当前,世界新增油气储量的60%来自深部地层,我国83%的深地油气资源仍有待探明开发,深层、超深层已成为油气资源重大发现的主阵地,我国“十四五”规划提出要瞄准深地深海等前沿领域,实施一批具有前瞻性、战略性的国家重大科技项目,而深层油气资源勘探开发是开展地球深部探测的重要组成部分,受到了广泛关注。截止2021年6月一项统计数据显示,我国塔里木盆地中36%的油井属于超深井,这些超深井贡献了石油和天然气总产量的51%,深层、超深层油气藏逐渐成为油气勘探重点,但此类储层普遍具有埋藏深、温度高、压力大、地层水盐度高和腐蚀性气体浓度高等特征[1],如多数探明的深层、超深层油气田,井深在6000~10000 m,温度高达320 ℃,井眼内压高达140 MPa,H2S含量高达40%且含大量水分(简称“三高一深”),使得此条件下服役的钢材面临着地层压力高、腐蚀性气体浓度高和工作环境温度高等特点,对钢材的耐蚀性能提出了新挑战和新要求。

根据常规油气田的开发工况环境特征,承力结构件可供选用的钢材主要有马氏体不锈钢、高合金奥氏体不锈钢、双相不锈钢、低碳钢和镍基合金等,而开发“三高一深”油气田时其苛刻的酸性工况环境特征,使得双相不锈钢和马氏体不锈钢成为了首选代表[2],但双相不锈钢Cr含量较高,生产成本昂贵且需要通过冷轧工艺提高强度,难以大规模生产应用,相比之下马氏体不锈钢通过合金成分优化和特定温度范围内的热处理,可形成耐腐蚀性钝化膜和由回火马氏体和逆变奥氏体组成的双相组织,使其在具备良好的强韧化力学性能匹配的同时兼具了优异的耐蚀性能,且生产成本较低,在“三高一深”油气田中的使用量逐年递增。近年来,为应对复杂的“三高一深”油气田腐蚀工况环境,国内外研究者从马氏体不锈钢合金成分、组织结构、热处理工艺和综合性能四要素之间的构效关系出发,相继研发了高性能、高附加值的超级马氏体不锈钢。然而,随着深层、超深层油气田开采技术的持续发展,不断恶化的“三高一深”油气田开采工况环境导致超级马氏体不锈钢的耐蚀性能持续变差,已无法很好的满足使用要求。因此,多举措改善“三高一深”油气田用马氏体不锈钢(简称马氏体不锈钢)的耐蚀性能,研发自主产权、耐蚀性能优异的马氏体不锈钢具有重要的战略意义,也是学术界的研究热点和工程领域的技术难题。

本文介绍了马氏体不锈钢的耐蚀机理,分析了马氏体不锈钢的主要腐蚀失效形式,综述了提升其耐蚀性能的优化措施,对比了各项耐蚀性能优化措施的优缺点,总结展望了马氏体不锈钢耐蚀性能优化措施存在的不足和未来的研究方向,为后续进一步研发具有优异耐蚀性能的“三高一深”油气田用新型马氏体不锈钢提供了参考。

1 马氏体不锈钢及其耐蚀机理介绍

马氏体不锈钢通常含量(质量分数)为:C 0.1%~1.0%、Ni 0%~4.0%、Cr 12%~17%,此外通过添加Mo、V、Nb、Al和Cu等合金元素并辅以恰当的热处理工艺,可形成含Cr钝化膜及由残余奥氏体/逆变奥氏体和板条马氏体组成的微观组织,表现出了良好的强韧性和耐蚀性匹配,近年来已被广泛应用于石油和天然气行业,主要用于制造油气田开采过程中所需的多种结构组件,包括井下管、封隔器、井口和采油树组件等,在解决因高温、高压和含Cl-、CO2及H2S等腐蚀性介质造成的油气田用钢材部件腐蚀失效问题方面成效显著[3]。根据马氏体不锈钢的组成成分可分为常规马氏体不锈钢、改性马氏体不锈钢和超级马氏体不锈钢等,常规马氏体不锈钢通常应用于温度高达125 ℃的CO2环境,主要提供比非合金钢或低合金碳钢更强的抗CO2腐蚀能力;改性马氏体不锈钢主要用于提高钢材在更高温度下的抗CO2腐蚀性能;超级马氏体不锈钢主要用于提升钢材在高氯化物浓度、H2S-CO2协同腐蚀环境下的耐高温腐蚀能力[4]。

马氏体不锈钢的腐蚀主要包括电偶腐蚀、均匀腐蚀、点腐蚀、缝隙腐蚀、晶间腐蚀、硫化物应力开裂和应力腐蚀开裂等,其腐蚀的本质是基体表面的保护性钝化膜被外部环境温度、应力和腐蚀介质等破坏而发生腐蚀失效行为。研究发现马氏体不锈钢具有耐蚀性能的根本原因是当其处于腐蚀性环境中时能在表面形成一层保护性钝化膜,钝化膜为马氏体不锈钢提供了耐蚀性保护作用,保护程度取决于钝化膜的附着力、厚度、连续性和一致性等[5]。研究表明马氏体不锈钢表面钝化膜主要由Cr2O3、Fe2O3、氢氧化物和Fe的各类化合物组成,且钝化膜的组成随着腐蚀介质溶液和成膜电解质pH的不同而发生变化,在室温下钝化膜的稳定性主要取决于Cl-浓度、溶液pH和H2S分压等因素[6]。因此,介绍马氏体不锈钢及其耐蚀机理,有助于分析其在“三高一深”油气田工况环境下的腐蚀失效形式。

2 马氏体不锈钢腐蚀失效形式分析

2.1 Cl- 腐蚀

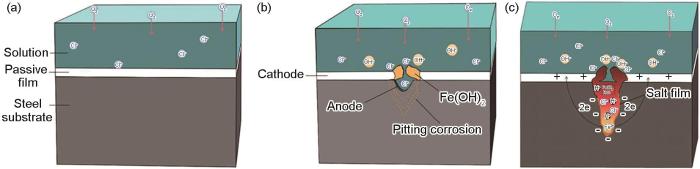

Cl-腐蚀是马氏体不锈钢普遍面临的腐蚀形式之一,Cl-腐蚀指Cl-吸附在钢材表面某些位点破坏了表面钝化膜,当钝化膜被破坏且缺乏自钝化能力时,裸露在外的微小金属成为阳极周围钝化膜成为阴极,大阴极小阳极结构导致阳极电流高度集中,腐蚀迅速向内发展[10],通常会形成20~30 μm的蚀孔,蚀孔形成后孔外被腐蚀产物阻塞,孔内外电流扩散受到阻滞,孔内成为闭塞区发生的阳极反应会释放大量金属阳离子积累在蚀坑内并与Cl-反应降低环境pH值,使得区域内电解质局部酸化,而Cl-存在于酸化环境中时会在钢材表面形成氯化物盐层以替代具有保护性能的钝化膜层,进而导致了较高的点蚀率,腐蚀类型主要有点蚀、坑蚀、缝隙腐蚀和晶间腐蚀等[11]。研究表明Cl-有很强的吸附能力可阻碍马氏体不锈钢钝化,Cl-还具有电场效应易与含氯溶液形成可溶性配合物而加速马氏体不锈钢阳极溶解,导致钢材以针孔或裂纹的形式腐蚀降解,图1为含水环境中Cl-加速阳极溶解的点蚀过程[12~15]。

