接地网是电力系统的重要组成部分,埋设于土壤中来释放入地电流,平衡电站电压[1~3]。接地极的正常服役是确保电网安全运行和可靠供电的重要保障,对人类生产生活至关重要[4,5]。接地极常年深埋于地下,受到土壤环境和杂散电流的影响,服役条件苛刻,腐蚀严重甚至穿孔断裂,影响人身安全,造成经济损失,成为电力行业一大难题[6,7]。常见的接地材料有铜、碳钢和镀锌钢以及其他金属包覆材料[8,9],铜耐蚀性好但价格高昂,对土壤污染严重[10,11];碳钢导电性好,但腐蚀严重[12];镀锌钢有锌镀层牺牲阳极保护,但一旦锌层消耗后基体钢的腐蚀极其严重,也不是理想接地材料[13,14]。因此研发一种成本低廉、耐土壤腐蚀、土壤/接地材料界面导电性良好的新型接地材料对电力系统接地极的安全服役具有重大意义。

铸铁生产和应用具有悠久的历史,是目前使用量仅次于钢材的金属材料。铸铁熔炼简单、成本低廉,具有良好的铸造性能和力学性能等优点[15]。科研工作者尝试在普通铸铁中添加各类合金元素调控组成结构以研发耐蚀铸铁,但熔炼过程复杂,成品率低[16]。在倡导可持续发展战略的今天,研究一种成本低、污染小的低合金铸铁表面改性方法,进而有效提升铸铁的耐蚀性具有重大意义[17]。渗碳是一种表面处理工艺,在金属试样表面产生含有碳化物的硬化层,能够有效提高金属材料硬度、耐磨性、强度和抗疲劳性能[18,19]。采用渗碳工艺对合金铸铁表面进行改性,尝试在铸铁表面产生一层碳化物,利用碳化物电位高、硬度高且强度好的特性,使合金铸铁在提升力学性能的同时兼顾耐蚀性,并增加土壤/接地材料界面导电性,以满足接地材料功能需求。

1 实验方法

选取合金铸铁作为基体材料,其化学组成(质量分数,%)为:C 3.75、Si 1.83、S 0.022、P 0.032、Mn 0.72、Cr 0.05、Ti 0.1、Re 0.2、Fe余量,机械加工为直径10 mm、高度5 mm的柱状试样。实验前每个铸铁试样依次采用400#至2000#的SiC砂纸逐级打磨,使用金相抛光机抛光至镜面,酒精清洗吹干后备用。

铸铁试样表面涂覆环氧树脂、固化,置于管式炉中,从室温开始,以5℃/min升温速率控制渗碳温度分别为750、800和900℃,保温时间分别为0、0.5和1 h,保温结束后炉冷至室温。渗碳过程中采用氮气保护。

将渗碳后的铸铁样品用环氧树脂冷镶,并对样品截面进行打磨、抛光和清洗,用光学显微镜观察渗碳铸铁试样渗碳层厚度,用JSM-7800F型扫描电镜(SEM)观察渗碳层显微形貌。用D8 Advance型X射线衍射分析仪(XRD)和LabRAM HR Evolution型Raman光谱分析铸铁样品表面渗碳层物相组成。

选择渗碳铸铁试样作为电极材料,底部用铜线焊接,除待测表面以外全部用硅橡胶密封,电极暴露面积为0.785 cm2。采用DH7006型电化学工作站测量渗碳铸铁试样在NS4土壤模拟液(KCl 0.122 g/L,NaHCO3 0.483 g/L,CaCl2 0.137 g/L,MgSO4·7H2O 0.131 g/L)中的动电位极化曲线[20],并与原始铸铁进行对比,通过腐蚀速率选取最优渗碳参数。电化学测试采用三电极体系,参比电极为饱和甘汞电极,辅助电极为铂电极,工作电极为渗碳铸铁。极化测量电位扫描范围为开路电位-0.1~0.1 V,扫描速率为0.1667 mV/s,采用Cview软件对极化曲线进行解析。阻抗测量频率范围为105~10-2 Hz,正弦波扰动信号峰值为10 mV,采用ZSimpWin软件对电化学阻抗谱进行解析,分析渗碳铸铁试样在土壤模拟溶液中的腐蚀过程。

将渗碳铸铁和原始铸铁的电极试样,置于土壤模拟液中浸泡,进行为期35 d的时效实验。运用三电极体系,每7 d进行一次电化学测量,比较试样在不同阶段的腐蚀行为。通过SEM观察腐蚀产物及石墨分布状况。将渗碳铸铁、原始铸铁和镀锌钢制作电化学测量电极试样,运用三电极体系,置于不同交流电流强度干扰的土壤模拟溶液中[21],进行电化学测量比较。

