选区激光熔化 (SLM) 是近年来一种新兴的金属增材制造技术,其凭借加工精度高、周期短等特点备受关注。316L不锈钢具有良好的耐腐蚀性及可焊接性,是海洋工程、生物医学、核电等诸多领域应用最为广泛的一种不锈钢[1],同时也是SLM领域中研究较早、工艺较为成熟的金属材料之一[2, 3]。研究表明,SLM技术加工的316L不锈钢 (简称SLM-316L) 的组织结构与传统方法生产的316L不锈钢有显著区别,SLM加工过程中,由于激光熔池的快速冷凝,导致SLM-316L不锈钢中存在高密度位错、亚晶结构、元素偏析等非平衡组织[4~6]。因此,SLM加工后,还需要通过后热处理消除残余应力和优化组织结构,以获得最佳的综合性能。

晶间腐蚀是奥氏体不锈钢服役过程中一种常见的失效形式,其发生、发展过程与奥氏体不锈钢中的界面结构、析出相等密切相关[7]。SLM-316L不锈钢的后热处理不仅能够完成残余应力消减和组织结构优化,同时也能改变其内部的界面结构,在某些特定情况下也会导致第二相析出[6, 8~10]。贫Cr理论认为,奥氏体不锈钢在敏化处理中M23C6沿奥氏体晶界析出,由于C在奥氏体晶格中的扩散速率远大于Cr,因此伴随着M23C6的形成,在其周围产生贫Cr区[11]。不锈钢的界面结构特征对M23C6形成热、动力学有显著影响。Watanabe[12]提出通过提高Σ3晶界比例来优化材料的耐晶间腐蚀的能力,也有研究[13]表明SLM-316L中Σ3晶界所占比重较大,不利于第二相析出从而使得其比传统316L不锈钢更耐晶间腐蚀。然而热处理后SLM-316L不锈钢晶界特性的改变又会对第二相析出产生影响。除了M23C6之外,σ相和Laves相也是导致不锈钢晶间腐蚀的重要因素。在SLM-316L不锈钢后热处理相关的研究表明,经过650~800 ℃热处理后在晶界处发现了M23C6与σ相和Laves相的析出[4, 14, 15]。我们前期工作[16]也表明,经过1150 ℃热处理后,有亚微米级的MnS颗粒物沿晶界析出,并且MnS也是热处理后SLM-316L不锈钢中的一个重要腐蚀起始位置。由此可见,后热处理势必会影响SLM-316L不锈钢的晶间腐蚀行为,然而目前相关的研究鲜有报道。

本文以含碳量有差异的两种SLM-316L不锈钢作为研究对象,探究后热处理对M23C6析出热、动力学的影响规律,阐明后热处理对晶间腐蚀行为的作用机制。首先,采用Thermal-calc软件进行热力学计算,明确SLM-316L不锈钢中各类析出相的形成温度范围,并以此为依据对SLM-316L不锈钢进行后热处理及敏化处理;随后,使用金相显微镜、透射电子显微镜 (TEM) 与扫描电子显微镜 (SEM) 对SLM-316L不锈钢的组织结构以及晶界析出相进行表征;最后,使用双环电化学再活化测试 (DL-EPR) 与过硫酸铵电解的方法评价SLM-316L不锈钢的耐晶间腐蚀性能。

1 实验方法

本文使用EOS 280设备以工艺参数 (200 W激光功率、800 mm/s扫描速度和120 μm层厚的打印参数) 加工两种不同含碳量的316L不锈钢,所使用的316L不锈钢粉末直径在15~45 μm。随后,将制备的试样线切割成尺寸为10 mm×10 mm×2 mm的块体,并将部分块体试样进行900 ºC×5 h热处理 (HT) 和650 ºC×5 h敏化处理 (ST)。采用碳硫分析仪分析两种试样中碳的含量,其中1#试样的碳含量为0.0090% (质量分数),2#试样的碳含量为0.0063%。

采用150目、400目、800目、2000目、5000目的砂纸对试样进行逐级打磨,接着采用金刚石抛光膏进行抛光,之后用纯水、无水乙醇清洗、干燥后用王水 (盐酸和硝酸的体积比为3∶1) 进行侵蚀。侵蚀后的试样,分别采用金相显微镜、Gemini SEM 300型 SEM分析试样的组织结构及析出相的分布。将试样打磨至50 μm,进行离子减薄,然后采用JEM 2100型TEM进一步分析试样的组织结构以及析出相的原子结构。

