海洋蕴藏着丰富的资源,受到广泛重视[1]。海洋也是各国海洋科学探索和先进海洋技术比拼的主战场,许多国家加快海洋装备的研制和部署[2,3]。海洋装备需要长期在苛刻的海洋环境中服役,必须要保证材料的可靠性,这就要求材料必须具备高性能,其中耐蚀性好、强度高是两个必要的条件。铝合金具有可塑性好、刚度高等优点,且兼具优良的导电性、导热性和耐腐蚀性能。高强铝合金因为具有较高的强度和韧性,起初应用于航空领域,后来逐渐应用到海洋工程领域[4~7]。高强铝合金虽然具有较为明显的优点,但是其内部结构较为复杂,存在金属间化合物和强化相,应力腐蚀敏感性较强,发生晶界腐蚀、点蚀、缝隙腐蚀的危险性较大[8~10]。另外,高强度铝合金焊接接头的腐蚀和性能退化问题逐渐凸显。一方面,苛刻的海水环境[11]以及复杂服役环境使得铝合金结构易受到腐蚀性离子和应力耦合作用,加剧侵蚀损伤的发生,另一方面铝合金焊接过程中产生包括自身化学成分、内部组织结构、焊接工艺、焊接缺陷、残余应力等问题,焊接工艺中不同的影响因素会导致腐蚀敏感区域不同,电化学电位也有所差异,从而导致发生的腐蚀程度不同,这些问题很大程度影响高强铝合金的使用寿命。

国内外许多学者对7075铝合金进行了不同的处理,提高了其耐蚀性能[12,13]。LY12CZ高强铝合金的应力腐蚀行为可能因极化电位不同而表现出两种机制[14]。高强铝合金焊接后,由于内部晶粒和化学成分分布不均,表面形成多个微电极,引发电偶腐蚀[15]。搅拌摩擦焊焊缝块区的Al基晶粒越细,钝化程度越强,耐腐蚀性越好。6005A铝合金母材的腐蚀疲劳裂纹主要由夹杂物和焊接缺陷区域的阳极溶解和氢气浓度引起[16]。铝合金应用时必须考虑其强度、韧性、特别是耐应力腐蚀特性[17~20]。高强铝合金中加入了Zn、Cu等合金元素高强铝合金热处理后,其强度会远高于低碳钢。然而7系高强铝合金的应力腐蚀敏感性高,限制了使用范围,有研究表明在实验室模拟低温海水环境溶液中,7系铝合金的应力腐蚀敏感性较强[21,22],这可能与铝合金自身内部结构有关。金属的应力腐蚀开裂脆性断裂过程,是由应力和介质共同作用下产生的[23]。许多研究人员通过实验室模拟试验解释了这种裂纹产生的类型[24]。金属发生应力腐蚀的过程中,裂纹使应力高度集中,使其周围区域发生变形,裂纹会不断地向内部发展,最终导致金属断裂失效。Dollah[25]研究了7系高强铝合金在模拟海洋环境中在不同应力下的腐蚀行为,结果表明应力会对铝合金的腐蚀敏感性造成影响。Tasi等[26]研究不同因素对铝合金的应力腐蚀的影响,表明应变速率的增大会降低铝合金的耐腐蚀性能。花天顺等[27]采用恒载荷的方法研究了7050系铝合金的腐蚀行为,结果表明溶液的pH值对7050的耐蚀性有较大影响。孟祥琦[28]研究了铝合金材料的应力腐蚀行为,结果表明当裂纹开始扩展后,材料形状发生改变,试样内部应力逐渐减小,随着应力腐蚀进程发展,试样应变缓慢增加。有研究表明,外加载荷的存在会影响高强铝合金的耐腐蚀性能[29]。

尽管铝合金在海洋环境中的腐蚀行为已被广泛研究,但铝合金焊接接头在力学-电化学耦合作用下的腐蚀以及腐蚀后的性能退化规律尚待深入分析。7系铝合金焊接接头在海洋环境下的腐蚀行为是一个比较复杂且相对快速的过程,在受力条件下,焊接接头表现出来的腐蚀行为更加复杂。本文通过模拟低温海水环境,研究不同应力下高强铝合金焊接的腐蚀行为,最后对腐蚀后的焊接接头进行退化性能测试,分析了其应力损失以及应力腐蚀敏感性,为高强铝合金焊接接头在极地、深海等低温海水环境中应用选材以及防护提供参考。

