奥氏体不锈钢具有较高的塑韧性、无磁性和优异的耐腐蚀性能,被广泛应用于汽车、核电、化工和医疗等行业[1~3],但其较低的屈服强度限制了应用范围。目前提高奥氏体不锈钢强度的主要途径是形变强化和细晶强化。经过冷变形和逆相变退火后能有效提高奥氏体不锈钢的强度和延伸率,但在冷变形过程中会发生形变诱导马氏体相变,并且马氏体含量与形变量有关,而在退火过程中形变诱导马氏体会逆转变为纳米级的奥氏体晶粒[4~7]。另外,奥氏体不锈钢还会应用在高温环境,例如在进行焊接或者热处理的过程中。当在敏化温度范围(427~816℃)内受热时,奥氏体中过饱和的碳会迅速地向晶界扩散,在晶界处与铬形成铬的碳化物[8,9]。由于铬的扩散速度太慢而得不到及时的补充,就会在晶界周围形成严重的贫铬区[10]。奥氏体不锈钢优异的耐蚀性跟表面钝化膜的致密性与稳定性密切相关,而形变诱导马氏体含量、碳化铬析出相和位错等缺陷会对奥氏体不锈钢的耐蚀性造成巨大影响。马氏体与奥氏体属于两个不同的相,腐蚀会优先发生在马氏体/奥氏体相界面处[11]。Hamdy等[12]研究了马氏体相变对奥氏体不锈钢在NaCl溶液中的点蚀行为的影响,结果表明马氏体的存在增加了不锈钢的点蚀敏感性,且马氏体的含量越高,材料的耐点蚀性能就越低。当材料暴露在腐蚀性环境时,碳化铬析出物周围的贫铬区会优先遭到腐蚀,从而引起晶间腐蚀。晶间腐蚀是奥氏体不锈钢常见的局部腐蚀形式之一,不锈钢发生的这类腐蚀往往不易被察觉,极易导致设备的突然损坏,因此具有巨大的危害性[13]。据统计,此类腐蚀约占总腐蚀类型的10.2%[14]。相关研究表明,热处理能够提高奥氏体不锈钢抗晶间腐蚀的能力[15],合理的热处理工艺不仅能够降低贫铬区的产生趋势,还能均匀化组织[16,17]。晶粒尺寸越小,越容易在敏化过程中析出碳化铬[18];也有研究表明,孪晶能够有效降低碳化物的析出,从而提高不锈钢耐晶间腐蚀性能[19,20]。因此有必要研究形变强化和细晶强化对奥氏体不锈钢耐点蚀能力以及敏化处理后的耐晶间腐蚀能力。

综上,通过对Fe-18Cr-8Ni奥氏体不锈钢进行冷轧变形和逆相变工艺,分别获得具有优异力学性能(高屈服强度和高延伸率)的冷轧(CR)钢和超细晶/细晶(UFG/FG)钢,而且在生产工艺上易于实现。本文结合透射电子显微镜(TEM)、电子背散射衍射(EBSD)、动电位极化和双环电化学动电位再活化曲线等方法,对原样、CR试样和UFG/FG试样的显微组织、晶粒尺寸分布和电化学腐蚀行为进行表征,最终揭示其腐蚀性能变化及腐蚀机理。

1 实验方法

实验采用厚约3 mm的Fe-18Cr-8Ni商用奥氏体不锈钢冷轧板材(标记为原样),其化学成分(质量分数,%)为C 0.04,Si 0.34,Mn 1.15,N 0.048,Cr 18.06,Ni 8.33,Mo 0.51,Fe余量。对Fe-18Cr-8Ni奥氏体不锈钢冷轧板在室温下进一步冷轧得到厚度减少10%和60%的冷轧样品。再选取60%冷轧样品在气氛保护的电阻炉中900℃保温3 min进行退火热处理。

