奥氏体不锈钢因为具有较好的力学性能、加工性能和耐腐蚀性能被选为反应堆堆内构件的主要结构材料。当前核电站的服役寿命正致力于延长至60年或更长时间,堆内构件材料在寿期内将受到高达80 dpa的中子辐照。此时,材料将受到严重的辐照损伤(如:辐照诱导相结构[1]、空洞[2]、位错环[3]等),进而降低其力学性能[2~4]和耐腐蚀性能,导致材料抗应力腐蚀性能(SCC)[1,4~7]降低,并进一步诱发辐照促进应力腐蚀开裂(IASCC)。IASCC是导致轻水堆(LWRs)堆芯部件开裂乃至失效的关键原因之一。自20世纪60年代300系列不锈钢燃料棒包壳[8]第一次发生IASCC事故以来,先后在沸水堆(BWRs)的高应力组件、低应力组件、焊接堆芯管以及压水堆堆内构件等关键部件发现了IASCC现象[8]。

SCC本身是一种应力、环境和材料微观结构等多因素耦合的现象[8],在IASCC中,由于辐照又可与各因素发生相互作用[4],使得其多因素耦合的行为和机制变得更加复杂。此外,水的辐照分解也曾被认为对IASCC有重要影响,但之后的研究表明[9,10],向冷却剂中添加H2可降低辐照分解产物的生成率,从而抑制水的辐解,所以对IASCC几乎无影响。国际上对奥氏体钢的IASCC现象已开展一系列试验研究,以期掌握中子辐照IASCC行为机制,实现对堆内构件老化状态和寿命的有效评估。由于中子辐照样品稀少且具有放射性,国内目前主要开展了基于离子辐照的IASCC试验研究,因为离子辐照效率高、成本低以及感生放射性极低,在IASCC机制研究中颇具优势。但其损伤深度浅、损伤截面不均匀的固有缺点使其在IASCC行为研究中饱受争议。因此相关IASCC试验研究工作亟待开展。本文通过调研总结国内外文献,综述了辐照对奥氏体钢IASCC裂纹萌生、扩展及敏感性变化行为的影响规律,分析了IASCC的微观机理,总结了辐照后退火(PIA)在IASCC研究中的应用,以期为抑制IASCC提供参考。

1 辐照对IASCC行为的影响规律

IASCC导致的失效过程一般会经历裂纹萌生、裂纹扩展和失稳断裂阶段,其中,失稳断裂阶段主要由力学因素控制[11]。因此对IASCC的研究主要集中在裂纹萌生和扩展阶段,也可用应力腐蚀敏感性的变化进行间接表征。

1.1 IASCC 裂纹萌生的行为规律

IASCC裂纹萌生占材料断裂失效过程的大部分时间,是IASCC研究的关键阶段。整个过程又包括先导期(物质发生变化,材料在特定环境中对IASCC敏感)、孕育期(材料存在微观渗透)和缓慢扩展期(裂纹扩展速率远小于裂纹扩展阶段)阶段[12],前两个阶段裂纹深度几乎不发生变化,第三个阶段裂纹缓慢扩展至几十至几百微米处。

1.2 IASCC 裂纹扩展的行为规律

IASCC裂纹萌生后将继续扩展,最终导致材料的失稳断裂。裂纹扩展速率是表征IASCC裂纹扩展行为的重要参数,一般通过在高温高压水中对CT(紧凑拉伸)试样保持恒定应力强度因子的同时利用DCPD原位测量裂纹长度来实现。

当前研究认为,辐照剂量、屈服强度、应力强度因子K、温度、加载类型是压水堆(低ECP环境)内IASCC裂纹扩展速率(CGR)的关键影响因素,其关系模型如

式中,

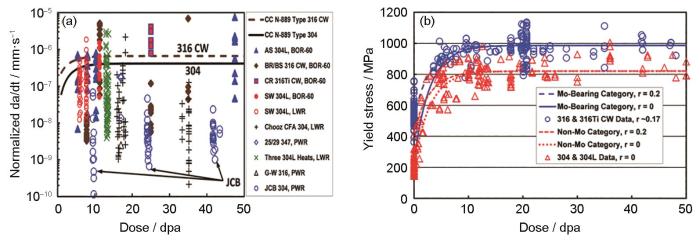

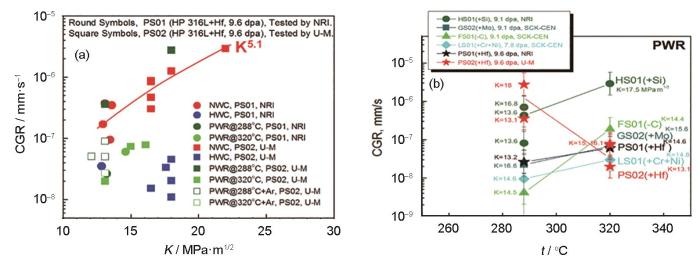

IASCC CGR随辐照剂量的增加而增加,且在8~10 dpa范围内达到饱和(图1a),值得注意的是,剂量对屈服强度的影响呈现出相同的趋势(图1b);此外,PWRs条件下每种中子辐照合金的CGR均随着应力强度因子(K)的增加呈现出增加的趋势(图2a),但具体的K指数仍受合金添加元素以及服役环境的影响[16];一般而言,在同等的K条件下,CGR随着服役温度的升高而增加(图2b),唯一例外的是合金PS02(+Hf),即掺杂Hf的高纯316L不锈钢(中子剂量9.6 dpa),其在288℃时的CGR比320℃高出约10倍左右。然而,温度对CGR的具体影响还需要在包括等效DH、电导率、ECP和加载历史等变量得到良好控制的实验条件下进一步验证。

