超双疏表面为保护B10合金免受腐蚀提供了一种有效策略。目前,人们已研究出多种方法制备超双疏表面。张吉昊等[16]通过常温铁盐刻蚀和低表面能物质修饰,成功在B10合金表面制备出长条状复合微纳米粗糙结构和低表面能分子膜构成的超双疏表面,大大提高B10合金基体耐蚀性能。Wen等[17]通过碱辅助氧化和置换反应以及表面改性的方法成功在Cu上构建出超双疏表面,该表面对水和几种表面张力更低的有机液体都具有超疏性,表现出优异的自清洁和耐蚀性能。Wan等[18]通过刻蚀和水热处理相结合的方法在Cu上制备出超疏水膜,水的接触角达157.7° ± 1°,在潮湿空气和3.5% (质量分数) NaCl溶液中具有非常好的耐腐蚀性和长期稳定性。此外,激光刻蚀[19]、化学沉积[20]、电沉积[21,22]等方法也常被用来制备超双疏表面。

本文采用简便高效的化学刻蚀法,利用S2O

1 实验方法

实验用B10合金(10 mm × 10 mm × 3 mm),主要成分为10% (质量分数) Ni,余量为Cu。化学试剂包括:(NH4)2S2O8,NaOH,全(十七)氟癸基三乙氧基硅烷(PFDTS,C16H19F17O3Si),99%无水乙醇等均为分析纯。

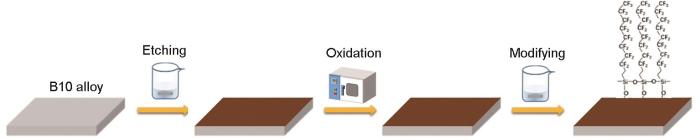

先用400#、800#、1200#和2000#的砂纸打磨B10合金,在丙酮和无水乙醇中各超声清洗10 min,去除表面污染物。将样品浸入20 mL 40 ℃的(NH4)2S2O8(质量浓度30 g/L)和NaOH (质量浓度100 g/L)的混合溶液中刻蚀5 h,用去离子水将试样表面冲洗干净后吹干。160 ℃下氧化1 h后自然冷却至室温。将试样浸入1.0%的PFDTS-乙醇溶液中1 h取出,60 ℃干燥45 min后自然冷却至室温。保持样品表面清洁,进行后续测试。制备流程示意图如图1所示。

图1

使用接触角测量仪(JC2000DM)测量静态接触角(CA)和滚动角(SA)。使用激光共聚焦显微镜(LSCM,VK-X260K)测量样品表面粗糙度和比表面积。使用扫描电子显微镜(SEM,Sigma300)观察样品表面形貌,通过其配备的X射线能量色散谱(EDS)测定样品表面元素。使用X射线衍射仪(XRD,Panalytical X'pert Powder)表征样品表面物相。使用配备的X射线光电子能谱仪(XPS,Thermo Scientific K-Alpha)分析样品表面成分。

使用CHI600E型电化学工作站,采用三电极体系,3.5%NaCl溶液为电解质溶液,测定样品电化学阻抗图谱(EIS)和动电位极化曲线。表面积1 cm2的样品为工作电极,铂片(1 cm × 2 cm)为对电极,饱和甘汞电极(SCE)为参比电极。EIS测试在开路电位(OCP)下进行,频率105~10-2 Hz,正弦波振幅10 mV。动电位极化曲线测试在开路电位±0.3 V和扫速1.0 mV/s条件下进行。

用Al2O3粉末、茶水和牛奶模拟污染物测试样品自清洁性能。通过如图2所示方法测试样品机械耐磨性能。

图2

图2

超双疏试样耐摩擦实验示意图

Fig.2

Schematic diagram of the friction experiment of the superamphiphobic sample

2 结果与讨论

2.1 试样表面润湿性和形貌分析

超双疏处理前后水和乙二醇在样品表面的接触角和滚动角测试结果如表1所示。测试结果表明,实验处理后,样品表面润湿性发生明显变化,水和乙二醇接触角分别由75.5°和43.7°提升至158.1°和151.2°,水的滚动角接近0°,乙二醇滚动角约为5°,实现超双疏效果。

