镍基718合金因力学性能优异、易加工且耐腐蚀性能好,被广泛用于制备反应堆燃料组件格架弹簧。格架弹簧是燃料组件核心部件,用于夹持定位、固定燃料棒,其服役环境十分苛刻。一方面,格架弹簧承受较大服役应力;另一方面,格架弹簧直接暴露于反应堆堆芯强中子辐照环境,基体内会产生大量结构损伤导致合金发生力学性能变化。同时,格架弹簧还直接与一回路高温高压水腐蚀环境接触。在上述腐蚀、应力、辐照等苛刻环境作用下格架弹簧存在发生开裂的风险,可能导致燃料棒破损,对核电站的安全性、可靠性和经济性产生重要影响。近年来国内外已经陆续出现因镍基718合金格架弹簧SCC导致的燃料棒破损现象。由于国内外对格架弹簧SCC机理的认知不足,目前尚不能解释格架弹簧发生SCC的根本原因。

密歇根大学Wang等[6]和Ning等[7]研究认为,δ相由于活性Nb含量高可以优先氧化,且会加剧局部变形的程度,会降低合金SCC的性能;Ning等[7]还认为γ′/γ″相沉淀相与δ相类似的作用。Garzarolli等[8,9]通过堆内研究表明,含有δ相的镍基718合金的抗辐照促进应力腐蚀开裂(IASCC)性能优于不含有δ相的镍基718合金。Leonard等[10]研究表明,裂纹在晶界δ相附近处停止扩展。因此,关于δ相对镍基718合金SCC的影响目前还存在争议。Wang等[6]和Demetriou等[11]的拉伸试验研究表明,镍基718合金中的碳化物和氮化物在高温氩气环境和常温空气环境中会开裂,且镍基718合金中碳化物富含活性Nb元素。因此,碳化物和氮化物也可能对镍基718合金SCC性能产生影响,亟需开展相关研究。

基于上述现状,本研究以两个厂家提供的标准工艺镍基718合金带材为对象,研究碳化物、氮化物等组织结构对镍基718合金SCC裂纹萌生行为的影响,以期为揭示镍基718合金格架弹簧SCC的机理提供参考。

1 实验方法

试验材料为两个厂家提供的沉淀硬化态镍基718合金带材(分别命名为带材A和B),均按照核电商用标准热处理工艺进行处理,即1080 ℃/47 s + 718 ℃/8 h + 621 ℃/8 h,两种镍基718合金带材的化学成分如表1所示。将10 mm × 10 mm × 1 mm的两种镍基718合金样品采用金相嵌镶粉进行热镶嵌。镶嵌后的样品采用#100,#400,#1000,#2000,#5000的SiC砂纸湿磨,并用1 μm的金刚石抛光膏进行机械抛光,随后使用王水侵蚀15 s,侵蚀后的样品置于酒精和去离子水中依次清洗,并在空气中干燥。采用Zeiss Axio Observer. Z1m光学显微镜观察合金的组织结构,采用FEI XL30的扫描电子显微镜(SEM)进一步观察组织结构。

表1 两种镍基718合金化学成分 (mass fraction / %)

Table 1

| Strip | C | Si | Mn | P | S | Cr | Ni | Mo | Al | Ti | Nb + Ta | Co | Fe |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| A | 0.009 | 0.05 | 0.26 | 0.003 | 0.001 | 18.28 | 53.4 | 3.07 | 0.51 | 1.03 | 5.11 | 0.0018 | Bal. |

| B | 0.01 | 0.04 | 0.26 | 0.006 | 0.001 | 18.08 | 53.6 | 3.06 | 0.52 | 1.02 | 5.04 | 0.002 | Bal. |

