合金焊接接头的SCC行为受到了学者们的广泛关注。Chung等[9]研究了焊缝热输入对A508钢焊接接头SCC敏感性的影响,随焊接输入热量上升,焊缝附近热影响区的晶粒粗化,SCC敏感性上升。Hou等[10]研究了A182-A533B焊接接头在高温水蒸气中的SCC裂纹扩展行为,裂纹倾向于在A182的Ⅰ型、Ⅱ型边界中延伸,并在焊缝处发生钝化。而Peng等[11]研究表明焊缝处的钝化裂纹可以被选择性晶界氧化重新激活,从而继续扩展。溶氧量和硫酸盐浓度增加均会加快裂纹扩展速率 (CGR)。焊缝区域的微观结构具有特殊性,会对金属焊接接头的SCC性能产生影响。焊缝附近富Cr的δ铁素体相可以降低材料在高温水蒸气中的氧化速率,焊缝附近析出的碳化物可以阻碍晶界滑移,抑制晶界氧化,从而降低SCC敏感度[12]。而Dong等[13]研究表明SA508-A52M异种金属焊接接头具有SCC敏感性,焊缝两侧强度不匹配和晶界铬贫化会导致裂纹在焊缝处萌生,并沿贫铬晶界发展。同时,焊缝处金属收缩引起残余应变,也会导致合金热影响区的SCC敏感性上升[14]。目前的研究主要关注焊接试样的晶界角度、微观硬度和残余应变[15],并以延展率[15]、截面裂纹深度[16]和开裂形貌[17]等评价试样的SCC敏感度。然而,对焊缝附近氧化层形貌和元素分布变化的分析较少,氧化层可能会随焊接区微观结构而变化,并对SCC行为造成影响。

2.25Cr1Mo钢作为蒸汽发生器的主要材料,对母材及其焊接接头在实际工况环境中的SCC行为研究仍不充分。为考察焊接对试样SCC性能的影响,并探究焊接接头的SCC方式,本文在500 ℃/0.1 MPa高温空气和水蒸气环境中对新型2.25Cr1Mo钢及其焊接接头试样开展SSRT实验,比较不同试样的应力-应变行为、力学性能和断口形貌,讨论了试样的SCC敏感度,并对焊接试样经SSRT后不同位置的氧化层开裂形貌进行分析。

1 实验方法

表1 实验钢和焊接金属的化学成分

Table 1

| Material | Cr | C | Si | Mn | P | S | Ni | V | Nb | Mo | Fe |

|---|---|---|---|---|---|---|---|---|---|---|---|

| Test steel | 2.37 | 0.13 | 0.077 | 0.47 | 0.002 | 0.0004 | 0.030 | 0.009 | <0.01 | 1.00 | Bal. |

| Weld metal | 2.20~2.50 | 0.07~0.12 | 0.15~0.50 | ≤0.90 | ≤0.01 | ≤0.005 | --- | ≤0.04 | ≤0.03 | 0.90~1.20 | Bal. |

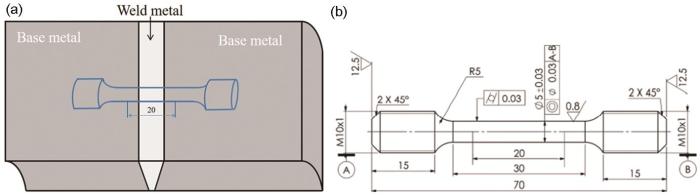

图1

图1

焊接接头及试样的示意图

Fig.1

Schematic drawings of sampling location (a) and the geometry and dimensions (mm) of the specimen (b)

SCC测试系统见参考文献[18]。本实验环境为500 ℃/0.1 MPa的水蒸气,应变速率为1×10-6/s,并在空气环境下对试样进行SSRT对照实验。所有试样在指定环境下经恒应变拉伸至断裂后,快速将反应釜冷却至室温,避免高温环境对断口形貌造成破坏。对清洗后的断口及标距表面进行微观分析。将试样沿轴线方向截开,对截面进行打磨和抛光后,置于硝酸酒精腐蚀液中,以暴露焊缝。采用ZEISS Gemini300扫描电镜 (SEM) 和Oxford MAX-50能谱分析仪 (EDS) 对截面氧化层进行、分析,以观察断口附近和焊缝两侧的开裂情况、氧化层形貌和元素分布。

