在蒸汽吞吐作业过程中,高压蒸汽引入的巨大的机械载荷和热应力,致使套管变形破坏[11~13]。蒸汽吞吐循环导致的热胀冷缩,使油管柱上产生一定的残余应力,当表面的残余应力累积到超过其抗拉强度时,管柱断裂失效[14]。总而言之,高温使得金属出现强度下降、均匀伸长率变化等情况,会直接或间接引发管柱因变形、缩颈、剪切、断裂等导致的失效。目前,低Cr系的油井管钢在CO2/H2S环境中的研究主要集中在Cr的保护性和自修复性、单一因素的影响机理、CO2和H2S共存时的控制机理、不同分压下的腐蚀产物及腐蚀行为等[15~19]。温度对低合金碳钢在CO2/H2S环境中腐蚀速率的研究表明,在120 ℃以下,随着温度的增加,腐蚀速率遵循先增加后降低的趋势,峰值温度出现在90 ℃左右,影响因素为气体溶解度、产物膜成膜以及组分气体控制作用等[20~22]。当前的研究大多在150 ℃以下的工况中开展,因此进一步研究油套管在更高温度的环境中的腐蚀行为和腐蚀机理十分必要。

针对稠油热采井油套管在超高温环境下的失效行为,本文对L80油套管钢,开展了350 ℃下的高温拉伸实验及模拟工况下的高温高压腐蚀实验,研究其在高温环境下的力学性能、拉伸断裂机理、腐蚀行为及其机理,旨在为稠油热采超高温井的选材和腐蚀防护提供数据及理论支撑。

1 实验方法

L80钢作为低合金调质钢,在石油与天然气开发中被作为油套管广泛使用。实验使用的试样取自API授权厂商生产的L80钢级油套管,其出厂状态下的使用性能均满足相关标准。其化学成分 (质量分数,%) 为:C 0.031、Cu 0.012、Mn 1.15、Cr 0.62、Si 0.34、Mo 0.15、N<0.0005、P<0.0002,组分元素和有害元素含量均满足API SPEC 5CT Casing and Tubing中对于L80钢级油套管的基本要求。

金属微观组织、高温拉伸和高温腐蚀测试所需试样,均按照GB/T 2975-2018,从实际管材中取样制得。试样用体积分数为4%的硝酸酒精蚀刻得到金相形貌,然后使用ZEISS Axio Examiner型电子显微镜进行观察。

室温及高温拉伸试验依据GB/T 228.1-2010和GB/T 228.2-2015,采用NCS-GNT100型万能试验机对圆柱型棒状试样进行实验,试样安装完成后保温30 min,拉伸速率设置为1 mm·min-1,进行拉伸试验。得到的试样断口使用ZEISS EV0 MA15扫描电子显微镜 (SEM)进行观察。

高温高压腐蚀实验参照GB 10124-1988开展,使用30 mm×10 mm×3 mm的平板试样。腐蚀溶液为油水混合溶液,其中汽油占83.1%,模拟地层水占16.9%。使用的模拟地层水矿化度为55150 mg/L,其成分 (mg/L) 为:KCl 151、NaCl 49030、NaHCO3 520、Na2SO4 1400、MgCl2 470、CaCl2 3570。腐蚀性气体成分及其分压为H2S 0.17 MPa、CO2 0.25 MPa、H2 0.16 MPa,总压为2 MPa。实验开始之前先对试样进行预处理,使用400#至1500#的砂纸逐级打磨,依次进行丙酮去油、去离子水冲洗、无水乙醇浸泡后,用冷风风干,最后使用精度0.0001 g的电子天平称重。装入试样后封釜,通入N2除氧6 h,紧接着按预设值依次通入H2S、CO2、H2,然后升温至设定温度,恒温恒压实验168 h。试样取出后,使用去离子水缓慢冲洗后,3个平行试样中的两个直接用去膜液 (10 g C6H12N4+100 mL HCl+900 mL H2O) 去膜、水冲、除水、风干后,进行失重测试。另一试样在SEM分析后,同样进行失重测试。而用于腐蚀产物成分分析的试样 (8 mm×8 mm×1 mm),清洗吹干后使用X射线光电子能谱仪Thermo Scientific K-Alpha对其进行分析,并利用XPSPEAK41软件对测试结果进行分峰拟合。