表1 超双疏处理前后试样表面润湿性变化

Table 1

| Liquid | Surface tension at 20 ℃ / mN·m-1 | Bare sample | Superamphiphobic sample | |

|---|---|---|---|---|

| Water | 72.8 | |||

| Ethylene glycol | 47.7 | |||

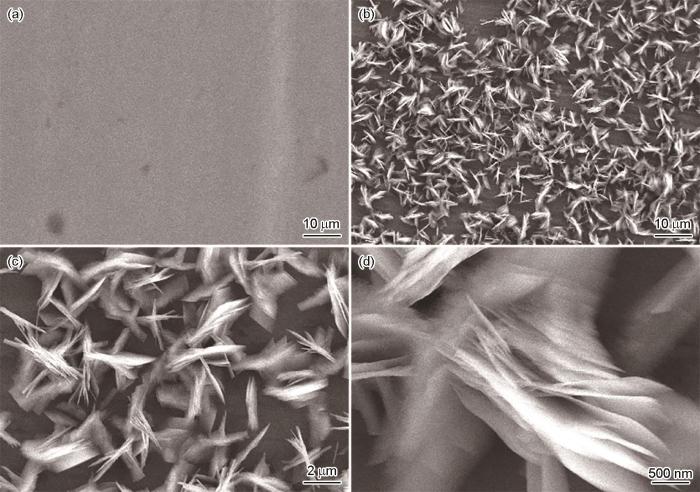

图3

图3

裸样与超双疏试样表面形貌

Fig.3

Surface morphologies of bare sample (a) and superamphiphobic sample at different magnification rates (b-d)

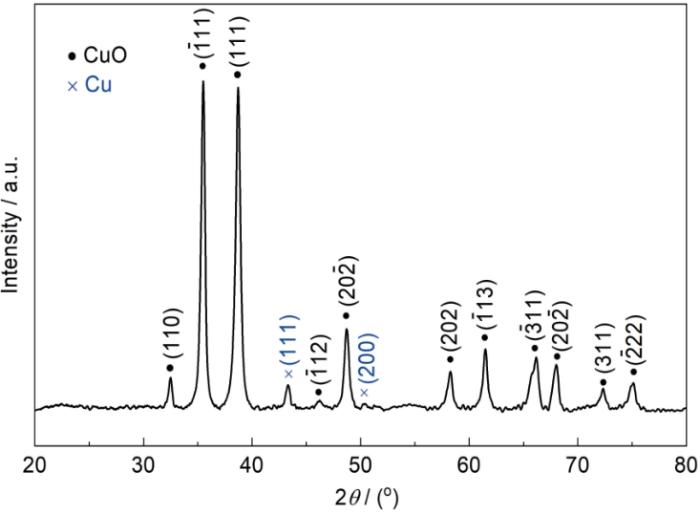

图4

图4

裸样和超双疏试样的LSCM像

Fig.4

Laser confocal main images (LSCM) (a, d), height images (b, e), and 3D images (c, f) of the surface of bare sample and superamphiphobic sample

