高熵合金(HEA)是一类由五种或五种以上元素组成的单相固溶体合金,每种元素的原子百分数通常在5%~35%之间。与传统合金相比,HEA具有优异的力学性能、耐蚀性以及抗氧化性等[1~3]。在这些合金中,AlCoCrFeNi体系是典型HEA,由于其具有良好的高温力学性能,被认为是潜在的高温结构材料[4~9]。目前大多数AlCoCrFeNi是通过真空电弧熔炼制备而成[10~12],有关其高温氧化性能也有所报道。Butler等[10]研究了不同Al含量对AlCoCrFeNi于1050 ℃空气中的抗氧化性能的影响,表明Al含量(原子分数)由8%增至30%时,HEA的氧化膜由外部较厚的Cr2O3膜和内部较薄的不连续Al2O3膜向外部较薄Cr2O3膜和内部较厚的连续Al2O3膜转化。此外,由于Si的第三组元效应,Si的加入可以提高含Al元素HEA的抗氧化性[13]。Li等[14]研究了不同Si含量的AlCoCrFeNiSi x 在1100 ℃空气中抗高温氧化性能,结果表明:该HEA由bcc相组成,加入Si之后,当Si含量(原子分数)> 9.1%时,有Cr3Si相析出,其尺寸和数量随Si含量的增加递增。适当的Si在合金中固溶,通过加快Al的扩散速度来促进致密单一Al2O3膜的形成,进而提高其抗氧化性能,而过高含量的Si会增加氧化膜的氧化物和形成该氧化物所消耗金属的体积比(PBR)值,导致氧化初期Al2O3膜严重剥落,从而降低其氧化性能。

1 实验方法

表1 采用LMD制备Al0.21Co0.17Cr0.13Fe0.11Ni0.18Si0.20高熵合金的工艺参数

Table 1

Scanning speed / mm·min-1 | AlCoCrFeNi powder feeding speed / g·min-1 | Si powder feeding speed / g·min-1 | Spot diameter / mm | Overlap rate / % | Protective gas flow rate / L·min-1 | Defocusing distance / mm |

|---|---|---|---|---|---|---|

| 800 | 3.4 | 0.18 | 1 | 50 | 15 | 5 |

表2 不同激光功率沉积的Al0.21Co0.17Cr0.13Fe0.11Ni0.18Si0.20化学成分(原子分数,%) (atomic fraction / %)

Table 2

| Laser power | Al | Co | Cr | Fe | Ni | Si |

|---|---|---|---|---|---|---|

| 700 W | 18.9 | 17.1 | 15.4 | 12.8 | 16.8 | 19.0 |

| 800 W | 22.2 | 15.9 | 12.2 | 10.2 | 18.0 | 21.5 |

| 900 W | 22.0 | 17.9 | 12.0 | 8.5 | 20.0 | 19.6 |

将LMD制成5 mm × 5 mm × 3 mm的小试样,依次使用120#、320#、600#、800#、1500#、2000# SiC砂纸进行打磨以及1.5 µm的金刚石抛光膏抛光,然后在C2H5OH溶液中超声清洗后放置在干燥器中备用。采用D8ADVANCE-A25型号X射线衍射仪(XRD)对3种功率下的沉积态HEA进行物相分析。经1∶1的H2SO4-H3PO4溶液电解腐刻后,上述HEA的晶粒尺寸由光学显微镜(OM)分析。

氧化实验在Setaram Setsys Evolution热重分析(TGA)仪上进行,氧化温度为1100 ℃,氧化气氛分别为含与不含10%H2O (体积分数,下同)的空气气氛。氧化样品化学镀Ni后经研磨抛光后,采用Phenom ProX G6 Desktop型号扫描电子显微镜(SEM)以及EDS对氧化膜进行微观结构与成分分析。

