事实上,采用LPBF技术制备铝合金存在诸多挑战:铝合金对激光由较高的反射率且粉末易氧化,多数铝合金凝固温度范围大,裂纹敏感性高,在激光加工过程中容易形成柱状晶粒和热撕裂裂纹等[8,9]。近年来,晶粒细化已被证实对于克服LPBF铝合金固有的热撕裂瓶颈至关重要[10,11]。采用Sc/Zr改性的方法制备铝合金粉末已经是目前广泛使用的方法,已经被成功运用到Al-Mg、Al-Zn-Mg-Cu等系列合金中[12~14]。微量Sc/Zr改性可使铝合金在LPBF过程中形成与基体高度相干的纳米Al3(Sc,Zr)析出相,在促进形成大面积细晶区保障铝合金成形性的同时进一步提高合金力学性能[15,16]。此外,通过孕育处理向铝合金基体中引入TiB2、TiC、TiN等增强相颗粒诱导晶粒细化也是制备LPBF铝合金的有效方法[17]。Al-Mg-Sc-Zr合金作为较为成熟的LPBF铝合金成分体系展现出优异的可打印性及力学性能,是非常理想的颗粒增强型铝合金的候选基体[18]。然而有关纳米颗粒对LPBF Al-Mg-Sc-Zr合金中的影响机制似鲜见报道,相关微观结构演变及对性能的影响仍有待进一步探究。

在实际服役环境中,铝合金面临局部腐蚀(如点蚀、晶间腐蚀)和应力腐蚀开裂等问题,严重影响其服役寿命和可靠性,因此关注探究LPBF铝合金的腐蚀行为具有非常重要的现实意义[19,20]。考虑到LPBF工艺的快速加热及冷却、逐层加工的特性,LPBF铝合金的腐蚀行为通常不同于传统铸造或变形合金[21]。Gu等[22]报道了LPBF Al-Mg-Sc-Zr合金的腐蚀行为存在各向异性,熔池边界为腐蚀优先发生的区域。Zhang等[23]直接证实了Al3(Sc,Zr)析出相在LPBF Sc/Zr改性铝合金的微阴极作用。但有关纳米颗粒增强型铝合金腐蚀性能还尚不清晰,因此深入探究纳米颗粒的添加对LPBF铝合金腐蚀行为的影响能够对于新型LPBF高强铝合金的开发以及实际应用具有重要的意义。

本文基于LPBF工艺成功制备出致密性良好的TiC改性Al-Mg-Sc-Zr合金,深入探究了纳米TiC颗粒对LPBF Al-Mg-Sc-Zr合金微观结构及腐蚀行为的影响,揭示LPBF TiC改性Al-Mg-Sc-Zr合金的局部腐蚀及应力腐蚀机制,预期研究的成果不仅为LPBF制备的TiC改性Al-Mg-Sc-Zr合金的性能优化,也为其在复杂服役环境下的可靠性评估与工程应用提供有意义的参考。

1 实验方法

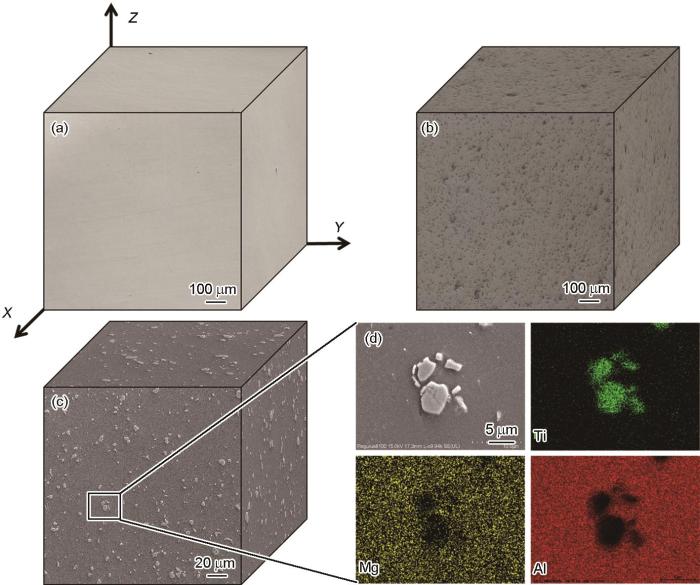

采用气体雾化法制备Al-Mg-Sc-Zr合金粉末,在雾化过程中使用高纯度氩气保护粉末免受氧化,选用粒径范围在15~53 μm的粉末进行后续实验。采用电感耦合等离子体原子发射光谱(ICP-AES)检测合金粉末成分(质量分数,%)为:Al 92.94、Mg 5.3、Sc 0.77、Zr 0.35、其它元素0.64。在上述基体合金粉末中添加质量分数为10%的纳米TiC颗粒,采用机械球磨混合的方法制得TiC改性的复合粉体。采用ZEISS Crossbeam 540型聚焦离子束扫描电镜(FIB-SEM)对大尺寸TiC颗粒的剖面进行能谱分析(EDS)并扫描元素,揭示大尺寸TiC颗粒的内部构造及其元素分布。

采用光纤激光EOS M400型功率1000 W的LPBF设备进行样品制备,为得到致密度高,成形性能良好的合金样品,对关键工艺参数进行了系统优化,确定采用的成形参数组合为:激光功率350 W,扫描速度1100 mm/s,扫描间距0.06 mm,粉末层厚0.03 mm,层间旋转角度为67°,打印前对基板进行预热,整个过程均在保护性氩气气氛下进行,以有效避免高温条件下的氧化反应。