2 结果与讨论

2.1 渗碳参数对渗碳层的影响

2.1.1 渗碳参数对渗碳层显微形貌的影响

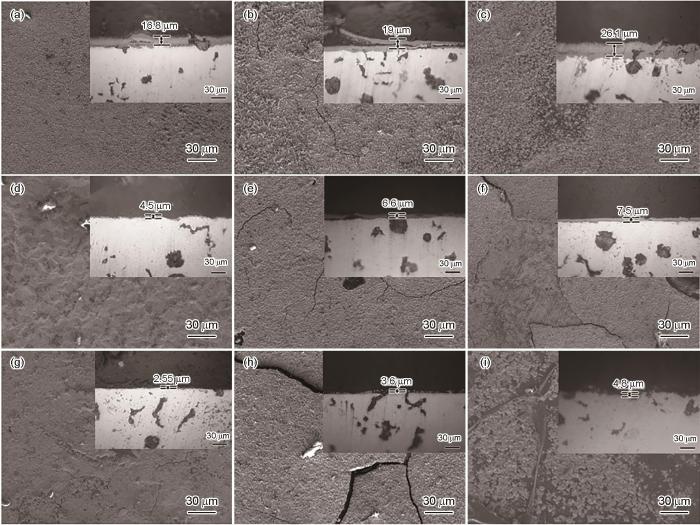

图1

图1

不同条件下形成的渗碳层的表面和截面显微形貌

Fig.1

Surface and cross-sectional micro-morphologies of the cast iron carburized at 750oC (a-c), 800oC (d-f) and 900oC (g-i) for 0 h (a, d, g), 0.5 h (b, e, h) and 1 h (c, f, i)

2.1.2 渗碳参数对渗碳层组成的影响

图2

图2

不同条件下形成的渗碳层的XRD谱和Raman谱

Fig.2

XRD patterns (a) and Raman spectroscopies (b) of carburized layers formed on the cast iron under different carburizing conditions