表2 裸样和超双疏试样表面粗糙度参数

Table 2

| Sample | Sa / μm | Sdr | Ratio of surface area and cross-sectional area |

|---|---|---|---|

| Bare | 0.72 | 0.38 | 1.09 |

| Superamphiphobic | 1.58 | 1.59 | 1.66 |

由SEM和LSCM结果可知,本实验能够改变B10合金表面粗糙度和表面形貌获得相互堆叠交错的微纳米级层片状复合结构,对于实现超双疏表面制备具有关键作用[26]。

2.2 试样表面物相和成分分析

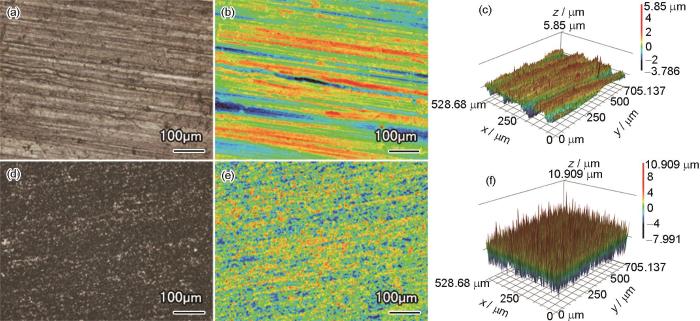

由超双疏试样表面物相XRD图谱(图5)可知,在2θ为35.54°、38.76°、48.73°、61.48°处检测到较强衍射峰,分别属于CuO的(

图5

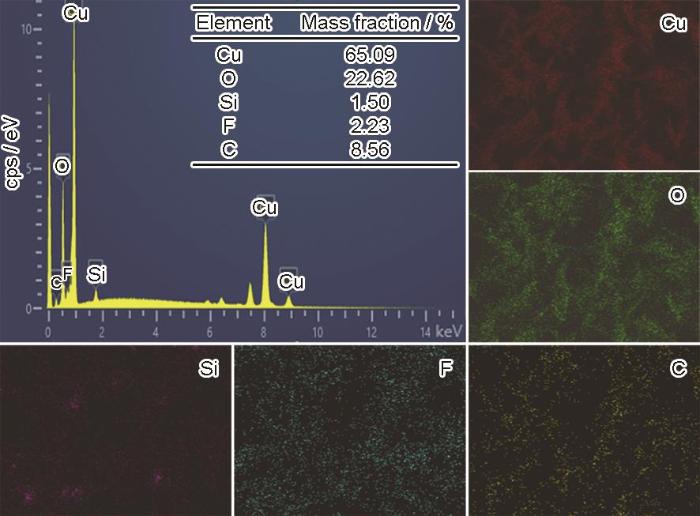

图6

图6

超双疏试样EDS面扫及各元素分布图像

Fig.6

EDS mapping of superamphiphobic sample and distribution map of each element

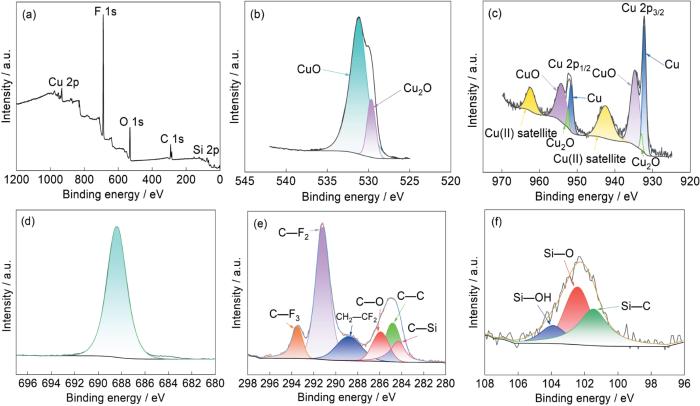

为进一步探究超双疏试样表面Cu的存在形式,对其进行了XPS测试,测试结果如图7所示。图7a中可观察到Cu、F、O、C和Si特征峰,对总谱图进行分峰拟合,得到各元素分谱图(图7b~f)。由O、Cu元素分谱图(图7b和c)可知,O元素分谱图中出现的峰值分别对应于CuO和Cu2O,经刻蚀和氧化后,在Cu 2p3/2区域的932.18、932.98及934.68 eV处,以及Cu 2p1/2区域的951.68、952.48及954.38 eV处分别出现了对应于Cu、Cu2O以及CuO的峰值,同时在942.58 及962.48 eV处出现了由于Cu2+的未填充(d9)价能级的存在导致的卫星峰。结合XRD、EDS结果可知,超双疏试样表面的层片状粗糙结构主要由Cu、CuO晶体以及未结晶Cu2O的组成。

图7

图7

超双疏试样XPS图谱

Fig.7

XPS spectra of superamphiphobic sample: (a) survey, (b) O 1s, (c) Cu 2p, (d) F 1s, (e) C 1s, (f) Si 2p

结合实验过程,可推断出生成CuO以及Cu2O的反应机理如下[27]:

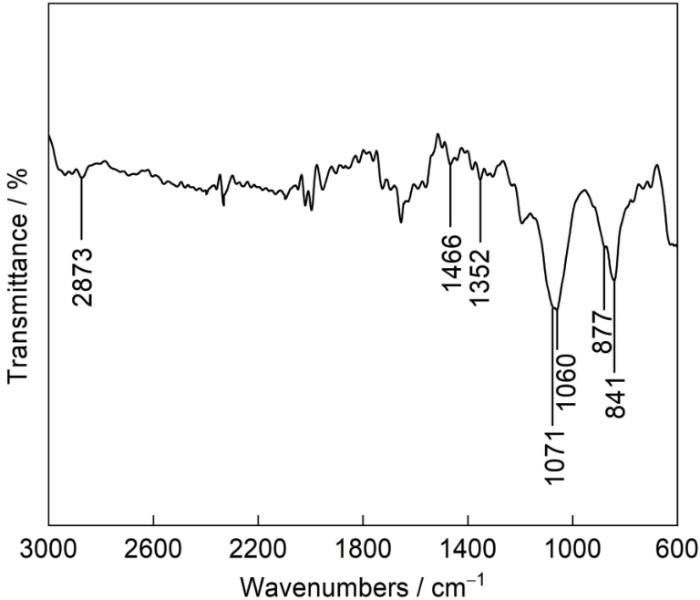

由图7所示超双疏试样的XPS测试结果可知,在F、C和Si元素分谱图(图7d~f)中可观察到C—F2、C—F3、CH2—CF2、C—O、C—C、C—Si、Si—O、Si—OH几种化学键的存在。图8为PFDTS修饰后超双疏表面的FT-IR光谱。由图中各吸收峰位置可得,在频率为2873和1466 cm-1处分别检测到了C—H键的伸缩振动峰和弯曲振动峰;在频率为1352和1071 cm-1处检测到了—CF2—和—CF3基团的伸缩振动峰;在频率为1060 cm-1处检测到了C—O键的伸缩振动峰;在频率为877和840 cm-1处检测到了Si—C键和Si—O键的伸缩振动峰。由EDS、XPS和FT-IR的测试结果及PFDTS在乙醇中会发生水解或醇解的反应原理,可推断出PFDTS通过水解或醇解反应与试样表面金属-羟基键(Me—OH)结合后附着到样品表面。PFDTS水解或醇解反应式以及连接到试样表面的原理[28]如下:

图8

图8

PFDTS修饰后超双疏表面红外图谱

Fig.8

FT-IR spectrum of the as-prepared superamphiphobic surface with PFDTS modification

由以上测试结果可知,经过超双疏处理后,呈层片状的CuO晶体和少量未结晶的Cu2O构成超双疏试样表面的粗糙结构,氟硅烷分子在超双疏试样表面相互交联构成低表面能分子膜,满足特殊粗糙表面和低表面能的要求[16],成功在B10合金基体上制备出超双疏表面。

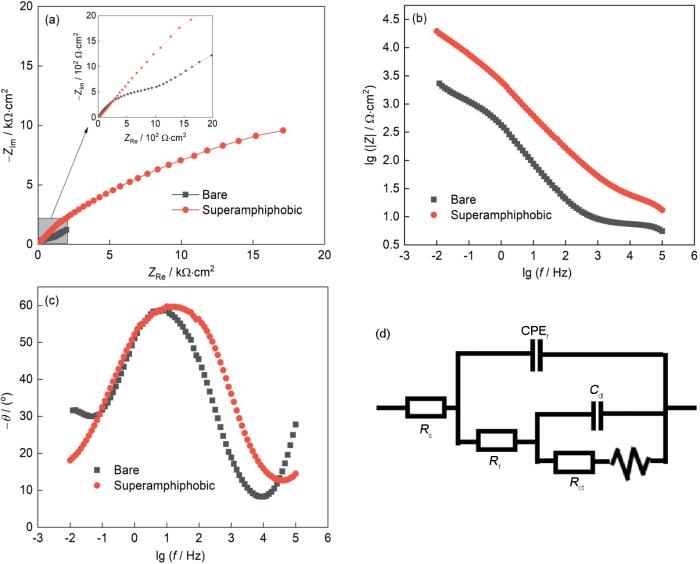

2.3 耐蚀性分析

由裸样和超双疏试样的Nyquist图及局部放大图(图9a)可得,超双疏试样容抗弧远大于裸样容抗弧,容抗弧越大,试样表面和腐蚀介质之间电子转移过程越困难,电阻越大,表明超双疏试样较于裸样耐蚀性能明显提升[29]。图9b反映频率和阻抗模值的关系。通常用低频区阻抗模值|Z|代表试样耐蚀性[16]。相同频率下,低频区裸样|Z|值为2.32 × 103 Ω·cm2,超双疏试样|Z|值为1.96 × 104 Ω·cm2,较裸样高一个数量级,表明超双疏膜层具有优异的缓蚀性能。图9c为裸样和超双疏试样的Bode相位角图。高频区(104~101 Hz)超双疏试样相位角值明显高于裸样,表明超双疏试样耐蚀性能更优,低频区(10-1~10-2 Hz)超双疏试样相位角值明显低于裸样,与Nyquist图容抗弧相对应。以上结果均表明超双疏试样耐蚀性能明显优于裸样。

图9

图9

裸样和超双疏试样在3.5%NaCl溶液中的电化学阻抗图谱

Fig.9

Nyquist (a), impedance module (b) and phase angle (c) plots of the bare sample and superamphiphobic sample in 3.5% NaCl solution and its equivalent circuit (d)

表3 裸样和超双疏试样电化学拟合参数

Table 3

| Sample | CPEf | Rf / kΩ·cm2 | Rct / kΩ·cm2 | Cdl / F·cm-2 | |

|---|---|---|---|---|---|

| Y0 / S·s n | n | ||||

| Bare | 5.301 × 10-4 | 0.7354 | 4.981 | 1.224 × 103 | 3.228 × 10-7 |

| Superamphiphobic | 1.297 × 10-4 | 0.6034 | 16.570 | 2.129 × 104 | 1.020 × 10-7 |