用线切割方法将样品切成10 mm × 10 mm × 3 mm大小,将切好的样品的待观察平面进行打磨抛光后,进行酒精超声处理。取不同构建平面的样品各一块进行微观结构表征。采用Keller试剂(2.5 mL HNO3 + 1.5 mL HCl + 1.0 mL HF + 95 mL H2O)对样品的表面进行侵蚀,分别用酒精、去离子水冲洗吹干后放置待用。采用光学显微镜(OM)对LPBF铝合金的微观组织进行观察,采用Regulus 8100型场发射电子显微镜(SEM)对LPBF合金的微观组织及形貌进行分析,工作电压为20 kV,探头工作距离为15 mm。采用配备的Tescan mira 3 LMH型电子背散射衍射电镜(EBSD)对LPBF铝合金样品进行分析,工作电压20 kV,扫描步长0.1 μm。采用TECNAI F20型透射电子显微镜(TEM)对LPBF铝合金样品的微观结构进行观察,并获得合金样品的选区衍射(SAED)及高分辨透射电镜图(HRTEM)。

将表面抛光的样品浸泡于3.5% (质量分数) NaCl溶液中,并置于恒温水浴锅中控制温度,浸泡特定时间后将样品取出,采用纯硝酸对样品进行除锈处理,为保证试验的重复性,采取不同构建平面样品各3块进行浸泡实验。采用Leica DCM8型激光共聚焦显微镜(CLSM)及SEM对样品表面腐蚀形貌进行分析。使用Multimode 8型原子力显微镜对样品进行扫描Kelvin探针力(SKPFM)测试,直接表征样品表面形貌及电位。慢应变速率拉伸实验在WDML-30型材料试验机进行,试样采用狗骨头状拉伸试样,应变速率为1 × 10-6 s-1,实验环境包括干燥空气环境和3.5% (质量分数) NaCl溶液环境,为保证数据的准确性,每组样品设置3个平行样,样品断裂并采用SEM对试样断口进行分析。

2 结果与讨论

2.1 微观结构

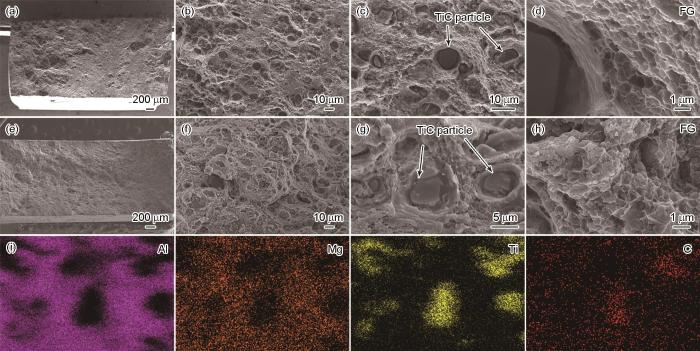

图1

图1

LPBF TiC改性Al-Mg-Sc-Zr合金的微观结构

Fig.1

OM images of LPBF Al-Mg-Sc-Zr alloy (a), OM images (b), SEM images (c) and corresponding the EDS results (d) of LPBF TiC-modified Al-Mg-Sc-Zr alloy

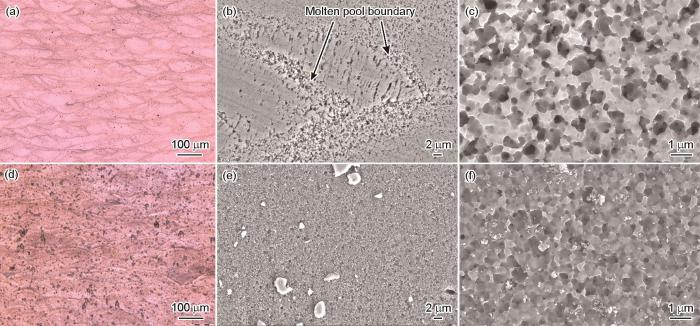

为进一步探究TiC颗粒添加对合金的影响,对两种合金进行了侵蚀以进一步探究其微观结构,结果如图2所示。可以看出,LPBF Al-Mg-Sc-Zr合金在XZ平面上呈现大量扇状熔池,这是激光加工制备合金的典型特征[16]。SEM形貌显示,合金由柱状等轴双峰晶粒结构组成,熔池内部为长柱状晶粒,而熔池边界为细小的等轴晶,这是由于纳米析出相Al3(Sc, Zr)颗粒分布在熔池边界引起了显著的晶粒细化。TiC改性的LPBF Al-Mg-Sc-Zr合金,在OM形貌中依旧可见扇状的熔池边界,但是SEM形貌显示,熔池内部已几乎没有长柱状晶粒,整个合金全部由细小的等轴晶组成。证实了TiC颗粒的添加对LPBF Al-Mg-Sc-Zr合金具有十分显著的晶粒细化作用。

图2

图2

TiC改性前后LPBF Al-Mg-Sc-Zr合金XZ平面侵蚀后的形貌

Fig.2

OM images (a, d) and SEM images (b, c, e, f) of XZ plane for LPBF Al-Mg-Sc-Zr alloy without TiC modification (a-c) and TiC modification (d-f)