2 实验结果

2.1 应力-应变行为

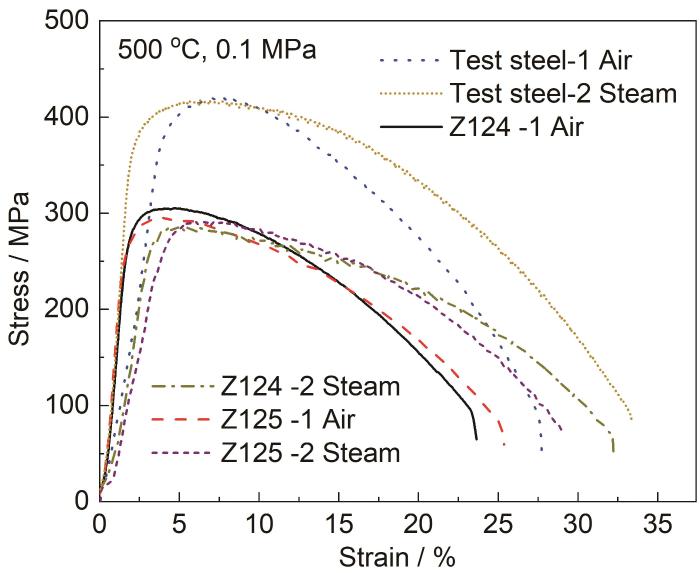

实验钢及Z124、Z125钢在500 ℃/0.1 MPa空气和水蒸气中的应力-应变曲线如图2所示。所有试样均未表现出加工硬化和明显的动态应变时效现象。

图2

图2

实验钢及其焊接接头的应力-应变曲线

Fig.2

Stress-strain curves of the test steel and its weld joints

表2为试样经SSRT后的抗拉强度、延展率、断裂时间和颈缩率。与实验钢相比,空气中焊接试样Z124、Z125钢的抗拉强度分别下降了27.54%和29.96%,高温水蒸气中Z124、Z125钢的抗拉强度分别下降了31.32%和30.16%。延展率主要受环境因素控制,当实验介质从空气转变为水蒸气时,试样的延展率和断裂时间上升,而颈缩率略微下降。焊接试样的颈缩率略低于母材。

表2 SSRT实验参数及力学性能

Table 2

| Specimen | Environment | Tensile strength / MPa | Elonga-tion / % | Fracture time / h | Reduction in area / % |

|---|---|---|---|---|---|

| Test steel-1 | Air | 421.20 | 27.74 | 77.19 | 93.41 |

| Test steel-2 | Steam | 417.40 | 33.41 | 95.65 | 92.16 |

| Z124-1 | Air | 305.19 | 23.64 | 68.09 | 91.49 |

| Z124-2 | Steam | 286.66 | 32.24 | 89.56 | 91.15 |

| Z125-1 | Air | 295.01 | 25.36 | 72.92 | 90.19 |

| Z125-2 | Steam | 291.52 | 29.01 | 80.69 | 88.95 |

2.2 断裂行为

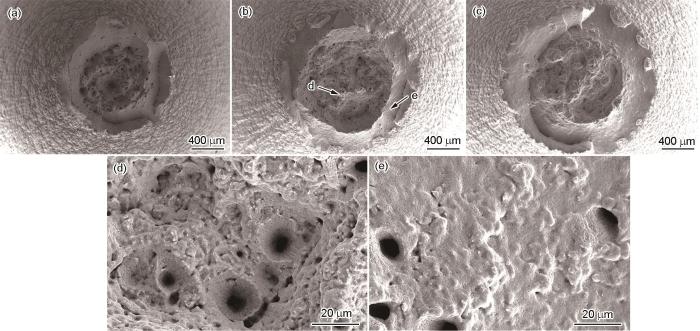

2.2.1 断口形貌

图3为试样在水蒸气环境中的断口形貌。实验钢-2与Z124-2、Z125-2钢的断口形貌近似,均为单纯韧窝形貌,并伴有氧化层覆盖。断口中心韧窝深、数量多,断口边缘韧窝数量下降,尺寸变小。未观测到冰糖状开裂形貌和沿晶裂纹,试样的断裂方式均为韧性断裂。

图3

图3

水蒸气中的断口形貌SEM图

Fig.3

SEM images of the fracture surfaces of the test steel and its weld joints in steam environment: (a) test steel-2, (b) Z124-2, (c) Z125-2, (d) center and (e) edge regions for Z124-2

2.2.2 标距表面形貌

图4

图4

SSRT试验用焊接接头试样Z124-2的照片

Fig.4

Photograph of the weld joint specimen Z124-2 before and after SSRT test (a) and high magnifi-cation view of the cracked region (b)