2 结果与讨论

2.1 显微结构

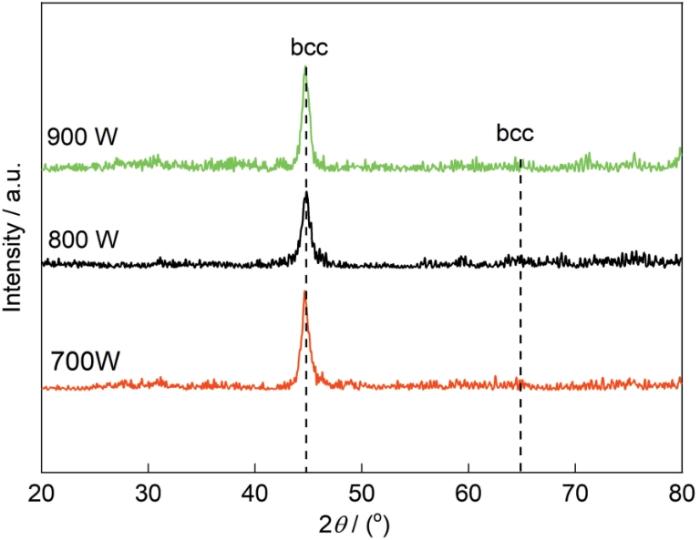

图1为700~900 W下沉积的Al0.21Co0.17Cr0.13Fe0.11-Ni0.18Si0.20的XRD图谱。可见,3种激光功率下获得的HEA均由bcc单相组成。图2a和b分别为激光功率700和900 W时沉积态Al0.21Co0.17Cr0.13Fe0.11Ni0.18Si0.20电解腐蚀后的组织形貌图。合金的晶内呈现亮白色,晶界呈现灰色,从图2a中的局部放大图可以看到有细小的枝晶从晶界处向晶内生长,700 W晶界处枝晶数量较900 W有所增加,这主要是因为枝晶的生长受到熔池温度梯度的影响,700 W熔池温度梯度低,利于形成更多细小的枝晶[23]。随着激光功率从700 W提升至900 W,该HEA的平均晶粒尺寸也相应的从(3.0 ± 0.9) μm提升至(4.1 ± 1.5) μm (图2c和d)。这一结果归因于激光功率不同所致。LMD过程中较大的激光功率会显著提升熔池的峰值温度,合金冷却速度减小,晶粒生长时间增加,从而导致了晶粒尺寸的增大[24]。

图1

图1

不同激光功率沉积的Al0.21Co0.17Cr0.13Fe0.11Ni0.18Si0.20的XRD图谱

Fig.1

XRD patterns of Al0.21Co0.17Cr0.13Fe0.11Ni0.18Si0.20 fa-bricated by LMD at different laser powers

图2

图2

700 W与900 W激光功率下沉积的Al0.21Co0.17Cr0.13Fe0.11Ni0.18Si0.20腐刻后微观形貌与晶粒大小分布图,(a)中插图为放大图像

Fig.2

Morphologies (a, b) and grain size distributions (c, d) of Al0.21Co0.17Cr0.13Fe0.11Ni0.18Si0.20 manufactured by LMD at 700 W (a, c) and 900 W (b, d). The inset in Fig.2a is a magnified image