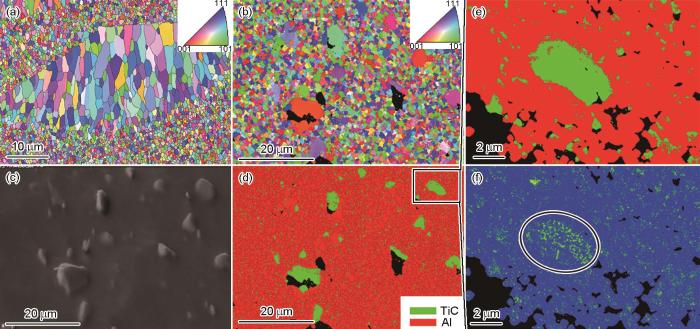

通过EBSD进一步对合金的晶粒组织进行进一步的分析。图3的反极图(IPF)更为直接地显示了LPBF Al-Mg-Sc-Zr合金的柱状等轴双峰晶粒结构,而图3b则表明了LPBF TiC改性Al-Mg-Sc-Zr合金的全等轴晶粒结构。图3c和d分别为对应图3b区域的形貌图以及相图,其中相图中绿色为TiC相,而红色为Al基体。结合对比分析可以得出:合金中等轴晶的尺寸十分细小,约为亚微米级,而形成的微米级的颗粒可以直接确定为TiC颗粒。IPF图中发黑的区域为未识别出的相,这是由于在抛光制备样品的过程中,TiC颗粒发生部分溶解脱落导致的。选取特定区域(图3e)采用核平均取向差(KAM)图(图3f)进一步分析微米级TiC颗粒周围5附近的微观应变的程度,蓝色为变形较小或者缺陷密度较低的区域,绿色和红色为变形较大或缺陷密度较高的区域[26,27],通过KAM图定性的分析可得:微米级TiC颗粒周围存在较高的局部晶格畸变和应变集中程度,这使得颗粒周围具有更高的化学活性,降低了表面保护膜的稳定性,微米级TiC颗粒和周围基体会形成局部微电偶电池,其周围较高的局部应变诱导加速了局部腐蚀的产生及发展,对LPBF铝合金的腐蚀行为产生重要的影响。

图3

图3

TiC改性前后LPBF Al-Mg-Sc-Zr合金XZ平面EBSD结果

Fig.3

IPF image (a) of LPBF Al-Mg-Sc-Zr alloy, IPF image (b), band contrast image (c), phase maps (d, e) and KAM image (f) of LPBF TiC-modified Al-Mg-Sc-Zr alloy

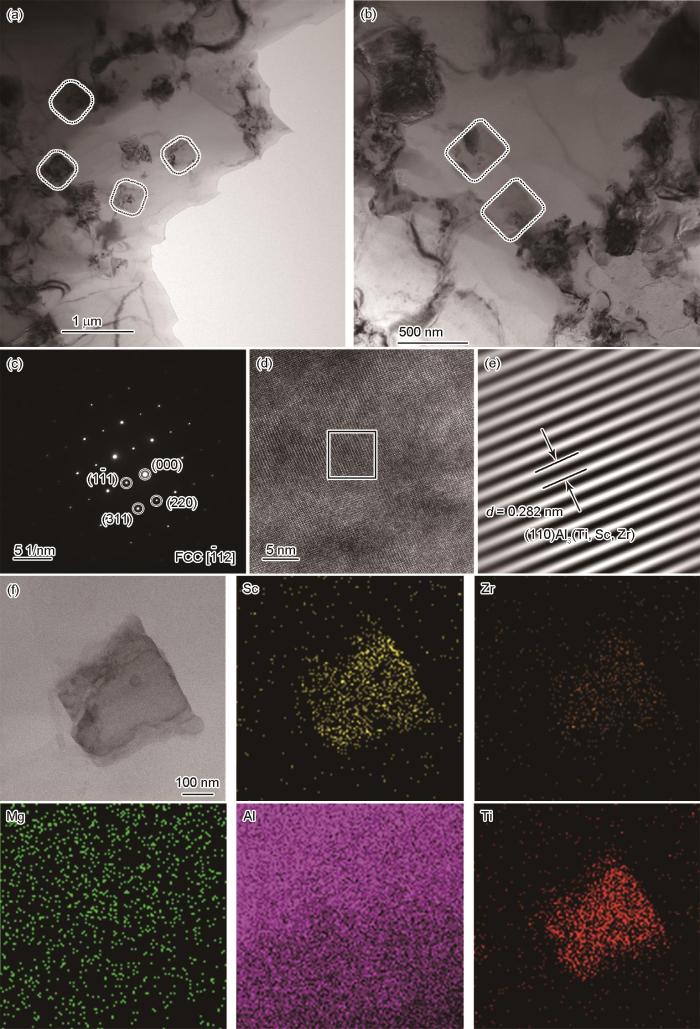

图4a和b为LPBF TiC改性Al-Mg-Sc-Zr合金XZ平面的TEM明场像,从图中能够清晰观察到大量近似立方体形貌的纳米析出相颗粒。通过图4f的EDS元素分布图可以得出,此种类型的纳米颗粒明显富集Ti、Sc、Zr和Al元素。图4c针对纳米颗粒的选区衍射结果证实了该颗粒具有面心立方L12型结构,在Sc/Zr改性的LPBF 铝合金中形成具有面心立方L12结构Al3(Sc, Zr)相已有大量报道[13,15]。图4d和e的HRTEM形貌同样佐证了这一结论,推断形成的纳米析出相为L12型Al3(Ti, Sc, Zr)相[18]。部分TiC纳米颗粒在熔池的高温作用下不稳定,分解的TiC将释放Ti原子,与基体Al反应生成初始Al3Ti相,同时诱导周围区域的Al、Sc、Zr元素使Sc与Zr固溶取代,演变形成具有L12结构的Al3(Ti, Sc, Zr)析出相[28]。

图4

图4

LPBF TiC改性Al-Mg-Sc-Zr合金的TEM结果

Fig.4

Bright images (a, b), SAED pattern (c), HRTEM images (d, e), STEM images and EDS mapping (f) of LPBF TiC-modified Al-Mg-Sc-Zr alloy