通常使用平均腐蚀速率 (v) 来表示金属的腐蚀程度,按

式中,v为腐蚀速率,mm/a;w1和w2为试样腐蚀前后质量,g;S为试样表面积,cm2;t为实验时间,h;ρ为试样材质密度,g/cm3。

2 结果与分析

2.1 金属显微组织

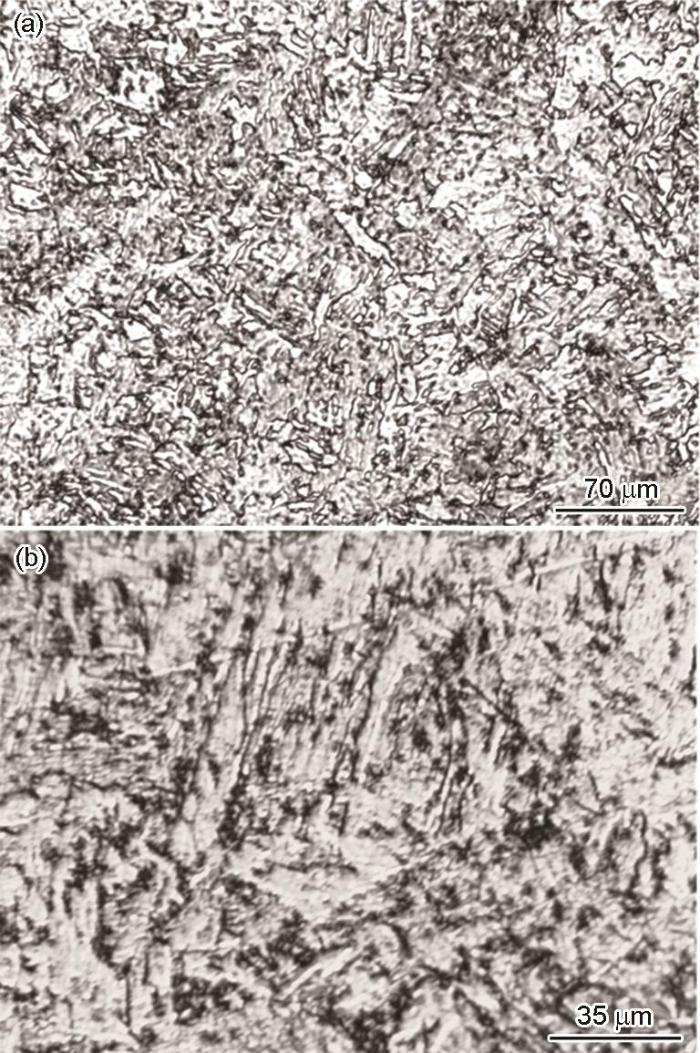

图1

图1

实验用L80套管钢显微组织

Fig.1

Microstructure of L80 casing steel for testing: (a) low magnification, (b) high magnification

2.2 高温拉伸

图2为大气环境中L80油套管在各温度下的应力-应变曲线。由图可见,L80钢在常温条件下出现明显的屈服现象,应力-应变关系曲线中存在明显的屈服平台,持续到4%左右的应变量时,屈服平台消失,在形变强化的作用下L80钢的强度随着应变的增加缓慢上升,这一阶段的应力-应变曲线连续且光滑。随实验温度的升高,应力-应变曲线中不再出现屈服平台,在150和250 ℃时,仅存在一个不太明显的屈服点。而温度升高至350 ℃时,屈服点消失,应变强化阶段变成一条平滑曲线。屈服平台在常温下显现,而在高温时消失,这与材料中置换、间隙原子及其扩散速率相关。置换和间隙原子会在金属材料的缺陷聚集成“气团”,“气团”会阻碍晶格滑移进而出现屈服平台。置换和间隙原子的扩散速率随温度升高快速上升,当趋近或超过位错运动的滑移速度时,组织中的“气团”不再对位错运动起到约束效果,屈服平台因而消失[24]。“屈服平台”的存在表明L80钢在拥有极高强度的同时,还具有极佳的塑性变形能力,能够在一定程度上避免油井管发生脆性断裂失效。

图2

图2

L80钢在大气环境中各温度下的拉伸应力-应变曲线

Fig.2

Tensile stress-strain curves of L80 steel at different temperatures in atmospheric environment

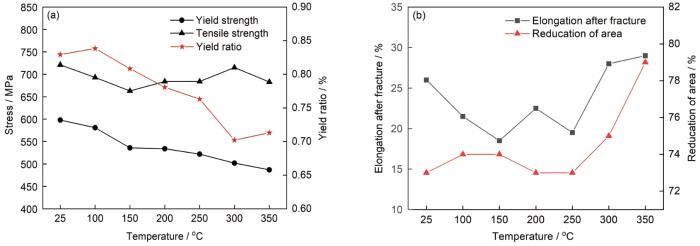

图3a为L80油套管钢的屈服强度、抗拉强度和屈强比随温度的变化规律。结果显示, L80钢的力学性能随温度的升高不断衰退,其中屈服强度随温度的衰减程度明显大于抗拉强度,屈强比也随温度上升而降低。实验钢的屈强比从25 ℃的0.83,下降至350 ℃时的0.71。这表明,随着温度的升高,L80钢在屈服后的塑性变形阶段产生的均匀伸长量不断增大。但是屈强比在350 ℃以内仍然保持在较高水平,有利于减轻油套管自重给井身结构带来的附加载荷。屈服强度随着拉伸温度的升高出现连续性衰减,从25 ℃时的598 MPa衰减至350 ℃时的487 MPa,屈服强度的折减率达到18.56%。这是因为拉伸温度升高,金属材料的原子间结合力不断降低,在应力作用下位错更容易萌生。抗拉强度的变化规律则与屈服强度完全不同,抗拉强度随温度先降低后升高,到达临界温度后,又持续降低。在25~150 ℃时,抗拉强度随温度升高不断下降。在200~300℃时,抗拉强度随温度的升高有略微提升。到达临界温度300℃以后,温度继续升高,抗拉强度持续下降。实验温度区间内,抗拉强度的最大折减率为8.04%,出现在150 ℃时。L80钢抗拉强度出现这种变化趋势,是因为在200~300 ℃的条件下出现的“蓝脆”现象。“蓝脆”使得材料的脆性增强而塑性降低,强度稍微有所增加,这在应力-应变曲线中也有所体现。这是因为低合金钢中的间隙溶质原子C、N会形成柯氏“气团”,导致位错钉扎,因此材料继续形变需要产生新的位错,最终材料内部位错密度提高,强度增加且塑性降低。随着拉伸温度继续升高,金属组织中的第二相和夹杂物对位错运动的阻碍和钉扎作用不断减弱,减轻或削弱合金钢的加工硬化,致使抗拉强度出现高温衰减[25,26]。

