolled CoCrNi MEA (b) corrosion in the presence of 50%KCl + 50% Na2SO4 film for 48 h

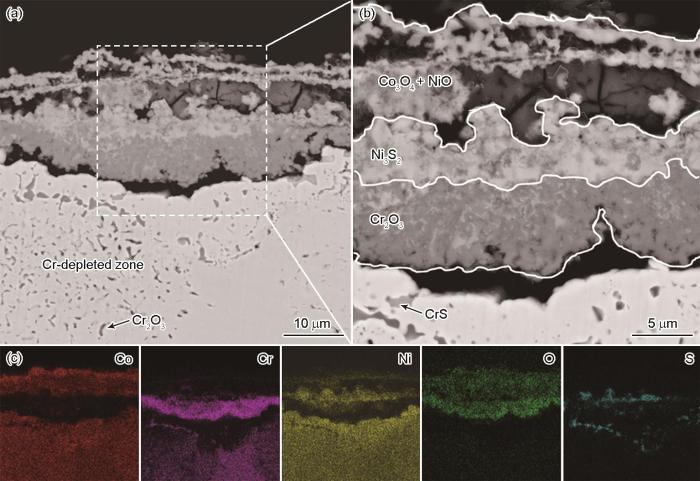

图9

图9

LPBF CoCrNi MEA在50%KCl + 50%Na2SO4盐膜腐蚀48 h后的截面形貌和元素EDS分布图

Fig.9

Cross-section morphologies of LPBF CoCrNi MEA of corrosion in the presence of 50%KCl + 50%Na2SO4 film for 48 h: (a) low magnification, (b) high magnification, (c) element EDS map

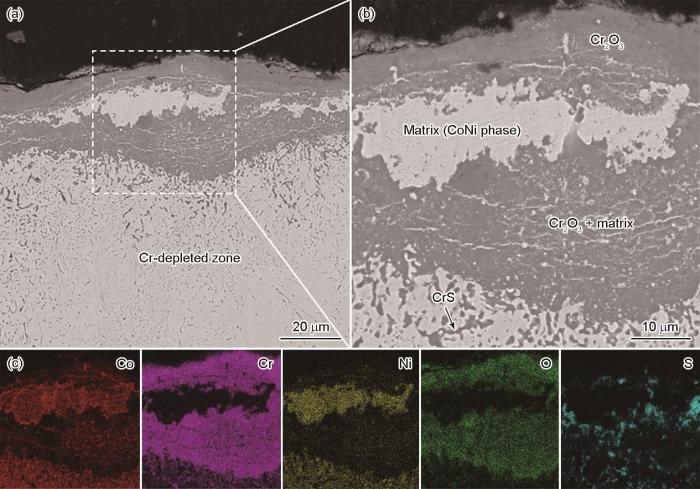

图10

图10

轧制CoCrNi MEA在50%KCl + 50%Na2SO4盐膜腐蚀48 h后的截面形貌和元素EDS分布图

Fig.10

Cross-section morphologies of rolled CoCrNi MEA of corrosion in the presence of 50%KCl + 50%Na2SO4 film for 48 h: (a) low magnification, (b) high magnification, (c) element EDS map

3 讨论

由上述结果分析可知,LPBF和轧制CoCrNi中熵合金在50%KCl + 50%Na2SO4盐膜作用下均发生了严重的腐蚀。电化学反应是金属熔融盐热腐蚀过程中的典型特征,主要表现为金属原子发生阳极反应而析出电子,腐蚀环境中的熔融盐和氧气发生阴极反应得到电子[25],具体反应式如下:

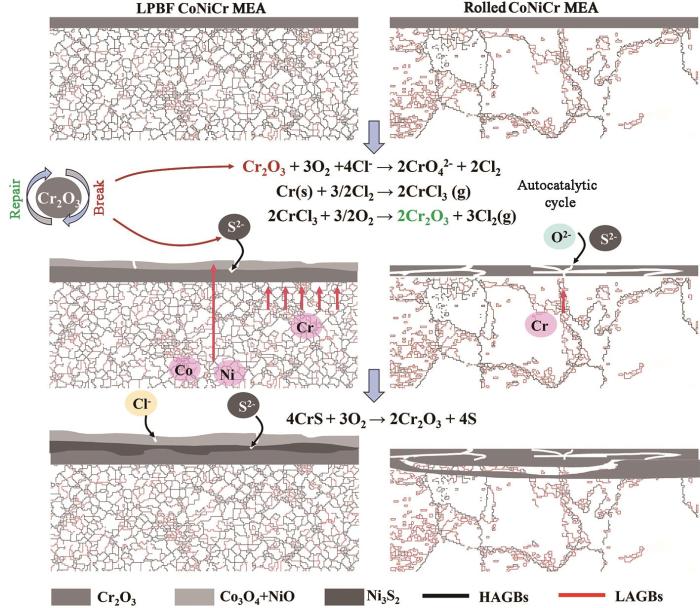

同时,在热腐蚀过程中,往往会经历氧化膜生成、氧化膜溶解、氧化膜破裂以及内氧/硫化过程[25]。晶界作为腐蚀反应的关键路径,其类型(HAGB/LAGB)显著影响元素扩散和腐蚀进程。EBSD统计结果(图4)显示LPBF合金中HAGB占比高达70.10%,而轧制合金仅为45.22%。由于HAGB原子排列高度无序且晶界能高,其作为快速扩散通道的能力远强于LAGB[26,27]。图11为LPBF与轧制CoCrNi MEA在50%KCl-50%Na2SO4熔融盐膜中的腐蚀机理示意图。对于LPBF CoCrNi MEA而言,合金中大量的晶界以及晶界中高比例的HAGB显著提升了Cr的扩散速率[30]。基于热力学分析,生成Cr2O3的Gibbs自由能低于CrS[31],这促使腐蚀初期合金表面快速形成致密的Cr2O3膜,阻抗谱呈现出双容抗特征[24,25],该保护膜有效抑制了O2-和S2-的向内扩散。然而,高温下Cr2O3催化Cl⁻氧化生成Cl2 (

图11

图11

LPBF与轧制CoCrNi MEA在50%KCl-50%Na2SO4熔融盐膜中的腐蚀机理示意图

Fig.11

Schematic diagram illustrating the corrosion mechanisms of LPBF and rolled CoCrNi MEAs under a 50%KCl-50% Na2SO4 molten salt film

这一过程中不断消耗合金中的Cr,造成基体内部出现Cr贫化区域。Cr的贫化会诱发合金中Ni和Co向外扩散,还因LPBF成形合金中的<001>择优取向特征导致Co/Ni沿特定晶面的扩散激活能显著降低[34],促进了Ni和Co沿Cr2O3膜裂纹快速外迁,最终在表层形成Co3O4和NiO。由于Cl-在Co3O4/NiO晶格缺陷处的优先吸附会引发局部电化学溶解[35],使外层Co3O4/NiO膜出现局部溶解和孔隙,这为S2-的渗透创造了通道,进而在NiO/Cr2O3界面S2-与Ni发生反应生成连续的Ni3S2。该硫化物层作为扩散屏障阻断了Cr2O3与Co3O4和NiO间的物质交换,抑制了尖晶石结构的固相合成。在硫化产物形成后,一方面由于Ni3S2在熔盐中的溶解度较低[26],有效抑制了Cl-对Cr2O3的化学侵蚀,促进内层Cr2O3膜的动态修复;另一方面Ni3S2导致了熔盐体系中的熔盐碱度升高[27],导致金属氧化物发生酸性溶解,使得腐蚀产物层疏松。在腐蚀产物层多层结构形成的过程中,少量O2-和S2-扩散到合金内部,在合金内部生成CrS和Cr2O3。但由于Cr2O3自愈合程度较高,阻挡了O2-和S2-向合金内部进一步扩散,因此抑制了合金的内腐蚀[36],保持了愈合和消耗的动态平衡。在达到平衡后,疏松产物层逐渐修复,开始起到保护作用,阻抗值也缓慢增加(表1)。

对于轧制CoCrNi MEA而言,在腐蚀初期,由于合金中较高的Cr含量,其表面生成相对连续的Cr2O3膜,阻抗谱表现为双容抗特征。然而,当Cl-与Cr2O3反应(如式

