国内外研究表明,阴极保护技术在海洋工程防护领域已形成较为系统的应用体系。Al-Zn-In系牺牲阳极是目前研究最广且应用最多的Al基牺牲阳极材料[8]。Bertolini等[9]研究表明,对于浸入3.5% (质量分数) NaCl溶液的砂浆柱,Al-Zn-In牺牲阳极可以有效抑制内部钢筋的锈蚀,但对于已锈蚀钢筋的防腐效果有限。Xie等[10]在传统铝基牺牲阳极中添加改性锐钛矿TiO2纳米管,得到了保护电流效率更高的新型Al光阳极复合材料,但目前该材料仍处于实验室阶段。此外,牺牲阳极法存在易受杂散电流影响、工作寿命较短且维护复杂等问题,因此外加电流法在实际海洋工程中的应用更加广泛[11]。外加电流法的成功应用在一定程度上依赖于阳极材料的发展,目前广泛应用的阳极材料包括高硅铸铁[12]和混合金属氧化物(MMO)[13]等。碳纤维增强聚合物(CFRP)材料因其轻质、强度高等优点,已被广泛应用于混凝土结构的加固[14]。同时其优良的导电性和耐蚀性使其成为具有发展前景的阳极材料[7]。Zhu等[15]证实CFRP材料在NaOH溶液、NaCl溶液和模拟孔隙溶液中的电化学与力学性能良好,论证了CFRP作为阳极材料的可行性。Lee-Orantes等[16]采用CFRP作为钢筋混凝土结构的阴极保护系统阳极材料,在150 d的保护实验中取得了良好的防护效果。胡霁月[17]对不同初始锈蚀率的钢筋混凝土桩基外覆CFRP并施加保护电流,研究表明不同锈蚀率下的最佳保护电流密度不同,对腐蚀程度为6%和12%的桩基,20 mA/m2的电流密度可以提供最佳阻锈效果。

本文将RC桩基置于课题组搭建的室内海洋环境模拟系统中,采用通电加速锈蚀技术使内部钢筋达到预设的理论锈蚀率,随后在干湿区包裹复合CFRP辅助阳极的纤维编织网增强混凝土(TRC)材料,构建阴极保护体系。利用无损监测方法,研究不同锈蚀率和保护时间下RC桩的表面裂纹拓展与电化学参数演变规律,为海工RC桩的腐蚀与防护提供参考。

1 实验方法

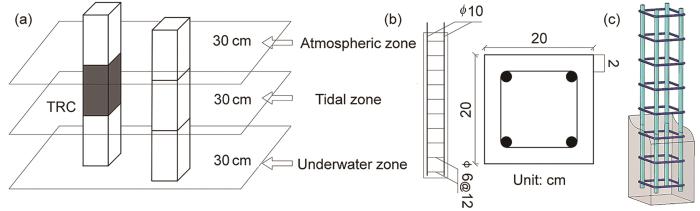

试件制备尺寸如图1所示的RC桩,高度为90 cm,横截面为20 cm × 20 cm的矩形。从上到下分为大气区(30 cm)、干湿区(30 cm)和水下区(30 cm)。纵向钢筋选用直径10 mm的HRB335钢筋,箍筋选用直径6 mm的HPB235钢筋,钢筋保护层厚度为2 cm。混凝土的混合比(质量比)为0.38∶0.8∶0.2∶1.11∶2.72(水∶水泥∶粉煤灰∶砂∶石)。水泥标号为P.O32.5,细骨料选用细度模数为2.82的河砂,骨料选用粒径为5~20 mm的石子。制备出的混凝土28 d立方体抗压强度为34.8 MPa。

图1

图1

RC试件尺寸及钢筋加固示意图

Fig.1

Schematic diagrams of dimension (a) and reinforcement (b, c) of reinforced concrete specimen

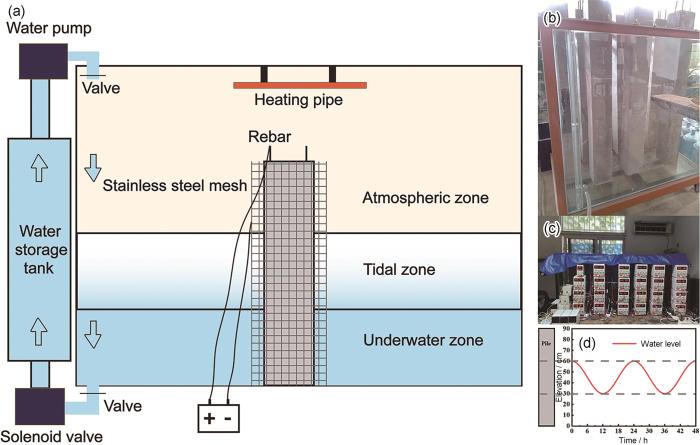

图2

图2

海洋环境模拟系统示意图

Fig.2

Schematic diagram of marine environment simulation system (a) on-site setup (b), DC power supplies (c) and water-level variation curve (d)

式中,t为通电时间,z为电荷数(Fe2+为+2),F为Faraday常数(96485 C/mol),Δm为理论质量损失,M为相对原子质量,I为电流密度(150 μA/cm2),S为钢筋的暴露面积。

