核能凭借其低碳稳定、高效集约的技术特性,在未来的发展中具有广阔的前景。然而,自20世纪50年代第一座核电站投运以来,全球范围内曾发生多次核事故,如切尔诺贝利核事故、福岛核事故等,造成了重大的社会和经济损失。运行经验表明,核电材料在高温高压水环境中发生的SCC是核电关键设备和部件失效的主要形式之一[1]。在此环境中,应力与腐蚀介质的协同作用会显著加速材料表面裂纹的萌生与后续扩展,最终引发设备的突发性、灾难性失效。因此,深入理解核电环境下材料的SCC失效机制,对于预测设备寿命和保障核电站安全运行具有重要意义。

304及316不锈钢等传统铸造或锻造的奥氏体不锈钢凭借其优良的综合性能,在国内外压水堆(PWR)一回路系统中得到了广泛应用,例如一回路主管道及堆内构件等[2~5]。然而,在制造复杂几何结构核电部件(如堆内滤网、定位格架等)方面,以选区激光熔化(SLM)为代表的增材制造技术相较于传统成型方式展现出了不可比拟的优势,逐渐成为了行业的研究热点[6,7]。但SLM技术因其高速加热和冷却的特点易在材料内部形成独特的微观结构和应力/应变状态等,如细小的晶粒、位错组态、各向异性、较高的残余应力等,从而影响材料的服役性能[8, 9]。然而,现有研究主要集中于不锈钢SLM工艺参数优化以及组织结构和力学性能、常规腐蚀性能之间的关系,针对模拟压水堆核电高温高压水环境中SCC行为的研究显著缺乏[10~12]。

基于上述现状,本文综述了核用增材制造不锈钢SCC行为的研究进展,具体包括了增材制造不锈钢的微观组织结构特性、核用不锈钢材料和SLM不锈钢在高温高压水中的SCC行为及其影响因素,并探讨了当前增材制造技术在核电应用领域的挑战和未来发展方向,以期为增材制造技术在核工业的安全可靠应用提供参考。

1 增材制造不锈钢的微观组织结构特性

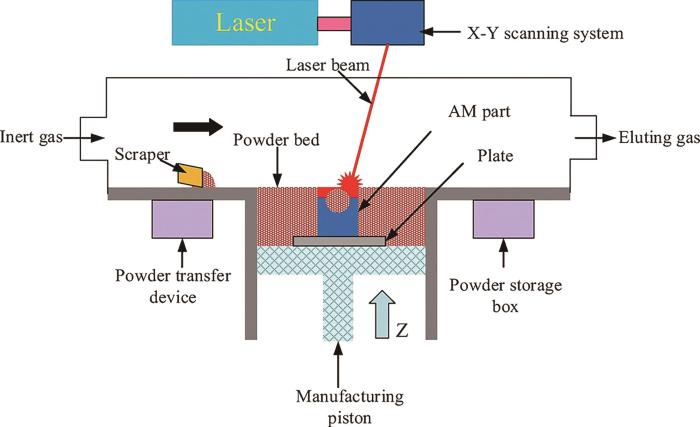

增材制造技术起源于上世纪80年代末,经过几十年的发展,金属的激光增材制造技术已经趋于成熟,在核电领域具有广阔的应用前景。该技术通过高能激光熔化金属粉末来制备构件,根据粉末供给的方式不同,可分为同轴送粉技术和粉末床技术;而根据能量来源的不同又可分为电子束成型或激光束成型等[13]。其中,SLM是基于粉末床熔融技术(PBF)的一种增材制造工艺,被认为是当前增材制造过程中制件精度最高、综合性能最优的成型方法之一[14]。图1展示了SLM成型的过程,它通过激光逐层完全熔化金属粉末来制造高精度零件,可直接从数字模型构建零件,不受模具设计和加工限制,因此适用于制作更为复杂且高精度的核电部件,如蜂窝状支撑结构及复杂冷却通道等[15]。

图1

1.1 SLM不锈钢的微观组织结构

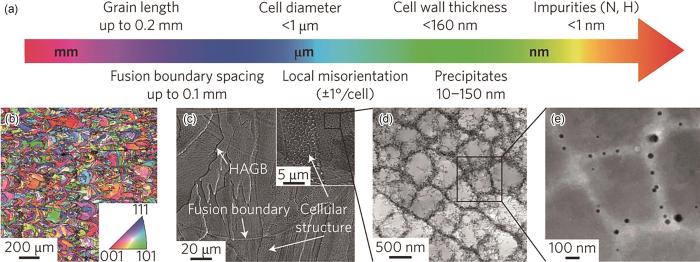

图2

图2

增材制造材料在不同尺度下的组织特征[8]

Fig.2

Microstructural characteristics of additive manufacturing materials at different scales: (a) size range of different special microstructures, (b) EBSD characterization results (IPF), (c) high-angle grain boundaries, fusion boundary and cellular structure measured by scanning electron microscopy, (d) cellular structures measured by transmission electron microscopy, (e) nanoscale precipitates within the cellular structures[8]

在微米级尺度上,能够观察到沿温度梯度方向生长的柱状晶和激光扫描形成的熔池边界。当观察面平行于构建方向时,可以看到细长柱状晶和鱼鳞状熔池线。图3a展示了熔池边界的形成过程,金属粉末在激光的移动扫描下会产生一个不断移动的熔化区域,在液体表面张力的作用下,熔化区域的边缘在冷却后会形成类似于焊缝的熔合线[18]。随着熔化-铺粉过程的不断交替,材料表面在熔化与凝固过程交替作用下形成鱼鳞状的熔化线,即所谓的熔池结构(图3b和c)[17]。同时,熔化与凝固过程交替过程中的热循环也使得SLM材料内部形成了独特的柱状晶结构。一方面,极高的冷却速度使得柱状晶快速沿热流方向生长,避免了二次枝晶臂的生长。另一方面,柱状晶的生长方向是由熔池边界附近的热流方向和晶体的最优生长方向共同决定的。对于奥氏体不锈钢等面心立方金属,其最优生长方向为[001]方向,因此,最新一层的生长方向为最接近温度梯度方向的[001]方向。

图3

图3

SLM材料中的熔池边界形成过程示意图[18]及观察面平行于SLM材料构建方向时所观察到的熔池结构[17]

Fig.3

Molten pool boundary in SLM materials: (a) schematic diagram of the formation process of molten pool boundary[18] (b, c) melten pool structure observed when the observation plane is parallel to the direction of SLM material construction[17]

在纳米尺度上,可以观察到材料内部的位错胞和纳米级夹杂物。SLM材料中存在高密度的位错(密度约为1015 m-2,相当于20%冷加工的不锈钢材料),大量位错的堆积与缠结会在其内部形成特有的位错胞结构[7,19]。关于位错胞的来源,学者提出了多种生成机制[20~23]。例如,Saeidi等[20]认为,位错结构源于快速凝固过程中的溶质偏析;Ramirez等[21]认为,位错是由枝晶之间的沉淀物引入的。Bertsch等[24]在此基础上,制备了具有不同几何特征的SLM 316L不锈钢,通过控制变量进行对比分析,研究表明,SLM技术制造过程中产生的高密度位错结构主要源于快速热循环导致的热应力。此外,制备环境中的氧会优先与粉末中易被氧化元素如Si、Mn等结合,在材料中形成以氧化物为主的纳米级夹杂物[25~27]。一方面,在金属粉末制备的过程中,氧化夹杂物几乎是不可避免的,例如,设备老化、环境污染等问题都会导致SiO2夹杂物的生成[28]。另一方面,金属构件制备过程中也会有氧化夹杂物的产生,制备环境中的氧主要来源于保护气体中掺杂的氧气和粉末表面的氧化物。保护气中的氧会直接与粉末中易氧化的元素相结合,直接形成氧化物;而粉末表面的氧化物首先需要在激光的作用下发生破裂和熔融并释放出氧,然后才会再重新生成氧化物[29]。

