随着全球能源需求不断增长,油气勘探逐步向深层超深层发展,定向钻井技术愈发重要,其主要依靠随钻测量系统来精确定位井眼位置。无磁钻铤作为其中的关键部件,不仅为钻头钻进提供所需的压力和刚性,还为随钻测量系统提供了一个无磁干扰的环境[1]。P550不锈钢作为一种高氮铬锰奥氏体不锈钢,因其高强度、低磁导率以及良好的耐蚀性,成为制造无磁钻铤的常用钢种。但其在服役过程中经常受到井壁磨损和钻井液腐蚀的共同作用,导致钻铤表面损伤甚至失效,而钻铤失效将引发严重的安全事故并造成巨大的经济损失[1,2]。因此,改善P550不锈钢的抗腐蚀磨损性能对于保障钻井安全和控制成本具有重要意义。激光熔覆技术作为一种先进的表面改性技术,能够对受损的无磁钻铤表面进行修复和加固,与传统表面改性技术相比,其具有强度高、稀释率低、热影响区小、界面呈冶金结合等特点[3]。

由于激光熔覆在制备熔覆层方面具有的独特优势,已有大量研究针对熔覆层的组织结构及其服役性能进行了深入的探讨。Song等[4]在P550不锈钢表面激光熔覆制备了IN625熔覆层,研究发现在富含Nb、Mo的枝晶间,Laves相、Al2O3颗粒与基体间形成微观电偶,磨损区与未磨损区间形成宏观电偶,这些电偶效应协同机械磨损,共同加速了熔覆层在3.5%(质量分数) NaCl中的腐蚀磨损失效。Yang等[5]在45钢表面激光熔覆了Ni625-xCr3C2熔覆层,研究表明Cr3C2的添加可细化晶粒,并且其在激光熔覆过程中分解形成了Cr7C3、Cr23C6等多种硬质碳化物相,提升了硬度,随Cr3C2增加,熔覆层摩擦系数与磨损率降低,在耐蚀性方面,Cr3C2的加入有助于形成具有修复能力的Cr2O3钝化膜,从而提升熔覆层的耐蚀性。Sun等[6]在不锈钢基体上熔覆了Fe基熔覆层,研究表明,在腐蚀磨损过程中,其磨损表面会形成一层富Fe2+和Fe3+的氧化膜,在磨损初期原有钝化膜被破坏,但随后形成的氧化膜促进了表面再钝化,起到了抑制腐蚀的屏障作用。

1 实验方法

1.1 样品制备

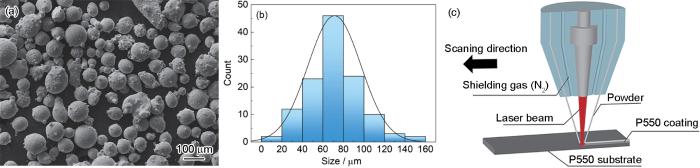

本文采用激光熔覆的方法,以P550不锈钢粉末为原料,在无磁钻铤P550不锈钢基体上制备了P550激光熔覆层。P550不锈钢及其粉末的化学成分(质量分数,%)为:Cr 18.30~21.00、Mn 20.50~21.60、Mo ≥ 0.50、Ni ≥ 1.40、N ≥ 0.60、C ≤ 0.06、Si ≤ 0.60、Fe余量。

图1

图1

P550不锈钢粉末的形貌、粒径分布及激光熔覆示意图

Fig.1

Morphology (a) and particle size distribution (b) of P550 stainless steel powder and schematic diagram of the laser cladding process (c)

无磁钻铤P550不锈钢基体和P550不锈钢熔覆层试样尺寸为10 mm × 10 mm × 10 mm。试样经240#~2000#SiC砂纸逐级打磨后,用2.5 μm金刚石抛光膏抛光,随即用去离子水和酒精清洗并吹干;将上述P550不锈钢基体及熔覆层试样在6 V电压下浸入10%草酸溶液中进行电解腐蚀,时长约30 s,待试样表面呈黯淡状态后,观察其光学显微形貌;将P550不锈钢熔覆层试样在2 V电压下浸入5%盐酸甲醇溶液中进行电解腐蚀,时长约3 s,随后观察其形貌。

1.2 微观结构表征

采用X射线衍射仪(XRD,Rigaku Ultima IV)对P550不锈钢基体及熔覆层进行物相分析,扫描速度为2 (°)/min,扫描角度为20°~100°。采用金相显微镜(MX6R)观察P550不锈钢基体和熔覆层的金相组织。采用扫描电子显微镜(SEM,EVO MA15)观察P550不锈钢基体和熔覆层的微观组织和磨损形貌,同时结合能谱仪(EDS,X-MAX N)分析不同区域的元素变化。采用三维光学轮廓仪(GTK-16-0314)测量磨痕的三维轮廓和平均截面轮廓。采用X射线光电子能谱仪(XPS,Thermoscientific NEXSA)对磨损后表面进行元素价态分析。

1.3 腐蚀磨损实验

腐蚀磨损实验通过往复式摩擦磨损实验机进行,该实验机与电化学工作站(CS310H)联用。实验前用环氧树脂封装样品,使暴露的试样面积为1 cm2;将封装后的样品作为工作电极(WE),饱和Ag/AgCl电极作为参比电极(RE),Pt电极作为辅助电极(CE)。动电位扫描范围为-1.2~1.2 V,扫描速率1 mV/s。采用直径5 mm的Si3N4陶瓷球作为对磨球,测试载荷10 N;往复频率2 Hz;单次往复行程2 mm;总行程28.8 m。

对材料进行开路电位(OCP)和阴极保护电位(-0.8 V)下的腐蚀磨损实验,将试样置于在3.5%NaCl溶液中腐蚀磨损,持续监测OCP变化,包括磨损开始前1000 s、腐蚀磨损时3600 s及磨损结束后1000 s。

