激光增材制造技术通过“结构-性能协同调控”方法,实现了复杂构件一体化成形与材料微观组织精确调控的深度融合。其逐层堆积的成形特点不仅显著提升了材料利用率、缩短了制造周期,更能通过工艺参数的精准优化实现构件力学性能的定向调控,大幅增强了复杂工况下的工艺适应性和结构可靠性[9~12]。然而,传统中高强铝合金选区激光熔化成形(SLM)工艺仍面临一些严峻挑战:较宽的凝固温度区间导致熔池液-固两相区停留时间显著延长,这不仅促进枝晶组织粗化并形成连续的枝晶间液相通道,更会因凝固收缩受阻而引发显著的热裂倾向[13]。针对上述挑战,研究重点开始转向微合金化策略。最新研究表明,Sc、Zr复合微合金化可诱导Al3(Sc,Zr)纳米金属间化合物的原位析出,通过双重作用机制显著改善SLM成形性:一方面,这些纳米颗粒作为异质形核核心,可实现熔池凝固组织的亚微米级细化调控;另一方面,其钉扎效应可大幅提升晶界结合能,有效抑制热裂纹萌生[14~16]。经过热处理后,SLM成形的Al-Mg-Sc-Zr合金具有高的强度和良好的延展性[17]。

然而,在实际服役过程中,铝合金构件面临着严峻的生物污损和微生物腐蚀(MIC)问题[18]。研究表明,铜绿假单胞菌(P. aeruginosa)可在金属表面快速成膜,从而加速其失效过程[19],如对双相不锈钢[20~22]、304不锈钢[23~26]、316L不锈钢[27]、C1018碳钢[28,29]、Cu[30,31]等金属都具有加速腐蚀的作用。此外,有研究[32]表明,P. aeruginosa可在Al-Cu-Li合金表面形成不连续的生物膜以及降低局部pH,从而加速其腐蚀。对于Al-Mg-Sc-Zr合金,一些研究人员仅在3.5% (质量分数) NaCl溶液中进行了腐蚀性能测试[33~35],而对增材制造铝合金在海洋环境中的腐蚀行为和MIC机制仍缺乏系统性探索,P. aeruginosa能否在Al-Mg-Sc-Zr合金表面成膜并影响其腐蚀行为目前还尚不清楚。

本文研究了P. aeruginosa在模拟海水环境中对增材制造Al-Mg-Sc-Zr合金腐蚀行为的影响规律,旨在阐明P. aeruginosa对增材制造铝合金的污损及腐蚀机制。该研究结果有望为增材制造铝合金在海洋环境中的生物污损及腐蚀机制提供新的见解,并可为增材制造Al-Mg-Sc-Zr合金未来在海洋工业上的广泛应用提供理论支撑。

1 实验方法

1.1 Al-Mg-Sc-Zr合金的制备

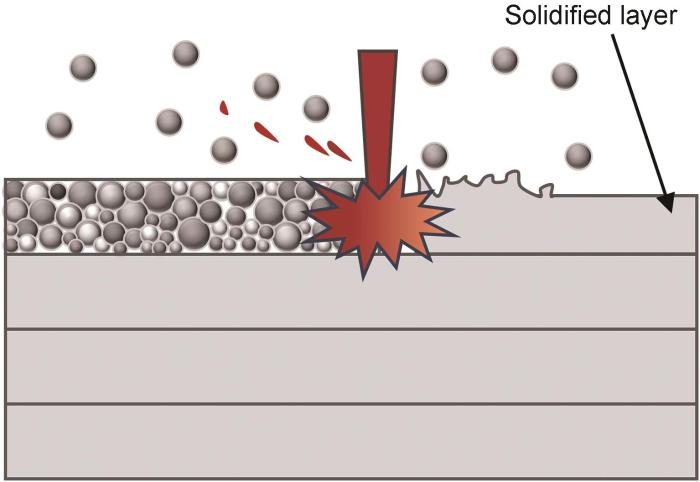

采用EOS M290激光粉床熔融成形设备制备所需的Al-Mg-Sc-Zr合金。实验选用5083变形铝合金作为基材,其成形过程如图1所示,通过表征成形块体的致密度及冶金缺陷特征优化工艺参数。根据前期探索,优化后的成形工艺参数为:激光功率370 W,扫描速度1000 mm/s,层厚0.03 mm,扫描间距0.12 mm。成形前的金属粉末和成形后的基体均使用Agilent ICPOES730电感耦合等离子体发射光谱仪(ICP-OES)进行了元素定量分析。金属粉末具体化学成分(质量分数,%)为:Mg 4.7315、Sc 0.8082、Mn 0.5390、Zr 0.3663、Si 0.3395、Fe 0.0368、Ti 0.0057、V 0.0038、Zn 0.0022、Cu 0.0003、Al余量。Al-Mg-Sc-Zr合金的化学成分(质量分数,%)为:Mg 4.717、Sc 0.8337、Mn 0.4037、Zr 0.3079、Si 0.0049、Fe 0.0266、Al余量。电化学测试以及浸泡测试所用工作电极的尺寸均为10 mm × 10 mm × 10 mm,其制备步骤如下:首先在试样背面钻孔并安装铜质螺钉,随后将铜导线焊接至螺钉处,最后采用环氧树脂对组装件进行密封,仅保留10 mm × 10 mm的表面积作为电化学测试的工作区域。将所有样品依次采用120#、240#、400#、600#、800#、1000#和1200#的碳化硅砂纸打磨、随后用无水乙醇清洗、最后在冷空气下干燥。实验前,将所有试样在紫外线灯下灭菌20 min。