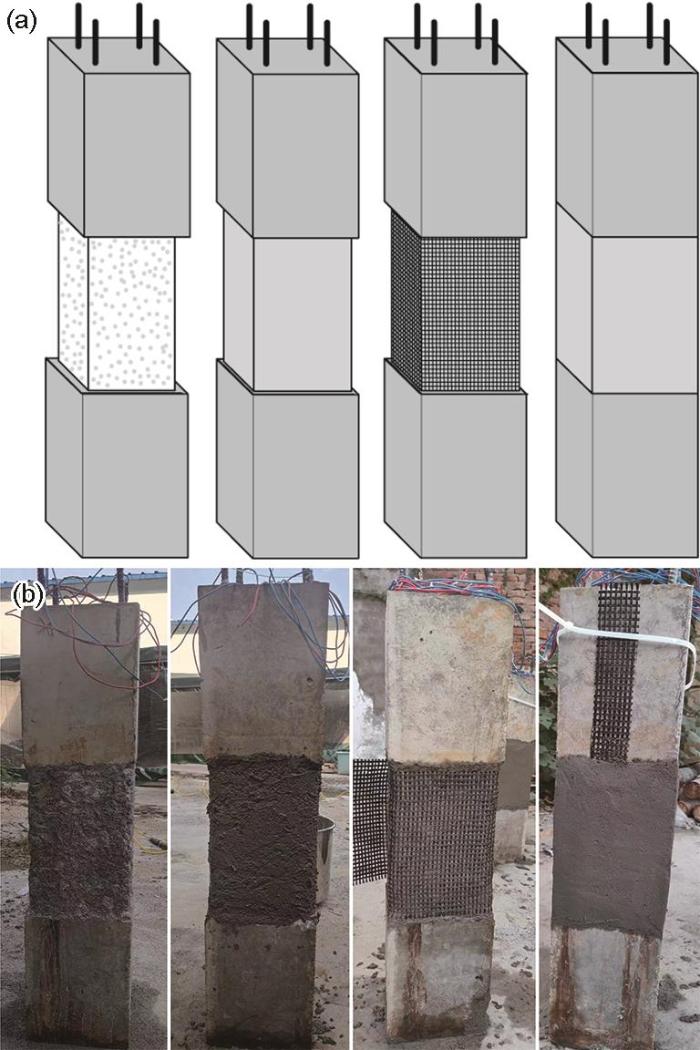

加速锈蚀阶段结束后,在RC桩侧面的干湿区进行凿毛和外包TRC,具体步骤如图3所示。TRC层养护28 d后,将RC桩重新放入试验水箱中,将混凝土内部纵向钢筋作为阴极连接电源的负极,CFRP作为阳极连接电源的正极,以此对RC桩施加阴极保护措施。保护电流大小设为563.3 µA,对应的保护电流密度为20 mA/m2,阴极保护的施加周期为90 d。

图3

图3

粘贴TRC保护材料的施工流程与示意图

Fig.3

Construction process (a) and physical schematic diagram (b) of pasting TRC protective material

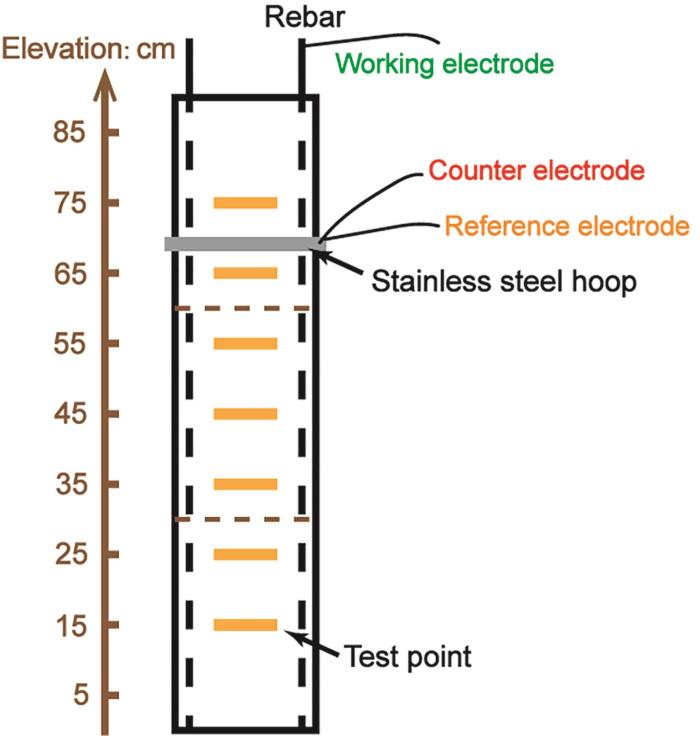

在RC桩的15~75 cm的高度范围内,每隔10 cm设置为一个测试点位。采用DH7000D电化学工作站进行线性极化和交流阻抗测试。具体来说,工作电极(WE)连接RC桩内部的纵向钢筋,每个测点处的工作电极面积为3.14 cm2,参比电极(RE)和对电极(CE)则连接至一个可沿桩体自由移动的不锈钢箍,如图4所示。以此采集不同理论锈蚀率(5%、10%和15%)和不同阴极保护时间时(30、60和90 d)的RC桩不同高度处的极化电阻(Rp)和电化学阻抗谱(EIS)。线性极化测试的扫描速率为0.1667 mV/s,电位范围是相对于开路电位(OCP)的-10~10 mV;EIS测试则使用15 mV的振幅,激励信号为频率105~10-2 Hz的正弦波。