2.2 局部腐蚀行为

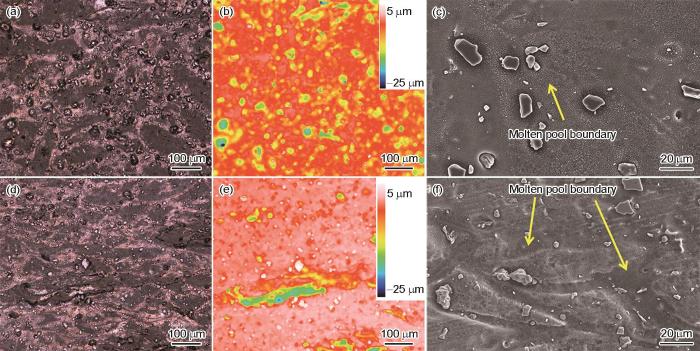

图5是LPBF TiC改性Al-Mg-Sc-Zr合金在3.5%NaCl溶液中浸泡5 d后的不同构建平面的腐蚀表面CLSM形貌及SEM形貌。图5b和e分别对应图5a和d的三维形貌图,其中颜色越深代表高度越低。可以明显看出合金的有两大明显的腐蚀特征:首先,XY平面上发现了大量沿激光扫描痕迹的长棒状的熔池,XZ平面上则显示出大量扇形熔池,这是由于两个平面上的熔池边界优先发生了腐蚀,使得熔池形貌得以显现出来。熔池边界的优先腐蚀行为与该区域密集分布的纳米析出相紧密相关,Al3(Ti, Sc, Zr)相作为微阴极相大量分布在熔池边界处引发了周围基体的溶解形成了腐蚀坑洞[22,29]。其次,在形成的具有微米尺寸的TiC颗粒周围发生了严重的局部腐蚀,由于颗粒分布较为均匀,导致引发的局部腐蚀在不同平面上都呈现随机分布的趋势。大尺寸颗粒与周围基体的电化学特性存在明显的差异,在腐蚀介质中会直接引发明显的电偶腐蚀[30]。SEM形貌也表明,大颗粒周围基体已经被腐蚀而形成了具有一定深度的凹坑,而且熔池边界(图5c和f中的箭头所示区域)由于优先发生腐蚀而显示出晶粒形貌或已经形成明显的腐蚀沟壑。

图5

图5

LPBF TiC改性Al-Mg-Sc-Zr合金浸泡实验后的腐蚀形貌

Fig.5

CLSM images (a, b, d, e) and SEM images (c, f) of XY plane (a-c) and XZ plane (d-f) for LPBF TiC-modified Al-Mg-Sc-Zr alloy after immersion

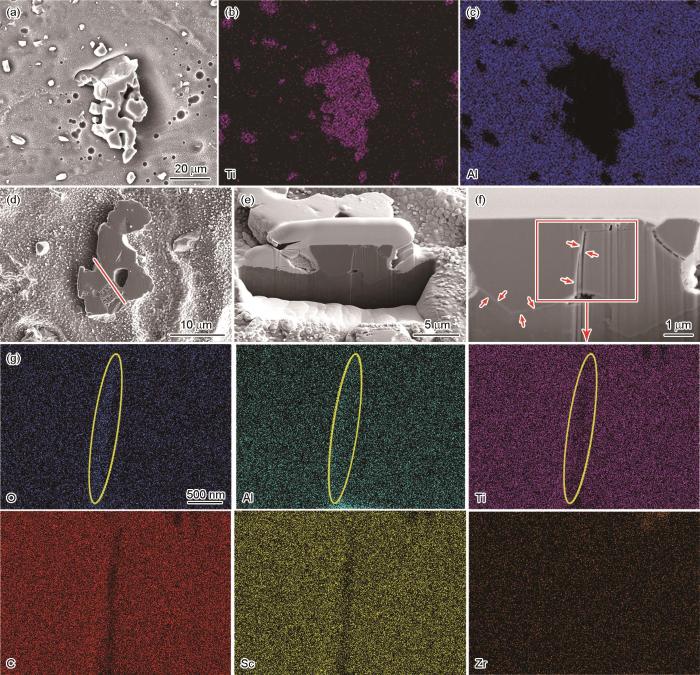

为进一步明确微米级TiC颗粒在合金中的腐蚀特征,针对浸泡5 d后合金表面的微米级颗粒的腐蚀形貌进行了详细探究。图6a~c直接证实了浸泡实验后合金表面的大尺寸颗粒为TiC颗粒,还可以发现部分TiC颗粒除了引发周围基体的腐蚀外,大尺寸颗粒自身还存在边缘溶解及内部腐蚀的迹象。随机选取某一位置的微米级TiC颗粒进行FIB-SEM测试以观察其截面形貌及元素分布。图6d红线位置的剖面如图6f所示,明显看出大尺寸颗粒内部存在众多边界,是由其它尺寸较小的颗粒“组装”而成,而这些边界区域(如图6f中的红色箭头所示)显示出明显的Al和O的富集。在LPBF加工过程中,纳米颗粒会不可避免地发生团聚,而在这些颗粒的接触边界会掺杂少量的Al。在腐蚀性环境中,微米尺寸TiC颗粒内部的Al也优先发生腐蚀,随着腐蚀的进一步加重,使得大尺寸颗粒无法保持其团聚结构,导致微米级TiC颗粒内部发生腐蚀或存在解体现象。

