激光处理技术具有高效、灵活和无污染的优点,而激光辐照的重熔和热效应已成为提升金属耐蚀性的潜在解决方案。Yu等[10]利用选择性激光熔化技术制备了17-4PH不锈钢,研究表明激光处理可通过细化晶粒尺寸提升材料的耐蚀性。Barroux等[3]和Meng等[11]的研究进一步表明,激光选区熔化增材制造技术减少了亚稳态空洞等缺陷,从而提高了17-4PH不锈钢的耐蚀性。上述研究主要利用高能量密度激光的快速熔化、凝固所产生组织改变来提高该类钢的耐蚀性。鉴于小功率便携式激光的快速发展,利用低功率纳秒脉冲激光提升不锈钢耐蚀性的研究逐渐受到关注。Yang等[12]的研究表明,低功率纳秒脉冲激光辐照通过影响304不锈钢钝化膜稳定性可显著改善其耐蚀性。Zhu等[13]利用纳秒激光辐照技术进一步探讨了不同激光参数对304不锈钢耐点蚀性能的影响,表明特定参数条件下,激光重熔效应使不锈钢形成了梯度结构,点蚀电位显著提高。然而,相关纳秒激光辐照技术在沉淀硬化不锈钢表面进行耐蚀改进的相关研究尚鲜见。

为此,本文基于正交试验设计,研究纳秒激光辐照对17-4PH不锈钢电化学腐蚀行为的影响;结合扫描电镜(SEM)形貌观察、电化学阻抗谱分析、钝化膜价态及表面钝化膜X射线光电子能谱仪(XPS)测试结果,探究纳秒激光辐照对17-4PH不锈钢电化学耐蚀的影响机理。

1 实验方法

实验所用的17-4PH不锈钢化学成分(质量分数,%)为:C 0.07,Si 1.00,Mn 1.00,P 0.040,S 0.030,Ni 3.00~5.00,Cr 15.00~17.50,Cu 3.00~5.00,Nb 0.15~0.45。通过线切割技术加工制备若干规格为15 mm×10 mm×8 mm的块状样品。所有样品按以下工艺进行热处理:1040 ℃ × 4 h (固溶) + 595 ℃ × 4 h (时效)。将热处理后的样品用80#砂纸打磨以清除表面氧化皮,之后用酒精清洗并吹干备用。其中,打磨后的样品为原始样品(标记为“Grinding”样品);选取部分打磨后的样品在质量分数为30%的HNO3溶液中浸泡30 min,进行化学钝化处理(标记为“Chemical passivation”样品)。

鉴于激光工艺参数较多,本研究选择功率、脉宽、搭接率3个参数为控制因素,每个因素选择3个参数值,按照L9 (33)正交设计(表1)对部分打磨后的样品进行激光辐照处理,每种参数均有3个平行样。所用激光器的型号为YLPN-10-30x240-200-R(IPG 200 W激光器),波长1064 nm,脉冲宽度最大240 ns,功率范围为0~200 W。

表1 激光处理L9 (33)正交实验参数设置

Table 1

| Level | A (power / W) | B (pulse width / ns) | C (overlap rate / %) |

|---|---|---|---|

| 1 | 120 | 30 | 65 |

| 2 | 130 | 120 | 70 |

| 3 | 140 | 240 | 75 |

实验采用三电极体系和CorrTest电化学工作站开展样品在3.5% (质量分数) NaCl溶液中的电化学性能测试,试样为工作电极,铂电极为辅助电极,AgCl/Ag电极(SSE)为参比电极。动电位极化曲线扫描范围为-0.35~1.5 V,扫描速率为0.5 mV/s,并计算各激光参数下3个平行样测得点蚀电位的平均值(E);电化学阻抗谱(EIS)测试频率为105~10-1 Hz,扰动电位幅值为10 mV,采用CS Studio软件对数据进行拟合;利用电容测试分析溶液中钝化膜半导体特性,其测试电位范围为0.2~-1.2 V,频率1 kHz,交流幅值10 mV。

