针对涂层失效的无损监测,研究者开发了一系列涂层传感器[16,17,29~43]。Mills等[32]以电化学噪声为基础设计了一种贴合于涂层表面的双电极,通过监测两电解池间的噪声电阻来计算涂层防护能力。Khalifeh等[35]与Savill等[44]开发了一种薄膜型传感器用来监测有机涂层吸水状况,传感器是基于无线电频率的变化,将薄膜型谐振器预先贴在金属基体表面,待涂料施工完成后,利用微带天线测试涂层由于吸水后引起的波形变化,从而监测涂层吸水率。Latif等[45]结合线性极化和微型应变传感器实现了对涂层失效过程的连续监测。微变形计监测涂层表面的应力变化,以此提供更加全面有效的监测数据。但埋入式传感器往往难以避免对涂层内部引入缺陷。我们也曾基于定频阻抗和微电子技术,研发了可用于涂层早期失效现场诊断的微型阻抗传感器,该传感器能够在服役状态下对涂层失效过程进行无损监测[29]。

本文开发了一种便携式单双电极阻抗探头,配合便携式阻抗分析仪,评测涂层的防护状态,并通过实验室和现场验证了该方法的可靠性。与传统的基于涂层/基底金属结合强度的测量技术相比,本方法的优势在于避免了对涂层的破坏,可以实现无损监测,尤其适用于现场大型钢结构涂层老化状态的快速无损测量,为油气管线涂层老化无损监测与防护等级分级提供了新思路。

1 实验方法

涂层钢板选用Q235钢,将其加工成150 mm ×70 mm × 2 mm的板状,依次采用180#和400#砂纸去除氧化皮并粗化表面,然后依次用乙醇和去离子水清洗,冷风吹干后在钢片表面喷涂底漆和面漆,室温下干燥24 h待用。涂层干膜厚度用415F/N型涂层测厚仪进行校核。4种涂层组成如下:1#涂层:双组份环氧底漆(50 μm);2#涂层:双组份环氧金属底漆(50 μm)+双组份聚氨酯面漆(30 μm);3#涂层:双组份环氧金属底漆(50 μm)+双组份聚氨酯面漆(30 μm)+聚氨酯金属漆(30 μm);4#涂层:双组份环氧金属底漆(50 μm)+双组份聚氨酯面漆(30 μm)+聚氨酯金属漆(30 μm)+双组份聚氨酯清漆(20 μm)。