1 实验方法

7xxx高强铝合金化学成分(质量分数,%)为:Zn 6.853,Mg 2.545,Cu 1.634,Fe 0.389,Si 0.103,Cr 0.236,Mn 0.182,Al余量。试验对象为高强铝合金焊接接头,焊接接头由氩弧焊方式制得。铝合金焊接接头应力-电化学腐蚀行为试样参考GB/T 15970.7-2000制备试样。预加应力试样尺寸如图1所示,单位mm。不加应力试样尺寸为30 mm × 50 mm × 3 mm。低温模拟实验是在低温箱中完成的,采用青岛天然海水浸泡,周期为1、5、10、15和20 d。模拟海水浸泡环境为常压,温度为5 ℃,溶解氧含量为3.5 mg/L。

图1

通过夹具给高强铝合金及其焊接接头施加不同大小的载荷,夹具为不锈钢材质,将试样放置于夹具中通过316L不锈钢的金属销和螺栓将试样固定在夹具上,通过拉伸试验机拉伸实现外加载荷施加。高强铝合金焊接接头施加载荷大小分别为0、25%σs、50%σs,屈服强度σs为455.83 MPa。

电化学测试试样制备。将高强铝合金与焊接接头不加应力试样加工为10 mm × 10 mm × 10 mm正方体试样,采用环氧树脂进行封样,露出工作面积为10 mm × 10 mm,打磨抛光后备用。外加应力试样先进行打磨抛光,使用恒载荷夹具进行应力加载。焊接接头带应力试样测试面积为0.3 cm2。电化学测试在Biologic VMP3型电化学工作站上进行,采用三电极体系,参比电极为饱和甘汞电极(SCE),辅助电极为铂片电极。待开路电位稳定后进行电化学阻抗谱(EIS)测试,频率范围为105~10-2 Hz。动电位极化曲线的扫描范围为-0.3~0.6 V,扫描速率为0.333 mV/s。

将完成浸泡实验的试样取出后,用数码相机拍摄表面宏观形貌,通过Zeiss Ultra55型扫描电子显微镜(SEM)观察浸泡腐蚀实验后的腐蚀试样的表面微观形貌,利用扫描电镜自带能谱仪(EDS)分析腐蚀产物元素分布。对浸泡完成的试样使用ESCALAB 250Xi型X射线光电子能谱仪(XPS)进行分析测试。

2 铝合金焊接接头力学-电化学腐蚀行为

2.1 宏观腐蚀形貌

图2为在不同应力下铝合金焊接接头在低温海水环境中浸泡1、5、10和20 d的宏观图片。浸泡初期,铝合金焊接接头表面变黑,随着浸泡时间增加,浸泡5 d、应力为25%σs时,焊接接头相较于基材腐蚀并不明显,应力增至50%σs时,焊接接头的腐蚀变得严重。在浸泡10 d、应力为25%σs时,开始出现点蚀痕迹,当应力增大至50%σs时,点蚀更为明显。浸泡20 d后,焊缝区表面腐蚀产物膜有轻微脱落现象。

图2

图2

不同应力下高强铝合金焊接接头在低温海水中浸泡不同周期的宏观形貌

Fig.2

Macroscopic morphologies of high-strength Al-alloy welded joint samples immersed in low temperature seawater for 1 d(a), 5 d (b), 10 d (c) and 20 d (d) under applied stresses of 0 (a1-d1), 25%σs (a2-d2) and 50%σs (a3-d3)