图3

图3

L80钢的力学性能随温度的变化情况

Fig.3

Variation of tensile strength (a) and plastic deformability (b) of L80 steel with temperature

L80钢在不同温度下的断后伸长率和断面收缩率如图3b所示。L80钢的断面收缩率呈现出一个先降低再增加的趋势,在150 ℃以下时,断口伸长率随温度升高不断降低。这是由于在25~150 ℃的温度区间内,L80钢存在明显的“屈服平台”,在此阶段内发生较大的塑性流动。温度升高,“屈服平台”减弱或消失,由塑性流动引入的变形量不断减小,最终断后伸长率不断降低。材料由于其内部的柯氏“气团”对位错运动的钉扎作用,故其断面收缩率在此温度区间内相对稳定,保持在73%左右。当拉伸温度达到临界温度后,位错运动受到的阻碍作用大大降低,同时高温作用下金属发生的动态再结晶作用,使得材料的软化程度加剧,变形抗力显著降低[27,28]。塑性和延展性随温度升高显著增强,这些直接表现在断后伸长率和断面收缩率的明显增加。

在25 ℃时,断口由裂纹源区、剪切脊区和剪切唇区组成。中心处为裂纹源区,呈菊花状向外扩散的是大尺寸的放射状剪切唇区,边缘部分的剪切唇区的面积极小,且大部分区域放射状的剪切脊直接从断口中心贯穿至边缘 (图4a)。温度上升至150 ℃以后 (图4b),断口表面不再出现剪切脊,断口由纤维状区和剪切唇区组成,且纤维状区的面积相较于常温状态有明显增大。同时,断口边缘处杯锥状的剪切唇变得十分明显,与断口表面呈45°分布在断口外围。温度继续上升至250~350 ℃时 (图4c、d),断口相较于150 ℃时未出现明显改变,仍由裂纹源区和剪切唇区组成,且剪切唇区面积随温度升高不断增加。总体来说,在25 ℃至350 ℃的温度区间内,随着温度的不断升高,纤维状裂纹源区的表面变得更加平整,表面的起伏明显降低,变得更加平整。同时,在150 ℃以上的高温状态,局部区域出现两个不同朝向且垂直剪切唇相交的特征形貌,但交汇无明显的韧性断裂特征。

图4

图4

L80钢在不同温度下的拉伸断口宏观形貌

Fig.4

Macro images of tensile fractures of L80 steel at 25 ℃ (a), 150 ℃ (b), 250 ℃ (c) and 350 ℃ (d)

通过对L80钢在不同温度下的断口纤维状裂纹源区的微观形貌进行观察,如图5所示,进一步确定其在不同温度下的断裂方式。在常温状态下 (图5a),L80钢的拉伸断口呈现明显的韧性断裂特征,纤维状裂纹源区表面由密集的韧窝构成,韧窝成等轴状或抛物线状。裂纹源区表面零散分布着少量的小尺寸孔洞。且在图中的标记区域显示,常温状态下,裂纹源区存在少量的小尺寸剪切脊和局部微区的解理台阶。在150 ℃ (图5b) 和250 ℃ (图5c) 下,裂纹源区主要由等轴状韧窝组成,其间夹杂少量抛物线状的撕裂韧窝。断口表面的小尺寸剪切脊数量明显减少,未发现台阶状的解理特征。相较于常温状态,孔洞的数量明显增加,尺寸更大且更加均匀。当温度上升至350 ℃时,裂纹源区几乎只有等轴状韧窝,表面的孔洞变得更加密集,还可以看到夹杂物和第二相颗粒从一些大尺寸孔洞中暴露出来。

图5

图5

不同温度下L80钢拉伸断口的裂纹源区微观形貌

Fig.5

Micro morphologies of the crack source areas of tensile fractures of L80 steel at 25 ℃ (a), 150 ℃ (b), 250 ℃ (c) and 350 ℃ (d)

通过对L80钢在不同温度下的拉伸断口进行分析,可知,L80钢在25~350 ℃的温度区间内,在拉伸应力作用下都是发生微孔聚合导致裂纹萌生和扩展的韧性断裂,均未出现脆性断裂。由于材料内部的碳化物和析出相硬度大于其他组织,存在弹塑性差异,在应力作用下就容易从基体组织中剥离产生孔洞。紧接着裂纹在应力三轴度最高、孔洞体积最大处萌生并沿危险截面扩展,相邻孔洞互相贯通直至试样断裂[29,30]。在常温状态下,由于材料的塑性变形能力不足,由微孔聚集形成的微裂纹通过微孔与周围的微裂纹相连,进行裂纹扩展。因此,相邻的两个微裂纹在变形应力的作用下,便导致剪切应力导致的剪切脊的出现。同理,裂纹源区中局部微小区域的小剪切脊和解理台阶也是材料塑性不足导致产生的。上述都是由于L80钢的屈强比极高,其在常温状态下塑性变形较弱,最终在拉伸断裂过程中显现出来。随着温度的升高,材料的变形和位错激活能随之增加,塑性流动性增强。拉伸过程中,局部微孔损伤产生后,相邻微孔聚集受到的阻碍作用明显减小,韧性裂纹更容易通过微孔聚合的方式向外扩展,形成更大的纤维状裂纹源区。伴随着升温引起的屈强比降低,使材料在塑性变形阶段产生更大的颈缩,在断裂时形成更大的剪切唇。对于高温状态下观察到的裂纹源区孔洞中的颗粒以及不同方向呈相交状态的剪切唇,都是材料中的析出相和夹杂物对拉伸过程中裂纹的萌生及扩展的影响所产生的结果。