使用Icon原子力显微镜 (AFM) 分析SLM-316L不锈钢试样中析出相与基体间的表面电位分布。扫描Kelvin探针力显微镜 (SKPFM) 实验所使用的探针为SCM-PIT型探针,其力常数为2.5 N/m,共振频率60~100 kHz。

DL-EPR电化学测试采用三电极体系 (阳极为制备的试样;阴极为铂片;参比电极为饱和甘汞电极SCE,0.242 V vs 标准氢电极) 在Autolab电化学工作站上进行。测试用的试样为背部焊接铜线工作面积为1.0 cm2的试样,电解液为0.50 mol H2SO4+0.03 mol KSCN水溶液。DL-EPR测试时,首先在-1.0 VSCE下恒电位极化60 s,以保证测试的可重复性;然后进行15 min开路电位 (OCP) 测试;随后进行循环动电位极化,先以100 mV/min的速度从-50 mV vs. OCP扫描到0 VSCE,再以相同的扫描速率反向扫描,以正向峰值电流 (Ia) 和反向峰值电流 (Ir) 的比值 (DOS=Ir/Ia) 评价试样的晶间腐蚀性能。DL-EPR测试在室温条件下进行,每组重复3次,以保证测试结果的准确性。

电解实验采用两电极体系在10% (NH4)2S2O8的水溶液中进行,其中制备的试样为阳极,304不锈钢板做阴极,工作电流密度为1 A/cm2。电解测试进行到10、60、120、180、240和300 s时,分别采用SEM和激光共聚焦显微镜 (CLSM,VK-250) 对电解后的试样形貌进行表征,分析晶间腐蚀动力学参数。

2 结果与讨论

2.1 Thermal-Calc热力学计算

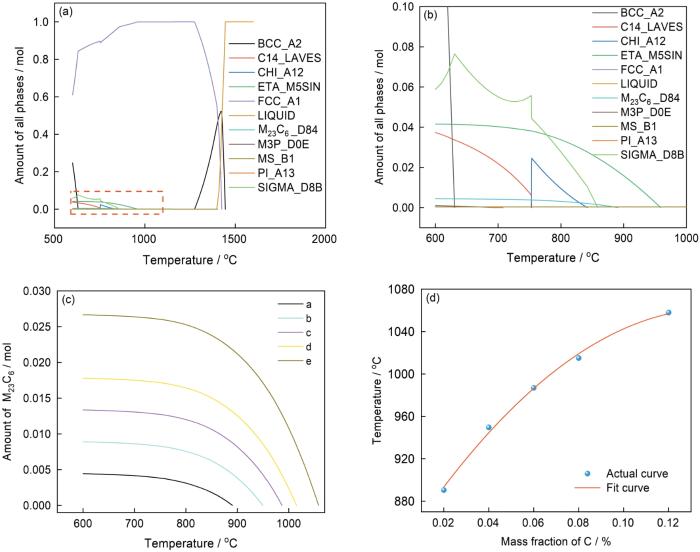

图1给出了316L不锈钢的Thermal-Calc计算结果,表1为Thermal-Calc计算时输入的参数成分,其中C质量分数为控制变量 (0.02%~0.12%)。从图1a和1b所示的316L不锈钢进行了600~1600 ℃热力学平衡相图表明,M23C6、σ相和Laves相等析出相在600~900 ℃进行热处理时中热力学上能够稳定存在,进一步在900 ℃下,仅M23C6可能存在。图1c为不同含碳量316L不锈钢中M23C6热力学稳定含量与温度之间的关系,从中可以看出,随着碳含量的增加M23C6的热力学稳定含量以及完全固溶温度逐渐升高。进一步,通过图1d还可见316L不锈钢中碳含量 (ωC) 与M23C6完全固溶温度 (

图1

图1

不同碳含量316L不锈钢的Thermal-Calc计算结果

Fig.1

Thermal-Calc results of the 316L stainless steels with different C contents: (a) thermodynamic equilibrium phase diagram, (b) magnified view of marked region in Fig.1a, (c) thermodynamic curves for M23C6, (d) relationship between the C content and solution temperature for M23C6

表1 Thermal-Calc计算时的参数成分输入 (不同含碳量316L不锈钢) (mass fraction / %)

