本文通过SMAT技术制备了梯度纳米孪晶结构,对孪晶结构进行了详细表征,并通过电化学试验确定了梯度结构样品的最佳耐蚀层。

1 实验方法

实验用S31254不锈钢采用ASTMA312中的成分标准,采用真空感应炉进行熔炼,主要化学成分 (质量分数,%) 为:C 0.0085, Cr 19.791,Ni 17.883,Cu 0.751,Nb 0.009,Si 0.632,Mn 0.809,Mo 5.830,Al 0.006,N 0.214,Fe余量。1.3 mm厚的热轧板经1220 ℃高温退火2 h后得到粗晶 (CG) 组织,对其进行SMAT处理[17]。在SMAT过程中,直径为2 mm的钢珠在封闭的容器中通过高功率超声装置以20 kHz的系统频率被加速,钢珠在高应变速率下随机撞击板材表面,使表层严重变形。板材两表面均进行45 min的SMAT处理以得到梯度结构 (GS) 样品。

测量梯度结构样品横截面的维氏显微硬度 (HV),每次测试在25 g的载荷下保持15 s的停留时间。使用配备了电子背散射衍射 (EBSD) 探头的Gemini SEM 300高分辨场发射扫描电镜 (SEM) 对梯度结构进行表征。在EBSD观察之前,对梯度样品的横截面进行机械抛光。采用FEI TECNAI G2 20S的透射电镜 (TEM) 对孪晶进行分析,TEM样品采用双喷减薄方法制备,双喷液选择8%高氯酸酒精溶液,电压为38 V,温度为-25~-30 ℃。

将GS样品打磨至不同厚度,逐层进行电化学腐蚀。电化学实验所用设备为平板电解池及CS350型电化学工作站。采用三电极测试体系,工作电极 (WE) 为待测试样,参比电极 (SCE) 和辅助电极 (CE) 分别为饱和甘汞电极和铂片电极。腐蚀测试环境为10% (质量分数) NaCl溶液,测试温度为室温。动电位极化测试待开路电位稳定后,从-0.2Vocp以0.5 mV/s的速率向阳极方向扫描至10-2 A/cm2时停止。电化学阻抗测试在恒定开路电位下,使用幅值为10 mV的正弦波为扰动信号,频率扫描范围为105~10-2 Hz,得到的实验数据使用Zsimpwin软件进行等效电路拟合。在进行电化学实验之前,所有样品进行机械抛光,并用无水乙醇清洗保证样品表面无杂质。

2 结果与讨论

2.1 显微组织分析

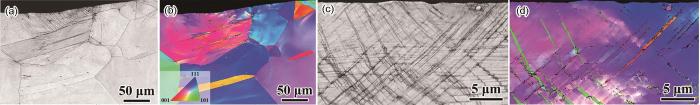

图1

图1

CG样品和GS样品横截面的微结构

Fig.1

Microstructures of CG and GS samples in cross section: (a) BC map of CG; (b) IPF map of CG; (c) BC map of GS; (d) IPF map of GS

图2为GS样品横截面的梯度层孪晶结构,从图2a和b中可以清晰地看到由塑性变形产生的变形孪晶,随深度增加,变形量逐渐较小,孪晶数量和密度随之减小,梯度层厚度约为300 μm,在距表层300 μm处仍存在少量变形。图2c和d为距表层约10 μm处的BC图和IPF图,使用40 nm扫描步长进行表征。IPF图可以反映晶体中不同晶粒的取向特征,S31254不锈钢具有单相的FCC结构,在FCC结构中,基体与孪晶之间存在着60°<111>的转轴关系,从图中可以更清晰地看到与基体取向明显不同的条带状组织,即为不同取向的变形孪晶,如图2d所示,孪晶之间彼此交错,相互作用,对梯度层组织起到了结构细化的作用,进而造成强化。除此之外,还存在大量的变形带和滑移带,其与孪晶也会产生相互作用。

图2

图2

GS样品横截面的微结构

Fig.2

Microstructures of GS samples in cross section: (a) BC map of GS in 300 μm deep; (b) IPF map of GS in 300 μm deep; (c) BC map of GS in 10 μm deep; (d) IPF map of GS in 10 μm deep