其中Rct1和Rct2分别代表裸样和超双疏试样电荷转移电阻,结合表3可得超双疏试样缓蚀效率为94.3%,表明超双疏表面对B10合金具有明显防腐作用。

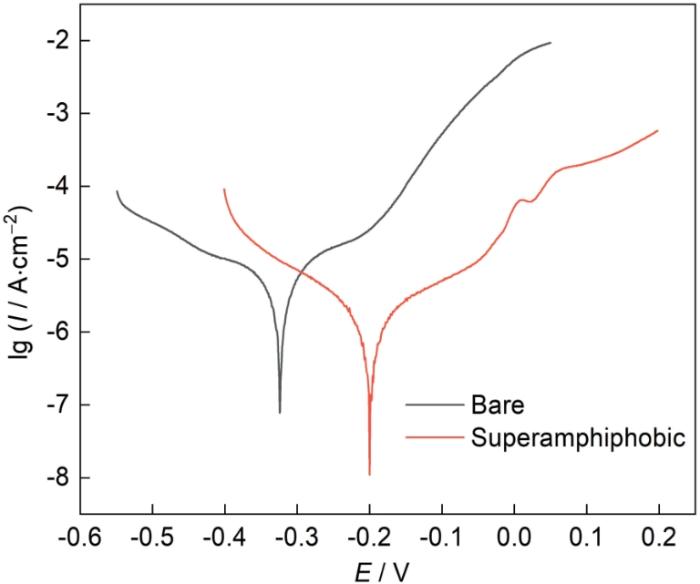

图10为裸样和超双疏试样在3.5%NaCl溶液中的动电位极化曲线。结果显示,裸样腐蚀电位为-0.324 V,腐蚀电流密度(Icorr)为1.192 × 10-5 A·cm-2;超双疏试样腐蚀电位正移至-0.204 V,Icorr为1.649 × 10-6 A·cm-2,较于裸样减小一个数量级。这归因于表面改性后,试样表面附着着氟硅烷构成的致密低表面能分子膜,它作为一层物理屏障,凭借其优异的超双疏性能有效阻止腐蚀性离子和B10合金直接接触,大幅降低电化学腐蚀行为的产生,使超双疏试样耐蚀性明显提升。

图10

图10

裸样和超双疏试样动电位极化曲线

Fig.10

Potentiodynamic polarization curves of bare sample and superamphiphobic sample

电化学测试结果表明,超双疏试样缓蚀效率达94.3%,和裸样相比,Rct增加一个数量级,Icorr减小一个数量级,腐蚀电位明显正移,表明超双疏试样耐蚀性能明显优于裸样。