图1

随着钻井深度的提高Cl-浓度通常会持续增加[16]。有研究表明,Cl-浓度和溶液pH是影响马氏体不锈钢耐Cl-腐蚀的主要因素。Li等[17]研究了Cl-浓度对14Cr12Ni3Mo2VN马氏体不锈钢腐蚀行为的影响,表明随着Cl-浓度增加,材料的开路电位负移,点蚀电位、阻抗和保护电位降低,表明腐蚀倾向增加。此外,钝化膜点缺陷增多,加速了腐蚀介质的传输,导致耐蚀性能降低。其进一步的研究[18]显示,在100 mmol·L-1 NaCl溶液中,pH = 9时耐蚀性能最佳。pH下降会减小阻抗,降低耐蚀性能。这些发现有助于构建更为全面和贴近实际应用的材料腐蚀失效模型。另一方面,Dong课题组[19]研究了不同Cl-浓度和pH对不同热处理工艺下Cr12Ni3Co12Mo4W超高强度马氏体不锈钢耐蚀性能的影响,研究表明钢材的腐蚀电位随着Cl-浓度的增加向负方向移动,腐蚀电流密度随着pH值的增加而减小,说明酸性环境对钢材的Cl-腐蚀起到了促进作用,且600 ℃回火温度下可获得逆变奥氏体组织,使钢材具有更好的耐蚀性能。这些研究结果为探究酸性高含氯化物油气田腐蚀环境下马氏体不锈钢的腐蚀机理提供了参考,也为优化马氏体不锈钢成分与热处理工艺提供了重要思路。值得一提的是,已有研究表明随着Cr含量从13%提高到16%时,马氏体不锈钢的耐Cl-腐蚀浓度可以从2400 mg/L提高至超过24000 mg/L[20]。因此,在考量钢材生产成本和高Cr含量引起的δ相区扩大无法进行热处理强化得到稳定奥氏体相区的前提下,可通过优化含Cr占比,研发满足使用要求的高铬系耐氯离子腐蚀马氏体不锈钢。

2.2 CO2 腐蚀

随着钻井深度增加,CO2的浓度和压力也随之增大[21],因此,深入研究CO2腐蚀机理可为选择适应“三高一深”油气田开发和油气集输过程中的耐蚀钢材提供指导。CO2腐蚀指CO2溶解在油气田采出水或冷凝水中生成HCO

然而,实际应用发现马氏体不锈钢在单纯CO2腐蚀环境中具有较好的耐蚀性能,但在高温、高压和高Cl-存在的恶劣环境下SCC事故频发不能满足使用要求[27]。因此,需要在传统13Cr马氏体不锈钢基础上,通过进一步降低C含量添加Ni和Mo,获得在高温工作环境中抗CO2腐蚀性能良好的超级13Cr马氏体不锈钢,确保其在恶劣油气田工况环境中安全服役。

2.3 H2S腐蚀

H2S腐蚀指H2S在有水存在环境下电离并与钢材发生电化学反应生成硫化铁等腐蚀产物的过程,腐蚀类型主要有氢脆(HE)、氢致开裂(HIC)和硫化物应力开裂(SSC)等。研究表明在一定的H2S浓度范围内马氏体不锈钢的均匀腐蚀速率随着H2S浓度升高而增加,当H2S浓度超过某一界限值时马氏体不锈钢的均匀腐蚀速率随着H2S浓度升高反而会下降,究其原因是随着H2S浓度的升高钢材表面生成的腐蚀产物膜厚度和密度增加,有效阻碍了腐蚀性离子向钢材基体表面迁移,为钢材基体提供了良好的防腐蚀保护作用[28],但在较高的H2S浓度下含硫腐蚀产物膜与钢材基体之间会出现明显开裂分层现象,腐蚀产物膜的保护作用受限马氏体不锈钢的腐蚀速率增大。

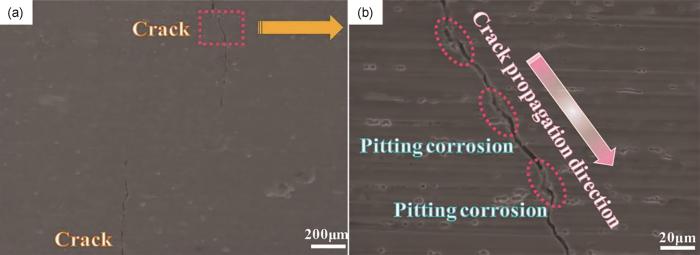

“三高一深”油气田中H2S的存在对马氏体不锈钢合金成分和耐蚀性能均提出了严苛要求,温度是影响马氏体不锈钢耐H2S腐蚀的主要因素,温度升高马氏体不锈钢耐H2S腐蚀能力降低,H2S浓度对马氏体不锈钢抗SSC性能也有显著影响,H2S浓度升高马氏体不锈钢抗SSC门槛值降低发生SSC的敏感程度增加。Lei等[29]深入探讨了13Cr马氏体不锈钢在H2S饱和溶液中浸泡后的电化学行为,认为随着浸泡时间的增加,腐蚀产物层虽变厚,但其结构出现缺陷,导致耐腐蚀性降低。特别是在高H2S分压下,腐蚀速率显著增加,表明了H2S对13Cr马氏体不锈钢的腐蚀影响随着其分压的升高而加剧。此外,氢气的渗透还降低了裸露合金基体的钝化特性,进一步加剧了腐蚀。而Yao等[30]聚焦于13Cr马氏体不锈钢在高温(150~350 ℃)含H2S环境中的机械性能退化和腐蚀失效机制,研究表明,在150~250 ℃温度区间局部腐蚀占主导地位,150 ℃时钢材发生应力取向氢致开裂,裂纹起源于钢材表面的侧面位置并逐渐向截面中心区域扩展,此过程如图2a和b所示,当温度从150 ℃升高至350 ℃时,钢材的均匀腐蚀速率最大值虽高达0.2960 mm/a但不会发生开裂,通过采取适当保护措施可使钢材在温度高达250~350 ℃、H2S分压高达0.17 MPa的井中安全服役。综合这两项研究可以看出,13Cr马氏体不锈钢在含H2S的环境中表现出一定的耐腐蚀性,但这种性能受到温度和H2S分压的显著影响。在低温条件下,局部腐蚀和应力腐蚀开裂是主要的腐蚀失效模式,而在高温条件下,均匀腐蚀成为主导。因此,对于13Cr马氏体不锈钢在H2S环境下的应用,需要根据具体的工作环境条件,采取相应的材料选择和防腐措施,以确保油气开采过程的安全可靠。

图2

此外,有报道指出马氏体不锈钢通常在pH > 4的H2S酸性环境中具有明显的耐腐蚀钝化保护行为无SSC现象发生,但在pH值较低的H2S酸性环境中服役时表面钝化会受阻形成的腐蚀产物膜内部缺陷较多,且随着工作温度的升高和服役时间的增加会发生H2S腐蚀失效[31]。因此,需要在传统13Cr马氏体不锈钢基础上持续优化合金成分研发新型耐H2S腐蚀马氏体不锈钢。