2.2 微观腐蚀形貌

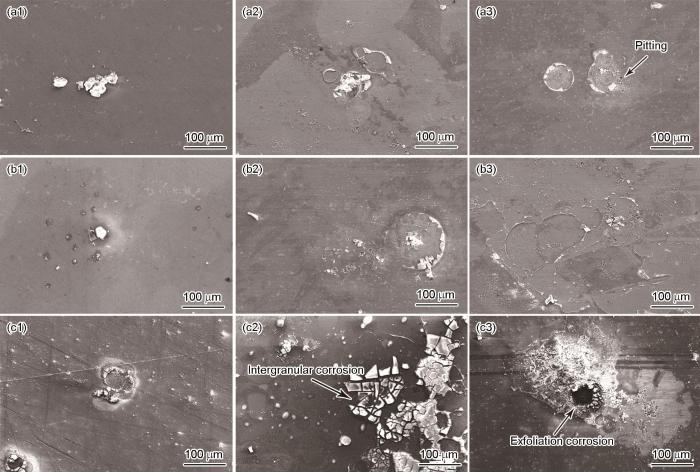

图3

图3

不同应力下高强铝合金焊接接头在低温海水中浸泡不同周期后表面形貌

Fig.3

SEM images of high-strength Al-alloy welded joint samples immersed in low temperature seawater for 1 d (a), 10 d (b) and 20 d (c) under the stresses of 0 (a1-c1), 25%σs (a2-c2) and 50%σs (a3-c3)

从表1合金试样表面腐蚀产物层的EDS成分分析可知,高强铝合金焊接接头表面腐蚀产物的主要元素为Al、O、Zn、Mg、Cu。当施加应力超过25%σs时,O含量增大,而Al、Mg元素含量减小。这主要是由于无应力作用时,高强铝合金焊接接头与海水中氧气反应形成致密氧化产物膜,对基体起到保护作用,氧含量较多。施加25%σs应力时表面腐蚀产物膜遭到破坏,使得离子进入膜层相对容易,一些金属氧化物会和Cl-结合转化为水溶性的氯化物或者氯氧化物,另外,有部分腐蚀产物膜开始剥落,从而氧含量降低。当外加应力增大到50%σs时,随着施加应力增加腐蚀产物表面出现裂缝,海水中的氧气和离子进入基体与其反应,腐蚀产物中氧含量增加。

表1 不同应力下高强铝合金焊接接头在低温海中浸泡20 d的EDS分析结果 (atomic fraction / %)

Table 1

| Pre-stress | O | Al | Zn | Mg | Cu |

|---|---|---|---|---|---|

| 0 | 46.45 | 45.72 | 0.85 | 4.45 | 0.17 |

| 25%σs | 41.82 | 52.74 | 0.87 | 4.00 | 0.14 |

| 50%σs | 46.73 | 47.41 | 1.97 | 3.03 | 0.38 |

2.3 极化特征分析

图4为铝合金焊接接头在无应力及25%σs、50%σs应力作用下,在模拟低温海水环境下浸泡不同周期的动电位极化曲线。将极化曲线进行拟合得出不同应力、不同周期下的自腐蚀参数如表2所示。根据电化学中的Faraday定律,I0越小,电化学腐蚀速率越慢,代表材料的耐腐性能更好。分析图4和表2,浸泡周期相同时,随着外加应力的增加,高强铝合金焊接接头的自腐蚀电位随之负移。腐蚀电位越负,表明材料的腐蚀倾向性越明显。有应力时比无应力时电位下降较大,说明在应力条件下,焊接接头的腐蚀敏感性更强。这可能是由于铝合金焊接接头在焊接过程中相当于进行一次热处理,其焊接接头晶粒与晶界的化学性质发生变化。析出相(Zn2Mg)与周围其他区域(Zn, Mg)相存在电位差,导致其电位变低,腐蚀敏感性变大,导致材料的耐蚀性变差[31]。从腐蚀学角度看,焊接区域组织更为致密均匀,能有效改善高强铝合金焊接接头内部组织的电化学不均匀性,降低材料形成局部腐蚀倾向,提高材料的耐蚀性,但是在结晶过程中,因为过冷度的问题会发生金属杂质偏析[32],从而导致高强焊接接头内部化学成分分布不均匀。同时高强铝合金焊接接头发生腐蚀破坏还受到外加应力的影响,这种拉伸应力对极化曲线的影响是一种力学-电化学效应,会在铝合金焊接接头的焊接缺陷及裂纹等应力集中区域得到加强,并加重局部腐蚀。