2.2 渗碳参数对基体的影响

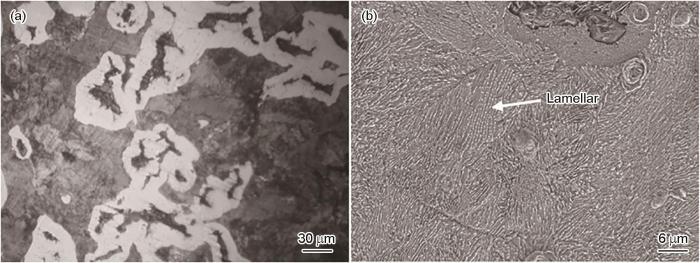

图3为原始铸铁基体的金相照片,通过图像分析软件可知,原始铸铁以碎块状、蠕虫状等石墨形态为主,石墨大小为7级,尺寸约为30~35 μm,基体渗碳体呈片层状分布。

图3

图3

原始铸铁基体的金相照片

Fig.3

Microstructures of graphite (a) and cementite (b) of original cast iron

2.2.1 渗碳参数对基体石墨的影响

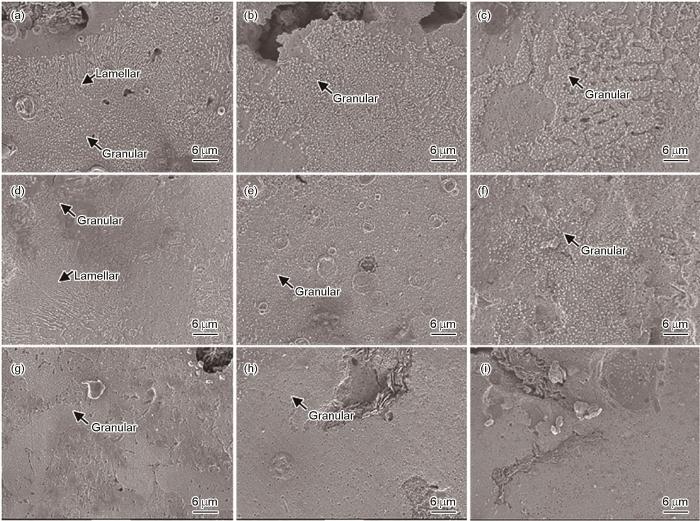

经过不同条件渗碳后基体石墨形态如图4所示。经过渗碳处理后,界面处小石墨数量显著增加,随着渗碳温度和保温时间增加,石墨颗粒有明显长大趋势。小石墨的产生有以下两种原因:(1) 在高温情况下,基体渗碳体发生分解(Fe3C → 3Fe + C),渗碳体转化为铁素体和石墨颗粒,温度和时间的增加促进其分解转化[27]。(2) 表面渗碳为基体内部提供碳源,提供石墨成核的动力,界面处细小石墨数量增加[28]。经750℃下保温0 h渗碳处理的样品基体中出现了不同程度细小石墨团聚,直径约为5~10 μm,呈球状或者蠕虫状均匀分布在基体中。从整体来说,石墨越细小,石墨分布范围越广,在腐蚀介质中形成的腐蚀微电池越多,大量均匀排布的腐蚀微电池削弱发生局部腐蚀的几率。腐蚀初期大量腐蚀微电池形成的腐蚀产物均匀分布在铸铁表面,可有效抑制腐蚀的进一步发展[29~31]。

图4

图4

不同条件渗碳后铸铁基体石墨形态图

Fig.4

Morphologies of graphite in cast iron substrate carburized at 750oC (a-c), 800oC (d-f) and 900oC (g-i) for 0 h (a, d, g), 0.5 h (b, e, h) and 1 h (c, f, i)

2.2.2 渗碳参数对基体渗碳体的影响

图5

图5

不同条件渗碳后铸铁基体中渗碳体形态

Fig.5

Morphologies of cementite in cast iron substrate carburized at 750℃ (a-c), 800oC (d-f) and 900oC (g-i) for 0 h (a, d, g), 0.5 h (b, e, h) and 1 h (c, f, i)

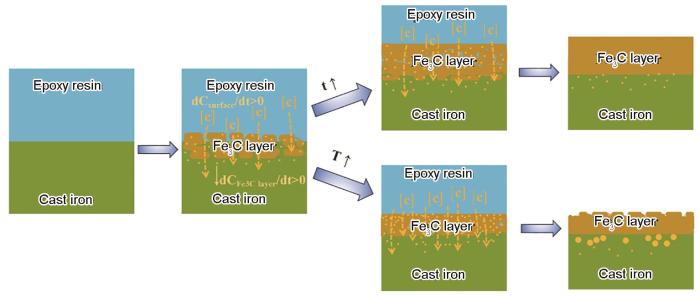

2.3 渗碳机理分析

环氧树脂渗碳机理如图6所示。在高温下,环氧树脂碳化解离出碳原子,在树脂与铸铁表面碳浓度差控制下扩散至铸铁表面,大量活性碳原子积聚在铸铁表面。当表面活性碳原子的浓度达到一定值时,活性碳原子开始扩散到铸铁基体中与基体反应,在铸铁表面形成过渡态碳化物(3Fe + C → Fe3C)[36]。过渡态碳化物不稳定,一方面继续吸收游离碳原子直至在给定的渗碳温度下达到碳在铸铁中的最大溶解度[36];另一方面在高温下过渡态碳化物分解为碳和Fe原子(Fe3C → 3Fe + C)。过渡态渗碳层与基体内部产生碳浓度差,为碳在铸铁基体中扩散提供动力,金属表面的碳逐渐扩散至基体金属中,界面处出现细小石墨(图4)。二者循环往复,在金属表面形成稳定渗碳层。

图6

图6

环氧树脂渗碳机理示意图

Fig.6

Schematic diagrams of carburizing process via heating epoxy resin

渗碳层厚度的变化由以下原因造成:(1) 渗碳温度较低时,碳原子扩散速率低,渗碳体形核缓慢,颗粒细小均匀,渗碳层均匀致密(图1a)。过渡态碳化物在低温下分解速率较低,同时过渡态渗碳层与基体表面的低浓度差导致扩散动力不足,抑制碳化物的分解。根据Gibbs自由能可知,只有温度小于764℃且碳活度大于1时,渗碳体才能生成[37]。碳化物形核速率大于其分解速率,随着保温时间或反应时间的增加,渗碳层厚度持续增加(图1a~c)[32]。(2) 渗碳温度升高表面碳源活性增加,扩散速率增加,为渗碳体形核创造良好条件[38]。铸铁表面迅速生成致密渗碳层,达到铸铁中最大溶解度,抑制渗碳反应进行,渗碳层厚度较低。渗碳温度增加,渗碳体稳定性降低,加速过渡态渗碳层分解,渗碳层厚度进一步降低。

2.4 渗碳参数对基体耐蚀性的影响

图7

图7

原始铸铁和不同渗碳条件样品在土壤模拟液中的极化曲线及拟合的腐蚀速率

Fig.7

Polarization curves (a) and fitting corrosion rates (b) of cast iron samples untreated and carburized under different conditions in NS4 simulated soil solution