2.4 H2S-CO2-Cl- 协同腐蚀

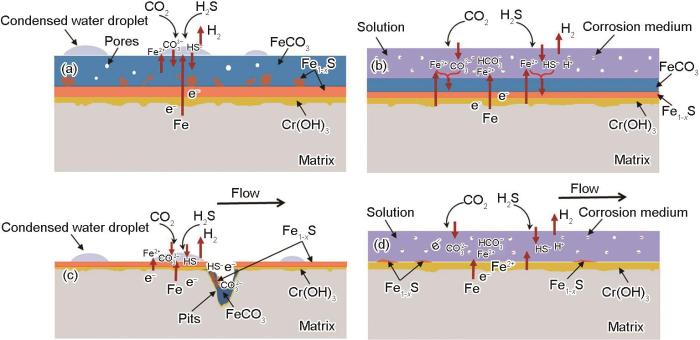

马氏体不锈钢在实际应用的过程中更多面对的是此类协同腐蚀环境,在H2S、CO2和Cl-共存环境下马氏体不锈钢的腐蚀失效程度主要取决于钢材表面形成的腐蚀产物膜结构和密度,若形成致密稳定的钝化膜可以阻止腐蚀,若形成疏松多孔的钝化膜有可能会增加腐蚀速率[34,35],钝化膜性能主要取决于马氏体不锈钢的合金成分、热处理工艺及所处的环境条件等。Zhao等[36]研究表明15Cr6Ni2Mo马氏体不锈钢在H2S-CO2-Cl-共存环境下,当CO2分压为4 MPa、H2S分压不超过0.5 MPa时钢材的平均腐蚀速率会随H2S分压的增加而增大,主要表现为均匀腐蚀,加载80%应力时钢材未发生明显的点蚀行为,且未出现裂纹或断裂,但当CO2分压为4 MPa、H2S分压为1 MPa、Cl-浓度为150 g·L-1并加载80%应力时,钢材的点蚀敏感性较高并出现了裂纹,究其原因是H2S分压的增加使SCC的诱发机制主要以硫化物诱发脆性断裂为主,明显降低了钢材的耐蚀性能。Wang等[37]研究了超高温、超临界H2S-CO2-Cl-协同腐蚀环境对超级13Cr马氏体不锈钢腐蚀行为的影响,结果表明钢材在超高温、超临界H2S-CO2-Cl-腐蚀介质下的腐蚀产物形态和成分随腐蚀介质流动状态变化而变化,如图3所示,静态条件下腐蚀产物由内层Cr(OH)3、中间层Fe1-x S和外层FeCO3层组成,腐蚀产物外层多孔且不完整,动态条件下腐蚀产物层很薄可观察到轻微的腐蚀产物层损伤,腐蚀产物的主要成分是Fe1-x S、Cr(OH)3和少量的FeCO3,研究结果对分析协同腐蚀介质流动状态影响马氏体不锈钢腐蚀行为及腐蚀产物层的形成机理提供了指导。Gao等[38]研究了不同温度下模拟CO2-H2S协同腐蚀油田冷凝水环境对低碳高强马氏体不锈钢腐蚀行为的影响,研究表明随着温度的升高钢材的腐蚀速率先增加后降低,100 ℃时腐蚀速率达到峰值为0.8463 mm/a,180 ℃时腐蚀速率最低,室温时腐蚀速率次之,在室温和180 ℃时少量H2S的存在对钢材基体的CO2腐蚀有抑制作用,形成的主要腐蚀产物是较为致密的FeS,而在100 ℃时CO2是腐蚀的主要控制因素,钢材基体表面生成的腐蚀产物主要是疏松开裂的FeCO3,研究结果为油田测试管柱的选择和设计提供了理论依据。综上所述,H2S-CO2-Cl-协同腐蚀是一个多因素、多机制的复杂过程。温度、压力和流速等因素的综合作用决定了腐蚀行为和机制。为了提高油井管材的耐腐蚀性能,未来的研究需要进一步探讨这些因素如何影响腐蚀产物的形成、生长和保护性能,以及它们如何与材料的微观结构和化学成分相互作用。

图3

图3

S13Cr MSS在超高温、超临界H2S-CO2体系中的局部腐蚀机理图[37]

Fig.3

Diagrams of the local corrosion mechanism of S13Cr MSS at ultra-high temperature in supercritical H2S-CO2 system: (a) static condition in supercritical CO2, (b) static condition in liquid medium, (c) dynamic condition in supercritical CO2, (d) dynamic condition in liquid medium[37]

此外,研究表明马氏体不锈钢在H2S-CO2-Cl-协同腐蚀下的局部腐蚀和SCC取决于大量外部和内部因素,具体包括腐蚀剂浓度、溶液酸度、钢材合金成分和热处理工艺、机械应力值、钢材表面腐蚀产物成分及形态、腐蚀环境作用持续时间和工作温度等[39]。因此,需要结合马氏体不锈钢在高温、高氯化物浓度和H2S-CO2共存环境下的腐蚀条件特点,研发强韧性好、耐蚀性优异特别是抗SCC性能优异的超级马氏体不锈钢。

3 马氏体不锈钢耐蚀性能改善措施

通过分析上述马氏体不锈钢的腐蚀失效形式发现,若要改善马氏体不锈钢的耐蚀性能,根本性做法是结合马氏体不锈钢的材质特征进行成分优化和组织调控并采取相应的外部保护措施等。实践已证实优化合金成分、调控微观组织、采用防腐涂层和添加缓蚀剂等是提高马氏体不锈钢耐蚀性能常用且有效的措施[40]。因此,选择合理的合金成分、微观组织、防腐涂层和缓蚀剂等改善马氏体不锈钢的耐蚀性能,可一定程度上解决马氏体不锈钢的腐蚀失效问题,确保其安全高效服役。

3.1 优化合金成分

马氏体不锈钢中的合金元素和含量对其钝化膜的化学成分、稳定性和厚度等起决定性影响作用[41],非金属夹杂物是导致马氏体不锈钢抗氢脆性能和抗硫化物应力开裂性能下降发生腐蚀失效的主要原因[42]。采用合金化技术优化马氏体不锈钢的合金元素种类和含量已成为改善其耐蚀性能的一项重要措施。另外,研究表明掺杂稀土元素对改善马氏体不锈钢耐蚀性能也有积极效果,稀土元素电子结构独特,容易失去外层电子变成正离子,常用作脱氧剂和脱硫剂,已成为冶金工业的重要添加剂[43]。马氏体不锈钢中添加稀土元素可调控非金属夹杂物特性、改变夹杂硫化物成分形态和降低S含量,且稀土元素化学性质活泼能优先与腐蚀介质反应形成保护性腐蚀锈层减缓马氏体不锈钢基体的腐蚀,马氏体不锈钢中固溶适量稀土元素能提高其耐点蚀和晶间腐蚀性能[44~47]。