图6

图6

浸泡实验后微米级TiC颗粒的SEM形貌及FIB结果

Fig.6

SEM images (a), EDS results (b, c), FIB-SEM results (d-g) of micro-sized TiC particle in LPBF TiC-modified Al-Mg-Sc-Zr alloy

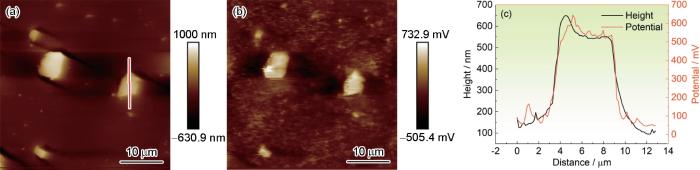

图7

图7

微米级TiC颗粒的SKPFM结果

Fig.7

Surface morphology map (a), surface potential diagram (b), and height and potential profiles of the line represented in the surface map (c) of micro-sized TiC particle in LPBF TiC-modified Al-Mg-Sc-Zr alloy

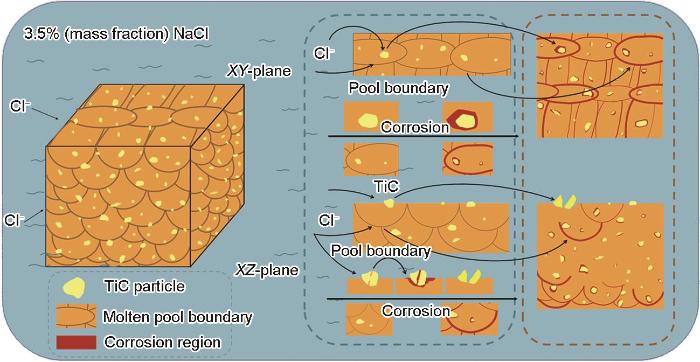

图8为TiC改性LPBF Al-Mg-Sc-Zr合金不同平面的腐蚀行为示意图。合金几乎由全等轴晶组成,其细小的晶粒和高密度晶界能够促进铝合金表面致密氧化膜的生成,阻止了合金与腐蚀性介质的直接接触,一定程度上提高了合金的耐腐蚀性[23]。在腐蚀性环境中,一旦表面氧化膜发生破裂,TiC颗粒和Al3(Ti, Sc, Zr)析出相就在合金腐蚀行为中起到了主导作用。在LPBF Sc/Zr改性的Al-Mg合金中,纳米级富含Sc/Zr元素的析出相优先在熔池边界处的细晶区形成且只存在于细晶区的现象是普遍存在的[31,32],而在LPBF TiC改性Al-Mg-Sc-Zr合金,纳米Al3(Ti, Sc, Zr)相同样优先在熔池边界处析出。因此,大量分布在熔池边界处的Al3(Ti, Sc, Zr)析出相作为阴极相会引发周围Al基体的优先腐蚀,导致XY平面上条棒状熔池及XZ平面上扇形熔池都由于边界优先腐蚀而显现出来。而形成的微米级TiC颗粒同样作为阴极相诱导局部腐蚀的发生,且这种团聚颗粒的随机分布较大程度上增大了局部腐蚀发生的概率。此外,微米级TiC颗粒内部也存在Al元素的富集,这些存在于内部边界处的Al也会优先于TiC颗粒腐蚀从而导致大尺寸颗粒内部发生溶解。

图8

图8

LPBF TiC改性Al-Mg-Sc-Zr合金的腐蚀行为示意图

Fig.8

Schematic diagram of the corrosion behavior for LPBF TiC-modified Al-Mg-Sc-Zr alloy

2.3 应力腐蚀行为

图9为TiC改性LPBF Al-Mg-Sc-Zr合金在干燥空气和3.5%NaCl溶液中的慢拉伸应力应变曲线。试样的抗拉强度及伸长率如图内数据所示,干燥空气环境中合金的抗拉强度为447.99 MPa,断裂伸长率为15.46%,而在溶液环境中,合金的抗拉强度下降至429.35 MPa,断裂伸长率下降至14.06%。可以看出在溶液环境中,合金的强度及韧性有一定程度的下降,但基本仍能保持原有的力学性能,可以推断TiC改性LPBF Al-Mg-Sc-Zr合金具有很好的抗应力腐蚀性能,在1 × 10-6 s-1应变速率条件下合金发生了较为轻微的应力腐蚀。