对极化曲线进行拟合解析可以获取腐蚀电流密度,进而换算铸铁的腐蚀速率,结果如图7b所示。从图中可以看出,随着渗碳温度增加,渗碳试样腐蚀速率先增加后降低。在渗碳温度为750℃时,渗碳层厚度较高,均匀致密,有效阻挡腐蚀介质渗入;界面细小石墨均匀分布在基体中,基体耐蚀性增加,在两者协同作用下试样自腐蚀电位最高。渗碳温度升高,渗碳层出现明显裂纹,腐蚀介质从裂纹处进入与活性基体反应,耐蚀性较差,自腐蚀电位下降。尽管渗碳温度为900℃时渗碳层厚度极低,但其界面处石墨明显长大,部分大石墨与渗碳层形成机械钉扎,阻断裂纹和石墨孔隙构成的腐蚀介质传质通道,腐蚀电位相对较高[40]。渗碳温度为800℃时既没有致密渗碳层抑制作用也没有界面处石墨的钉扎作用,腐蚀介质从裂纹处快速侵蚀至内部基体,自腐蚀电位最低,耐蚀性最差。经750℃下保温0 h渗碳处理的样品渗碳层较厚,表面均匀致密,基体细小石墨数量最多,自腐蚀电位较高,阴极阳极曲线明显左移,最终拟合的腐蚀速率最低,为0.04 mm/a。

2.5 土壤模拟液时效实验

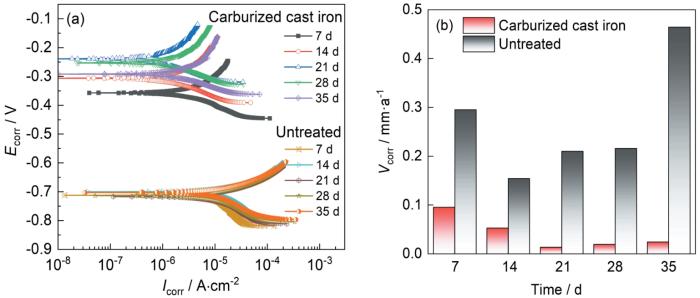

图8

图8

原始以及经750℃下保温0 h渗碳处理的铸铁在土壤模拟液中浸泡不同时间后的极化曲线以及相应的腐蚀速率

Fig.8

Electrochemical polarization curves (a) and fitting corrosion rates (b) of cast iron samples untreated and carburized at 750oC for 0h after immersion in NS4 simulated soil solution for different time

从图8b可以看出经750℃下保温0 h渗碳处理的铸铁腐蚀速率随时间增加而逐渐降低,直至保持在一个较低的速度,呈现较好的耐蚀性;相比之下,原始铸铁腐蚀速率随时间增加而逐渐增加,腐蚀速率较大。

图9为原始以及经750℃下保温0 h渗碳处理的铸铁在NS4土壤模拟液中浸泡不同时间后的电化学阻抗曲线。两种试样的Nyquist图呈双容抗弧特征,腐蚀过程主要受电荷转移过程控制[41]。Nyquist图圆弧跨度越大,表明电荷转移难度越大,由图9a和d比较可知在腐蚀介质中致密渗碳层的物理屏蔽作用较强,保护作用更好[42~44]。根据图9a和d等效电路图拟合得到表1阻抗谱拟合参数。对于原始铸铁,Rs对应溶液电阻,Rf对应腐蚀产物层电阻,Qf为腐蚀产物膜引起的电容,Rct对应腐蚀产物层/基体界面处的电荷转移电阻,Qdl为双电层电容;对于渗碳铸铁,Rs对应溶液电阻,Rf对应渗碳层膜电阻,Qf为渗碳层引起的电容,Rct对应渗碳层/基体界面处的电荷转移电阻[42],Qdl为双电层电容。

图9

图9

原始以及经750℃下保温0 h渗碳处理的铸铁在NS4土壤模拟液中浸泡不同时间后的电化学阻抗曲线

Fig.9

EIS curves of cast iron samples untreated (a-c) and carburized (d-f) at 750oC for 0 h after immersion in NS4 simulated soil solution for different time