Table 1

| Sample | Cr | Ni | Mo | Mn | Si | P | S | C | N | Fe |

|---|---|---|---|---|---|---|---|---|---|---|

| a | 17.5 | 10.4 | 2.7 | 1.2 | 0.4 | 0.02 | 0.01 | 0.02 | 0.15 | Balance |

| b | 17.5 | 10.4 | 2.7 | 1.2 | 0.4 | 0.02 | 0.01 | 0.04 | 0.15 | Balance |

| c | 17.5 | 10.4 | 2.7 | 1.2 | 0.4 | 0.02 | 0.01 | 0.06 | 0.15 | Balance |

| d | 17.5 | 10.4 | 2.7 | 1.2 | 0.4 | 0.02 | 0.01 | 0.08 | 0.15 | Balance |

| e | 17.5 | 10.4 | 2.7 | 1.2 | 0.4 | 0.02 | 0.01 | 0.12 | 0.15 | Balance |

2.2 组织结构分析

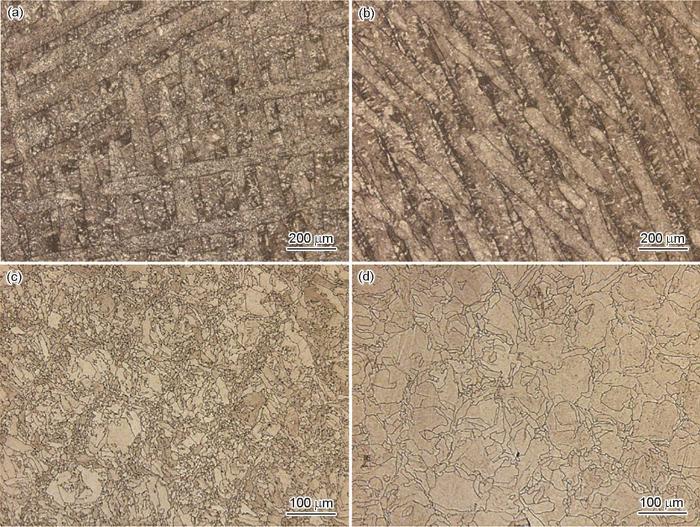

图2为SLM-316L不锈钢热处理前后金相组织。图2a和b分别为1#和2#试样未经过热处理的金相图,从图中可以清晰地观察到两种试样的打印路径,1#中两个相邻层之间的打印路径90°相交,2#试样中相邻层上打印路径的夹角为60°,这个差异取决于它们的打印策略[17]。图2c和d展示了两种试样经过900 ℃×5 h热处理后的金相组织,可以看出经过热处理后两种试样的打印路径都完全消失,并且呈现形状不规则的晶粒,与2#试样相比,1#试样的晶粒尺寸更小,晶界处“黑点”更多。“黑点”为侵蚀剂腐蚀形成的腐蚀坑,可见后文中的SEM腐蚀坑形貌。此外,对比之前研究结果可以看出[4, 5, 18],900 ℃×5 h热处理对SLM-316L的晶粒尺寸和形状基本没有影响。由此可以判定,1#和2#试样在晶粒几何性质上的差异主要源自于它们各自加工时复杂的热历史。

图2

图2

不同热处理后的SLM-316L不锈钢金相组织结构

Fig.2

Microstructure of SLM 316L stainless steel after different heat treatments: (a) 1# as-received, (b) 2# as-received, (c) 1# 900 ℃×5 h, (d) 2# 900 ℃×5 h