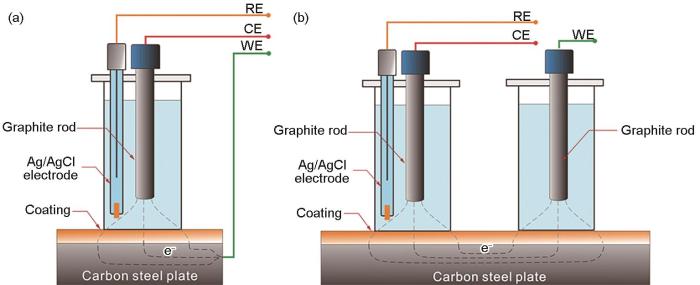

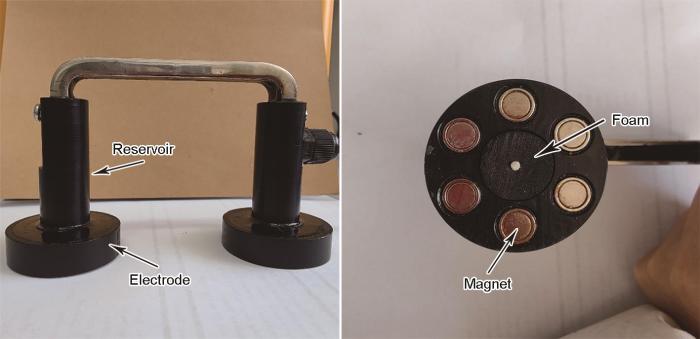

电化学阻抗(EIS)采用CS350电化学工作站测试,电解池分为单双两种方式。(1) 单电解池方式:电解池为内径1.5 cm的玻璃管(底部有密封硅胶圈),并通过冷凝管夹固定在涂层试样表面,内充30 mL 3.5% (质量分数) NaCl溶液,石墨棒为对电极,Ag/AgCl电极为参比电极,工作电极为钢板底面焊有导线的涂层试样,如图1a所示。该方法可测带涂层垂直方向的阻抗,极化电流线垂直向下并从涂层钢板流向WE。(2) 双电解池方式:阻抗测量如图1b所示,其中一个电解池内插入一根石墨棒和一只Ag/AgCl参比电极并分别连接到电化学工作站的CE和RE端子,另一个电解池只插入一根石墨棒并连接电化学工作站的WE端子。通过测量两电解池间的阻抗来评估涂层的老化状态。此时极化电流将首先从CE出发,垂直通过涂层,然后在涂层/钢板界面发生电化学反应后转为电子电流并通过钢板流向另一个电解池,在二次穿过涂层/钢板界面转换为电化学电流后回到工作电极WE。阻抗测试参数:交流幅值20 mV,扫频范围105~10-2 Hz,对数扫描,10点/10倍频。

图1

图1

电解池电化学阻抗测试示意图

Fig.1

Schematic diagram for coating impedance tests: (a) single electrolytic cell, (b) double electrolytic cell

2 结果与讨论

2.1 单电解池测试

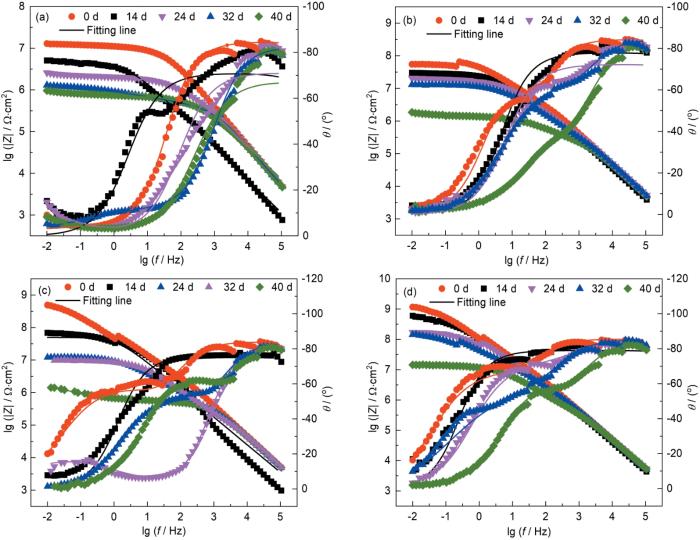

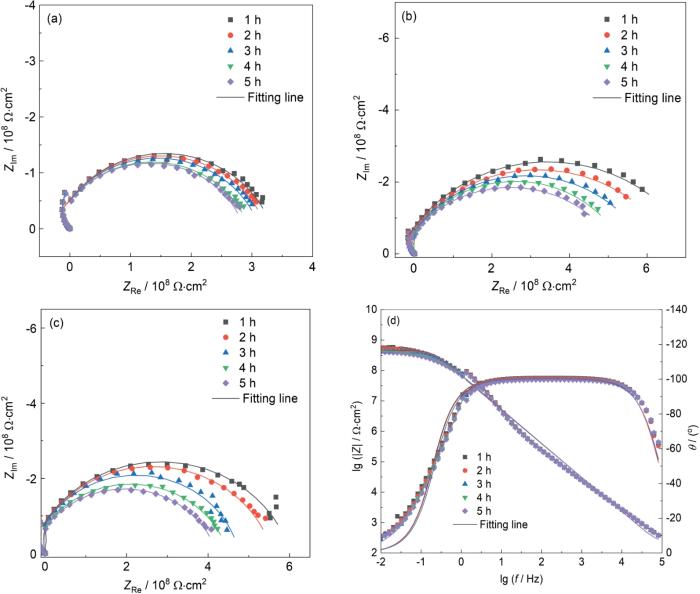

将涂层试样放入中性盐雾箱内按GB/T 10125-2021进行中性盐雾加速(NSS)试验,每隔一段时间取出测量试样的EIS。图2为4种复合涂层经不同NSS时间后的EIS。低频阻抗|Z|0.01 Hz越高表明涂层屏蔽性能越好。可见经过40 d的盐雾试验后,所有涂层的低频阻抗|Z|0.01 Hz均下降了1~2个数量级。经过40 d盐雾试验后,厚涂层(3#和4#)的阻抗值仍在107 Ω·cm2,具有一定的保护性,但薄涂层大都降到106 Ω·cm2以下,接近失去保护能力。