图1

图2

图2

IASCC数据中CGR随应力强度因子和辐照温度的变化规律[16]

Fig.2

Variation of CGR with stress intensity factor (K) (a) and irradiation temperature (b) in IASCC datas[16] (The matrix of samples with different numbers in the figure is high purity 316L stainless steel, and the contents in brackets represent the alloying elements adulterated or removed), The K dependence of the Hf addition alloy samples PS01 (round symbols) and PS02 (square symbols) irradiated to 9.6 dpa and tested in NWC, HWC, and PWR water CGR as a function of temperature for solute addition alloys tested at NRI, SCK-CEN, and U-M in PWR at 288oC and 320oC

1.3 IASCC 敏感性的行为规律

IASCC敏感性是评价堆芯材料抗IASCC性能的重要指标,通常使用慢应变速率拉伸试验(SSRT)数据进行表征。目前研究主要采用中子辐照后样品开展。此外,出于降低研究成本、提高研究效率等方面考虑,也常用离子辐照模拟中子辐照开展IASCC敏感性研究。

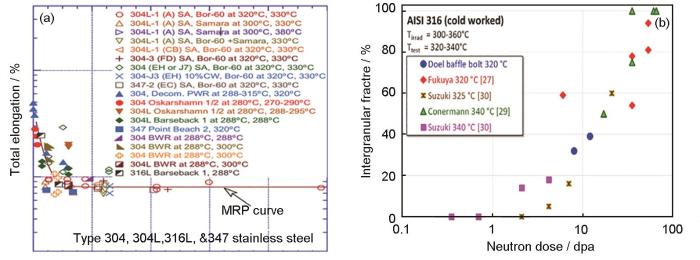

图3

图3

中子辐照IASCC敏感性参数随剂量的变化[10,19]

Fig.3

Variation of IASCC sensitivity parameters with dose of neutron irradiation: (a) Yield strength and total elongation as a function of neutron dose for solution-annealed Type 304, 304L, 316L, and 347 stainless steels at 270-380oC[10], (b) Dose dependency of IASCC susceptibility of irradiated 316 stainless steel in a PWR environment with neutron exposure[19]

离子辐照IASCC样品只能单面局部受照而且剂量梯度大,因此通常通过裂纹信息(裂纹数量密度、平均长度、长度密度等)和微观组织信息(局部变形程度)等参数对IASCC敏感性进行间接表征。相关研究表明,辐照剂量对上述参数具有明显的正相关效应,即随着辐照剂量增加IASCC敏感性逐渐增大[20]。

基于中子、离子辐照的IASCC试验研究结果均表明,辐照剂量增加会提高IASCC敏感性,且在特定表征参数上存在着剂量饱和值。

综上,辐照促进了IASCC裂纹的萌生与扩展,表现为IASCC敏感性的增加:压水堆一回路水环境中IASCC裂纹萌生阈值剂量为~3 dpa,阈值应力为约40%屈服应力;IASCC CGR饱和剂量为8~10 dpa;中子辐照后样品总延伸率的饱和剂量为~10 dpa,IG%随剂量的增加而持续增长。然而,由于裂纹萌生位置的随机性以及中子辐照样品难以获得,导致裂纹萌生时间与剂量的相关性缺乏足够且可靠的数据支持;另一方面,不同的实验条件及数据筛选方法导致IASCC CGR数据呈现出很大的分散性。此外,当前大部分关于裂纹萌生与扩展的实验数据均偏向于工程目的,如裂纹萌生阈值剂量、阈值应力、失效时间等,缺乏对IASCC的机理探索及理论支撑,因此有必要围绕IASCC微观机理开展深入研究。

2 IASCC 机制研究

IASCC是一种复杂的现象,由辐照、应力、水化学等多种因素共同作用产生,局部变形、晶界氧化、辐照硬化、辐照诱导偏析(RIS)、辐照肿胀等因素都有助于引发IASCC[21],然而目前还无法确定何种因素起主导作用。