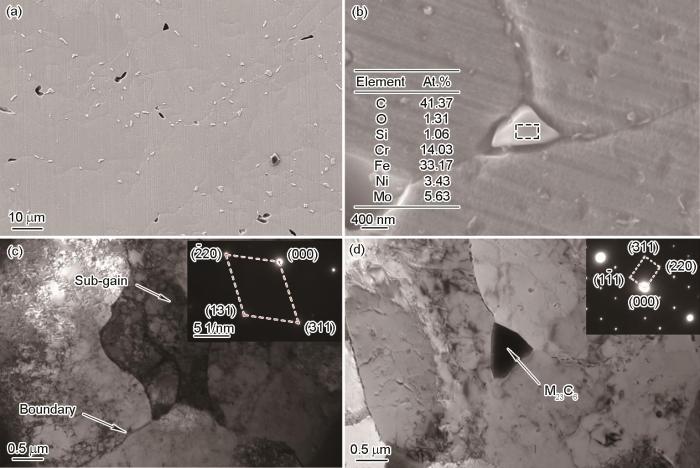

图3为1# SLM-316L不锈钢试样组织结构的SEM和TEM分析结果。如图3a所示,1#试样经过900 ℃×5 h热处理后,晶界处有大量的第二相析出,而在热处理之后的2#试样中没有发现晶界析出相。图中出现了黑色的空洞,为上文提到的“黑点”。结合图1a中的热力学计算结果可以初步判定,晶界析出相为碳化物。图3c和d分别为热处理前后1# SLM-316L不锈钢的TEM图,从图中可以看出,未热处理1#试样中存在亚晶结构,并且在亚晶界处有大量的位错富集;经过900 ℃×5 h热处理试样中的亚晶结构及位错基本消失,在晶界处观察微米尺度的析出相,通过对衍射花样的标定 (图3d) 可以进一步确定析出相为面心立方结构的M23C6。文献中报道,SLM-316L不锈钢的晶界和亚晶界处有Mo富集,含Mn、Si的纳米氧化物颗粒弥散分布在晶粒内部和晶界处。Chao等[19, 20]曾报道,Cr、Mo、Mn等元素的偏析能够通过参加M23C6的形成反应,从而促进其析出的动力学过程。

图3

图3

1# SLM-316L不锈钢试样组织结构的微观结构

Fig.3

Microstructure of 1# SLM-316L stainless steel sample: (a) SEM image after 900 ℃×5 h heat treatment, (b) M23C6 precipitated at grain boundaries, (c) TEM images of SLM-316L without overheating treatment, (d) TEM image of SLM-316L after heat treatment at 900 ℃×5 h

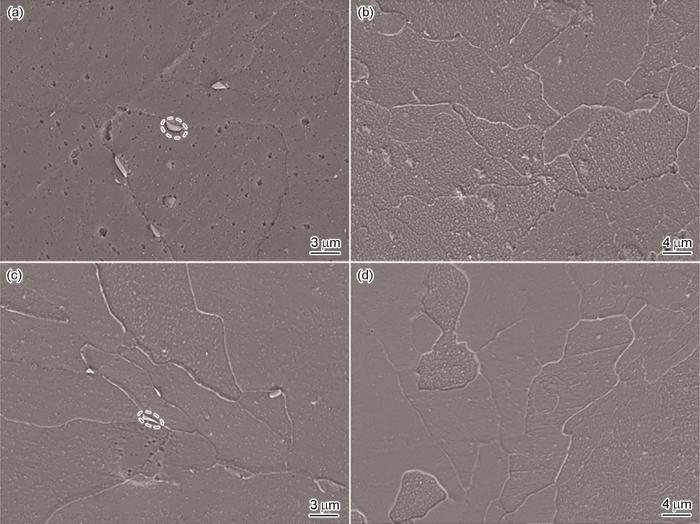

为了探索影响1#和2#试样中晶界析出相形成的原因,设计了如下的热处理工艺:1#试样:900 ℃×2 h、980 ℃×2 h;2#试样:870 ℃×2 h、900 ℃×2 h。图4展示了1#和2# SLM-316L不锈钢试样热处理之后组织结构的SEM图,其中1#试样经过900 ℃×2 h热处理后晶界上有碳化物析出相形成 (图4a),而经过980 ℃×2 h的试样中基本上观察不到晶界析出相 (图4b);900 ℃×2 h热处理之后的2#试样中没有发现晶界析出相 (图4c),当热处理温度降低到870 ℃时,能够在晶界处观察到析出相,并且析出相成分与900 ℃×2 h的1# SLM-316L不锈钢相近 (图4d)。通过对M23C6析出热、动力学的分析可知,随着热处理温度升高,Cr的扩散速率增加,M23C6的形成速率也增加,但是当温度过高时,析出相将重新固溶到基体。图4所示的实验结果表明,1#试样中M23C6的完全固溶温度在900~980 ℃之间,而2#试样中M23C6的完全固溶温度在870~900 ℃之间。根据

图4

图4

不同热处理条件下两种SLM-316L不锈钢SEM图像

Fig.4

SEM images of two kinds of SLM-316L stainless steel under different heat treatment conditions: (a) 1# 900 ℃×2 h, (b) 1# 980 ℃×2 h, (c) 2# 870 ℃×2 h, (d) 2# 900 ℃×2 h