图2

图2

环氧涂层阻抗随盐雾老化时间的变化曲线

Fig.2

Bode plots of epoxy coating versus the duration of salt spray test: (a) two-component epoxy metal primer, (b) two-component epoxy metal primer + two-component polyurethane finish, (c) two-component epoxy metal primer + two-component polyurethane finish + polyurethane metal finish, (d) two-component epoxy metal primer + two-component polyurethane finish + polyurethane metal finish + two-component polyurethane varnish

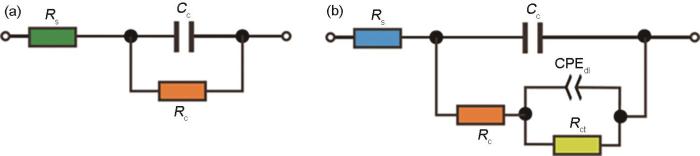

图3

图3

分别用于未老化涂层和老化涂层的EIS等效电路模型

Fig.3

Equivalent circuits (EC) for EIS fitting of intact (a) and degraded (b) coatings, Rs: solution resistance, Rct: charge transfer resistance, CPEdl: double layer capacitance, Rc: coating resistance, Cc: coating capacitance

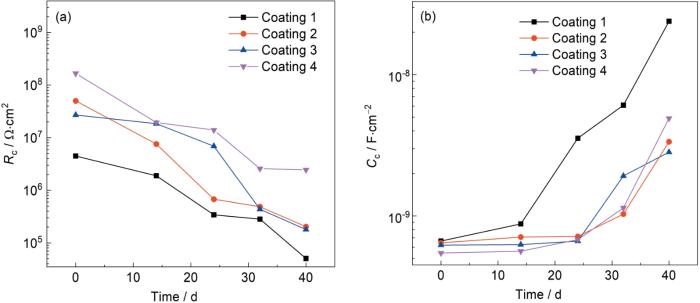

图4

图4

4种环氧涂层样品的涂层电阻Rc和涂层电容Cc随盐雾时间的变化曲线

Fig.4

Time dependence of coating resistance Rc(a) and capacitance Cc(b) of 4 epoxy coating samples

随盐雾时间延长,涂层电阻逐渐减小,涂层电容逐渐增大。涂层底漆和面漆的总厚度越大,涂层电阻越大。具有多层底漆和面漆的涂层4,其Rc最高而Cc最低,且下降或上升趋势较缓慢,表明多道漆膜有助于增加电解质扩散阻力,对基体的保护性好。

2.2 双电解池阻抗测试

传统单电解池虽然能够快速测量涂层阻抗,但这种方式需要在涂层基体金属上引出导线并作为工作电极,这可能会破坏涂层表面,不适合大面积涂装使用。双电解池方案无需在涂层基体表面引出电缆连接线,解决了传统单电解池的引线难题。单电解池可以测量腐蚀介质从涂层表面纵向扩散至金属基体的难易程度;而双电解池则可以用于测量两电极间腐蚀介质横向及纵向扩散的难易程度。随着涂层老化,涂层内部微裂纹增加,腐蚀介质渗入导致涂层阻抗下降,据此可以表征涂层内的缺陷发育程度。