2.3 高温高压腐蚀

图6为L80钢在不同温度下的腐蚀速率。从图中可以看到,试样的腐蚀速率从150 ℃时的0.0923 mm·a-1持续增加至350 ℃时的0.8283 mm·a-1,且温度越高增长速率越快。温度对腐蚀速率的影响主要体现在:温度升高致使反应速度加快,腐蚀速率增加;温度升高,气体在反应介质中的溶解度降低;腐蚀产物的成膜机制及其在腐蚀介质中的溶解性可能会随温度的变化而变化。温度对L80钢腐蚀速率及腐蚀机理的影响,在后文中予以分析研究。

图6

图6

不同温度下L80钢在模拟工况中的腐蚀速率

Fig.6

Corrosion rates of L80 steel in the simulated conditions with different temperatures

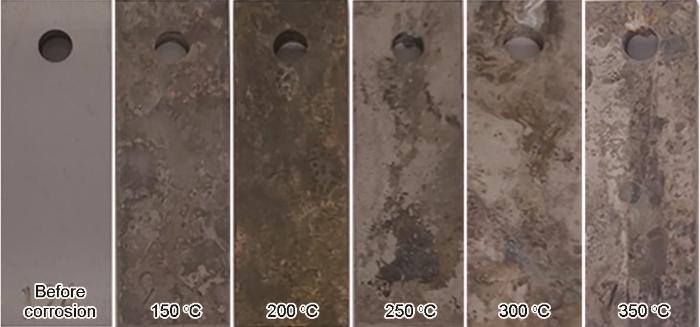

图7为L80钢在不同温度下的模拟地层水中腐蚀7 d后,试样表面腐蚀产物膜的宏观形貌。不难看出,实验后试样的失去原有的金属光泽,表面为暗灰色,且腐蚀产物分布均匀。对比不同温度的结果发现,温度在250 ℃以下时,试样表面的凹坑数量较少,表面的起伏较小。当温度为300 ℃时,产物覆盖区域面积增加,腐蚀产物颜色加深。温度升高至350 ℃,腐蚀进一步加剧,试样表面的凹坑分布更加均匀密集,且深度增加。随着反应温度的升高,金属表面的腐蚀不断加重,同时产物膜与金属基体因结合强度增强,产物膜不易损伤脱落,最终生成的产物膜颜色随实验温度升高而加深。

图7

图7

L80钢在不同温度下腐蚀7 d后试样的宏观形貌

Fig.7

Macro morphologies of L80 steel before and after 7 d corrosion at different temperatures

为进一步研究高温条件下温度对L80钢腐蚀机理的影响,使用SEM对去膜前后的试样表面进行观察。通过分析图8中各温度下的腐蚀产物膜形态,可以看出,150 ℃下的产物膜表层由小颗粒堆积而成,且致密性较差,下层组织呈团絮状;温度升高至200 ℃时,下层的团絮状物质基本被上层的小颗粒完全覆盖,仅有局部区域存在缺陷;当腐蚀温度达到250 ℃后,表层完全被规则的六面体晶体覆盖,局部区域分布着微小孔洞,未见裂纹;温度继续升高,产物膜表面的晶体继续长大,产物膜的致密性继续增强。推测下层的团絮状物质为FeS,而溶液环境中生成的FeS存在多种形态、分散性较好、容易从表面脱落,故底层的硫化物产物膜致密性较差。表层的小颗粒及六面体晶体为FeCO3,其形状规则、堆积紧密,形成的膜层更为完整。

图8

图8

L80钢在不同温度下腐蚀7天后的表面SEM形貌

Fig.8

SEM morphologies of L80 steel after corrosion for 7 d at 150 ℃ (a), 200 ℃ (b), 250 ℃ (c), 300 ℃ (d) and 350 ℃ (e)

图9为L80钢在不同温度下腐蚀7 d后去除表面腐蚀产物膜的微观形貌。总的来说,L80钢在实验温度区间内都显现出均匀腐蚀特征。在150 ℃时,试样仅出现轻微腐蚀,腐蚀后试样表面仍残留初始的机加工痕迹,局部区域出现较浅的腐蚀坑;当温度到达200 ℃,去膜后的表面均匀分布大量凹坑,腐蚀加剧;温度升高至250 ℃,腐蚀坑的数量增加,深度加深;升温至300 ℃以后,去膜后的试样表面不再出现明显的腐蚀坑,表面更加平整。结果表明随温度进一步升高,腐蚀加剧速率不断增加的同时,腐蚀也变得更加均匀。通过观察去膜后的试样表面不难发现,温度升高,L80钢的腐蚀速率明显增加且朝着均匀腐蚀的方向不断发展。