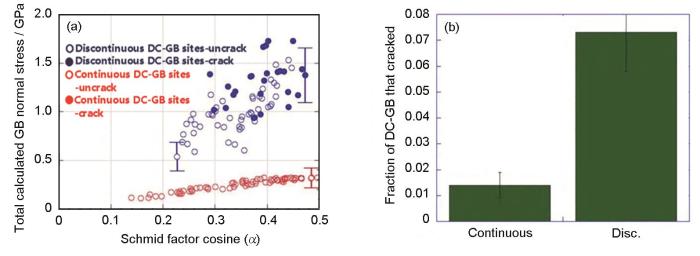

2.1 局部变形

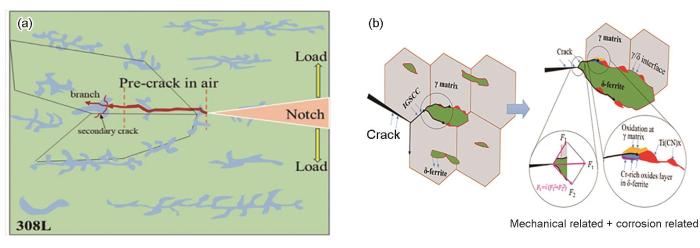

局部变形导致IASCC的机理在于:辐照产生的缺陷以及低层错能合金会大幅降低运动位错交滑移的可能性,导致位错运动局域化增强,诱发位错通道(DC)[7,22]。位错通道是奥氏体钢局部变形的主要方式,也是位错运动阻力最小的路径。一方面,位错通道中位错密度高,一个新启动的位错通道传输至晶界会导致晶界附近位错塞积,当对样品施加较高的应力时,更多的位错将会加入位错队列,在某一时刻,先导位错会被并入晶界,成为外源晶界位错(EGBD),并进一步分解为晶界位错(GBD)。随着应力作用下的晶格位错被不断“挤压”至晶界,造成晶界位错上的应力不断增大,当其达到一定程度时,会发生剧烈剪切应变,引起残余应变集中,导致邻近晶粒的位错源开动,从而促进局部晶界滑移(晶界变形)或楔形裂纹成核,引起试样表面保护性氧化膜破裂,导致IASCC裂纹萌生或现有裂纹扩展。另一方面,位错通道与晶界(GB)的作用方式包括连续DC-GB作用和非连续DC-GB作用[23],前者易发生在HH型晶界处,而后者倾向于在LL型晶界处产生。非连续DC-GB交界处产生的法向应力往往高于连续DC-GB交界处[24](图4a),导致较高的局部应力集中[25],IGSCC裂纹更容易产生[23~25](图4a和b)。

图4

图4

DC-GB位置处的法向应力及开裂情况统计[23,24]

Fig.4

Statistics of normal stress and cracking at DC-GB position : (a) Total calculated stress acting normal to the grain boundary as a function of the crystallographic orientation of the deforming grain and the geometric orientation of the grain boundary normal vector[24], (b) Cracking statistics at different DC-GB locations[23]

2.2 晶界氧化

有文献指出[36,37],增加辐照剂量可以促进晶界氧化,从而促进IASCC裂纹萌生,这是辐照诱导偏析(RIS)引起的晶界Cr贫化所致。然而,研究[38]表明,当样品不受应力且在模拟PWR一回路水中长期浸泡后,辐照反而提高316L奥氏体钢的晶界抗氧化性,这是因为在辐照晶界处偏析的Si由于高扩散率和对O的亲和性优先向外扩散并被氧化。一方面,晶间氧化物尖端的富Si氧化物可以作为O的临时扩散屏障阻止O的流失;另一方面,Si优先扩散产生的空位极大地提高了Cr向氧化物前沿的传输效率,导致氧化物尖端的Cr含量升高。Si和Cr的富集结合可以增强晶界抗氧化能力,最终导致晶界氧化速率降低。与之情况不同的是,304奥氏体不锈钢的晶界氧化仍然以晶界贫Cr为主导因素,这是因为辐照致Fe、Cr、Ni在晶界处的偏析程度与在位错环处相当,而辐照致Si在304不锈钢位错环处的偏析数倍于晶界处[39],晶界处少量的Si富集既无法阻止O的流失,也无法促进Cr向氧化物前沿扩散,即,对304不锈钢而言,辐照仍然发挥着促进晶界氧化的作用。综上,传统意义上辐照致晶界贫Cr是晶界氧化的主导因素,但晶界及裂尖处Si的富集也在晶界氧化甚至IASCC进程中具有潜在作用,这主要取决于晶界基底元素的含量以及由辐照引起的主要元素(如Cr、Si等)在晶界处的偏析程度。因此,需进一步深入工作以理清辐照影响不同奥氏体钢晶界氧化的具体机制,此外,还需对应力作用下辐照对晶界氧化的影响行为展开进一步研究,以探明应力-辐照-氧化影响IASCC的协同机制。

2.3 辐照硬化

2.4 辐照诱导偏析(RIS)

式中,Ma为原子量,

2.5 辐照肿胀与辐照蠕变

压水堆服役寿命延至60年甚至80年意味着处于堆芯的奥氏体钢将会受到高达80 dpa的中子辐照,高剂量下空洞肿胀导致材料脆化以及“辐照松弛-辐照肿胀”先后发生引起的再加载在材料中产生拉伸或剪切载荷,二者在高温高压水的氧化作用下可共同诱发IASCC裂纹的萌生及扩展。

2.6 辐照诱导相变

(1) 电化学效应:γ相易氧化,导致裂尖部分钝化,形成阳极,δ相不易氧化,形成阴极,γ/δ界面构成的微电偶腐蚀电池加剧γ相的氧化,使裂纹尖端严重钝化,导致裂尖应变/应力集中降低,裂尖扩展速率降低。