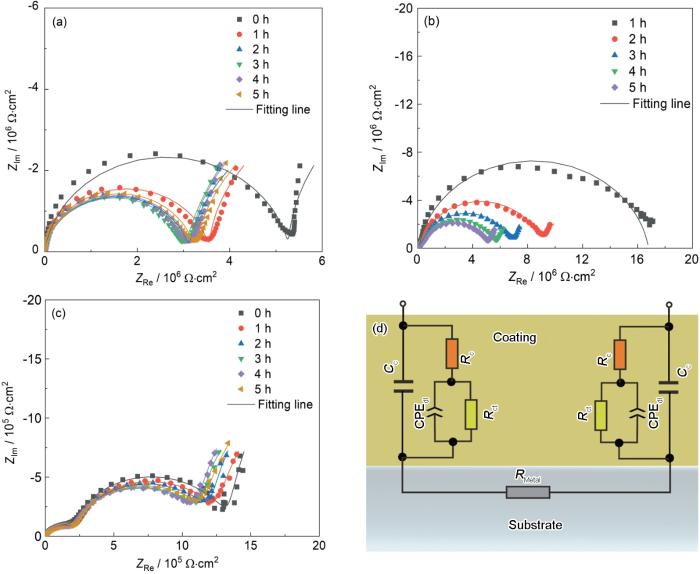

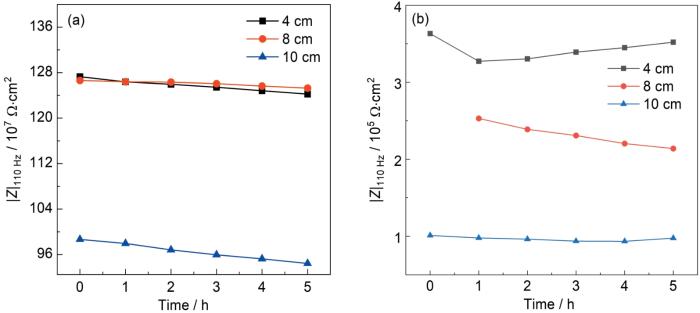

为考察电解池间距和电解液浸润时间(即电解质注入电解池后的静置时间)对阻抗测量的影响,测量中在涂层钢板表面固定一电解池,改变另一电解池的位置,逐步增加两电解池中心距(4、8和10 cm),采用双电解池分别对盐雾老化前后的1#涂层样品进行EIS测试,结果如图5和6所示。图5显示未经盐雾老化的1#涂层具有良好的屏蔽性,Nyquist图中仅有一个半圆弧,低频阻抗|Z|0.01 Hz高达108 Ω·cm2,表明腐蚀介质此时还没抵达涂层/碳钢界面,腐蚀可忽略不计。随着双电解池间距增大,|Z|0.01 Hz也逐渐增大,且呈现正相关的趋势。1#涂层老化后的EIS如图6,老化后涂层的Nyquist图中均出现了2~3个半圆弧。当间距为4 cm时,1#涂层老化前后|Z|0.01 Hz由3.20 × 108 Ω·cm2降至4.48 × 106 Ω·cm2,间距为8 cm时,涂层|Z|0.01 Hz由5.61 × 108 Ω.cm2下降至5.76 × 106 Ω·cm2,间距为10 cm时,涂层|Z|0.01 Hz由5.74 × 108 Ω·cm2下降至1.55 × 106 Ω·cm2。涂层阻抗下降了2个数量级,可见采用双电解池方案评价涂层老化状态也是可行的。

图5

图5

基于双电解池测量的未老化1#涂层在不同电解池间距下的阻抗谱随浸泡时间的变化曲线

Fig.5

Time dependence of EIS of intact coatings tested by the dual-electrolytic cell with immersion time and the cell spacings of 4 cm (a), 8 cm (b) and 10 cm (c, d)

图6

图6

盐雾老化40 d后的1#涂层阻抗随双电解池间距及浸泡时间的变化曲线

Fig.6

Time dependence of EIS of the coating sample 1# subject to 40 d salt spray versus immersion time and cell spacings of 4 cm (a), 8 cm (b), 10 cm (c) and equivalent circuit of impedance measured by the dual-electrolytic cell (d), in which the RMetal represent the ohmic resistance of metal substrate between two cells, Rct the hybrid anodic and cathodic charge transfer resistance of each cell, CPEdl the double layer capacitance, and Cc and Rc the capacitance and resistance of coatings under the two single cell

选择电解池间距为4 cm、浸泡时间为3 h的EIS,并根据图6d中的等效电路对图5和6的EIS进行拟合,计算盐雾试验前后的涂层电阻Rc和涂层电容Cc分别为4.8 × 108 Ω·cm2和3.5 × 10-9 F·cm-2,经过40 d盐雾试验后,Rc降至1.1 × 106 Ω·cm2,而Cc增加到5 × 10-6 F·cm-2,即分别下降和增加了大约2个数量级。这一变化幅度比同样条件下的单电解池阻抗测试结果要大10倍(图4),造成这种差异的原因可能是盐雾对涂料表层的降解更为显著,导致水平方向比纵深方向的微裂纹更多,因此电解液沿涂层水平方向扩散更为容易。而双电解池间的涂层阻抗显然受电解质水平渗透比纵深渗透更为显著,因此与单电解池的纵向阻抗相比,双电解池测量的水平阻抗对盐雾侵蚀更敏感。