图9

图9

不同温度下试样表面去除腐蚀产物后的SEM形貌

Fig.9

SEM morphologies of L80 steel after corrosion for 7 d at 150 ℃ (a), 200 ℃ (b), 250 ℃ (c), 300 ℃ (d) and 350 ℃ (e) and then removing corrosion product films

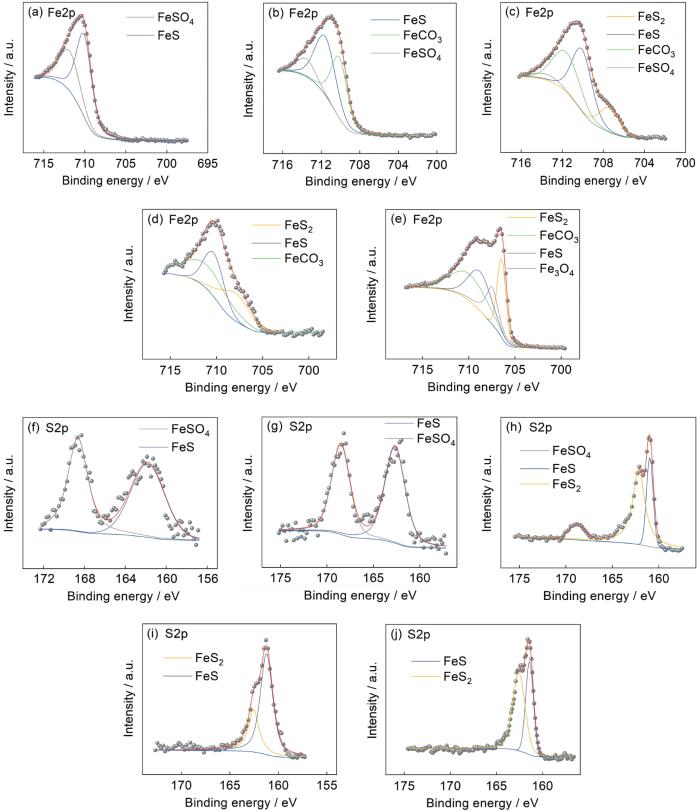

图10为不同温度下的腐蚀产物膜进行X射线光电子能谱 (XPS) 测试,结合Fe2p和S2p轨道的峰值进行分析,结果如下:在150 ℃时,腐蚀产物主要由FeS,未检测到FeCO3和FeS2;温度为200 ℃时,出现少量的FeCO3、FeS2,产物膜主要仍由FeS构成;当温度超过200 ℃之后,腐蚀产物的组成成分基本保持不变,主要由FeS、FeS2和FeCO3组成。其中FeS2的含量随着温度的升高不断增加,FeS和FeCO3的含量基本保持不变。另外,在150~250 ℃的区间内,检测到了少量的FeSO4存在,硫化物中的S被高温氧化成了SO42-。由能谱分析可知,该实验温度区间内,腐蚀产物膜主要由H2S腐蚀产生的FeS、FeS2和CO2腐蚀产生的FeCO3组成,且随温度升高,硫化物的含量增加,碳酸亚铁含量基本保持稳定。

图10

图10

不同温度下腐蚀产物的XPS图谱

Fig.10

XPS spectra of corrosion products formed on L80 steel after corrosion for 7 d at 150 ℃ (a, f), 200 ℃ (b, g), 250 ℃ (c, h), 300 ℃ (d, i) and 350 ℃ (e, j)

结合腐蚀产物形貌与XPS测试结果随温度的演化规律进行分析。结果可知,该体系下L80钢的腐蚀产物膜为双层结构,腐蚀产物主要由Fe-S和FeCO3组成,主体部分为内层的FeS,少量的FeCO3分布在外层,且随温度升高,腐蚀产物中FeS的占比增加。尽管温度升高后腐蚀速率加快,腐蚀产物在金属表面的积累加快。然而,该工况下腐蚀反应由H2S控制,腐蚀产物中的FeCO3在高温环境下容易向FeS转化,而FeS产物膜的结构较为松散且容易从基体脱落,故此时的腐蚀产物膜并不能有效减缓基体的腐蚀。同时由于FeCO3和FeS分布的不均匀性,造成不同位置的腐蚀产物膜对金属基体的保护效果不一,最终形成蚀坑或台阶状腐蚀。温度更高时,腐蚀速率增加使得产物膜各处的差异性随产物膜厚度增加而削弱,最终演变成均匀腐蚀。

同时,随着温度的升高,CO2的溶解度不断降低,FeCO3更容易在金属表面附着结晶[31,32],故最外层生成一层致密的FeCO3膜。然而,温度升高对腐蚀速率的加速作用明显大于腐蚀产物膜厚度和致密性增加带来的保护作用,故温度升高,试样的腐蚀产物膜的保护性增强,但腐蚀速率却不断增加。另一方面,FeS的生成速率远大于铁氧化物,而表层保护性较好的FeCO3厚度较薄,故腐蚀速率随温度升高不断加快。该模拟工况中CO2与H2S的分压比为1.49,不同于常规条件下CO2腐蚀速率随温度的变化规律,该工况下腐蚀速率随温度升高不断增加,且腐蚀产物中FeS的占比随温度升高不断增大,结果表明该体系下的腐蚀速率受H2S腐蚀控制。