图4

图4

不同应力下高强铝合金焊接接头在低温海水中浸泡不同周期的极化曲线

Fig.4

Polarization curves of the welded joint immersed in low-temperature seawater under different stresses for 1 d (a), 5 d (b), 10 d (c) and 20 d (d)

表2 不同应力下高强铝合金焊接接头在低温海水中浸泡不同周期极化拟合结果

Table 2

| Immersion time / d | Pre-stress | Self-corrosion potential E0 / V | Self-corrosion current density I0 / A·cm-2 |

|---|---|---|---|

| 1 | 0 | -0.652 | 0.395 × 10-6 |

| 25%σs | -0.693 | 2.023 × 10-6 | |

| 50%σs | -0.754 | 4.467 × 10-6 | |

| 5 | 0 | -0.757 | 0.775 × 10-6 |

| 25%σs | -0.856 | 4.6 × 10-6 | |

| 50%σs | -0.820 | 6.94 × 10-6 | |

| 10 | 0 | -0.766 | 0.983 × 10-6 |

| 25%σs | -0.813 | 15.58 × 10-6 | |

| 50%σs | -0.897 | 15.37 × 10-6 | |

| 20 | 0 | -0.801 | 2.36 × 10-6 |

| 25%σs | -0.838 | 12.56 × 10-6 | |

| 50%σs | -0.846 | 17.2 × 10-6 |

2.4 电化学阻抗分析

图5

图5

不同应力下高强铝合金焊接接头在低温海水中浸泡不同周期后的电化学阻抗谱

Fig.5

EIS of high-strength Al-alloy welded joint immersed in low temperature seawater under different stresses for 1 d (a), 5 d (b), 10 d (c) and 20 d (d)

图6

表3 高强铝合金焊接接头低温海水条件下阻抗拟合结果

Table 3

| Immersion time / d | Pre-stress | Rs / Ω·cm2 | Rct / 103 Ω·cm2 | Rf / Ω·cm2 |

|---|---|---|---|---|

| 1 | 0 | 10.17 | 8.805 | 1.328 |

| 25%σs | 7.09 | 5.037 | 29.45 | |

| 50%σs | 12.74 | 2.764 | 32.76 | |

| 5 | 0 | 8.29 | 7.577 | 3.659 |

| 25%σs | 10.32 | 4.237 | 1.489 | |

| 50%σs | 6.554 | 0.865 | 2.489 | |

| 10 | 0 | 13.3 | 3.850 | 847.2 |

| 25%σs | 6.679 | 3.783 | 29.03 | |

| 50%σs | 8.834 | 1.453 | 149.4 | |

| 20 | 0 | 7.81 | 3.409 | 2200 |

| 25%σs | 8.593 | 1.564 | 3.391 | |

| 50%σs | 6.725 | 0.789 | 538.9 |

由表3可见,在浸泡周期相同条件下,随着施加应力的增加,焊接接头的Rct值逐渐减小。铝合金焊接接头无应力条件下Rct值比施加50%σs应力时的Rct值大数倍,说明当应力达到一定程度时,焊接接头的耐蚀性退化较多。这可能是因为高强铝合金焊接接头在焊接过程中焊接处存在较多的气孔,气孔周围容易生成裂纹[33],当无应力或者低应力时,裂纹生成和扩展比较缓慢,对腐蚀影响不大,但当应力增大至50%σs时,裂纹随之扩大。海水中的Cl-等离子通过裂纹进一步渗透到焊接接头的内部。在聚集到一定浓度后,造成原有氧化膜的破裂,材料表面形成点蚀坑,使得氧化膜变得不稳定或破裂,从而导致Rct值下降。同样在外加应力相同的条件下,随着浸泡时间的增加,焊接接头内部裂纹会一直扩展,Rct值大致呈不断减小的趋势。这表明无论是浸泡时间还是外加应力的增加,都会导致焊接接头的Rct值减小,耐蚀性能逐渐变差。

2.5 腐蚀产物分析

图7为焊接接头在受到50%σs应力下浸泡20 d后腐蚀产物中的Al,Mg和Zn的XPS谱。50%σs应力下浸泡20 d后,Al 2p的XPS峰有两个,对应的结合能为73.86和75.2 eV;说明Al的腐蚀产物以Al2O3和Al(OH)3为主。Mg 1s的XPS峰有两个,对应的结合能为1303.8 和1304.1 eV;说明Mg在腐蚀产物中以MgO和Mg(OH)2为主。Zn 2p的两个XPS峰对应的结合能为1022.1和1044.8 eV,说明Zn在腐蚀产物中以ZnO为主。