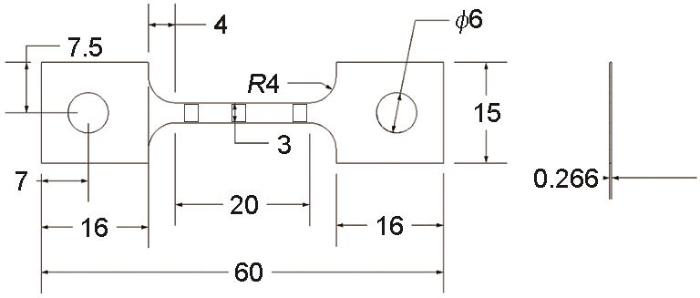

高温空气拉伸实验试样长60 mm,厚度为0.266 mm,具体试样尺寸如图1所示。实验温度为315 ℃,拉伸速率为2.5 × 10-4 s-1。

图1

慢应变速率拉伸(SSRT)实验样品尺寸与高温拉伸实验样品相同。SSRT实验样品一面为原始表面,另一面采用#100,#400,#1000,#2000,#5000的SiC砂纸打磨后,使用1 μm的金刚石抛光膏进行机械抛光,随后采用0.02 μm的氧化硅精细抛光悬浮液在绒布上抛光2 h,使析出相凸显,最后采用酒精超声、去离子水清洗表面,晾干备用。

SSRT实验包含高温氮气环境SSRT实验和高温高压水环境SSRT实验。高温氮气环境SSRT实验在320 ℃氮气环境中采用SCC试验机开展,拉伸速率为3 × 10-7 s-1,在10%应变中止实验,取出样品进行SEM观察分析。高温高压水SSRT实验在320 ℃、15.5 MPa的1200 mg/L B(以H3BO3形式)+ 2.2 mg/L Li (以LiOH·H2O形式)动态循环水溶液中采用SCC试验机开展。升温前,通入高纯氮气除氧直至溶解氧浓度低于5 μg/L,并持续通入氮气。在温度和压力稳定后,开始SSRT实验。实验采用间断式慢应变速率拉伸的方法,拉伸速率为3 × 10-7 s-1,在不同应变中止实验,取出样品进行SEM观察分析;设置的中止应变分别为10%、15%,最后拉断样品。每次取出样品后,采用SEM原位跟踪观察裂纹萌生和扩展情况,并选取特定区域统计裂纹数量、长度等信息。样品拉断后,进行断口观察。