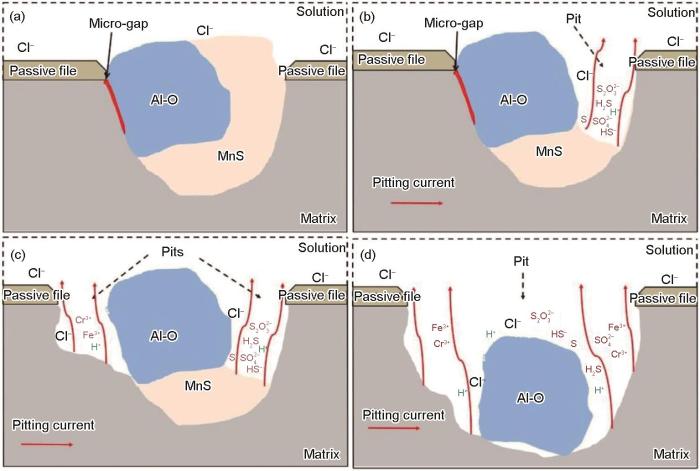

Zhang等[48]研究了添加Co对马氏体时效不锈钢耐Cl-点蚀性能的影响,研究表明添加6% (质量分数) Co后钢材的平均奥氏体晶粒尺寸减小了一半,淬火马氏体板条束得到了细化,富Cu相析出被抑制,逆变奥氏体含量得到了提高,钢材的自腐蚀电流密度从2.471 µA减小到2.005 µA,点蚀电位从0.1190 V增大到0.2685 V,明显降低了钢材对Cl-的点蚀敏感性,研究对添加微量合金元素提高马氏体不锈钢的耐点蚀性能有指导意义。Liu等[49]研究了氮化对HP-13Cr马氏体不锈钢在恶劣CO2和CO2-H2S共存环境下腐蚀性能的影响,研究发现氮扩散过程中在晶界富集并强化了晶界,添加在钢材表面的N和Cr形成了化合物,显著降低了钢材的腐蚀速度,提高了氮化处理钢材在恶劣CO2和CO2-H2S共存环境下的耐蚀性能,研究对指导马氏体不锈钢氮化处理提高其在恶劣腐蚀环境下的耐蚀性能有借鉴价值。Zang等[50]研究了添加稀土钇(Y)对20Cr13马氏体不锈钢耐Cl-腐蚀性能的影响,研究发现钢材的Ac3温度和淬火温度在添加0.02%稀土Y后均得到了明显升高,进而对钢材的组织转变产生了影响,导致钢材中铁素体含量发生了变化,显著提高了钢材的耐Cl-腐蚀性能,研究对添加稀土元素优化马氏体不锈钢的热处理参数提高其耐蚀性有指导作用。Wang等[51]研究了添加稀土La、Ce对13Cr4Ni马氏体不锈钢耐Cl-腐蚀性能的影响,研究发现未添加稀土时钢材中的主要夹杂物为Al2O3/MnS、Al2O3和MnS,该类夹杂物可诱导点蚀坑萌生和扩展,如图4所示,降低了钢材的耐Cl-腐蚀性能,而添加稀土后钢材中的Al2O3/MnS、Al2O3和MnS夹杂物均已消失,取而代之的是(La、Ce、Cr、Fe)-O和(La、Ce、Cr、Fe)-O-S型夹杂物,且添加0.021%稀土La、Ce可显著减少钢材中夹杂物的数量和面积,使钢材的阳极溶解优先发生在夹杂物和基体边界处,(La、Ce、Cr、Fe)-O型夹杂物在局部酸性环境中化学溶解或与钢材基体分离,其化学溶解物质(La3+和Ce3+)集中在点蚀坑中抑制了点蚀坑的继续生长,使钢材表现出了优异的耐Cl-腐蚀性能,研究对添加稀土元素改善马氏体不锈钢的耐蚀性能提供了参考。

图4

图4

Al2O3/MnS在13Cr4Ni MSS中诱导点蚀坑萌生和扩展示意图[51]

Fig.4

Schematic diagrams of the initiation and propagation of Al2O3/MnS induced pits for 13Cr4Ni MSS: (a) Al2O3/MnS-type inclusions during immersion in Cl- containing solution, (b) preferential dissolution of MnS as an anodic phase, (c) anodic dissolution of Al2O3 at microgap in contact with the substrate, (d) complete dissolution of MnS and nonparticipation of Al2O3 in the electrochemical reaction[51]

3.2 调控微观组织

轧制和热处理是调控马氏体不锈钢微观组织改善其耐蚀性能传统且常用的方法[52],工业化生产中一般采用热轧、冷轧和热处理调控马氏体不锈钢微观组织优化其耐蚀性能[53]。研究表明调控微观组织可避免电解液通过位错、变形带、夹杂和孪晶等微通道渗透形成腐蚀成核,对钝化膜的生长速度、致密度及腐蚀成核部位均有决定性影响,使具有不同微观组织的钢材表现出差异化的腐蚀失效行为[54]。马氏体不锈钢经较高温度和较小变形量轧制后回火热处理生成的逆变奥氏体稳定性好,不易转变为二次马氏体,能进一步提高其逆变奥氏体含量,逆变奥氏体相比马氏体耐蚀性能更好[55]。马氏体不锈钢通常利用轧制提高逆变奥氏体含量,借助高温回火消除淬火过程中引入的淬火应力,降低可逆氢陷阱位错密度和钉扎热成形钢中的可扩散氢等提高其抗SSC性能[56]。

陈肇翼等[57]研究了热轧过程对13Cr超级马氏体不锈钢组织变化的影响,认为较小的轧制变形量和较高的轧制温度有助于Ni的扩散,回火后形成了更多含量的逆变奥氏体,高含量的逆变奥氏体对酸性环境下钢材的耐蚀性能产生了积极效果,研究对利用轧制工艺配合高温回火生成更多稳定的逆变奥氏体提高钢材的耐蚀性能提供了技术参考。Salahi等[58]研究了冷轧变形过程中AISI 420马氏体不锈钢组织演变对其耐Cl-腐蚀性能的影响,表明钢材经25%和50%压应力轧制后表现出了更高的局部点蚀敏感性,轧制变形后钢材表面钝化膜抗均匀腐蚀和点蚀的稳定性降低,究其原因为随着轧制变形程度的增加,钢材微观组织中形成了更多碎片状析出相并被贫Cr区包围,引发了微电偶效应恶化了钢材的耐Cl-腐蚀性能,研究对利用冷轧变形调控马氏体不锈钢组织影响其耐蚀性提供了技术指导。Zhao等[59]研究了热处理过程中超级13Cr马氏体不锈钢组织演变对其抗CO2腐蚀性能的影响,表明回火钢材中富Ni逆变奥氏体含量随着回火温度的升高而增加,提高了腐蚀产物膜的稳定性,有效抑制了钢材的进一步腐蚀,且回火温度越高钢材抗CO2腐蚀性能越强,研究对指导设计回火温度调控钢材微观组织提升其耐蚀性能提供了参考。Wang等[60]研究了淬火、一步和两步回火热处理后超级13Cr马氏体不锈钢组织变化对其耐Cl-腐蚀性能的影响,发现钢材经两步回火热处理后生成的逆变奥氏体体积分数最高为13.5% (体积分数),两步回火钢材的点蚀电位更高,腐蚀电流密度更低,钝化膜更厚,两步回火生成的逆变奥氏体对钢材的耐蚀性能产生了积极效果,研究为借助热处理调控钢材微观组织改善其耐蚀性能提供了热处理工艺指导。Song等[61]研究了等温/分级回火对6Cr13马氏体不锈钢组织变化及耐Cl-腐蚀性能的影响,表明等温和分级回火均可提高逆变奥氏体在室温下的稳定性,逆变奥氏体体积分数随着等温和分级回火温度的升高而增大,在400 ℃回火时钢材表现出了最佳的耐蚀性能,进一步升高热处理温度钢材的耐蚀性能随之降低,研究对指导设计耐蚀性能较好的马氏体不锈钢的热处理工艺提供了参考。