图7

图7

高强铝合金焊接接头在低温海水浸泡后XPS能谱图

Fig.7

XPS spectra of high-strength Al-alloy welded joint immersed in low-temperature seawater: (a) Al, (b) Mg, (c) Zn

7xxx高强铝合金属于Al-Zn-Mg-Cu系,当高强铝合金与海水接触后,与氧气反应生成氧化膜,铝合金表面生成的氧化膜覆盖在基体表面,在一定程度上阻碍了腐蚀进程,从而减缓腐蚀。高强铝合金中的第二相η (MgZn2,Mg2Si)与基体相比电位较负,形成电位差,第二相作为微电池结构中的阳极,率先开始溶解,而铝基体作为阴极未被腐蚀,随着第二相溶解并脱落,暴露出铝基体,此时铝基体与表面氧化膜形成电位差,基体作为阳极,开始反应溶解。此外Zn2+作为析出离子,会得到电子沉积在氧化膜的表面。施加应力后,会导致铝合金内部晶粒出现位错现象,腐蚀产物膜被破坏,基体与腐蚀坑周围的膜层产生电位差,使得腐蚀坑内部产生裂纹,随着浸泡时间的增加,点蚀坑内部会出现更大的裂纹,海水中的Cl-不断从裂纹进入基体内部,铝基体此时作为阳极溶解,腐蚀速率会增大。

3 铝合金焊接接头力学性能退化分析

3.1 微观断口形貌分析

图8

图8

低温海水中不同应力下高强铝合金焊接接头浸泡1和15 d后微观断口形貌

Fig.8

Microscopic fracture morphologies of the welded joint after immersion in low-temperature seawater for 1 d (a) and 15 d (b) under the stresses of 25%σs (a1, b1) and 50%σs (a2, b2)

3.2 性能退化分析

表4为不同应力下高强铝合金在低温海水中浸泡不同周期后的拉伸数据。可以看出,随着浸泡时间增长和外加应力的增大,屈服强度与抗拉强度均呈下降趋势。焊接接头内的第二相经过焊接工艺处理后,晶粒尺寸与大小发生改变,在力学-电化学腐蚀后,力学性能变差,耐腐蚀性能也同样受到影响。

表4 不同应力下铝合金焊接接头在低温海水中浸泡不同周期后的拉伸数据

Table 4

| Immersion time / d | Pre-stress | Yield strength / MPa | Tensile strength / MPa |

|---|---|---|---|

| 1 | 25%σs | 211 | 270 |

| 50%σs | 175 | 225 | |

| 5 | 25%σs | 163 | 241 |

| 50%σs | 150 | 220 | |

| 15 | 25%σs | 150 | 218 |

| 50%σs | 145 | 178 |

表5为应力作用下铝合金焊接接头在低温海水中浸泡不同周期后的断裂数据结果。可以看出,浸泡时间相同时,随着外加应力增大,焊接接头的δ和Ψ随之减小。在浸泡1 d、25%σs应力时,δ和Ψ最大分别为10.85%和11.383%。说明此时的应力腐蚀倾向性最低。当浸泡15 d、50%σs应力时,δ和Ψ最小,分别为8.56%、9.861%,说明此时的应力腐蚀敏感性最强。

表5 不同应力下铝合金焊接接头在低温海水中浸泡不同周期后的断裂数据

Table 5

| Immersion time / d | Pre- stress | Post-fracture elongation (δ) / % | Section shrinkage (Ψ) / % |

|---|---|---|---|

| 1 | 25%σs | 10.85 | 11.383 |

| 50%σs | 10.15 | 11.041 | |

| 5 | 25%σs | 10.81 | 10.564 |

| 50%σs | 9.24 | 10.220 | |

| 15 | 25%σs | 9.87 | 10.250 |

| 50%σs | 8.56 | 9.861 |

4 结论

(1) 在预加应力和海水电化学腐蚀耦合作用下,高强钢铝合金焊接接头产生了点蚀、晶间腐蚀和剥落腐蚀。

(2) 外加应力对铝合金腐蚀的影响是一种力学-电化学效应,会在铝合金焊接接头的焊接缺陷及裂纹等应力集中区域得到加强。随着应力增加、浸泡时间增长,焊接接头腐蚀电位变负,电荷转移电阻变小,腐蚀敏感性变大,耐蚀性变差。

