为解决这一问题,目前常采用密封、阳极化处理及表面喷涂等方法来降低电偶腐蚀倾向[6]。其中,有机涂层凭借其方便可靠的优点,在腐蚀防护领域得到了较为广泛的应用[7,8]。有研究指出,有机涂层的防护性能主要是通过屏蔽作用来实现的[9,10]。通过形成屏障,有机涂层可以防止腐蚀介质和金属材料之间的直接接触,从而避免腐蚀现象的发生[11~13]。因此,有机涂层的腐蚀防护性能与其完整性和涂层电阻密切相关[14~17]。此外,在涂层的制备过程中,缓蚀剂和牺牲阳极材料的加入也可以在一定程度上提高涂层的防护性能[18]。例如某些富锌涂层和智能涂层即使在损伤[19]后也能有效地保护基底金属。然而,防护涂层的构建并非一劳永逸的。在其服役的过程中,腐蚀介质仍可以通过扩散作用,通过涂层的孔隙等微通道作用于基材表面并对基材产生损伤[20]。当腐蚀介质在局部到达基材时,极易诱发大阴极小阳极的形成,并加速基材的腐蚀[21]。因此,对涂层损伤程度的准确评价是非常有意义的。

目前,有机涂层的损伤程度主要是通过涂层物理,化学以及电化学性质的改变研究来评价[22~25]。早在上个世纪,Kendig和Scully[26]采用电化学阻抗法的方法,对有机涂层的防护性能进行了相关的评价。Kim和Itoh[27]通过加速实验研究了具有缺陷的钢材涂层寿命并建立了一种涂层降解模型来预测涂层的剩余寿命。此外,Lee和Chang[28]也采用了加速实验的方法,研究了氯化橡胶涂层和聚氨酯涂层的失效机制,并通过回归分析提出了寿命评价模型,结果表明,热喷涂涂料的使用寿命是普通涂料的两倍以上。Guseva等[29]在对飞机涂层寿命评价的过程中发现,在涂层失效早期,有机涂层光泽度的下降可以作为涂层损伤的重要指标之一。Hirohata等[30]讨论了涂层的腐蚀深度和腐蚀扩散距离,并利用功率函数模型对有机涂层的使用寿命进行了评价。然而,这些研究都集中在涂层本身的评价及寿命预测,并没有关注到涂层防护体系失效引起的整体结构力学承载性的下降。

因此,本文采用加速实验方法,分别对带有涂层的300M钢、2024铝合金和5A06铝合金与钛合金耦接组合件进行了湿热、盐雾和霉菌实验。在此基础上,通过层次分析法(AHP)对加速实验之后涂层的失效程度进行了综合评价并用电化学阻抗谱进行了验证。同时,测试了加速实验后涂层件的力学性能。最后,探讨了涂层失效程度与其力学性能损伤之间的关系。

1 实验方法

本实验选用300M钢(正火态)、2024铝合金(固溶时效态)、5A06铝合金(固溶时效态)和TC12(退火态)超强韧钛合金作为实验材料,其合金成分如表1所示。

表1 300M钢、2024与5A06铝合金以及TC12钛合金的化学成分

Table 1

| Material | C | Si | Mn | Ni | Cr | Mo | V | P | S | Cu | Mg | Zn | Sn | Zr | Nb | Fe | Al | Ti |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 300M steel | 0.42 | 1.57 | 0.82 | 1.93 | 0.84 | 0.38 | 0.08 | 0.01 | 0.01 | 0.84 | - | - | - | - | - | Bal. | - | - |

| 2024 Al-alloy | - | 0.50 | 0.52 | - | 0.10 | 4.10 | 1.45 | 0.25 | - | - | - | - | Bal. | - | ||||

| 5A06 Al-alloy | - | 0.20 | 0.62 | - | - | - | - | - | - | 0.08 | 6.23 | 0.12 | - | - | - | 0.01 | Bal. | 0.05 |

| TC12 Ti-alloy | - | - | - | - | 1.26 | 2.84 | - | - | - | - | - | - | 1.80 | 1.82 | 1.96 | 0.15 | 6.25 | Bal. |