图4

2 结果与讨论

2.1 表面形貌与分形维数

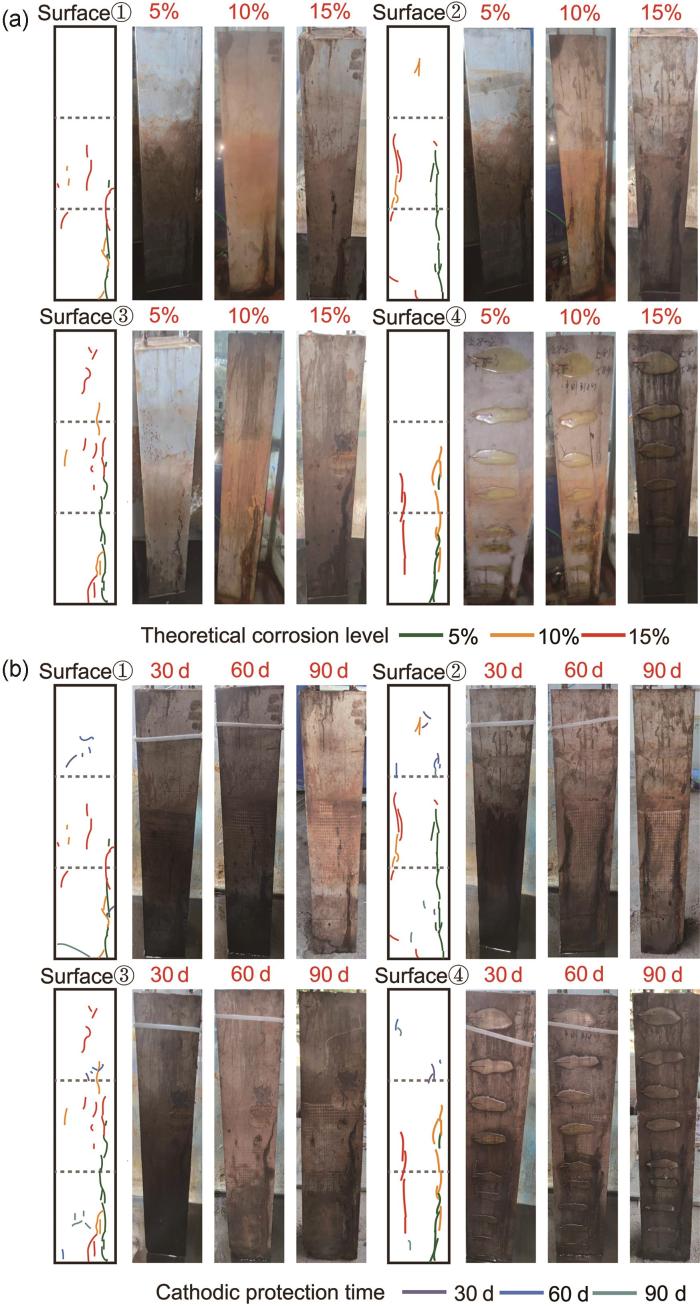

基于图5的裂纹形貌图分析表明,微裂纹初始萌生于干湿区和水下区。当锈蚀率达到5%时,纵向裂纹相互连接,在桩的每侧分别形成一或两条主裂缝,并随锈蚀发展而纵向扩展。当锈蚀率超过10%时,干湿区与水下区的微裂纹数量显著增加。至严重腐蚀阶段(15%),主裂缝在水下区呈现横向桥接趋势。在阴极保护的前30 d,裂纹拓展趋缓,而30 d之后的新裂纹萌生数量略有回升。由于干湿区外附了TRC保护层,因此裂纹的生长主要集中在大气区和水下区。

图5

图5

锈蚀与阴极保护阶段的裂纹拓展

Fig.5

Propagation of cracks during corrosion (a) and cathodic protection (b) stages

分形维数可定量表征混凝土表面裂纹的复杂程度,二者呈现正相关关系[20]。一般来说,锈蚀阶段的分形维数大小随锈蚀时间的延长而上升,而阴极保护阶段的数值则相对稳定,甚至出现一定程度的下降[21]。基于图5中的裂纹形貌复绘图像,使用Image J软件(盒计数法)计算表面裂纹的分形维数[21],结果如图6所示。随着锈蚀的发展,整体呈上升趋势。锈蚀率为15%时,大气区、干湿区和水下区的分形维数分别是1.206、1.317和1.381。阴极保护阶段的分形维数波动幅度更小,表明裂缝的复杂程度在该阶段没有明显变化[22]。施加90 d的保护电流后,大气区和水下区的分形维数大小为1.235和1.391。值得注意的是,水下区分形维数始终高于其他区域,这与裂纹桥接形成的复杂网状结构相关。同时裂纹局部细节拓展的随机性会在一定程度上影响整体的自相似结构,进而影响分形维数的值[23]。因此,分形维数与锈蚀率之间的定量关系需进一步研究。