2.4 自清洁性能分析

超双疏表面由于其特殊润湿性,具有特殊的自清洁性能[14],优异的自清洁性能不仅能保持超双疏表面清洁,还能减少腐蚀性物质与超双疏表面的作用时长,从而延缓其腐蚀。

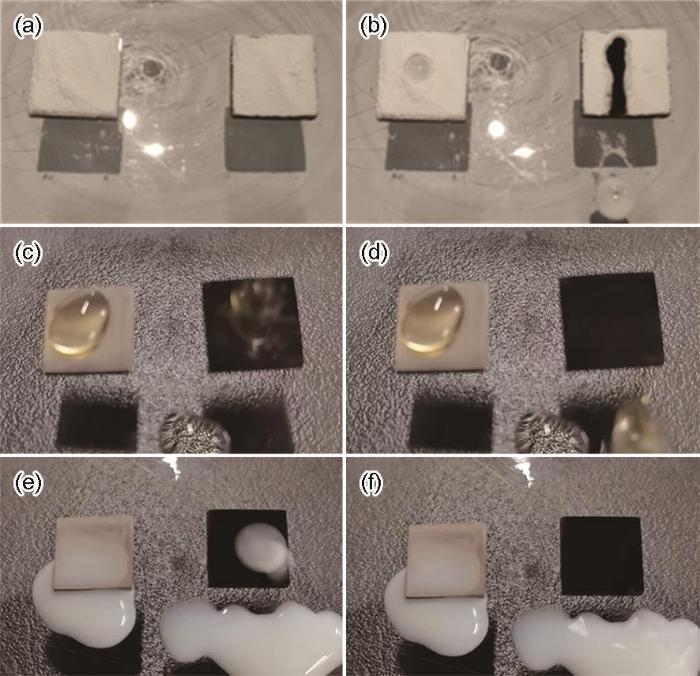

如图11所示,分别用Al2O3粉末、茶水和牛奶模拟自然界污染物测试超双疏试样的自清洁性能。对于Al2O3粉末的测试结果表明,水滴刚接触超双疏试样表面时,会迅速滚落并将均匀铺展在超双疏试样表面的Al2O3粉末全部带走,留下一条洁净通道,试样表面没有明显水痕;在裸样表面,水滴不会将Al2O3粉末顺利清理掉,还会导致其黏附到基体表面,难以清除。对于茶水和牛奶的测试结果表明,在大量茶水或牛奶冲刷后,裸样表面会附着有茶水或牛奶,而超双疏试样表面没有茶水或牛奶残留,始终保持清洁。

图11

图11

裸样(左)和超双疏试样(右)自清洁实验

Fig.11

Self-cleaning experiment of the bare sample (left) and superamphiphobic sample (right) Al2O3 powder (a, b), tea (c, d) and milk (e, f) simulate natural pollutants

自清洁性能测试结果表明,本实验制备的超双疏表面具备优越的自清洁能力,能在B10合金服役过程中减少表面与腐蚀性介质接触,起到缓蚀效果,提高其耐蚀性能。

2.5 耐摩擦性能分析

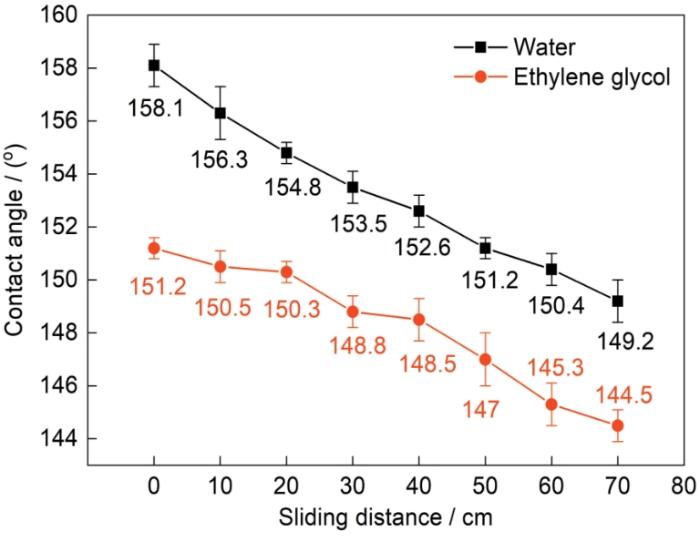

图12为水和乙二醇在超双疏表面接触角随滑动距离的变化。结果显示,对于本实验所制备的超双疏表面,当滑动距离小于20 cm时,水和乙二醇接触角保持在150°以上,表明试样表面形貌和氟硅烷分子膜没有受到明显破坏,样品仍保持超双疏性能。随着滑动距离增加,样品表面对水仍保持超疏性,但对乙二醇失去超疏性。当滑动距离大于60 cm时,样品对水和乙二醇均失去超疏性,表明此时试样表面遭受磨损程度增大,低表面能分子膜及特殊的微纳米粗糙结构遭到一定破坏,试样表面失去超双疏性能。但其仍保持较好的疏水疏油性能,能对基体起到一定保护效果。耐摩擦测试结果表明,制得的超双疏表面在较长滑动距离内,仍能对基体具备一定保护效果,起到缓蚀作用,证明其具有较好的机械耐磨性能[30,31]。

图12

图12

水和乙二醇在超双疏表面接触角随滑动距离的变化

Fig.12

Change of contact angle of water and ethylene glycol on the surface with sliding distance

3 结论

(1) 通过强碱刻蚀、氧化和氟硅烷修饰,在B10合金表面构建出超双疏表面。工艺条件为40 ℃下刻蚀5 h,160 ℃氧化1 h,1.0% PFDTS修饰1 h。制得的试样表面水和乙二醇接触角分别达到158.1°和151.2°,水的滚动角接近0°,乙二醇滚动角约为5°,达到超双疏表面的标准。

(2) 试样经过强碱刻蚀和氧化,表面生成主要由CuO构成的层片状微纳米粗糙结构,经氟硅烷修饰,表面附着着相互交联的低表面能分子膜,赋予B10合金表面超双疏性能。

(3) 超双疏试样和裸样相比,腐蚀电位正移至-0.204 V,腐蚀电流密度减小为1.649 × 10-6 A·cm-2,较裸样减小一个数量级,表明超双疏试样耐蚀性能明显优于裸样,自清洁性能测试表明超双疏表面具备优异自清洁性能,机械耐磨性能测试表明超双疏表面在较长滑动距离内,仍能对基体保持一定保护作用。

参考文献

The applications of Cu substrate in liquid metal cooling systems

[J].