图1

图1

Al-Mg-Sc-Zr合金成形过程示意图

Fig.1

Schematic diagram of forming process for the Al-Mg-Sc-Zr alloy

1.2 P. aeruginosa 细菌的培养

P. aeruginosa细菌(MCCC 1A00099)购买自中国海洋微生物菌种保藏管理中心自然资源部第三海洋研究所,并在实验室用含KNO3的Luria-Bertani培养基(LB-NO3)进行了富集培养。LB-NO3培养基成分如下[36]:NaCl (5 g)、KNO3 (10 g)、酵母提取物(5 g)、胰蛋白胨(10 g)、去离子水(1 L)。根据ASTM D1141-98标准[37],模拟海水的化学成分如下:NaCl 24.53 g、MgCl2 5.20 g、Na2SO4 4.09 g、CaCl2 1.16 g、KCl 0.695 g、NaHCO3 0.201 g、KBr 0.101 g、H3BO3 0.027 g、SrCl2 0.025 g、NaF 0.003 g、去离子水1 L。利用1 mol/L的NaOH溶液将LB-NO3培养基的pH调节在7.0到7.2之间。接种前,培养基在121 ℃下高压灭菌20 min。实验前,P. aeruginosa菌株在恒温震荡培养箱中活化12 h。14 d实验期间,在荧光显微镜下利用血球计数板对溶液中的细菌数量进行计数。

1.3 电化学测试

所有电化学测试均在Corrtest电化学工作站(CS310X)上完成。电化学测试采用三电极系统,其中工作电极为Al-Mg-Sc-Zr合金(暴露面积为1 cm2),对电极为方形铂片(10 mm × 10 mm × 1 mm),参比电极为饱和甘汞电极(SCE)。实验分为两组,分别为无菌组和接菌组,无菌组为10%LB-NO3培养基+ 90%模拟海水,接菌组为10%含P. aeruginosa菌种的LB-NO3培养基+ 90%模拟海水。所有电化学测试均在开路电位(OCP)波动小于1 mV后进行。电化学阻抗谱(EIS)测试的扫描频率范围为105~10-2 Hz,正弦电位扰动为10 mV,分别在第1、3、5、7、10和14 d对Al-Mg-Sc-Zr合金的EIS谱图进行了连续监测。浸泡14 d后,对Al-Mg-Sc-Zr合金进行了动电位极化曲线测试,扫描速率为0.5 mV/s,扫描范围为-300 mV至1000 mV (vs. OCP)。为了实时监测细菌生长代谢对试样腐蚀行为的具体影响,所有试样均在原模拟液中进行电化学测试。EIS测试过程中,P. aeruginosa不会死亡或生长代谢异常,这是因为EIS测试仅施加了10 mV的正弦扰动电位,该电位对试样表面及溶液中P. aeruginosa细胞的生长基本无影响。然而,极化曲线测试施加的过负或过正电位可能会对P. aeruginosa的生长代谢产生影响。为了避免该影响,在第14 d实验结束时进行了极化曲线测试,因此不会影响14 d实验期间P. aeruginosa的生长代谢。

1.4 表面形貌观察及成分分析

浸泡14 d后,通过PHENOM XL扫描电子显微镜(SEM)观察试样在非生物和生物介质中的腐蚀产物和生物膜形貌。在形貌观察前,将生物介质中的试样浸泡于含4%戊二醛的磷酸盐缓冲液(PBS) (pH在7.0至7.2之间)中8 h以固定生物膜,随后依次用25%、50%、75%和100%的无水乙醇溶液进行脱水处理。利用DAPI染色剂对试样表面的生物膜进行染色,在黑暗环境中染色20 min,并利用荧光显微镜观察P. aeruginosa细胞在试样表面的分布情况。DAPI染色剂可以穿透细胞膜完整性丧失的死细胞或固定细胞,与DNA结合后发出蓝色荧光。通过SEM配备的能量色散光谱仪(EDS)对试样表面的腐蚀产物膜和生物膜的元素组成进行了分析。通过K-Alpha型X射线光电子能谱仪(XPS)对试样表面腐蚀产物中Al、Mg、N和P的化学价态进行了表征。首先,利用SEM找到具有典型腐蚀产物的测量位置,随后利用XPS对该位置进行了表征。去除试样表面腐蚀产物后,利用NPFLEX-1000白光干涉仪对试样表面的点蚀形貌进行了观察,并对点蚀坑进行了测量。

2 结果与讨论

2.1 Al-Mg-Sc-Zr合金的金相及SEM图像

图2

图2

Al-Mg-Sc-Zr合金的金相图像及SEM二次电子图像

Fig.2

Metallographic images (a, b) and SEM secondary electron images (c, d) of the Al-Mg-Sc-Zr alloy

2.2 pH和细菌生长曲线

图3

图3

测试溶液的pH值、细胞含量变化以及试样表面的细菌荧光图像

Fig.3

Changes in pH value and cell counts of the test solution (a) and fluorescence images of P. aeruginosa cells on the Al-Mg-Sc-Zr alloy surfaces (b)

当有机碳源充足时,P. aeruginosa可以优先利用有机碳源(如乳酸)作为其生长所需的能量来源,而硝酸盐会作为电子受体,总反应如下所示[36]:

从上述反应可以看出,P. aeruginosa会消耗质子并产生OH-,导致pH升高。因此,与无菌组相比,接菌组中溶液的pH偏高。随着腐蚀的进行,溶液pH缓慢下降,这可能是由于腐蚀过程中释放的Al3+发生如下水解反应[2]:

14 d后,利用DAPI染色剂对接菌溶液中的试样表面进行染色,荧光形貌如图3b所示。可以看出,P. aeruginosa可附着在铝合金表面,呈现不均匀分布状态,可能会对Al-Mg-Sc-Zr合金的腐蚀产生不利影响。

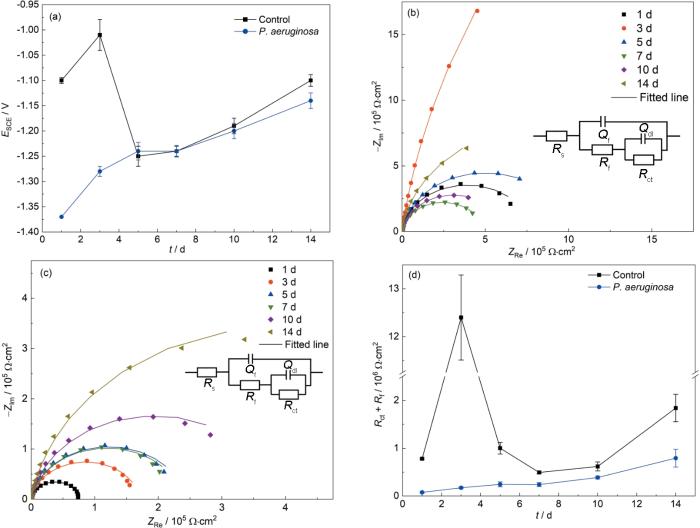

2.3 电化学测试结果

图4为Al-Mg-Sc-Zr合金在14 d实验期间连续监测的OCP和EIS结果。如图4a所示,在接菌环境中,该合金的OCP随时间呈上升趋势,而在无菌环境中该合金的OCP则先正移后负移,最后又缓慢上升。接菌环境中Al-Mg-Sc-Zr合金的OCP值小于无菌环境,表明P. aeruginosa导致该合金的腐蚀倾向增大。图4b和c分别为无菌和接菌环境中Al-Mg-Sc-Zr合金的Nyquist图,利用图中所示等效电路模型来拟合该合金在无菌和接菌环境中的EIS谱图,其中Rs代表测试溶液的电阻,Qf和Rf分别代表腐蚀产物膜或生物膜的电容和电阻,Qdl和Rct分别代表双电层的电容和电阻。拟合得到的相应参数被列于表1中。图4d为Al-Mg-Sc-Zr合金的极化电阻Rp (对于电容型EIS,Rp = Rct + Rf)随时间变化的趋势。在接菌环境中,Al-Mg-Sc-Zr合金的Rp值随时间不断增大,这可能是由于其表面腐蚀产物与生物膜的持续累积所致。而在无菌环境中,铝合金的Rp值随时间先增大后减小,最后又缓慢上升。这可能是因为前期合金表面形成了保护性的钝化膜,但在海水中该钝化膜可能随后被破坏。海水中的Cl-可以穿透氧化膜的薄弱区域,引发局部腐蚀,导致在第3至5 d OCP急剧负移。最后随着腐蚀产物的积累,减缓了Cl-的扩散,使腐蚀速率降低,电位缓慢正移。

图4

图4

14 d实验期间无菌组与接菌组中合金的OCP值和EIS数据

Fig.4

OCP values (a) and Nyquist diagrams of the Al-Mg-Sc-Zr alloy in the sterile (b) and inoculated media (c), and the Rct + Rf values of the Al-Mg-Sc-Zr alloy from curve-fitting of the EIS spectra (d), and equivalent circuit models used for curve-fitting of the EIS spectra displayed in Fig.4b and Fig.4c during the 14 d experiment

表1 Al-Mg-Sc-Zr合金在非生物和生物介质中EIS谱的电化学参数

Table 1

| Condition | t / d | Rs / Ω·cm2 | Qf / 10-6 S·cm-2·s n | Rf / 103 Ω·cm2 | Qdl / 10-6 S·cm-2·s n | Rct / 103 Ω·cm2 |