采用场发射扫描电镜(SUPARR55,SEM)观察样品在动电位极化测试前后的表面形貌;利用X射线光电子能谱仪(Axis Supra+,XPS)测试不锈钢表面中各元素的化学态,采用单色Al Kα (1486.6 eV)源激发光电子,以C 1s峰作为标准峰对实验中的电子偏移进行校正,利用Thermo Avantage软件分析拟合后的谱图。

2 结果与讨论

2.1 基于点蚀电位的正交试验分析

表2 正交试验结果及极差分析

Table 2

| Experimental number | A (power / W) | B (pulse width / ns) | C (overlap rate / %) | Pitting potential, E / V |

|---|---|---|---|---|

| L1 | 120 | 30 | 65 | 0.232 |

| L2 | 120 | 120 | 70 | 0.394 |

| L3 | 120 | 240 | 75 | 0.341 |

| L4 | 130 | 30 | 75 | 0.271 |

| L5 | 130 | 120 | 70 | 0.345 |

| L6 | 130 | 240 | 65 | 0.321 |

| L7 | 140 | 30 | 70 | 0.318 |

| L8 | 140 | 120 | 65 | 0.247 |

| L9 | 140 | 240 | 75 | 0.255 |

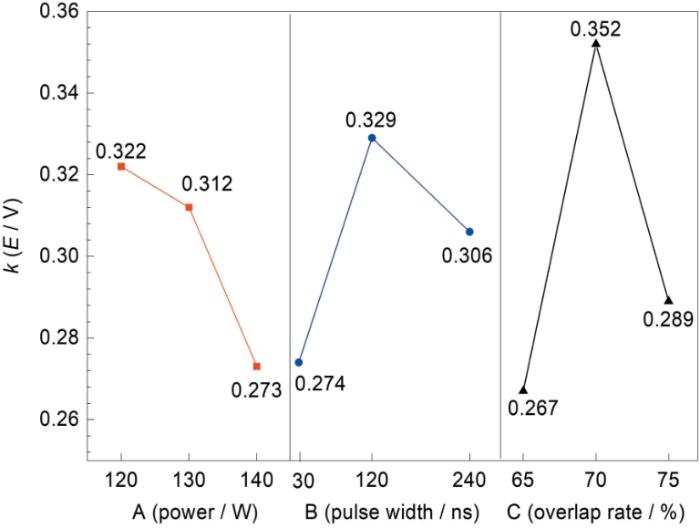

| k1 (E) | 0.322 | 0.274 | 0.267 | |

| k2 (E) | 0.312 | 0.329 | 0.352 | |

| k3 (E) | 0.273 | 0.306 | 0.289 | |

| R (E) | 0.049 | 0.055 | 0.086 | |

| Factor ranking | R(E): C > B > A | |||

| Optimal solution | Pitting potential: A1B2C2 | |||

图1

图1

点蚀电位平均值随各因素、水平的变化曲线

Fig.1

Variations of the average pitting potential with different factors and levels

为进一步研究激光辐照对17-4PH不锈钢电化学耐蚀性的影响,另选取部分打磨后样品在30%HNO3溶液中进行化学钝化处理,与打磨未做任何处理的样品以及3种激光辐照(L1、L2、L6)样品一并用于后续的讨论(共5种状态:化学钝化、只打磨未钝化、3种激光钝化状态)。