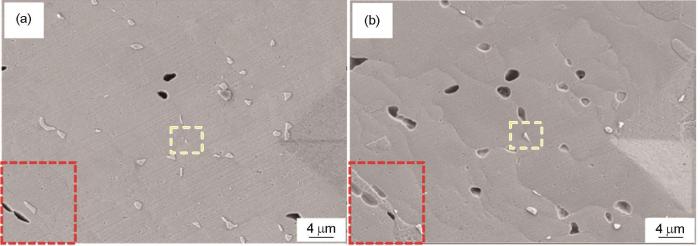

图5

图5

原位观测不同电解时间SLM 316L不锈钢晶间腐蚀形貌的SEM像

Fig.5

SEM images of intergranular corrosion morphology of SLM 316L stainless steel with 10 s (a) and 30 s (b) of electrolysis in situ observed

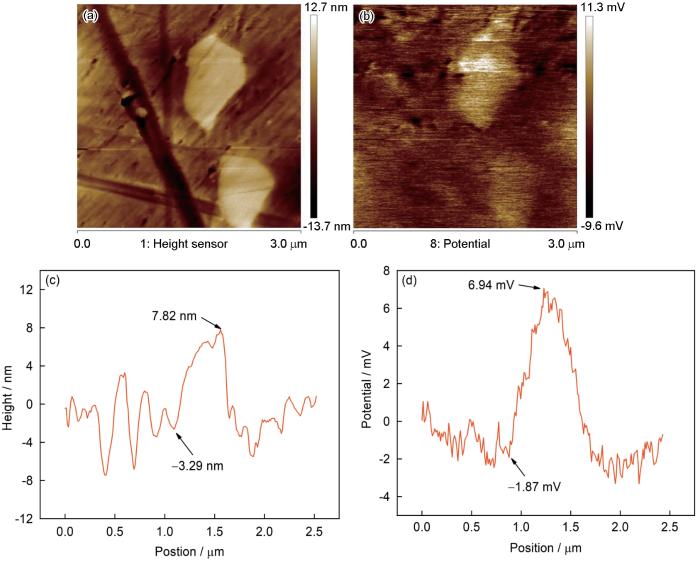

2.3 SKPFM测试

图6

图6

1# SLM-316L不锈钢经过900 ℃后热处理析出的M23C6的SKPFM形貌和电势测量结果

Fig.6

SKPFM morphology and potential measurement results of M23C6 precipitated from 1# SLM-316L stainless steel after heat treatment at 900 ℃: (a) microscopic surface morphology, (b) potential distribution in the corresponding region, (c, d) results of electric potential in line scan area

2.4 晶间腐蚀分析

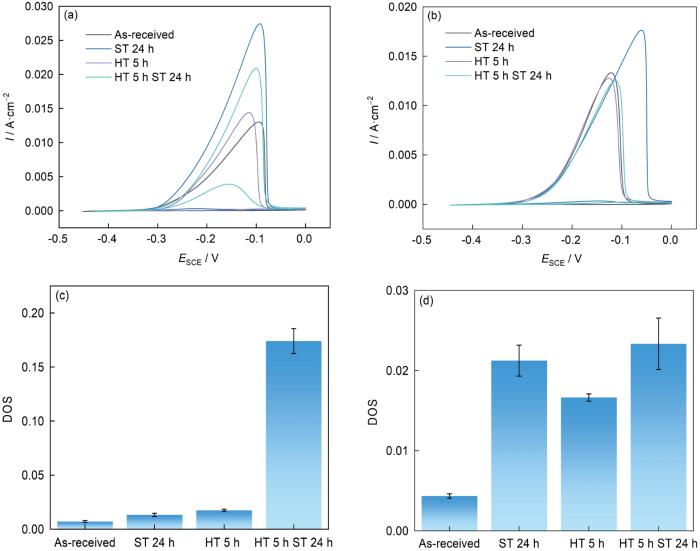

图7

图7

两种碳含量的SLM 316L不锈钢的DL-EPR测试结果图:

Fig.7

DL-EPR test results of SLM 316L stainless steel with two carbon contents: (a) 1# SLM-316L stainless steel, (b) 2# SLM-316L stainless steel, (c) statistical diagram of DOS value of sample 1#, (d) statistical diagram of DOS value of sample 2#