产生的S进一步向内扩散与活泼元素反应。由于腐蚀介质在腐蚀过程中不断向合金内部扩散,因此阻抗谱呈现明显的扩散规律。此外,电化学腐蚀是熔盐引发的热腐蚀的典型特征。一般而言,晶界处因高自由能态及原子排列无序、化学不均匀性[38],在热腐蚀过程中更容易发生腐蚀。具体表现为晶界处原子优先失去电子发生氧化反应,而相对稳定的晶粒内部则发生还原反应,从而构成了腐蚀微电偶[39]。这种微观电偶腐蚀效应有明显的电流集中现象,加剧了局部区域的腐蚀进程。因此,尽管LPBF CoCrNi中较高的晶界密度有利于Cr向外扩散,但由于其较高的晶界密度也促进了合金表面的电化学反应,从而导致LPBF成形合金在腐蚀过程中的电化学阻抗模值低于轧制合金。

4 结论

CoCrNi MEA在两种工艺下成形后,均呈现单相面心立方的γ相固溶体结构。LPBF CoCrNi MEA由胞状晶与柱状晶组成,沿<001>方向择优生长。轧制CoCrNi MEA为等轴晶结构,低角度晶界比例和位错密度高于前者。

在650 ℃的50%KCl + 50%Na2SO4熔融盐环境下腐蚀48 h过程中,LPBF CoCrNi MEA在腐蚀周期内呈双容抗弧响应。轧制CoCrNi MEA在腐蚀初期电化学阻抗谱呈双容抗特征,随着腐蚀时间延长转变为扩散特征。

LPBF CoCrNi MEA在腐蚀48 h后腐蚀产物层呈现梯度化多层结构,包括外层Co3O4、NiO、Ni3S2和内层Cr2O3。轧制CoCrNi MEA形成单一的Cr2O3膜,合金内部存在严重的内腐蚀。

参考文献

Microstructural development in equiatomic multicomponent alloys

[J].

High-entropy alloys: A critical review

[J].

Nanostructured high-entropy alloys with multiple principal elements: Novel alloy design concepts and outcomes

[J].

Effects of lattice distortion and chemical short-range order on the mechanisms of deformation in medium entropy alloy CoCrNi

[J].

Reasons for the superior mechanical properties of medium-entropy CrCoNi compared to high-entropy CrMnFeCoNi

[J].

Exceptional damage-tolerance of a medium-entropy alloy CrCoNi at cryogenic temperatures

[J].High-entropy alloys are an intriguing new class of metallic materials that derive their properties from being multi-element systems that can crystallize as a single phase, despite containing high concentrations of five or more elements with different crystal structures. Here we examine an equiatomic medium-entropy alloy containing only three elements, CrCoNi, as a single-phase face-centred cubic solid solution, which displays strength-toughness properties that exceed those of all high-entropy alloys and most multi-phase alloys. At room temperature, the alloy shows tensile strengths of almost 1 GPa, failure strains of similar to 70% and K-JIc fracture-toughness values above 200 MPa m(1/2); at cryogenic temperatures strength, ductility and toughness of the CrCoNi alloy improve to strength levels above 1.3 GPa, failure strains up to 90% and K-JIc values of 275 MPa m(1/2). Such properties appear to result from continuous steady strain hardening, which acts to suppress plastic instability, resulting from pronounced dislocation activity and deformation-induced nano-twinning.

High-temperature oxidation behaviour of CoCrNi medium-entropy alloy

[J].

High-temperature oxidation behaviour of low-entropy alloy to medium- and high-entropy alloys

[J].

High-temperature oxidation behavior of laser additively manufactured AlCoCrFeNiSi high entropy alloy

[J].

激光增材制造AlCoCrFeNiSi高熵合金的氧化行为

[J].利用激光熔化沉积技术(LMD)增材制造了具有单相bcc结构的Al<sub>0.21</sub>Co<sub>0.17</sub>Cr<sub>0.13</sub>Fe<sub>0.11</sub>Ni<sub>0.18</sub>Si<sub>0.20</sub> (原子分数)高熵合金(HEA),其晶粒尺寸随着激光功率从900 W降低至700 W而逐步减小。在1100 ℃“干”空气和含10%H<sub>2</sub>O (体积分数)的“湿”空气的恒温氧化实验表明:该HEA能稳定生长单一的Al<sub>2</sub>O<sub>3</sub>膜;晶粒尺寸减小导致所生长Al<sub>2</sub>O<sub>3</sub>膜的氧化速度降低;H<sub>2</sub>O蒸气加快Al<sub>2</sub>O<sub>3</sub>膜生长速度。

Anomalous solidification microstructures in Co-free Al x CrCuFeNi2 high-entropy alloys

[J].