1.2 SLM不锈钢中的成型缺陷

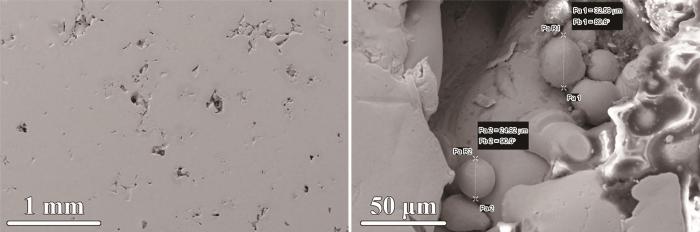

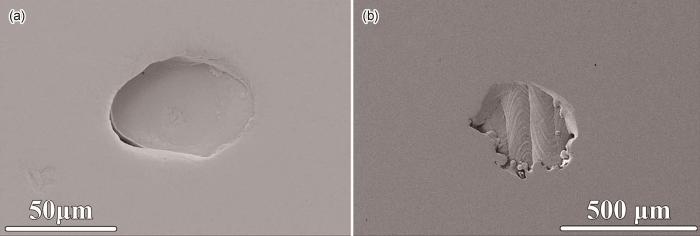

SLM成型使得材料内部形成上述微观组织结构的同时,还会在材料内部形成空隙、气孔等成型缺陷。尽管现有SLM通过工艺控制能使材料的致密度达到99.9%以上,但相较于锻造材料,其内部仍会不可避免的存在少量本征缺陷,从而对材料的SCC行为产生显著影响[30]。这些缺陷的形成主要与SLM工艺参数的选择以及过快的凝固速率有关。例如,当参数选取不当时,未熔化金属粉末之间的空隙以及制备过程中未排出的气体会在材料快速凝固过程中分别形成结合缺陷和气孔[18,31]。图4为未熔化粉末在凝固过程中形成的结合缺陷,图5a为制备过程中残留气体导致的气孔[31]。最后,由于凝固速率过快,金属粉末在短时间内经历固-液-固变化产生的热应力会造成材料的开裂,这种开裂在宏观上表现为层状空隙(图5b)[31]。

图4

图5

1.3 SLM工艺参数对组织结构的影响

SLM制备过程中的主要工艺参数主要包括激光功率、扫描速度、间距和层厚等,它们共同影响着材料的致密度和微观组织结构,进而决定了性能。

层厚是决定增材材料成型效率的主要因素之一,也是影响材料服役性能的重要参数,分为名义层厚和实际层厚。名义层厚是指粉末缸体每次下降的高度,而实际层厚则是每次成型的实际厚度[36]。由于粉末中孔隙的存在,实际层厚通常小于名义层厚。因此,一般情况下所说的“层厚”均指“名义层厚”。层厚增加对增材材料成型效率和服役性能存在协同影响。虽然层厚增大会显著提高材料制备的效率,但层厚的无限制增大也会引入新的问题,比如成型缺陷的增多等,从而降低材料的服役性能,因此,多数增材材料的层厚一般控制在10~50 μm之间[37~39]。近年来,大量研究表明,在实际成型过程中,铺粉层厚的提高可以显著提高生产效率,在扫描速度相同的情况下,80 μm层厚下的成型效率几乎是20 μm层厚下成型效率的5倍;若同时调整扫描速度等其他参数,两种层厚在工艺优化后的成型效率差距可接近10倍[40,41]。但反过来,层厚增加带来的则是粉末难以充分熔化、缺陷增多、工艺优化窗口变窄及表面粗糙度增大等一系列影响材料性能的问题[42]。在未来的工艺优化过程中,需要选取适当的层厚及其他工艺参数,再结合恰当的后续处理工艺,在降低孔洞、气孔等缺陷和保证成型质量的基础上,可进一步提高成型效率。

由此可见,增材制造工艺受激光功率、扫描速度、间距和层厚等的共同作用,建立这些工艺参数和成型质量(致密度)的关系是非常重要的。Dutt等[46]通过正交实验法测定了不同工艺参数和SLM316L合金性能之间的关系,给出了相关参数和合金性能的经验公式。

其中,VED为体积能量密度(J/mm3),P为激光功率(W),v为扫描速度(mm/s),t为层厚(mm),d为扫描间距(mm)。随着体积能量密度的增加,材料的致密度迅速增加至99%后又缓慢降低。体积能量密度不足会导致激光不能完全熔化金属粉末,未熔化粉末以及熔池之间难以产生良好的搭接。而体积能量密度过高则会导致局部过热,造成金属蒸发和飞溅现象,未及时逸出的气体会被困在材料内部,在冷却过程中成为气孔[49]。

2 核用不锈钢材料在高温高压水中SCC机理

图6

2.1 应力腐蚀开裂裂纹萌生机理

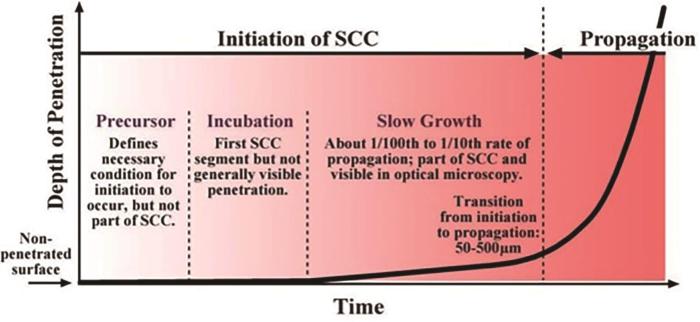

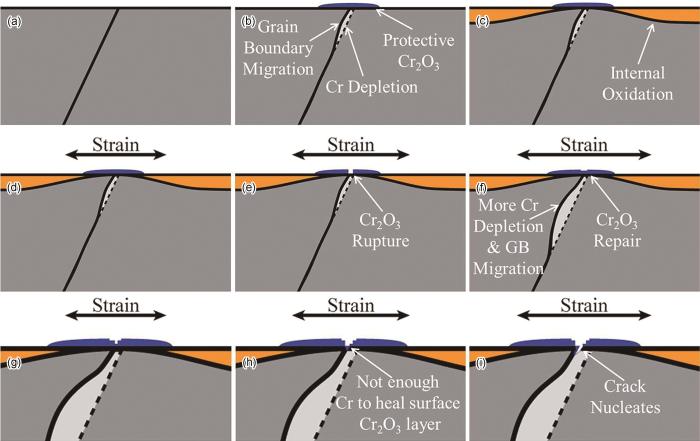

SCC萌生过程又可具体细分为裂纹前驱体时期、孕育时期和缓慢增长时期。在前驱体时期,材料表面在服役环境下逐渐形成局部缺陷或成分变化,为后续的裂纹孕育提供必要条件。孕育时期是SCC裂纹萌生的临界期,材料表面的缺陷逐步发展为微小的裂纹。当裂纹萌生过程达到最后的缓慢增长期时,微裂纹尺寸逐渐增大,并可在光学显微镜下观察材料表面的裂纹。

图7

图7

690合金SCC裂纹萌生机理示意图[51]

Fig.7

Schematic diagram of SCC crack initiation mechanism in 690 alloy: (a-c) In the unstressed state, oxidation occurs on the material surface, (d-f) oxide film cracks under the action of stress, and Cr at the grain boundaries diffuses to the surface to form a new oxide film, (g-i) Cr near the grain boundaries is exhausted, unable to form a protective oxide film, and intergranular cracking occurs[51]

2.2 应力腐蚀裂纹扩展机理

SCC裂纹扩展模型较多,如Macdonald等[52]提出的环境耦合断裂模型、Galvele等[53]提出的表面原子活动模型等。其中,由Andresen等[54,55]提出的氧化滑移模型因其能准确描述奥氏体不锈钢及镍基合金在高温高压水中的SCC过程而得到学界普遍认可。该模型认为,在高温高压水环境中,裂纹尖端的材料基体表面能够生成一层具有保护性的氧化膜,该膜的存在可以有效阻止基体的进一步氧化。然而,在应力与外部环境共同作用下,氧化膜会发生破裂,从而导致裂纹继续扩展。这种基体氧化与氧化膜破裂之间的周期性过程促使裂纹扩展,并最终导致材料失效。基于氧化滑移模型,Andresen等[54,56]进一步建立了裂纹扩展速率的定量预测方法,并提出只有当氧化膜发生破裂时,材料内部的裂纹才会以较快速率扩展。此外,裂纹扩展速率不仅与表面氧化电荷密度相关,还与材料裂纹尖端处氧化膜破裂频率有关。结合Faraday定律及材料表面的实际情况,得到

其中,Vt为裂纹扩展速率(mm/s),M和ρ分别为裂尖金属材料的摩尔质量(g/mol)和密度(g/cm3),f为Faraday常数(C/mol),z为金属原子在氧化反应中总的电子转移数目,I0为自腐蚀电流密度(A/m2),n为电流衰减系数,εF为裂尖氧化物断裂应变,εct为裂尖应变速率(s-1),t0为裸露金属表面以自腐蚀电流密度腐蚀的时间(s)。