2 实验结果

2.1 组织结构

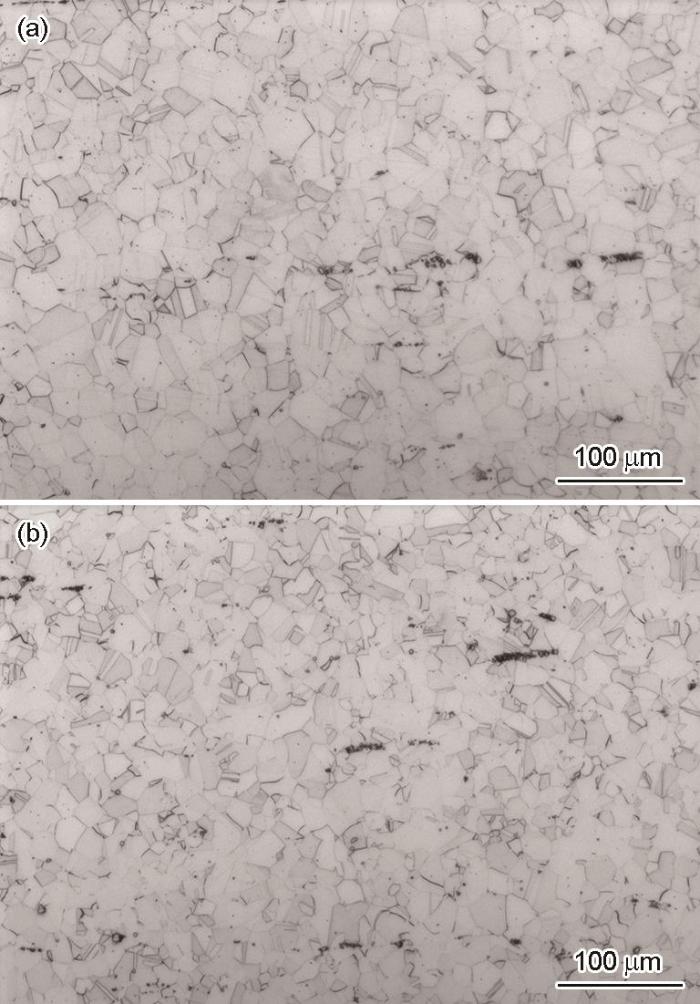

图2

图2

两种镍基718合金带材组织结构形貌

Fig.2

Microstructures of A (a) and B (b) types of nickel based 718 alloy strips

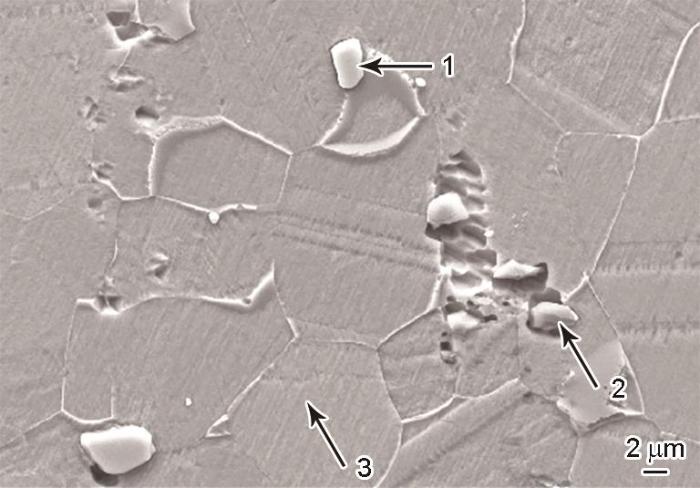

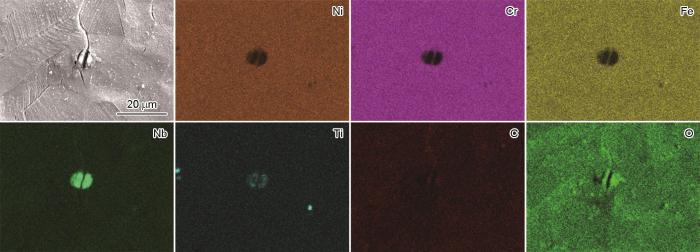

图3

表2 图3中3个位置处EDS分析结果 (mass fraction / %)