3.3 采用防腐涂层

防腐涂层在预防油气田用马氏体不锈钢内外部腐蚀方面应用广泛,外部涂层主要使钢材与外部环境(如湿气、海水、污垢等)之间形成屏障,为钢材提供更好的机械保护;内部涂层主要保护钢材管壁不受流动性介质影响,提高管道平整度和流动特性,防止酸、水分、电解质、碳氢化合物和酸性气体的腐蚀,减少结垢和沉积[62]。有文献报道,通过物理气相沉积(PVD)技术沉积氮化物涂层可提高马氏体不锈钢的耐蚀性能[63~65],而离子辅助沉积(IAD)技术是将传统物理气相沉积与各种离子辅助源结合起来处理钢材表面的一种组合技术[66,67],该组合技术能提高涂层保护膜在低沉积温度下的性能,提升涂层的结合强度、密度和沉积原子迁移率[68,69],有助于马氏体不锈钢发挥更佳的耐蚀性保护作用。

Olia等[70]采用阴极电弧PVD技术在17-4PH马氏体不锈钢表面沉积了多层氮化物涂层,研究了多层氮化物涂层对钢材耐Cl-腐蚀性能的影响,表明沉积了氮化物涂层的钢材基体腐蚀电位进一步向正电位方向移动,沉积了CrN/CrAlN多层涂层的钢材与未沉积涂层和沉积了TiN/TiAlN多层涂层的钢材相比具有更优的耐蚀性能,且涂层中的铝有助于保护性钝化膜的形成,进一步提高了涂层对钢材基体的保护作用,研究对调控涂层元素组成定向制备保护性能更优的防腐涂层提供了技术借鉴。Xi等[71]采用IAD技术在AISI 420马氏体不锈钢表面沉积了3种类型的ZrN涂层(单层、多层和梯度层),研究了沉积ZrN涂层的钢材在酸性Cl-溶液中的腐蚀性能,表明沉积ZrN单层、多层和梯度层涂层均显著提高了钢材在酸性Cl-腐蚀环境中的耐蚀性能,腐蚀电流密度分别降低了83.0%、99.8%和95.8%,且因ZrN多层和梯度层涂层可抑制部分柱状晶体的生长减少涂层内部的微孔数量,其改善钢材耐蚀性能的效果优于ZrN单层涂层。另外,ZrN梯度层涂层因具有最优的力学性能和耐电化学腐蚀性能,沉积该涂层后钢材表现出了最佳的耐蚀性能,图5为钢材在酸性Cl-腐蚀环境下的表面形貌SEM图像,研究对制备结合度和耐蚀性较好的马氏体不锈钢防腐涂层提供了技术参考。

图5

3.4 添加缓蚀剂

Loto等[75]研究了添加重铬酸钾(K2Cr2O7)缓蚀剂对12Cr马氏体不锈钢耐酸性Cl-腐蚀性能的影响,表明K2Cr2O7缓蚀剂对钢材腐蚀的保护是通过金属表面吸附和氧化反应相结合实现的,吸附有助于阳极极化到足够高的电位,从而形成非常薄的水合氧化铁达到了保护钢材基体的效果,研究对添加无机缓蚀剂提高马氏体不锈钢耐蚀性能提供了应用参考,但考虑到环境和安全问题其应用在一定程度上受到了限制。Hernandez等[76]研究了用棕榈油合成的咪唑类缓蚀剂对UNS S41425型超级马氏体不锈钢耐H2S腐蚀性能的影响,表明添加缓蚀剂同时影响了钢材的阳极和阴极电化学反应,改善了钝化膜性能,明显降低了钢材在H2S腐蚀环境下的腐蚀速率,另外,当添加的缓蚀剂浓度达到一定程度时可最大化降低钢材的腐蚀速率,研究为指导添加环境友好型咪唑类缓蚀剂提升钢材的耐H2S腐蚀性能提供了指导。Raji等[77]研究了以马铃薯提取物为表面活性剂的苯甲酸钠缓蚀剂对马氏体不锈钢耐酸性点蚀性能的影响,表明添加该组合缓蚀剂能够在马氏体不锈钢表面形成一层粘附性较强的防护膜,当缓蚀剂浓度为1.0 mol/L时苯甲酸钠是一种有效的耐酸性点蚀缓蚀剂,缓蚀率达到了32.58%,研究对采用组合缓蚀剂提升石油钻井平台用马氏体不锈钢耐酸性点腐蚀性能提供了参考。

综上,科学设计马氏体不锈钢的合金成分,选择恰当的热处理工艺调控马氏体不锈钢的微观组织,采用防腐涂层和添加缓蚀剂等改善油气田用马氏体不锈钢的耐蚀性能是必要且可行的。同时,为进一步指导工程实践,以便有针对性的选择马氏体不锈钢耐蚀性能改善措施,在提升马氏体不锈钢耐蚀性能的同时尽可能地降低生产成本,本文分析对比了以上改善马氏体不锈钢耐蚀性能措施的优缺点,详见表1。

表1 马氏体不锈钢耐蚀性能改善措施的优缺点

Table 1

| Improvement measures | Advantages | Disadvantages |

|---|---|---|

| Optimize Alloy composition | Long-term and effective, and simple | It is easy to form intergranular inclusion segregation and induce pitting corrosion |

| Regulate microstructure | Obvious effect, stable | It is difficult to regulate the microstructure in a directional manner and the uncertainty is high |

| Adopt anti-corrosive coating | Simple, wide range of anti-corrosion | The preparation cost is high, and the bonding between the coating and the substrate is insufficient |

| Add Corrosion inhibitors | Inexpensive, efficient and simple | The dosage is large, which is easy to cause pitting or perforation in small parts that are not completely passivated |

4 总结与展望

随着油气田勘探开发技术的不断发展,马氏体不锈钢的服役工况环境持续恶化,现有马氏体不锈钢耐蚀性能优化研究相较其使用要求,仍存在H2S-CO2-Cl-协同腐蚀尚未形成完整、统一的研究理论体系,微量合金种类及含量的选择仍以经验为主缺乏科学理论指导,添加稀土元素对马氏体不锈钢抗SCC性能的影响研究不深入和针对不同“三高一深”油气田工况环境改善马氏体不锈钢耐蚀性能采用的热处理工艺缺乏普适性规范等问题。

未来,根据不同“三高一深”油气田工况环境对服役马氏体不锈钢耐蚀性能的差异化要求,需要结合工况环境参数,借助理论研究和性能测试数据系统研究马氏体不锈钢的耐蚀性能,针对性、定向化开展马氏体不锈钢耐蚀性能优化工作,主要包括:(1) 聚焦马氏体不锈钢腐蚀机理,探究其在高温、高压和多种类腐蚀介质协同下的腐蚀产物类型和保护层有利织构生成机理,构建在主导性腐蚀介质钢材的腐蚀速率、腐蚀产物和保护层失效等数据库,并利用计算机分析处理建模,运用腐蚀机理与数据分析结果针对性开展马氏体不锈钢腐蚀失效预测,降低运行成本和安全隐患;(2) 瞄准新型耐腐蚀马氏体不锈钢发力,进一步强化稀土元素在马氏体不锈钢中的作用机理和认识水平,科学指导确定马氏体不锈钢中添加的稀土种类和加入量,并不断发展稀土添加技术,提高稀土收得率,实现稳定化、规模化生产,定制化研发耐蚀性能符合要求的新型马氏体不锈钢。

参考文献

A review of reservoir damage during hydraulic fracturing of deep and ultra-deep reservoirs

[J].