2 结果与讨论

2.1 微观结构与物相分析

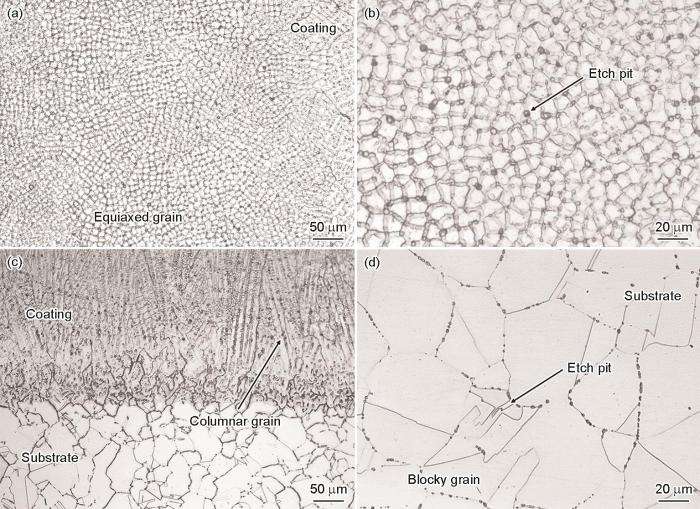

图2展示了P550不锈钢基体与熔覆层经10%草酸溶液电解腐蚀后的光学显微组织。由图2b和d可见,熔覆层的晶粒尺寸相较于基体明显减小,基体和熔覆层的平均晶粒尺寸约为42.85和10.37 μm。熔覆层正面为均匀细小的等轴晶,其截面由柱状晶构成,相比之下,基体的显微组织为粗大的块状晶粒。根据凝固理论,熔覆层不同区域的组织形貌主要由G/R值决定[10],其中G为熔池前沿的温度梯度,R为凝固速率。激光照射到基体表面时所形成的熔池温度较高,但基体整体的温度较低,形成较高的温度梯度,在固液界面处,G/R值较大,有利于已形核的晶粒沿与热传导相反的方向生长,从而形成了垂直于熔合线处的柱状晶[11]。随着凝固过程向熔池表面进行,熔覆层顶部与外界空气作用产生对流传热与辐射传热,G逐渐减小,随着激光束的移动,表层液体的R增大,G/R值下降,促使细小的等轴晶形成[10]。

图2

图2

P550不锈钢基体与熔覆层经10%草酸溶液电解腐蚀后的光学显微组织

Fig.2

Optical microstructures of P550 stainless steel substrate and coating after electrolytic etching in 10% oxalic acid solution: (a, b) surfaces, (c) cross-section, (d) substrate

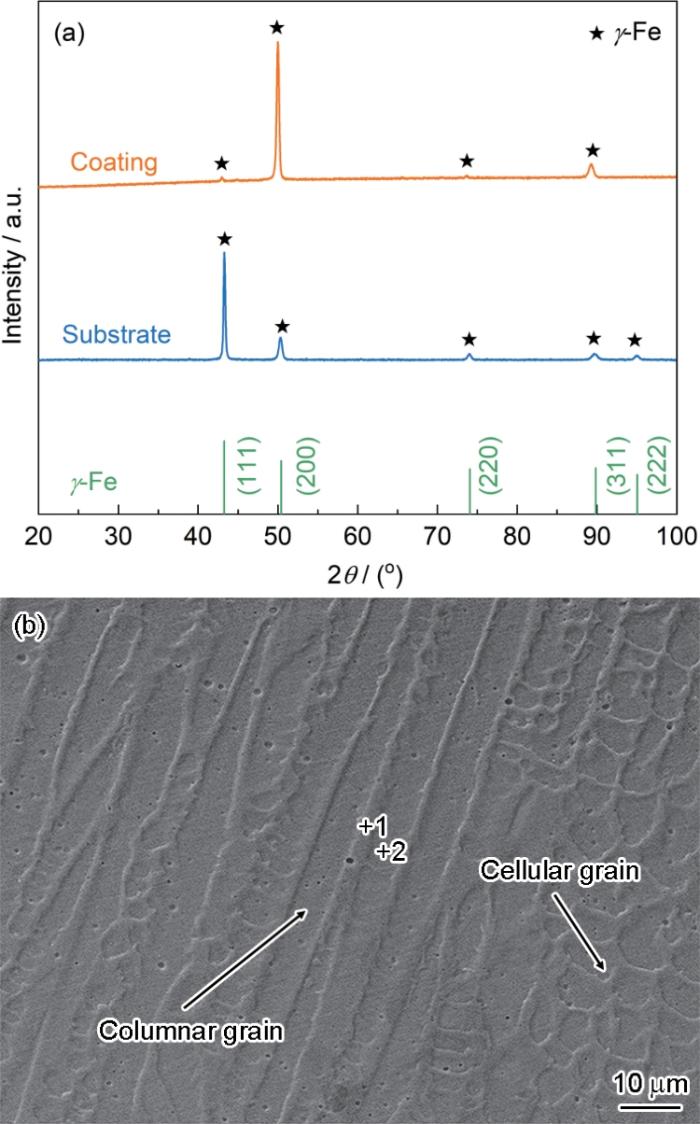

图3a展示了P550不锈钢基体和熔覆层的XRD图谱,通过与标准XRD图谱对比,可以确定P550不锈钢基体与熔覆层的物相均为面心立方(FCC)结构的γ-Fe。图3b展示了P550不锈钢熔覆层横截面的SEM图像,图中可见大量柱状晶与少部分胞状晶,同时发现圆形的微小气孔分布在晶界和晶内,这主要和激光熔覆过程中N原子的过饱和析出有关[9]。图3b中标记点1(晶界)和点2(晶内)的元素含量EDS分析结果如表1所示,晶界处Mn、N、Ni元素含量高于晶内,Cr、Si元素含量略高于晶内,晶内Fe、C元素含量均高于晶界;此外,晶界处检出Mo元素,晶内未检出。有研究表明,Mn的标准电极电位比Fe和Cr更负[13],Mn的富集将破坏钝化膜的完整性,易形成MnS夹杂,引发点蚀[14~16]。因此,P550不锈钢熔覆层晶界处将被优先腐蚀,宏观上表现为图2b中的点蚀坑。

图3

图3

P550不锈钢基体与熔覆层的XRD图谱和P550不锈钢熔覆层横截面的SEM形貌

Fig.3

XRD patterns of P550 stainless steel substrate and coating (a) and SEM cross-sectional morphology of P550 stainless steel coating (b)