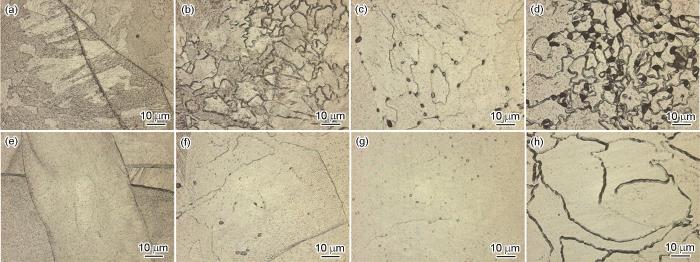

随后,采用过硫酸铵电解实验进一步分析1#和2# SLM-316L不锈钢的晶间腐蚀行为。如图8所示,未热处理的试样经过120 s电解后,其打印路径上出现腐蚀痕迹 (图8a和e),这表明打印路径 (激光熔池边界) 是其腐蚀的最敏感位置,这是由于能量输入不足导致层间结合不良或颗粒未熔化而产生的气孔和缺陷多集中于熔池边界,缺陷的存在以及残余应力的集中导致该区域更容易被腐蚀[21]。经过敏化处理后,晶界处出现明显的腐蚀痕迹,其中1#试样比2#试样更明显 (图8b和f),即1#试样具有更高的晶间腐蚀敏感性。经过900 ºC×5 h热处理后,1#试样出现晶界析出相,腐蚀优先在析出相周边发生,并沿着晶界扩散,而2#试样没有明显的腐蚀痕迹 (图8c和g)。900 ºC×5 h+650 ºC×24 h处理的1#和2#试样都出现较为严重的晶间腐蚀[22],其中1#试样中除了沿着晶界的腐蚀沟壑,还有碳化物脱落形成腐蚀坑出现 (图8d和f)。综上所述,900 ºC×5 h热处理能够导致1#和2# SLM-316L不锈钢耐晶间腐蚀性能恶化,并且碳含量较低的2#试样的耐晶间腐蚀性能要优于1#试样。

图8

图8

经过不同热处理后两种SLM 316L不锈钢的电解2 min晶间腐蚀形貌

Fig.8

Intergranular corrosion morphology of 1# SLM-316l stainless steels (a-d), 2# SLM-316L stainless steel (e-h) after 2 min electrolysis after as-received (a, e), ST/2 h (b, f), 900 ºC/5 h (c, g) and 900 ºC/5 h+ST/24 h (d, h)