Collapse failure analysis of S13Cr-110 tubing in a high-pressure and high-temperature gas well

[J].

Sour service domains of 13Cr martensitic stainless steels: a review of state-of-art knowledge vis-à-vis ANSI/NACE MR0175/ISO 15156

[J].

Evaluation of post weld heat treatments and susceptibility to sulfide stress corrosion cracking of simulated HAZ in forged supermartensitic stainless steel UNS S41427

[J].

A comparative study of primary and secondary passive films formed on AM355 stainless steel in 0.1 M NaOH

[J].

Focused review on factors affecting martensitic stainless steels and super martensitic stainless steel passive film in the oil and gas field

[J].

Eco-friendly silane-based coating for mitigation of carbon steel corrosion in marine environments

[J].Losses from corrosion contribute roughly 3-5% of the gross domestic product of developed nations, and among the many methods used to avoid corrosion, using silane-based coatings is seen to be of the biggest importance due to their low toxicity and superior adhesive qualities. It is essential to develop an anti-corrosion coating that is efficient, economical, and eco-friendly. The corrosion resistance and durability of various silane-based coatings such as 1,2-bis(triethoxysilyl)ethane (BTSE), bis[3-(triethoxysilyl)propyl]tetrasulfide (TESPT), and vinyltrimethylsilane (VTES) for carbon steel 1018 substrates were investigated in a high-salinity environment (4.5 wt % NaCl). The corrosion resistance performance was evaluated via potentiodynamic polarization (PDP) and electrochemical impedance spectroscopy (EIS) techniques. Results revealed that the TESPT film (pH ≈ 7) has the best corrosion resistance performance on the carbon steel surface in the aggressive chloride environment, that is, 99.6%. The high corrosion resistance of the TESPT film is due to the hydrophobic nature of this silane, which leads to the formation of a stable and dense film. These results were supported by X-ray photoelectron spectroscopy (XPS), scanning electron microscopy (SEM), and energy-dispersive X-ray spectroscopy (EDX) analyses.© 2023 The Authors. Published by American Chemical Society.

Corrosion inhibition of Erigeron canadensis L.extract for steel in HCl solution

[J].

小蓬草提取物对钢在HCl介质中的缓蚀作用

[J].以外来入侵杂草小蓬草(Erigeron canadensis L.)为原料通过超声波辅助提取制备小蓬草提取物(ECE)。利用失重法、电化学法、金属表面测试表征首次研究了以ECE作为缓蚀剂对钢在1.0 mol/L HCl介质中的缓蚀性能及作用机理。结果表明:ECE对钢在1.0 mol/L HCl介质中具有良好的缓蚀性能,缓蚀率随ECE浓度的增加而增大。40℃下,300 mg/L的ECE的缓蚀率最佳,达到93.7%。ECE在钢表面的吸附符合Langmuir吸附等温模型。20~50℃下,标准吸附Gibbs自由能范围为-28.37~-27.60 kJ/mol,吸附作用类型为物理吸附与化学吸附相结合的混合吸附。动电位极化曲线表明ECE为通过“几何覆盖效应”作用的混合抑制型缓蚀剂;Nyquist图谱呈单一容抗弧,钢/酸界面的电荷转移电阻随ECE浓度升高而增大,同时,双电层电容下降。金相显微镜、原子力显微镜(AFM)、接触角、FTIR和UV-Vis等测试表明ECE吸附在钢表面形成缓蚀膜层后使钢在HCl介质中的腐蚀明显减缓,并增强了钢表面的疏水能力。

Study on fatigue crack growth rate of 15CrMo steel based on stress ratio and corrosion environment

[J].

The role of Cl- in the formation of the corrosion products and localised corrosion of 15Cr martensite stainless steel under an CO2-containing extreme oilfield condition

[J].

Beneficial effect of reversed austenite on the intergranular corrosion resistance of martensitic stainless steel

[J].

Corrosion behavior of a high-strength steel E690 in aqueous electrolytes with different chloride concentrations

[J].

Effect of SO

Corrosion resistances of metallic materials in environments containing chloride ions: a review

[J].

Unmasking chloride attack on the passive film of metals

[J].Nanometer-thick passive films on metals usually impart remarkable resistance to general corrosion but are susceptible to localized attack in certain aggressive media, leading to material failure with pronounced adverse economic and safety consequences. Over the past decades, several classic theories have been proposed and accepted, based on hypotheses and theoretical models, and oftentimes, not sufficiently nor directly corroborated by experimental evidence. Here we show experimental results on the structure of the passive film formed on a FeCr15Ni15 single crystal in chloride-free and chloride-containing media. We use aberration-corrected transmission electron microscopy to directly capture the chloride ion accumulation at the metal/film interface, lattice expansion on the metal side, undulations at the interface, and structural inhomogeneity on the film side, most of which had previously been rejected by existing models. This work unmasks, at the atomic scale, the mechanism of chloride-induced passivity breakdown that is known to occur in various metallic materials.

Analysis and countermeasures of corrosion cracking of an oil pipe

[J].

某超深井油管腐蚀开裂分析及对策研究

[J].

Research on the corrosion behavior of 14Cr12Ni3Mo2VN stainless steel in different concentrations of NaCl solution

[J].

Research on the corrosion behavior of 14Cr12Ni3Mo2VN stainless steel in a NaCl solution with different pH

[J].

Effects of chloride ion concentration and pH values on the corrosion behavior of Cr12Ni3Co12Mo4W ultra-high-strength martensitic stainless steel

[J].

Corrosion inhibition by Cr-bearing rebar in concrete due to combined deterioration of carbonation and chloride attack

[J].

CO2 corrosion law and its application to analysis of tubing in deep and super deep wells

[J].

深井油管CO2腐蚀规律及其应用研究

[J].

Wellbore integrity and corrosion of carbon steel in CO2 geologic storage environments: a literature review

[J].

Corrosion resistance of 13Cr stainless steel against high temperature and high pressure carbon dioxide

[J].

高温高压下超级13Cr不锈钢抗CO2腐蚀性能

[J].

A thermodynamic and kinetic study of the formation and evolution of corrosion product scales on 13Cr stainless steel in a geothermal environment

[J].

Effect of acidizing process on the stress corrosion cracking of HP-13Cr stainless steel in the ultra-depth well environment

[J].

Effect of extremely high CO2 pressure on the formation of the corrosion film on 13Cr stainless steel

[J].

CO2 corrosion behaviors of 13Cr steel in the high-temperature steam environment

[J].

Stability of passive film and pitting susceptibility of 2205 duplex stainless steel in CO2/H2S-containing geothermal environment

[J].

Electrochemical behaviour of martensitic stainless steel after immersion in a H2S-saturated solution

[J].

New insight into the fitness of 13Cr stainless steel in H2S-containing environment at high temperature

[J].

Sulfide stress corrosion study of a super martensitic stainless steel in H2S sour environments: metallic sulfides formation and hydrogen embrittlement

[J].

Influence of Cr content on characteristics of corrosion product film formed on several steels in artifitial stratum waters containing CO2-H2S-Cl-

[J].