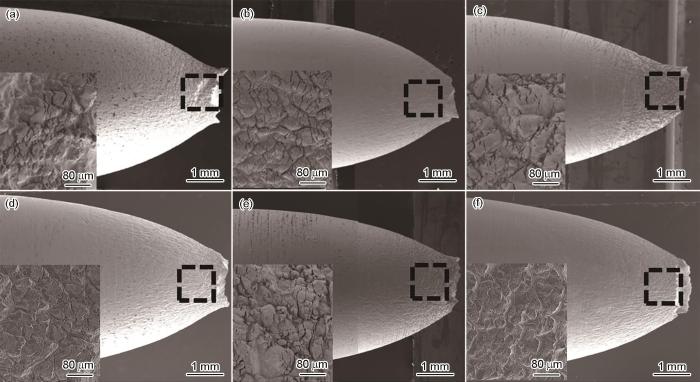

图5

图5

试样标距表面SEM形貌

Fig.5

SEM surface images of various samples in the gage sections: (a) test steel-1, (b) test steel-2, (c) Z124-1, (d) Z124-2, (e) Z125-1, (f) Z125-2

2.2.3 截面形貌和元素分布

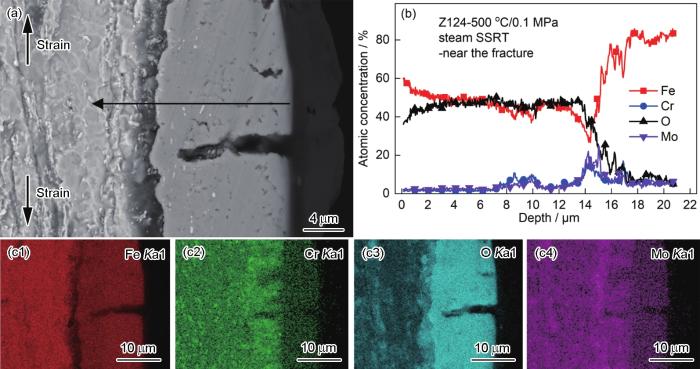

对Z124-2钢横截面靠近断口处进行SEM、EDS分析如图6所示。氧化层为双侧膜结构,总厚度约为16 μm,外层与内层的厚度相近。0~8 μm处为氧化外层,层内Fe、O富集但Cr、Mo贫化。8~16 μm处为氧化内层,富Fe、O、Cr、Mo。在11~13 μm处,层内Cr、Mo占比下降,而13~16 μm内Cr、Mo含量突增,Fe、O含量相应下降。结合面扫描结果,内氧化层中Cr、Mo存在间断分布现象,这可能与应变作用有关。氧化层内裂纹沿垂直载荷方向发展,裂纹穿过外氧化层,并在内氧化层中钝化,并未向基体内部延伸。微裂纹和孔洞大多存在于外氧化层,内氧化层的缺陷较少。

图6

图6

Z124-2经SSRT后的横截面形貌及EDS结果 (靠近断口)

Fig.6

Cross-sectional morphology of Z124-2 after SSRT (near the fracture) (a), EDS line scannings along marked black line (b) and elemental mappings of Fe (c1), Cr (c2), O (c3), Mo (c4)

对Z124钢横截面靠近焊缝处进行观察如图7所示。焊缝两侧氧化层的形貌近似,外层存在微裂纹,但未观察到垂直载荷方向的长裂纹。焊缝两侧氧化层的厚度存在差异,焊接金属侧氧化层总厚度为10 μm左右,比基体侧氧化层薄。焊接金属侧b区域EDS线扫结果显示,双层氧化膜结构仍存在。富Cr、Mo的氧化内层厚度小于外层,约为3 μm。与断口相比,焊缝附近氧化内层Cr、Mo未出现突降现象,内层仍保持致密结构。

图7

图7

Z124-2经SSRT后的横截面形貌及EDS结果 (靠近焊缝)

Fig.7

Cross-sectional morphology of Z124-2 after SSRT (near the fusion boundary) (a) and EDS elemental line scannings along marked black line (b, c)

3 分析与讨论

3.1 新型2.25Cr1Mo钢及其焊接接头的力学性能

高温水蒸气环境中试样的延展率比空气环境大。Akbari等[21]指出,合金表面钝化膜的结构会对试样的力学性能产生影响。在水蒸气中试样的氧化速率加快,裂纹愈合速率加快,裂纹扩展速度受到抑制,开裂程度有所缓解,因此延展率增大。