2.2 典型工艺下动电位极化曲线及腐蚀表面形貌

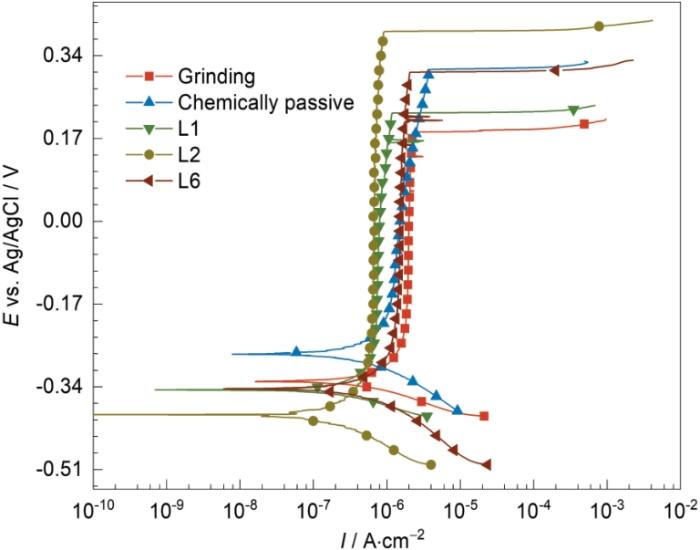

不同状态的样品在3.5%NaCl溶液中的动电位极化曲线如图2所示。由图可知,5组样品的极化曲线变化趋势基本一致,在阳极区,随电极电位的升高直接进入钝化区;在腐蚀电位下均能够发生自钝化,均呈现显著钝化特征。相对于原始样品,即使在低功率和低搭接率条件下,样品L1的点蚀电位提高约25%;而随着激光功率和搭接率的增加,样品L6的点蚀电位进一步提升,与化学钝化的效果相当;在最佳激光辐照参数下,样品L2的钝化区宽度最大,点蚀电位较原始样品至少提升1.3倍。综上, 纳秒激光辐照能够显著影响17-4PH不锈钢的腐蚀行为,提高了样品抗局部腐蚀的能力,增强了材料的耐腐蚀性。

图2

图2

不同条件表面处理的17-4PH不锈钢样品的动电位极化曲线

Fig.2

Potentiodynamic polarization curves of 17-4PH stainless steel samples with different surface treatments

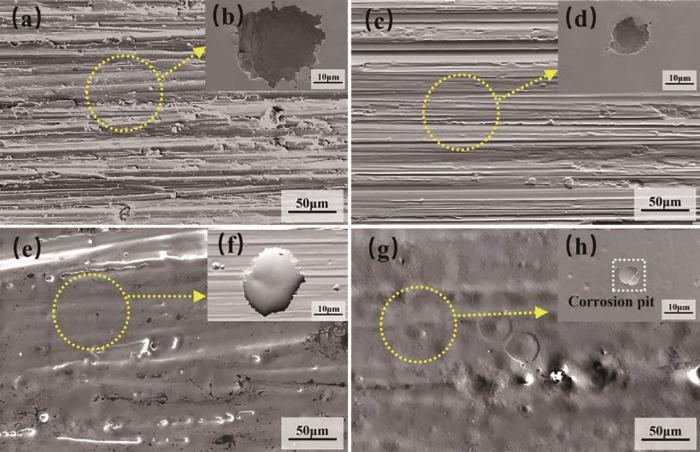

图3

图3

不同条件下表面处理样品在3.5%NaCl溶液中动电位测试前后表面与点蚀形貌

Fig.3

Surface morphologies of surface pre-treated 17-4PH stainless steel samples before and after polarization test in 3.5%NaCl solution: (a, b) grinding, (c, d) chemical passivation, (e, f) L1, (g, h) L2

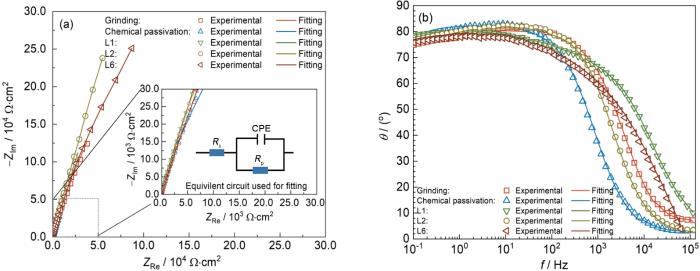

2.3 电化学阻抗谱

图4

图4

不同条件表面处理的17-4PH不锈钢在3.5%NaCl溶液中的EIS与等效电路

Fig.4

Nyquist (a) and Bode (b) plots of surface pre-treated 17-4PH stainless steel samples in 3.5%NaCl solution, the inset in Fig.4a shows corresponding equivalent circuit model

在Bode相图(图4b)中,所有样品均表现出单一时间常数,其变化趋势相似:在低频范围内,相位角随着频率的增加缓慢增大,集中在75°~80°之间;原始样品的相位角最低,说明其在溶液中界面双电层结构不稳定。随频率进一步升高,相位角在中频区达到峰值后单调下降,高频区接近0°,这表明在高频范围内,样品的溶液电阻占主导地位;对应最佳激光辐照样品(L2)的相位角最高,表明界面双电层结构较为稳定,钝化膜的致密性和保护性显著提升。