图5

因此,辐照极大地削弱了δ相抑制SCC的重要作用。

2.7 辐照后退火(PIA)在IASCC机制研究中的应用

在辐照条件下,奥氏体不锈钢基体中将形成小缺陷簇、位错环、沉淀和空洞等多种微观缺陷,溶质元素在晶界等缺陷阱处也会发生辐照诱导偏析。这些微尺度的变化被认为是导致晶间裂纹敏感性增加的原因,但由于它们在辐照下同时出现,因此很难分离出确切的机制。由于退火时间与温度的增加可以逐步消除辐照诱导的损伤(位错环、辐照诱导偏析、沉淀物等)[73,80~85],如在400~700℃范围内,辐照诱导形成的G相与α相大幅下降;在500~1000℃范围内,辐照产生的空洞数量大幅减少;而在800~1100℃范围内,辐照致He气泡的密度也在逐步下降至稳定,这为分离出控制IASCC敏感性的主要微观结构特征提供了机会[73]。因此,辐照后退火(PIA)理论上是一种分离IASCC诸多机制的手段。

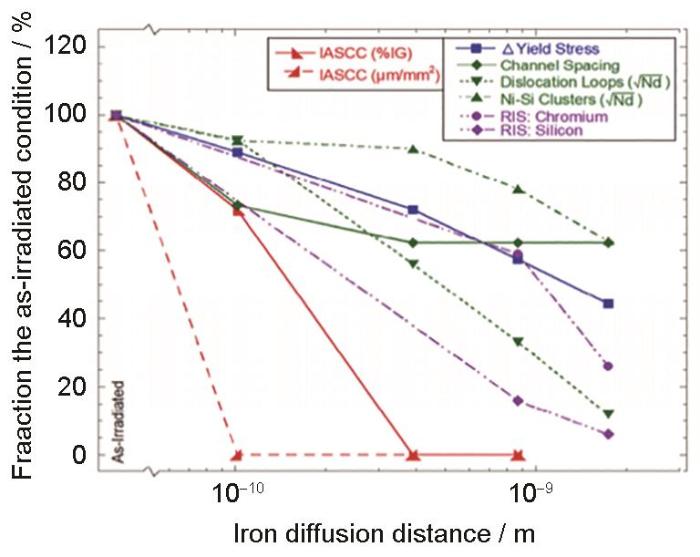

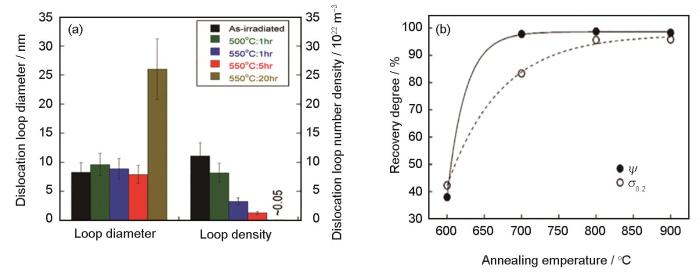

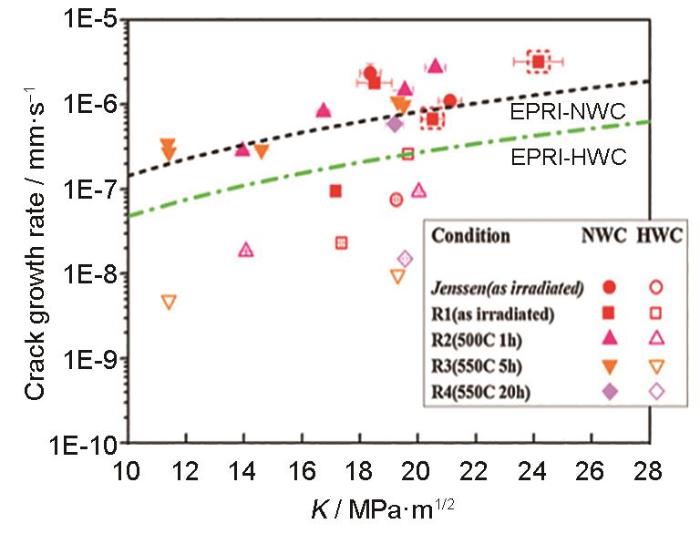

研究[85,86]指出,随着退火时间的延长以及退火温度的升高,奥氏体钢的IASCC敏感性、辐照硬化、位错通道间距、位错缺陷以及主要元素的偏析程度等检测特征均有不同程度地降低,但并没有任何一种机制随退火条件的变化与IASCC敏感性的变化完全相同(图6)。更具体地说,大多数被检测的特征在500℃退火后的变化很小,其中,IASCC缓解的变化最大,并且位错通道间距表现出与IASCC缓解极为相似的趋势:500℃ 1 h与550℃ 1 h退火后迅速下降,之后保持不变,表明局部变形与IASCC的相关性最强。此外,晶界Si的RIS与IASCC缓解的相关性仅次于局部变形。然而,有研究[6,87]认为,IASCC作用机制优先级为:局部变形>辐照硬化>RIS(Cr),表明在特定条件下的RIS与IASCC的相关性需要被重新审视。

图6

图7

Fig.7

Variation of microscopic defects and mechanical properties with annealing conditions: (a) size and number density of dislocation loops in 304L stainless steel irradiated to 5.9 dpa under different annealing conditions[85], (b) recovery of yield strength (