原样、10%冷轧(CR)、原样60%冷轧900℃退火3 min(UFG/FG)试样的显微组织通过Axioplan 2 Imaging Zeiss型光学显微镜(OM)、JEM-2100型TEM和配备EBSD装置的SUPRA-40型场发射扫描电子显微镜(FE-SEM)进行表征。电化学实验采用三电极体系,待测试样制备成工作电极,参比电极为饱和甘汞电极(SCE),辅助电极为Pt电极。实验温度为25℃,溶液为3.5%NaCl溶液和10%H2SO4-CuSO4溶液。通过电化学工作站(PARSTAT 2273)测试动电位极化曲线和双环电化学动电位再活化曲线。动电位极化测试电位范围为-1.4~1.4 V,扫描速率0.5 mV/s。对上述3种钢试样在马弗炉内进行650℃下敏化操作1 h,随炉冷却,通过SEM对敏化后样品形貌进行表征。双环电化学动电位再活化测试的扫描速率为1.667 mV/s,从自腐蚀电位开始向阳极方向进行动电位扫描,至选定的钝化电位后立即以相同的速率回扫至自腐蚀电位,直到再活化电流变为0,测得再活化率。

2 实验结果

2.1 微观组织

图1

图1

3种钢试样的显微组织形貌

Fig.1

Microstructures of original sample (a), CR sample (b) and UFG/FG sample (c)

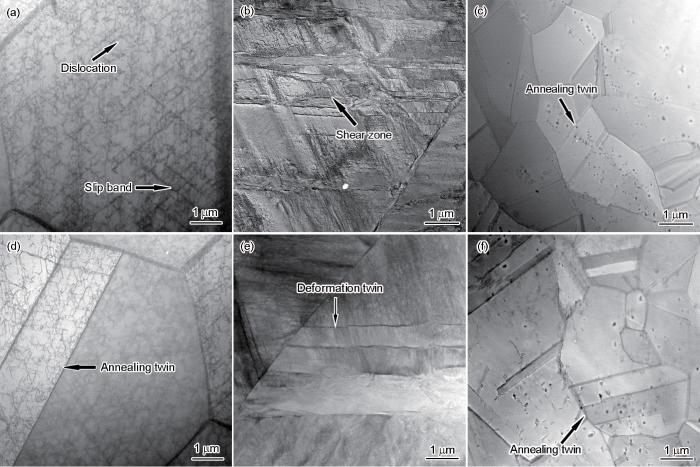

利用TEM对3种钢试样的微观组织结构进一步表征,见图2。原样中含有大量的位错以及位错运动产生的滑移带,并且还存在部分退火孪晶,位错主要在晶界及孪晶界处聚集。CR试样中存在大量的剪切带,位错在剪切带附近聚集,并且还存在部分形变孪晶。UFG/FG试样晶粒尺寸非常细小,存在部分亚微米级的晶粒(UFG),并且还观察到大量退火孪晶,组织内部位错等缺陷极少。经退火处理后,奥氏体不锈钢中位错密度下降,形变奥氏体和逆相变奥氏体几乎均发生回复再结晶,促进新的晶粒快速长大。

图2

图2

3种钢试样的TEM形貌

Fig.2

TEM morphologies of original sample (a, d), CR sample (b, e) and UFG/FG sample (c, f)