表1 图3b中P550不锈钢熔覆层标记位置1和2的EDS元素含量结果

Table 1

| Site | Fe | Cr | Mn | C | N | Ni | Mo | Si |

|---|---|---|---|---|---|---|---|---|

| 1 | 44.83 | 18.24 | 22.37 | 8.43 | 1.02 | 3.81 | 0.98 | 0.33 |

| 2 | 50.84 | 18.02 | 16.95 | 10.85 | 0.51 | 2.59 | - | 0.24 |

2.2 腐蚀磨损行为分析

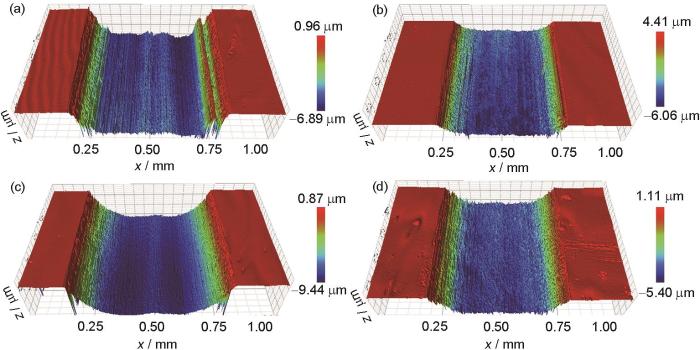

图4

图4

P550不锈钢基体与熔覆层在不同电化学状态下的磨损表面三维轮廓

Fig.4

3D surface profiles of the wear tracks on P550 stainless steel substrate and coating after tribological testing under different electrochemical conditions: (a) coating at OCP, (b) coating at cathodic protection potential, (c) substrate at OCP, (d) substrate at cathodic protection potential

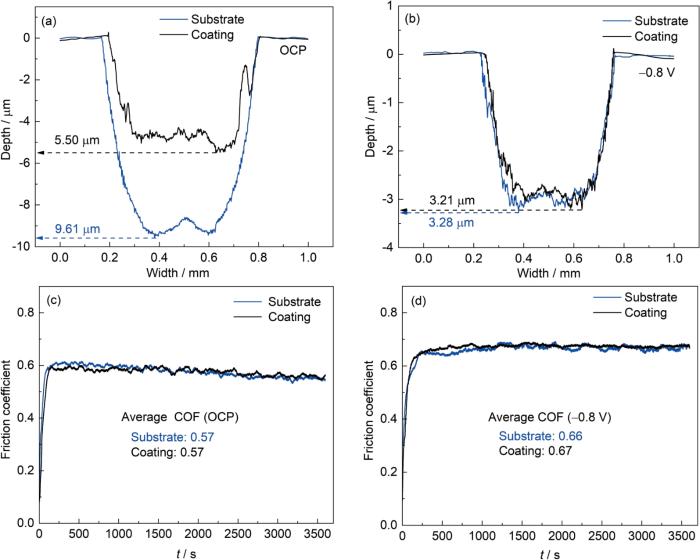

图5a和b分别展示了P550不锈钢基体与熔覆层在OCP下和阴极保护电位下磨损表面的截面平均深度,在OCP条件下,P550不锈钢基体的最大磨痕深度大于熔覆层。结合磨痕长度,得到基体的磨损体积损失为92.00 × 10-4 mm3、熔覆层的磨损体积损失为49.58 × 10-4 mm3。摩擦系数(COF)是摩擦力与正压力之比,OCP条件下,P550不锈钢熔覆层的平均摩擦系数与基体差别不大如图5c所示。在腐蚀磨损过程中施加适宜的阴极电位,可以有效地抑腐蚀作用,其磨损体积损失可近似认为是纯机械磨损[17]。阴极保护电位下,P550不锈钢基体和熔覆层的最大磨痕深度和平均摩擦系数相差不大,二者的磨损体积损失分别为27.40 × 10-4和25.04 × 10-4 mm3,表明当腐蚀作用的影响被消除后,两种材料的机械摩擦行为相近。但P550不锈钢基体的磨损体积损失仍略大于熔覆层,根据Hall-Petch关系,晶粒越细,晶界密度越高,对位错运动的阻碍作用就越强[18],磨损开始时,P550不锈钢熔覆层表面对于塑性变形的抗力更大,宏观上表现为更低的磨损体积损失。同时与OCP条件相比,两种材料的摩擦系数在阴极保护下都显著增大,这主要是由于在阴极保护电位条件下,材料表面无法形成具有润滑作用的腐蚀产物[19,20]。

图5

图5

P550不锈钢基体与熔覆层在不同电化学状态下的磨痕截面平均深度分布及摩擦系数

Fig.5

Average cross-sectional depth profiles and friction coefficients of P550 stainless steel substrate and coating under different electrochemical conditions: (a, b) average cross-sectional depth profiles of wear tracks under OCP and cathodic protection potential, (c, d) corresponding coefficients of friction as a function of time at OCP and cathodic protection potential