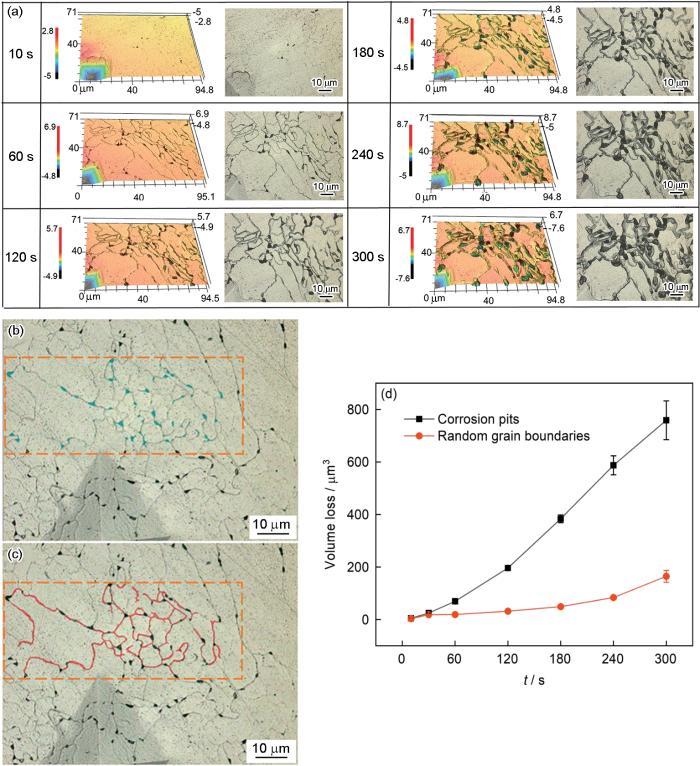

为进一步探究SLM-316L不锈钢晶间腐蚀机制及动力学规律,对900 ºC×5 h+650 ºC×24 h处理的1#试样分别进行10、60、120、180、240和300 s的原位电解实验。如图9a所示,电解10 s时,晶界处发生轻微的腐蚀,并且在部分析出相附近形成腐蚀坑,这与SKPFM测试结果一致;随着电解时间的延长,晶界处的腐蚀愈加严重,腐蚀坑的数量和深度均增加。对图9b-d中标记的晶界与腐蚀坑的区域进行损失体积测量。图9d给出了电解后析出相附近腐蚀坑和晶界处沟壑体积的统计结果。从图9d中可以看出,腐蚀坑都随着时间延长而增加,析出相附近腐蚀坑的体积损失大于晶界处沟壑的体积;由此可知,900 ºC×5 h+650 ºC×24 h处理试样的晶间腐蚀过程描述为:M23C6周边的不锈钢基体发生优先发生溶解,这标志着晶间腐蚀的萌生,随后晶间腐蚀沿晶界扩展,其中腐蚀坑呈三维扩展趋势,而晶界处沟壑则以二维平面扩散为主。

图9

图9

原位观察0~300 s电解浸蚀SLM-316L不锈钢的CLSM图

Fig. 9

CLSM of SLM-316L stainless steel electrolytically etched from 0 to 300 s observed in-situ: (a) change of intergranular corrosion morphology, (b) corrosion pits measurement area, (c) grain boundary measurement area, (d) curve of loss volume of grain boundary and corrosion pits

2.5 后热处理对SLM-316L不锈钢晶间腐蚀行为的作用机制

本文中的实验结果表明,热处理前后SLM-316L不锈钢的晶间腐蚀机制均符合贫Cr理论[16, 19, 23],即650 ℃敏化处理时,在M23C6奥氏体晶界处形核长大,由于Cr在奥氏体晶格中扩散速率远小于C,因而Cr与C反应生成M23C6后,会在其周围形成贫Cr区,在腐蚀环境中贫Cr区优先溶解,成为晶间腐蚀的起始位置。2#试样的晶粒尺寸比1#试样更大,细小的晶粒提供了更大的晶界面积,从而为第二相提供了更多的形核位点,但是当晶粒尺寸小到一定程度时,形核时所需要的C要扩散每一个位点,从而导致M23C6在形核时C无法满足形核临界值,因此M23C6不能析出。所以在晶粒尺寸较小的SLM-316L中晶粒大小对晶间腐蚀的影响较小[14]。此外,通过比较后热处理 (900 ºC×5 h) 前后SLM-316L不锈钢晶间腐蚀行为还可以发现,所选的后热处理工艺能够降低其耐晶间腐蚀性能。后热处理对SLM-316L不锈钢的作用机制可以归纳为以下两个方面:

当后热处理温度 (900 ºC) 大于M23C6完全固溶温度 (

3 结论

原始SLM-316L不锈钢中存在亚晶界、位错以及打印路径等非平衡态结构,经过900 ℃×5 h后,SLM-316L不锈钢中的非平衡结构消失,在含碳量较高的1# SLM-316L不锈钢试样的晶界处有微米级M23C6,而含碳量较低的试样中没有形成M23C6。

含碳量较高的SLM-316L不锈钢表现出的耐晶间腐蚀性能弱于含碳量较低的试样,并且由于晶界处大尺寸M23C6的析出使得900 ºC×5 h热处理后SLM-316L不锈钢的耐晶间腐蚀性能进一步恶化。

900 ºC×5 h热处理后SLM-316L不锈钢的晶间腐蚀的萌生以大尺寸M23C6的周边贫铬区域的优先溶解为标志,随后分别围绕M23C6析出相和沿晶界扩散形成腐蚀坑和沟壑,其中腐蚀坑呈三维扩散趋势,而晶界处沟壑则以二维平面扩散为主。

参考文献

Corrosion behavior of 316L stainless steel in media containing pyomelanin secreted by Pseudoalteromonas lipolytica

[J].

海洋假交替单胞菌Pseudoalteromonas lipolytica分泌黑色素加速316L不锈钢腐蚀机理的研究

[J].

Microstructure and corrosion behavior of SLM-Ti6Al4V with different fabrication angles in F--containing solutions

[J].

不同打印角度SLM-Ti6Al4V组织结构及其在含氟离子溶液中的腐蚀行为

[J].