为了对孪晶组织进行更小尺度的观察,进行了TEM表征。图3a和b分别为最表层和距表层40 μm处的TEM明场像。由于晶粒尺寸较大,并未观察到晶界,而孪晶清晰可见,选区电子衍射斑点证明了孪晶的存在。最表层纳米尺度变形孪晶数量多、密度大,约为4.22 μm-2,不仅存在一次孪晶,还存在二次孪晶,充分细化了该位置处的FCC基体,同时位错密度也较高,与孪晶相互作用。在距表层40 μm处,纳米尺度变形孪晶的数量明显减少,密度约为1.50 μm-2,而位错密度依然较高,同时大量的变形带与孪晶相互交割,同样细化了基体。这些观察均与EBSD观察到的结果相对应,因此,通过SMAT大塑性变形后,在样品中形成了显著的纳米尺度变形孪晶密度梯度结构。

图3

图3

GS样品的TEM图像

Fig.3

Bright field image at surface (a) and bright field image at depth of 40 μm (b). Inset in each map: the corresponding selected area electron diffraction (SAED) pattern of twin, all with the [011] zone axis

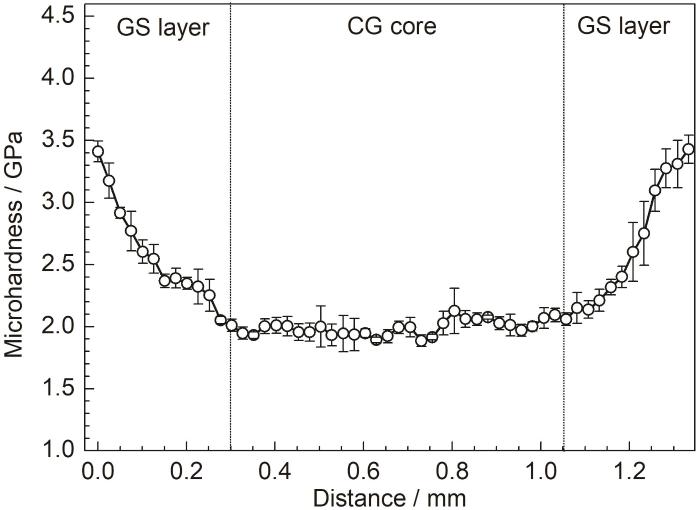

为进一步对梯度结构进行表征并确认梯度层厚度,对GS样品的横截面进行显微维氏硬度测试,其沿深度方向的分布规律如图4所示。GS样品总厚度约为1.3 mm,样品两侧最表层处硬度最大,约为3.4 GPa,相比之下,芯部粗晶层硬度最小,约为2.0 GPa。在两者之间,随着与表层距离的增加,硬度逐渐减小,直到约300 μm处达到稳定,也就是说,梯度层厚度约为300 μm,约占样品总厚度的45%。最表层硬度如此之高的原因在于,该层经历了最大程度的塑性变形,因此产生了最高密度的纳米孪晶和位错,孪晶界与晶界相同,同样具有细化组织的作用,产生类似细晶强化的效果,所以,表层强度和硬度非常之高。随着深度增加,孪晶密度减少,细化作用减弱,硬度自然降低。显微硬度的观察也与微结构观察结果一致,通过SMAT技术成功制备出纳米孪晶密度梯度结构。

图4

图4

GS样品横截面的显微维氏硬度分布

Fig.4

Distribution of HV values in cross section of GS specimen

2.2 电化学结果分析

梯度结构具有非常优异的耐蚀性能,为了表征制备的纳米孪晶密度梯度结构的耐蚀性,分别对GS样品的不同层进行了电化学测试,得到的动电位极化曲线如图5所示。由图可见,所有曲线的大致走势均相同,说明腐蚀机理相似,主要分为4个阶段。首先,随着电位逐渐正移,电流密度逐渐下降;其次,电流密度降到最低点即自腐蚀电位 (Ecorr) 后开始进入溶解区;随着电位继续正移进入钝化区,不同层深处的钝化区都很明显,且覆盖的电位范围都比较大,说明梯度结构的耐蚀性较好。自腐蚀电位和点蚀电位都是评价耐蚀性的重要指标,其值越大,说明金属的耐蚀性越强。图5c总结了梯度结构不同层深处的自腐蚀电位和点蚀电位随层深的变化趋势,从图中可以看出,从40 μm开始,随着层深的增加,自腐蚀电位逐渐增大,在80 μm处达到最大,之后随着层深的继续增加,自腐蚀电位逐渐减小,并且各层点蚀电位差异很小,说明梯度结构中,随层深的增加耐蚀性先增加后减小,在80 μm处耐蚀性最好。