表3 17-4PH不锈钢在3.5%NaCl溶液中EIS的等效电路拟合结果

Table 3

| Samples | Rs / Ω·cm2 | CPE1 / μΩ-1·cm-2·s n | n | Rp / 105 Ω·cm2 |

|---|---|---|---|---|

| Grinding | 5.2 | 2.3 | 0.90 | 7.6 |

| Chemical passivation | 4.0 | 1.5 | 0.92 | 23.2 |

| L1 | 6.0 | 2.1 | 0.82 | 6.6 |

| L2 | 6.4 | 0.9 | 0.93 | 47.8 |

| L6 | 6.4 | 2.2 | 0.84 | 17.8 |

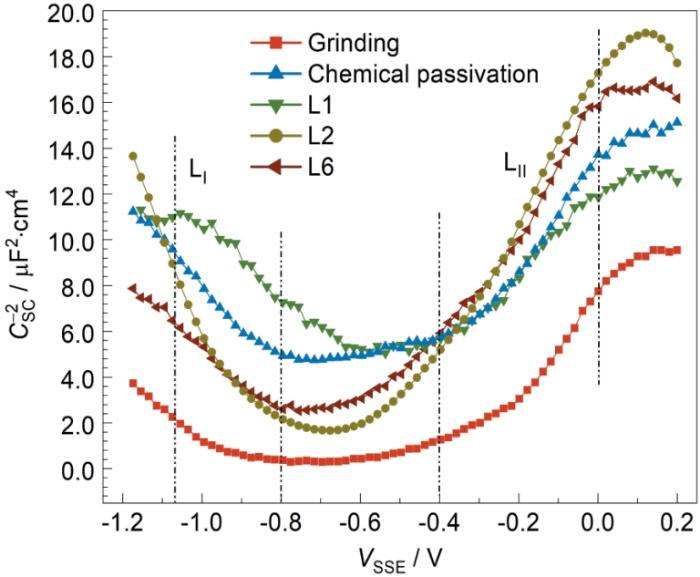

2.4 半导体特性分析

式中,CSC为钝化膜空间电荷电容,ε为钝化膜的介电常数(取值15.6[17]),ε0为真空介电常数(8.85 × 10-14 F·cm-1),ND和NA分别是施主和受主载流子浓度,V为外施加电压,VFB为半导体的平带电位,k为Boltzmann常数,e为电荷量,T为热力学温度。

图5

图5

不同条件表面处理的17-4PH不锈钢样品在3.5%NaCl溶液中的Mott-Schottky曲线

Fig.5

Mott-Schottky curves of surface pre-treated 17-4PH stainless steel samples in 3.5%NaCl solution