表1 不同时间下NS4土壤模拟液中铸铁的阻抗谱拟合参数

Table 1

| Time / d | Untreated | Carburized cast iron | |||||

|---|---|---|---|---|---|---|---|

| Rs / Ω∙cm2 | Rf / Ω∙cm2 | Rct / Ω∙cm2 | Rs / Ω∙cm2 | Rf / Ω∙cm2 | Rct / Ω∙cm2 | ||

| 7 | 516.3 | 410.8 | 642.8 | 455.9 | 390.7 | 6142 | |

| 14 | 462.1 | 405 | 928.5 | 365.7 | 385.2 | 7175 | |

| 21 | 530.8 | 437.5 | 732.2 | 417.5 | 358.4 | 7382 | |

| 28 | 306.9 | 309.4 | 898.5 | 447 | 409.7 | 7593 | |

| 35 | 397.2 | 268 | 428.8 | 381.85 | 376.2 | 6928 | |

对于原始样品,铸铁基体在土壤模拟液中Rct较小,具有较高的活性,Rf随着时间增加先增加后降低,表明腐蚀产物疏松多孔,容易脱落暴露基体金属,腐蚀产物膜不稳定,对基体腐蚀抑制作用较小。对于渗碳样品,由于表面渗碳层稳定性较高,且相对完整,对腐蚀介质的物理屏蔽作用很强,腐蚀介质传质过程受阻,基体活性较低,有较高的Rct值。从图9f来看,渗碳铸铁阻抗值随着时间增加而升高,表明腐蚀初期,渗碳铸铁表面存在微小孔洞等缺陷,没有完全达到隔离腐蚀介质的作用,腐蚀中后期,腐蚀产物在渗碳层缺陷处沉积,使渗碳层更加致密,耐蚀性更好,渗碳样品整体阻抗值远高于原始铸铁。

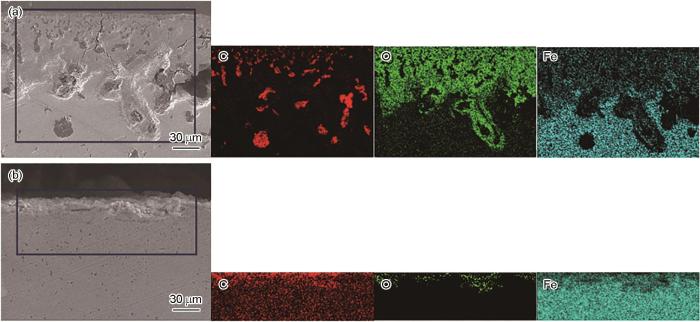

图10为原始以及经750℃下保温0 h渗碳处理的铸铁在NS4土壤模拟液中浸泡35 d后形成的腐蚀产物截面形貌。图10可以看出,原始铸铁腐蚀极其严重,腐蚀产物体积为其被腐蚀基体的3~5倍,腐蚀产物中有明显裂纹,而经750℃下保温0 h渗碳处理的铸铁几乎未被腐蚀,证明经750℃下保温0 h渗碳处理的铸铁具有良好耐蚀性。表1中原始铸铁和渗碳铸铁膜电阻Rf值随着腐蚀时间增加逐渐降低,Rf值降低代表了腐蚀产物导电性增加[18],均为铸铁腐蚀产物中大量石墨存在导致(图10b)。渗碳铸铁渗碳层Fe3C导电率为铁氧化物的两倍多,导电性能更加优异[45],即使后期渗碳层破裂发生腐蚀,腐蚀产物导电性依旧优于原始铸铁。

图10

图10

原始以及经750℃下保温0 h渗碳处理的铸铁在NS4土壤模拟液中浸泡35 d后的截面形貌

Fig.10

Cross-sectional morphologies of cast iron samples untreated (a) and carburized (b) at 750oC for 0 h after immersion in NS4 simulated soil solution for 35 d

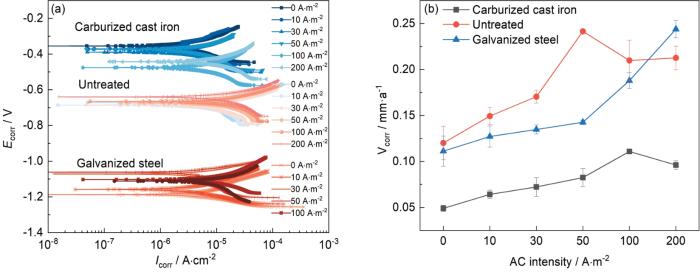

2.6 模拟交流电流干扰实验

为了更好的凸显渗碳后铸铁的耐蚀性能,选取原始铸铁、镀锌钢和上述经750℃下保温0 h渗碳处理的样品进行对比研究。图11为原始和经750℃下保温0 h渗碳处理的铸铁以及镀锌钢在NS4土壤模拟液中不同交流电流强度下的极化曲线及拟合腐蚀速率。由图可知,3种材料自腐蚀电流密度随着交流电流强度增加而增加,其中经750℃下保温0 h渗碳处理的铸铁在不同交流电流强度下开路电位最高,自腐蚀电流密度最低,腐蚀速率远低于原始铸铁和镀锌钢。原始铸铁表面活性高,腐蚀严重;镀锌钢后期由于锌和钢基体的耦合作用,遭受电偶电流和交流干扰产生的协同效应,腐蚀相对严重[21,47];渗碳铸铁渗碳层耐蚀性、稳定性和导电性均较好,避免作为接地极材料腐蚀、断裂引起的用电事故影响正常供电,满足接地材料功能需求[21,48]。