2.2 “干”空气氧化行为

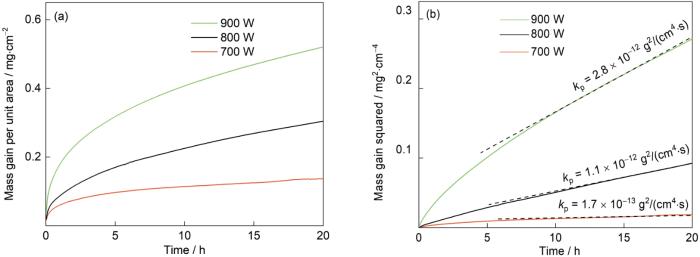

图3a为不同激光功率沉积的Al0.21Co0.17Cr0.13Fe0.11-Ni0.18Si0.20在1100 ℃“干”空气中氧化20 h的动力学曲线,可以看出,激光功率的增加明显降低了所制备的HEA的抗氧化性能。700 W下的HEA氧化增重仅0.14 mg/cm2,而900 W下的氧化增重达到了0.52 mg/cm2。图3b为图3a相应的氧化增重的平方与时间的关系图,对曲线进行线性拟合可知,在经历约5 h后的初期氧化后,3种激光功率下的HEA的稳态氧化动力学曲线均符合抛物线规律,其稳态氧化抛物线速率常数kp也相应的从700 W时的1.7 × 10-13 g2/(cm4·s)增至800 W时的1.1 × 10-12 g2/(cm4·s)以及900 W时的2.8 × 10-12 g2/(cm4·s)。

图3

图3

不同激光功率沉积的Al0.21Co0.17Cr0.13Fe0.11Ni0.18Si0.20在“干”空气中的氧化增重曲线及氧化增重平方随时间的变化曲线

Fig.3

Oxidation kinetics (a) and corresponding parabolic plots (b) of Al0.21Co0.17Cr0.13Fe0.11Ni0.18Si0.20 fabricated by LMD at different laser powers during 20 h exposure to dry air at 1100 oC

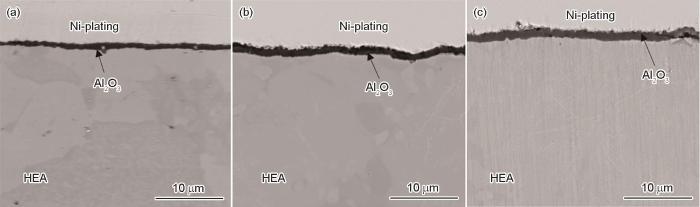

图4为不同激光功率沉积的AlCoCrFeNiSi氧化20 h后的截面SEM形貌。3种不同激光功率沉积的HEA均生成单一深灰色的、连续而致密的氧化膜,它与基体结合良好,氧化及冷却过程中没有发生氧化膜的剥落。EDS分析显示该氧化膜主要由Al和O组成,推定它为Al2O3。该氧化膜的平均厚度由700 W时的0.9 μm,增至800 W时的1.3 μm与900 W时的1.6 μm。

图4

图4

不同激光功率沉积的Al0.21Co0.17Cr0.13Fe0.11Ni0.18Si0.20在“干”空气中氧化20 h后的截面形貌

Fig.4

Cross-sectional morphologies of Al0.21Co0.17Cr0.13Fe0.11Ni0.18Si0.20 fabricated by LMD at 700 W (a), 800 W (b) and 900 W (c) after 20 h exposure to dry air at 1100 oC

2.3 “湿”空气氧化行为

图5为不同激光功率沉积的Al0.21Co0.17Cr0.13Fe0.11-Ni0.18Si0.20在1100 ℃下的“空气+ 10%H2O”中的氧化动力学曲线及其相应的抛物线曲线图,与“干”空气中的氧化曲线相比,“湿”空气中的氧化曲线发生轻微抖动,这与后者气流流量些许变化所致有关。从图5a可见,HEA在“湿”空气中的氧化速度随激光功率增加而相应加快。并且,3种激光功率下的HEA的“湿”氧化动力学仍符合抛物线规律,稳态氧化时的kp 值由700 W时的9.4 × 10-13 g2/(cm4·s),增至800 W时的2.5 × 10-12 g2/(cm4·s)以及900 W时的7.5 × 10-12 g2/(cm4·s)。对比同一功率下HEA在“干”空气中的氧化速度,可以发现10%H2O的添加促进了氧化。

图5

图5

不同激光功率沉积的Al0.21Co0.17Cr0.13Fe0.11Ni0.18Si0.20在“湿”空气中的氧化增重曲线及氧化增重平方随时间的变化曲线

Fig.5

Oxidation kinetics (a) and corresponding parabolic plots (b) of Al0.21Co0.17Cr0.13Fe0.11Ni0.18Si0.20 fabricated by LMD at different laser powers during 20 h exposure to wet air at 1100 oC