图8

综上,局部变形与辐照硬化对IASCC的影响机制本质上都是辐照致位错塞积所引起的材料性能变化,然而,晶界应力状态与IASCC的相关性要强于局部变形;晶界氧化是IASCC裂纹萌生的关键步骤;RIS主要通过辐照诱导晶界处Cr的偏析来影响IASCC,然而,许多次要元素的偏析对IASCC的影响机制还没有被很好地理解;辐照肿胀与辐照蠕变相继出现,但二者对IASCC的作用截然相反;辐照诱导相变对IASCC的作用主要体现在奥氏体钢中

3 总结与展望

堆内构件不锈钢的IASCC是核电老化状态评估、寿命管理及许可证延续(LTO)论证的重要内容,目前国内外针对IASCC行为以及敏感性评价进行了大量实验,包括恒载荷、直流电位降监测(DCPD)和慢拉伸等,在IASCC机制方面取得了一系列进展,包括局部变形、晶界氧化、辐照硬化、RIS、辐照肿胀以及辐照诱导相变等,同时关于PIA在IASCC中的应用研究方面也取得了一定进展,包括评价IASCC作用机制的相关性和抑制IASCC的萌生与扩展等,但仍存在一些问题有待解决,主要包括以下几个方面:

(1) 辐照主要影响IASCC裂纹萌生和扩展,但裂纹萌生位置的随机性使得实验观测的裂纹萌生时间精度不高,并且中子辐照条件的缺乏导致裂纹萌生时间与剂量的相关性缺乏足够的可靠数据支持,此外,由于加热方式、实验室条件、测试过程的不同,IASCC CGR数据呈现出很大的分散性,尚需改进并统一IASCC裂纹萌生及扩展的测试和数据筛选、修正及归一化方法,此外,由于中子辐照样品稀缺且试验难度较大,导致中子试验数据较少,工程应用的可靠性差,需进一步在归一化试验的前提下,统计分析中子试验数据,科学构建IASCC失效预测模型。

(2) IASCC机制框架基本完善,但仍然有个别细节仍需进行补充研究,比如晶界处局部变形与应力状态的相互依存关系、应力作用下辐照对晶界氧化的影响规律、RIS与IASCC相关性的有效评价、晶界处次要元素的偏析行为及其对IASCC的作用、马氏体相与α相对IASCC的作用机制等。尽管目前IASCC作用机制的优先级已通过PIA手段得到一定程度地量化,但PIA不能彻底分离辐照诱导的微结构及微化学,导致其在研究单一微观特征对IASCC的作用机制上存在一定局限性。此外,如何阐明各机制间的耦合效应对IASCC的影响是评价堆内构件老化状态以及预测其服役寿命应重点关注的问题。

我国由于中子、质子辐照实验难度大、数据难以获得,一般使用重离子辐照模拟中子辐照的实验环境,尽管在IASCC机制方面取得了一些进展,但并不能满足获得高剂量辐照下对IASCC现象一些规律性认识的要求,距离在实际工况下压水堆堆内构件IASCC行为的预测仍有一段距离,尚需在现有研究的基础上深入开展IASCC行为机理实验研究,充分吸收国外的经验和成果,解决退役材料的热室测试技术,建立离子辐照与中子辐照IASCC行为机制的映射关系,为我国进一步优化核电老化状态评估体系、建立起可用于堆内构件IASCC失效预测模型提供充分的数据支持和可靠的机理研究保障。

参考文献

The studies of irradiation assisted stress corrosion cracking on reactor internals stainless steel under Xe irradiation

[J].

Void swelling of AISI 321 analog stainless steel irradiated at low dpa rates in the BN-350 reactor

[J].

Irradiation induced dislocation loop and its influence on the hardening behavior of Fe-Cr alloys by an Fe ion irradiation

[J].

Evaluation of stress corrosion cracking of irradiated 304L stainless steel in PWR environment using heavy ion irradiation

[J].

Impact of localized deformation on IASCC in austenitic stainless steels

[J].

Localized deformation and IASCC initiation in austenitic stainless steels

[J].

Characterization of ion irradiation effects on the microstructure, hardness, deformation and crack initiation behavior of austenitic stainless steel: Heavy ions vs protons

[J].

A historical perspective on understanding IASCC

[J].Irradiation assisted stress corrosion cracking (IASCC) emerged over six decades ago with cracking of stainless steel fuel cladding, and it subsequently affected a wide range of components at much lower fluences than the fuel cladding. It was originally viewed as a distinct and mysterious phenomenon, with many hundreds of possible radiation effects playing a role. Oddly, given this complexity, for decades there was misplaced hope that minor compositional variations - such as reduced S or P - would make a dramatic difference. In the 1980s, common dependencies in irradiated and unirradiated materials were observed both in plant experience and laboratory data. Knowledge of SCC in unirradiated materials provided hypotheses of the key irradiation contributions, which led to critical tests of the ideas. Simplistic, short term tests gave way to more sophisticated and sensitive experiments that have had a big impact on our understanding of IASCC, which remains incomplete. (C) 2019 Elsevier B.V.

Effects of fluence and dissolved oxygen on IASCC in austenitic stainless steels

[A].

A review of irradiation effects on LWR core internal materials-IASCC susceptibility and crack growth rates of austenitic stainless steels

[J].