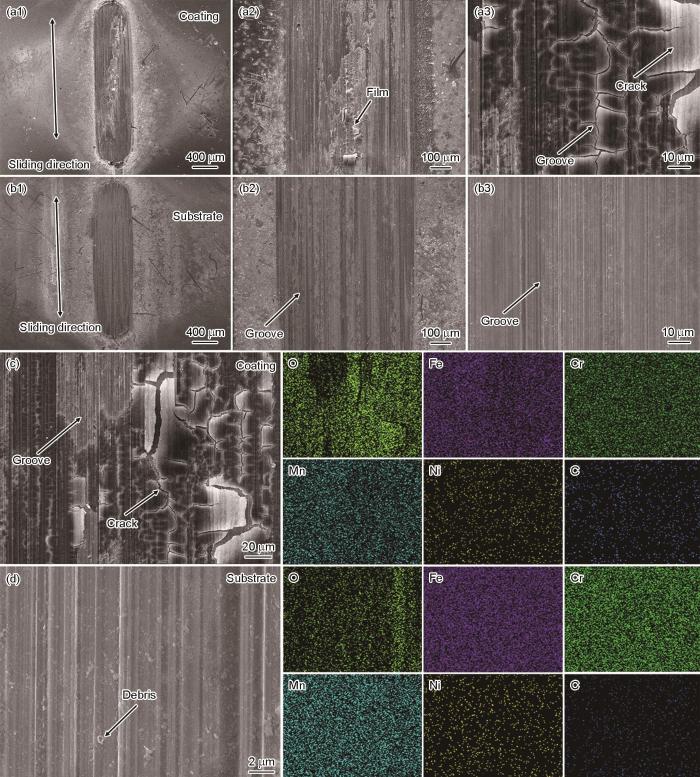

图6

图6

OCP下P550不锈钢熔覆层与基体的磨损表面SEM形貌及元素分布图

Fig.6

SEM morphologies and corresponding elemental distribution maps of the worn surfaces of P550 stainless steel coating (a, c) and substrate (b, d) under OCP

图7呈现了阴极保护电位条件下,P550不锈钢熔覆层与基体在腐蚀磨损后的SEM形貌及对应的元素分布,与OCP条件下相比,熔覆层与基体的磨损表面显得更加清洁,P550不锈钢基体与熔覆层磨损表面均呈现出大量细微犁沟,基体表面还观察到了细小的磨粒。P550不锈钢基体与熔覆层的能谱分析结果均保持一致:Fe、Cr、Mn、Ni等元素分布均匀,O元素信号微弱呈零星分布,这表明阴极保护电位条件下,P550不锈钢基体与熔覆层表面的腐蚀作用均受到明显抑制。

图7

图7

阴极保护电位条件下P550不锈钢熔覆层与基体的磨损表面SEM形貌及元素分布

Fig.7

SEM morphologies and corresponding elemental distribution maps of worn surfaces of P550 stainless steel coating (a, c) and substrate (b, d) under OCP

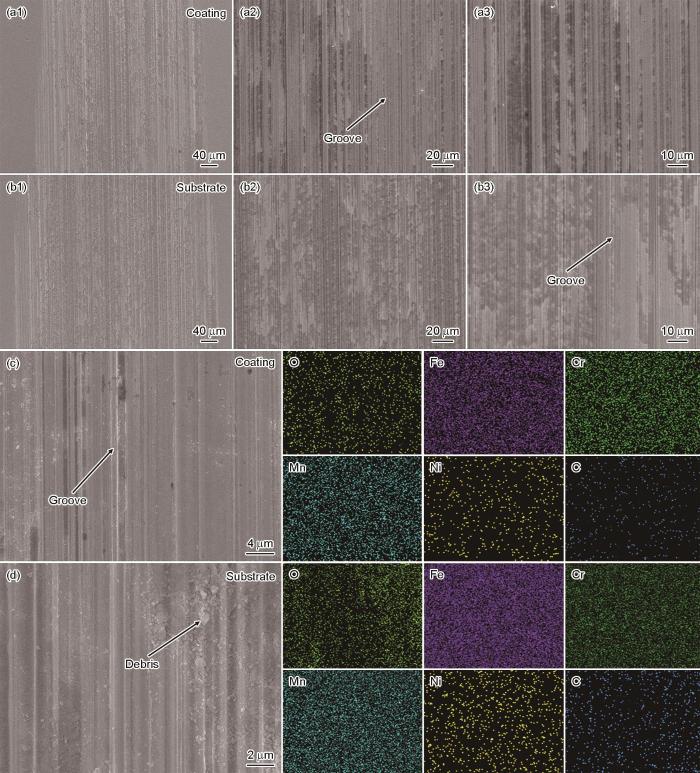

2.3 电化学行为分析

图8a为P550不锈钢基体与熔覆层在静态时的动电位极化曲线,Ecorr与Ipass分别表示材料表面的自腐蚀电位与钝化电流密度。从图8a可知,静态下P550不锈钢熔覆层的钝化区间约为0.71 V,显著高于基体的0.26 V,这与晶界为钝化膜的形成提供了大量活性位点有关[23],熔覆层细小的等轴晶中存在高密度的晶界,这使得钝化膜能在熔覆层上瞬时形成,从而形成结构均匀的保护膜。另外,一些研究也直接观察到在金属表面,钝化膜优先在晶界处形成,并且在晶界处的钝化膜更厚[24]。晶界处N、Cr、Ni、Mo元素的富集也强化了其再钝化能力。N是提升不锈钢钝化能力和抗点蚀性能作用较强的合金元素之一,其能与H+反应生成NH4+,阻止点蚀的扩展[25]。N通过与Cr、Mo、Ni协同作用同样能够提升局部耐蚀性[26~28]。

图8

图8

P550不锈钢基体与熔覆层在静态和腐蚀磨损中的动电位极化曲线及开路电位

Fig.8

Potentiodynamic polarization curves of P550 stainless steel substrate and coating under static conditions (a), during tribocorrosion (b), and their corresponding open circuit potentials (c)