3 SLM不锈钢高温高压水中应力腐蚀开裂行为及其影响机制

3.1 SLM不锈钢SCC行为研究现状

与传统锻态不锈钢SCC行为类似,SLM不锈钢的SCC行为同样分为裂纹萌生和裂纹扩展两个主要阶段,区别在于SLM不锈钢特殊组织结构对这两个阶段的影响。在裂纹萌生方面,Zhou等[57,58]的研究结果表明,增材316L不锈钢中位错胞结构和元素偏析对SCC裂纹的萌生起到了抑制作用,而残余应变和各向异性则提高了SCC敏感性。Zhang等[59]在含氢高温高压水中通过慢应变速率拉伸试验(SSRT)实验比较了传统锻造态不锈钢和SLM不锈钢的SCC裂纹萌生敏感性,证实了SLM不锈钢中位错胞结构和氧化夹杂物在促进氧化膜形成和抑制氧化膜破裂过程中所起到的积极作用。在裂纹扩展方面,Lou等[30,60]对增材316L在高温高压水中的腐蚀疲劳及应力腐蚀裂纹扩展行为进行了研究,揭示了增材材料各向异性、纳米级氧化夹杂物以及孔洞的不利影响,结果表明,传统不锈钢的SCC裂纹扩展速率是SLM不锈钢的75%[30]。因此,综合比较二者的SCC敏感性,SLM不锈钢的SCC敏感性要低于传统锻态不锈钢。

3.2 SLM不锈钢SCC行为影响因素

3.2.1 元素成分差异对SCC行为的影响

虽然SLM和传统锻造态不锈钢主要元素种类一致,且主要元素(Fe、Cr、Ni)含量近乎一致,但SLM不锈钢在金属粉末制备环节中可对部分不利于SCC行为的微量元素成分进行调控,使得粉末中的Mn、Si含量显著降低,提高了SLM不锈钢保护膜的稳定性,进而降低制件的SCC萌生敏感性[59]。

Zhang等[59]在含氢高温高压水中比较了锻造态不锈钢和SLM不锈钢的SCC裂纹萌生敏感性,在Cr相差不大的情况下,两者的Si含量相差约10倍,Mn含量相差约30倍,这使得SLM不锈钢的裂纹萌生长度低于传统锻造态不锈钢。Mn、Si含量影响SCC萌生的作用机理已经较为明确,并充分在传统材料中得到了验证。Toor等[64]比较了主要成分相近的304不锈钢与高Mn-N钢之间的SCC敏感性,认为Mn通过促进点蚀发生并抑制再钝化过程,导致高Mn-N钢表现出更高的SCC敏感性。Dong等[65]研究表明,在含氢高温高压水环境中的Mn氧化物会发生溶解现象,导致氧化膜呈现多孔特征,降低了膜的强度,从而易于引发机械开裂,提高了SCC敏感性。对于Si,Li等[66]的研究指出Si对SCC敏感性的消极影响,其作用主要体现在3个方面:Si会显著降低材料层错能,进而加剧晶界附近应力集中,加速裂纹扩展过程中膜破裂阶段;Si氧化膜与基体界面的结合性较差,其容易脱落,从而削弱抗SCC能力;由于Si氧化反应自由能较低,会优先在晶界处氧化,从而导致晶界机械性能下降。

3.2.2 晶粒及晶界的结构差异对SCC行为的影响

与传统锻态不锈钢相比,SLM不锈钢的微观组织在晶粒与晶界尺度上呈现出显著差异,主要包括更细的晶粒尺寸、更高的晶界密度,以及晶内普遍存在的高密度位错网络(位错胞)。这些独特的微观组织结构从萌生和扩展影响着材料的SCC行为。

对于SCC萌生,在初期成膜过程中,SLM不锈钢的高晶界密度为溶质原子提供了更多的扩散路径,显著促进原子向材料表面的扩散,从而加速氧化膜的形成,提高了成膜效率,进而增强了材料对SCC萌生的抵抗能力。在膜破裂过程中,高密度的晶界和位错胞结构共同阻碍位错运动,可有效分散位错滑移,避免应力集中。因此,SLM不锈钢的保护性氧化膜生成速度更快,膜破裂过程更加困难,综合提高了材料的SCC萌生抗力。

应力腐蚀裂纹一旦萌生后,便会在应力与腐蚀介质的协同作用下持续扩展。在扩展初期,裂纹通常表现为穿晶应力腐蚀开裂(TGSCC)。此时,裂纹的扩展速率主要受到基体晶粒内部位错运动阻力的影响。当裂纹扩展超出一个晶粒尺寸范围后,可能逐渐转变为沿晶应力腐蚀开裂(IGSCC)。因此,材料的晶粒及晶界的组织结构直接决定了SCC裂纹的扩展速率。SLM不锈钢中细化的晶粒和位错胞结构从TGSCC和IGSCC两方面降低了SCC的裂纹扩展速率,从而有效延缓了材料的SCC失效进程。当TGSCC裂纹在晶粒内部扩展时,位错胞结构能够阻碍位错的运动,同时,细小的晶粒能够显著均匀化位错滑移,与位错胞结构共同降低材料的TGSCC扩展速率[67]。当TGSCC裂纹转为IGSCC裂纹,沿晶界进行扩展时,晶粒尺寸的减小提高了晶界的密度和面积,从两方面提高了材料IGSCC抗性:高密度晶界能频繁改变裂纹尖端的扩展方向,缓解裂纹尖端的应力集中程度,进而减缓IGSCC裂纹的扩展;另一方面,晶粒细化带来的晶界面积的增加,使得IGSCC裂纹需要扩展更长的路径才能引发SCC失效,进而有效降低了材料的SCC失效风险。

3.2.3 熔池结构对SCC行为的影响

从裂纹扩展角度来看,SLM制件内部大量的熔池结构可能成为SCC过程中裂纹扩展的优先方向[18,68,69]。SCC裂纹扩展在熔池边界处的扩展行为与晶界相近,但SLM材料中的鱼鳞状熔池边界对裂纹扩展具有两面性影响:一方面,熔池边界是熔化的液态金属与凝固的固态金属的交界区域,也是成型过程中温度梯度最大的区域,在凝固过程中会产生大量的残余应力,高残余应变的熔池边界作为裂纹扩展的优先路径,降低了其扩展所需克服的阻力。现有的大量研究都发现了这一情况,例如:Suryawanshi等[70]在SLM铝合金的疲劳实验中观察到,裂纹沿熔池边界扩展的趋势明显;Huang等[71]在熔池边界附近观察到大量的微裂纹,在应力作用下,这些微裂纹会在周围产生新的裂纹,而当这些新生裂纹靠近主裂纹时,更倾向于与主裂纹桥接,从而成为主裂纹的一部分或导致主裂纹分叉。另一方面,熔池边界呈现出连续的弧形轨迹分布特征,当应力腐蚀裂纹扩展至该区域时,其扩展路径会受到显著影响。具体表现为:裂纹尖端在遇到熔池边界时,由于界面处晶体取向的突变和残余应力的重新分布,会产生明显的扩展方向偏转现象。这种偏转效应一方面增加了裂纹扩展的曲折程度,另一方面也导致裂纹尖端应力场发生重定向,从而有效消耗了裂纹扩展的驱动力[70]。这种由鱼鳞状熔池边界诱导的裂纹偏转机制,能够显著提高裂纹扩展阻力,对抑制应力腐蚀裂纹的进一步扩展起到了潜在的阻碍作用。然而,现有研究仅限于熔池边界在疲劳裂纹扩展中所产生的影响,后续研究需深入研究熔池边界这一结构影响增材材料高温高压水应力腐蚀裂纹扩展速率的作用机理。

3.2.4 第二相和夹杂物对SCC行为的影响

而在夹杂物方面,SLM不锈钢中的夹杂物以SiO2等氧化物为主,硫化物含量极低。硫化物的降低减少了因硫化物溶解而产生的点蚀坑位密度,降低了SLM不锈钢SCC的敏感性[81~83]。Laleh等[84]对MnS的减少做出了解释,由于该工艺极高的冷却速率,Mn和S在扩散结合形成MnS夹杂物前即已完成凝固,这导致材料中硫化物含量显著降低,从而有效减少了由硫化物溶解而产生的SCC裂纹萌生位点。对于以SiO2为主的纳米级夹杂物,Zhang等[59]的实验证明了纳米氧化物对降低增材材料SCC敏感性的积极作用:纳米级氧化物可以作为有效的位错钉扎点位,阻碍位错运动,从而提高材料的SCC抗力;但Wu等[28]则从多方面分析了SLM不锈钢内部SiO2夹杂物的潜在不利影响:夹杂物机械性能与材料基体及晶界之间存在的差异会导致夹杂物附近的应力集中,促进了局部腐蚀的发生;晶界处的夹杂物会削弱晶界处的界面结合强度;由于夹杂物与晶界之间的电化学电势差异,会造成晶界的阳极溶解。考虑到SCC行为繁多的影响因素以及夹杂物在SLM不锈钢中的分布随机性,还需要进行更多的实验来分析夹杂物对SLM不锈钢的利害关系。