Stress-based study on the initiation of stress corrosion cracking of irradiated 304 stainless steel

[D].

基于应力的辐照304不锈钢应力腐蚀裂纹萌生研究

[D].

Crack initiation testing of thimble tube material under PWR conditions to determine a stress threshold for IASCC

[J].

Corrosion monitoring techniques for detection of crack initiation under simulated light water reactor conditions

[J].

Dissolved hydrogen concentration and proton irradiation effect on crack initiation behavior of 304L stainless steel

[A].

Technical basis part 2 for Code Case N-889: reference stress corrosion crack growth rate curves for irradiated austenitic stainless steels in light water reactor environments

[J].

The key factors affecting crack growth behavior of neutron-irradiated austenitic alloys

[A].

Modification of the FRI crack growth model formulation from a mathematical viewpoint

[J].

Elastic-plastic analysis of growing cracks

[A].

Microstructure, mechanical properties and IASCC susceptibility of stainless steel baffle bolts after 30 years of operation in a PWR

[J].

Irradiation assisted corrosion and stress corrosion of nuclear-grade 304 stainless steel in high temperature and high pressure water

[D].

核级304不锈钢辐照促进高温高压水环境腐蚀与应力腐蚀研究

[D].

Intergranular stress corrosion cracking of ion irradiated 304L stainless steel in PWR environment

[D].

Local strain distribution near grain boundaries under tensile stresses in highly irradiated SUS316 stainless steel

[J].

Relationship between localized strain and irradiation assisted stress corrosion cracking in an austenitic alloy

[J].

Quantitative linkage between the stress at dislocation channel–Grain boundary interaction sites and irradiation assisted stress corrosion crack initiation

[J].Localized deformation has emerged as a key factor in the crack initiation process for irradiated steels, as cracks are observed to nucleate preferentially at these sites. Using high resolution electron backscatter diffraction (HREBSD), the local stress tensor surrounding the dislocation channel-grain boundary interaction sites was quantified and coupled with fully determined grain boundary plane orientation information to determine, for the first time, the relationship between grain boundary normal stress and intergranular crack initiation in irradiated austenitic stainless steel. A Fe-13Cr-15Ni alloy was strained in simulated boiling water reactor, normal water chemistry after quantifying the residual stress tensor at discontinuous dislocation channel grain boundary interaction sites where grain boundaries were determined to be well oriented with respect to the loading axis. Local stresses at the grain boundary were observed to reach magnitudes greater than 1.5 GPa at a distance of 200 nm from the intersection between the dislocation channel and the grain boundary. A pseudo-threshold stress of 0.9 GPa was measured, below which no cracking was observed. As the stress acting normal to the grain boundary increased above this value, the susceptibility to cracking increased with the cracking fraction reaching 100% at the high end of the stress range. This study shows for the first time that not only does intersection between discontinuous dislocation channels and grain boundaries result in peak local stresses, but the magnitude of the local tensile stress drives the crack initiation process. (C) 2019 Acta Materialia Inc. Published by Elsevier Ltd.

Study on irradiation assisted stress corrosion cracking of nuclear grade 304 stainless steel

[J].Irradiation assisted stress corrosion cracking (IASCC) of austenitic stainless steel core components is one major concern for maintenance of nuclear power plants. Previous studies on the IASCC had mainly focused on the effect of irradiation on changes in deformation modes and interaction of dislocation channels with grain boundary. The role of corrosion in IASCC, however, has not received sufficient attentions. In the process of stress corrosion cracking (SCC), corrosion occurs simultaneously with localized deformation in the vicinity of the crack tip. This indicates that corrosion is one of the potential contributors to IASCC. In this work, IASCC of proton-irradiated nuclear grade 304 stainless steel (304SS) was investigated. The IASCC tests were conducted by interrupted slow strain rate tensile (SSRT) tests at 320 ℃ in simulated primary water of pressurized water reactor containing 1200 mg/L B as H3BO3 and 2.3 mg/L Li as LiOH·H2O, with a dissolved hydrogen concentration of 2.6 mg/L. Following the SSRT tests, the localized deformation, corrosion and IASCC of the specimens were characterized. The results revealed that increasing the irradiation dose promoted residual strain accumulation at slip steps and grain boundaries of nuclear grade 304SS. Since the slip step usually transmitted or terminated at the grain boundary, it eventually promoted localized deformation at the grain boundary. Specially, the slip step transmitted at grain boundary led to slip continuity at the grain boundary. In contrast, a slip discontinuity was observed at the grain boundary where the slip step terminated, which caused a much higher strain accumulation by feeding dislocations to the grain boundary region. Further, formation of the slip discontinuity was related to the Schmidt factor pair type of the adjacent grains. The irradiation resulted in a depletion of Cr and an enrichment of Ni at grain boundary, while the magnitude of Cr depletion and Ni enrichment increased with increasing the irradiation dose. Following the SSRT tests, intergranular cracking was observed on surfaces of the irradiated specimens, while the number of the cracks was increased by a higher irradiation dose and applied strain. This suggested a higher IASCC susceptibility of nuclear grade 304SS in the primary water. Meanwhile, significant intergranular oxidation ahead of the crack tip was observed, while both the width and length of the oxide were larger at a higher irradiation dose. The synergic effect of irradiation-promoted deformation and intergranular corrosion was the primary cause for the IASCC of the irradiated steel.