3 结论

(1) 温度对L80钢的力学性能影响显著,屈服强度和抗拉强度都随温度升高出现明显衰减,受间隙溶质原子钉扎作用的影响,抗拉强度的衰减明显小于屈服强度。

(2) 随着温度升高,L80钢的断裂方式由常温下微孔聚集诱发局部剪切撕裂扩展转化为以微孔聚合为主导向外扩展,主要是由于温度对材料的内部形变和激活能的影响,塑性流动性增加,微孔聚合能力增强。

(3) 温度对L80钢在CO2/H2S体系中的腐蚀速率影响显著,腐蚀速率随温度升高持续增加,温度越高腐蚀速率的增幅越大,且随温度升高腐蚀在微观层面变得更加均匀。

(4) 温度与腐蚀产物膜的形态和晶体构型密切相关,腐蚀产物膜由位于底层的FeS和表层的FeCO3组成,腐蚀由H2S腐蚀控制,腐蚀产物膜中的FeS含量随温度升高明显增加,表层FeCO3的致密性也随温度升高而增强。

参考文献

New progress and next development directions of heavy oil development technologies in Shengli oilfield

[J].

胜利油田稠油开发技术新进展及发展方向

[J].

Preliminary discussion on current status and development direction of heavy oil recovery technologies

[J].Heavy oil reserves account for more than 2/3 of the discovered crude oil resources in the world. Due to the high viscosity and poor fluidity of heavy oil, its recovery is difficult, with high technical requirements. According to the characteristics of many types and large depth changes of heavy oil reservoirs in China, the current status of heavy oil recovery at home and abroad and the main technical direction of improving recovery efficiency were analyzed and summarized; combining with the field production performance, the adaptability, application potential and main technical challenges of existing commercial recovery technologies to different types of heavy oil reservoirs were discussed. The results show that steam huff and puff is still the main method of heavy oil recovery in China. However, most of the oil fields have entered the end period of production, and the recovery efficiency is low. At present, the application scope of mature replacement technologies (steam flooding, SAGD and in-situ combustion) is limited, so it is urgent to develop new replacement technologies. The series of heavy oil development technologies in the middle and deep layers are relatively mature, but the EOR technologies for deep, ultra-deep and complex types (such as fractured/karst cave) of heavy oil reservoirs are not yet mature. It is of more practical significance and application prospect to strengthen the research on frontier technologies such as generating steam downhole, solvent assisted, in-situ upgrading and gasification. The research results can be used for reference and guidance to expand the research field and direction of heavy oil recovery technologies.

稠油开采技术现状与发展方向初步探讨

[J].

Evaluation and development countermeasures for nonproducing reserves of heavy oil reservoirs in Shengli oilfield

[J].Shengli Oilfield, rich in heavy oil resources, still has nearly 3.20×10<sup>8</sup>t proven reserves that have not been effectively developed after years of technical research and development. In order to realize the effective development of nonproducing reserves of different types of heavy oil reservoirs, the reserves characteristics and development difficulties were systematically analyzed, the heavy oil reservoirs were divided into five types, namely sensitive heavy oil, deep low-permeability heavy oil, super heavy oil, edge-bottom water heavy oil and ultra-thin layer, and development countermeasures were prepared for different types of nonproducing reserves with comprehensive application of physical modeling, numerical simulation, laboratory testing, and other methods. It was found in the study that sensitive heavy oil reservoirs could be developed with technologies such as moderate sand production, heavy oil viscosity reduction and cold recovery, and oil layer combustion; deep low-permeability heavy oil reservoirs could be developed with technologies of fracturing assisted solubilization and viscosity reduction, and viscosity reduction and displacement; super heavy oil reservoirs could be developed with E-SAGD, HECS and other EOR technologies to improve the fluidity of crude oil; edge-bottom water heavy oil reservoirs could be developed with bottom-water steam flooding, viscosity reduction and cold recovery, and microbial oil recovery to reduce the effect of edge-bottom water on development; the thin heavy oil reservoirs could be developed mainly with short-radius horizontal well, and fracturing + viscosity reduction and cold recovery to increase the controlled reserves of single well. The technologies and findings obtained in the study are of great significance in guidance and reference for the development of similar reserves at home and abroad.

胜利油田稠油未动用储量评价及动用对策

[J].胜利油田稠油资源丰富,经过多年技术攻关和开发建设,仍有近3.20×10<sup>8</sup>t探明储量未得到有效动用。为实现不同类型稠油未动用储量的有效开发,系统分析了储量特点及开发难点,将其划分为敏感稠油、深层低渗稠油、特超稠油、边底水稠油和超薄层稠油5种类型,综合应用物理模拟、数值模拟、室内实验等方法,制订了不同类型未动用储量的开发对策。研究表明:敏感稠油油藏可采用适度出砂、稠油降黏冷采、火烧油层等技术,深层低渗稠油油藏可采用压裂辅助增溶降黏、降黏引驱技术开发,特超稠油油藏可采用E-SAGD、HECS强化采油技术提高原油流动性,边底水稠油油藏可通过底水蒸汽驱、降黏冷采、微生物采油技术减少边底水对开发的影响,薄层稠油油藏主要考虑短半径水平井、压裂+降黏冷采技术增加单井控制储量。研究形成的技术与认识对国内外相似储量的动用有一定的指导和借鉴意义。

Present situation and development trend of the thermal/chemical flooding technology of heavy oil

[J]. J.

稠油热/化学驱油技术现状及发展趋势

[J].