3.2.5 各向异性和成型缺陷对SCC行为的影响

此外,增材制造工艺中难以完全避免的孔洞、气孔等冶金缺陷,是导致其SCC性能劣化的另一关键因素。Lou等[30]比较了孔隙率对增材材料裂纹扩展速率的影响,结果表明,增材材料中的孔洞也是影响其裂纹扩展速率的重要因素之一,在含氧服役环境中,低孔隙率材料的裂纹扩展速率是高孔隙率材料裂纹扩展速率的70%。增材制造不锈钢的疲劳实验说明了缺陷对材料的不利影响:当材料承受外部载荷时,其内部孔洞周围会形成明显的应力集中区域,这导致SCC的主裂纹及二次裂纹均呈现明显的向缺陷位置扩展的特征[18,68]。尽管现有研究并没有直接阐述孔洞等缺陷在SCC中的消极影响,但不可否认的是,增材材料中的孔洞无疑是影响其SCC敏感性的重要因素之一。

3.2.6 应力/应变状态对SCC行为的影响

材料的应力/应变状态是影响压水堆高温高压水环境中奥氏体不锈钢应力腐蚀开裂的重要因素之一。SLM不锈钢制件中的残余应力主要来源于其制备过程中的热应力、收缩应力和相变应力。与焊接过程中的热应力类似,热应力来自于制备过程中的热循环,由于激光扫描中心区域与已凝固材料接触液相区域具有不同凝固速率,因此SLM工艺中更高温度梯度必然会导致更大的内生热应力[85];其次是凝固过程中的收缩应力[86]。液态金属的凝固通常是不均匀进行的,会产生一定程度的收缩效应;最后是在某些SLM材料成型过程中出现相变所引起的相变应力,例如,在部分SLM镍基合金中可观察到γ′相生成,新相之间势必会引入一定残余应力[87]。虽然这些内应力可以在一定程度上通过后续恰当的热处理工艺得到缓解,但为了保留SLM工艺的特殊微观组织(如细晶、位错胞等)并维持优异的力学性能,热处理工艺相对较为温和,因而这些应力/应变并不会完全消解。

从机理上看,高残余应变将对SLM不锈钢的SCC行为产生显著的不利影响。尽管直接针对此效应的研究尚少,但大量关于传统锻态不锈钢的研究已清晰揭示了应变对SCC的促进作用。例如,在SCC裂纹萌生方面,Nono等[88]比较了不同冷加工条件下316L不锈钢在含氢高温高压水中的应力腐蚀萌生敏感性,不论是SCC裂纹的长度还是数量,50%冷加工的316L不锈钢都要高于未经过冷加工处理的同种材料。在SCC裂纹扩展方面,Sun等[89]研究了不同冷加工程度的316LN不锈钢在高温高压水中的应力腐蚀裂纹扩展行为,在相同水化学条件下,20%冷加工和30%冷加工316LN不锈钢的裂纹扩展速率分别为未经过冷加工变形316LN不锈钢裂纹扩展速率的4倍和7倍。

对于SCC的萌生行为,现有研究认为在应力/应变的作用下,材料表面的高局部残余应变促进了SCC[90]。此外,Kuniya等[82]还发现了MnS在对材料SCC萌生敏感性的不利影响,在高温高压水中,点蚀和MnS溶解所产生的坑位,在应力/应变的作用下则更容易成为SCC优先萌生的位点。虽然SLM不锈钢通过优化成分的方式减少了硫化物的含量,减少了因MnS溶解而产生的坑位数量,但其制备过程中的孔洞分布具有不确定性,材料表面的孔洞同样也会起到类似于坑位的效果,在应力/应变的作用下促进SCC裂纹的萌生。但由于SLM不锈钢特有的高密度晶界、位错胞结构以及纳米级氧化夹杂物的存在,这些微观结构特征会有效减少了应力/应变的不利影响[59]。鉴于现有研究并未完全厘清SCC萌生行为和组织结构之间的复杂关系,并不能进一步说明应力/应变状态对SLM不锈钢SCC萌生敏感性的作用机理。

对于SCC裂纹扩展行为,根据Andresen和Ford[54,55]的氧化滑移模型以及断裂理论[91],晶界处的高残余应变不仅加快了裂纹尖端基体氧化和氧化膜破裂的过程,促进了裂纹的扩展,还会降低裂纹扩展所需的临界应力值,从多方面对材料SCC扩展行为产生了不利影响。高残余应变本质上是高密度的位错,当裂纹尖端的基体发生氧化时,高密度的位错为高温高压水中氧和金属离子的扩散提供了通道,促进了氧化物的生成,即晶界处的高残余应变会加剧晶界的氧化开裂[92~94]。当基体发生氧化后,氧化膜会在外界载荷和高残余应变的协同作用下产生较大的应变梯度,导致氧化膜的快速破裂,使金属基体重新暴露在水化学环境中,加速基体氧化-氧化膜破裂这一循环过程[89]。

3.2.7 水化学环境对SCC行为的影响

无论是传统锻造态不锈钢还是增材制造不锈钢,都无法避免水化学环境对其SCC行为的影响。水化学条件直接决定了腐蚀反应的热力学驱动力和动力学过程,涉及溶解氧浓度、pH值、离子浓度、温度以及其他化学参数。这些因素通过改变材料表面氧化膜的稳定性、裂纹尖端的电化学反应及介质的侵入行为,显著影响SCC裂纹的萌生与扩展。目前关于增材制造不锈钢不同水化学条件下的SCC行为研究有限,例如:Cruz等[95]研究了增材316L不锈钢在氯化铁溶液中的SCC行为,Lou等[30]比较了不同后处理条件下,增材316L不锈钢的SCC裂纹扩展速率。虽然这些实验比较了增材制造不锈钢和传统锻态不锈钢之间的SCC行为差异,但并未阐明高温高压水化学环境中单一变量对增材不锈钢SCC行为的作用规律和机理,现阶段仅能通过水化学环境对传统锻态不锈钢SCC行为影响机理来合理推测这些变量对SLM不锈钢SCC行为的微观作用机制。

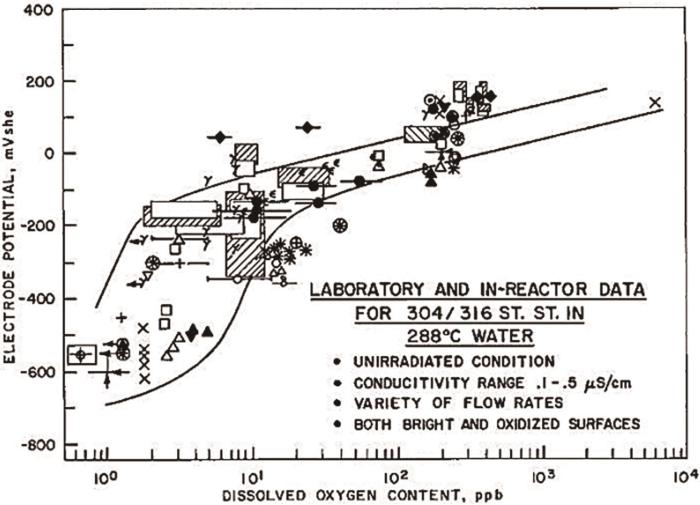

溶解氧是核电站一回路环境中最重要的氧化剂,PWR中溶解氧主要来源于辐射分解副产物以及管路循环不畅区域(如螺栓缝隙、辅助管道)截留的空气[96]。其在水环境中的存在会通过改变材料表面的氧化膜结构和电化学电位来影响材料的SCC抗性,溶解氧浓度对SCC行为具有双重作用:一方面,从氧化膜角度来看,根据Pourbaix图可知,尽管高浓度溶解氧有助于形成材料表面的氧化膜,但能够有效保护材料并保持稳定性的致密尖晶石结构内层膜需要在较低的氧含量下才能维持,因而高溶解氧将加速氧化膜的破裂及再生循环过程[97]。另一方面,从电化学反应角度分析,溶解氧含量直接影响不锈钢材料表面的电化学电位。图8展示了在高温高压水环境下,溶解氧和电化学电位之间的关系[98]。裂纹尖端附近的氧化膜发生破裂后,暴露在高温高压水中的新鲜的金属表面会大量消耗周围环境中的溶解氧来形成新的氧化膜。同时,由于裂纹区域相对狭窄,限制了其与外界环境之间进行水化学交换,因此裂纹尖端的溶解氧浓度在SCC过程中始终保持在一个较低的水平。此时,裂纹尖端内外的高溶解氧浓度差会显著加速阳极溶解反应,从而导致裂纹快速扩展。