图11

图11

原始和经750℃下保温0 h渗碳处理的铸铁以及镀锌钢在NS4土壤模拟液中不同交流电流强度下的极化曲线及拟合腐蚀速率

Fig.11

Polarization curves (a) and corresponding corrosion rates (b) of untreated and 750oC/0 h carburized cast iron and galvanized steel in NS4 soil simulated solution at different AC current intensities

3 结论

(1) 最优渗碳参数为以5℃/min从室温升至750℃后炉冷,铸铁表面有渗碳层生成,均匀致密,与基体结合较好,厚度约16.8 μm。渗碳层能够抑制腐蚀介质渗入,铸铁自腐蚀电位显著提高,自腐蚀电流密度降低,拟合腐蚀速率约为0.04 mm/a。

(2) 经750℃下保温0 h渗碳处理的铸铁界面出现许多细小石墨,由基体渗碳体高温分解与表面渗碳引起;基体残留大量片层状渗碳体保证其基体力学性能。

(3) 在土壤模拟液中,渗碳铸铁腐蚀速率低,渗碳层导电率高,导电性和耐蚀性显著提升;在交流电流干扰试验中,渗碳铸铁耐蚀性能远高于镀锌钢和原始铸铁,满足接地材料功能功能需求。

参考文献

Research advances of soil corrosion of grounding grids

[J].

Safety performance of large grounding grid with fault current injected from multiple grounding points

[J].

A new optimization design for grounding grid

[J].

Causes, forms and remedies of substation grounding grid corrosion

[A].

Soil corrosion characteristics of Q235 steel grounding material used in power grid in Anhui Province

[J].

安徽省电网接地材料Q235钢的土壤腐蚀特性及规律性研究

[J].

Electrochemical study of the corrosion rate of carbon steel in soil: evolution with time and determination of residual corrosion rates under cathodic protection

[J].

Surface potential and resistance of grounding grid systems in homogeneous soil

[J].

Comparative study on the corrosion behaviours of high-silicon chromium iron and Q235 steel in a soil solution

[J].

An investigation of earth grid performance using graphene-coated copper

[J].

Long-term corrosion-induced copper runoff from natural and artificial patina and its environmental impact

[J].The overall objective of this paper is to present an extensive set of data for corrosion-induced copper dispersion and its environmental interaction with solid surfaces in the near vicinity of buildings. Copper dispersion is discussed in terms of total copper flows, copper speciation and bioavailability at the immediate release situation, and its changes during transport from source to recipient. Presented results are based on extensive field exposures (eight years) at an urban site, laboratory investigations of the runoff process, published field data, generated predictive site-specific runoff rate models, and reactivity investigations toward various natural and manmade surfaces, such as those in soil, limestone, and concrete. Emphasis is placed on the interaction of copper-containing runoff water with different soil systems through long-term laboratory column investigations. The fate of copper is discussed in terms of copper retention, copper chemical speciation, breakthrough capacities, and future mobilization based on changes in copper concentrations in the percolate water, computer modeling using the Windermere Humic Aqueous Model, and sequential extractions. The results illustrate that, for scenarios where copper comes in extensive contact with solid surfaces, such as soil and limestone, a large fraction of released copper is retained already in the immediate vicinity of the building. In all, both the total copper concentration in runoff water and its bioavailable part undergo a significant and rapid reduction.

Corrosion behavior of copper in a simulated grounding condition in electric power grid

[J].

铜在电网接地工况下的腐蚀行为研究

[J].通过室内模拟加速实验、电化学测试以及X射线衍射 (XRD)、扫描电子显微镜 (SEM) 等手段对通电工况下铜接地网材料在酸性土壤环境中的腐蚀特征进行了研究。结果表明,通电条件对Cu的腐蚀行为有较大影响,Cu的腐蚀速率随外加电流密度的增大而逐渐增大;腐蚀产物以CuO和Cu<sub>2</sub>O为主,Cu<sub>2</sub>O的占比随外加电流密度的增大而减小。

Effects of alternating stray current on the corrosion behaviours of buried Q235 steel pipelines

[J].

The effects of Cl- and direct stray current on soil corrosion of three grounding grid materials

[J].

Corrosion of galvanized steel in soils

[J].

Effect of low carbon equivalent on microstructure and properties of gray cast iron

[J].

低碳当量对灰铸铁组织和性能的影响

[J].