CO2-H2S-Cl-共存的地层水环境中Cr含量对钢的腐蚀产物膜特性的影响

[J].采用带有电磁驱动轴的高温高压釜,通过失重法评价了L80、L80Cr13、22Cr、25Cr钢在含CO<sub>2</sub>、H<sub>2</sub>S、Cl<sup>-</sup>的地层水中的腐蚀速率,采用SEM、EDS及XRD对其表面腐蚀产物膜进行了分析,利用AFM分析腐蚀后材料表面的粗糙度,使用CLSM分析腐蚀后材料表面的点蚀情况。结果表明,在CO<sub>2</sub>分压为0.12 MPa、H<sub>2</sub>S分压为0.003 MPa,Cl<sup>-</sup>浓度为150.8 g/L,温度为80 ℃的地层水中,试样转速为100 r/min的条件下,4种钢材均匀腐蚀速率由大到小排序为L80Cr13>L80>22Cr>25Cr。L80Cr13钢表面的腐蚀产物膜主要是由Cr<sub>2</sub>O<sub>3</sub>与Cr(OH)<sub>3</sub>组成,该腐蚀产物膜在Cl<sup>-</sup>的作用下局部地方破损;L80Cr13钢发生了明显的点蚀,最大点蚀深度为11.037 μm。L80钢表面的腐蚀产物膜主要是由FeS以及疏松的FeCO<sub>3</sub>组成,该产物膜对L80钢具有一定的保护作用,但L80钢仍旧有轻微的点蚀,最大点蚀深度为1.855 μm。22Cr、25Cr钢表面仅有一层钝化膜,且该钝化膜对基体具有良好的保护作用,基体几乎没有发生点蚀。

The effect of different brines and temperatures on the competitive degradation mechanisms of CO2 and H2S in API X65 carbon steel

[J].

Research on the evolution of corrosion products of 17-4PH martensitic stainless steel in the tropical marine environment

[J].

Influence mechanism of heat treatment on corrosion resistance of Te-containing 15-5PH stainless steel

[J].

Effect of CO2/H2S and applied stress on corrosion behavior of 15Cr tubing in oil field environment

[J].

Effects of flow velocity on the corrosion behaviour of super 13Cr stainless steel in ultra-HTHP CO2-H2S coexistence environment

[J].

Effect of temperature on corrosion behavior and mechanism of S135 and G105 steels in CO2/H2S coexisting system

[J].

Stress corrosion cracking of metals and alloys in aggressive H2S-CO2-Cl- environments

[J].

Corrosion resistance of 13Cr steels

[J].

Electrochemical dissolution behavior of stainless steels with different metallographic phases and its effects on micro electrochemical machining performance

[J].

Modification of inclusions by rare earth elements in a high-strength oil casing steel for improved sulfur resistance

[J].

The role of rare earths on steel and rare earth steel corrosion mechanism of research progress

[J].

Effects of rare earth elements on inclusions and impact toughness of high-carbon chromium bearing steel

[J].High-carbon chromium bearing steels with different rare earth (RE) contents were prepared to investigate the effects of RE on inclusions and impact toughness by different techniques. The results showed that RE addition could modify irregular Al2O3 and MnS into regular RE inclusions. With the increase of RE content, the reaction sequence of RE and potential inclusion forming elements should be O, S, As, P and C successively. RE inclusions containing C might precipitate in molten steel and solid state, but the precipitation temperature was significantly higher than that of carbides in high-carbon chromium bearing steel. For experimental bearing steels, the volume fraction of inclusions increased steadily with the increase of RE content, but smaller and more dispersed inclusions could be obtained by 0.018% RE content compared with bearing steel without RE, whereas the continuous increase of RE content led to an increasing trend for inclusion size and a gradual deterioration for inclusion distribution. RE addition could improve the transverse impact toughness and isotropy of bearing steel, and for modified high-carbon chromium bearing steel by RE alloying, the increase of RE content continuously increased both transverse and longitudinal impact toughness until excessive RE addition.

Effects of magnetic field and rare earth addition on corrosion behavior of Al-3.0wt%Mg alloy

[J].

Effects of rare earth on microstructure and impact toughness of low alloy Cr-Mo-V steels for hydrogenation reactor vessels

[J].The effects of rare earth (RE) on the microstructure and impact toughness of low alloy Cr-Mo-V bainitic steels have been investigated where the steels have RE content of 0 to 0.048 wt.%. The results indicate that the normalized microstructures of the steels are typical granular bainite (GB) composed primarily of bainitic ferrite and martensite and/or austenite (M-A) constituents. The M-A constituents are transformed into ferrite and carbides and/or agglomerated carbides after tempering at 700 °C for 4 h. The addition of RE decreases the onset temperature of bainitic transformation and results in the formation of finer bainitic ferrite, and reduces the amount of carbon-rich M-A constituents. For the normalized and tempered samples, the ductile-to-brittle transition temperature (DBTT) decreases with increasing RE content to a critical value of 0.012 wt.%. Lower DBTT and higher upper shelf energy are attributed to the decreased effective grain size and lower amount of coarse agglomerated carbides from the decomposition of massive M-A constituents. However, the addition of RE in excess of 0.012 wt.% leads to a substantial increase in the volume fraction of large-sized inclusions, which are extremely detrimental to the impact toughness.

Effect of La on the corrosion behavior and mechanism of 3Ni weathering steel in a simulated marine atmospheric environment

[J].

Effect of cobalt on the microstructure and corrosion behavior of martensitic age-hardened stainless steel

[J].To evaluate the influence of cobalt on the microstructure and pitting behavior of martensitic age-hardened stainless steel (MASS), the microstructures and electrochemical behaviors were characterized by optical microscopy, scanning electron microscopy, transmission electron microscopy, x-ray photoelectron spectroscopy, potentiodynamic curve, electrochemical impedance spectroscopy, and Mott-Schottky analysis. Results indicated that adding cobalt reduced the grain size of the original austenite, refined the lath martensite, inhibited the precipitation of Cu-rich phases, and increased the content of reversed austenite. Compared with the cobalt-free steel, the cobalt-containing steel has a higher pitting potential, lower corrosion current density, and higher pitting resistance. The primary components of the passive film grown on the cobalt-free steel included (Cr, Fe) oxides, such as Cr2O3, Cr(OH)(3), FeOOH, and Fe2O3. The cobalt-containing steel included the aforementioned components as well as Co, which was attributed to the formation of the passive film in the forms of CoFe2O4, Co(OH)(2), and CoO. In addition, the synergy of the refined lath martensite and the precipitation of the Cu-rich phase induced an increase in corrosion resistance in MASS containing cobalt.

Characterization and corrosion behavior of high-nitrogen HP-13Cr stainless steel in CO2 and H2S environment

[J].

Effect of yttrium addition on microstructure, mechanical and corrosion properties of 20Cr13 martensitic stainless steel

[J].The effects of rare-earth yttrium (Y) element on the microstructure, mechanical properties and corrosion properties of 20Cr13 martensitic stainless steel were investigated by optical microscopy, scanning electron microscopy and tensile test. Electrochemical experiments were carried out to study the effect of rare-earth element Y addition on corrosion resistance. The results showed that the addition of 0.02 wt.% rare-earth yttrium to martensitic stainless steel could affect the microstructure transformation, and Ac3 temperature was obviously increased. In the stainless steel after heat treatment, there were more pro-eutectoid ferrite in the steel with 0.02 wt.% yttrium. The mechanical test results showed that the addition of 0.02 wt.% yttrium could significantly improve the tensile strength and elongation of the steel, which was related to the influence of yttrium element on inclusions in the test steel. With the quenching temperature of 0.02 wt.% yttrium steel increasing, the content of the ferrite in steel was affected and the corrosion resistance was remarkably improved.