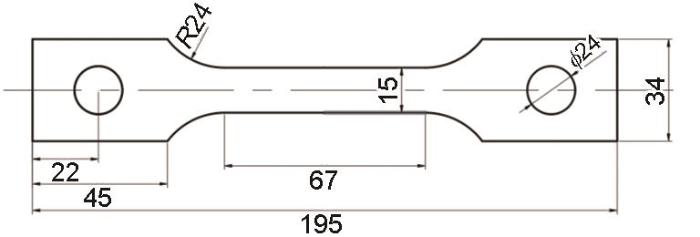

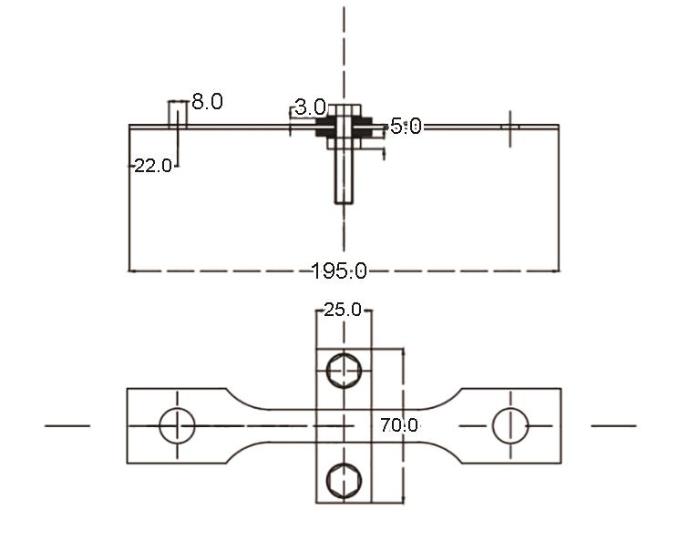

首先,通过机加工得到尺寸如图1所示的样品,并清洗以去除表面油污和氧化物。其次,分别采用离子镀铝和阳极氧化工艺,对清洗的300M钢和铝合金进行表面处理。第三,分别对300M钢和两种铝合金样品表面喷涂H06-1011防腐环氧底漆(40 ± 10 μm)和QH-15防腐环氧底漆(50 ± 10 μm),随后在70℃的温度下固化2 h。待充分固化之后,再分别在样品表面上喷涂QSF-15耐候聚氨酯无光磁漆(40 ± 10 μm),并在100℃的温度下进行高温固化1 h得到实验所用有机涂层样品。其中,涂层厚度约为80~100 μm。最后,按照图2所示的方法,利用两片超强韧钛合金片将涂层样品夹持在中央,并在其两端用螺丝紧固,得到表2所示的不同有机涂层耦接体系组合件。其中,绝缘耦接是指在涂层样品和钛合金片之间涂覆一层XM-33航空密封胶。为了确保实验结果的准确性,在实验过程中,每种耦接模式分别设置3组平行实验,以确保实验结果的准确性。

图1

图2

图2

钛合金与对偶材料的耦接方式示意图

Fig.2

Schematic diagrams of the coupling mode between titanium alloy plate and mating material

表2 涂层样品及耦接模式

Table 2

| Sample | Specimen type and the connecting method |

|---|---|

| 1 | Coated 300M steel specimen without accelerated tests |

| 2-4 | Single coated 300M steel specimen after accelerated tests |

| 5-7 | Coated 300M steel specimen directed coupled with Ti-alloy |

| 8-10 | Coated 300M steel specimen coupled with Ti-alloy by an insulating method |

| 11 | Coated 2024 Al-alloy specimen without accelerated tests |

| 12-14 | Single coated 2024 Al-alloy specimen after accelerated tests |

| 15-17 | Coated 2024 Al-alloy specimen directed coupled with Ti-alloy |

| 18-20 | Coated 5A06 Al-alloy specimen coupled with Ti alloy by an insulating method |

| 21 | Coated 5A06 Al-alloy specimen without accelerated tests |

| 22-24 | Single coated 5A06 Al-alloy specimen after accelerated tests |

| 25-27 | Coated 5A06 Al-alloy specimen directed coupled with Ti-alloy |

| 28-30 | Coated 300M steel specimen coupled with Ti-alloy by an insulating method |

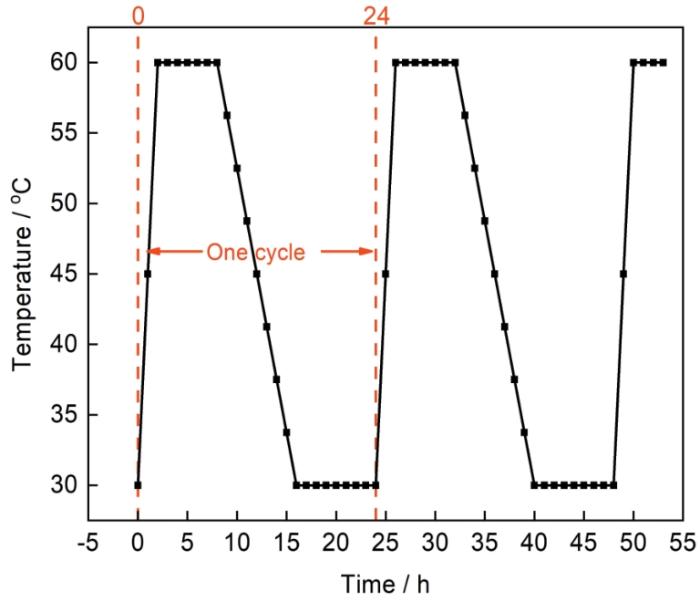

在加速实验的过程中,分别参照GJB150.9A-2009,GJB150.10A-2009,GJB150. 11 A -2009标准,依次进行湿热实验、霉菌实验和盐雾实验,即“三防”加速实验。其中,湿热实验按照图3所示的加热曲线在近中性去离子水中进行10个周期。在霉菌实验前,将耦接样品置于试验箱内进行预热处理(温度(30 ± 1)℃,相对湿度(95% ± 5%) 5 h。然后,通过喷雾器将混合孢子悬浮液喷洒在样品表面,并在(30 ± 1)℃的恒温条件和95% ± 5%恒相对湿度条件下进行28 d的霉菌实验。盐雾实验是在27℃的温度和不高于50%的相对湿度下进行的,在整个盐雾实验期间,控制盐溶液沉降率在1~3 mL/(80 cm2·h)。

图3

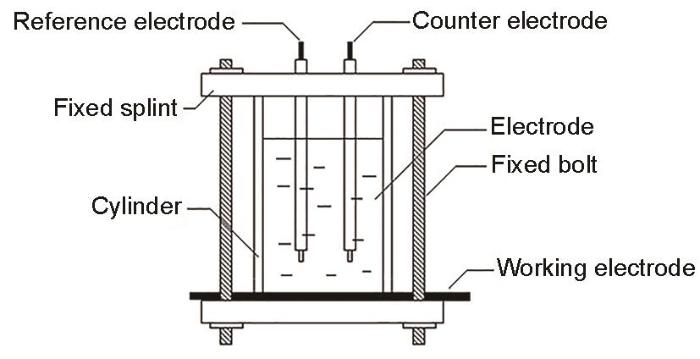

在加速实验结束后,首先通过目视观察,并记录不同样品的表面状态。同时,根据ASTM5894-96,ISO 7253:1996(E)和GB/T1766-2008标准对涂层样品的表面状态进行评定。其次,将样品拆解并通过Gamry 600+电化学工作站和MTS809万能拉伸试验机分别测试涂层样品的电化学阻抗谱和拉伸性能。最后,通过ZEISS Gemini 300扫描电子显微镜(SEM)观察并分析了不同涂层样品的断口形貌。