图6

图6

锈蚀与阴极保护阶段的分形维数

Fig.6

Fractal dimensions during corrosion (a) and cathodic protection (b) stages

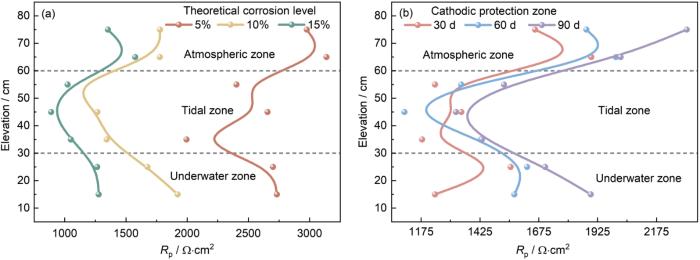

2.2 线性极化电阻

图7为不同理论锈蚀率和保护时间下的Rp。总的来说,Rp随着锈蚀进程而显著减小,且锈蚀率5%~10%阶段的降幅高于10%~15%的阶段。当锈蚀率为15%时,水下区、干湿区和大气区的Rp较5%的情况分别平均下降了46.8%、42.9%和47.8%。同时在整个加速锈蚀阶段干湿区的Rp 明显小于其他区域。揭示干湿区腐蚀最为严重,水下区次之,大气区的腐蚀情况较轻。

图7

图7

不同阶段不同高度处的Rp

Fig.7

Rp values at different heights during corrosion (a) and cathodic protection (b) stages

阴极保护阶段各区域Rp随保护时间增加而呈现波动上升趋势,前30 d升幅最大。经90 d保护后,水下区、干湿区和大气区的Rp较保护前的数值分别平均上升了49.39%、44.90%和41.51%,总体恢复到锈蚀率为5%~10%的水平。结果表明,该电流密度可有效抑制严重锈蚀RC桩的进一步劣化,其中大气区防护效果最优,这与其无水流扰动的环境更利于钢筋钝化膜再生密切相关[24]。

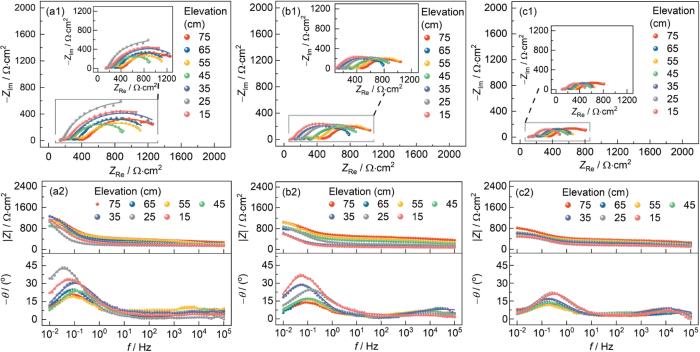

2.3 EIS

图8

图8

RC桩在加速锈蚀阶段的EIS谱图

Fig.8

EIS spectra of RC pile during accelerated corrosion stage: (a) 5%, (b) 10%, (c) 15%

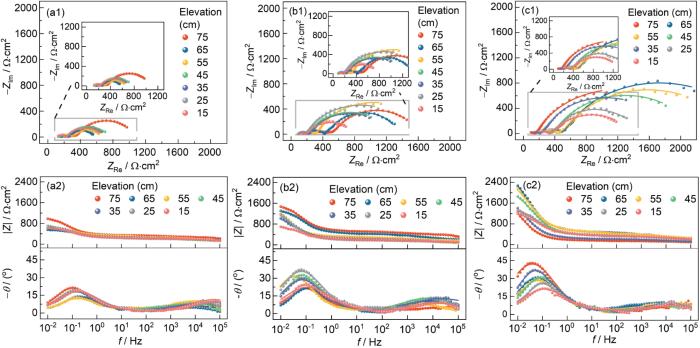

图9

图9

RC桩在阴极保护阶段的EIS谱图

Fig.9

EIS spectra of RC pile during cathodic protection stage: (a) 30 d, (b) 60 d, (c) 90 d

Nyquist图的低频区容抗弧半径(rlow)表征电荷转移电阻(Rct),其值与钢筋耐蚀性正相关[27]。加速锈蚀阶段,随锈蚀率的提升,各高程rlow呈持续收缩趋势。腐蚀程度为5%时,RC桩的不同区域存在锈蚀差异,干湿区的rlow小于大气区,进一步小于水下区。随锈蚀加剧,区域差异性减弱。至锈蚀率达到15%时,各高程rlow趋近。进入阴极保护阶段,各高程rlow均有所增加,表明钢筋耐蚀性逐步恢复。在阴极保护施加的前60 d,各区域数值增幅相近,之后水下区rlow趋于稳定,而干湿区和大气区在第60~90 d仍持续增长。

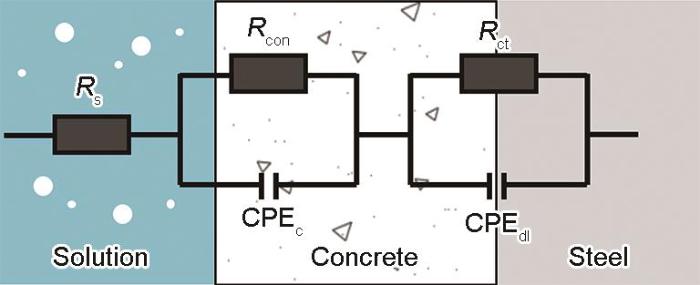

基于对阻抗谱特征的讨论,确定了图10所示的等效电路,并利用Zview软件对结果进行拟合。该电路中的Rs、Rcon和Rct和分别表示溶液电阻、混凝土覆盖层电阻和电荷转移电阻,CPEc和CPEdl分别表示混凝土覆盖层电容和双电层电容。