The corrosion behavior of Ti6Al4V fabricated by selective laser melting in the artificial saliva with different fluoride concentrations and pH values

[J].

The effect of sub-grain structure on intergranular corrosion of 316L stainless steel fabricated via selective laser melting

[J].

Pitting behavior of SLM 316L stainless steel exposed to chloride environments with different aggressiveness: Pitting mechanism induced by gas pores

[J].

Heat treatment effect on the microstructure and corrosion behavior of 316L stainless steel fabricated by selective laser melting for proton exchange membrane fuel cells

[J].

Formation of M23C6-type precipitates and chromium-depleted zones in austenite stainless steel

[J].

Enhanced corrosion resistance of additively manufactured 316L stainless steel after heat treatment

[J].The microstructures and passivation behavior of selective laser melted 316L stainless steel (SLM SS316L) after various heat treatments (500 °C, 950 °C, and 1100 °C) were investigated. The electrochemical results showed that the SLM SS316L sample that was heat treated at 950 °C exhibited the lowest passive current density. The microstructural characterization analysis indicated that the subgrain structures transformed from dislocation-rich subgrain boundaries into island-like cellular trace structures after heat treatment at 950 °C. This led to improved corrosion resistance due to the elimination of dislocations and the homogenization of the composition. Compositional analyses of the passive film indicated that there was no notable change in the passive film composition after heat treatment at 500 °C and 950 °C. However, heat treatment at 1100 °C promoted the formation of Cr(OH)3 in the passive film, resulting in a reduced corrosion resistance. Based on these results, heat treatment at 950 °C appears to be an adequate post-process for SLM SS316L to optimize the microstructure, while also improving corrosion resistance.

Mechanical properties and corrosion behavior of selective laser melted 316L stainless steel after different heat treatment processes

[J].Irregular grains, high interfacial stresses and anisotropic properties widely exist in 3D-printed metallic materials, and this paper investigated the effects of heat treatment on the microstructural, mechanical and corrosion properties of 316 L stainless steel fabricated by selective laser melting. Sub-grains and low-angle boundaries exist in the as-received selective laser melted (SLMed) 316 L stainless steel. After heat treatment at 1050 °C, the sub-grains and low-angle boundaries changed slightly, and the stress state and strength decreased to some extent due to the decrease of dislocation density. After heat treatment at 1200 °C, the grains became uniform, and the dislocation cells vanished, which led to a sharp decline in the hardness and strength. However, the ductility was improved after recrystallization heat treatment. The passive film thickness and corrosion potential of the SLMed 316 L stainless steel decreased after heat treatment, and the pitting potential also decreased due to the accelerated transition from metastable to steady-state pitting; this accelerated transition was caused by the presence of weak passive films at the enlarged pores after heat treatment, especially for an adequate solid solution treatment.

Heat treatment degrading the corrosion resistance of selective laser melted Ti-6Al-4V alloy

[J].

Beneficial effect of reversed austenite on the intergranular corrosion resistance of martensitic stainless steel

[J].

An approach to grain boundary design of strong and ductile polycrystals

[J].

Grain boundary character distribution in an additively manufactured austenitic stainless steel

[J].

On the unusual intergranular corrosion resistance of 316L stainless steel additively manufactured by selective laser melting

[J].

Thermal stability and microstructural evolution of additively manufactured 316L stainless steel by laser powder bed fusion at 500-800 ℃

[J].

Effect of heat treatment on the microstructure and passive behavior of 316L stainless steel fabricated by selective laser melting

[J].

热处理对SLM-316L不锈钢组织结构及钝化行为的影响机制

[J].

Corrosion behavior of 316L austenitic steel processed by selective laser melting, hot-isostatic pressing, and casting

[J].

The enhancement of microstructure on the passive and pitting behaviors of selective laser melting 316L SS in simulated body fluid

[J].

The effect of post-processing heat treatment on the microstructure, residual stress and mechanical properties of selective laser melted 316L stainless steel

[J].

Correlation between process parameters, microstructure and properties of 316 L stainless steel processed by selective laser melting

[J].

Stress corrosion cracking of 316L manufactured by laser powder bed fusion in 6% ferric chloride solution

[J].

Microstructure and intergranular corrosion of the austenitic stainless steel 1.4970

[J].

Improvement of corrosion resistance of SS316L manufactured by selective laser melting through subcritical annealing

[J].