表2 P550不锈钢基体与熔覆层在腐蚀磨损过程中的动电位极化曲线拟合结果

Table 2

| Materials | Ecorr / V | Ipass / A·cm-2 |

|---|---|---|

| Substrate | -0.45 | 1.42 × 10-4 |

| Coating | -0.54 | 1.30 × 10-4 |

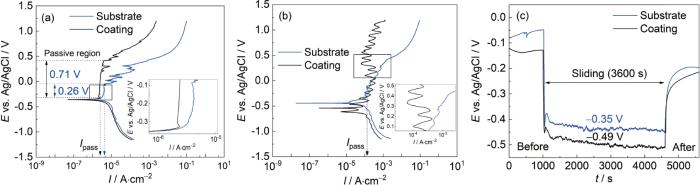

2.4 腐蚀磨损表面元素分析

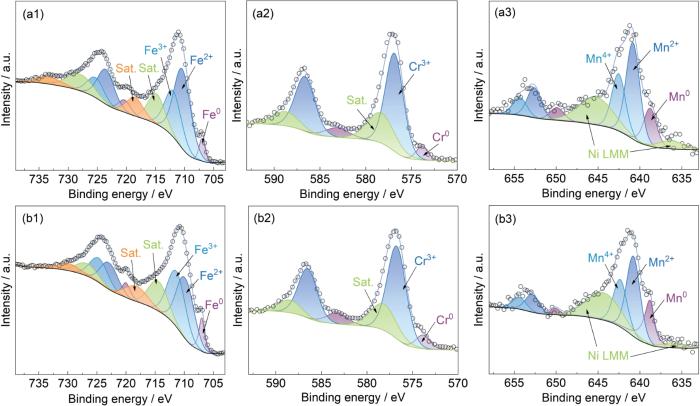

图9a1~a3与b1~b3为P550不锈钢熔覆层与基体在OCP下磨损表面的Fe 2p、Cr 2p和Mn 2p高分辨XPS光谱。在Fe 2p中,706.7和720.0 eV左右的结合能对应Fe0 [33],709.8和722.9 eV左右的结合能对应Fe2+,711.35和724.69 eV左右的结合能对应Fe3+。对于Cr 2p,光谱揭示了Cr0 (573.8和583.3 eV)和Cr3+ (576.7 eV和586.5 eV)的存在[34]。Mn 2p图谱显示Mn0的结合能为638.8和650.1 eV,Mn2+的结合能为640.8和652.9 eV,Mn4+的结合能为642.3和654.39 eV[33],同时在Mn 2p的光谱中检测到了Ni的Auger峰。

图9

图9

OCP条件下P550不锈钢熔覆层与基体磨损表面的Fe 2p、Cr 2p和Mn 2p高分辨XPS光谱

Fig.9

High-resolution Fe 2p, Cr 2p, and Mn 2p XPS spectra for worn surfaces of the P550 stainless steel coating (a) and substrate (b) tested under OCP

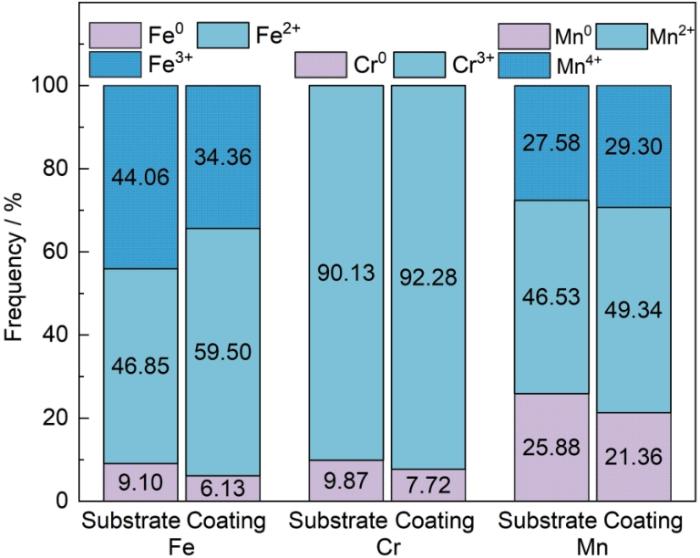

图10

图10

根据XPS图谱计算获得的元素价态组成

Fig.10

Elemental valence state compositions calculated from the XPS spectra

2.5 腐蚀与磨损交互作用分析

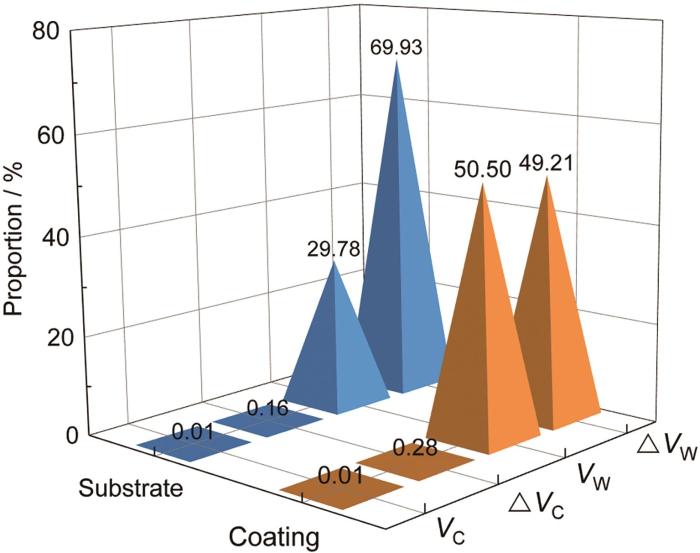

为进一步量化腐蚀与磨损的交互作用,采用Waston等[38]提出的协同法来量化分析各部分体积损失,具体计算方法如下:

式中,VT表示材料总体积损失量,可以通过OCP条件下的腐蚀磨损轮廓得到,VW表示材料在无腐蚀情况下的纯机械磨损量,可通过阴极保护电位的磨损轮廓得到,VC表示静态下仅因腐蚀造成的损失量。VS表示材料在因腐蚀磨损交互作用造成的体积损失量,具体可以分为因磨损促进腐蚀增量∆VC,以及因腐蚀促进磨损增量∆VW。根据Faraday定律,VC与∆VC可由式(

表3 P550不锈钢基体与熔覆层腐蚀磨损后各体积损失分量表

Table 3

| Materials | VT / 10-4 mm-3 | VW / 10-4 mm-3 | VC / 10-4 mm-3 | VS / 10-4 mm-3 | ∆VC / 10-4 mm-3 | ∆VW / 10-4 mm-3 |

|---|---|---|---|---|---|---|

| Substrate | 92.00 | 27.40 | 7.47 × 10-3 | 64.59 | 1.51 × 10-1 | 64.44 |

| Coating | 49.58 | 25.04 | 4.33 × 10-3 | 24.54 | 1.40 × 10-1 | 24.40 |

图11

图11

P550不锈钢基体与熔覆层腐蚀磨损后各体积损失分量占比柱状图

Fig.11

3D bar chart illustrating proportions of various volume loss components for P550 stainless steel substrate and coating after tribocorrosion testing