Study of copper-nickel nanoparticle resistive ink compatible with printed copper films for power electronics applications

[J].

Surface characterization and corrosion behavior of 90/10 copper-nickel alloy in marine environment

[J].

Copper-nickel alloy friction surfaced coating on steel substrates for marine applications

[J].

Combined experimental and simulation study on corrosion behavior of B10 copper-nickel alloy welded joint under local turbulence

[J].

Corrosion failure 90/10 cupronickel tubes in a desalination plant

[J].

Insight to corrosion mechanism of 90/10 copper-nickel alloys under different sea depths

[J].

Superhydrophobic surface modification for corrosion protection of metals and alloys

[J].

Enhancing the lifespan and durability of superamphiphobic surfaces for potential industrial applications: A review

[J].

Hybrid superamphiphobic anti-corrosion coating with integrated functionalities of liquid repellency, self-cleaning, and anti-icing

[J].Superhydrophobic materials have shown tremendous potential in various fields. However, the adhesion, wetting, and pinning of low-surface-tension liquids greatly limit their multifunctional applications. Therefore, the creation of superamphiphobic coatings that combine superhydrophobic and superoleophobic properties through a simple preparation strategy is desirable. In this study, we successfully developed an organic-inorganic hybrid superamphiphobic coating on Q235 carbon steel using aluminum oxide nanoparticles, organosilanes, and waterborne epoxy resin <em>via</em> a versatile spray-coating technique. The coating exhibited high contact angles (> 151°) and low sliding angles (< 7°) for water and oil liquids, demonstrating excellent superamphiphobic characteristics. Electrochemical tests demonstrated significant improvements in charge transfer resistance and low-frequency modulus for the superamphiphobic coating. The corrosion potential shifted positively by 590 mV, and the corrosion current density decreased by four orders of magnitude. Additionally, the coating endured 480 h of salt spray and 2400 h of outdoor atmospheric exposure, showcasing superior anti-corrosion capacity. Freezing tests of water droplets at -10 °C and -15 °C confirmed that the coating significantly prolonged the freezing time with reduced ice adhesion strength. We believe that the designed superamphiphobic coating with integrated functionalities of self-cleaning, anti-corrosion, anti-icing, and anti-liquid-adhesion can provide important solutions for extending the lifespan of materials in marine and industrial environments.

Superamphiphobic TiO2 film by sol-gel dip coating method on commercial pure titanium

[J].

Facile preparation of superamphiphobic phosphate-Cu coating on iron substrate with mechanical stability, anti-frosting properties, and corrosion resistance

[J].

Super-robust superamphiphobic surface with anti-icing property

[J].Compared with superhydrophobic surfaces, superamphiphobic surfaces have a wider commercially availability. However, the initially fragile nature of micro or nano-structures hinders the large-scale applications of superamphiphobic surfaces. In this work, we report free-standing monoliths with durable superamphiphobic properties not only in the outer layer surfaces but also extending throughout the whole volume, which will demonstrate permanent superamphiphobicity. The monolith surface can repel a series of organic solutions with a surface tension as low as 36.4 mN m(-1), and display good self-cleaning effect toward to blood or viscous mud. In addition, the monolith can maintain the superhydrophobicity no matter whether facing corrosive solution attack or mechanical abrasion, indicating the excellent chemical and mechanical properties. The monolith surfaces also display delayed-icing property and easy de-icing process.

A rapid two-step method for fabrication of superhydrophobic-superoleophobic nickel/copper alloy coating with self-cleaning and anticorrosion properties

[J].

Preparation of a superhydrophilic and superoleophobic sponge for continuous oil/water and oil/oil separation

[J].

Preparation and corrosion resistance of superamphiphobic surface on B10 Cu-alloy

[J].

B10铜合金超双疏表面的制备及其性能研究

[J].采用FeCl<sub>3</sub>盐溶液刻蚀以及氟硅烷修饰的方法,在B10铜合金基体上成功制备出具有良好耐蚀性的超双疏表面,其对水与乙二醇的接触角分别为158°和151°。采用扫描电子显微镜(SEM)、激光扫描共聚焦显微镜(LSCM)、X射线衍射仪(XRD)、能谱仪(EDS)和X射线光电子能谱(XPS)等手段对其表面微观形貌、化学成分进行表征。通过电化学阻抗谱(EIS)测试以及Tafel极化曲线探究了超双疏试样的耐腐蚀性能。结果表明,相较于裸样,超双疏试样的自腐蚀电位正移至-0.248 V,腐蚀电流密度(I<sub>corr</sub> = 2.05 × 10<sup>-6</sup> A·cm<sup>-2</sup>)降低了一个数量级,展现出优异的耐腐蚀性能;在3.5%(质量分数)NaCl溶液中浸泡5 d后,超双疏试样的电荷转移电阻仍明显高于裸样,保持着较好的耐蚀性。

Simple fabrication of superamphiphobic copper surfaces with multilevel structures

[J].