2.2 晶粒尺寸统计

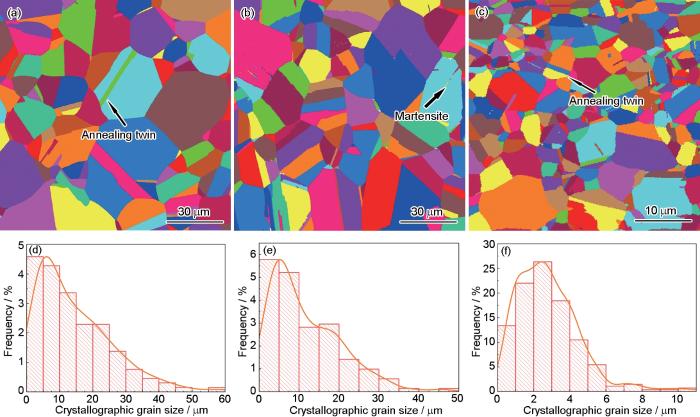

对原样、CR试样和UFG/FG试样进行EBSD分析,以晶体学上取向差2°为晶界统计3个试样的晶粒尺寸,见图3。可知,原样的晶粒尺寸粗大、分布不均匀,存在部分退火孪晶。晶粒尺寸分布在1.0~57.6 μm,平均晶粒尺寸为14.5 μm (图3a)。CR试样中经过10%冷轧变形后已经形成少量的形变诱导马氏体,在之前的工作中通过XRD和TEM已经证明CR试样中有少量马氏体存在,其含量为2%[21]。晶粒尺寸分布在1.0~45.8 μm,平均晶粒尺寸为11.6 μm。UFG/FG试样呈现均匀的超细晶/细晶结构,存在部分退火孪晶,晶粒尺寸分布在0.32~10.9 μm,平均晶粒尺寸为2.8 μm。经过冷轧变形和退火处理后,试样的有效晶粒尺寸明显下降。

图3

图3

3种钢试样的EBSD图和晶粒尺寸分布图

Fig.3

EBSD diagrams (a-c) and grain size distribution images (d-f) of original sample (a, d), CR sample (b, e) and UFG/FG sample (c, f)

2.3 动电位极化曲线

图4为原样、CR试样和UFG/FG试样在3.5%NaCl溶液中的动电位极化曲线。可以看出,3种试样的动电位极化曲线分为3个区域,分别为阴极区、钝化区和过钝化区。当电位低于自腐蚀电位时(阴极区),原样的阴极电流密度明显高于CR试样和UFG/FG试样,说明在NaCl溶液中原样表面吸氧腐蚀速率较快。当电位高于自腐蚀电位低于破钝电位之间时(钝化区),随着电位的升高,3种试样的电流密度值基本保持不变,说明3种试样在NaCl溶液中有着较好的钝化行为。原样的钝化区从-0.375~0.375 V,CR试样的钝化区从-1~0.4 V,UFG/FG试样的钝化区从-1.125~0.7 V,可看出UFG/FG试样钝化区更宽,CR试样钝化区宽度次之,原样的钝化区宽度最窄。当电位高于破钝电位之后(过钝化区),随着电位的升高,3种试样的电流密度也随之增加,说明试样表面钝化膜已经被击穿,表面发生稳态点蚀。一般材料表面钝化膜被击穿时对应的电位称为点蚀电位,钝化区对应的电流密度称为维钝电流。根据动电位极化曲线得到的腐蚀电位Ecorr 、腐蚀电流密度Icorr 和点蚀电位Epit如表1所示,可以看出原样的腐蚀电位最高(-0.38 V)且腐蚀电流密度最低(1.02 × 10-14 A·cm-2),CR试样的腐蚀电位(-0.98 V)和腐蚀电流密度(2.47 × 10-11 A·cm-2)其次,而UFG/FG试样的腐蚀电位最低(-1.12 V)且腐蚀电流密度最大(5.09 × 10-10 A·cm-2)。原样的点蚀电位最低,CR试样的点蚀电位其次,UFG/FG试样的点蚀电位最高。点蚀电位越高,说明试样的耐点蚀性越好。由以上结果可知,奥氏体不锈钢经过冷轧变形后点蚀电位提高,说明在NaCl溶液中耐点蚀能力上升。