图9

图9

LPBF TiC改性Al-Mg-Sc-Zr合金的拉伸应力-应变曲线

Fig.9

Stress-strain curves of LPBF TiC-modified Al-Mg-Sc-Zr alloy

为了进一步对LPBF TiC改性Al-Mg-Sc-Zr合金的应力腐蚀机理进行研究,分别对在干燥空气和3.5%NaCl溶液中的拉伸断口进行SEM观察,其结果如图10所示。通过图10a和e的低倍形貌能够看出,两种合金的断口形貌都呈现韧性+脆性混合断裂的模式。高倍形貌(图10b和f)则表明韧性断裂区除了存在大量韧窝外,还可见大量尺寸不一的颗粒,这些颗粒表面平整且都嵌入在基体中。通过图10c和g及对应的EDS面扫结果可以证实,这些颗粒为微米级的TiC颗粒。图3已经表明这些大尺寸的颗粒往往由于与基体之间的电化学活性差异而形成腐蚀微电池,引发局部腐蚀。在应力和腐蚀介质协同下,局部腐蚀产生的蚀坑或微裂纹等成为应力腐蚀的起源,发展为应力腐蚀裂纹(SCC)。裂纹形成后,其内部由于金属离子水解易形成自催化加速腐蚀环境,加速裂纹的扩展,最终导致合金发生断裂。在腐蚀环境中,LPBF TiC改性Al-Mg-Sc-Zr合金的力学性能指标有所下降,说明微米级TiC颗粒在腐蚀环境中成为了性能劣化的起源点,并诱发了局部腐蚀,最终在与应力的协同作用下,导致了合金的强韧性损失。图10d和h则展示了细晶区域的断口形貌,可见大量细小的韧窝,与等轴晶的尺寸及边界相吻合。大面积的细晶区域是合金具有优异的抗应力腐蚀性能的关键,细晶区高密度的晶界为合金表面氧化膜的形成提供了便利条件,有利于形成更致密均匀的表面膜,一定程度上减缓了局部腐蚀的萌生。此外,细晶组织的塑性变形能力更好,能够改善应力分布,不易形成高度局域化的应力集中,从而会延缓裂纹的萌生,而且细晶区能够提供了众多曲折的途径,不利于裂纹的扩展。大量细小、取向随机的晶界会成为裂纹扩展的障碍,当主裂纹尖端遇到晶界时,可能发生偏转、分叉,从而形成多个微裂纹,有效地降低裂纹的扩展速率。

图10

图10

Al-Mg-Sc-Zr合金在干燥空气及3.5%NaCl溶液中的SSRT断口SEM形貌及EDS结果

Fig.10

Fracture SEM morphologies of LPBF TiC-modified Al-Mg-Sc-Zr alloy in air (a-d) and in solution (e-h) and EDS results of Fig.10g (i)

图11为在干燥空气和3.5%NaCl溶液中的拉伸断口的侧截面SEM形貌图。在空气中的拉伸样品断口能够观察到明显的颈缩现象,其侧面存在一些由于机械破坏而产生的裂纹。而在溶液中的样品侧面可以观察到由大量的局部腐蚀产生的腐蚀坑洞及微裂纹,其表面裂纹数量较空气中的样品明显增多。结合图5可得,这些表面产生的腐蚀区域是在腐蚀环境中优先发生腐蚀的熔池边界及微米级TiC颗粒存在的位置。进一步放大腐蚀区域如图11f所示,可以观察到这些腐蚀坑已经具有一定的深度,坑内部已经观察到被腐蚀出的细晶形貌。由此可以得出结论,在腐蚀介质中合金出现明显的局部腐蚀-断裂协同失效行为,表面局部腐蚀的萌生处极易成为应力腐蚀裂纹的起源及扩展区域,加速合金的断裂。

图11

图11

Al-Mg-Sc-Zr合金在干燥空气及3.5%NaCl溶液中的SSRT断口侧边SEM形貌

Fig.11

Fracture SEM images of LPBF TiC-modified Al-Mg-Sc-Zr alloy in air (a-c) and in solution (d-f)

3 结论

(1) 激光粉末床熔融法制备的TiC改性Al-Mg-Sc-Zr块状合金的底、侧两个截面都呈现尺寸细小的亚微米级晶粒组成的显微组织,纳米TiC颗粒的引入促进纳米Al3(Ti, Sc, Zr)相的生成,进一步显著细化晶粒,实现了柱状等轴双峰晶粒结构向全等轴晶结构的转变,而合金的熔池边界由于大量微阴极Al3(Ti, Sc, Zr)相的存在成为了腐蚀易发生的区域。

(2) 由于纳米TiC颗粒的团聚,在合金内形成了微米级的TiC聚集颗粒,在底、侧两截面都见到有这类颗粒随机分布,大尺寸TiC颗粒拥有比周围基体更高的电位且周围分布更高的位错密度使其成为局部腐蚀优先发生的区域及应力腐蚀裂纹的起源。

(3) 激光粉末床熔融法制备的TiC改性Al-Mg-Sc-Zr合金展现了优异的耐蚀性能及抗应力腐蚀性能,这可以归结于其精细的晶粒结构对表面保护膜生成的促进作用以及对应力腐蚀裂纹萌生及扩展的阻碍作用。

参考文献

Making sense of 3-D printing: Creating a map of additive manufacturing products and services

[J].

Additive manufacturing of metals

[J].

Research status of laser additive manufacturing for metal: A review

[J].

A review on selective laser sintering/melting (SLS/SLM) of aluminium alloy powders: Processing, microstructure, and properties

[J].

Effect of aspergillus aculeatus on corrosion behavior of 5A02 Al-alloy in coastal atmospheric environment of Hainan island

[J].

海南滨海大气环境中棘孢曲霉对铝合金腐蚀行为影响

[J].通过模拟海南滨海大气环境来研究棘孢曲霉对5A02铝合金的腐蚀行为影响机理。利用平板培养法筛选出棘孢曲霉,将其孢子悬浮液滴到试样表面并设置对照组,置于30 ℃恒温箱中,利用扫描电子显微镜(SEM)、能谱仪(EDS)和X射线光电子能谱(XPS)对试样表面腐蚀形貌和成分进行分析,并观察霉菌的生长状态。使用电化学工作站及扫描Kelvin探针(SKP)分析铝合金表面不同时间棘孢曲霉作用下的腐蚀电位。结果表明,棘孢曲霉会对铝合金材料造成局部腐蚀,腐蚀产物主要由AlO(OH)、Al<sub>2</sub>O<sub>3</sub>和MgO组成。棘孢曲霉生命活动会产生以草酸为主的多种有机酸,造成环境pH值出现先降低后上升的趋势,可加速腐蚀过程。有菌组的电位变化幅度更大且整体电位较无菌组更负,且有菌组电位随着时间的变化先升高后降低。腐蚀机理主要为霉菌代谢产物腐蚀和氧浓差腐蚀,Cl<sup>-</sup>起到促进霉菌生长和加速腐蚀的作用。

Microstructural, corrosion and mechanical properties of additively manufactured alloys: A review

[J].