图8

为了降低溶解氧对材料SCC敏感性的影响,在实际服役过程中,会通过在水溶液中充入氢气的方法来还原由水分解产生的氧气,从而降低水中的溶解氧含量,对材料提供一定的保护。然而,H的存在也可能诱发氢致脆化,加剧SCC行为。

4 结语与展望

增材制造技术为核电关键部件的生产提供了一种重要的新方法,其在复杂结构成型与设计灵活性方面具有显著优势。尽管如此,其制备的不锈钢在高温高压水环境下的SCC行为仍缺乏系统评估,这已成为制约其在核电领域工程化应用的核心瓶颈。分析表明,增材制造不锈钢的SCC行为主要受到其微观结构和应力/应变状态的综合作用。一方面,细晶、高密度晶界等特征对提高SCC抗性有积极效果;另一方面,残余应力、工艺缺陷(如孔洞)和组织各向异性等则会劣化其SCC抗性。当前的研究已经初步揭示了这些因素的影响规律,但对其内在作用机制的理解仍不充分。在未来的研究中应该重点关注以下方面:

(1) 揭示工艺参数及后续热处理工艺对微观组织结构的影响。增材制造的工艺参数(如激光功率、扫描速度、层厚等)及后续热处理制度是决定最终微观组织与服役性能的关键。目前,针对高效成型工艺的探索仍处于起步阶段,尚未形成系统的研究结果。因此,亟需系统地研究工艺参数与热处理制度对增材制造不锈钢微观结构(如胞状亚晶、位错网络)和应力/应变分布的演化规律,为实现组织和性能的调控提供理论基础。

(2) 分离并阐明关键微观组织结构对增材制造不锈钢SCC行为的影响机制,在此基础上,开发基于机器学习的制备工艺参数-增材材料微观组织结构-SCC性能预测模型。增材制造不锈钢具有熔池边界、外延生长的柱状晶及亚晶胞等异于传统锻造不锈钢的独特微观结构。因此,基于传统材料的SCC研究结论无法完全适用于对增材材料的服役行为评价。当前研究仅关注综合SCC抗力,而未能明确单一微观结构特征在SCC萌生及扩展阶段所扮演的角色。在未来的工作中,应通过精细调控工艺参数与热处理制度,获得具有特定微观结构特征的样品,进而结合高温高压水环境下的SCC实验,分离并阐明熔池边界、晶粒取向、亚结构等关键因素的主控作用及其物理机制。最终目标是在建立组织结构与SCC抗力的定量模型的基础上,通过机器学习,将工艺参数、组织结构和SCC敏感性三者相结合,为增材制造核用部件的环境相容性评价提供直接的理论依据。

(3) 建立增材制造不锈钢辐照促应力腐蚀开裂(IASCC)的量化理论模型。在核反应堆的严苛工况下,高通量中子辐照将通过级联碰撞在材料内部引入大量的位移损伤与缺陷,显著改变材料的微观结构与性能,即辐照损伤。增材制造不锈钢独特的微观结构与辐照损伤之间的交互作用机制仍存在较大争议,是该领域的前沿科学问题。因此,澄清其特殊的组织结构(如高密度位错网络、亚晶界)如何影响辐照缺陷的产生、演化及与基体的交互作用是至关重要的。未来的研究必须致力于开展系统性的辐照实验与多尺度模拟,建立“增材制造工艺—微观组织结构—辐照损伤—IASCC行为”之间的内在关联,从而为先进核反应堆关键部件的材料设计与制造提供关键的理论支撑。

参考文献

Failure analysis of pipelines and welding joints in nuclear power plant

[J].

核电厂管道及焊接接头失效案例综述

[J].

A review of stress corrosion cracking of austenitic stainless steels in PWR primary water

[J].

Review of thermal aging of nuclear grade stainless steels

[J].

核级不锈钢的热老化研究进展

[J].综述了热老化对核级铸造和焊接奥氏体不锈钢组织、结构和性能的影响、热老化动力学行为以及热老化脆性评估方法与寿命预测等方面的研究进展,分析了不锈钢的热老化脆性机制,指出了不锈钢热老化研究存在的问题及进一步的研究方向。

Microstructure in 316LN stainless steel fatigued at low temperature

[J].

Research on damage evolution and damage model of 316LN steel during forging

[J].

Tribological property of selective laser melting-processed 316L stainless steel against filled PEEK under water lubrication

[J].

Twinning behavior in deformation of SLM 316L stainless steel

[J].

High-strength Damascus steel by additive manufacturing

[J].

Tensile properties and microstructures of laser-formed Ti-6Al-4V

[J].

Microstructure and corrosion behavior of 316L stainless steel prepared using different additive manufacturing methods: A comparative study bringing insights into the impact of microstructure on their passivity

[J].

The microstructure, mechanical properties and corrosion resistance of 316L stainless steel fabricated using laser engineered net shaping

[J].

Cellular dislocation structure effects on the strength, toughness and corrosion resistance of selective laser melted 316L stainless steel

[D].

胞状位错结构对激光选区熔化316L不锈钢强韧性的影响与耐蚀机理研究

[D].

Defect prevention in selective laser melting components: Compositional and process effects

[J].A model to predict the conditions for printability is presented. The model focuses on crack prevention, as well as on avoiding the formation of defects such as keyholes, balls and lack of fusion. Crack prevention is ensured by controlling the solidification temperature range and path, as well as via quantifying its ability to resist thermal stresses upon solidification. Defect formation prevention is ensured by controlling the melt pool geometry and by taking into consideration the melting properties. The model’s core relies on thermodynamics and physical analysis to ensure optimal printability, and in turn offers key information for alloy design and selective laser melting process control. The model is shown to describe accurately defect formation of 316L austenitic stainless steels reported in the literature.

Emergy-based environmental impact evaluation and modeling of selective laser melting

[J].

Differences in microstructure and properties between selective laser melting and traditional manufacturing for fabrication of metal parts: A review

[J].

Effect of selective laser melting (SLM) process parameters on microstructure and mechanical properties of 316L austenitic stainless steel

[J].

Microstructure and fatigue damage of 316L stainless steel manufactured by selective laser melting (SLM)

[J].

X-ray diffraction Rietveld analysis of cold worked austenitic stainless steel

[J].

Hardened austenite steel with columnar sub-grain structure formed by laser melting

[J].

Novel precipitate-microstructural architecture developed in the fabrication of solid copper components by additive manufacturing using electron beam melting

[J].

Dislocation network in additive manufactured steel breaks strength-ductility trade-off

[J].

Intrinsic strain aging, Σ3 boundaries, and origins of cellular substructure in additively manufactured 316L

[J].

Origin of dislocation structures in an additively manufactured austenitic stainless steel 316L

[J].In this experiment, the origin of dislocation structures in AM stainless steels was systematically investigated by controlling the effect of thermal stress through geometric constraints for the first time. Stainless steel 316L parts were produced in the form of "1D" rods, "2D" walls, and "3D" rectangular prisms to evaluate the effect of constraints to thermal expansion/shrinkage on the development of defect microstructures and to elucidate the origin of additively manufactured (AM) dislocation microstructures. Dislocation density, organization, chemical micro-segregation, precipitate structures, and misorientations were analyzed as a function of increasing constraints around solidifying material in 1D, 2D, and 3D components built using both directed energy deposition (DED) and powder-bed selective laser melting (SLM). In DED parts, the dislocation density was not dependent on local misorientations or micro-segregation patterns, but evolved from approximately rho(perpendicular to)approximate to 10(12) m(-)(2) in 1D parts to rho(perpendicular to) approximate to 10(14) m(-2) in 3D parts, indicating that it is primarily thermal distortions that produce AM dislocation structures. In DED 3D parts and SLM parts, dislocation densities were highest (rho(perpendicular to) approximate to 10(14) m(-2)) and corresponded to the formation of dislocation cells approximately 300-450 nm in diameter. Dislocation cells overlapped with dendrite micro-segregation in some but not all cases. The results illustrate that dendritic micro-segregation, precipitates, or local misorientations influence how the dislocations organize during processing, but are not responsible for producing the organized cell structures. This work shows that AM dislocation structures originate due to thermal distortions during printing, which are primarily dictated by constraints surrounding the melt pool and thermal cycling. (C) 2020 Acta Materialia Inc. Published by Elsevier Ltd.