图10

图8和9显示原始数据与拟合曲线吻合良好,结果详见图11及表1。较高的Rcon值表明混凝土覆盖层致密,而较低的Rcon值则反映其松散或脱落[30]。加速锈蚀阶段,随锈蚀率增加,各高程Rcon均呈下降趋势。尤其是锈蚀率10%~15%的阶段Rcon的降速显著加快,这与锈蚀产物积累引发混凝土覆盖层集中脱落有关。各锈蚀阶段中,大气区Rcon始终高于干湿区和水下区,源于后两者更易受Cl-渗透与水侵蚀共同作用[3]。阴极保护阶段,干湿区因TRC保护材料包裹致Rcon大幅提升,而水下区与大气区仅出现小幅波动性上升,表明外加电流阴极保护对混凝土覆盖层修复效果有限,或该测试条件下混凝土电化学状态易受较大干扰[31]。

图11

图11

在腐蚀和阴极保护阶段不同高度处的Rcon和Rct

Fig.11

Rcon(a, c) and Rct (b, d) at corrosion stage (a, b) and cathodic protection stage (c, d)

表1 RC桩阻抗谱数据的拟合结果

Table 1

| Test stage | Test time | Elevation / cm | Rs / Ω·cm2 | Rcon / Ω·cm2 | CPEc / S·sec n ·cm-2 | n1 | Rct / Ω·cm2 | CPEdl / S·sec n ·cm-2 | n2 | χ2 |

|---|---|---|---|---|---|---|---|---|---|---|

| Corrosion stage | 33 d | 15 | 66.3 | 166.5 | 6.32 × 10-4 | 0.19 | 1398.2 | 3.79 × 10-3 | 0.73 | 2.22 × 10-2 |

| (5%) | 25 | 45.8 | 198.6 | 9.86 × 10-4 | 0.24 | 1565.6 | 6.84 × 10-3 | 0.85 | 1.56 × 10-2 | |

| 35 | 59.4 | 322.2 | 5.09 × 10-4 | 0.14 | 1213.4 | 2.65 × 10-3 | 0.71 | 5.64 × 10-2 | ||

| 45 | 126.7 | 159.4 | 1.67 × 10-4 | 0.36 | 721.5 | 2.96 × 10-3 | 0.72 | 3.37 × 10-2 | ||

| 55 | 137.2 | 302.0 | 1.12 × 10-4 | 0.37 | 821.2 | 3.04 × 10-3 | 0.75 | 9.63 × 10-2 | ||

| 65 | 63.4 | 368.6 | 8.79 × 10-5 | 0.21 | 926.2 | 3.31 × 10-3 | 0.78 | 2.28 × 10-2 | ||

| 75 | 75.6 | 565.7 | 3.46 × 10-4 | 0.13 | 924.8 | 3.12 × 10-3 | 0.72 | 3.05 × 10-2 | ||

| 65 d | 15 | 64.4 | 120.3 | 4.93 × 10-3 | 0.13 | 613.2 | 3.15 × 10-3 | 0.83 | 2.66 × 10-2 | |

| (10%) | 25 | 97.6 | 130.6 | 5.52 × 10-4 | 0.25 | 774.3 | 3.21 × 10-3 | 0.64 | 2.72 × 10-2 | |

| 35 | 122.8 | 264.5 | 3.89 × 10-5 | 0.42 | 633.4 | 2.57 × 10-3 | 0.77 | 2.58 × 10-2 | ||

| 45 | 101.2 | 153.1 | 6.76 × 10-5 | 0.46 | 622.1 | 3.62 × 10-3 | 0.62 | 2.35 × 10-2 | ||

| 55 | 141.3 | 192.8 | 4.67 × 10-5 | 0.44 | 714.2 | 3.39 × 10-3 | 0.72 | 6.46 × 10-3 | ||

| 65 | 65.1 | 341.6 | 4.23 × 10-4 | 0.15 | 476.9 | 3.86 × 10-3 | 0.79 | 2.63 × 10-2 | ||

| 75 | 77.5 | 484.9 | 1.39 × 10-4 | 0.19 | 602.2 | 3.65 × 10-3 | 0.73 | 6.80 × 10-3 | ||

| 98 d | 15 | 52.3 | 62.5 | 3.46 × 10-5 | 0.52 | 355.2 | 2.71 × 10-3 | 0.75 | 4.12 × 10-2 | |

| (15%) | 25 | 65.6 | 65.4 | 9.21 × 10-5 | 0.44 | 355.8 | 3.43 × 10-3 | 0.72 | 3.64 × 10-2 | |

| 35 | 124.4 | 125.8 | 4.15 × 10-5 | 0.50 | 413.3 | 3.57 × 10-3 | 0.76 | 3.57 × 10-2 | ||

| 45 | 138.9 | 147.2 | 8.30 × 10-5 | 0.42 | 332.4 | 3.32 × 10-3 | 0.63 | 4.32 × 10-2 | ||

| 55 | 158.0 | 171.6 | 4.79 × 10-5 | 0.49 | 357.5 | 3.71 × 10-3 | 0.64 | 3.47 × 10-2 | ||

| 65 | 69.7 | 264.0 | 2.64 × 10-4 | 0.16 | 337.3 | 4.56 × 10-3 | 0.76 | 1.65 × 10-2 | ||