表4 不同条件表面处理的17-4PH不锈钢在3.5%NaCl溶液中形成的钝化膜的掺杂浓度

Table 4

| Sample | Grinding | Chemical passivation | L 1 | L 2 | L 6 |

|---|---|---|---|---|---|

| ND / 1021 cm-3 | 1.505 | 0.696 | 0.823 | 0.410 | 0.585 |

| NA / 1021 cm-3 | 1.167 | 0.613 | 0.749 | 0.385 | 0.528 |

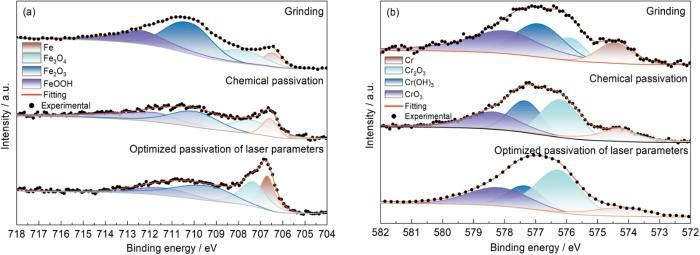

2.5 不锈钢钝化膜成分分析

图6a为Fe 2p3/2的4个特征峰,分别显示Fe单质[Fe(met) 706.47 eV],Fe2+氧化物[Fe2+(ox) 707.9 eV],Fe3+氧化物[Fe3+(ox) 710.17 eV]与Fe3+氢氧化物[Fe3+(hyd) 712.33 eV][22,23],其中激光辐照形成样品中Fe2+(ox)的相对面积比例显著高于原始样品和化学钝化样品。图6b中Cr 2p3/2的XPS谱分别由Cr单质[Cr(met) 574.45 eV],Cr3+氧化物[Cr3+(ox) 575.86 eV],Cr3+氢氧化物[Cr3+(hyd) 776.90 eV],Cr6+氧化物[Cr6+(ox) 577.89 eV]的4个特征峰组成,相应的结合能与文献报道一致[22,23]。拟合结果表明,化学钝化样品表面存在相对较多的Cr3+(hyd),但激光辐照样品Cr3+(ox)的相对面积均高于原始与化学钝化样品,说明纳秒激光辐照能够促使不锈钢表面形成更多Cr氧化膜保护基体。

图6

图6

不同条件表面处理的17-4PH不锈钢表面钝化膜的XPS光谱

Fig.6

XPS fine spectra of Fe 2p 3/2 (a) and Cr 2p 3/2 (b) of passivation films on 17-4PH stainless steel with different surface treatments

表5 不同条件表面处理的17-4PH不锈钢钝化膜成分的XPS分析结果(相对原子浓度)

Table 5

| Relative atomic concentration | Grinding | Chemical passivation | Optimal laser passive |

|---|---|---|---|

| {[Crox]+[Crhyd]}/{[Crox]+[Crhyd]+[Crmet]} | 0.855 | 0.836 | 0.898 |

| {[Feox]+[Fehyd]}/{[Feox]+[Fehyd]+[Femet]} | 0.920 | 0.673 | 0.777 |

| {[Crox]+[Crhyd]}/{[Feox]+[Fehyd]} | 0.174 | 1.124 | 5.972 |

2.6 分析与讨论

实验结果表明,优化激光参数样品点蚀电位为0.394 V (表2),相较于原始与钝化样品分别提升约130%与20%。分析认为上述现象的产生归因于:激光辐照作用有利于促使不锈钢表面形成更高浓度的铬氧化层,在NaCl溶液中形成更致密的钝化膜,从而保护基体,阻止进一步腐蚀,提高不锈钢的耐蚀性能。

研究指出,Fe氧化物的形成主要受动力学控制,这是由于Fe离子/原子的迁移能力较强,在低温或较缓慢的氧化过程中,Fe倾向于形成氧化物[30,31]。然而,激光辐照过程中,光斑区域的温度常常超过1000 ℃,热效应显著[28]:与Fe氧化物相比,Cr氧化形成Cr2O3的反应Gibbs自由能变化更负,这意味着在热力学上氧化铬的形成具有更大的优势[31]。尽管Fe离子迁移能力强于Cr离子,但纳秒激光高温短时效应,不足以使Fe离子大规模迁移扩散,从而限制了Fe的富集程度。因此,高温环境下Cr比Fe更容易发生化学反应,促使更多的氧化铬形成于样品表面,表5中Cr、Fe氧化物浓度也能证明激光热效应下的氧化行为。由激光辐照引起的热氧化行为在许多文献中得到了证实,其中作用在奥氏体不锈钢表面形成的厚度达到能达到几十纳米[25,26]。

3 结论

(1) 通过正交试验发现,搭接率是影响17-4PH不锈钢点蚀电位的最显著因素,其次为脉宽和功率。实验表明,随功率增加,点蚀电位呈单调递减趋势,而脉宽与搭接率的增加使点蚀电位表现出“先升后降”的变化规律。当激光参数为功率120 W、脉宽120 ns、搭接率70%时,样品点蚀电位达到最高值为0.394 V。