|---|---|---|---|---|---|---|

| Control | 1 | 8.388 | 7.136 | 12.21 | 0.500 | 767.1 |

| 3 | 8.697 | 6.516 | 6.624 | 0.795 | 12360 | |

| 5 | 8.741 | 7.168 | 5.129 | 1.088 | 998.6 | |

| 7 | 8.425 | 9.302 | 6.481 | 0.875 | 485.3 | |

| 10 | 8.702 | 15.17 | 3.384 | 0.826 | 614.9 | |

| 14 | 8.664 | 14.59 | 2.380 | 1.000 | 1834 | |

| P. aeruginosa | 1 | 7.523 | 11.35 | 33.30 | 1.348 | 42.66 |

| 3 | 8.014 | 9.817 | 0.0204 | 6.085 | 171.5 | |

| 5 | 8.386 | 9.704 | 0.0345 | 6.827 | 243.6 | |

| 7 | 8.292 | 9.527 | 0.0349 | 7.767 | 238 | |

| 10 | 8.524 | 10.500 | 0.0442 | 8.158 | 386.6 | |

| 14 | 8.485 | 12.55 | 0.0589 | 7.692 | 791.3 |

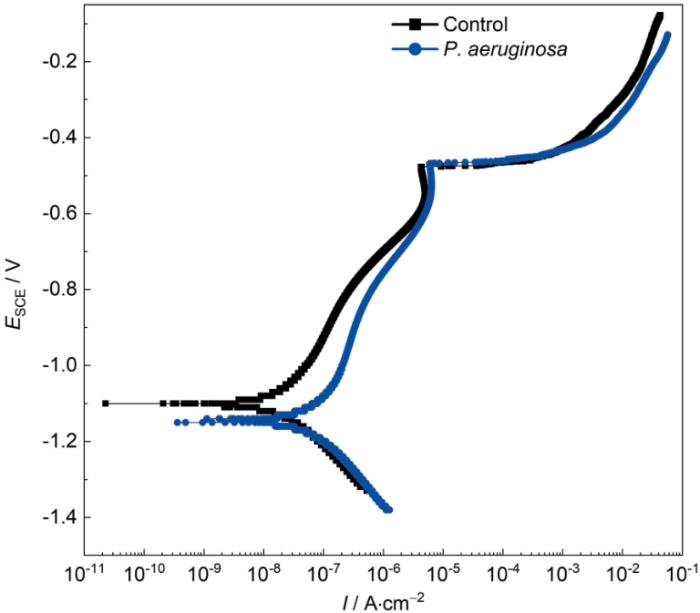

在无菌和接菌环境中浸泡14 d后,测量了Al-Mg-Sc-Zr合金的动电位极化曲线,如图5所示。与无菌组相比,该合金在接菌环境中的阳极和阴极反应都被显著加速,拟合后的参数见表2。由表2可知,P. aeruginosa的存在使得腐蚀电位发生负移,且该合金在接菌环境中的腐蚀电流密度约为无菌环境中的3.3倍。以上数据表明,该合金在接菌环境中的腐蚀速率明显大于无菌环境,即P. aeruginosa可显著加速Al-Mg-Sc-Zr合金的腐蚀。从二者极化曲线上的阳极区来看,两者均出现了明显的钝化现象,并且几乎在同一电位下发生钝化膜破裂现象,这说明P. aeruginosa的存在并未显著改变该合金钝化膜的破裂电位,但在含P. aeruginosa溶液中钝化电流密度较高,说明P. aeruginosa可能降低铝合金表面膜的保护性。P. aeruginosa可能通过调控局部化学微环境或电化学界面过程,从而加速钝化膜溶解及失效后的金属溶解过程。

图5

图5

试样在无菌和接菌环境中浸泡14 d后的动电位极化曲线

Fig.5

Potentiodynamic polarization curves of Al-Mg-Sc-Zr alloy after 14 d of immersion in the sterile and inoculated media

表2 试样在无菌和接菌环境中通过拟合动电位极化曲线所得到的相关电化学参数

Table 2

| Condition | Ecorr vs. SCE / V | Icorr / 10-8 A·cm-2 |

|---|---|---|

| Control | -1.098 | 2.08 |

| NRB | -1.147 | 6.78 |

2.4 微观形貌表征

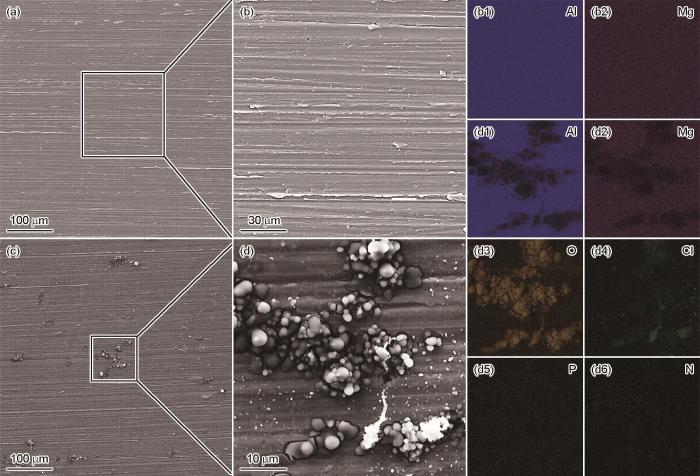

图6为14 d实验后,无菌和接菌环境中Al-Mg-Sc-Zr合金表面的SEM形貌以及EDS面扫描结果。对比图6b和d中形貌可见,该合金在无菌环境中几乎观察不到腐蚀的痕迹。然而,接菌环境中合金表面存在大量球状腐蚀产物,且周围分布着P. aeruginosa细菌细胞。图6b1和b2中的面扫描结果表明,无菌环境下合金表面均匀分布着Al(94.98%)和Mg (5.02%),这属于合金本身的元素成分。图6d1~d6的面扫描结果表明,合金表面的球状腐蚀产物主要由Al (67.49%)和O (27.69%)组成。此外,合金表面还分布着微量的N (0.09%)和P(0.41%),这两种元素可能由P. aeruginosa代谢产生。值得注意的是,接菌环境中合金表面还存在一些Cl,可能会对合金腐蚀产生不利影响。图中结果表明,生物膜不均匀覆盖在金属表面,导致局部电化学腐蚀差异。此外,Cl在腐蚀产物中可能如上述水解反应方程

图6

图6

浸泡14 d后试样表面的SEM形貌与EDS面扫描元素分布图

Fig.6

Morphologies of surface films: (a, b) SEM images and (b1, b2) EDS mapping results from (b) after 14 d of immersion in the sterile media; (c, d) SEM images and (d1-d6) EDS mapping results from (d) after 14 d of immersion in the inoculated media