Present situation and development trend of heavy oil thermal recovery technology

[J].

稠油热采技术现状及发展趋势

[J].

Technical progress and novel methods of foreign thermal recovery

[J].

国外热力采油技术进展及新方法

[J].

Damage mechanism of casing for thermal recovery of heavy oil well and casing coupon technology experiment

[J].In view of the long-term high temperature and high pressure of the casing and frequent casing damage in the process of steam flooding, a statistical analysis of the casing damage in the steam flooding of the Qi 40 Block in Liaohe Oilfield was conducted, and the mechanical and thermodynamic study was conducted for the casing damage process. The results showed that when steam was injected into the oil well, the casing temperature raised, resulting in thermal expansion force which increased with temperature; when the thermal expansion force was greater than the cementing resistance of the casing, the casing broke away from the cement sheath and expanded freely, and an inclined plane effect was produced on the contact surface of them, making the thermal expansion force change from the longitudinal elastic force to the increasing lateral squeezing force that brought extrusion damage to the casing, which is the complete casing damage mechanism. Based on the damage mechanism, the casing coupon technology was developed. Preliminary tests have shown that the casing coupon can greatly increase its cementing force and reduce the probability of casing damage. The study results are of important significance for improving the development benefits of heavy oil old areas.

稠油热采井套管损坏机理及套管挂片技术实验

[J].针对蒸汽驱采油过程中套管长期处于高温高压状态导致套管损坏现象频繁等问题,统计分析辽河油田齐40块蒸汽驱套管损坏状况,对套管损坏过程进行力学和热力学研究。研究结果表明:油井注汽时,套管温度升高,产生热膨胀力,热膨胀力随温度升高而增大;当热膨胀力大于套管固井胶结阻力时,套管挣脱水泥环自由伸缩,同时在两者接触面产生斜面效应,使热膨胀力由纵向弹性力转变为不断增大的横向挤压力,导致套管挤压损坏,形成一套完整的套管损坏机理。据此研发了套管挂片技术,经初步试验表明,套管挂片可大幅提高其固井胶结力,降低套管损坏几率。研究成果对提高稠油老区开发效益具有重要参考意义。

A mechanical model for predicting casing creep load in high temperature wells

[J].

Induced H2S formation during steam injection recovery process of heavy oil from the Liaohe Basin, NE China

[J].

Experimental determination of in situ hydrogen sulfide production during thermal recovery processes

[J].

Mechanical analysis on casing damage and discussion on dynamic mechanism

[J].

套管损坏的力学分析及动力学机制探讨

[J].

Casing failure mechanism of thermal production wells and casing strength optimization design

[J].

热采井套损机理及套管强度优化设计

[J].

Method for designing casing stem strength in heavy-oil steam injection wells

[J].

稠油热采井套管柱强度设计方法研究

[J].

Casing plastic damage analysis considering non-uniform stress in thermal recovery well

[J].

耦合非均匀地应力的热采井套管塑性损伤分析

[J].

Corrosion behavior and life prediction of high grade OCTG in full-life-cycle environment of high temperature high pressure gas well

[J].

高钢级油井管在高温高压气井全生命周期环境中的腐蚀行为及寿命预测

[J].采用高温高压腐蚀测试系统研究了140ksi高钢级油井管在高温高压气井全生命周期单环境和连续多环境中的腐蚀行为。结果表明,140ksi高钢级油井管在全生命周期单环境和连续多环境中的腐蚀速率均呈现为CR<sub>鲜酸</sub>>CR<sub>残酸</sub>>CR<sub>地层水</sub>>CR<sub>凝析水</sub>的趋势,其中连续多环境中腐蚀行为表现出一定的“遗传效应”。地层水腐蚀介质中,140ksi高钢级油井管在单环境和连续多环境的腐蚀速率均随实验周期增加而减小,60 d后腐蚀速率趋于稳定。基于点蚀速率结果,采用有限元方法计算得到不同腐蚀状态下140ksi高钢级油井管的服役寿命。

Corrosion behavior of low-alloy steel containing 1% chromium in CO2 environments

[J].

Evaluation of actual corrosion status of L80 tubing steel and subsequent electrochemical and SCC investigation in lab

[J].

L80油管钢实际腐蚀状况评估及室内电化学和应力腐蚀研究

[J].

Electrochemical noise of stress corrosion cracking of P110 tubing steel in sulphur-containing downhole annular fluid

[J].Stress corrosion cracking (SCC) is considered as the main risk of tubing steels during the exploitation of oil and gas fields, which could result in sudden and catastrophic failures of downhole tubing. Especially in annular downhole environment, P110 tubing steel is prone to sulfide stress corrosion cracking and hydrogen embrittlement (HE) where S2- could be originated from bio-reduction of SO42- inspired by sulfate-reducing bacteria (SRB). Currently, extensive work have been performed to investigate the influence factors on SCC and mechanism of tubing steels, but limited researches have been conducted on the SCC of P110 tubing steel in annular downhole environment, particularly, on the early detection of SCC. In this work, the SCC behavior of P110 low alloy steel in simulating sulphur-containing annular fluid (SAF) and the effect of S2- concentration on the initiation and propagation of crack were investigated by slow stress rate test (SSRT), non-destructive electrochemical noise (ECN), SEM and EIS techniques. The results showed that, during the elastic stress stage, the addition of S2- accelerated the breakdown of passivation film on the surface of P110 steel tensile specimen. There are many short duration current transients caused by metastable pits on ECN curves. The transformation time of metastable to stable pits is shortened significantly by the addition of S2-, which not only promotes the growth of pits but the initiation of cracks from the stable pits under the action of tensile stress. Compared with the ECN spikes from metastable pits, the spikes associated to the advance of cracks are featured by longer average duration (about 400 s), stronger amplitude (40 μA), and higher charge (about 4000 μC). As a result, the susceptibility of P110 steel to SCC increases with S2- concentration, and the propagation of SCC is dominated by anodic dissolution characteristic of discontinuous advance.