核用304不锈钢辐照促进应力腐蚀开裂研究

[J].

Numerical simulation on the local stress and local deformation in multi-point stretch forming process

[J].

Crack initiation of neutron-irradiated 304 L stainless steel in PWR primary water

[J].

Decoupling the roles of grain boundary oxidation and stress in IASCC of neutron-irradiated 304L stainless steel

[J].

Stress corrosion crack initiation in Alloy 690 in high temperature water

[J].

An overview of internal oxidation as a possible explanation of intergranular stress corrosion cracking of alloy 600 in PWRs

[A]. BruemmerS, FordP, WasG. Ninth International Symposium on Environmental Degradation of Materials in Nuclear Power Systems- Water Reactors [M].

A high-resolution characterization of irradiation-assisted stress corrosion cracking of proton-irradiated 316L stainless steel in simulated pressurized water reactor primary water

[J].

Insights into the superior stress corrosion cracking resistance of FeCrAl alloy in high temperature hydrogenated water: the critical role of grain boundary oxidation

[J].

Degradation of grain boundary strength by oxidation in Alloy 600

[A].

How oxidized grain boundaries fail

[J].

Micro-mechanical measurement of fracture behaviour of individual grain boundaries in Ni alloy 600 exposed to a pressurized water reactor environment

[J].

Grain boundary oxidation of neutron irradiated stainless steels in simulated PWR water

[A].

Grain boundary oxidation of proton-irradiated nuclear grade stainless steel in simulated primary water of pressurized water reactor

[J].Grain boundary (GB) oxidation of proton-irradiated 304 nuclear grade stainless steel in primary water of pressurized water reactor was investigated. The investigation was conducted by studying microstructure of the oxide and oxide precursor formed at GB on an "atom-by-atom" basis by a combination of atom-probe tomography and transmission electron microscope. The results revealed that increasing irradiation dose promoted the GB oxidation, in correspondence with a different oxide and oxide precursor formed at the GB. Correlation of the oxide and oxide precursor with the GB oxidation behavior has been discussed in detail.

Study of irradiation damage in domestically fabricated nuclear grade stainless steel

[J].<p>The radiation-induced segregation (RIS) and microstructure evolution such as dislocation loops and cavities are major microstructural causes for the irradiation-assisted stress corrosion cracking (IASCC) of austenitic stainless steel (SS) core components. While a couple of studies have been reported on the irradiation induced damage in nuclear grade (NG) austenitic SS, the evolution of dislocation loop density and size and its correlation with the mechanical properties have still remained incompletely understood. In addition, the correlation between the segregation at the grain boundary and that at the dislocation loop has received limited attentions. In particular, there is still a lack of a systematic study of the irradiation damage in domestically fabricated NG austenitic SS. In this work, the proton-irradiation induced microstructural damage in domestically fabricated 304NG SS was characterized, in an effort to correlate the RIS and the dislocation loop density and size with the irradiation dose, as well as the dislocation loop density and size with the radiation-induced hardening. The results revealed that the radiation-induced microstructure damage was mainly dislocation loops with a few micro-voids. The loop density was in the order of 10<sup>22</sup> m<sup>-3</sup> with an average size of <10 nm. The square root of the product of loop density and size (<i>Nd</i>)<sup>0.5</sup>, scaled linearly with the square root of irradiation dose with a factor of 6.8×10<sup>3</sup> dpa<sup>-0.5</sup>mm<sup>-1</sup>. The loops were believed to be mainly responsible for the hardening in 304NG SS, which also scaled linearly with (<i>Nd</i>)<sup>0.5</sup> with a factor of 1.16×10<sup>-2</sup> HV<sub>0.025</sub>mm. A comparative analysis about the segregation at the grain boundary and at the dislocation loop was conducted. While the depletion of Cr and enrichment of Ni at the dislocation loop and grain boundary showed no difference, the enrichment of Si at the dislocation loop could be of about 6 times of that at the grain boundary. In addition, the loop density and loop size, as well as RIS and radiation-induced hardening were all increased by a higher dose and tended to saturate by a dose of 3.0~5.0 dpa.</p>

国产核用不锈钢辐照损伤研究

[J].

Clarifying the mitigation effect of proton irradiation on the intergranular oxidation of 316L stainless steel in high temperature water

[J].

Low-temperature annealing: a process to mitigate irradiation-assisted stress corrosion cracking

[J].

Review of stress corrosion cracking of structural materials in nuclear power plants

[J].

堆芯结构材料辐照促进应力腐蚀开裂研究现状

[J].

Mechanism of irradiation assisted stress corrosion crack initiation in thermally sensitized 304 stainless steel

[J].

Irradiation strengthening and embrittlement

[A].

The effect of hardening source in proton irradiation-assisted stress corrosion cracking of cold worked type 304 stainless steel

[A].

Formulating stress corrosion cracking growth rates by combination of crack tip mechanics and crack tip oxidation kinetics

[J].

Life prediction by mechanistic modeling and system monitoring of environmental cracking of iron and nickel alloys in aqueous systems

[J].

Quantitative prediction of environmentally assisted cracking

[J].