About metastable cellular structure in additively manufactured austenitic stainless steels

[J].

Mechanical properties and corrosion behavior of selective laser melted 316L stainless steel after different heat treatment processes

[J].Irregular grains, high interfacial stresses and anisotropic properties widely exist in 3D-printed metallic materials, and this paper investigated the effects of heat treatment on the microstructural, mechanical and corrosion properties of 316 L stainless steel fabricated by selective laser melting. Sub-grains and low-angle boundaries exist in the as-received selective laser melted (SLMed) 316 L stainless steel. After heat treatment at 1050 °C, the sub-grains and low-angle boundaries changed slightly, and the stress state and strength decreased to some extent due to the decrease of dislocation density. After heat treatment at 1200 °C, the grains became uniform, and the dislocation cells vanished, which led to a sharp decline in the hardness and strength. However, the ductility was improved after recrystallization heat treatment. The passive film thickness and corrosion potential of the SLMed 316 L stainless steel decreased after heat treatment, and the pitting potential also decreased due to the accelerated transition from metastable to steady-state pitting; this accelerated transition was caused by the presence of weak passive films at the enlarged pores after heat treatment, especially for an adequate solid solution treatment.

Characterization of nano-scale oxides in austenitic stainless steel processed by powder bed fusion

[J].

Insights into the role of SiO2 inclusions on the corrosion behavior of SLM 304 L stainless steel in high temperature pressurized water

[J].

Non-metallic inclusions in 17-4PH stainless steel parts produced by selective laser melting

[J].

On the stress corrosion crack growth behaviour in high temperature water of 316L stainless steel made by laser powder bed fusion additive manufacturing

[J].

The influence of the process parameters on the microstructure and properties SLM processed 316L stainless steel

[J].

An investigation into melting modes in selective laser melting of Inconel 625 powder: Single track geometry and porosity

[J].

Experimental investigation into the single-track of selective laser melting of IN625

[J].

Factor analysis of selective laser melting process parameters and geometrical characteristics of synthesized single tracks

[J].Properties of the parts manufactured by selective laser melting (SLM) depend strongly on the each single laser‐melted track and each single layer, as well as the strength of the connections between them. The purpose of this paper to establish links between the principal SLM parameters (laser power density, scanning speed, layer thickness), properties of the powder and geometrical characteristics of single tracks. This study will provide a theoretical and technical basis for production of parts from metal powders.

Effect of laser energy density on the microstructure, mechanical properties, and deformation of Inconel 718 samples fabricated by selective laser melting

[J].Inconel 718 samples were fabricated by selective laser melting (SLM). The effects of line laser energy densities in the range 0.1-0.3J/mm on the microstructure, mechanical properties, and deformation of these samples were investigated. The fewest pores and best mechanical properties were realized at 0.2 J/mm with a yield strength of 775 MPa, ultimate tensile strength of 1055 MPa, and elongation of 29.5%. Fine dimples were uniformly distributed on the fracture surface under 0.2 J/mm. An Electron Backscatter Diffraction (EBSD) test revealed a mixture of fine columnar and equiaxed grains that promote strength while maintaining high plasticity. The prisms cut from these samples bent outwards, indicating great residual stresses in the samples. Their deformation increased with increasing laser energy density. Therefore, stress release treatment is necessary for SLM parts. (C) 2019 Elsevier B.V.

Effect of layer thickness and particle size distribution on microstructure and mechanical properties of mold steel by additive manufacturing

[D].

粉末层厚和粒径对增材制造模具钢组织和性能的影响研究

[D].

Anisotropy reduction of additively manufactured AlSi10Mg for metal mirrors

[J].

Metal additive manufacturing: Technology, metallurgy and modelling

[J].

Mechanical behavior of selective laser melted 316L stainless steel

[J].

Research on high layer thickness fabricated of 316L by selective laser melting

[J].Selective laser melting (SLM) is a potential additive manufacturing (AM) technology. However, the application of SLM was confined due to low efficiency. To improve efficiency, SLM fabrication with a high layer thickness and fine powder was systematically researched, and the void areas and hollow powders can be reduced by using fine powder. Single-track experiments were used to narrow down process parameter windows. Multi-layer fabrication relative density can be reached 99.99% at the exposure time-point distance-hatch space of 120 μs-40 μm-240 μm. Also, the building rate can be up to 12 mm3/s, which is about 3–10 times higher than the previous studies. Three typical defects were found by studying deeply, including the un-melted defect between the molten pools, the micro-pore defect within the molten pool, and the irregular distribution of the splashing phenomenon. Moreover, the microstructure is mostly equiaxed crystals and a small amount of columnar crystals. The averages of ultimate tensile strength, yield strength, and elongation are 625 MPa, 525 MPa, and 39.9%, respectively. As exposure time increased from 80 μs to 200 μs, the grain size is gradually grown up from 0.98 μm to 2.23 μm, the grain aspect ratio is close to 1, and the tensile properties are shown as a downward trend. The tensile properties of high layer thickness fabricated are not significantly different than those with a coarse-powder layer thickness of low in previous research.

Increasing productivity of laser powder bed fusion manufactured Hastelloy X through modification of process parameters

[J].

The role of powder layer thickness on the quality of SLM printed parts

[J].

Optimizing quality of additively manufactured Inconel 718 using powder bed laser melting process

[J].

Selective laser melting process of large-size Ti6Al4V powder

[J].

大粒径Ti6Al4V粉末激光选区熔化成形工艺研究

[J].

Numerical simulation of selective laser melting of 304 L stainless steel

[J].This paper used the smoothed particle hydrodynamics (SPH) method to construct a three-dimensional mathematical model of the selective laser melting (SLM) process of 304 L austenitic stainless steel. Important driving force models for the melt pool in the SLM process were developed, including a surface tension model, a boundary normal-modified wetting effect model, a Marangoni shear force model, and a recoil pressure model. Meanwhile, the virtual particle boundary method prevented particles from flying over the solid boundary. Artificial viscosity, artificial stress, and artificial heat were added to correct the SPH equation, which provided a guarantee for the accuracy and speed of the numerical simulation of the SLM process. Finally, the temperature field and velocity field in the SLM process were explored according to the constructed mathematical model. The evolution mechanism in the melting process was analyzed, and the influence of different laser powers on the shape of the molten pool was mainly analyzed, which provided a reference for optimizing the laser parameters to reduce the surface roughness of the formed specimen.

Optimization of selective laser melting (SLM) additive manufacturing process parameters of 316L austenitic stainless steel

[J].

Energy density analysis on single tracks formed by selective laser melting with CoCrMo powder material

[J].

On the limitations of volumetric energy density as a design parameter for selective laser melting

[J].

Investigation of interaction between vapor plume and spatter during selective laser melting additive manufacturing

[J].

激光选区熔化增材制造中金属蒸气与飞溅相互作用研究

[J].

Stress corrosion crack growth behavior of nuclear grade 316 stainless steel in pressurized high temperature water

[D].

核级316不锈钢在高温高压水环境中的应力腐蚀裂纹扩展行为研究

[D].

Stress corrosion crack initiation in alloy 690 in high temperature water

[J].

Theoretical estimation of crack growth rates in type 304 stainless steel in boiling-water reactor coolant environments

[J].The coupled-environment fracture model (CEFM) for inter-granular stress corrosion cracking (IGSCC) of sensitized type 304 (UNS S30400) stainless steel (SS) in light-water reactor (LWR) heat-transport circuits was extended by incorporating steel corrosion, hydrogen (H2) oxidation, and hydrogen peroxide (H2O2) reduction in addition to oxygen (O2) reduction as charge-transfer reactions occurring on the external surfaces. A theoretical fracture mechanics approach was incorporated to estimate the crack-tip strain rate, and a void nucleation model was included to account for ductile failure at very negative potentials. In the CEFM, coupling between the internal and external environments and the need to conserve charge are the key physical and mathematical constraints that determine the rate of crack advance. The model provides rational explanations for the effects of O2, H2O2, H2, conductivity, stress intensity, and flow velocity on the crack growth rate (CGR) in sensitized type 304 SS in simulated LWR in-vessel environments. The CEFM was proposed as the basis of a deterministic method for estimating component lifetimes in LWR heat-transport circuits.