3.2 新型2.25Cr1Mo钢及其焊接接头的SCC敏感性

开裂模式可以评价SCC敏感度[22],当开裂由穿晶韧性断裂向沿晶脆性断裂过渡时,SCC敏感性随之增大。3种试样在水蒸气中,开裂模式均未发生由韧向脆的转变,这说明其晶界仍保持较高强度,材料抵抗沿晶应力腐蚀开裂 (IGSCC) 的性能较好。Sun等[23]认为试样断口呈现外脆内韧特征,并以断口IGSCC区域占比评价SCC敏感度。实验钢、Z124、Z125钢的中心和边缘区域均为韧性断裂,当实验环境从空气向水蒸气转变时,开裂形貌未发生明显变化。Yukio等[24]在高温水蒸气中对铁马氏体钢F82H进行SSRT实验,断口为单纯韧窝形貌,未观测到IGSCC发生。基于断口形貌可以认为,新型2.25Cr1Mo钢及焊接接头的SCC敏感性较低。

其中,

图8

图8

实验钢及其焊接接头的抗拉强度、SCC敏感度和颈缩率

Fig.8

Tensile strength,SCC susceptibility (a) and reduction (b) of test steel and its weld joints

有研究以标距表面裂纹密度评价SCC敏感性[18]。棒状试样经受拉伸应变后产生塑性变形,变形会导致微裂纹在晶粒内部及晶界处萌生,并作为水蒸气向内扩散和氧化的通道[31]。Kuang等[32]研究表明试样发生了明显的IGSCC,断裂形貌表明基体晶界被侵蚀,沿晶微裂纹在应力作用下扩展,彼此相连形成长裂纹。因此可以通过统计标距表面裂纹密度来反映试样的SCC敏感性。然而在本实验中,经SSRT后裂纹全部集中在氧化层内,未扩展至基体内部,此时晶界受富铬的内氧化层保护,未受到严重侵蚀,如图6所示。晶界仍保持良好强度,断口得以呈现完全韧性断裂形貌。对于以韧性断裂为主的试样,统计标距表面裂纹密度难以反映试样的SCC敏感性。同时,Z124、Z125钢的氧化现象严重,裂纹容易变浅或被氧化层覆盖,误差较大。

基于开裂模式、强度和塑性的分析,新型2.25Cr1Mo钢及其焊接接头在高温水蒸气中的SCC敏感性较低。

3.3 新型2.25Cr1Mo钢焊接接头在高温水蒸气中的开裂方式

Ullrich等[33]认为2.25Cr1Mo钢在120~215 ℃水蒸气中发生晶界氧化,断口呈现IGSCC形貌,SCC敏感度较高。而本试验中,高温加速合金氧化,导致裂尖前方形成致密的富铬钝化膜,能够抑制晶界氧化,降低SCC敏感性。在恒应变下,裂纹在外氧化层中萌生并向内氧化层扩展,由于高温水蒸气的氧化性,“裂纹发展-新氧化层形成”这一过程循环进行。如图6a所示,裂纹并未穿透内氧化层,这是因为一方面富铬内层的强度较高,裂纹发展速度下降;另一方面,随裂纹靠近基体,裂尖处Cr离子的扩散速度加快,新氧化层形成速度加快,表现为裂纹总体发展速率降低。在SSRT过程中,基体受富铬内层的保护,受腐蚀的影响较小 (图6b),基体外存在2 mm左右的Cr突增层,在这一层内,没有观测到裂纹,因此试样的SCC敏感性较低。

4 结论

(1) 采用1×10-6/s的应变速率进行SSRT,高温水蒸气环境中试样的抗拉强度略微下降,延展率明显上升。新型2.25Cr1Mo钢的强度和塑性优于其焊接接头。焊接线能量对材料抗拉强度和延展率的影响不明显。

(2) 新型2.25Cr1Mo钢及焊接试样在高温水蒸气中均发生单纯韧性断裂,基于断口形貌、强度和塑性的分析,3种试样在水蒸气环境中的SCC敏感性均较低。

(3) 新型2.25Cr1Mo钢焊接试样的焊接区耐腐蚀性较差,但氧化层内没有发生开裂,对SCC敏感性的影响不大。

参考文献

Development of steam generator main materials for fast reactor

[J].

钠冷快堆蒸汽发生器主材研究进展

[J].

Effect of temperature and dissolved oxygen on stress corrosion cracking behavior of P92 ferritic-martensitic steel in supercritical water environment

[J].