图 4

图 4

涂层样品电化学测试时电解池示意图

Fig.4

Schematic diagram of the electrolytic cell for the electrochemical test of coated specimen

最后,利用电子万能试验机,以0.1 kN/s的加载速率在室温(25℃)下测试了加速实验后涂层样品的拉伸性能,并根据

其中,FB为最大载荷(N),S0为样品初始截面积(m2)。L0和L1分别为拉伸前和断裂后的长度(mm)。

2 层次分析法的建立

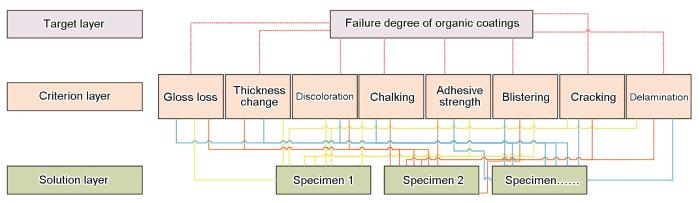

图5

由图可见,层次分析法是将研究的问题分成三层。其中,最上层为目标层,表示要解决的问题;中间层为决策层,表示影响因素;最底层是备选方案,在本工作中主要指的是不同的涂层样品。在明确层次结构之后,通过构造判断矩阵计算决策层影响因素的权重。

因此,在通过综合评价法,建立有机涂层的评价模型的过程中,首先需要明确影响涂层损伤程度的因素。通过前期实验,选择了失光率、厚度变化、变色、粉化、附着力、起泡、开裂和剥离8个指标作为有机涂层的决策层。通过比较得到任意两个因素的相对重要程度并构建了如表3所示的重要性比较表。

表 3 不同关键评价指标重要性比较

Table 3

| Indicator | α | β | γ | δ | ε | ζ | η | θ |

|---|---|---|---|---|---|---|---|---|

| α | 1 | 1/2 | 1/3 | 1/4 | 1/6 | 1/7 | 1/8 | 1/9 |

| β | 2 | 1 | 1/2 | 1/3 | 1/5 | 1/6 | 1/7 | 1/8 |

| γ | 3 | 2 | 1 | 1/2 | 1/4 | 1/5 | 1/6 | 1/7 |

| δ | 4 | 3 | 2 | 1 | 1/3 | 1/4 | 1/5 | 1/6 |

| ε | 6 | 5 | 4 | 3 | 1 | 1/2 | 1/3 | 1/4 |

| ζ | 7 | 6 | 5 | 4 | 2 | 1 | 1/2 | 1/3 |

| η | 8 | 7 | 6 | 5 | 3 | 2 | 1 | 1/2 |

| θ | 9 | 8 | 7 | 6 | 4 | 3 | 2 | 1 |

其中,α到θ分别表示失光率、厚度变化、变色、粉化、附着力、起泡、开裂和剥离。然后,将表3中的数据以矩阵的形式表示(

在

在层次分析法中,我们构建的两两比较矩阵应为正互反矩阵,当正互反矩阵满足aij × ajk = aik时,该正互反矩阵才是一致矩阵。因此,为了确保矩阵的质量,我们需要对矩阵(3)进行一致性检测[40]。在一致性检测过程中,首先需要求出矩阵(3)的特征向量并得到其最大特征值。然后,依据

其中,n表示矩阵的阶数,λmax为最大特征值。因此,该8阶矩阵的C.I值计算结果为0.0507。根据

对于随机一致性指数R.I.,8阶矩阵的平均随机一致性指数为1.41[41]。在本研究中,基于

其中,y是涂层在腐蚀试验后的综合评价值,wj 为权重系数,xj 为各指标的单项值。

对于涂层损伤单项值的获取,本实验参考GB1766-2008获得。其中,涂层的厚度和光泽度可以通过厚度仪和光泽度仪直接测得,每组样品测试5个点以上以确保实验结果的准确性。厚度变化率和失光率可以通过

其中,T0和A0是实验前样品的平均厚度和平均光泽度,T1和A1是加速实验之后涂层的平均厚度和光泽度。当该两项变化不超过3%时,认为此时没有出现该损伤,该项评分等级为0,当变化率依次为4%~15%、16%~30%、31%~50%、51%~80%以及>80%时,该项评分等级记为1~5。涂层的变色等级主要通过目视比色法得到,通过参考标准比色卡,得到加速实验前后涂层对应的色卡号,然后根据比色卡号的差值得到变色单项评级。当灰卡等级为5级至4级之间时,认为涂层没有发生变色,该项指标评分等级为0,当灰卡等级为4~3级,3~2级,2-1~2级,1~2-1级及小于1级时,涂层的单项评价等级为1~5;粉化主要是通过天鹅绒布擦拭的方法得到,通过观察擦拭后天鹅绒布上的颜料粒子数量得到粉化单项评级,其颜料粒子从多到少评级分别记为5~0级;开裂、起泡和分层均是通过目视法观察损伤的密度和单一损伤的大小来评价得到其单项评级,其损伤由重到轻依次评价为5~0级;附着力评价主要是通过电动漆膜画圈试验仪画圈得到。观察试验之后涂层表面划痕,如果只有1区域出现剥落,则评级为1级,若7区域出现剥落则评级为7级,若所有区域均没有出现剥落,则评级为0级。