3D printing of Aluminium alloys: Additive manufacturing of Aluminium alloys using selective laser melting

[J].

A review of selective laser melting of aluminum alloys: Processing, microstructure, property and developing trends

[J].Selective laser melting (SLM) is an attractive rapid prototyping technology for the fabrication of metallic components with complex structure and high performance. Aluminum alloy, one of the most pervasive structural materials, is well known for high specific strength and good corrosion resistance. But the poor laser formability of aluminum alloy restricts its application. There are problems such as limited processable materials, immature process conditions and metallurgical defects on SLM processing aluminum alloys. Some efforts have been made to solve the above problems. This paper discusses the current research status both related to the scientific understanding and technology applications. The paper begins with a brief introduction of basic concepts of aluminum alloys and technology characterization of laser selective melting. In addition, solidification theory of SLM process and formation mechanism of metallurgical defects are discussed. Then, the current research status of microstructure, properties and heat treatment of SLM processing aluminum alloys is systematically reviewed respectively. Lastly, a future outlook is given at the end of this review paper.

Main defects observed in aluminum alloy parts produced by SLM: From causes to consequences

[J].

Coupling effects of SiC and TiB2 particles on crack inhibition in Al-Zn-Mg-Cu alloy produced by laser powder bed fusion

[J].

Enhanced strength and ductility in Al-Zn-Mg-Cu alloys fabricated by laser powder bed fusion using a synergistic grain-refining strategy

[J].Grain refinement is critical to surpassing the bottlenecks of inherent hot tearing of high-strength aluminum alloys fabricated by additive manufacturing (AM). In this study, a synergistic grain-refining strategy including heterogeneous nucleation, solute-driven growth restriction and nanoparticle-induced growth restriction was introduced to control the microstructure of Al-Zn-Mg-Cu alloys during the laser powder bed fusion (LPBF) process. Crack-free Al-Zn-Mg-Cu alloys with significantly refined grains were safely fabricated via LPBF by coincorporation of TiC and TiH2 particles. In-situ L12-Al3Ti particles were produced to promote the heterogeneous nucleation. The grain growth was restricted by adding Ti solute, while introduced TiC nanoparticles (NPs) improved the density of heterogeneous nucleation sites and blocked grain growth physically. The resultant elimination of columnar grains and hot cracks in the (1 wt.%) TiC- and (0.8 wt.%) TiH2-modified Al-Zn-Mg-Cu alloy resulted in excellent ultimate tensile strength (UTS) of 593 ± 24 MPa, yield strength (YS) of 485 ± 41 MPa and elongation (EL) of 10.0% ± 2.5% under the T6 condition. This study provides new insights into improving the grain microstructure and mechanical properties of high-strength aluminum alloys during LPBF.

Effect of bimodal microstructure on the tensile properties of selective laser melt Al-Mg-Sc-Zr alloy

[J].

Selective laser melting of a novel Sc and Zr modified Al-6.2Mg alloy: Processing, microstructure, and properties

[J].

Superior mechanical properties of a selective-laser-melted AlZnMgCuScZr alloy enabled by a tunable hierarchical microstructure and dual-nanoprecipitation

[J].

An additively manufactured Al-14.1Mg-0.47Si-0.31Sc-0.17Zr alloy with high specific strength, good thermal stability and excellent corrosion resistance

[J].A novel Al-14.1Mg-0.47Si-0.31Sc-0.17 Zr alloy was applied in the printing process of selective laser melting (SLM), and the corresponding microstructural feature, phase identification, tensile properties and corrosion behavior of the AlMgSiScZr alloy were studied in detail. As fabricated at 160 W and 200 mm/s, the Mg content of bulk sample decreased to 11.7 wt% due to the element vaporization at high energy density, and the density of this additively manufactured AlMgSiScZr alloy was 2.538 g/cm 3, which is 4.2 %~8.5 % lighter than that of other SLM-processed Al alloys. After heat-treated (HT) at 325 ℃ and 6 h, the microstructure was almost unchanged with an alternate distribution of fine equiaxed crystals and coarse columnar crystals. Nano-sized Al3(Sc, Zr) and Mg2Si phases precipitated dispersedly in the Al matrix, and the tensile strength increased from 487.6 MPa to 578.4 MPa for precipitation strengthening and fine grain strengthening. With a fine grain size of 2.53 μm, an excellent corrosion resistance was obtained for the as-printed (AP) AlMgSiScZr alloy. While the corrosion resistance of HT sample decreased slightly for the formation of non-dense oxide layer and pitting corrosion induced by diffuse precipitation distribution. This SLM-printed AlMgSiScZr alloy with high specific strength, good thermal stability and excellent corrosion resistance has broad prospects for the aerospace and automotive applications.

Study on selective laser melting of high-strength Al-Mg-Sc-Zr aluminum alloy

[D].

Al-Mg-Sc-Zr高强铝合金选区激光熔融工艺研究

[D].

Additive manufacturing of ceramic particle-reinforced aluminum-based metal matrix composites: A review

[J].