| 75 | 71.5 | 341.0 | 1.67 × 10-4 | 0.18 | 483.9 | 3.85 × 10-3 | 0.62 | 1.77 × 10-2 | ||

| Cathodic protection | 30 d | 15 | 50.4 | 132.7 | 7.79 × 10-6 | 0.59 | 475.8 | 3.43 × 10-3 | 0.69 | 6.13 × 10-2 |

| stage | 25 | 61.6 | 132.3 | 3.11 × 10-5 | 0.46 | 469.1 | 3.47 × 10-3 | 0.60 | 4.35 × 10-2 | |

| 35 | 100.1 | 564.5 | 5.98 × 10-5 | 0.43 | 453.2 | 3.85 × 10-3 | 0.76 | 4.97 × 10-2 | ||

| 45 | 114.5 | 537.6 | 1.02 × 10-4 | 0.42 | 485.7 | 3.89 × 10-3 | 0.77 | 3.70 × 10-2 | ||

| 55 | 141.7 | 509.1 | 6.43 × 10-6 | 0.66 | 322.5 | 9.15 × 10-4 | 0.43 | 4.53 × 10-2 | ||

| 65 | 54.8 | 120.9 | 7.26 × 10-5 | 0.48 | 304.6 | 3.90 × 10-3 | 0.77 | 5.76 × 10-2 | ||

| 75 | 45.6 | 396.7 | 1.98 × 10-4 | 0.17 | 682.3 | 4.31 × 10-3 | 0.84 | 3.35 × 10-2 | ||

| 60 d | 15 | 66.4 | 185.5 | 9.56 × 10-6 | 0.58 | 654.7 | 2.05 × 10-3 | 0.67 | 6.88 × 10-2 | |

| 25 | 72.6 | 264.2 | 9.89 × 10-5 | 0.36 | 1383.4 | 2.10 × 10-4 | 0.75 | 6.73 × 10-2 | ||

| 35 | 135.4 | 543.5 | 3.10 × 10-5 | 0.45 | 1002.1 | 2.18 × 10-3 | 0.72 | 6.26 × 10-2 | ||

| 45 | 158.5 | 589.8 | 1.90 × 10-5 | 0.51 | 1033.3 | 2.03 × 10-3 | 0.78 | 7.64 × 10-2 | ||

| 55 | 159.3 | 580.4 | 1.58 × 10-4 | 0.44 | 1388.2 | 5.49 × 10-3 | 0.77 | 2.48 × 10-2 | ||

| 65 | 91.9 | 237.5 | 1.45 × 10-5 | 0.57 | 785.8 | 1.33 × 10-3 | 0.79 | 3.01 × 10-2 | ||

| 75 | 60.0 | 305.1 | 2.85 × 10-4 | 0.15 | 1067.9 | 3.67 × 10-3 | 0.86 | 3.34 × 10-2 | ||

| 90 d | 15 | 51.7 | 227.2 | 1.01 × 10-4 | 0.39 | 995.6 | 2.48 × 10-3 | 0.67 | 6.69 × 10-2 | |

| 25 | 86.2 | 130.6 | 3.72 × 10-6 | 0.68 | 1134.2 | 1.02 × 10-3 | 0.52 | 1.16 × 10-2 | ||

| 35 | 130.5 | 603.2 | 1.32 × 10-5 | 0.52 | 1644.9 | 1.12 × 10-3 | 0.65 | 1.53 × 10-2 | ||

| 45 | 136.6 | 574.9 | 1.74 × 10-4 | 0.24 | 1795.4 | 2.09 × 10-3 | 0.79 | 4.36 × 10-2 | ||

| 55 | 139.3 | 551.5 | 1.09 × 10-4 | 0.32 | 2144.2 | 1.87 × 10-3 | 0.54 | 5.75 × 10-2 | ||

| 65 | 71.5 | 125.0 | 6.92 × 10-5 | 0.45 | 2411.5 | 2.13 × 10-3 | 0.77 | 2.78 × 10-2 | ||

| 75 | 50.9 | 313.6 | 6.91 × 10-5 | 0.20 | 2089.2 | 1.65 × 10-3 | 0.73 | 4.21 × 10-2 | ||

电荷转移电阻Rct的变化同样呈现显著规律性。随锈蚀率增加,各高程的Rct均显著下降并趋近,表明电荷传递阻力降低。施加阴极保护后,Rct值开始回升,其中大气区的增幅略高于干湿区,进一步高于水下区。经90 d的保护后,大气区、干湿区和水下区的Rct较保护前分别回升了448%、406%和200%。该趋势与低频区rlow变化规律一致,印证阴极保护对钢筋耐蚀性提升的差异化效果。

2.4 不均匀锈蚀与阴极保护差异性讨论

根据以上的研究结果,RC桩在干湿区、水下区与大气区表现出显著的锈蚀及阴极保护效果差异。加速锈蚀阶段,干湿区因持续干湿循环增强混凝土毛细孔吸收作用,加速了氧气和Cl-的渗透,导致较高腐蚀速率并破坏钢筋表面完整性[3]。水下区得益于混凝土水化作用强化的基体强度,叠加低Cl-的渗透率和缺氧环境,钢筋腐蚀进程最慢。大气区虽与氧气接触充分,但Cl-的含量最低,腐蚀速率处于中间水平。