(3) 高强铝合金焊接接头腐蚀产物主要为Al2O3、Al(OH)3、MgO、Mg(OH)2和ZnO。当受到应力超过25%σs时,随着应力增加,腐蚀产物中的O元素含量升高,Al元素含量降低。

(4) 随着应力增大和浸泡时间延长,腐蚀后铝合金的断口出现紧缩,力学性能退化,断后伸长率和断面收缩率均降低,应力腐蚀敏感性增强。

参考文献

Research progress of stress corrosion cracking of Ti-alloy in deep sea environments

[J].

钛合金深海应力腐蚀研究进展

[J].基于对钛合金应用及研究报道的梳理,综述了钛合金深海应力腐蚀产生原因及机理,探讨了静水压力、溶解氧含量、pH值和温度等深海环境因素对应力腐蚀开裂的影响,以期为今后钛合金深海应力腐蚀开裂等局部腐蚀行为及机制的深入研究提供参考,为优化钛合金组织性能,建立深海先进钛合金材料体系提供支撑。

A comparative experimental approach to ecotoxicology in shallow-water and deep-sea holothurians suggests similar behavioural responses

[J].Exploration of deep-sea mineral resources is burgeoning, raising concerns regarding ecotoxicological impacts on deep-sea fauna. Assessing toxicity in deep-sea species is technologically challenging, which promotes interest in establishing shallow-water ecotoxicological proxy species. However, the effects of temperature and hydrostatic pressure on toxicity, and how adaptation to deep-sea environmental conditions might moderate these effects, are unknown. To address these uncertainties we assessed behavioural and physiological (antioxidant enzyme activity) responses to exposure to copper-spiked artificial sediments in a laboratory experiment using a shallow-water holothurian (Holothuria forskali), and in an in situ experiment using a deep-sea holothurian (Amperima sp.). Both species demonstrated sustained avoidance behaviour, evading contact with contaminated artificial sediment. However, A. sp. demonstrated sustained avoidance of 5mgl copper-contaminated artificial sediment whereas H. forskali demonstrated only temporary avoidance of 5mgl copper-contaminated artificial sediment, suggesting that H. forskali may be more tolerant of metal exposure over 96h. Nonetheless, the acute behavioural response appears consistent between the shallow-water species and the deep-sea species, suggesting that H. forskali may be a suitable ecotoxicological proxy for A. sp. in acute (≤24h) exposures, which may be representative of deep-sea mining impacts. No antioxidant response was observed in either species, which was interpreted to be the consequence of avoiding copper exposure. Although these data suggest that shallow-water taxa may be suitable ecotoxicological proxies for deep-sea taxa, differences in methodological and analytical approaches, and in sex and reproductive stage of experimental subjects, require caution in assessing the suitability of H. forskali as an ecotoxicological proxy for A. sp. Nonetheless, avoidance behaviour may have bioenergetic consequences that affect growth and/or reproductive output, potentially impacting fecundity and/or offspring fitness, and thus influencing source-sink dynamics and persistence of wider deep-sea populations.Copyright © 2017 Elsevier B.V. All rights reserved.