图7

图7

1#涂层样品的中频阻抗|Z|110 Hz随电解池间距和浸泡时间的变化曲线

Fig.7

Time dependence of the 110 Hz-impedance (|Z|110 Hz) of the coating sample 1# versus spacings and immersion time subject to salt spray test of: (a) 0 d, (b) 40 d

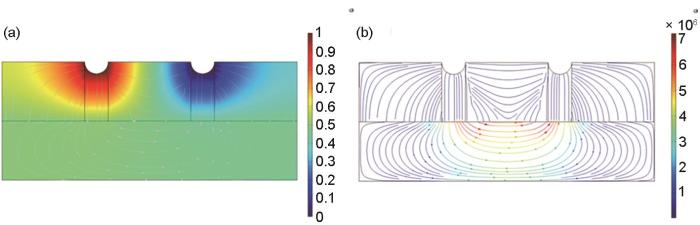

2.3 双电解池静电场仿真

通过COMSOL Multiphysics对双电极间的电流分布进行了仿真,该模型由涂层探头和带涂层钢板组成。为对涂层内的电流和电位分布进行模拟,在涂层表面两电极间施加1 V电位差用于模拟实际测试过程中两电极间的极化电位,整个模型采用超细化网格划分。两电极间涂层内的电流和电位仿真结果分别如图8a和b,可见在电位激励下,两电极间的响应电流先从电位较高的电极1垂直向下流至金属基底,然后由金属基底传导至电位较低的电极2,并从涂层-金属界面垂直向上流至电极2-涂层界面。由于金属基体的导电性远远高于涂层,因此很大一部分电流将通过金属基体流动,这样计算的双电解池间阻抗将是单电解池阻抗的两倍,其电流流动如图6d中的等效电路。当然双电解池之间也有一部分电流是水平流动:从一个电解池流向另一个电解池,但其比例取决于双电解池间的间距和浸泡时间。

图8

图8

COMSOL Multiphysics二维仿真示意图

Fig.8

Schematic diagram of two-dimensional simulation by COMSOL Multiphysics: (a) electrolytic potential, (b) current distribution between the two electrolytic cells

2.4 便携式涂层阻抗探头设计

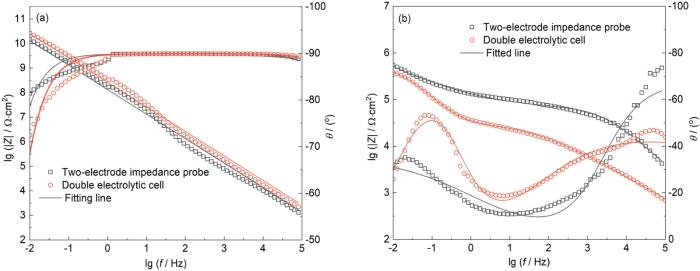

与传统单电解池涂层阻抗测试相比,双电解池的优势在于不需要在金属基体引出导线,不会对涂层完整性造成破坏。为此,我们以双电解池为雏形,设计了一种可用于在线监测的双探头传感器,如图9。该传感器外壳采用铝合金制作,实现完整的电磁屏蔽。两个手柄分别内置一个316L不锈钢弹簧顶针作为电极,底盘表面安装有多个强磁铁,可吸附在钢板表面。电极周围黑色部分为吸水泡沫,电极内部设计有储液区,底部有保水海绵,用于充分浸润所接触的涂层区。待电解质充分浸润电极区域的涂层后,即可通过连接到CS353便携式阻抗测试仪进行涂层阻抗测试。为检验该双电极传感器测试装置的稳定性和可靠性,选用不同涂层对该双电极探头进行可靠性评价。

图9

图10

图10

基于双电极探头与双电解池测量的环氧富锌涂层的Bode图

Fig.10

Comparison of EIS of Zn-rich epoxy coatings measured by the two-electrode probe and dual-electrolytic cell: (a) pristine ZRE coating, (b) ZRE coating after 40 d salt spray test