3 结果与讨论

3.1 涂层表面形貌分析

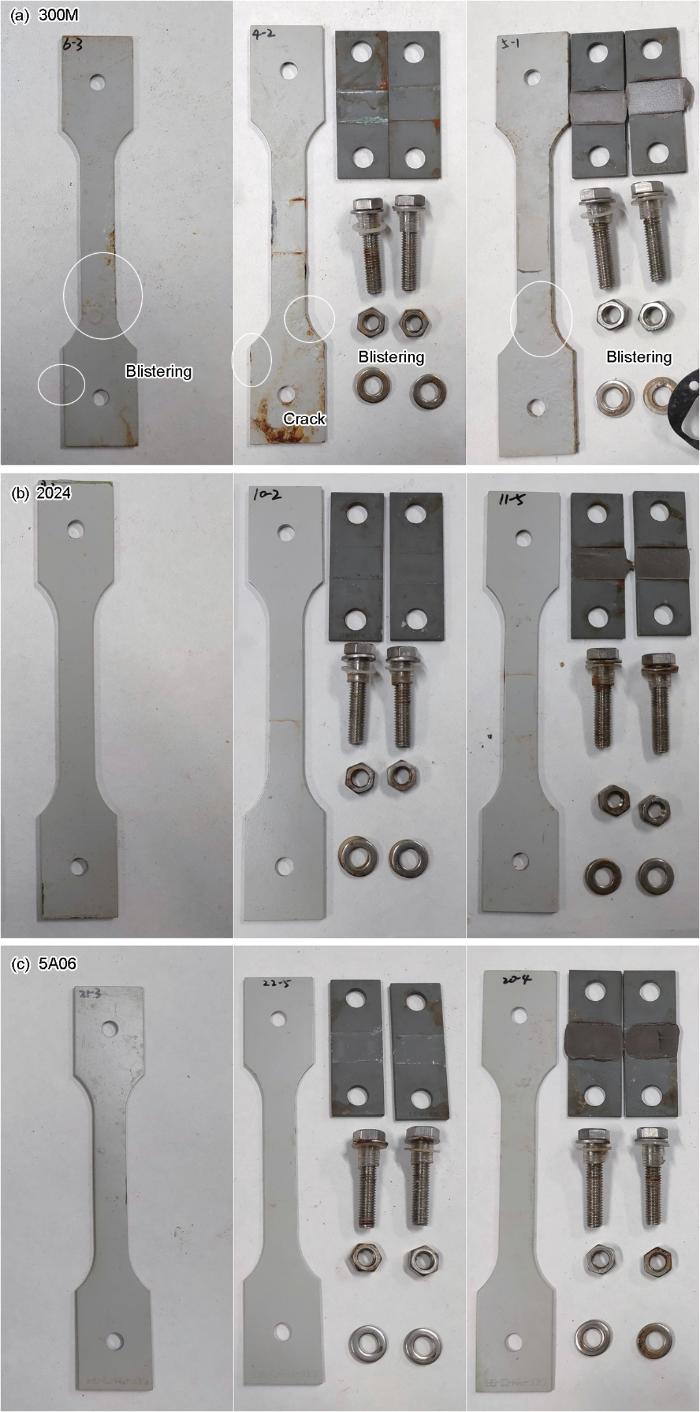

图6

图6

加速实验后涂层样品表面形貌图

Fig.6

Macro morphologies of coated 300M steel (a), coated 2024 Al-alloy (b) and coated 5A06 Al-alloly (c) samples after accelerated testing (From left to right, single sample, directly coupled sample, and insulated coupled sample)

3.2 有机涂层失效的综合评价

表4 加速实验后涂层的单项指标评级

Table 4

| Samples | Connecting | Thickness | Gloss | Discoloration | Chalking | Adhesive | Blistering | Cracking | Delamination |

|---|---|---|---|---|---|---|---|---|---|

| modes | |||||||||

| loss | strength | ||||||||

Coated 300M steel | As-received | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 |

| Directly coupling | 1 | 2 | 2 | 0 | 1 | 3 | 2 | 2 | |

| Insulated coupling | 5 | 1 | 1 | 0 | 0 | 3 | 0 | 0 | |

| Single | 2 | 2 | 1 | 0 | 1 | 2 | 0 | 0 | |

Coated 2024 Al-alloy | As-received | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 |

| Directly coupling | 2 | 0 | 0 | 1 | 1 | 0 | 0 | 0 | |

| Insulated coupling | 2 | 1 | 0 | 1 | 0 | 0 | 0 | 0 | |

| Single | 2 | 2 | 0 | 0 | 0 | 0 | 0 | 0 | |

Coated 5A06 Al-alloy | As-received | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 |

| Directly coupling | 3 | 1 | 1 | 1 | 1 | 0 | 0 | 0 | |

| Insulated coupling | 5 | 1 | 1 | 1 | 0 | 0 | 0 | 0 | |

| Single | 2 | 2 | 1 | 0 | 0 | 0 | 0 | 0 |

表5 涂层失效的综合评价值与阻抗模值

Table 5

| Sample | Connecting mode | Comprehensive evaluation value | Low frequency impedance modulus Ω·cm-2 |