Emerging conservation challenges and prospects in an era of offshore hydrocarbon exploration and exploitation

[J].Globally, extensive marine areas important for biodiversity conservation and ecosystem functioning are undergoing exploration and extraction of oil and natural gas resources. Such operations are expanding to previously inaccessible deep waters and other frontier regions, while conservation-related legislation and planning is often lacking. Conservation challenges arising from offshore hydrocarbon development are wide-ranging. These challenges include threats to ecosystems and marine species from oil spills, negative impacts on native biodiversity from invasive species colonizing drilling infrastructure, and increased political conflicts that can delay conservation actions. With mounting offshore operations, conservationists need to urgently consider some possible opportunities that could be leveraged for conservation. Leveraging options, as part of multi-billion dollar marine hydrocarbon operations, include the use of facilities and costly equipment of the deep and ultra-deep hydrocarbon industry for deep-sea conservation research and monitoring and establishing new conservation research, practice, and monitoring funds and environmental offsetting schemes. The conservation community, including conservation scientists, should become more involved in the earliest planning and exploration phases and remain involved throughout the operations so as to influence decision making and promote continuous monitoring of biodiversity and ecosystems. A prompt response by conservation professionals to offshore oil and gas developments can mitigate impacts of future decisions and actions of the industry and governments. New environmental decision support tools can be used to explicitly incorporate the impacts of hydrocarbon operations on biodiversity into marine spatial and conservation plans and thus allow for optimum trade-offs among multiple objectives, costs, and risks. © 2015 Society for Conservation Biology.

Research of electrochemical corrosion performance of aluminum alloy offshore drill served in deep ocean

[J].

深海用铝合金海工钻杆抗电化学腐蚀性能的研究

[J].

Corrosion behaviors of aluminum alloys in different harbors

[J].

不同港口海域铝合金腐蚀行为研究

[J].

Corrosion behavior of riveted pair of 6A01 Al-alloy-/304 stainless steel-plate used for high-speed train

[J].

高速列车铆接件中6A01铝合金腐蚀行为研究

[J].利用失重法、扫描电子显微镜 (SEM)、能谱仪 (EDS)、X射线衍射仪 (XRD)、3D超景深显微镜等方法分析了试样的腐蚀动力学、锈层成分、腐蚀形貌。结果表明:偶接后铝合金发生了电偶腐蚀,电偶腐蚀速率是自腐蚀速率的8~10倍。铝合金主要腐蚀产物为Al<sub>2</sub>O<sub>3</sub>、Al(OH)<sub>3</sub>、AlO(OH)、AlCl<sub>3</sub>,腐蚀产物的变化影响了铝合金的腐蚀过程,产物的龟裂加速了腐蚀,而产物的致密化起到了保护作用。

Research progress on corrosion and protection of typical warship metal materials

[J].

典型舰船用金属材料腐蚀与防护研究进展

[J].

Corrosion and protection of aluminum alloy for marine engineering

[J].

海洋工程用铝合金的腐蚀与防护研究进展

[J].

Effect of nitrate and galvanic couple on crevice corrosion behavior of 7075-T651 Al-alloy in neutral NaCl solution

[J].

中性氯化钠溶液中硝酸根和电偶对7075-T651铝合金缝隙腐蚀行为影响研究

[J].

Localized corrosion mechanism of 5083-H111 Al alloy in simulated dynamic seawater zone

[J].

5083-H111铝合金在模拟动态海水环境中的局部腐蚀机制

[J].采用开路电位 (OCP)、电化学阻抗谱 (EIS),并结合扫描电子显微镜 (SEM) 和X射线光电子能谱 (XPS) 技术,研究了5083-H111铝合金在模拟动态海水环境中的电化学行为,并探讨了局部腐蚀机制。5083-H111铝合金的金属间化合物以Al-Fe和Mg-Si相为主,点蚀主要分布于金属间化合物周围;Al-Fe相在腐蚀过程中充当阴极,与周围Al基体构成微腐蚀电池,促使Al基体的点蚀。Mg-Si相在腐蚀过程中最初充当阳极,当其发生选择性溶解导致脱合金化逐渐形成富Si相后,变为阴极,促使Al基体发生点蚀。5083-H111铝合金表面生成的腐蚀产物为Al(OH)<sub>3</sub>、Al<sub>2</sub>O<sub>3</sub>和AlCl<sub>3</sub>。腐蚀产物在腐蚀初期对Al基体起到良好的保护作用,导致OCP正移,极化电阻 (R<sub>p</sub>) 增大;腐蚀后期 (36~56 d),初始腐蚀产物会发生局部脱落,在脱落位置Al基体再次发生局部腐蚀,导致OCP负移,R<sub>p</sub>急剧减小。随着暴露时间的延长,部分金属间化合物在腐蚀后期会发生脱落,形成腐蚀空腔。

Corrosion behaviors of 5083 aluminum alloy in tropical marine environment

[J].