对于P550不锈钢基体和熔覆层,静态下材料表面因腐蚀造成的体积损失是极其微小的,占比仅为0.1%,但在腐蚀磨损过程中,∆VW却显著增加,其占总磨损量的比例在P550不锈钢基体中达69.93%,在熔覆层中达49.51%。这说明在腐蚀磨损过程中,腐蚀对于磨损具有强烈的放大效应[39]。磨损开始后材料会迅速发生腐蚀,在其表面生成疏松的腐蚀产物和点蚀坑。而在这样的表面上进行磨损,将造成更多的材料损失。P550不锈钢基体由于其更慢的再钝化能力,∆VW较大。对于P550不锈钢熔覆层,细小的晶粒赋予其更快的再钝化能力,同时熔覆层磨损表面富含Fe2+氧化层的生成也进一步降低了∆VW。

3 结论

(1) 与P550不锈钢基体的粗大块状晶粒相比,其激光熔覆层呈现细小的等轴晶结构,且晶界处存在N、Ni、Mo等元素的偏析。结构与成分上的协同作用,使熔覆层在静态下的钝化区间达到0.71 V,较基体的0.26 V有明显提升。

(2) P550不锈钢熔覆层表面生成的富Fe2+氧化层能有效抵御机械作用造成的损伤,显著减少磨损体积损失;而基体磨痕表面形成的富Fe³⁺氧化层在磨损中易破碎形成磨粒,反而加剧基体损伤,导致更大的磨损体积损失。

(3) P550不锈钢熔覆层的动电位极化曲线呈现持续钝化特征,原因在于细晶结构形成的高密度晶界为钝化膜提供了丰富的活性位点,而晶界处的高N含量又进一步促进了钝化膜的快速修复。

(4) P550不锈钢熔覆层由于其较好的再钝化能力及表面保护性氧化层的生成,显著抑制了腐蚀对磨损的促进作用;而基体因再钝化能力较差,其材料损伤由腐蚀加速磨损机制主导。

参考文献

High nitrogen alloyed steels for nonmagnetic drill collars. Standard steel grades and latest developments

[J].

The synergistic effect of wear-corrosion in stainless steels: a review

[J].

Research status and progress of laser clad coatings on 42CrMo steel [J] J

42CrMo钢表面激光熔覆涂层的研究现状及进展

[J].42CrMo钢作为高强度合金钢,在机械制造、汽车工程、石油化工、航天航空等领域得到广泛应用,然而,为应对更严苛的使用环境并拓宽其应用范围,进一步提升其耐磨性和耐蚀性显得尤为迫切。文章综述了近年来42CrMo钢表面激光熔覆涂层的国内外研究进展,分析了熔覆材料、工艺优化、熔覆层微观组织与显微硬度、耐磨性及磨损机理、耐蚀性及耐蚀机理等方面研究进展及存在问题,并对42CrMo钢表面激光熔覆技术的发展趋势进行了展望,旨在为提升42CrMo钢的综合性能提供理论依据和技术参考。

Microstructure and tribocorrosion mechanism of laser additive manufacturing IN625 coating

[J].

Laser cladded Ni625-xCr3C2 coatings: microstructure, tribocorrosion and electrochemical properties

[J].

The roles of microstructural anisotropy in tribo-corrosion performance of one certain laser cladding Fe-based alloy

[J].Because of the microstructural anisotropy for laser cladding materials, the tribo-corrosion performance can vary significantly with different directions. In this study, one certain Fe-based coating was fabricated by laser cladding. To study the effects of anisotropy, three working surfaces (0°, 45°, and 90° to the building direction) were machined from the laser cladding samples; as-cast samples with an approximately homogeneous structure were prepared as controls. The tribo-corrosion tests were conducted in a 3.5 wt% NaCl solution with varying normal loads (5, 10, and 15 N). The results demonstrated that the 45° surface has superior friction stability, corrosion resistance, and wear resistance. This was directly related to the crystal orientation and grain boundary density. In addition, a refined microstructure may enhance tribo-corrosion properties by increasing deformation resistance and decreasing surface activity.

Research progress in and defect improvement measures for laser cladding

[J].Laser cladding, a cutting-edge surface modification technique for metals, offers a novel approach to enhancing the wear and corrosion resistance of substrates due to its rapid heating and cooling capabilities, precise control over coating thickness and dilution rates, and non-contact processing characteristics. However, disparities in the physical properties between the coating material and the substrate, coupled with the improper utilization of process parameters, can lead to coating defects, thereby compromising the quality of the coating. This paper examines the effects of material systems and process parameters on laser cladding composite coatings and shows that cracking is mainly caused by thermal and residual stresses. This article summarizes the methods for crack improvement and prevention in five aspects: the selection of processes in the preparation stage, the application of auxiliary fields in the cladding process, heat treatment technology, the use of auxiliary software, and the search for new processes and new structural materials. Finally, the future development trends of laser cladding technology are presented.

Hot cracking susceptibility in laser weld metal of high nitrogen stainless steels

[J].

Study on nitrogen pores, microstructure, and mechanical properties of nickel-free high-nitrogen stainless steel fabricated via LDED regulated by heat input

[J].

Promoting the columnar to equiaxed transition and grain refinement of titanium alloys during additive manufacturing

[J].Preventing columnar grain formation during additive manufacturing has become a significant challenge. Columnar grains are generally regarded as unfavourable as their presence can impart solidification defects and mechanical property anisotropy, however, the thermal conditions experienced during additive manufacturing make columnar grains difficult to avoid. In this work the thermal conditions during solidification (cooling rate, temperature gradients) are characterised during wire based additive manufacturing. For the selection of deposition conditions that favour equiaxed grain formation, the role of alloy constitution is explored in three classical alloy design regimes: an alloy containing no grain refiners (Ti-6Al-4V); an alloy only containing grain refining solutes (Ti-3Al-8V-6Cr-4Mo-4Zr); and an alloy containing both grain refining solute and nucleant particles (Ti-3Al-8V-6Cr-4Mo-4Zr + La2O3). Substantial refinement and equiaxed grain formation is achieved in the latter case which is attributed to beta-Ti nucleation on La2O3. However, the thermal environment is dynamic during additive manufacturing and equiaxed grain formation is only achievable when temperature gradients decrease sufficiently to permit constitutional supercooling. (C) 2019 Acta Materialia Inc. Published by Elsevier Ltd.