Intergranular stress corrosion cracking in simulated BWR water of 316L stainless steels manufactured with different procedures

[J].

Research progress on stress corrosion cracking of stainless steel for nuclear power plant in high-temperature and high-pressure water

[J]. J.

核电站用不锈钢在高温高压水中应力腐蚀开裂行为的研究进展

[J].

Creep behaviour of post-weld heat-treated 2.25Cr-1Mo ferritic steel base, weld metal and weldments

[J].

The oxidation behaviour of the weld metal, heat affected zone and base metal in the weldments of 2.25Cr-1Mo steel

[J].

Effect of environmental variables on galvanic corrosion performance of welded joint of nuclear steam turbine rotor

[J]. J.

环境变量对核电汽轮机转子钢焊接接头电偶腐蚀性能的影响

[J].

Review of stress corrosion cracking of structural materials in nuclear power plants

[J]. J.

核电结构材料应力腐蚀开裂的研究现状与进展

[J].

Stress corrosion cracking in the heat-affected zone of A508 steel welds under high-temperature water

[J].

Microstructure and stress corrosion cracking of the fusion boundary region in an alloy 182-A533B low alloy steel dissimilar weld joint

[J].

Role of water chemistry and microstructure in stress corrosion cracking in the fusion boundary region of an Alloy 182-A533B low alloy steel dissimilar weld joint in high temperature water

[J].

Microstructure and stress corrosion cracking of a SA508-309L/308L-316L dissimilar metal weld joint in primary pressurized water reactor environment

[J].

Correlation of microstructure and stress corrosion cracking initiation behaviour of the fusion boundary region in a SA508 Cl. 3-Alloy 52M dissimilar weld joint in primary pressurized water reactor environment

[J].

Stress corrosion cracking of fusion boundary for 316L/52M dissimilar metal weld joints in borated and lithiated high temperature water

[J].

Microstructure, local mechanical properties and stress corrosion cracking susceptibility of an SA508-52M-316LN safe-end dissimilar metal weld joint by GTAW

[J].

Effect of surface treatments on microstructure and stress corrosion cracking behavior of 308L weld metal in a primary pressurized water reactor environment

[J].

Microstructure and intergranular stress corrosion cracking susceptibility of a SA508-52M-316L dissimilar metal weld joint in primary water

[J].

Behavior and susceptibility to stress corrosion cracking of a nickel-based alloy in superheated steam and supercritical water

[J].

Influence of welding line energy on mechanical performance of WEL-TEN80A steel's welding joint

[J].

焊接线能量对WEL-TEN80A钢焊接接头力学性能的影响

[J].

Effect of SMAW heat input on properties of Q345R steel welded joint

[J].

手工电弧焊线能量对Q345R焊接接头性能的影响

[J].

Effect of long-term service exposure on microstructure and mechanical properties of Alloy 617

[J].

Tensile and stress corrosion cracking behavior of ferritic-martensitic steels in supercritical water

[J].

The corrosion and stress corrosion cracking behavior of a novel alumina-forming austenitic stainless steel in supercritical water

[J].

Stress corrosion cracking susceptibility of a reduced-activation martensitic steel F82H

[J]. J.

Environmental effects on the stress corrosion cracking susceptibility of 3.5NiCrMoV steels in high temperature water

[J].

Effects of corrosion potential, dissolved oxygen, and chloride on the stress corrosion cracking susceptibility of a 316NG stainless steel weld joint

[J].

Comparative study on the stress corrosion cracking susceptibility of AZ80 and AZ31 magnesium alloys

[J].

Stress corrosion cracking behavior of interstitial free steel via slow strain rate technique

[J].

Stress corrosion cracking of a recent rare-earth containing magnesium alloy, EV31A, and a common Al-containing alloy, AZ91E

[J].

A Critical review of the stress corrosion cracking (SCC) of magnesium alloys

[J].

A research on the corrosion and stress corrosion cracking susceptibility of 316L stainless steel exposed to supercritical water

[J].

The effect of cold rolling on grain boundary structure and stress corrosion cracking susceptibility of twins in alloy 690 in simulated PWR primary water environment

[J].

Investigation of the stress corrosion cracking behavior on T24 material under the operational conditions in the water wall

[J].

High temperature oxidation behavior of ferritic steel in supercritical water at 550-700°C

[J].

High temperature oxidation in the context of life assessment and microstructural degradation of weldments of 2.25Cr-1Mo steel

[J].