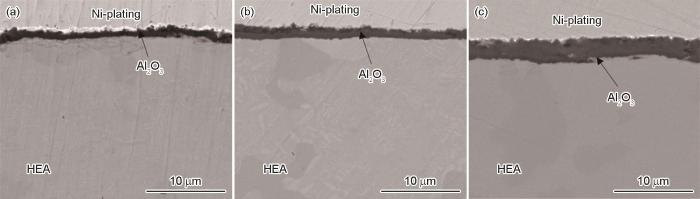

图6为不同激光功率沉积的Al0.21Co0.17Cr0.13Fe0.11-Ni0.18Si0.20氧化20 h后的截面SEM形貌。与“干”空气中相比,3种不同激光功率沉积的HEA生成的是浅灰色的连续的单一Al2O3层。同一功率下HEA在“湿”空气中的氧化膜厚度较“干”空气中有所增加,三种不同激光功率沉积的HEA氧化膜平均厚度分别由“干”空气中的0.9、1.3、1.6 μm增加至“湿”空气中的1.3、1.7、2.9 μm。显而易见,10%H2O促进了氧化膜的生长。

图6

图6

不同激光功率沉积的Al0.21Co0.17Cr0.13Fe0.11Ni0.18Si0.20在“湿”空气中氧化20 h后的截面形貌

Fig.6

Cross-sectional morphologies of Al0.21Co0.17Cr0.13Fe0.11Ni0.18Si0.20 fabricated by LMD at 700 W (a), 800 W (b) and 900 W (c) after 20 h exposure to wet air at 1100 oC

2.4 讨论

2.4.1 晶粒尺寸对氧化性能的影响

从实验结果可知,当激光功率从900 W降低到700 W时,相应所增材制造的Al0.21Co0.17Cr0.13Fe0.11Ni0.18Si0.20在1100 ℃“干”空气环境下的稳态氧化抛物线速率常数kp值由2.8 × 10-12 g2/(cm4·s)降至1.7 × 10-13 g2/(cm4·s),即降低一个数量级。这一结果显然与激光功率降低优化了沉积态该HEA显微结构有关。虽然沉积态的该HEA皆由单一的bcc相组成,但随着激光功率降低,这一HEA的晶粒尺寸明显减小,枝晶更多。