Correlating oxidation resistance to stress corrosion cracking of 309L and 308L stainless steel claddings in simulated PWR primary water

[J].

Characterization of interfacial reactions and oxide films on 316L stainless steel in various simulated PWR primary water environments

[J].

Microstructural and microchemical mechanisms controlling intergranular stress corrosion cracking in light-water-reactor systems

[J].

Influence of chromium depletion on intergranular stress corrosion cracking of 304 stainless steel

[J].

IGSCC of non-sensitized stainless steels in high temperature water

[J].

The effect of post-irradiation annealing on the stress corrosion crack growth rate of neutron-irradiated 304L stainless steel in boiling water reactor environment

[J].

Effect of cold work and slow strain rate on 321SS stress corrosion cracking in abnormal conditions of simulated PWR primary environment

[J].

Effects of impurities on environmentally assisted crack growth of solution-annealed austenitic steels in primary water at 325oC

[J].

Effects of Si on SCC of irradiated and unirradiated stainless steel and nickel alloys

[J].

Void swelling and irradiation creep in light water reactor (LWR) environments

[A].

Irradiation-assisted stress corrosion cracking

[J].

Irradiation-induced precipitation and inverse coarsening of G-phase in austenitic stainless steel weld metal

[J].

Irradiation response of delta ferrite in as-cast and thermally aged cast stainless steel

[J].

Influence of microstructure on the corrosion behavior of a Ni-Si alloy

[J].

Environmental embrittlement and grain-boundary fracture in Ni3Si

[J].

Microstructural origin of the skeletal ferrite morphology of austenitic stainless steel welds

[J].

Microstructural development and solidification cracking susceptibility of austenitic stainless steel welds

[J].

The effect of roll-processing orientation on stress corrosion cracking of warm-rolled 304L stainless steel in oxygenated and deoxygenated high temperature pure water

[J].

Stress corrosion cracking of uni-directionally cold worked 316NG stainless steel in simulated PWR primary water with various dissolved hydrogen concentrations

[J].

Microstructural characterization of SCC crack tip and oxide film for SUS 316 stainless steel in simulated PWR primary water at 320oC

[J].

The electrochemistry in 316SS crevices exposed to PWR-relevant conditions

[J].

Stress corrosion cracking behavior of 316L stainless steel with varying microstructure in ammonium chloride environment

[J].

不同组织的316L不锈钢在NH4Cl环境下应力腐蚀行为与机理

[J].采用动电位极化曲线、电化学阻抗谱以及U形弯试样浸泡实验研究了不同组织 (原始组织、固溶组织与敏化组织) 的316L不锈钢在NH<sub>4</sub>Cl环境下的应力腐蚀开裂 (SCC) 行为与机理,分析了NH<sub>4</sub>Cl浓度对不同热处理状态的316L不锈钢应力腐蚀行为和机理的影响。结果表明:不同组织的316L不锈钢在NH<sub>4</sub>Cl环境中均具有明显的SCC敏感性,原始组织、固溶组织、敏化组织的SCC敏感性依次升高;随着NH<sub>4</sub>Cl溶液浓度升高,316L不锈钢不同组织的钝化膜稳定性降低,原始组织、固溶组织及敏化组织在NH<sub>4</sub>Cl环境下,破钝电位依次降低,维钝电流密度依次升高,阻抗值依次减小,钝化膜更加活泼易破坏,饱和NH<sub>4</sub>Cl浓度下极易发生点蚀导致SCC的萌生。316L不锈钢在NH<sub>4</sub>Cl环境中的SCC裂纹扩展机制主要为穿晶型阳极溶解机制。

Environmentally assisted cracking of forged 316LN stainless steel and its weld in high temperature water

[J].

Technical Note: the effect of retained ferrite on localized corrosion in duplex 304L stainless steel

[J].

Failure investigation of 321 stainless steel pipe to flange weld joint

[J].

Effect of δ-ferrite on the stress corrosion cracking behavior of 321 stainless steel

[J].

Physical metallurgical development of stainless steels

[A].

Effect of low dose irradiation of heavy ion on electrochemical corrosion and IASCC behavior of austenitic steel

[J].

Effect of heavy ion irradiation on the electrochemical behavior of 321 stainless steel

[J].

Investigation of high temperature annealing effectiveness for recovery of radiation-induced structural changes and properties of 18Cr-10Ni-Ti austenitic stainless steels

[J].

Post-irradiation annealing effects of austenitic stainless steels in IASCC

[A].

Separation of Microstructural and microchemical effects in irradiation assisted stress corrosion cracking using post-irradiation annealing

[J].

Effects of low-temperature annealing on the microstructure and grain boundary chemistry of irradiated type 304SS and correlations with IASCC

[A].

Influence of post irradiation annealing on the mechanical properties and defect structure of AISI 304 steel

[J].

Evolution of the radiation-induced defect structure in 316 type stainless steel after post-irradiation annealing

[J].

Effect of post-irradiation annealing on the irradiated microstructure of neutron-irradiated 304L stainless steel

[J].

Effects of post-irradiation annealing on the IASCC susceptibility of neutron-irradiated 304L stainless steel

[J].

Localized deformation as a primary cause of irradiation assisted stress corrosion cracking

[R].