|---|---|---|---|

| Coated 300M | As-received | 0.000 | 1.13 × 1010 |

| Directly coupling | 1.914 | 1.21 × 107 | |

| Insulated coupling | 0.645 | 3.09 × 107 | |

| Single | 0.529 | 3.88 × 108 | |

| Coated 2024 Al-alloy | As-received | 0.000 | 2.10 × 1010 |

| Directly coupling | 0.207 | 4.60 × 109 | |

| Insulated coupling | 0.139 | 5.77 × 109 | |

| Single | 0.114 | 6.96 × 109 | |

| Coated 5A06 Al-alloy | As-received | 0.000 | 5.54 × 109 |

| Directly coupling | 0.304 | 2.38 × 109 | |

| Insulated coupling | 0.273 | 2.97 × 109 | |

| Single | 0.154 | 2.99 × 109 |

从表4可以看出,300M钢涂层样品在加速实验之后出现了多种损伤模式。其中非耦接样品的损伤较轻,没有出现开裂和剥离。直接耦接样品的涂层出现了轻微的剥离,同时,还出现了开裂损伤,其损伤程度最为严重,这说明直接耦接会在一定程度上加速涂层的损伤。对于2024铝合金涂层样品,均出现了厚度的减薄和光泽度的下降。此外,直接耦接样品的附着力也出现了轻微的下降。对于5A06铝合金涂层样品,其非耦接样品出现了减薄、光泽度下降及变色3种损伤形式,直接耦接样品还出现了轻微的粉化和附着力的下降。

从表5中可以看出,3种不同的有机涂层防护体系在经过“三防”加速实验后,直接耦接涂层样品均呈现出最高的综合评分和最低的低频阻抗模值。这表明在加速实验过程中,直接耦接会强化大阴极小阳极的作用,从而导致涂层体系的耐蚀性出现明显的下降。这表明采用绝缘措施可以一定程度上降低涂层样品的电偶腐蚀倾向。此外,加速实验之后,虽然不同涂层体系的综合评分均小幅增加,但是除了300M涂层样品外,其他样品的综合评价值都小于1.0,其低频阻抗模值均大于108 Ω·cm2,说明涂层体系仍然具有良好的耐蚀性。直接耦接300M涂层样品的综合评价值大于1.0而小于2.0,其低频阻抗模值大于107 Ω·cm2,说明其涂层仍具有较好的耐蚀性。此外,由表5还可以看出,对于不同的试验组,涂层的综合评分值与其低频阻抗模值均呈明显的负相关关系,即涂层的综合评分越高,其对应的低频阻抗模值越低,其防护效果越差。

3.3 涂层体系的力学性能

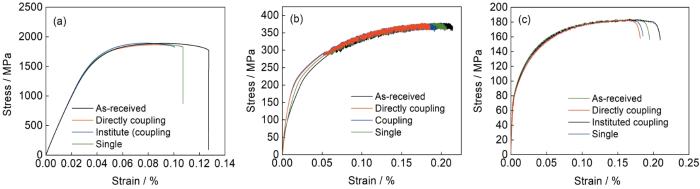

利用电子万能试验机,测定了“三防”加速实验后涂层样品的应力-应变曲线,结果如图7所示。

图7

图7

加速实验后涂层样品的应力-应变曲线

Fig.7

Stress-strain curves of coated specimens of 300M steel (a), 2024 Al alloy (b) and 5A06 Al alloy (c) after accelerated testing

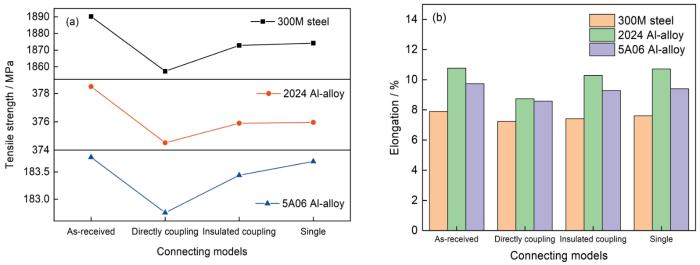

图8

图8

不同耦接方式涂层样品加速实验后的抗拉强度及断裂伸长率

Fig.8

Tensile strengths (a) and elongations (b) of coated specimens with different connecting modes after accelerated testing

图9

图9

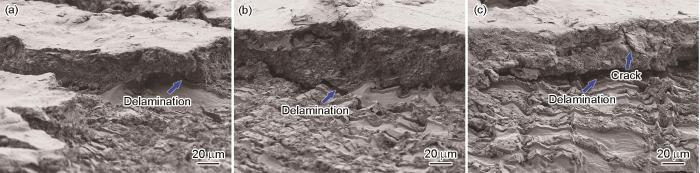

300M合金钢涂层样品加速实验后的断口形貌

Fig.9

Fracture morphologies of coated 300M steel samples after accelerated testing: (a) only coated sample, (b) insulated coupled sample, (c) directly coupled sample

由图8a可见,对于所有涂层样品,其空白组均具有最高的抗拉强度。经三防试验之后,样品的抗拉强度均出现一定程度的下降。这说明在加速实验过程中,腐蚀介质通过扩散作用到达基材与涂层的界面,并对涂层样品的力学性能产生了一定的影响。对于同种涂层体系,直接耦接涂层样品均具有最低的抗拉强度,这进一步地说明了直接耦接组在加速实验中具有最严重的电偶腐蚀损伤。