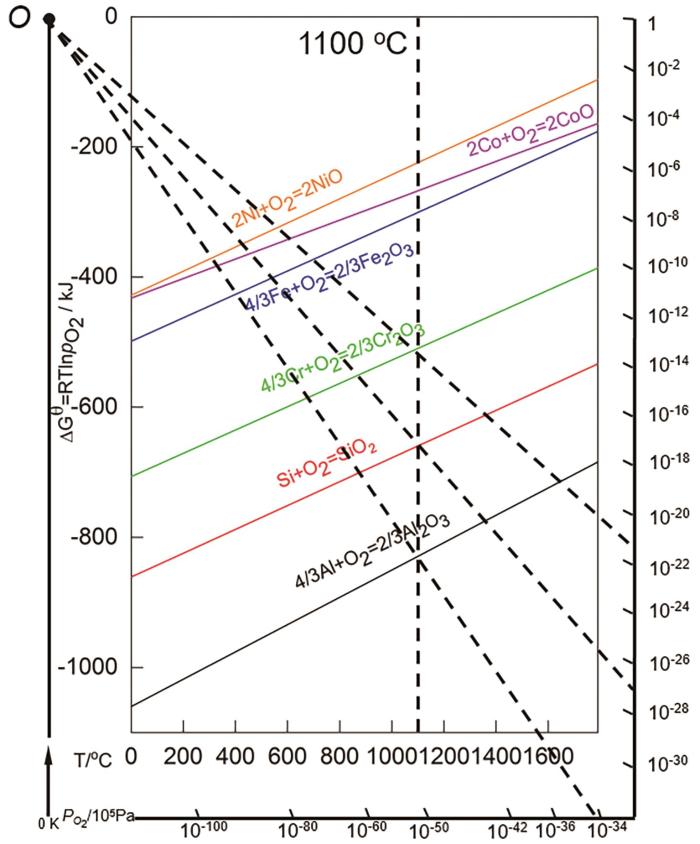

众所周知,晶粒细化可以导致合金产生大量晶界和三角晶界,它们不仅可以充当热生长氧化物的形核位点,还可以充当供给氧化物核快速生长的“短路”扩散通道。当氧化开始时,该HEA晶粒细化有利于Al、Cr、Si的相应氧化物Al2O3、Cr2O3、SiO2的形核和生长,图7为所计算的该HEA中不同金属及其氧化物的Ellingham-Richardson图可以看到,所生成Al2O3、Cr2O3、SiO2反应的平衡氧分压(

图7

图7

HEA中各组成元素及其氧化物的Ellingham-Richardson图

Fig.7

Ellingham-Richardson diagram for corresponding oxides of constituent elements of AlCoCrFeNiSi

2.4.2 H2O蒸气对氧化性能的影响

从1100 ℃“湿”空气下的实验结果看,3种激光功率条件下所沉积的Al0.21Co0.17Cr0.13Fe0.11Ni0.18Si0.20都只形成Al2O3膜且其生长速度均服从抛物线规律,说明Al2O3膜的热生长与“干”空气中的一样受氧化膜中O2-与Al3+的扩散控制。但在相同的激光功率条件下,“湿”空气中的氧化速度要明显快于“干”空气下的,说明H2O蒸气的存在促进了Al2O3膜中O2-、Al3+的扩散。

3 结论

(1) 3种激光功率下所制备的上述HEA均为bcc单相结构,随激光功率增加,HEA晶粒尺寸增大,枝晶减少。

(2) 在“干”空气中氧化,3种激光功率下的HEA均形成单一连续而致密的Al2O3膜,但其热生长速度随着激光功率增大而明显减小,说明HEA的氧化受晶粒尺寸的影响大,晶粒细化有利于提高抗氧化性能。

(3) 在“湿”空气中氧化,3种激光功率下的HEA所形成的氧化膜及其生长速度变化规律与“干”空气中的相同,但在同一功率沉积条件下,“湿”空气下的氧化速度明显快于“干”空气下的,说明H2O蒸气促进了Al2O3膜的生长。

参考文献

High-entropy alloys

[J].Alloying has long been used to confer desirable properties to materials. Typically, it involves the addition of relatively small amounts of secondary elements to a primary element. For the past decade and a half, however, a new alloying strategy that involves the combination of multiple principal elements in high concentrations to create new materials called high-entropy alloys has been in vogue. The multi-dimensional compositional space that can be tackled with this approach is practically limitless, and only tiny regions have been investigated so far. Nevertheless, a few high-entropy alloys have already been shown to possess exceptional properties, exceeding those of conventional alloys, and other outstanding high-entropy alloys are likely to be discovered in the future. Here, we review recent progress in understanding the salient features of high-entropy alloys. Model alloys whose behaviour has been carefully investigated are highlighted and their fundamental properties and underlying elementary mechanisms discussed. We also address the vast compositional space that remains to be explored and outline fruitful ways to identify regions within this space where high-entropy alloys with potentially interesting properties may be lurking.

Research and application progress of high-entropy alloys

[J].

Strengthening-Toughening mechanism and mechanical properties of span-scale heterostructure high-entropy alloy

[J].High-entropy alloys overcome the limitations posed by traditional alloys due to features such as high strength, toughness, high wear resistance, and corrosion resistance. These alloys are novel metallic materials with excellent application potential; however, typically an inverse relationship is observed between the strength and ductility of a metal, which includes high-entropy alloys. Therefore, the design and development of high entropy alloys with high strength and high ductility have become a limitation in current research. Recently, heterostructure design has achieved great success in strengthening and toughening traditional metallic materials. Heterostructured and high-entropy alloys has garnered much attention and research interest to realize the strength and toughness of high-entropy alloys with high strength and high ductility. This study reviews the existing design models for heterostructures from the heterostructure scale perspective. Furthermore, the effects of different heterostructures on the strengthening and toughening mechanism and mechanical properties were analyzed, and future microstructural designs with high strength and toughness were anticipated.