Alloying of cast iron and classification of alloy cast iron

[J].

铸铁的合金化及合金铸铁的分类

[J].

Research status in corrosion resistant cast iron under marine environment

[J].

海洋环境下耐蚀铸铁的研究现状

[J].

Microstructure evolution and corrosion property of medium-carbon alloy steel after high-temperature carburization process

[J].

Research progress of ion implantation composite surface modification technology

[J].

离子注渗复合表面改性技术研究进展

[J].

Corrosion process and mechanism analysis of the HFW pipe in NS4 and Yingtan soil simulated solution

[J].

HFW焊管在NS4及鹰潭土壤模拟溶液中的腐蚀及机理分析

[J].

Galvanic effect and alternating current corrosion of steel in acidic red soil

[J].

Self-lubricating and anti-corrosion amorphous carbon/Fe3C composite coating on M50NiL steel by low temperature plasma carburizing

[J].

The high temperature property of Ni/WC infiltrated composite layer on cast iron substrate

[J].

Effect of austenitizing temperature on friction and wear properties of austempered ductile iron

[J].

奥氏体化温度对等温淬火球墨铸铁摩擦磨损性能的影响

[J].

Plasma carburizing of sintered pure iron at low temperature

[J].

Micro raman spectroscopy and electron probe microanalysis of graphite spherulites and flakes in cast iron

[J].

Cementites decomposition of a pearlitic ductile cast iron during graphitization annealing heat treatment

[J].

Carbon diffusion in cementite (Fe3C) and Hägg carbide (Fe5C2)

[J].

Corrosion behavior and mechanism of vermicular graphite cast iron in neutral salt spray

[J].

蠕墨铸铁中性盐雾腐蚀行为及机理研究

[J].

Strengthening cast iron by use of rare earth elements

[J].

使用稀土元素实现铸铁高强度化的方法

[J].

Research on the alkali corrosion resistance property of low alloy cast iron containing rare earth

[J].

加稀土低合金铸铁耐碱腐蚀性能研究

[J].

Effect of discharge temperature during annealing at 750oC on microstructure and properties of QT450-10 nodular cast iron

[J].

750℃退火出炉温度对QT450-10球墨铸铁组织与性能的影响

[J].利用光学显微镜、扫描电镜等方法研究了在750℃退火工艺下不同出炉温度对QT450-10球墨铸铁的珠光体含量、渗碳体形态、抗拉强度以及硬度的影响。结果表明,球墨铸铁试样在经过不同出炉温度下的微观组织均由铁素体、石墨球、石墨颗粒以及少量渗碳体组成。由于珠光体的分解、渗碳体残留以及石墨颗粒的形成导致在750℃出炉空冷时试样的抗拉强度下降7%左右、布氏硬度下降13%左右。随着出炉温度的降低,试样残留渗碳体的分解以及石墨颗粒的长大,导致抗拉强度、硬度均有所下降,当出炉温度为100℃时试样的抗拉强度下降10%左右、布氏硬度下降20%左右。

Corrosion shape and corrosion mechanism of pearlite

[J].

珠光体片层腐蚀形态与机理

[J].

Effect of heat deformation heating temperature on microstructure evolution and hardness of GCr15SiMn cementite

[J].

加热温度对GCr15SiMn渗碳体组织的影响

[J].

Pseudo-passive films on cast irons: a strategy to mitigate corrosion by acting directly on microstructure

[J].

Reactive flow simulation of vacuum carburizing by acetylene gas

[J].

Research progress of metal dusting mechanisms and countermeasures

[J].

金属粉化机理及应对措施的研究进展

[J].

Effect of reaction temperature and gas composition on formation of iron carbide

[J].

反应温度、气氛对碳化铁制备过程的影响

[J].

In situ observation of graphitization of cementite in ductile cast iron during heating

[J].

球墨铸铁加热过程中渗碳体石墨化的原位观察

[J].

Corrosion and wear properties of carburized layer on TC6 titanium alloy in different environments

[J].

TC6钛合金渗碳层在不同介质环境中的腐蚀磨损性能

[J].

Study on soil corrosion of carbon steel by Electrochemical impedance spectroscopy (EIS)

[J].

碳钢在土壤中腐蚀的电化学阻抗谱特征

[J].根据钢铁材料在不同湿度的沈阳、大港和鹰潭三种类型土壤介质中的电化学阻抗谱特征,提出了土壤腐蚀的等效电路模型;同时讨论了湿度对钢铁土壤腐蚀电化学行为的影响。

Improving corrosion resistance of Ti-6Al-4V alloy through plasma-assisted PVD deposited nitride coatings

[J].