Selective laser melting additive manufactured Inconel 718 superalloy parts: High-temperature oxidation property and its mechanisms

[J].

Effect of scanning speed on the high-temperature oxidation resistance and mechanical properties of Inconel 625 alloys fabricated by selective laser melting

[J].

Reasons and prevention measures for high-temperature corrosion of water-cooled walls in coal-fired boilers

[J].

燃煤锅炉水冷壁高温腐蚀形成原因及防治措施

[J].

Corrosion analysis of high-temperature superheater tubes of a waste incineration boiler

[J].The effect of an aqueous extract of Cupressus sempervirens on the corrosion manner of carbon steel in 1M hydrochloric acid solution has been measured by mass reduction, hydrogen evolution, electrochemical frequency modulation (EFM), potentiodynamic polarization, and electrochemical impedance spectroscopy (EIS) methods The efficiency of Cupressus sempervirens extract was examined with increasing dose of the extract and the temperature. The parameters of thermodynamic of corrosion and adsorption processes were measured and discussed. The extract was adsorbed on surface of metal chemically and was obtain obey Temkin isotherm. The potentiodynamic polarization resulted lead to the extract is mixed inhibitor type. The results given from the various methods were in best agreement.

某垃圾焚烧锅炉内高温过热器管腐蚀分析

[J].

High temperature corrosion behavior of Sanicro 25 steel in high-sulfur coal ash/simulated flue gas

[J].

Sanicro 25钢在高硫煤灰/模拟烟气中的高温腐蚀行为研究

[J].

A review of metal additive manufacturing technologies: Mechanism of defects formation and simulation of melting and solidification phenomena in laser powder bed fusion process

[J].

Additively manufactured high strength and ductility CrCoNi medium entropy alloy with hierarchical microstructure

[J].

Microstructure and mechanical behavior of additively manufactured CoCrFeMnNi high-entropy alloys: Laser directed energy deposition versus powder bed fusion

[J].

Microstructures and mechanical behaviors of additive manufactured Inconel 625 alloys via selective laser melting and laser engineered net shaping

[J].

Electrochemical impedance studies of the initial-stage corrosion of 310S stainless steel beneath thin film of molten (0.62Li, 0.38K)2CO3 at 650 oC

[J].

Electrochemical impedance spectroscopy (EIS): An efficient technique for monitoring corrosion processes in molten salt environments in CSP applications

[J].

Electrochemical impedance spectroscopy investigation of alloy Inconel 718 in molten salts at high temperature

[J].

Electrochemical impedance study of (Na, K)2SO4 induced hot corrosion of pure nickel and Ni-based superalloy M38G

[J].

(Na, K)2SO4沉积引起的纯Ni和M38G合金热腐蚀的电化学阻抗研究

[J].

Corrosion electrochemical-impedance of Fe-Cr alloys in eutectic (Li, K)2CO3 mixture at 650 oC

[J].

Fe-Cr合金在650 ℃共晶(Li, K)2CO3熔盐中的腐蚀电化学阻抗谱研究

[J].应用电化学阻技术并结合物相分析技术研究了合金元素Cr对Fe在650℃(Li,K)2CO3共晶熔盐中的腐蚀行为的影响。结果表明,加入5%和10%Cr不能改善Fe的耐腐蚀性能,而加入20%和25%Cr则能显著提高其耐腐蚀性能;Fe及Fe-Cr合金腐蚀电化学阻抗谱呈双容抗弧特征,合金腐蚀受荷电粒子在氧化膜中的迁移控制。提出将合金表面形成的氧化膜理想化为一电容器,并建立了氧化物电容与双电层电容相串联的等效电路来描述合金腐蚀的阻抗特征.此外,根据所提供等效电路对合金腐蚀电化学阻抗谱进行了解析.