高熵合金跨尺度异构强韧化及其力学性能研究进展

[J].高熵合金突破了传统合金设计理念的桎梏,具有高强度、高硬度、高耐磨性及抗腐蚀性,是一种具有巨大发展前景的新型金属材料。然而,金属材料的强度与塑性之间存在倒置矛盾关系,高熵合金仍受困于这一难题。因此,设计开发兼具高强度与高塑性的高熵合金材料已成为目前研究热点与难点。近年来,异构设计理念在传统金属材料强韧化这一问题上得到发展,如何设计异构高熵合金以实现高熵合金强韧化,使合金兼具高强度与高塑性,引起了科研人员的重视。本文从异构显微组织尺度出发,综述了目前存在的异构显微结构设计方法,分析了不同异构组织对其强韧化机制及力学性能的影响,并对未来高强韧高熵合金显微结构设计进行了展望。

Phase separation in equiatomic AlCoCrFeNi high-entropy alloy

[J].The microstructure of the as-cast AlCoCrFeNi high entropy alloy has been investigated by transmission electron microscopy and atom probe tomography. The alloy shows a very pronounced microstructure with clearly distinguishable dendrites and interdendrites. In both regions a separation into an Al-Ni rich matrix and Cr-Fe-rich precipitates can be observed. Moreover, fluctuations of single elements within the Cr-Fe rich phase have been singled out by three dimensional atom probe measurements. The results of investigations are discussed in terms of spinodal decomposition of the alloying elements inside the Cr-Fe-rich precipitates. Copyright © 2012 Elsevier B.V. All rights reserved.

Corrosion mechanism of annealed equiatomic AlCoCrFeNi tri-phase high-entropy alloy in 0.5 M H2SO4 aerated aqueous solution

[J].

Microstructure and mechanical property of as-cast, -homogenized, and -deformed Al x CoCrFeNi (0 ≤ x ≤ 2) high-entropy alloys

[J].

Microstructure and compressive properties of AlCrFeCoNi high entropy alloy

[J].

Homogenization of Al x CoCrFeNi high-entropy alloys with improved corrosion resistance

[J].

Heat treatment impacts the micro-structure and mechanical properties of AlCoCrFeNi high entropy alloy

[J].

Oxidation behavior of arc melted AlCoCrFeNi multi-component high-entropy alloys

[J].

High temperature oxidation behavior of Al0.6CrFeCoNi and Al0.6CrFeCoNiSi0.3 high entropy alloys

[J].

Effects of Al addition on the microstructure and mechanical property of Al x CoCrFeNi high-entropy alloys

[J].

New insights in the oxidation behavior of (FeCoCrNi)94Al4Ti2Si x high entropy alloys at 1100 oC

[J].

Oxidation behavior of AlCoCrFeNiSi x high-entropy alloys at 1100 oC

[J].

Additive manufacturing of metallic components-process, structure and properties

[J].

Laser additive manufacturing of metallic components: materials, processes and mechanisms

[J].

Additive manufacturing of metals

[J].

Ultra-high temperature oxidation resistant refractory high entropy alloys fabricated by laser melting deposition: Al concentration regulation and oxidation mechan-ism

[J].

Laser additive manufacturing of CrMnFeCoNi high entropy alloy: Microstructural evolution, high-temperature oxidation behavior and mechanism

[J].

High temperature oxidation study of direct laser deposited Al X CoCrFeNi (X = 0.3, 0.7) high entropy alloys

[J].