图4

图4

3种钢试样在3.5%NaCl溶液中的动电位极化曲线

Fig.4

Potentiodynamic polarization curves of three steels in 3.5%NaCl solution

表1 3种钢试样在3.5%NaCl溶液中的点蚀电位、腐蚀电位和腐蚀电流密度

Table 1

| Steel sample | Epit / V | Ecorr / V vs SCE | Icorr / A·cm-2 |

|---|---|---|---|

| Original | 0.41 | -0.38 | 1.02 × 10-14 |

| CR | 0.48 | -0.98 | 2.47 × 10-11 |

| UFG/FG | 0.75 | -1.12 | 5.09 × 10-10 |

2.4 敏化处理后晶间腐蚀敏感性

2.4.1 敏化处理后的显微组织

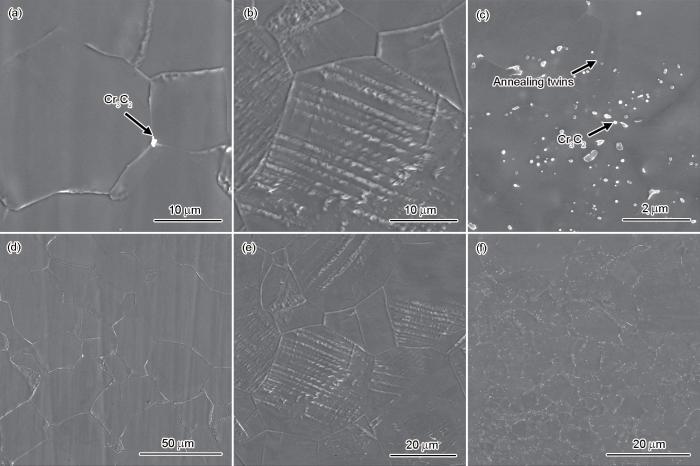

图5为3种钢试样经敏化处理后的显微组织,原样表面比较干净,在晶界处出现极少量的碳化铬析出。CR试样在晶粒内部出现大量变形带,在晶界和晶粒内部均无析出相的存在。UFG/FG试样晶粒尺寸明显细化,晶粒内出现退火孪晶;析出相数量明显增多,不管在晶界上还是晶粒内部都均匀分布。

图5

图5

3种钢试样经敏化处理后的SEM显微组织

Fig.5

SEM microstructure of original sample (a, d), CR sample (b, e) and UFG/FG sample (c, f) after sensitization treatment

2.4.2 晶间腐蚀敏感性

图6a是3种钢试样在饱和CuSO4溶液中的动电位极化曲线,可以看出原样的腐蚀电位为0.0207 V,CR试样的腐蚀电位为0.0172 V,UFG/FG试样的腐蚀电位为0.0435 V;原样的腐蚀电流密度为0.0396 A·cm-2,CR试样的腐蚀电流密度为0.0547 A·cm-2,UFG/FG试样的腐蚀电流密度为0.0040 A·cm-2,3个样品耐CuSO4腐蚀能力相近。采用了双环电化学动电位再活化法用于快速评价不锈钢对晶间腐蚀的敏感性,图6b为3种钢试样在饱和CuSO4溶液中双环电化学动电位再活化曲线。根据曲线得到的再活化扫描电流密度峰值Ir、活化扫描电流密度峰值Ia、Ir/Ia比值计算得到的再活化率如表2所示,可以看出UFG/FG样品的再活化率0.39%远低于原样的45.34%和CR试样的33.60%,说明经过60%冷轧900℃退火3 min后的UFG/FG样品对晶间腐蚀的敏感性最低,而原样和CR试样对晶间腐蚀敏感性较高。

图6

图6

3种钢试样在饱和CuSO4溶液中的动电位极化曲线和再活化曲线

Fig.6

Potentiodynamic polarization curve (a) and reactivation curve (b) of three steels in saturated CuSO4 solution

表2 3种钢试样晶粒尺寸和耐腐蚀性能

Table 2

| Steel sample | Average grain size / μm | Epit / V | Ir / A·cm-2 | Ia / A·cm-2 | Reactivation ratio |