图5

图5

GS样品的不同层在10%NaCl溶液中的动电位极化曲线

Fig.5

Potentiodynamic polarization curves from 40 μm to 80 μm layer (a), from 80 μm to 230 μm (b) in 10%NaCl solution of GS specimenand Ecorr and Epit distance curves (c)

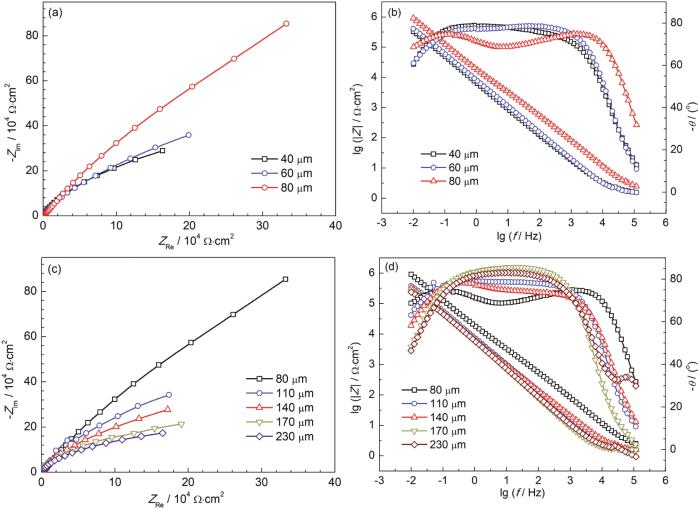

图6

图6

GS样品的不同层在10%NaCl溶液中的电化学阻抗谱

Fig.6

Nyquist (a, c) and Bode (b, d) diagrams of impedance spectra from the 40 μm layer to the 80 μm layer (a, b) and from the 80 μm layer to the 230 μm layer (c, d) in 10%NaCl solution of GS specimen

梯度结构的耐蚀性可能与两个因素有关,一是孪晶密度,二是表面粗糙度。已有研究[23]表明,两者对于耐蚀性的影响均较大。在梯度结构中,孪晶可以降低钝化膜的成核能因而具有更好的耐蚀性[24],但是靠近表层处表面粗糙度和位错密度过高,凹坑内部形成的钝化膜基可能厚度比光滑表面更薄[25],甚至会破坏钝化膜的完整性,因此当深度小于80 μm时,孪晶虽多,表面却更粗糙,导致钝化膜不易形成或者稳定性较差,进而导致耐蚀性下降;而在80 μm处其孪晶密度仍然较高,但粗糙度和位错密度并不像表层那样高,因此其钝化膜较易形成且稳定性较好,耐蚀性能最好;当深度大于80 μm时,虽然粗糙度下降,光滑表面增加,但孪晶密度也下降,因此钝化膜不易形成。这也正是梯度结构耐蚀性随深度增加先增加后降低的重要原因。

3 结论

(1) 经过SMAT处理后在S31254超级奥氏体不锈钢中制备得到了梯度结构,表层为高密度纳米尺度变形孪晶,随着距表层深度的增加,孪晶密度逐渐降低,芯部仍为粗晶组织。

(2) 梯度层中高密度纳米孪晶细化组织,显著提高了硬度。

(3) 梯度结构中,不同层的耐蚀性由孪晶密度和表面粗糙度共同决定,距表层80 μm处耐蚀性最好。

参考文献

Inverse effect of strain rate on mechanical behavior and phase transformation of superaustenitic stainless steel

[J].

Critical pitting temperature for type 254 SMO stainless steel in chloride solutions

[J].

Research on the welding technique of 254SMo super austeitic stainless steel

[J].

超级奥氏体不锈钢254SMo焊接工艺

[J].

Corrosion resistant properties & welding of 6%Mo super austenitic stainless steel

[J].

6%Mo超级奥氏体不锈钢耐蚀特性及其焊接

[J].

Corrosion resistance of super austenitic stainless steel 254SMo welded joint

[J].

超级奥氏体不锈钢254Smo焊接接头耐蚀性能

[J].

Crevice corrosion behavior of several super stainless steels in a simulated corrosive environment of flue gas desulfurization process

[J].

几种超级不锈钢在模拟烟气脱硫环境中的缝隙腐蚀行为研究

[J].

Development, application and characteristic of super austenitic stainless steel

[J].

超级奥氏体不锈钢的发展, 性能与应用 (上)

[J].

Corrosion behavior of four corrosion-resistant alloys in ultra-supercritical boiler flue gas condensate

[J].

4种耐蚀合金在超超临界锅炉烟气冷凝液中的腐蚀行为研究

[J].