Columnar to equiaxed transition in solidification processing

[J].

The intergranular corrosion susceptibility of metastable austenitic Cr-Mn-Ni-N-Cu high-strength stainless steel under various heat treatments

[J].The intergranular corrosion (IGC) behavior of a new metastable austenitic Cr–Mn–Ni–N–Cu high-strength stainless steel under various heat treatments was studied. The samples were solution treated at 1050 °C for 30 min and then aged at 600 to 900 °C for 10 to 300 min, respectively. The IGC susceptibility of aged samples was investigated using a double-loop electrochemical potentiokinetic reactivation (DL-EPR) test in a solution of 0.1 M H2SO4 and 0.002 M KSCN and the 10% oxalic acid etch. The surface morphologies of samples were characterized using optical microscopy and the scanning electron microscopy after electrochemical tests. Two time-temperature-sensitization diagrams were plotted based on the DL-EPR test and oxalic acid etching. No IGC and precipitate were observed for samples aged at 600 °C and 900 °C. For samples aged at 650 °C to 750 °C, the IGC susceptibility and the amount of precipitate both increased with the extended aging time. For samples aged at 800 °C and 850 °C, the amount of precipitate increased as the aging time was prolonged. However, only the sample aged at 800 °C for 60 min showed slight intergranular corrosion in the DL-EPR test. The IGC of the Cr–Mn–Ni–N–Cu austenitic stainless steel originated from the precipitation of Cr23C6 and Cr2N at the grain boundaries. The chromium-depleted zones near grain boundaries stood as the corrosion nucleation sites, but the dissolution of the weak area followed a consistent crystallographic orientation along each grain boundary.

Standard electrode potentials and temperature coefficients in water at 298.15 K

[J].A great deal of solution chemistry can be summarized in a table of standard electrode potentials of the elements in the solvent of interest. In this work, standard electrode potentials and temperature coefficients in water at 298.15 K, based primarily on the ‘‘NBS Tables of Chemical Thermodynamic Properties,’’ are given for nearly 1700 half-reactions at pH=0.000 and pH=13.996. The data allow the calculation of the thermodynamic changes and equilibrium constants associated with ∼1.4 million complete cell reactions over the normal temperature range of liquid water. Estimated values are clearly distinguished from experimental values, and half-reactions involving doubtful chemical species are duly noted. General and specific methods of estimation of thermodynamic quantities are summarized.

Quasi-in-situ ex-polarized TEM observation on dissolution of MnS inclusions and metastable pitting of austenitic stainless steel

[J].

Pitting corrosion behavior in advanced high strength steels

[J].

Corrosion behaviour of low-manganese stainless steels

[J].

Tribocorrosion behaviour of AISI 304 stainless steel in 0.5M NaCl solution

[J].

The influence of grain size on the abrasive wear resistance of hardox 500 Steel

[J].High-strength martensitic steels with boron are among the leading materials widely recognized for their exceptional resistance to abrasive wear. These steels exhibit some of the highest strength indices among bulk steels, a result of their specific chemical composition, thermomechanical rolling processes at the steel mill, and the use of pure, high-quality ores. With hardness values ranging from 400 to 650 HBW, they are ideal for demanding applications such as excavator buckets, plow blades, shafts, wear-resistant bars, and container liners. One critical microstructural property contributing to their high mechanical performance is the prior austenite grain size (PAG). A finer grain structure is associated with enhanced plasticity, and plastic deformation plays a significant role in abrasive wear mechanisms. However, this relationship between grain size and wear resistance is not well-documented in the literature, with few studies providing specific quantitative data. To address this gap, the authors conducted a study to examine the effect of prior austenite grain size on wear resistance when exposed to loose abrasive electrofused alumina no. 90. The findings indicate that applying targeted heat treatment can increase hardness by 58 Brinell units compared to the as-delivered condition. Moreover, as grain size increases from 18 µm to 130 µm, the relative abrasive wear resistance coefficient Kb decreases from 1.00 (for Hardox 500 steel in its as-delivered state) to 0.80 for austenitized material treated at 1200 °C.

Interaction behavior of wear and corrosion of highstrength marine steels for polar navigation vessels [J] J

极地航行船舶用高强钢的磨损腐蚀交互作用机制

[J].极地船舶在冰区航行时将受到冰摩擦和海水腐蚀的双重影响,而船舶用钢磨损和腐蚀间的交互作用机制尚未明晰。本文选用EH40、FH40和921A船舶用钢作为实验材料,通过力学-电化学结合的方法研究不同牌号钢材在模拟海水中的磨损腐蚀行为。结果表明:3种船舶用钢均发生磨粒磨损,磨痕表面生成分布不同的摩擦膜。其中,921A钢由于具有较高硬度、较稳定的马氏体结构,呈现出最佳的耐磨蚀性能,FH40钢次之,EH40钢最差。虽然由腐蚀直接引起的体积损失在总体积损失中占比较低,但腐蚀能显著加剧钢材的磨损。FH40和EH40钢的腐蚀磨损由纯机械摩擦占主导地位,由腐蚀引发的磨损增量分别占比18.5%和32.8%。921A钢由腐蚀引发的磨损增量占比则是纯机械摩擦占比的两倍,腐蚀加速机械磨损现象明显。

Tribo-corrosion performance of 7075-T6 Al-alloy in 3.5%NaCl solution [J] J

7075-T6铝合金在3.5%NaCl溶液中的摩擦腐蚀性能研究

[J].

Effect of oxide layers and near surface transformations on friction and wear during tool steel and boron steel interaction at high temperatures

[J].

Effects of tribo-film on wear resistance of additive manufactured cobalt-based alloys during the sliding process

[J].

Effect of grain refinement on the corrosion resistance of 316L stainless steel

[J].The effect of hydrostatic extrusion (HE) on the microstructure, uniform corrosion, and susceptibility to a localized attack of 316L stainless steel was studied. Both qualitative and quantitative analyses of inclusions before and after HE were carried out. The multiplication of non-metallic inclusions after HE lowered the stability of the passive film over a broad range of pH, while refinement of the matrix had a minor effect on it. The refined materials were prone to metastable pitting, but their pitting corrosion resistance was improved.