热带海洋环境中5083铝合金腐蚀行为研究

[J].

Role of gradient nanograined surface layer on corrosion behavior of aluminum 7075 alloy

[J].

Microstructure and corrosion evolution of additively manufactured aluminium alloy AA7075 as a function of ageing

[J].

Corrosion behavior and mechanical properties of Al-Zn-Mg aluminum alloy weld

[J].

Galvanic corrosion behavior of friction stir welded AZ31B magnesium alloy and 6N01 aluminum alloy dissimilar joints

[J].

Study on corrosion fatigue behavior and mechanism of 6005A aluminum alloy and welded joint

[J].

Retrogression and reaging of 7075 T6 aluminum alloy

[J].

Stress corrosion cracking of superplastically formed 7475 aluminum alloy

[J].

Electrical conductivity variations in X2096, 8090, 7010 and an experimental aluminium lithium alloy

[J].

The electrode potential dependence of environment-assisted cracking of AA 7050

[J].

Electrochemical behavior and localized corrosion associated with Al7Cu2Fe particles in aluminum alloy 7075-T651

[J].

Revisiting stress-corrosion cracking and hydrogen embrittlement in 7xxx-Al alloys at the near-atomic-scale

[J].The high-strength 7xxx series aluminium alloys can fulfil the need for light, high strength materials necessary to reduce carbon-emissions, and are extensively used in aerospace for weight reduction purposes. However, as all major high-strength materials, these alloys can be sensitive to stress-corrosion cracking (SCC) through anodic dissolution and hydrogen embrittlement (HE). Here, we study at the near-atomic-scale the intra- and inter-granular microstructure ahead and in the wake of a propagating SCC crack. Moving away from model alloys and non-industry standard tests, we perform a double cantilever beam (DCB) crack growth test on an engineering 7xxx Al-alloy. H is found segregated to planar arrays of dislocations and to grain boundaries that we can associate to the combined effects of hydrogen-enhanced localised plasticity (HELP) and hydrogen-enhanced decohesion (HEDE) mechanisms. We report on a Mg-rich amorphous hydroxide on the corroded crack surface and evidence of Mg-related diffusional processes leading to dissolution of the strengthening η-phase precipitates ahead of the crack.© 2022. The Author(s).

Pit-to-crack transition in pre-corroded 7075-T6 aluminum alloy under cyclic loading

[J].

Challenges in modelling the evolution of stress corrosion cracks from pits

[J].

The study of stress corrosion cracking in aluminum alloy 7075 (W) under tensile loading by eddy current measurement

[J].

Effect of pH on stress corrosion cracking of 7050-T7451 aluminum alloy in 3.5wt%NaCl solution

[J].

Corrosion behavior of 7050 aluminum alloy after micro-arc oxidation under constant load in NaCl solution with different pH values

[J].

恒载荷下的微弧氧化后7050铝合金在不同pH值NaCl溶液中的腐蚀行为

[J].

Experimental study on stress corrosion and corrosion fatigue behavior of aluminum alloy materials

[D].

铝合金材料的应力腐蚀及腐蚀疲劳特性实验研究

[D].

Stress corrosion behavior of 6061 aluminum alloy for aviation under constant load

[J].

航空用6061铝合金恒载荷应力腐蚀行为

[J].

Corrosion behavior of two kinds of high strength aluminum alloys in simulated marine atmospheric environment

[J].

高强铝合金6061和7075在模拟海洋大气环境中的腐蚀行为

[J].

Study of 7075 alloy atmospheric corrosion test in the marine environment

[D].

7075铝合金海洋环境大气腐蚀试验研究

[D].

Stress corrosion testing of 7A52 aluminum alloy and 25CrMnSiA steel weldments in marine atmospheric environment

[J].

7A52铝合金及25CrMnSiA钢焊接件海洋大气应力腐蚀试验研究

[J].

Characterization and detection of stainless steel and aluminum alloy during stress corrosion cracking in typical environment

[D].

不锈钢和铝合金在典型环境中的应力腐蚀特征与检测方法

[D].