由图8b可见,经过三防实验之后,所有样品的断裂延伸率均出现一定程度的下降,表明涂层体系失效会导致涂层基材的塑性出现了一定程度的恶化。对比3种涂层体系发现,300M钢在经过三防实验之后断裂延伸率变化最小,其断裂延伸率变化量小于1%。其中,直接耦接样品的断裂延伸率总是最低的,这说明直接耦接样品涂层失效程度较大,引起的基材断裂延伸率的损伤最严重,塑性下降明显。这可能是因为对于有机涂层体系,涂层本身具有一定的微缺陷,在失效过程中腐蚀介质可以通过微缺陷扩散,对基材产生一定的影响。所以,绝缘耦接依旧可以在一定程度上降低电偶腐蚀损伤。当异种金属耦接在一起时,会进一步加大大阴极小阳极作用,加速涂层体系失效,并进一步导致基材力学性能受到最严重的损伤。

由图9a可见,对于非耦接和绝缘耦接涂层样品,其断口处呈现出相似的断裂特征,涂层与基材的界面处没有明显的分层现象。然而,对于直接耦接涂层样品,在有机涂层和基材的界面处有明显的剥离这可能与局部电偶腐蚀发生引起的涂层鼓泡现象有关。一般地,在有机涂层的制备过程中,不可避免的会存在一定数量的固有缺陷,这些微缺陷的存在会为腐蚀介质在有机涂层中的传输提供微通道,从而加速腐蚀介质的传递过程。在加速实验中,当腐蚀介质通过微缺陷渗透并作用于有机涂层与金属界面处时,由于两种材料之间存在较高的电偶腐蚀倾向,金属材料会作为小阳极而加速溶解。随着腐蚀产物的不断堆积,最终导致涂层出现局部的鼓泡现象。

图10

图10

2024铝合金涂层样品加速实验后的断口形貌

Fig.10

Fracture morphologies of coated 2024 Al alloy samples after accelerated testing: (a) only coated sample, (b) insulated coupled sample, (c) directly coupled sample

由图11可见,5A06铝合金涂层样品的断口形貌与2024铝合金类似。3组样品断口形貌图中均可以看到明显的分层现象。其中,非耦接组的分层现象最不明显,而直接耦接组样品具有十分明显的分层现象。此外,有机涂层内部也出现了轻微的开裂现象。产生分层现象的原因可能与电偶腐蚀有关。经过阳极化处理之后,铝合金表面粗糙度大幅增加,这有利于增加有机涂层的附着力。然而,在加速实验过程中,腐蚀介质会通过渗透作用到达涂层与阳极氧化膜界面,由于电位差的存在,阳极氧化膜层上凸起位置被不断腐蚀溶解,从而导致有机涂层与阳极氧化层之间附着力的下降。因此,在拉伸过程中,涂层与阳极氧化膜间会出现分层的现象。同时,有机涂层与阳极氧化膜间附着力的下降又会导致涂层体系防护性能的恶化,在后续的加速实验过程中,基材更容易受到腐蚀介质的侵蚀,并最终导致整个涂层体系力学性能的恶化。由于直接耦接样品电偶腐蚀倾向最大,因此其涂层与阳极氧化膜间的分层现象最为严重,力学性能下降幅度最大,这与前面的研究结果是一致的。

图11

图11

5A06铝合金涂层样品加速实验后的断口形貌

Fig.11

Fracture morphologies of 5A06 Al alloy samples after accelerated testing: (a) only coated sample, (b) insulated coupled sample, (c) directly coupled sample

3.4 涂层综合评价值与力学承载性的关系

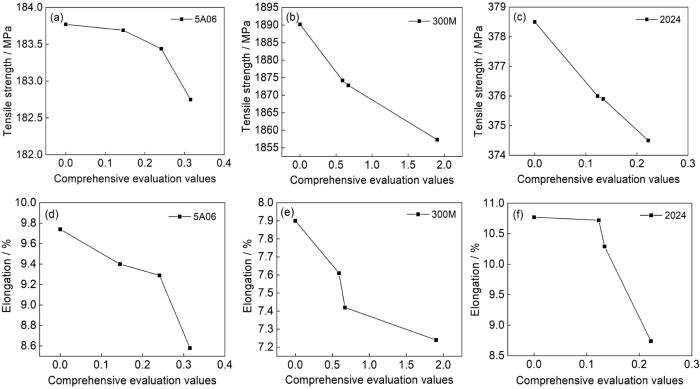

有机涂层的构建主要是为了降低基材的腐蚀损伤,并维持其良好的力学性能。因此,相较于单纯的涂层防护性能评价,涂层体系力学承载性的评价更为重要。抗拉强度是金属由均匀塑性形变向局部集中塑性变形过渡的临界值,是金属在静拉伸条件下的最大承载能力,是金属材料的强度指标,延伸率是金属材料的塑性指标。此外,材料的抗拉强度在一定程度上还可以反应出材料的疲劳性能,并且通过抗拉强度来预测材料的疲劳性能凭借着低成本,短周期的优势也被越来越多的学者关注[38]。因此,建立涂层样品强度、断裂延伸率与其涂层综合评价值之间的关系,可以将涂层体系的损伤程度与整个涂层体系的力学承载性相结合,从而为涂层体系的寿命预测提供借鉴。为此,本文进一步研究了不同涂层体系的抗拉强度和断裂延伸率与涂层失效综合评价值之间的关系,其结果如图12所示。

图12

图12

涂层体系抗拉强度及断裂延伸率与综合评分之间的关系

Fig.12

Relationships between tensile strength (a-c) and elongation (d-f) and comprehensive evaluation value for coated 300M steel (a, d), coated 2024 Al-alloy (b, e) and coated 5A06 Al-alloy (c, f)