Electrochemical impedance studies of molten (0.9Na, 0.1K)2SO4-induced hot corrosion of the Ni-based superalloy M38G at 900 oC in air

[J].

Comparison on hot corrosion behaviors of Ni-base superalloy DD5, DD10 and DSM11

[J].

镍基高温合金DD5、DD10和DSM11热腐蚀行为比较

[J].

Corrosion mechanism of cold forged 316 stainless steel in molten FLiNaK salt

[J].

Study of corrosion behavior of Inconel 625 cladding metal in KCl-MgCl2 molten salt under isothermal and thermal cycling conditions

[J].

Thermal oxidation behavior of CoCrNi medium-entropy alloy bond coatings deposited using laser cladding process

[J].

Hot corrosion behavior of Inconel 625 alloys fabricated by selective laser melting

[J].

激光选区熔化Inconel 625合金的高温热腐蚀行为

[J].

Hot corrosion of T91 steel in molten mixture of KCl + Na2SO4 + K2SO4

[J].

T91钢在KCl + Na2SO4 + K2SO4熔融盐中的热腐蚀行为研究

[J].研究了T91钢在600,650和700 ℃10%KCl+10%K<sub>2</sub>SO<sub>4</sub>+80%Na<sub>2</sub>SO<sub>4</sub> (质量分数) 混合熔融盐中的热腐蚀行为。采用XRD,SEM /EDS对腐蚀产物膜相组成和形貌进行了分析。结果表明,T91钢在腐蚀过程中均表现为失重,特别是在650和700 ℃下失重尤为严重。600 ℃下的腐蚀产物膜主要由Fe<sub>3</sub>O<sub>4</sub>组成;而650和700 ℃下的腐蚀产物膜基本剥落殆尽,EDS分析表明残留的腐蚀产物中S含量较高,这导致腐蚀产物严重剥落。熔盐中Cl可与Cr<sub>2</sub>O<sub>3</sub>反应生成挥发性的CrO<sub>2</sub>Cl<sub>2</sub>,导致腐蚀进一步加速。

Hot corrosion behavior of Pt + Hf co-modified NiAl coating in the mixed salt of Na2SO4-NaCl at 900 oC

[J].

Effects of overlapping process on grain orientation and microstructure of nickel-based single-crystal superalloy DD491 fabricated by selective laser melting

[J].Aero-engine turbine blades are operated under harsh conditions such as high temperature, pressure, and load. Therefore, weak grain boundaries at high temperatures should be eliminated from the turbine blades, whereas convection channels inside the blades should be added to dissipate heat. Achieving integrated manufacturing of specialized microstructure in complex components has been a long-term research priority in turbine blade manufacturing. Nickel-based single-crystal superalloys are key materials for manufacturing single-crystal turbine blades for aero-engines, and selective laser melting (SLM) is feasible and technically advantageous for manufacturing complex components with single-crystal microstructures. Owing to the extremely high temperature gradient and scanning speed during SLM, the melt pool is unstable, thereby interrupting directional crystal growth. The metallurgical environment of SLM is further complicated by the large number of overlapping tracks and stacking layers. The quality of the overlaps is critical for the integrity of the single-crystal structure during SLM. Herein, the effects of scanning hatch (h = 0.06, 0.09, 0.12, and 0.15 mm) on the melt track morphology, metallurgical defects, crystal orientation, and microstructure of DD491 fourth-generation nickel-based single-crystal superalloy were investigated. Directionally solidified and solution-aged DD6 single-crystal superalloy rods were used as the substrate, and DD491 powder was coated to a thickness of 40 μm. Electron backscatter diffraction was used to characterize the crystal orientation of the samples. Results show that low power/low speed (S1) and high power/high speed (S4) combinations of laser power and scanning speed provide geometrically and metallurgically stable conditions for directional crystal growth, and the grains at the bottom of the melt track can orient the substrate to achieve [001] directional growth. Different types of crystal orientation defects were observed in different regions, including equiaxed stray grains in the top middle region, [010] and [100] columnar stray grains in the top side regions, and small orientation deviation in the internal region. The scanning hatch affected the crystal orientation in the overlapping regions mainly through the remelted proportion of the old melt pool and the substrate microstructure of the new melt pool during solidification. The higher overlapping ratio with a smaller scanning hatch was beneficial for reducing stray grain defects on both sides of the melt tracks. The role of residual heat on solidification conditions was related to the heat gradient vector of laser input, and multitrack overlapping samples under the S1 process accommodated higher residual heat without causing orientation deviation in the overlapping regions. The multitrack overlapping samples under S1, h = 0.06 and0.09 mm, had maximum pole densities along the y-z plane as high as 47.66 and 46.85, respectively, exhibiting a typical [001] single-crystal structure.