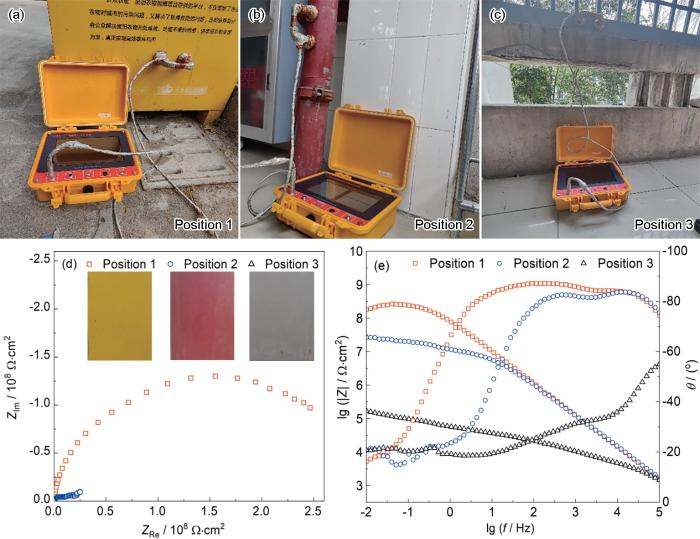

为进一步检验双电极涂层探头对现场涂层的适用性,用CS353便携式阻抗测试仪与双电极涂层探头组成的装置测量了户外钢结构表面的涂层阻抗,如图11a~c。测试前,分别选取表面涂层状态显著不同的3个部位,并分别以position 1,position 2和position 3代表,阻抗测试结果如图11d和e。其中图11d中还插入了3个部位的涂层表面形貌照片。图11d显示3个部位的涂层阻抗呈现显著差异,其中位置1的涂层阻抗模为1.72 × 108 Ω·cm2,说明该处涂层完整,对腐蚀介质具有良好的屏蔽性能。位置2的涂层阻抗模值为2.49 × 107 Ω·cm2,其值略小于位置1的涂层。位置3的涂层阻抗模已降至1.60 × 105 Ω·cm2,说明该处涂层长期暴露后老化严重,对基体的防护性显著下降。将阻抗结果与涂层形貌对比,可见双电极探头测试的涂层阻抗与涂层表面状态具有较好相关性。

图11

图11

采用双电极探头测量3种户外钢结构的涂层阻抗

Fig.11

EIS measurement of outdoor coatings based on the two-electrode probe (a-c), the Nyquist plot and the inset photos of coating morphology at 3 different coated locations (d), and the corresponding Bode plot (e)

工程上,针对现场涂层评价的快速无损要求,还可只测量中、高频区(103~101 Hz) 2~3个频点的阻抗值[29],通过阻抗的虚部值ZIm(f)来计算涂层电容Cc:

其中,f为频率,d为涂层厚度,ε和ε0分别为涂层的相对介电常数和真空介电常数。当涂层老化吸水后,其相对介电常数ε增加,据此可评价涂层的降解程度。这种中频法可避免测量低频(例如10-2 Hz)阻抗所带来的强烈干扰。

3 结论

(1) 采用传统三电极单电解池和双电解池方案测量了盐雾老化的环氧和聚氨酯涂层,发现双电解池阻抗可灵敏反映涂层的老化程度。由于双电解池可反映涂层垂直方向和水平方向的腐蚀介质扩散阻力,因而对涂层内部微裂纹比单电解池更敏感。通过COMSOL对涂层内的静电场进行了二维建模,进一步验证了双电解池方案的可行性。

(2) 由于电解液渗入涂层需要一定的时间,双电解池测试的阻抗与电解液浸润时间和电解池间距有关,一般需要浸泡3 h以上才能达到基本稳定;但阻抗值与电解池间距并不是线性相关,这是因为两电解池间的涂层扩散通道的复杂性所致。

(3) 以双电解池阻抗测试方案为原型,设计了一款可用于大型钢构涂层老化评价的双电极阻抗探头,现场测试表明,该探头能快速反映现场涂层的不同老化程度。双电极阻抗探头解决了常规涂层监测需工作电极导线与金属基体连接的问题,可以做到完全无损测量,适合于工程上大面积涂装防护性能的无损检测。

参考文献

Analysis method and detection technology of metal corrosion characteristics

[J].

金属腐蚀特性分析方法与检测技术

[J].

Corrosion and protection of metals

[J].

Effect of thermal ageing on the optical properties and pore structure of thermal barrier coatings

[J].

Failure mode analysis and life prediction of organic coatings in marine environment

[A].

有机涂层防护体系在海洋环境下失效模式的分析及其寿命预测

[A].

Investigations on aging behavior and mechanism of polyurea coating in marine atmosphere

[J].

Deterioration mechanism of vanadium dioxide smart coatings during natural aging: uncovering the role of water

[J].

Effects of accelerated environmental aging on glass fiber reinforced thermoset polyurethane composites

[J].