Effects of rare earth modifying inclusions on the pitting corrosion of 13Cr4Ni martensitic stainless steel

[J].In this study, the pitting corrosion behavior of 13Cr4Ni martensitic stainless steel (BASE) and that modified with rare earth (REM) in 0.1 mol/L NaCl solution were characterized. Techniques such as automatic secondary electron microscope (ASPEX PSEM detector), scanning electron microscope (SEM), transmission electron microscope (TEM), scanning Kelvin probe force microscope (SKP), potentiodynamic and potentiostatic polarizations were employed. The results obtained indicate that BASE steel contains Al2O3/MnS, Al2O3 and MnS inclusions, while REM steels contain (La, Ce, Cr, Fe)-O and (La, Ce, Cr, Fe)-O-S inclusions. Compared with BASE steel, REM steel is more susceptible to induce the metastable pitting nucleation and repassivation, whereas it restrains the transition from metastable pitting to stable pitting. Adding 0.021% rare earth element to BASE steel can reduce the number and area of inclusions, while that of 0.058% can increase the number and enlarged the size of inclusions, which is also the reason that pitting corrosion resistance of 58REM steel is slightly lower than that of 21REM steel. In the process of pitting corrosion induced by Al2O3/MnS inclusions, MnS is preferentially anodic dissolved, and also the matrix contacted with Al2O3 is subsequently anodic dissolved. For REM steels, anodic dissolution preferentially occurs at the boundary between inclusions and matrix, while (La, Ce, Cr, Fe)-O inclusions chemically dissolve in local acidic environment or are separated from steel matrix. The chemically dissolved substance (La3+ and Ce3+) of (La, Ce, Cr, Fe)-O inclusions are concentrated in pitting pits, which inhibits its continuous growth.

Jominy end quench test of martensitic stainless steel X30Cr13

[J].

The effect of heat treatment on the plasma nitriding of hot-rolled 17-7PH stainless steel

[J].

Effects of alloying elements and microstructure on stainless steel corrosion: a review

[J].

Dissolution behavior of carbide in 4Cr13 martensitic stainless steel during austenitizing

[J].

A review of current state and prospect of the manufacturing and application of advanced hot stamping automobile steels

[J].<p>Ultrahigh strength steels are highly competitive materials for vehicles to concurrently meet the increasing demand of the weight reduction and passenger safety. Hot stamping is the key forming technology to manufacture automobile components with high strength. Hot stamping steel and its manufacturing technology experienced a fast development in the past decade. This paper reviewed the state of the art of the manufacturing and applications of hot stamping steels/components in the following aspects: (1) hot stamping steels (from traditional MnB steels to recently newly developed hot stamping steels); (2) forming technologies (from traditional hot stamping process to industry 4.0 intelligent production); (3) novel hot stamping + quenching & partitioning (Q&P) process and fundamentals of deformation assisted heat treatments; (4) simulation techniques for hot stamping process (modeling of the temperature-stress field, microstructure field and simulation of the manufacturing process); (5) the assessments of in-service performance of hot stamped components. Finally, the trends of the development of hot stamping steels and related forming technologies in the future will be discussed.</p>

先进热成形汽车钢制造与使用的研究现状与展望

[J].汽车采用超高强钢是实现轻量化兼顾安全性的必由之路,热冲压成形是高强汽车零件成形的关键工艺。近10年来,热成形钢及其零件制造技术迅速发展。本文从以下几方面对热成形钢/零件制造与使用现状进行了综述:(1) 热成形钢材料(从传统MnB钢到最近新发布的一些热成形新钢种);(2) 工艺(热成形传统工艺到工业4.0智能化生产);(3) 热成形淬火配分(Q&P)创新工艺研究现状及形变热处理基本原理;(4) 热成形过程的仿真模拟(热/力场、组织场、工艺等的模拟);(5) 热成形零件的使用服役评价。并对今后热成形汽车钢制造与使用前景作出展望。

Effect of rolling process on microstructure of 13Cr supermartensitic stainless steel

[J].

轧制工艺对13Cr超级马氏体不锈钢组织的影响

[J].对13Cr超级马氏体不锈钢进行轧制温度1000~1100℃,变形量40%~60%的轧制实验,轧制后进行水冷和回火处理。对不同轧制工艺下的试样的显微组织进行观察,用X射线衍射(XRD)检测回火后的逆变奥氏体含量,在扫描电镜(SEM)下观察并分析回火后试样的Ni元素分布。结果表明,在各轧制工艺下试样均发生了再结晶,晶粒尺寸随着轧制温度的升高及变形量的减小而增大;经轧制水冷并回火处理后的试样,Ni元素发生富集并促进逆变奥氏体形成,随着轧制温度的升高及轧制变形量的减小,Ni元素的富集程度增大,回火后的逆变奥氏体含量增加。

Effects of microstructural evolution on the corrosion properties of AISI 420 martensitic stainless steel during cold rolling process

[J].

Influence of microstructure on the corrosion behavior of super 13Cr martensitic stainless steel under heat treatment

[J].

Prominent role of reversed austenite on corrosion property of super 13Cr martensitic stainless steel

[J].

Corrosion resistance improvement in 6Cr13 martensitic stainless steel via quenching-tempering and partitioning

[J].

Current downhole corrosion control solutions and trends in the oil and gas industry: a review

[J].

Tribological behaviour of a hyperlox coating deposited over nitrided martensitic stainless steel

[J].

Experimental studies of the effect of Ti interlayers on the corrosion resistance of TiN PVD coatings by using electrochemical methods

[J].

Nanocomposite multilayer binary nitride coatings based on transition and refractory metals: structure and properties

[J].

Low-temperature deposition of nanocrystalline Al2O3 films by ion source-assisted magnetron sputtering

[J].

Study on developments in protection coating techniques for steel

[J].

Physico-mechanical properties of Ti-Zr coatings fabricated via ion-assisted arc-plasma deposition

[J].

Ion-substituted calcium phosphate coatings deposited by plasma-assisted techniques: a review

[J].

Corrosion study of TiN, TiAlN and CrN multilayer coatings deposit on martensitic stainless steel by arc cathodic physical vapour deposition

[J].

Improvement of erosion-corrosion behavior of AISI 420 stainless steel by ion-assisted deposition ZrN coatings

[J].

Synthesis of schiff-based derivative as a novel corrosion inhibitor for mild steel in 1 M HCl solution: optimization, experimental, and theoretical investigations

[J].

Research progress of organic corrosion inhibitors in metal corrosion protection

[J].

Synergistic inhibition effect of walnut green husk extract and sodium lignosulfonate on the corrosion of cold rolled steel in phosphoric acid solution

[J].

Electrochemical corrosion resistance and inhibition behaviour of martensitic stainless steel in hydrochloric acid

[J].

Use of an imidazol synthetized from palm oil as a corrosion inhibitor for a supermartensitic stainless steel in H2S

[J].

Corrosion inhibition of martensitic stainless steel by sodium benzoate in acidic medium: Solanum tuberosum extract as surfactant

[J].