Local passivation of metals at grain boundaries: In situ scanning tunneling microscopy study on copper

[J].

Effect of nitrogen on the corrosion resistance of 6Mo super austenitic stainless steel

[J].6Mo super austenitic stainless steel (SASS) with nitrogen contents of 0.2 and 0.4 (wt.%) was melted, and solution treatments at 1100, 1180, and 1250 °C for 30 min were performed. The effects of nitrogen on the microstructure and pitting resistance of the two steels that signed as 0.2N and 0.4N samples were investigated. At a heat-treatment temperature of 1180 °C, the alloy demonstrates the highest corrosion resistance, attributed to the combined effects of grain size and precipitates. The structure of the passivation film changes with increasing nitrogen content, with the Cr/Fe ratio is significantly higher in the 0.4N sample compared to the 0.2N sample. Moreover, the increase in nitrogen content results in thicker Cr and Mo oxide layers and higher levels of NH3 and NH4+, thereby improving the corrosion resistance of the stainless steel.

Synergistic effect of Ni and N on improvement of pitting corrosion resistance of high nitrogen stainless steels

[J].

Effect of nitrogen content on corrosion behavior of high-nitrogen austenitic stainless steel

[J].\n A series of electrochemical tests combined with the techniques of scanning electron microscopy (SEM), electron backscatter diffraction (EBSD) and X-ray photoelectron spectroscopy (XPS) were used to study the effect of nitrogen content on the composition, structure and protectiveness of passive films, which were formed on the surfaces of high-nitrogen austenitic stainless steels (HNSS) in 0.5 mol/L NaCl solution. The results showed that the HNSS with higher nitrogen content had a larger proportion of low-angle grain boundaries, and it also had a lower corrosion current density in 0.5 mol/L NaCl solution and thus a lower corrosion rate. The existence of a larger proportion of stable oxides (e.g., Cr\n 2\n O\n 3\n ) in the passive films facilitates the passivation/repassivation process and contributes to the high corrosion resistance of HNSS.\n

Synergy between molybdenum and nitrogen on the pitting corrosion and passive film resistance of austenitic stainless steels as a pH-dependent effect

[J].

Tribocorrosion behaviours of AISI 310 and AISI 316 austenitic stainless steels in 3.5%NaCl solution

[J].

Tribocorrosion study of martensitic and austenitic stainless steels in 0.01 M NaCl solution

[J].

Synergistic tribo-corrosion behavior of TC4 alloy in artificial seawater containing sulfur ions

[J].

TC4钛合金在含S2-海水中的腐蚀磨损行为研究

[J].

Tribocorrosion properties of AISI 1045 and AISI 2205 steels in seawater: Synergistic interactions of wear and corrosion

[J].Tribocorrosion denotes an irreversible material degradation for several metallic components used in corrosive environments, and it arises from the interplay between chemical, mechanical, and electrochemical processes. In this study, some investigation has been performed to compare the tribocorrosion behavior of AISI 1045 steel and AISI 2205 duplex stainless steel sliding against an alumina pin in seawater. The lowering in the open circuit potential (OCP) of AISI 2205 during the tribocorrosion demonstrates that its protective passive film was damaged by wear and resulted in a wear-accelerated corrosion in the wear track. However, sliding was found to accelerate the corrosion of the unworn areas for AISI 1045, leading to an anodic shift of the OCP. Moreover, the total material loss increased with an increase in the applied potential for both materials. It was revealed that AISI 1045 was more sensitive to corrosion under sliding than AISI 2205. Therefore, pure corrosion loss and corrosion-induced wear constituted the primary reasons for the degradation of AISI 1045 at applied anodic potentials.

XPS analysis of passive film on stainless steel

[J].

XPS analysis of the passive film formed on austenitic stainless steel coated with conductive polymer

[J].

Passive films on stainless steels—chemistry, structure and growth

[J].

Effect of iron oxide debris on the reciprocating sliding wear of tool steels

[J].

Tribocorrosion behavior and degradation mechanism of 316L stainless steel in alkaline solution: Effect of tribo-film

[J].

Methods of measuring wear-corrosion synergism

[J].

Tribo-corrosion performance of atmospheric plasma sprayed FeCoCrNiMn high entropy alloy coatings

[J].

大气等离子喷涂FeCoCrNiMn高熵合金涂层的耐海水腐蚀与磨损性能

[J].研究了采用大气等离子喷涂技术制备的FeCoCrNiMn高熵合金涂层在模拟海水环境中的耐腐蚀与磨损性能。FeCoCrNiMn高熵合金涂层由单相FCC固溶体组成;涂层平均硬度为221.1HV<sub>0.2</sub>,高于304不锈钢基体的表面平均硬度159.1HV<sub>0.2</sub>。在3.5%NaCl溶液中,FeCoCrNiMn高熵合金涂层在5 N和10 N载荷下的磨损体积分别为1.21 × 10<sup>-2</sup>和1.42 × 10<sup>-2</sup> mm<sup>3</sup>,相差17%,其主要磨损机制为腐蚀磨损和氧化磨损;在去离子水中该涂层在5 N和10 N载荷下的磨损体积分别为1.15 × 10<sup>-2</sup>和1.28 × 10<sup>-2</sup> mm<sup>3</sup>,相差11%,主要磨损机制为黏着磨损和氧化磨损。综合比较,NaCl溶液中涂层的磨损体积高于其在去离子水中的磨损体积,且涂层在NaCl溶液中5 N和10 N载荷下的磨损体积差值大于在去离子水中的磨损体积差值,说明磨损体积随载荷增大而增大的幅度受腐蚀介质影响,NaCl溶液的腐蚀效应对摩擦磨损起到促进作用。同时,在NaCl溶液中,低载荷磨损样品的开路电位可在静置浸泡阶段较短时间内恢复到接近摩擦前水平,而高载荷磨损样品由于机械损伤较大,开路电位上升缓慢,难以恢复到摩擦前水平,说明摩擦磨损造成的机械损伤会加剧腐蚀。