EIS studies of coated metals in accelerated exposure

[J].

Accelerated life testing of thermoplastic polyurethane encapsulants used in underwater acoustic sensor

[J].

Thermal aging of acrylic-urethane network: kinetic modeling and end-of-life criteria combined with mechanical properties

[J].

Variation of the mechanical properties of E-glass/epoxy composites subjected to hygrothermal aging

[J].

Galvanic corrosion of T2 Cu-alloy and Q235 steel in simulated beishan groundwater environment

[J].

T2铜合金和Q235钢在模拟北山地下水环境中的电偶腐蚀行为研究

[J].

Correlation between accelerated aging of coating and natural exposure test

[J].

涂层加速老化与自然曝晒试验的相关性分析

[J].

Deterioration processes of organic coatings under the low-frequency alternation of wetting and drying condition

[J].

低频率干湿交替环境中有机涂层失效过程

[J].

Real-time monitoring of the degradation of metallic and organic coatings using electrical resistance sensors

[J].

On-line corrosion monitoring technology for high-speed train in dynamic service circumstance

[J].

高速列车动态服役环境腐蚀在线监测技术研究

[J].基于电化学原理和无线通信技术,研制了高速列车材料腐蚀状态智能监控系统,分别在海南文昌、湖北武汉、山东青岛三地的环境腐蚀试验站及京广高铁在役高速动车组上进行了部署,并连续开展了6个月以上的腐蚀数据在线采集及分析,掌握了动车组车体铝合金材料及涂层6个月的腐蚀老化规律,为预测车辆结构材料的腐蚀风险、评估涂层的寿命衰减,加强动车组全生命周期安全管理提供了重要的数据支撑。

Pipeline corrosion and coating durability monitoring under insulation of nuclear power plant

[J].

核电厂保温层下管道腐蚀与涂层耐久性监测

[J].

Degradation formula and working lifetime prediction for high-temperature coating

[J].

Failure prediction of waterborne barrier coatings during folding

[J].

Life prediction for anticorrosive coatings on steel bridges

[J].

Interfacial delamination of porous thermal barrier coatings based on SEM image processing in finite element model

[J].

Prediction of coating adhesion loss due to stretching

[J].

Failure analysis and damage development trend research of aero-engine high-pressure turbine blades

[J].

发动机HPT叶片失效分析及损伤发展趋势研究

[J].

Lifetime prediction model for barrier-type corrosion-resistant coating

[J].

封闭型耐蚀涂层的寿命预测模型研究

[J].以封闭型耐蚀涂层为研究对象,通过阴极剥离试验得到了阴极剥离抗力与涂层厚度和时间的函数关系,分析、论证了电化学阻抗表征涂层耐蚀性能的有效性。研究了涂层在循环老化过程中的电化学阻抗变化规律,分析了电化学阻抗与涂层厚度、老化时间之间的数值关系,并建立了封闭型涂层的寿命预测模型。结果表明,涂层寿命预测值与涂层的目标使用寿命值具有可比性。

Degradation behavior of an epoxy corrosion-resistant coating in NaCl solution

[J].

一种环氧耐蚀涂层在NaCl溶液中的劣化行为研究

[J].围绕涂层的电化学阻抗、吸水率、附着力研究了一种环氧耐蚀涂层在NaCl溶液中的劣化行为。结果表明涂层浸泡至5350 h后依然具有良好的保护性能,涂层电化学阻抗、吸水率和附着力的变化趋势存在着相关性,电解质溶液与树脂材料的物理/化学反应可能是涂层劣化的主要机制,温度是涂层劣化的重要影响因素,涂层厚度的影响作用不明显。

Influence of simulated deep sea pressured-flowing seawater on failure behavior of epoxy glass flake coating

[J].

深海压力-流速耦合环境对环氧玻璃鳞片涂层失效行为的影响

[J].采用吸水率测试EIS、附着力测试SEM、FT-IR等方法,对比研究常压-静态环境 (0.1 MPa-0 m/s)、流体流动环境 (0.1 MPa-4 m/s)、高静水压力环境 (10 MPa-0 m/s) 和压力-流速耦合环境 (10 MPa-4 m/s) 下环氧玻璃鳞片涂层的失效行为和机制。实验结果表明,耦合环境下,填料与涂层基体间的界面结合被显著削弱,涂层的物理结构发生严重破环,腐蚀介质在涂层中加速扩散,并在涂层缺陷和涂层/金属界面处大量聚集,导致涂层吸水率大幅上升,力学性能显著下降,附着力迅速丧失,发生大面积鼓泡,快速失效。

Effect of alternating pressure on electrochemical behavior of solvent-free epoxy coating in simulated ultra-deep sea environment

[J].