Application of the surface-mobility stress corrosion cracking mechanism to nuclear materials

[J].

Fundamental modeling of environmental cracking for improved design and lifetime evaluation in BWRs

[J].

Quantitative prediction of environmentally assisted cracking

[J].It has long been recognized that the stress corrosion cracking (SCC) and corrosion fatigue cracking susceptibility of various alloy and environment systems is dependent upon complex interactions between stress, material, and environmental parameters. This complexity can lead to scatter in cracking responses that, in turn, leads to difficulty in predicting the life of engineering structures. F.P. Ford was the 1995 recipient of the W.R. Whitney Award sponsored by NACE International. The present work is taken from his award lecture at CORROSION/95 held in March 1995 in Orlando, Florida. His lecture focused on how these interactions may be predicted quantitatively for ductile alloys in aqueous environments with knowledge of the cracking mechanism. This capability may lead to life prediction of critical structures in, for instance, boiling-water nuclear reactors (BWR).

Crack tip microsampling and growth rate measurements in low-alloy steel in high-temperature water

[J].The importance of the dissolution of manganese sulfide (MnS) inclusions in environmentally assisted cracking (EAC) of pressure vessel steels in high-temperature water is well recognized. However, no direct measurement of the crack tip chemistry that develops during EAC has been performed, and only estimates exist for the dissolution rate of MnS and the resulting sulfur (S) levels in the crack. In the present work, microsampling of the crack tip solution in ASTM A533(B) low-alloy steel (0.013% S) exposed to constant and cyclic loading in 288°C water under various test conditions was used to measure the crack tip S concentration directly, while simultaneously monitoring crack length. A reversing direct current (DC) potential drop method was used to monitor crack length continuously. Ion chromatography (IC) and inductively coupled plasma (ICP) were used to measure the dissolved S species in the microsampled solutions. Most experiments involved varying the corrosion potential by changing the dissolved oxygen (O2) concentration in high-purity water. At 10 ppm O2, high crack growth rates were observed, and the microsampled solutions contained between 1 ppm and 2 ppm S, ~ 10 times higher than at 0 ppm O2, where crack growth rates were low. Measurements in room-temperature solutions showed most S was present as sulfate (SO42−), although in the high-temperature deaerated water in the crack, MnS undoubtedly dissolved to form hydrogen sulfide ions (HS−) and hydrogen sulfide (H2S). Decreasing the loading frequency also lowered the crack growth rate and the crack tip S concentration. Very high microsampling rates effectively flushed the crack tip chemistry, decreasing the crack tip S content and crack growth rate.

Printed cellular structure enhancing re-passivation of stress corrosion cracking in high-temperature water

[J].

Integrated effects of non-equilibrium microstructures on stress corrosion cracking susceptibility of post-treated laser powder-bed-fusion 316 L stainless steels

[J].

Insights into the stress corrosion cracking resistance of a selective laser melted 304L stainless steel in high-temperature hydrogenated water

[J].

Corrosion fatigue crack growth of laser additively-manufactured 316L stainless steel in high temperature water

[J].

Stress corrosion crack initiation of alloy 600 in PWR primary water

[J].

Effect of cold work and slow strain rate on 321SS stress corrosion cracking in abnormal conditions of simulated PWR primary environment

[J].

Grain boundary segregation in austenitic stainless steels and its effect on intergranular corrosion and stress corrosion cracking

[J].

Manganese effects on repassivation kinetics and SCC susceptibility of high MN-N austenitic stainless steel alloys

[J].

The environmental degradation behavior of FeNiMnCr high entropy alloy in high temperature hydrogenated water

[J].

Effects of impurities on environmentally assisted crack growth of solution-annealed austenitic steels in primary water at 325 oC

[J].Effects of impurities (Si, P, and S) in steel on environmentally assisted cracking (EAC) behavior of solution-annealed austenitic steels in pressurized water reactor (PWR) primary water at 325°C were investigated. The basic chemical composition of the steels was 12% Cr-28% Ni, simulating the grain boundary (GB) composition of irradiated Type 304 (UNS S30400) stainless steel. The EAC crack growth behavior of the steels was examined by performing trapezoidal wave cyclic loading testing on precracked specimens. Results showed that Si significantly affected the EAC by promoting intergranular cracking, with only 0.48% Si promoting almost fully intergranular cracking under trapezoidal wave loading; increasing the crack growth rate; and tending to make cracking easier in the near-surface region rather than in the center of specimens. Only transgranular cracking with relatively low crack growth rates took place in the steels without Si but doped with S and P, respectively. The stress corrosion cracking (SCC) velocities of the steels during trapezoidal wave cyclic loading were estimated. It also was found that the oxide films formed on Si-doped steels in the water were easier to detach than those on Si-free steels during ultrasonic vibration. Three possible mechanisms were proposed to explain the Si effect on EAC behavior. The present results suggest that a radiation-induced low Cr/high (Ni, Si) GB layer in Type 304 steel can be intrinsically susceptible to intergranular SCC in PWR primary water.

Role of grain size on the stress corrosion cracking of 7475 aluminum alloys

[J].

Fatigue characteristics of steels manufactured by selective laser melting

[J].

Tensile, fracture, and fatigue crack growth properties of a 3D printed maraging steel through selective laser melting

[J].

Simultaneous enhancements of strength and toughness in an Al-12Si alloy synthesized using selective laser melting

[J].

Fracture behavior of PH15-5 stainless steel manufactured via directed energy deposition

[J].

Influence of microstructure and manganese sulfides on corrosion resistance of selective laser melted 17-4 PH stainless steel in acidic chloride medium

[J].

Intragranular cellular segregation network structure strengthening 316L stainless steel prepared by selective laser melting

[J].

Stress corrosion cracking of type 304 stainless steel weldments in the active state

[J].Slow strain rate tests (SSRT) were conducted in solutions of hydrochloric acid (HCl) + sodium chloride (NaCl) at ambient temperature on type 304 (UNS S30400) stainless steel (SS) weldments that exhibited a duplex ferrite-austenite structure in the weld fusion zone. Results indicated the weld fusion zone corroded preferentially. Stress corrosion cracking (SCC) initiated and propagated along the ferrite-austenite interphase. Austenitic dendrite was observed by scanning electron microscopy (SEM) in the fracture surface morphology. This interfacial cracking was attributed to the formation of a complex cell structure consisting of weld fusion zone/parent metal with delta-ferrite/austenite in the weld zone. The delta-ferrite was microanodic phase. The proposed model of SCC for type 304 SS weldments in HCl + NaCl was film formation-slip (film rupture)-dissolution-crack propagation. Because of the presence of the complex cell structure, the surface film was nonuniform, which was favorable for crack initiation. SCC propagated faster through the active path of delta-ferrite than through the matrix.

Towards understanding the effect of deformation mode on stress corrosion cracking susceptibility of grade 2205 duplex stainless steel

[J].

Role of residual ferrites on crevice SCC of austenitic stainless steels in PWR water with high-dissolved oxygen

[J].

Environmentally assisted crack growth in 308L stainless steel weld metal in simulated primary water

[J].

Effect of δ-ferrite content on the stress corrosion cracking behavior of cast austenitic stainless steel in high-temperature water environment

[J].The slow strain rate tests (SSRT) at a nominal strain rate 1× 10−6/s were conducted to evaluate the mechanical properties of CF8A cast austenitic stainless steel (CASS) in air and high-temperature water environments. CF8A CASS is mainly composed of a matrix of γ phase dispersed with δ ferrites and is affected slightly by aging heat treatment. The hardness value of γ phase did not change with aging time, while that of δ ferrite increased with increasing the aging time. The SSRT results showed that a loss in elongation of a high δ-ferrite specimen was more significant than that of the low δ-ferrite specimens. The SCC paths of the low δ-ferrite specimen were along the links between δ ferrites dispersed in the matrix. For the high δ-ferrite specimen, most of the cracks were observed to propagate through the chromium depletion regions in the ferrite grains, which were preferentially oxidized during the SSR test in water. However, the elongation did not decrease further after aging time was longer than 2,400 h, which was consistent with the trend of hardness measurements.

Role of δ-ferrite in stress corrosion cracking retardation near fusion boundary of 316NG welds

[J].

Environmentally assisted cracking of forged 316LN stainless steel and its weld in high temperature water

[J].