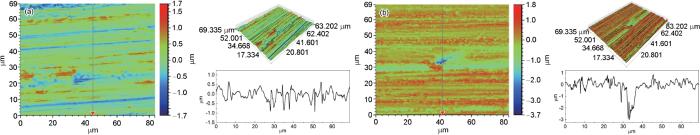

图7

图7

去除腐蚀产物后试样表面腐蚀形貌

Fig.7

2D and 3D color images of the Al-Mg-Sc-Zr alloy surfaces after removal of corrosion products in the sterile medium (a) and in the inoculated medium (b)

为进一步确定腐蚀产物成分,利用XPS对Al-Mg-Sc-Zr合金表面腐蚀产物的元素价态进行了分析。在无菌环境中,Al 2p谱图主要在74.9和72.9 eV处出现2个峰,分别对应于样品表面的Al2O3与Al (图8a1);在Mg 1s谱图中主要在1303.5和1303.9 eV处出现2个峰,分别对应于样品表面的Mg与MgO (图8a2);在N 1s谱图中主要在400.1和399.7 eV处出现2个峰,这可能对应于一些吸附在金属表面有机物中的N元素(图8a3);P 2p谱图主要在133.8 eV处出现1个峰,对应于HPO

图8

图8

浸泡14 d后Al-Mg-Sc-Zr合金表面的XPS图谱

Fig.8

High-resolution XPS spectra Al 2p (a1), Mg 1s (a2), N 1s (a3) and P 2p (a4) for Al-Mg-Sc-Zr alloy in the sterile medium; Al 2p (b1), Mg 1s (b2), N 1s (b3) and P 2p (b4) for Al-Mg-Sc-Zr alloy in the inoculated medium

2.5 P. aeruginosa 诱导Al-Mg-Sc-Zr合金的腐蚀机理

根据上述实验结果,提出了P. aeruginosa诱导Al-Mg-Sc-Zr合金腐蚀的可能机理(图9)。如图9所示,P. aeruginosa通过分泌胞外聚合物(EPS)附着于铝合金表面,形成分布不均的生物膜,生物膜内部的局部pH微环境可能有显著差异。Hollmann等[38]分析了铜绿假单胞菌生物膜中的实时三维pH变化,表明菌落核心内环境具有高度酸性(pH约为3.5~4.5),而这些菌落的外缘则表现出略微酸性的pH (5.5~6.0)。因此,生物膜下方的局部酸化可能促进氧化铝的溶解(图9II),这一解释与Kolics等[39]报道的结果一致,在0.1 mol/L NaCl溶液中,当pH低于4时,由于活性金属的溶解和氧化膜的不稳定,纯铝表面的纳米级Al2O3层显著减少。此外,在有菌环境中,Al-Mg-Sc-Zr合金表面监测到的Cl-可能被吸附在生物膜中,与P. aeruginosa协同破坏了氧化膜。另外,生物膜的粘附性结构还会阻碍氧气扩散,导致生物膜内部与外部形成氧浓度梯度。氧浓度差异促使铝合金表面形成阳极(低氧区)和阴极(高氧区),引发局部电偶腐蚀,加速点蚀的发展(图9中的III)。

图9

图9

P. aeruginosa诱导Al-Mg-Sc-Zr合金的腐蚀示意图

Fig.9

Schematic diagram of P. aeruginosa induced corrosion of Al-Mg-Sc-Zr alloy

从图中还可看出,在实验初期,当有机碳源充足时,P. aeruginosa可从有机碳源中获取生命活动所需的能量。根据生物催化阴极硝酸盐还原(Biocatalytic cathodic nitratereduction,BCNR)理论[40],当环境中有机碳源匮乏时,P. aeruginosa生物膜可以催化硝酸盐还原反应的进行,并从Fe中获取能量进行自身代谢。在本文中,试样表面生物膜下的P. aeruginosa细胞能以Al-Mg-Sc-Zr合金中的Al、Mg元素以及微量Fe元素作为能量来源,产生的电子可用于细胞内部的硝酸盐还原反应,该氧化还原反应产生的能量可维持细菌的生命活动以及生长代谢,从而显著恶化合金的腐蚀性能(图9IV)。此外,生物膜可以作为有机碳源的扩散屏障,导致膜下与金属基体接触的固着细胞处于饥饿状态,只能将金属作为唯一能量来源,这会显著加速其腐蚀过程。从图3a看,腐蚀可能很快就进入到图9IV的模式。

3 结论

(1) EIS结果显示,合金在接菌条件下的阻抗值远小于无菌条件,表明细菌显著降低了合金的腐蚀稳定性。此外,与对照组相比,细菌显著促进了合金的阳极溶解,腐蚀电流密度增大约3.3倍。

(2) 无菌条件下合金在模拟海水中具有优异的耐蚀性,表面基本无明显点蚀坑;而在接菌条件下,P. aeruginosa可在合金表面形成生物膜,加速点蚀损伤。

(3) P. aeruginosa能从合金的Al、Mg元素中获取电子,在细胞内部用于硝酸盐还原反应从而获取生存所需能量,同时异质生物膜会导致氧浓差电池的形成,加速了局部腐蚀的扩展,并恶化了合金的腐蚀性能。

参考文献

Effect of Aspergillus aculeatus on corrosion behavior of 5A02 Al-alloy in coastal atmospheric environment of Hainan Island

[J].