|---|---|---|---|---|---|

| Original | 14.5 | 0.41 | 0.00448 | 0.00988 | 45.34% |

| CR | 11.6 | 0.48 | 0.32029 | 0.95314 | 33.60% |

| UFG/FG | 2.8 | 0.75 | 0.00038 | 0.98559 | 0.39% |

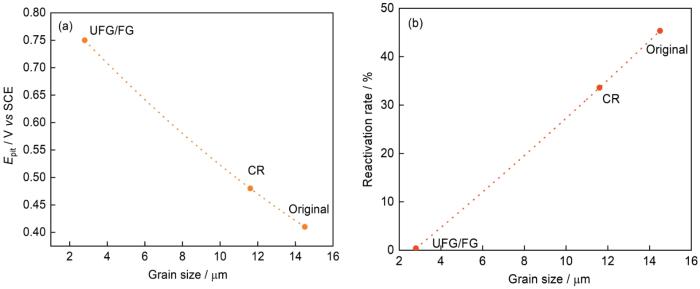

图7为3种钢试样的点蚀电位、再活化率与晶粒尺寸的分布曲线。可以看出随着试样晶粒尺寸的减小,3种试样在NaCl溶液中的点蚀电位也随之增加,说明晶粒尺寸的细化提高了奥氏体不锈钢在NaCl溶液中的抗点蚀能力。而再活化率也随着晶粒尺寸的减小而下降,说明晶粒尺寸的细化降低了奥氏体不锈钢对晶间腐蚀敏感性,提高了其耐晶间腐蚀能力。

图7

图7

3种钢试样的点蚀电位-晶粒尺寸曲线和再活化率-晶粒尺寸曲线

Fig.7

Pitting potential -grain size curve (a) and reactivation rate-grain size curve (b) of three steels

3 讨论

3.1 形变强化和逆相变退火对微观组织的影响

原样Fe-18Cr-8Ni奥氏体不锈钢的显微组织为粗大的奥氏体晶粒,在晶粒内部分布着生产过程中产生的细小位错、层错及少量退火孪晶。经过10%冷轧变形后,CR试样受到应力作用发生塑性变形,形成剪切带、形变孪晶和形变马氏体。由于奥氏体的层错能低,位错滑移过程中会导致全位错分解为不全位错和层错,根据研究表明,ε-马氏体是由层错在每个第二(111)平面上重叠形成的,而孪晶晶胚是由3个层错在连续平面上重叠形成[22,23]。ε-马氏体或形变孪晶晶胚可以通过在平行于其平面(111)上形成的其他核的重叠而变厚。此外,ε-马氏体仅充当从γ相转变到α'-马氏体过程的中间相。同时,冷轧过程中形成的形变组织还会细化晶粒。60%冷轧试样经过900℃退火3 min处理后制备的UFG/FG试样具有平均2.81 μm的超细无缺陷晶粒,内部位错少。当冷轧变形量增加到60%时,形变诱导马氏体含量也随之增加。再经过900℃退火后,形变马氏体快速发生切变逆相变形成含有高位错密度的逆相变奥氏体,随后形变奥氏体和逆相变奥氏体发生再结晶长大成为亚微米/微米级别。

3.2 形变强化和逆相变退火对点蚀的影响

根据NaCl溶液中的动电位极化结果可知,3种试样的耐点蚀能力为:原样<CR试样<UFG/FG试样。经过10%冷轧变形后CR试样的平均晶粒尺寸为11.6 μm,跟原样的平均晶粒尺寸14.5 μm相比略微降低。对于UFG/FG试样,经过冷轧退火处理后几乎没有马氏体的生成,但是平均晶粒尺寸大幅度下降(2.81 μm),也就意味着更多晶界的存在。相关研究表明,马氏体的生成会降低奥氏体不锈钢的耐点蚀性能,而晶粒尺寸的细化则会提高其耐点蚀能力。马氏体与奥氏体是两个不同的相且马氏体比奥氏体更容易腐蚀,因此材料暴露在腐蚀性环境中时可能会优先沿着马氏体/奥氏体的相界面发生腐蚀,并且马氏体的生成可能对奥氏体不锈钢表面钝化膜的完整性造成破坏,因此降低了材料在NaCl溶液中的耐点蚀性能[24]。而晶粒尺寸的细化会导致晶界密度的增加,增加Cr在晶界中的扩散速率,这将有利于表面形成Cr含量更高的钝化膜,提高钝化膜的致密性和稳定性从而提高抗点蚀性能[25]。此外,晶粒尺寸的细化有利于形成更浅的点蚀坑,更容易由亚稳态到再钝化[26]。因此,CR试样的点蚀电位相对于原样略有上升,尽量试样中有2%左右马氏体含量的增加可能会提高点蚀的敏感性,但晶粒尺寸的细化是其提高抗点蚀性能的主要原因。UFG/FG试样的点蚀电位相对于原样大幅度的提高与其更细小的晶粒尺寸密不可分。