由图12a~c可见,对于3种涂层样品,其抗拉强度和综合评价值呈现出明显的负相关关系。随着综合评分的增加,其抗拉强度逐渐降低。此外,对比3种涂层体系可以看出,当综合评分超过0.3时,抗拉强度开始出现较为明显的下降。这说明在涂层失效的早期,有机涂层对腐蚀介质的传递具有较强的屏蔽作用,因此涂层的抗拉强度下降不明显。随着涂层失效程度的加剧,其屏蔽作用逐渐减弱,腐蚀介质透过涂层作用于基材。基材/涂层界面发生腐蚀并最终导致其力学强度的下降。

由图12d~f可见,随着综合评分的增加,涂层体系的断裂延伸率呈现出逐渐下降的趋势,二者呈明显的负相关关系。与抗拉强度不同的是,随着涂层综合评分的增加,其断裂延伸率下降幅度较低。

4 结论

(1) 经“三防”加速实验之后,所有涂层样品的塑性和抗拉强度均出现一定程度的下降,这与涂层失效过程中腐蚀介质通过涂层中的微缺陷扩散到涂层/基材界面,导致电偶腐蚀的发生有关。

(2) 耦接方式对耦接涂层样品的涂层体系失效程度将产生一定的影响。绝缘连接将有助于避免涂层耦接件涂层的加速失效。

(3) 根据层次分析法,基于涂层体系8种失效模式,建立的涂层体系综合评价模型是合理的。实验结果表明,涂层体系失效程度的综合评价值越高,涂层体系的低频阻抗模值越低,其耐蚀性降低。同时,涂层基材的抗拉强度和断裂伸长率的损伤程度明显。

参考文献

Corrosion behaviour of Ti-6Al-4V alloy in concentrated hydrochloric and sulphuric acids

[J].

Research on application technology of titanium alloy in marine pipeline

[J].

船舶海水管路钛合金应用技术研究

[J].

Effect of passive film on the galvanic corrosion of titanium alloy Ti60 coupled to copper alloy H62

[J].

Effects of electroplated coatings on corrosion behavior of Ti-1023/30CrMnSiA galvanic couple

[J].

Research on coupling metal corrosion induced by titanium alloy

[A].

钛合金引起的耦接金属腐蚀研究

[A].

Progress in research on galvanic corrosion behavior and protection

[J].

电偶腐蚀与防护的研究进展

[J].

Preparation and anticorrosion performance of M-phenylenediamine-graphene oxide/organic coating

[J].

间苯二胺-氧化石墨烯/有机涂层的制备及防腐性能研究

[J].

Epoxy/organosiloxane modified cationic acrylic emulsion composite coating

[J].

环氧树脂/有机硅氧烷改性阳离子丙烯酸乳液复合涂层的研究

[J].利用合成的有机硅氧烷改性的阳离子型丙烯酸 (SMCWA) 乳液中的胺基能够固化环氧树脂的原理,在碳钢板表面制备耐腐蚀环氧树脂/SMCWA乳液复合涂层。利用激光纳米粒度仪对SMCWA乳液粒径进行表征,使用Fourier变换红外光谱仪 (FT-IR) 和扫描电子显微镜 (SEM) 对复合涂层进行结构和形貌分析,利用CuSO<sub>4</sub>点滴、电化学测试和中性盐雾实验研究复合涂层的耐蚀能力。结果表明,合成的SMCWA乳液粒径小,分布均匀。相较于空白SMCWA乳液涂层,环氧树脂/SMCWA乳液复合涂层的致密性和耐腐蚀性均得到增强,其中环氧树脂/SMCWA乳液质量比为9.5/0.5的复合涂层,CuSO<sub>4</sub>点滴时间提高了116 s,电化学阻抗提高了4倍,腐蚀电流密度下降了一个数量级,耐盐雾能力大幅增强。

Anticorrosive acrylic intelligent paint

[J].

Al2O3 coatings on zinc for anti-corrosion in alkaline solution by electrospinning

[J].The severe corrosion accompanied with hydrogen evolution reaction has become the main obstacle restricting the utilization of zinc as an electrode in alkaline batteries. Al2O3 coating helps control the corrosion of zinc in alkaline solution. Herein, a stable Al2O3 coating is fabricated through facile electrospinning from Al(NO3)3 as an efficient anti-corrosion film on zinc. The electrospinning technique facilitates uniform dispersion of Al2O3 particles, therefore the corrosion inhibition efficiency could be up to 88.5% in this work. The Al2O3 coating prevents direct contact between zinc and the alkaline solution and minimize hydrogen evolution. Further, the effects of the thickness of Al2O3 coating on corrosion behavior of zinc are investigated through hydrogen evolution reaction, Tafel polarization, and impedance test. The results show that the thicker Al2O3 coating possessed better corrosion inhibition efficiency due to the higher corrosion resistance and lower porosity. The 18 μm Al2O3 coating on zinc provides corrosion current density of 60.6 mA/cm2, while the bare zinc substrate delivers as much as 526.3 mA/cm2.This study presents a promising approach for fabricating Al2O3 coating for corrosion-resistant applications.

Fabrication of Fe3O4@SiO2 nanocomposites to enhance anticorrosion performance of epoxy coatings

[J].