海南滨海大气环境中棘孢曲霉对铝合金腐蚀行为影响

[J].通过模拟海南滨海大气环境来研究棘孢曲霉对5A02铝合金的腐蚀行为影响机理。利用平板培养法筛选出棘孢曲霉,将其孢子悬浮液滴到试样表面并设置对照组,置于30 ℃恒温箱中,利用扫描电子显微镜(SEM)、能谱仪(EDS)和X射线光电子能谱(XPS)对试样表面腐蚀形貌和成分进行分析,并观察霉菌的生长状态。使用电化学工作站及扫描Kelvin探针(SKP)分析铝合金表面不同时间棘孢曲霉作用下的腐蚀电位。结果表明,棘孢曲霉会对铝合金材料造成局部腐蚀,腐蚀产物主要由AlO(OH)、Al<sub>2</sub>O<sub>3</sub>和MgO组成。棘孢曲霉生命活动会产生以草酸为主的多种有机酸,造成环境pH值出现先降低后上升的趋势,可加速腐蚀过程。有菌组的电位变化幅度更大且整体电位较无菌组更负,且有菌组电位随着时间的变化先升高后降低。腐蚀机理主要为霉菌代谢产物腐蚀和氧浓差腐蚀,Cl<sup>-</sup>起到促进霉菌生长和加速腐蚀的作用。

Localized corrosion mechanism of 2024 aluminum alloy in a simulated dynamic seawater/air interface

[J].A seawater corrosion test platform to simulate the dynamic seawater/air interface is constructed, comprising an electric putter, a time relay, and four corrosion electrochemical sensors. The localized corrosion mechanism of 2024 aluminum alloy in a simulated dynamic seawater/air interface is investigated by corrosion potential monitoring, electrochemical impedance spectroscopy (EIS), electrochemical noise (EN) measurements, and the analysis of the surface and cross-section morphology. The differences in the corrosion behavior at the seawater/air interfacial region and that of full immersion region are discussed. The results showed that the corrosion products at the dynamic seawater/air interfacial region are continuously distributed, which is mainly due to the dissolved Al3+ flowing from the pits and reacting with the oxygen in the dynamic seawater/air interfacial region. The distribution of corrosion products in the entire leaching area is more dispersed. As aluminum alloy is immersed and removed from water periodically, the corrosion potential fluctuates periodically with an amplitude of 5-10 mV. Due to the high corrosion potential in the seawater/air interfacial region, the aluminum alloy above the waterline behaves as the cathode, and that below the waterline acts as the anode. However, because of the subtle difference in the corrosion potential, the galvanic corrosion effect is not obvious. The results of EIS revealed that the high-frequency capacitive arc radius of both seawater/air interfacial region and full immersion zone increased first and then decreased, and the corrosion product film in the interface zone had better corrosion resistance than that in the full immersion zone. The results of the EN test showed that the fluctuation amplitude of current noise decreased first and then increased, indicating that the local corrosion sensitivity decreased first and then increased. The slope of the high-frequency linear region of the power spectral density of current noise was less than -20 dB/dec, indicating that the corrosion type was local corrosion. The pit size at the seawater/air interface was much smaller than that in full immersion region, because the oxygen in the seawater/air interface region could be easily reduced within the pits by consuming H+, thereby increasing the pH value within the pits.

2024铝合金在模拟动态海水/大气界面环境中的局部腐蚀机制

[J].搭建了由电动推杆、时间继电器及4个腐蚀电化学传感器组成的模拟动态海水/大气界面(简称为水气界面)腐蚀测试平台,综合采用腐蚀电位监测、电化学阻抗谱(EIS)技术、电化学噪声(EN)技术以及表面和截面形貌分析,研究了2024铝合金在模拟动态水气界面区的局部腐蚀行为与机制,并比较了其与全浸区腐蚀行为的差异性。结果表明,动态水气界面区腐蚀产物呈“连续分布”特征,主要是由于试样向上移出水面过程中蚀孔内阳极溶解产生的Al<sup>3+</sup>流出,与界面区丰富的氧结合生成腐蚀产物;全浸区腐蚀产物分布较为分散。水气界面区随着铝合金浸入和移出水面,腐蚀电位呈现周期性“下降-上升”波动,波动幅值为5~10 mV。全浸区与水气界面区的水线上方由于腐蚀电位较高所以为阴极区,水线下方为阳极区;但腐蚀电位差异不大,因此宏观腐蚀电池作用不明显。EIS结果表明,水气界面区高频容抗弧半径均呈现先增大后减小趋势,界面区的腐蚀产物膜由于覆盖度大,比全浸区的腐蚀产物膜耐蚀性好。EN结果表明,水气界面区电流噪声的波动幅值先减小后增大,表明局部腐蚀敏感性先减小后增大,电流噪声的功率谱密度(PSD)高频线性区斜率均小于-20 dB/dec,表明其腐蚀类型均为局部腐蚀。和全浸区相比,水气界面区的蚀孔尺寸小,孔蚀发展速率较慢,这主要是因为水气界面区的O含量高,O<sub>2</sub>通过扩散到达蚀孔内部发生还原反应,消耗H<sup>+</sup>,进而提升蚀孔内的pH值。

Corrosion characteristics of 5A06 Al-alloy exposed in natural deep-sea environment

[J].

深海环境5A06铝合金腐蚀行为与表面特性

[J].通过自主研制的高效串型深海环境试验装置在西太平洋深海自然环境下开展了5A06铝合金的腐蚀行为实验,分析了5A06铝合金在500,800,1200和2000 m深海环境下暴露1 a的腐蚀形貌、腐蚀规律和电化学行为。实海结果显示,5A06铝合金的腐蚀形式以点蚀为主,平均腐蚀速率随海水深度增加先升高后降低,最大值出现在水深500 m处,为17 μm/a,是浅表海水环境下的3.1倍;而在800~2000 m水深范围,5A06铝合金腐蚀状况大大减弱,腐蚀速率在0.9~1.4 μm/a水平,800 m时仅为浅表海水的0.21倍,2000 m时则为0.14倍。电化学测试结果显示,试样自腐蚀电位随海水深度增加而正移,2000 m深度下达到-0.640 V (vs. Ag/AgCl);电荷转移阻抗随着试验深度的增加而显著增大,2000 m深度下达到了最大值,为1.91×10<sup>8</sup> Ω·cm<sup>2</sup>。

Localized corrosion mechanism of 5083-H111 Al alloy in simulated dynamic seawater zone

[J].