这种不均匀锈蚀直接影响阴极保护效果:腐蚀较轻的水下区对保护电流需求较低,过量电流易引发氢脆风险[32]。而腐蚀严重的干湿区因电流分布不均难以获得充分保护。钢筋钝化膜破坏与锈蚀产物堆积加剧表面不规则性,进一步干扰保护电流的均匀分布。因此,需针对不同区域特性优化保护系统,例如对不同区域的RC桩施加不同大小的保护电流,或采用不同的保护方法,其具体策略有待进一步研究。

Note: 33 d (5%), 65 d (10%) and 98 d (15%) refer to the points in time corresponding to theoretical corrosion degrees of 5%, 10%, 15%, respectively

3 结论

(1) 混凝土表面裂纹在锈蚀阶段主要萌发于水下区和干湿区,阴极保护阶段则集中在水下区和大气区。各区域分形维数随锈蚀进程波动性上升,15%锈蚀率下大气区、干湿区和水下区的分形维数分别为1.206、1.317和1.381。阴极保护阶段分形维数相对稳定,90 d后大气区和水下区数值分别为1.235和1.391。

(2) Rp随锈蚀率增加显著下降,15%锈蚀率时水下区、干湿区和大气区数值较5%锈蚀率分别降低46.8%、42.9%和47.8%。干湿区Rp始终低于其他区域,表明其腐蚀速率最高。经90 d阴极保护后,各区域Rp较保护前分别回升49.39% (水下区)、44.90%(干湿区)和41.51% (大气区)。

(3) 低频区相位角分析显示,加速锈蚀阶段干湿区相位角最小,锈蚀程度最严重;阴极保护90 d后大气区恢复幅度最大,区域差异显著。

(4) Rcon随锈蚀率升高持续下降,干湿区和水下区降幅尤为显著。阴极保护阶段干湿区因TRC材料包裹使Rcon大幅提升,而大气区和水下区仅呈现小幅波动性增长。

(5) Rct随锈蚀率升高显著降低,随保护时长延长显著回升。90 d阴极保护后,大气区、干湿区和水下区的值较保护前分别平均回升了448%、406%和200%

参考文献

Evaluation of steel corrosion-induced concrete damage using electrical resistivity measurements

[J].

Crevice corrosion of reinforcing steel in carbonated simulated concrete pore solutions contaminated by chloride

[J].

Steel corrosion rates in concrete in contact to sea water

[J].

Cathodic protection of new and old reinforced concrete structures

[J].

State-of-the-art review of cathodic protection for reinforced concrete structures

[J].Cathodic protection (CP) limits the corrosion of a metal surface by making it the cathode of an electrochemical cell. This can be achieved either by using a more active sacrificial anode to create a driving current, or by using inert anodes and impressing a current onto the cathode surface using an external direct current (DC) source. Impressed current cathodic protection (ICCP) is preferred where widespread protection is required, particularly in reinforced concrete structures. ICCP needs a constant DC power supply that is usually provided through a grid connection or independent generators. This paper presents the currently available CP systems for reinforced concrete, particularly ICCP, and the possibility of using self-sufficient and renewable energy systems. The potential for overcoming the mismatch (due to intermittent current) in energy provision from renewable sources with energy needs for CP (constant current) is discussed by exploring methods of storing energy and examining the level of protection provided by intermittent current. Areas that require further research to optimise the design of such systems are highlighted.

Protection performance of the submerged sacrificial anode on the steel reinforcement in the conductive carbon fiber mortar column in splash zones of marine environments

[J].

Bond performance between corroded steel bars and concrete in cathodic protection system with CFRP as anode

[J].

Research progress of sacrificial anode materials in deep sea

[J].

牺牲阳极材料在深海中的研究进展

[J].

Prevention of steel corrosion in concrete exposed to seawater with submerged sacrificial anodes

[J].

Design of new al photoanode composite for cathodic protection based on photocatalytic material and sacrificial anode

[J].

A critical review of the science and engineering of cathodic protection of steel in soil and concrete

[J].After a century of history of cathodic protection (CP) of iron and steel, this paper critically reviews the state of the art in the science and engineering and assesses the fitness of CP as an effective technology to tackle the challenges related to infrastructure corrosion. This paper focuses on CP of iron-based alloys embedded in porous media, such as soil or concrete, as these two major applications of CP technology share many similarities. First, the scientific understanding of CP is reviewed and different competing theories are discussed. There is wide agreement that corrosion protection of steel is achieved thanks to a combination of immediate activation polarization and the beneficial changes in electrolyte chemistry that are gradually occurring at the steel surface when a protection current is flowing toward a steel electrode. A major and well-documented technological advantage of these "chemical effects" is that the protective effect of CP is maintained during temporal loss of protection current, e.g., due to survey work related shut-offs or anodic interference. However, the relationships between these chemical concentration changes in the porous medium and the protection current are complex, and, as this review shows, cannot reliably be described with state-of-the-art approaches. Moreover, in this paper, different hypotheses for the mechanism of corrosion protection in heterogeneous situations (galvanic elements), as they are generally occurring in practice, are discussed. It is revealed that understanding the working mechanism of CP in heterogeneous conditions remains a critical scientific challenge. The longstanding debate concerns the question whether CP results mainly in a reduction of number and size of actively corroding areas, or in a reduction of the corrosion rate at the actively corroding sites. Additionally, the literature addressing the interrelation between microbiologically influenced corrosion and CP is here reviewed, and recent progress as well as limitations of the existing literature are highlighted. In a second part, engineering practice and CP protection criteria are reviewed. It is found that the approaches stipulated in international standard are unreliable. This can be traced back to the assessment criteria being empirical and incapable of adequately taking into account the complexity of the underlying processes. Finally, recommendations for future developments are made. Particular opportunities are seen in embracing the progress made in numerical modeling, such as reactive transport modeling in porous media, and considering the interdependence between the involved processes, namely the interdependence between transport processes, chemical reactions, and electrode kinetics.