Pit initiation on sensitized Type 304 stainless steel under applied stress: Correlation of stress, Cr-depletion, and inclusion dissolution

[J].

Effect of MnS inclusions on stress corrosion cracking in low-alloy steels

[J].Effect of MnS inclusions on the stress corrosion cracking (SCC) of low-alloy steel in 288°C oxygenated pure water was studied using slow strain rate tensile (SSRT) test. MnS inclusions dissolve and can act as starting points of SCC. At high amounts of dissolved oxygen (about 8 ppm), pitting corrosion and MnS inclusions act as starting points of SCC, while at low amounts of dissolved oxygen (about 0.2 ppm), MnS inclusions dominate the SCC initiation. The probability of MnS inclusions existing on the specimen side surface is an important factor for SCC initiation susceptibility of the material. The number of SCC starting points in intermediate sulfur content material (about 0.015 wt%S) is larger than that in low-sulfur content material (about 0.004 wt%S). The existence of MnS inclusions also affects the SCC propagation, particularly at low, dissolved oxygen (about 0.2 ppm).

Effects of corrosion and cracking of sulfide inclusions on pit initiation in stainless steel

[J].

Unanticipated drastic decline in pitting corrosion resistance of additively manufactured 316L stainless steel after high-temperature post-processing

[J].

Hot cracking mechanism affecting a non-weldable Ni-based superalloy produced by selective electron Beam Melting

[J].

Effect of cooling rate on the microporosity in the fusion zone of electron beam welded IN738LC joint

[J].

Cracking during thermal post-processing of laser powder bed fabricated CM247LC Ni-superalloy

[J].

SCC behavior of SUS316L in the high temperature pressurized water environment

[J].

Effect of cold work level on the crack propagation behaviour of 316LN stainless steel in high-temperature pressurized water

[J].

Combined effects of machining-induced residual stress and external load on SCC initiation and early propagation of 316 stainless steel in high temperature high pressure water

[J].

Mechanical behavior of materials (2nd ed.)

[J].

Atom-probe tomography characterization of the oxidation of stainless steel

[J].

Dependence of stress corrosion cracking for cold-worked stainless steel on temperature and potential, and role of diffusion of vacancies at crack tips

[J].The growth rate of stress corrosion cracking (SCC) was measured for nonsensitized and sensitized, cold-worked Type 316 (UNS S31600, CW316) and Type 304 (UNS S30400, CW304) in hydrogenated and oxygenated pressurized water reactor (PWR) primary water, each containing standard boron and lithium additions. First, the dependences of crack growth rates on temperature were measured in low- and high-potential water in the range from 250°C to 360°C. Intergranular morphology was observed for nonsensitized CW316 in both low- and high-potential water. However, no significant growth of SCC was observed for sensitized CW316 in low-potential water. Similar 1/T temperature dependencies were observed both in hydrogenated PWR primary and oxygenated water for nonsensitized CW316 in the temperature range between 250°C and 330°C. However, the peak rate occurred about 330°C to 350°C. The peak temperature seems to shift to a lower temperature with decreasing cold work in hydrogenated PWR primary water. Second, to assess what appeared to be a common temperature dependency in both hydrogenated and oxygenated water, grain boundary creep (GB creep) was studied in air using CW316; intergranular creep cracking (IG creep cracking) was observed after low-temperature creep tests in air. The crack occurred perpendicular to the direction of tensile stress. Cavities were observed ahead of creep crack tip and near the creep crack. Finally, to determine the cause of formation of the crack embryos, Auger electron spectroscopy (AES) analyses were performed at the tips of the creep and SCC. Significant nickel enrichment and iron and chromium depletion were observed at the tips of the creep crack, near the cavities, and at the tip of the stress corrosion crack when specimens were tested in hydrogenated and oxygenated, high-temperature water. These results suggest that diffusion of vacancies to the tip could be considered as one of the important growth processes for IGSCC in hydrogenated and oxygenated high-temperature water on nonsensitized CW316/304. The extent to which grain boundary diffusion interacts with other electrochemical processes is probably important but is not defined.

Investigations on the SCC initiation behavior of cold worked 316 L in high temperature oxygenated water at constant loads

[J].

Stress corrosion cracking of 316L manufactured by laser powder bed fusion in 6% ferric chloride solution

[J].

SCC crack growth rate of cold worked 316L stainless steel in PWR environment

[J].

Quantitative assessment of submodes of stress corrosion cracking on the secondary side of steam generator tubing in pressurized water reactors: Part 1

[J].The work in this article is part of a project to develop a quantitative description of stress corrosion cracking (SCC) on the secondary side of pressurized water reactor (PWR) steam generator tubing based on existing information from operating plants and from laboratory experiments. This work is the second step in developing a predictive model for SCC on the secondary side. The first step involved developing a statistical framework into which dependencies of the various submodes of SCC can be inserted. The results of the present work will lead to quantitative descriptions of corrosion processes that, in turn, will be incorporated into the statistical framework. The chemistry of heat-transfer crevices will then be assessed to determine the proper inputs to the dependencies of the various submodes of SCC, and these will be connected to bulk environments. The modeling here is directed toward predicting the early occurrence of SCC that is too shallow to be detected by nondestructive examination (NDE).

Stress corrosion crack propagation behavior of domestic forged nuclear grade 316L stainless steel in high temperature and high pressure water

[J].Stress corrosion cracking growth rates of domestic forged nuclear grade 316L stainless steel (SS) were successfully measured in high temperature and high pressure water at various temperatures and under various loading mode. A direct current potential drop (DCPD) technique was used to monitor the crack growth throughout the test. The crack growth rate decreases with the increasing dissolved hydrogen content and the decreasing dissolved oxygen content. The crack growth rate under trapezoidal loading mode is bigger than that under constant loading. The fracture surface has typical intergranular stress corrosion cracking (IGSCC) characteristics.

国产锻造态核级管材316L不锈钢在高温高压水中的应力腐蚀裂纹扩展行为

[J].采用直流电位降(DCPD)方法, 实现了模拟核电站高温高压水环境中的国产锻造态核级管材316L不锈钢应力腐蚀裂纹扩展速率的实时检测.断口观察表明, 国产316L不锈钢在高温高压水环境中表现出明显的沿晶应力腐蚀开裂(IGSCC)行为.降低溶解O含量, 增加溶解H含量能够显著降低应力腐蚀裂纹扩展速率;梯形波载荷下的裂纹扩展速率大于恒载荷下的扩展速率, 裂纹扩展速率随着(t<sub>fl</sub>=t<sub>rs</sub>)/t<sub>h</sub>比值的增加而升高.

Emerging issues and fundamental processes in environmental cracking in hot water

[J].In the absence of definitive data, mechanistic and modeling approaches to describe environmental cracking in high-temperature water are forced to depend too strongly on speculative hypotheses. Because data often exhibit a scatter of a factor of about 1,000, the last two decades have focused on improved and critical experiments and identifying the common threads across many materials and environments. The present data provide excellent insight into many issues, and good insights into others. They also identify new/emerging issues in the broad area of environmental cracking, e.g., related to dK/da, reloading effects, and fracture toughness and tearing resistance. Environmental cracking depends on many interdependent variables, and the only comprehensive way of tackling this problem is to identify the underlying processes that control stress corrosion cracking (SCC). This paper discusses the processes that must be understood and modeled, and the challenges in expanding the predictions to emerging phenomena.

Effects of chloride and oxygen on stress corrosion cracking of cold worked 316/316L austenitic stainless steel in high temperature water

[J].

Stress corrosion cracking of stainless alloys in alkaline sulfide solutions

[J].The resistance of commercial austenitic, ferritic, and duplex alloys to stress corrosion cracking in a 5% NaOH–2% Na2S–2% Na2CO3–0.2% Na2SO4–0.1% NaCl solution at 150°C has been studied by immersion tests and electrochemical measurements. The effects of alloy composition, solution composition, and test temperature on the occurrence of stress corrosion cracking were examined. It was found that either high chromium or high nickel contents were necessary to increase stress corrosion cracking resistance and that the presence of sodium chloride, sodium carbonate, and sodium sulfate had little effect on stress corrosion cracking resistance. Cracking of U-bend stressed specimens was found to occur at a potential near the active/passive transition range of SUS304L (UNS S30403). The results are discussed with reference to electrochemical behavior and the analyses of surface corrosion films.

Stress corrosion cracking behavior of cold-drawn 316 austenitic stainless steels in simulated PWR environment

[J].