5083-H111铝合金在模拟动态海水环境中的局部腐蚀机制

[J].采用开路电位 (OCP)、电化学阻抗谱 (EIS),并结合扫描电子显微镜 (SEM) 和X射线光电子能谱 (XPS) 技术,研究了5083-H111铝合金在模拟动态海水环境中的电化学行为,并探讨了局部腐蚀机制。5083-H111铝合金的金属间化合物以Al-Fe和Mg-Si相为主,点蚀主要分布于金属间化合物周围;Al-Fe相在腐蚀过程中充当阴极,与周围Al基体构成微腐蚀电池,促使Al基体的点蚀。Mg-Si相在腐蚀过程中最初充当阳极,当其发生选择性溶解导致脱合金化逐渐形成富Si相后,变为阴极,促使Al基体发生点蚀。5083-H111铝合金表面生成的腐蚀产物为Al(OH)<sub>3</sub>、Al<sub>2</sub>O<sub>3</sub>和AlCl<sub>3</sub>。腐蚀产物在腐蚀初期对Al基体起到良好的保护作用,导致OCP正移,极化电阻 (R<sub>p</sub>) 增大;腐蚀后期 (36~56 d),初始腐蚀产物会发生局部脱落,在脱落位置Al基体再次发生局部腐蚀,导致OCP负移,R<sub>p</sub>急剧减小。随着暴露时间的延长,部分金属间化合物在腐蚀后期会发生脱落,形成腐蚀空腔。

Development of high-performance aluminum alloys

[J].

高性能铝合金研究进展

[J].

Development of high strength aluminum alloys and processing techniques for the materials

[J].The fundamental theories for the development of high strength aluminum alloys and processing techniques for the materials are briefly reviewed in this paper. It specifically focuses on alloying design, casting, homogenization, solution treatment, quenching, pre-stretching and ageing that have been extensively studied recently. Based on these discussions, some perspectives and suggestions have been proposed, which will benefit the development and applications of high strength aluminum alloys.

高强铝合金的发展及其材料的制备加工技术

[J].本文简述了国内外高强铝合金发展的理论基础及其材料的制备加工技术. 针对大规格高性能铝合金材料的成分设计、熔炼、均匀化、固溶、淬火、预拉伸以及时效各工序的相关技术的研究热点和发展进行了介绍和讨论. 并对我国该类铝合金及其发展和应用提出了建议.

Aerocraft aluminum alloys and their materials processing

[J].

航空铝合金及其材料加工

[J].

Recent developments in advanced aircraft aluminium alloys

[J].

Laser additive manufacturing of high-performance metal components

[J].

高性能金属构件的激光增材制造

[J].

Materials' fundamental issues of laser additive manufacturing for high-performance large metallic components

[J].

高性能大型金属构件激光增材制造: 若干材料基础问题

[J].简要介绍了高性能大型金属构件激光增材制造的技术特点、国内外研究进展及技术发展面临的挑战,分析了大型金属构件激光增材制造的"高性能材料制备"与"复杂结构直接制造"有机融合、"控形/控性"一体化的独特特征。指出高性能大型关键金属构件激光增材制造技术的发展和工程应用,将在很大程度上取决于人们对激光增材制造过程中对激光/金属交互作用行为及能量吸收利用机制、内部冶金缺陷形成机制及力学行为、移动熔池约束快速凝固行为及构件晶粒形态演化规律、非稳态循环固态相变行为及显微组织形成规律、内应力演化规律及构件变形开裂预防方法等材料基础问题的深入研究。

Laser additive manufacturing of metallic components: Materials, processes and mechanisms

[J].

Additive manufacturing of metals

[J].

Study on the friction and wear properties of selective laser melted Al-Cu-Mg alloy

[J].

SLM成形Al-Cu-Mg合金的摩擦磨损性能

[J].

Selective laser melting of a novel Sc and Zr modified Al-6.2 Mg alloy: Processing, microstructure, and properties

[J].

SLM-processed Sc- and Zr-modified Al-Mg alloy: Mechanical properties and microstructural effects of heat treatment

[J].

Columnar to equiaxed transition in Al-Mg(-Sc)-Zr alloys produced by selective laser melting

[J].

Microstructures and mechanical property of AlMgScZrMn-a comparison between selective laser melting, spark plasma sintering and cast

[J].

The biofilm-metal interface: A hotspot for microbiologically influenced corrosion

[J].

Inhibition effect on microbiologically influenced corrosion of Ti-6Al-4V-5Cu alloy against marine bacterium Pseudomonas aeruginosa

[J].

Accelerated corrosion of 2205 duplex stainless steel caused by marine aerobic Pseudomonas aeruginosa biofilm

[J].

Enhanced resistance of 2205 Cu-bearing duplex stainless steel towards microbiologically influenced corrosion by marine aerobic Pseudomonas aeruginosa biofilms

[J].

Influence of the α fraction on 2205 duplex stainless steel corrosion affected by Pseudomonas aeruginosa

[J].