Influence of auxiliary anode parameter optimization on the performance of cathodic protection system

[J].

辅助阳极参数优化对阴保系统性能的影响

[J].

Discussion on the service life of MMO noble metal oxide anode

[J].

MMO贵金属氧化物辅助阳极使用寿命的探讨

[J].

Durability of CFRP-confined seawater sea-sand concrete (SSC) columns under wet-dry cycles in seawater environment

[J].

Mechanical and electrochemical performance of carbon fiber reinforced polymer in oxygen evolution environment

[J].Carbon fiber-reinforced polymer (CFRP) is recognized as a promising anode material to prevent steel corrosion in reinforced concrete. However, the electrochemical performance of CFRP itself is unclear. This paper focuses on the understanding of electrochemical and mechanical properties of CFRP in an oxygen evolution environment by conducting accelerated polarization tests. Different amounts of current density were applied in polarization tests with various test durations, and feeding voltage and potential were measured. Afterwards, tensile tests were carried out to investigate the failure modes for the post-polarization CFRP specimens. Results show that CFRP specimens had two typical tensile-failure modes and had a stable anodic performance in an oxygen evolution environment. As such, CFRP can be potentially used as an anode material for impressed current cathodic protection (ICCP) of reinforced concrete structures, besides the fact that CFRP can strengthen the structural properties of reinforced concrete.

Cathodic protection in reinforced concrete elements, using carbon fibers base composites

[J].

Experimental investigation of corroded RC column under CFRP/conductive adhesive strengthening and cathodic protecting

[D].

碳纤维布/导电胶加固与阴极保护锈蚀RC柱机理及性能研究

[D].

Numerical and experimental investigation on the chloride ion resistance of reinforced concrete piles externally bonded with CFRP sheets under dry-wet cycles

[J].

Three-dimensional corrosion pit measurement and statistical mechanical degradation analysis of deformed steel bars subjected to accelerated corrosion

[J].

Research on mechanical characteristics, fractal dimension and internal structure of fiber reinforced concrete under uniaxial compression

[J].

Fractal-fracture analysis and characterization of impact-fractured surfaces in different types of concrete using digital image analysis and 3D nanomap laser profilometery

[J].

Image analysis and fractal geometry to characterize soil desiccation cracks

[J].

On the fractal dimension of fracture surfaces of concrete elements

[J].

Passivation and electrochemical behavior of 316L stainless steel in chlorinated simulated concrete pore solution

[J].

Corrosion resistance of 2205 stainless steel bar in modified coral concretes

[J].

改性珊瑚混凝土中2205不锈钢钢筋的耐蚀性研究

[J].对比了直接掺入粉煤灰、水泥浆或水泥-偏高岭土复合浆增强处理珊瑚粗骨料等改性方案对珊瑚混凝土中2205不锈钢钢筋腐蚀速率的影响。结果表明,珊瑚混凝土中2205不锈钢钢筋长期处于钝化状态;掺入粉煤灰可降低2205不锈钢钢筋腐蚀速率,但直接掺入的粉煤灰会引起珊瑚混凝土强度明显下降。采用P.O 52.5水泥浆或P.O 52.5水泥 + 偏高岭土复合浆增强珊瑚粗骨料,再用增强粗骨料制备的珊瑚混凝土强度与对照组试样强度差异较小,但骨料增强的珊瑚混凝土中2205不锈钢钢筋腐蚀速率明显降低,采用P.O 52.5水泥 + 偏高岭土复合浆增强粗骨料的试样中2205不锈钢钢筋腐蚀速率最低。综合考虑,P.O 52.5水泥 + 偏高岭土复合浆增强珊瑚粗骨料,其制备的珊瑚混凝土具有较高强度,2205不锈钢钢筋的腐蚀速率最低,这种复合浆增强珊瑚粗骨料方案是提高不锈钢钢筋珊瑚混凝土结构耐久性的有效途径。

EIS equivalent circuit model prediction using interpretable machine learning and parameter identification using global optimization algorithms

[J].

Electrochemical impedance spectroscopy─A tutorial

[J].

Electrochemical corrosion behavior of 2304 duplex stainless steel in a simulated pore solution in reinforced concrete serving in marine environment

[J].

2304双相不锈钢钢筋在混凝土孔隙模拟液中的电化学腐蚀行为研究

[J].

EIS study of passivation of austenitic and duplex stainless steels reinforcements in simulated pore solutions

[J].

Monitoring reinforcement corrosion and corrosion-induced cracking using non-destructive x-ray attenuation measurements

[J].

The corrosion-inhibitory influence of graphene oxide on steel reinforcement embedded in concrete exposed to a 3.5M NaCl solution

[J].