Direct measurement of colloidal interactions between polyaniline surfaces in a UV-curable coating formulation: the effect of surface hydrophilicity/hydrophobicity and resin composition

[J].The interactions between polyaniline particles and polyaniline surfaces in polyester acrylate resin mixed with 1,6-hexanediol diacrylate monomer have been investigated using contact angle measurements and the atomic force microscopy colloidal probe technique. Polyaniline with different characteristics (hydrophilic and hydrophobic) were synthesized directly on spherical polystyrene particles of 10 μm in diameter. Surface forces were measured between core/shell structured polystyrene/polyaniline particles (and a pure polystyrene particle as reference) mounted on an atomic force microscope cantilever and a pressed pellet of either hydrophilic or hydrophobic polyaniline powders, in resins of various polymer:monomer ratios. A short-range purely repulsive interaction was observed between hydrophilic polyaniline (doped with phosphoric acid) surfaces in polyester acrylate resin. In contrast, interactions between hydrophobic polyaniline (doped with n-decyl phosphonic acid) were dominated by attractive forces, suggesting less compatibility and higher tendency for aggregation of these particles in liquid polyester acrylate compared to hydrophilic polyaniline. Both observations are in agreement with the conclusions from the interfacial energy studies performed by contact angle measurements.

Water and corrosion resistance of epoxy-acrylic-amine waterborne coatings: effects of resin molecular weight, polar group and hydrophobic segment

[J].

UV and corrosion protective behavior of polymer hybrid coating on mild steel

[J].

Cationic reduced graphene oxide as self-aligned nanofiller in the epoxy nanocomposite coating with excellent anticorrosive performance and its high antibacterial activity

[J].

Graphene-based polymer nanocomposites as barrier coatings for corrosion protection

[J].Graphene has attracted various academic and industrial interest due to its unique electrical, mechanical, chemical and thermal properties. The exceptional lamellar structure of graphene and its derivatives have been identified as anti-corrosive additives in the formulation of polymeric coatings. Graphene can prevent the diffusion of oxygen and water molecules to the surface of meta-based materials by creating highly tortuous pathways, thereby protecting the metal from oxidation-corrosion. In this paper, the utilization of graphene and its derivatives in the formulation of various polymer matrices as barrier coatings was explored. This review paper introduces the fundamentals and the current progress of anti-corrosive coating technology. The most commonly used synthesis methods of graphene-based polymer composites (GPC) such as solution and melt mixing, and in-situ polymerization are compiled. An emphasis is given to the mechanism of barrier properties provided by GPC's in terms of their state of dispersion and the intrinsic properties. The advantages and limitations are also discussed to address the challenges for future research and potential applications of graphene-based polymer composites.

Development of a warning system for defects onset in organic coatings on large surfaces

[J].

Research progress on application of halloysite nanotubes for modification of smart anti-corrosion coating

[J].

埃洛石纳米管负载改性及其在智能防腐涂层中的应用研究进展

[J].

Polymer-based nanocomposite coatings for anticorrosion applications

[A]. HosseiniM, MakhloufA S H.

Nanocomposite organic coatings for corrosion protection of metals: a review of recent advances

[J].

Research progress of galvanic corrosion in marine environment

[J].

海洋环境中金属电偶腐蚀研究进展

[J].

Electrochemical measurements of time-of-wetness and atmospheric corrosion rates

[J].

Evaluation of corrosion behavior of coated metals with AC impedance measurements

[J].AC impedance measurements have been performed in 0.5 N NaCl for coated steel and aluminum alloys which had been subjected to different surface treatment procedures. These procedures included phosphating for steel and exposure to a conversion coating for the Al alloys. A polybutadiene coating of 8 ± 2 μm thichness was applied by spin coating. The AC impedance measurements made it possible to follow the penetration of electrolyte into the coating and to detect the initiation of corrosion at the metal/coating interface. A general model has been used to analyze the impedance data in terms of reactions occurring during the interaction of the coated metals with the environment. Based on this analysis the different pretreatment procedures have been ranked in terms of their efficiency in providing corrosion protection by the organic coating. A comparison between impedance results and visual observation over several days of the corroded and the delaminated areas under the coating confirm that AC impedance data can be used to characterize organic coating/metal systems.

Anticorrosive performance of epoxy/clay nanocomposites pretreated by hexafluorozirconic acid based conversion coating on St12

[J].

Novel approach to correlate degree of surface deterioration to coating impedance for laboratory test panels coated with two types of primers

[J].

Basic aspects of electrochemical impedance application for the life prediction of organic coatings on metals

[J].

Accelerated exposure tests as evaluation tool for estimating life of organic coatings on steel bridges

[J].

Service life prediction for steel bridge coatings with type of coating systems

[J].

Service life prediction for aircraft coatings

[J].

Corrosion accelerated exposure experiment simulating under seawater environment for organic coated steel materials

[J].

Study and evaluation on organic coatings by electrochemical impedance spectroscopy

[J].

电化学阻抗谱方法研究评价有机涂层

[J].

Failure behavior of nano-SiO2 fillers epoxy coating under hydrostatic pressure

[J].

Effect of salt spray corrosion exposure on the mechanical performance of different technical class reinforcing steel bars

[J].

Highspeed-plasma-laser-cladding of thin wear resistance coatings: a process approach as a hybrid metal deposition-technology

[J].

The analytic hierarchy process—what it is and how it is used

[J].

when should fuzzy analytic hierarchy process be used instead of analytic hierarchy process?

[J].

Damage assessment of the corrosion-resistant performances for organic coating systems after accelerated tests using analytic hierarchy process

[J].

A novel prediction model for fatigue strength

[J].

一种新型的疲劳强度预测模型

[J].疲劳破坏是工程应用构件失效的最主要原因之一.但由于疲劳实验成本过高,有必要用力学性能对疲劳强度进行预测.基于真实应力应变曲线,建立了一种新型的疲劳强度预测模型,并运用这种模型计算疲劳强度,与“升降法”和Basquin公式计算的疲劳强度作对比.结果表明:该模型仅需通过抗拉强度和加工硬化强度就可得到材料的疲劳强度,并且适用于其他钢种,极大地节约了成本,精确度也较高.