Acceleration of corrosion of 304 stainless steel by outward extracellular electron transfer of Pseudomonas aeruginosa biofilm

[J].

Investigation of microbiologically influenced corrosion inhibition of 304 stainless steel by D-cysteine in the presence of Pseudomonas aeruginosa

[J].

Mitigation of microbiologically influenced corrosion of 304L stainless steel in the presence of Pseudomonas aeruginosa by Cistus ladanifer leaves extract

[J].

Salvia officinalis extract mitigates the microbiologically influenced corrosion of 304L stainless steel by Pseudomonas aeruginosa biofilm

[J].The mitigation of microbiologically influenced corrosion (MIC) of 304L stainless steel (SS) against Pseudomonas aeruginosa by a Salvia officinalis extract was investigated using electrochemical and surface analysis techniques. The extract was characterized by HPLC-Q-TOF-MS and its antibiofilm property was evaluated. The data revealed the presence of well-known antimicrobial and anticorrosion compounds in the extract. The S. officinalis extract was found effective in preventing biofilm formation and inhibiting mature biofilm. Electrochemical results indicated that P. aeruginosa accelerated the MIC of 304L SS, while the extract was found to prevent the MIC with an inhibition efficiency of 97.5 ± 1.5%. This was attributed to the formation of a protective film by the adsorption of some compounds from the extract on the 304L SS surface.Copyright © 2019 Elsevier B.V. All rights reserved.

Role of marine Bacillus subtilis and Pseudomonas aeruginosa in cavitation erosion behaviour of 316L stainless steel

[J].

Electron transfer mediators accelerated the microbiologically influence corrosion against carbon steel by nitrate reducing Pseudomonas aeruginosa biofilm

[J].Electron transfer is a rate-limiting step in microbiologically influenced corrosion (MIC) caused by microbes that utilize extracellular electrons. Cross-cell wall electron transfer is necessary to transport the electrons released from extracellular iron oxidation into the cytoplasm of cells. Electron transfer mediators were found to accelerate the MIC caused by sulfate reducing bacteria. However, there is no publication in the literature showing the effect of electron transfer mediators on MIC caused by nitrate reducing bacteria (NRB). This work demonstrated that the corrosion of anaerobic Pseudomonas aeruginosa (PAO1) grown as a nitrate reducing bacterium biofilm on C1018 carbon steel was enhanced by two electron transfer mediators, riboflavin and flavin adenine dinucleotide (FAD) separately during a 7-day incubation period. The addition of either 10ppm (w/w) (26.6μM) riboflavin or 10ppm (12.7μM) FAD did not increase planktonic cell counts, but they increased the maximum pit depth on carbon steel coupons considerably from 17.5μm to 24.4μm and 25.0μm, respectively. Riboflavin and FAD also increased the specific weight loss of carbon steel from 2.06mg/cm to 2.34mg/cm and 2.61mg/cm, respectively. Linear polarization resistance, electrochemical impedance spectroscopy and potentiodynamic polarization curves all corroborated the pitting and weight loss data.Copyright © 2017 Elsevier B.V. All rights reserved.

Microbiologically influenced corrosion of C1018 carbon steel by nitrate reducing Pseudomonas aeruginosa biofilm under organic carbon starvation

[J].

Biocorrosion of copper by nitrate reducing Pseudomonas aeruginosa with varied headspace volume

[J].

Microbiologically influenced corrosion of Cu by nitrate reducing marine bacterium Pseudomonas aeruginosa

[J].

Microbiologically influenced corrosion of Al-Cu-Li alloy by Pseudomonas aeruginosa

[J].

Pitting and intergranular corrosion of Scalmalloy® aluminium alloy additively manufactured by Selective Laser Melting (SLM)

[J].

Influence of scanning strategy and parameter on microstructural feature, residual stress and performance of Sc and Zr modified Al-Mg alloy produced by selective laser melting

[J].

Corrosion behavior of Al-6.8Zn-2.2Mg-Sc-Zr alloy with high resistance to intergranular corrosion

[J].

Biologically competitive effect of Desulfovibrio desulfurican and Pseudomonas stutzeri on corrosion of X80 pipeline steel in the Shenyang soil solution

[J].

Biofouling and corrosion of magnesium alloys WE43 and AM60 by Chlorella vulgaris in artificial seawater

[J].

Fluorescent nanosensors reveal dynamic pH gradients during biofilm formation

[J].\n Understanding the dynamic environmental microniches of biofilms will permit us to detect, manage and exploit these communities. The components and architecture of biofilms have been interrogated in depth; however, little is known about the environmental microniches present. This is primarily because of the absence of tools with the required measurement sensitivity and resolution to detect these changes. We describe the application of ratiometric fluorescent pH-sensitive nanosensors, as a tool, to observe physiological pH changes in biofilms in real time. Nanosensors comprised two pH-sensitive fluorophores covalently encapsulated with a reference pH-insensitive fluorophore in an inert polyacrylamide nanoparticle matrix. The nanosensors were used to analyse the real-time three-dimensional pH variation for two model biofilm formers: (i) opportunistic pathogen\n Pseudomonas aeruginosa\n and (ii) oral pathogen\n Streptococcus mutans\n. The detection of sugar metabolism in real time by nanosensors provides a potential application to identify therapeutic solutions to improve oral health.\n

Effect of pH on thickness and ion content of the oxide film on aluminum in NaCl media

[J].

Theoretical modeling of the possibility of acid producing bacteria causing fast pitting biocorrosion

[J].