3.3 形变强化和逆相变退火对晶间腐蚀的影响

经过敏化处理后,原样、CR试样和UFG/FG试样的再活化率随着晶粒尺寸的细化而减少,说明奥氏体不锈钢耐晶间腐蚀的能力提高。对于原样和CR试样,敏化处理后在原样的晶界处出现极少量的碳化铬析出,而CR试样中无明显析出物,在碳化铬析出物周围形成的贫铬区容易发生腐蚀,从而提高了原样的晶间腐蚀速率。经过60%冷轧900℃退火3 min的UFG/FG试样在敏化处理后晶粒尺寸明显细化,碳化铬析出物含量增多。根据传统的腐蚀理论晶粒细化会提高奥氏体不锈钢的晶间腐蚀速率,这是因为随着晶粒尺寸的细化,晶界数量和面积增多,析出相形成的区域面积占比也增多,从而增加材料的晶间腐蚀速率[27]。然而在本研究中UFG/FG试样的耐晶间腐蚀能力却增强。根据Stawstrom和Hillert[28]对脱敏所需时间(ts)的阐述:

式中,

4 结论

(1) 经过10%冷轧变形后奥氏体不锈钢中形成少量形变马氏体,晶粒尺寸减少,经过逆相变退火后,形变奥氏体和逆相变奥氏体发生再结晶长大成为亚微米/微米级别。

(2) 经过冷轧和逆相变退火工艺后提高了奥氏体不锈钢耐点蚀性能。这是由于晶粒尺寸的细化导致晶界密度的增加,有利于表面形成高Cr含量的钝化膜,提高了钝化膜的致密性与稳定性。

(3) 冷轧变形和逆相变退火工艺提高了奥氏体不锈钢耐晶间腐蚀的能力。碳化铬析出物周围形成的贫铬区提高了晶间腐蚀敏感性,而在超细晶/细晶组织中Cr的快速扩散促进了贫铬区的快速愈合,提高耐晶间腐蚀性能。

参考文献

The use of stainless steel in structures

[J].

Electrochemical behavior of 316L stainless steel in Cl- containing acetic acid solution under high temperature

[J].

Stainless steel: Progress in thermomechanical treatment

[J].

The effect of cold work on structure and properties of AISI 304 stainless steel

[J].

Effect of cold rolling on microstructure and mechanical properties of AISI 301LN metastable austenitic stainless steels

[J].

Effect of strain-induced martensite on the formation of nanocrystalline 316L stainless steel after cold rolling and annealing

[J].

Austenitic stainless steel intergranular corrosion cause analysis and countermeasures

[J].

奥氏体不锈钢晶间腐蚀原因分析和对策

[J].

NaCl induced corrosion of three austenitic stainless steels at high temperature

[J].

新型奥氏体不锈钢高温NaCl腐蚀行为研究

[J].

New concept of the mechanism of intergranular corrosion of stainless steels

[J].

Influence of heat treatment process on microstructure and corrosion resistance of ultrafine Bainite steel

[J].