NaCl induced corrosion of three austenitic stainless steels at high temperature

[J].

新型奥氏体不锈钢高温NaCl腐蚀行为研究

[J].

Gradient nanostructured materials

[J].

梯度纳米结构材料

[J].本文简要综述了近年来国内外关于梯度纳米结构材料的研究进展, 包括梯度纳米结构的分类, 梯度纳米结构材料的主要性能特点及制备加工技术. 对梯度纳米结构材料面临的一些基础科学问题和工业应用探索进行了讨论和展望.

Effect of surface mechanical attrition treatment on corrosion behavior of 316 stainless steel

[J].

Effect of surface nanocrystallization on the corrosion behaviour of AISI 409 stainless steel

[J].

Nanostructure formation mechanism of α-titanium using SMAT

[J].

Microstructures and mechanical properties of a gradient nanostructured 316L stainless steel processed by rotationally accelerated shot peening

[J].

Architectured surface layer with a gradient nanotwinned structure in a Fe-Mn austenitic steel

[J].

Revealing the deformation mechanisms of nanograins in gradient nanostructured Cu and CuAl alloys under tension

[J].A gradient nanostructured (GNS) surface layer was induced on coarse-grained (CG) Cu and CuAl alloys by means of surface mechanical grinding treatment. The GNS/CG Cu-4.5Al sample subjected to tensile tests yields at a higher strength and fails at a higher uniform elongation (similar to 42%) in comparison with the GNS/CG Cu and Cu-2.2Al samples. The microstructures of the GNS/CG samples before and after tension at different strains were systematically investigated by transmission electron microscope. It is revealed that grain coarsening dominates the plastic deformation of nanograins in the GNS/CG Cu sample while the propensity of deformation twinning in nanograins increases in the GNS/CG CuAl samples. The experimental results suggested a transition of deformation mechanism of nanograins from grain coarsening to the partial dislocation associated deformation twinning in the GNS/CG Cu and CuAl alloys with increasing Al solute concentration. The obvious activation of deformation twinning accommodates the large tensile plasticity of the surface nanograins in the GNS/CG Cu-4.5Al sample. This work demonstrated that the partial dislocation associated deformation twinning is an effective deformation mechanism to retard the strain localization and to improve the tensile ductility of nanograins. (C) 2019 Acta Materialia Inc. Published by Elsevier Ltd.

Nanostructured surface layer on metallic materials induced by surface mechanical attrition treatment

[J].

Strain-induced ultrahard and ultrastable nanolaminated structure in nickel

[J].Heavy plastic deformation may refine grains of metals and make them very strong. But the strain-induced refinement saturates at large strains, forming three-dimensional ultrafine-grained (3D UFG) structures with random orientations. Further refinement of this microstructure is limited because of the enhanced mobility of grain boundaries. Very-high-rate shear deformation with high strain gradients was applied in the top surface layer of bulk nickel, where a 2D nanometer-scale laminated structure was induced. The strongly textured nanolaminated structure (average lamellar thickness of 20 nanometers) with low-angle boundaries among the lamellae is ultrahard and ultrastable: It exhibits a hardness of 6.4 gigapascal--which is higher than any reported hardness of the UFG nickel--and a coarsening temperature of 40 kelvin above that in UFG nickel.

Graded nanostructures produced by sliding and exhibiting universal behavior

[J].

Gradient structured copper by rotationally accelerated shot peening

[J].A new technology—rotationally accelerated shot peening (RASP), was developed to prepare gradient structured materials. By using centrifugal acceleration principle and large steel balls, the RASP technology can produce much higher impact energy compared to conventional shot peening. As a proof-of-concept demonstration, the RASP was utilized to refine the surface layer in pure copper (Cu) with an average grain size of ~85 nm. The grain size increases largely from surface downwards the bulk, forming an 800 μm thick gradient-structured surface layer and consequently a micro-hardness gradient. The difference between the RASP technology and other established techniques in preparing gradient structured materials is discussed. The RASP technology exhibits a promoting future for large-scale manufacturing of gradient materials.

Electrochemical corrosion behavior of nickel coating with high density of nano-scale twins

[J].

高密度纳米孪晶镍镀层的电化学腐蚀行为

[J].

Extra strengthening and work hardening in gradient nanotwinned metals

[J].

Layer-by-layer corrosion behavior of 316LN stainless steel with a gradient-nanostructured surface

[J].

The nucleation and growth of two-dimensional anodic films under galvanostatic conditions

[J].