交变压力对无溶剂环氧涂层在模拟超深海环境下的电化学行为

[J].通过EIS和LEIS对环氧粉末涂层和无溶剂环氧液体涂层分别在模拟超深海环境中0.1~20和0.1~30 MPa交变压力腐蚀环境下浸泡480 h的失效行为进行了研究,分析了超深海交变压力对涂层耐腐蚀性能的影响,并利用SEM观察了浸泡后涂层/Q345钢界面的表面形貌。研究表明,两种涂层在0.1~30 MPa交变压力作用下涂层的失效过程较为明显,环氧粉末涂层在0.1~30和0.1~20 MPa交变压力浸泡480 h后涂层阻抗值分别下降了2个和1个数量级,无溶剂环氧液体涂层在同样环境下浸泡后阻抗值分别下降了3个和2个数量级,说明了环氧粉末涂层在交变压力条件下对Q345的保护性能更优,阻绝离子渗透能力更强。从LEIS结果分析出在较高交变压力下,涂层微观局部腐蚀扩散速率更快。

Relationship between corrosion failure degree of organic coatings and mechanical properties for dissimilar metal assamblies

[J].

耦接件涂层失效程度与其力学损伤之间的关系

[J].以300M钢,2024和5A06铝合金涂层体系作为实验材料,采用不同的耦接模式将其与钛合金耦接,并依次进行了湿热、盐雾和霉菌加速实验。然后,利用层次分析法(AHP),分析建立了有机涂层失效综合评价模型,并通过电化学阻抗谱(EIS)对评价结果进行了验证。最后,利用万能拉伸试验机,测试了加速实验后涂层样品的力学性能,建立了涂层失效程度与其力学性能损伤之间的关系。结果表明,经过加速实验之后,耦接涂层样品的抗拉强度和断裂延伸率均出现一定程度的下降,且其下降程度与耦接方式有关。同时,经过加速实验之后,涂层样品力学性能与其综合评价结果呈明显的负相关关系。

Impedance sensor for the early failure diagnosis of organic coatings

[J].

Design of the armament corrosion monitoring system based on CdS coating aging probe and MCU

[J].

基于单片机和CdS涂层老化探头的装备腐蚀监测系统设计

[J].

Electrochemical measurements used for assessment of corrosion and protection of metallic materials in the field: a critical review

[J].

Continuing work to enable electrochemical methods to be used to monitor the performance of organic coatings in the field

[J].

Characterisation of accelerated ageing devices for prediction of the service life of acrylic-melamine/urethane thermosets

[J].

Study on aging and service life prediction of FEVE coating

[J].

In this article, the change of gloss and color of FEVE fluorocarbon coating has been studied in xenon lamp weatherometer, and by use of metallographic microscope and ATR-FTIR, the surface morphology and molecular structure of the coating has also been investigated. The results showed that the ester group is the weakest part in FEVE resin. Finally FEVE service life of the coating in Hainan dampheat environment was predicted by environment stress quantitative model.

FEVE涂层的老化与服役寿命预测研究

[J].

Development of a radio frequency resonator for monitoring water diffusion in organic coatings

[J].

Localized electrochemical impedance spectroscopy for studying the degradation of organic coatings

[J].

A software tool for lifetime prediction of thermal barrier coating systems

[J].

Application of scanning kelvin probe in the study of protective paints

[J].

Cut-edge corrosion behavior assessment of newly developed environmental-friendly coating systems using the Scanning Vibrating Electrode Technique (SVET)

[J].

Review—on the application of the Scanning Vibrating Electrode Technique (SVET) to corrosion research

[J].

Localized corrosion of the Mg alloys with inhibitor-containing coatings: SVET and SIET studies

[J].

Acoustic properties of plasma-sprayed coatings and their applications to non-destructive evaluation

[J].

In situ and dynamic observation of coating failure behavior

[J].

Design of a chipless RFID tag to monitor the performance of organic coatings on architectural cladding

[J].

Structural monitoring system for proactive detection of corrosion and coating failure

[J].