(2) 最佳激光辐照能显著提高17-4PH不锈钢耐蚀性,动电位极化测试后腐蚀坑更小且更均匀;Rp值已超过106 Ω·cm2,CPE1值最低,表面钝化膜致密性和均匀性优于化学钝化样品;Mott-Schottky测试曲线中,钝化膜中施主浓度ND与受主浓度NA值较原始样品分别降低72%和67%,有效减少了离子迁移,增强了钝化膜的保护效果。XPS的结果表明,样品表面氧化铬浓度高,Cr/Fe浓度比接近6,促使不锈钢表面形成更多Cr氧化膜保护基体,不容易遭受侵蚀离子的破坏。

(3) 纳秒激光辐照通过瞬时高温热氧化行为,促进Cr优先氧化形成氧化铬,在减少表面缺陷与粗糙度同时,优化钝化膜结构,显著提高不锈钢的抗点蚀能力,有效改善了不锈钢表面的耐蚀性能。

参考文献

Investigating the impact of pre-deformation on age hardening and pitting corrosion resistance of 17-4PH stainless steel

[J].

Localized corrosion of 15-5PH and 17-4PH stainless steel in NaCl solution

[J].

Pitting corrosion of 17-4PH stainless steel manufactured by laser beam melting

[J].

Facile chromaticity approach for the inspection of passive films on austenitic stainless steel

[J].

Effect of chemical composition and microstructure parameters on carbon and low-alloy steel corrosion resistance

[J].

Influence of chemical composition and microstructure parameters of tubing steels on their corrosion resistance

[J].

Alternative to nitric acid passivation of 15-5 and 17-4PH stainless steel using electrochemical techniques

[J].

Electrochemical behavior of stainless steel in acidic environments: influence of chloride ions

[J].

Fe-based sacrificial anodes for cathodic protection of 17-4PH stainless steel

[J].

铁基牺牲阳极对17-4PH不锈钢的阴极保护

[J].

Iso-Material Manufactured 17-4PH stainless steel to enhance the nano-indentation, corrosion, and cavitation erosion behavior

[J].

Femtosecond laser treatment for improving the corrosion resistance of selective laser melted 17-4PH stainless steel

[J].

Mechanism of surface corrosion resistance of 304 stainless steel processed by nanosecond laser pulses

[J].

Enhance corrosion resistance of 304 stainless steel using nanosecond pulsed laser surface processing

[J].

Effect of trace water in ammonia on breaking passive film of stainless steel during gas nitriding

[J].

Improvement on the pitting corrosion resistance of 304 stainless steel via duplex passivation treatment

[J].

The electronic properties of sputtered chromium and iron oxide films

[J].

On the effect of build orientation and residual stress on the corrosion of 316L stainless steel prepared by selective laser melting

[J].

Impedance spectroscopy at semiconductor electrodes: review and recent developments

[J].

Application of PDM (point defect model) on 2205 duplex stainless steel

[J].

点缺陷模型在2205双相不锈钢中的应用

[J].

Effect of secondary passivation on corrosion behavior and semiconducting properties of passive film of 2205 duplex stainless steel

[J].

Capacitance behaviour of passive films on ferritic and austenitic stainless steel

[J].

Resolving surface chemical states in XPS analysis of first row transition metals, oxides and hydroxides: Cr, Mn, Fe, Co and Ni

[J].

XPS characterization of Co and Cr pigmented copper solar absorbers

[J].

Passivation-induced physicochemical alterations of the native surface oxide film on 316L austenitic stainless steel

[J].

Understanding the role of oxide layers on color generation and surface characteristics in nanosecond laser color marking of stainless steel

[J].

Mechanism for control of laser-induced stainless steel oxidation

[J].

Corrosion resistance of AISI 304 stainless steel modified both femto- and nanosecond lasers

[J].

Challenges in the theory of electron transfer at passive interfaces

[J].

Surface oxidation phenomenon and mechanism of AISI 304 stainless steel induced by Nd: YAG pulsed laser

[J].

Thermodynamic analysis and experimental study of masked corrosion protection of 304 stainless steel processed with nanosecond pulsed laser

[J].

An XPS and ToF-SIMS study of the passive film formed on a model FeCrNiMo stainless steel surface in aqueous media after thermal pre-oxidation at ultra-low oxygen pressure

[J].

The measurement of interface strength of TiN coating/substrate by laser spallation

[J].