井下含硫环空液中P110油管钢应力腐蚀开裂的电化学噪声特征

[J].

Effect of chromium on corrosion behavior of P110 steels in CO2-H2S environment with high pressure and high temperature

[J].

Effect of temperature on the corrosion rate of oil tubing and casing

[J]. J.

温度对油套管用钢腐蚀速率的影响

[J].

Effect of temperature on CO2/H2S corrosion rate of oil tube steels

[J].

温度对油管钢CO2/H2S腐蚀速率的影响

[J].

Effect of temperature and CO2/H2S partial pressure ratio on corrosion behaviors of BG90SS tubing steel

[J].

温度和CO2/H2S分压比对BG90SS钢管腐蚀行为的影响

[J].

Development and current situation of pipeline steels

[J].

管线钢的研究进展

[J].

Oxygen-molybdenum interaction with dislocations in Nb-Mo single crystals at elevated temperatures

[J].

High temperature tensile perforamnce of 42CrMo casting ring blank

[J].

42CrMo铸造环坯高温拉伸性能

[J].以常用轴承材料42CrMo钢为研究对象,采用Gleeble-3500热力试验模拟机,通过高温拉伸试验,分析了铸造42CrMo钢的高温拉伸力学性能。建立了抗拉强度模型,并验证了模型的准确性;计算了硬化系数和应变速率敏感系数。结果表明,铸造42CrMo钢的硬化系数随加热温度升高而减小,随应变速率增大而增大。应变速率敏感系数则随温度升高而增大,随应变速率增加而减小。

Hot deformation behavior and dynamic recrystallization of Cu-Cr-Zr-Ce alloy at elevated temperature

[J].

Cu-Cr-Zr-Ce合金高温热变形行为及动态再结晶

[J].

Dynamic recrystallization behavior of a superaustenitic stainless steel containing 16%Cr and 25%Ni

[J].

Investigation of metallic ductile fracture by void-based meso-damage model

[J].

基于微孔贯通细观损伤模型的金属韧性断裂分析

[J].

Continuum theory of ductile rupture by void nucleation and growth: Part I. Yield criteria and flow rules for porous ductile media

[J].Widely used constitutive laws for engineering materials assume plastic incompressibility, and no effect on yield of the hydrostatic component of stress. However, void nucleation and growth (and thus bulk dilatancy) are commonly observed is some processes which are characterized by large local plastic flow, such as ductile fracture. The purpose of this work is to develop approximate yield criteria and flow rules for porous (dilatant) ductile materials, showing the role of hydrostatic stress in plastic yield and void growth. Other elements of a constitutive theory for porous ductile materials, such as void nucleation, plastic flow and hardening behavior, and a criterion for ductile fracture will be discussed in Part II of this series. The yield criteria are approximated through an upper bound approach. Simplified physical models for ductile porous materials (aggregates of voids and ductile matrix) are employed, with the matrix material idealized as rigid-perfectly plastic and obeying the von Mises yield criterion. Velocity fields are developed for the matrix which conform to the macroscopic flow behavior of the bulk material. Using a distribution of macroscopic flow fields and working through a dissipation integral, upper bounds to the macroscopic stress fields required for yield are calculated. Their locus in stress space forms the yield locus. It is shown that normality holds for this yield locus, so a flow rule results. Approximate functional forms for the yield loci are developed.

In situ synchrotron X-ray diffraction study of surface scale formation during CO2 corrosion of carbon steel at temperatures up to 90°C

[J].

Effect of temperature on corrosion behavior of X70 steel in an artificial CO2-containing formation water

[J].

温度对X70钢在含CO2地层水中腐蚀行为影响

[J].利用高温高压反应釜,采用失重、SEM、XRD、EDS和电化学方法研究了不同温度下X70管线钢在含CO<sub>2</sub>地层水中的腐蚀行为。讨论了X70钢CO<sub>2</sub>腐蚀机理的热力学和动力学机制。结果表明:温度通过影响FeCO<sub>3</sub>过饱和度、晶粒形核率和长大速率,进而影响X70钢腐蚀速率。在温度为30 ℃时,FeCO<sub>3</sub>的过饱和度较小,不能在X70钢表面连续析出,难以形成保护性产物膜,X70钢腐蚀速率较高。温度为60~90 ℃时,FeCO<sub>3</sub>的形核速率大于生长速率,X70钢表面形成致密的FeCO<sub>3</sub>膜,腐蚀速率开始下降。继续升温至120和150 ℃,FeCO<sub>3</sub>的形核速率小于生长速率,X70钢表面不能形成完整的具有保护性的FeCO<sub>3</sub>膜,或膜内应力增大导致膜破裂。FeCO<sub>3</sub>膜与基体金属形成电偶电池,发生局部腐蚀。