Microstructure evolution and strengthening mechanisms of a high-performance TiN-reinforced Al-Mn-Mg-Sc-Zr alloy processed by laser powder bed fusion

[J].In this work, a high-strength crack-free TiN/Al-Mn-Mg-Sc-Zr composite was fabricated by laser powder bed fusion (L-PBF). A large amount of uniformly distributed L1<sub>2</sub>-Al<sub>3</sub>(Ti, Sc, Zr) nanoparticles were formed during the L-PBF process due to the partial melting and decomposition of TiN nanoparticles under a high temperature. These L1<sub>2</sub>-Al<sub>3</sub>(Ti, Sc, Zr) nanoparticles exhibited a highly coherent lattice relationship with the Al matrix. All the prepared TiN/Al-Mn-Mg-Sc-Zr composite samples exhibit ultrafine grain microstructure. In addition, the as-built composite containing 1.5 wt% TiN shows an excellent tensile property with a yield strength of over 580 MPa and an elongation of over 8 %, which were much higher than those of wrought 7xxx alloys. The effects of various strengthening mechanisms were quantitatively estimated and the high strength of the alloy was mainly attributed to the refined microstructure, solid solution strengthening, and precipitation strengthening contributed by L1<sub>2</sub>-Al<sub>3</sub>(Ti, Sc, Zr) nanoparticles.

Corrosion mechanism and development of the Zn-containing 5xxx series Al alloy for shipbuilding industry

[D].

舰船用含Zn5xxx系铝合金的抗腐蚀机理及板材开发

[D].

Research progress on hydrogen embrittlement mechanism of high strength Al-alloy

[J].

高强铝合金氢脆机理研究进展

[J].氢脆是高强铝合金在服役环境中应用所面临的问题之一。本文首先总结了氢的来源及其与高强铝合金的相互作用,介绍了氢脆的主要机制,包括氢促局部塑性(HELP)、氢促解聚(HEDE)、氢诱导位错发射模型(AIDE)和混合模型。随后,分析并讨论了高强铝合金微观结构(如第二相、位错、晶界等)和环境因子(如温度、湿度、应变速率等)对氢脆敏感性的影响。最后,指出在氢脆过程中,氢、第二相和裂纹之间的协同作用,以及多种环境因素耦合效应对高强铝合金氢脆敏感性的影响是亟待解决的问题。此外,通过调控不可逆氢陷阱的结构和数量是缓解氢脆的有效途径之一。

Corrosion behaviors of selective laser melted aluminum alloys: A review

[J].Selective laser melting (SLM) is an ideal method to directly fabricate products with high geometrical complexity. With low density and good corrosion resistance, aluminum alloys are widely used as important structural materials. Microstructures and mechanical properties of SLMed aluminum alloys have been recently widely studied. Corrosion behavior as a vital concern during the service of SLMed aluminum alloy parts has also drawn many attentions. Previous studies have found that SLM-processed aluminum alloys exhibit better corrosion resistance compared to the casted and wrought counterparts for both Al-Si alloys and high strength 2xxx Al alloys, which is mainly due to the unique microstructure features of SLMed Al alloys. For Al-Si alloys, with different shapes of Si networks, the different building planes show discrepant corrosion behaviors. Owing to the rougher surface with relatively larger numbers of defects, the as-printed surface is vulnerable to corrosion than the polished. Heat treatment has a negative effect on corrosion resistance due to the breakup of Si networks. The microstructure features correlated with the corrosion behaviors were also reviewed in this paper. Some suggestions on the future study of corrosion behaviors of SLMed Al alloys were put forward.

Anisotropic corrosion behavior of Sc and Zr modified Al-Mg alloy produced by selective laser melting

[J].

Anisotropic response in corrosion behavior of laser powder bed fusion Al-Mn-Mg-Sc-Zr alloy

[J].

Recent advances in inoculation treatment for powder-based additive manufacturing of aluminium alloys

[J].

ZrC + TiC synergically reinforced metal matrix composites with micro/nanoscale reinforcements prepared by laser powder bed fusion

[J].

The influence of grain structure on the corrosion behaviour of 2A97-T3 Al-Cu-Li alloy

[J].

Mechanical properties and corrosion behavior of selective laser melted 316L stainless steel after different heat treatment processes

[J].Irregular grains, high interfacial stresses and anisotropic properties widely exist in 3D-printed metallic materials, and this paper investigated the effects of heat treatment on the microstructural, mechanical and corrosion properties of 316 L stainless steel fabricated by selective laser melting. Sub-grains and low-angle boundaries exist in the as-received selective laser melted (SLMed) 316 L stainless steel. After heat treatment at 1050 °C, the sub-grains and low-angle boundaries changed slightly, and the stress state and strength decreased to some extent due to the decrease of dislocation density. After heat treatment at 1200 °C, the grains became uniform, and the dislocation cells vanished, which led to a sharp decline in the hardness and strength. However, the ductility was improved after recrystallization heat treatment. The passive film thickness and corrosion potential of the SLMed 316 L stainless steel decreased after heat treatment, and the pitting potential also decreased due to the accelerated transition from metastable to steady-state pitting; this accelerated transition was caused by the presence of weak passive films at the enlarged pores after heat treatment, especially for an adequate solid solution treatment.

Enhanced mechanical properties of a novel heat resistant Al-based composite reinforced by the combination of nano-aluminides and submicron TiN particles

[J].

Influence of scanning strategy and parameter on microstructural feature, residual stress and performance of Sc and Zr modified Al-Mg alloy produced by selective laser melting

[J].

Insight into TiN inclusion induced pit corrosion of interstitial free steel exposed to aerated NaCl solution

[J].

Effect of aging treatment on the microstructure and mechanical properties of Al-3.02Mg-0.2Sc-0.1Zr alloy printed by selective laser melting

[J].

Selective laser melting of rare earth element Sc modified aluminum alloy: Thermodynamics of precipitation behavior and its influence on mechanical properties

[J].