热处理工艺对超细贝氏体钢显微组织及耐腐蚀性能的影响

[J].采用一步贝氏体等温转变、两步贝氏体等温转变和淬火工艺对中碳钢进行热处理,对不同实验钢的显微组织、物相分布、原位腐蚀和电化学性能进行了表征和测试。结果表明,与一步贝氏体等温工艺和淬火工艺相比,两步贝氏体等温转变工艺后形成的超细贝氏体钢中残余奥氏体含量更小,组织更加均匀。在贝氏体铁素体-残余奥氏体形成的微电偶作用下,超细贝氏体钢中贝氏体铁素体相选择性溶解,产生点蚀坑并沿着板条方向扩展,而均匀分布的薄膜状残余奥氏体阻碍了腐蚀的进一步发展。电化学测试结果显示,在0.5% (质量分数) NaCl溶液中两步贝氏体钢的耐腐蚀性能较一步贝氏体钢和马氏体钢更为优异。

The corrosion behavior of niobium bearing cold deformed austenitic stainless steels in 3.5% NaCl solution

[J].

Effect of nitrogen and sensitization on the microstructure and pitting corrosion behavior of AISI type 316LN stainless steels

[J].

Grain refinement strengthening of a micro-crystalline high nitrogen austenitic stainless steel

[J].

The strengthening effect of nitrogen on austenitic stainless steel

[A].

Precipitation of σ-phase in high-nitrogen austenitic 18Cr-18Mn-2Mo-0.9N stainless steel during isothermal aging

[J].

Evaluation of the effect of grain size on chromium carbide precipitation and intergranular corrosion of 316L stainless steel

[J].

Tracking the evolution of intergranular corrosion through twin-related domains in grain boundary networks

[J].Tailoring the grain boundary network is desired to improve grain boundary-dependent phenomena such as intergranular corrosion. An important grain boundary network descriptor in heavily twinned microstructures is the twin-related domain, a cluster of twin-related grains. We indicate the advantages of using twin-related domains and subsequent statistics to provide new insight into how a grain boundary networks respond to intergranular corrosion in a heavily twinned grain boundary engineered 316L stainless steel. The results highlight that intergranular corrosion is typically arrested inside twin-related domains at coherent twins or low-angle grain boundaries. Isolated scenarios exist, however, where intergranular corrosion propagation persists in the grain boundary network through higher-order twin-related boundaries.

Improving the intergranular corrosion resistance of austenitic stainless steel by high density twinned structure

[J].

Insights into the plasticization mechanism in different 18Cr-8Ni austenitic stainless steel: study of the phase reverted structure versus cold-deformed structure

[J].

Twinnability predication for fcc metals

[J].

Twinning of deformation-induced ε-martensite in Fe-30Mn-6Si shape memory alloy

[J].

Deformation induced martensite in an AISI 301LN stainless steel: characterization and influence on pitting corrosion resistance

[J].

Dependence of corrosion properties of AISI 304L stainless steel on the austenite grain size

[J].The corrosion resistance of austenitic stainless steels is known to be hampered by the loss of chromium available for passive surface layer formation as a result of chromium carbide precipitation at austenite grain boundaries during annealing treatments. Although high-temperature annealing can promote carbide dissolution leading to better corrosion resistance, grain coarsening also results, which would lead to poorer mechanical properties. Processing methods to achieve both good corrosion resistance and mechanical properties are thus highly desirable for austenitic stainless steels. In the present study, we show that the corrosion resistance of AISI 304L stainless steel can be improved by grain refinement into the ultrafine-grained regime. Specifically, samples with different austenite grain sizes in the range of 0.65–12 μm were studied by potentiodynamic polarization and electrochemical impedance spectroscopy tests in a 3.5 wt.% NaCl solution. All samples showed a typical passive behavior with similar corrosion potential, but the corrosion current density decreased significantly with decreasing grain size. The results show that the sample with the finest grain size had the best corrosion resistance due to a higher resistance of the passive layer to pitting attacks. This study indicates that grain refinement which improves mechanical properties can also significantly improve the corrosion resistance of AISI 304L stainless steel.

Effect of grain size on pitting corrosion of 304L austenitic stainless steel

[J].

Intergranular corrosion of stainless steel

[J].

An improved depleted-zone theory of intergranular corrosion of 18-8 stainless steel

[J].