搭接工艺对选区激光熔化镍基单晶高温合金DD491晶体取向与微观组织的影响

[J].镍基单晶高温合金是制造航空发动机单晶涡轮叶片的关键材料,选区激光熔化(SLM)制造单晶组织和复杂结构具有技术优势和可行性。在SLM中,熔道与熔道之间的搭接质量对单晶组织的完整性至关重要。本工作在4种激光功率和扫描速率的组合工艺下,探究了扫描间距(0.06、0.09、0.12和0.15 mm)对第四代镍基单晶高温合金DD491熔道微观形貌、冶金缺陷、晶体取向和微观组织的影响。结果表明,低功率、低速率和高功率、高速率的工艺参数能够为晶体定向生长提供稳定的几何形态和冶金条件,熔道底部晶体能够延续基底取向实现[001]定向生长。熔道内不同区域存在不同类型的晶体取向缺陷,包括顶部中间等轴晶、顶部[010]和[100]柱状杂晶、内部小角度取向偏差等。较小扫描间距的熔道重熔率较高,有利于减少熔道两侧的杂晶缺陷。

Theoretical study in adsorption behavior of S and Cl on surface and its effect on corrosion performance of γ-FeM (111) (M = Cr, Ni, Mn, Mo, Cu, Ce)

[J].

S、Cl表面吸附及其对γ-FeM(111) (M =Cr、Ni、Mn、Mo、Cu、Ce)腐蚀的理论研究

[J].

Comparing the intergranular oxidation of Ni-Cr and Ni-Al model alloys in 480 oC hydrogenated steam

[J].

High-temperature corrosion resistance of Inconel 718 fabricated by selective laser melting

[J].

激光选区熔化Inconel 718合金高温腐蚀性能

[J].

Progress in interfacial thermodynamics and grain boundary complexion diagram

[J].Grain boundaries (GBs), a crucial component of microstructures, have a significant influence on the properties of materials. The GB complexion (GBC) transitions are essential information to accurately explain numerous material phenomena. However, owing to the complexity of GB structures and the difficulty in observation of GBC transitions, there is still no direct evidence and mechanism explanation for these material phenomena. With the advancement of characterization equipment, especially spherical aberration-correction transmission electron microscopy, coupled with powerful computer simulation, the establishment of interfacial thermodynamic models to construct different types of GBC diagrams, which provide a broad prospect for the study of GB structures and GBC transitions, is essential. In this paper, the progress of interface thermodynamics and GBC diagrams from the aspects of the classification and characterization of GBs and GBC transitions, interface thermodynamic models, and the construction of GBC diagrams were reviewed. The paper also looks forward to the future development of interface thermodynamics and GBC diagrams.

界面热力学与晶界相图的研究进展

[J].

The role of grain boundaries in the corrosion process of Fe surface: Insights from ReaxFF molecular dynamic simulations

[J].Intergranular corrosion is the most common corrosion phenomenon in Fe-based alloys. To better understand the mechanism of intergranular corrosion, the influence of grain boundaries on Fe-H2O interfacial corrosion was studied using molecular dynamics simulation based on a new Fe-H2O reaction force field potential. It is found that the corrosion rate at the polycrystalline grain boundary is significantly faster than that of twin crystals and single crystals. By the analysis of stress, it can be found that the stress at the polycrystalline grain boundary and the sigma5 twin grain boundary decreases sharply during the corrosion process. We believe that the extreme stress released at the grain boundary will promote the dissolution of Fe atoms. The formation of vacancies on the Fe matrix surface will accelerate the diffusion of oxygen atoms. This leads to the occurrence of intergranular corrosion.