The research on preparation of superhydrophobic surfaces of pure copper by hydrothermal method and its corrosion resistance

[J].

Adjustable oil adhesion on superamphiphobic copper surfaces for controlled oil droplet transport

[J].

Fabrication of superamphiphobic Cu surfaces using hierarchical surface morphology and fluorocarbon attachment facilitated by plasma activation

[J].

Simple fabrication of superhydrophobic/superoleophobic surfaces on copper substrate by two-step method

[J].

A study of corrosion on electrodeposited superhydrophobic copper surfaces

[J].

Optimization of selective copper extraction from chalcopyrite concentrate in presence of ammonium persulfate and ammonium hydroxide

[J].

Forces at superhydrophobic and superamphiphobic surfaces

[J].

Metallic surfaces with special wettability

[J].Metals are important and irreplaceable engineered materials in our society. Nature is a school for scientists and engineers, which has long served as a source of inspiration for humans. Inspired by nature, a variety of metallic surfaces with special wettability have been fabricated in recent years through the combination of surface micro- and nanostructures and chemical composition. These metallic surfaces with special wettability exhibit important applications in anti-corrosion, microfluidic systems, oil-water separation, liquid transportation, and other fields. Recent achievements in the fabrication and application of metallic surfaces with special wettability are presented in this review. The research prospects and directions of this field are also briefly addressed. We hope this review will be beneficial to expand the practical applications of metals and offer some inspirations to the researchers in the fields of engineering, biomedicine, and materials science.

Recent progress in superhydrophobic and superamphiphobic coatings for magnesium and its alloys

[J].

Preparation of superhydrophobic surface on copper substrate and its corrosion resistance

[J].

铜基超疏水表面的制备及其耐蚀性研究

[J].以十二硫醇作为疏水剂,采用化学刻蚀和高温氧化在铜基体上构造超疏水表面,以提高铜基体的耐蚀性。结果表明,当化学刻蚀8 min、高温氧化6 h、十二硫醇修饰15 min,基体表面形成了具有足够粗糙度并可以捕获大量空气的网状层叠结构,此时基体表面疏水性最好,水的接触角为165.50°。动电位极化曲线表明,超疏水表面的腐蚀速率明显降低,腐蚀电流密度由7.43×10<sup>-5</sup>下降至4.31×10<sup>-6</sup> A·cm<sup>-2</sup>。电化学阻抗谱表明,超疏水表面的电荷转移电阻明显高于铜基体,说明其具耐蚀性相较于铜基体也得到了提高。与当前制备超疏水表面的方法相比,本方法具有廉价、简单、环保的特点。

Construction and corrosion behaviors of a bilayer superhydrophobic film on copper substrate

[J].

Preparation of superamphiphobic surface on Al-alloy and its corrosion resistance

[J].

铝合金超双疏表面的制备及其耐蚀性研究

[J].采用盐溶液刻蚀和水浴处理的方法,结合氟硅烷的表面修饰,在5083铝合金基体上制备出了超双疏表面。采用场发射扫描电子显微镜 (FE-SEM)、X射线衍射 (XRD)、X射线光电子能谱 (XPS)、接触角测量和电化学测试等方法研究了超双疏铝合金表面的微观形貌、化学成分、疏水疏油性和耐蚀性。结果表明,水和乙二醇在该表面上的接触角分别为 158°和154.3°,展现出良好的超双疏性能;与基体相比,超双疏试样的腐蚀电位明显正移,腐蚀电流密度由4.016×10<sup>-6</sup> A·cm<sup>-2</sup>下降至1.531×10<sup>-7</sup> A·cm<sup>-2</sup>;在3.5% (质量分数) NaCl溶液中浸泡5 d后,超双疏试样的电荷转移电阻仍明显高于基体,提高了5083铝合金基体的耐蚀性。

Recent advances on the abrasion resistance enhancements and applications of superhydrophobic materials

[J].

Spray-coating of superhydrophobic aluminum alloys with enhanced mechanical robustness

[J].