Influence of tempering temperature on corrosion resistance of EH890 marine engineering steel

[J].In order to investigate the influence of different tempering temperatures on the corrosion resistance of the EH890 marine engineering steel, the phase and microstructure of the steel originally quenched and tempered at different temperatures were analyzed by X-ray diffrotometry and field emission scanning electron microscopy. The corrosion behavior under different heat treatment conditions was studied by electrochemical experiments. The influence of tempering temperature on corrosion was calculated and analyzed in combination with microhardness and dislocation density. The results show that the original quenched microstructure of the EH890 steel consists of lath bainite, and a small amount of granular bainite and quasi-polygon ferrite with thin film retained austenite. With the increase of tempering temperature, the bainite lath is coarsened continuously, and the ferrite and retained austenite are decomposed and transformed. When the tempering temperature reaches 350 ℃, the fine dispersed carbides and the second phase begin to precipitate at the boundary of bainite. With the increase of the tempering temperature, the corrosion resistance of the steel shows a trend of increasing first and then decreasing. On the one hand, tempering can eliminate the high dislocation density caused by quenching and reduce the corrosion tendency of the specimen. On the other hand, with the increase of the tempering temperature, the dispersed second phase continuously precipitates from the matrix and forms local galvanic interaction with the matrix, which destroys the integrity of passivation film and reduces its protective effect on the matrix. Under the combined action of the two factors, a more protective passivation film is formed on the surface of the specimen tempered at 350 ℃, which shows optimized pitting resistance.

回火温度对EH890海洋工程用钢耐蚀性能的影响

[J].为探究回火温度对EH890海洋工程用钢耐蚀性能的影响,采用X射线衍射仪、场发射扫描电镜分析了原始淬火态和不同回火温度下EH890钢的物相及微观组织,通过电化学试验研究了不同热处理状态下的腐蚀行为,并结合显微硬度、位错密度计算分析了回火温度对其腐蚀的影响规律。结果表明,EH890钢原始淬火态组织为板条贝氏体,少量粒状贝氏体及准多边形铁素体和薄膜状残留奥氏体,随着回火温度的提高,贝氏体板条不断粗化,铁素体与残留奥氏体分解转化,回火温度达到350℃时,贝氏体边界处开始析出弥散细小的碳化物及第二相。随回火温度的升高,试样钢的耐蚀性能呈现先上升后下降的趋势。一方面,回火处理降低了因淬火产生的高位错密度,减轻试样的腐蚀倾向;另一方面,随着回火温度的升高,弥散第二相不断从基体析出,与基体形成局部电偶作用,破坏钝化膜的完整性,降低钝化膜对基体的保护作用,降低腐蚀抗力。在两种因素的综合作用下,经350℃回火试样表面形成了更具保护性的钝化膜,表现出最佳的耐蚀性能。

Corrosion behavior of typical grounding materials in artificial alkaline soil solution

[J].

典型接地材料在碱性土壤模拟液中的腐蚀行为研究

[J].通过电化学阻抗谱和极化曲线电化学测试技术研究了Q235钢、镀锌钢和纯铜在山东典型碱性土壤模拟液中的腐蚀电化学行为,利用金相显微镜和激光共聚焦显微镜 (CLSM) 对其极化后的表面腐蚀形貌进行了分析。结果表明,3种金属材料在该种碱性模拟环境下发生不同程度的腐蚀,其阳极过程都为金属的阳极溶解,而阴极过程为吸氧反应。Q235钢的耐腐蚀性最差,Q235钢和镀锌钢发生全面腐蚀,纯铜表面发生点蚀,3种金属的耐腐蚀程度为:纯铜>镀锌钢>Q235钢。

Microstructure and physical properties of iron carbide films formed by plasma enhanced chemical vapor deposition

[J].

Understand the AC induced pitting corrosion on pipelines in both high pH and neutral pH carbonate/bicarbonate solutions

[J].

Corrosion kinetics and patina evolution of galvanized steel in a simulated coastal-industrial atmosphere

[J].The corrosion kinetics and patina (corrosion products) layer evolution of galvanized steel submitted to wet/dry cyclic corrosion test in a simulated coastal-industrial atmosphere was investigated. The results show that zinc coating has a greater corrosion rate during the initial period and a lower corrosion rate during the subsequent period, and the patina composition and structure can greatly affect the corrosion kinetics evolution of zinc coating. Moreover, Zn5(OH)6(CO3)2 and Zn4(OH)6SO4 are identified as the main stable composition and exhibit an increasing relative amount; while Zn12(OH)15Cl3(SO4)3 cannot stably exist and diminish in the patina layer as the corrosion develops.

Analysis the influence of corrosion layer on the grounding performance of grounding electrodes

[J].