Laser additively manufacturing of Al0.5CoCrFeNiTi0.5 high-entropy alloys with increased resistances to corrosion 3.5%NaCl and oxidation at 1000 oC

[J].

Insights into the effects of grain size variation and FCC phase formation on the oxidation behavior of laser additively manufactured BCC AlCoCrFeNi high entropy alloy

[J].

Grain growth of Ni-based superalloy IN718 coating fabricated by pulsed laser deposition

[J].

Enhancement of strength-ductility balance of the laser melting deposited 12CrNi2 alloy steel via multi-step quenching treatment

[J].

High temperature corrosion of nanocrystalline metallic materials

[J].

纳米晶金属材料的高温腐蚀行为

[J].

Nanoscale assembly of high-temperature oxidation-resistant nanocomposites

[J].Structural considerations for designing a high-temperature oxidation-resistant metallic material are proposed, based on the dependence of the material structure on a promotion of the development of a protective scale of chromia or alumina. The material should have numerous sites on its surface for nucleating the protective oxides at the onset of oxidation and abundant grain boundaries in deeper areas for simultaneously supplying sufficient flux of the protective-oxide-forming elements toward the surface for a rapid linkage of the oxide nuclei through their lateral growth. Based on these considerations, we fabricated, using an electrochemical deposition method, novel nanocomposites which have a nanocrystalline metal matrix containing Cr and/or Al nanoparticles dispersed at the nano length scale. The validity of the design considerations is verified by comparing the high-temperature oxidation of a typical Ni-Cr nanocomposite system with two types of conventional Ni-Cr materials having similar or higher Cr content but different structure: one is a composite having a nanocrystalline Ni matrix containing Cr microparticles dispersed at the microscale and the other are micron-grained Ni-Cr alloys with the Cr distribution at the atomic length scale.

Electrochemical assembly of Ni-xCr-yAl nanocomposites with excellent high-temperature oxidation resistance

[J].

High temperature oxidation behavior of ultrafine grained ODS Nickel-based superalloy prepared by spark plasma sintering

[J].

放电等离子烧结超细晶ODS镍基合金的高温氧化行为研究

[J].通过机械合金化 (MA) 和放电等离子烧结 (SPS) 制备了Cr<sub>2</sub>O<sub>3</sub>颗粒强化的超细晶结构镍基高温合金 (ODS合金)。对比研究了不添加氧化物颗粒合金 (Base合金) 和ODS合金样品的微观结构和高温氧化行为。结果表明,在1200 ℃烧结过程中,Cr<sub>2</sub>O<sub>3</sub>完全转变为Al<sub>2</sub>O<sub>3</sub>。由于SPS快速烧结及弥散分布的原位Al<sub>2</sub>O<sub>3</sub>颗粒钉扎,抑制了晶粒长大,ODS合金具有十分细小的晶粒结构,其平均晶粒尺寸为0.98 μm;Base合金平均晶粒尺寸稍大,为1.54 μm。ODS合金在900 ℃下具有较好的抗氧化性能和较低的氧化速率,得益于其表面迅速生成了连续致密的内层α-Al<sub>2</sub>O<sub>3</sub>膜,能有效地阻止Ti和Cr向外扩散,表面生成少量保护性较差的TiO<sub>2</sub>和NiCr<sub>2</sub>O<sub>4</sub>。而Base合金表面则生成了以Al<sub>2</sub>O<sub>3</sub>为内层,TiO<sub>2</sub>和Cr<sub>2</sub>O<sub>3</sub>为中间层以及NiCr<sub>2</sub>O<sub>4</sub>为外层的多层结构氧化膜,并且其在初期的氧化速率较快,为1.66×10<sup>-7</sup> mg<sup>2</sup>·cm<sup>-4</sup>·s<sup>-1</sup>,是ODS合金的2倍多。

Some water vapor effects during the oxidation of alloys that are α-Al2O3 formers

[J].

Effects of water vapour on the oxidation of chromia formers

[J].