Table 2

| Position | Ni | Cr | Fe | Nb | C | Ti | N |

|---|---|---|---|---|---|---|---|

| Location 1 | 1.82 | 0.78 | 0.86 | 69.76 | 17.58 | 9.20 | - |

| Location 2 | 3.37 | 1.83 | 1.41 | 4.12 | 5.36 | 62.85 | 21.05 |

| Location 3 | 49.35 | 17.94 | 17.46 | 4.82 | 6.43 | 1.01 | - |

2.2 力学实验及慢应变速率拉伸实验结果

2.2.1 力学性能结果

表3 两种镍基718合金带材力学性能

Table 3

| Alloy | Rp0.2 / MPa | A / % | |

|---|---|---|---|

| Strip A | 1089 | 1280 | 18.5 |

| Strip B | 1112 | 1299 | 19 |

2.2.2 慢应变速率拉伸实验结果

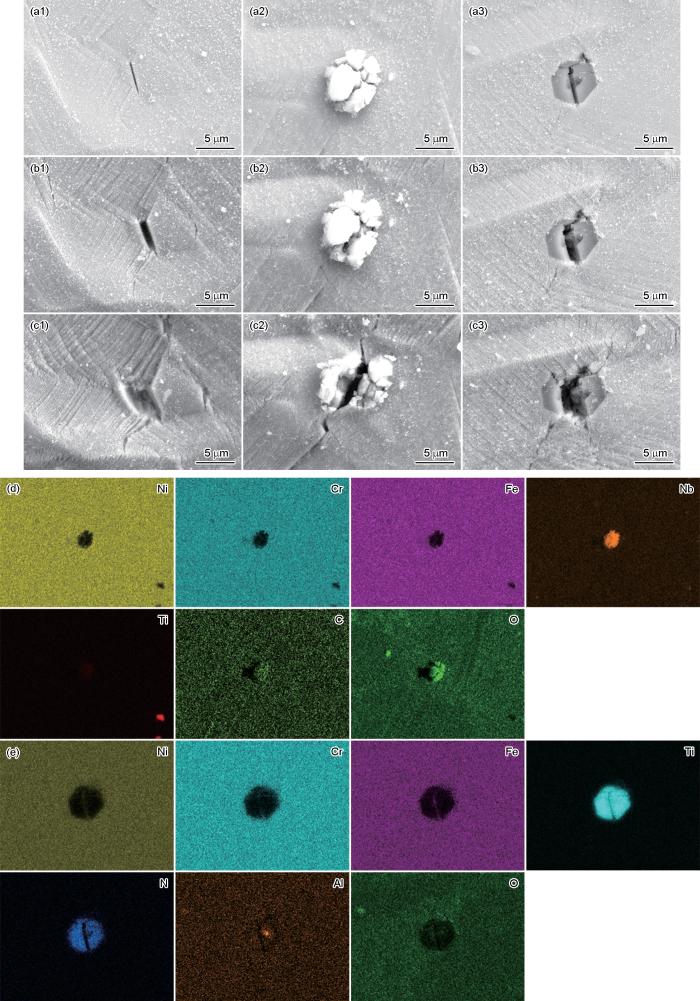

图4

图4

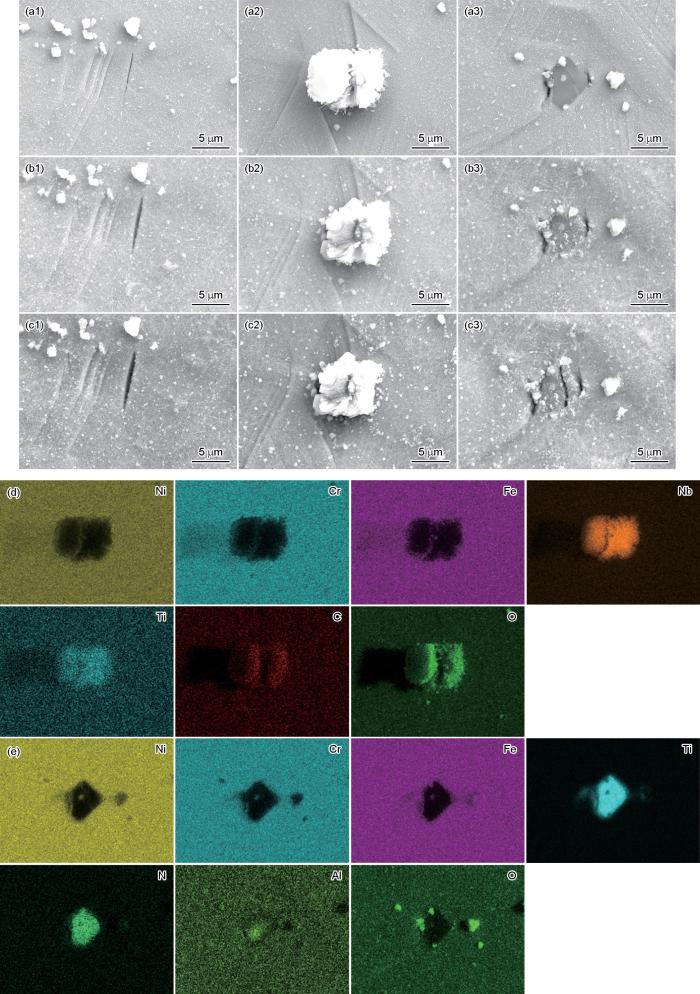

高温高压水环境镍基718合金A种带材SSRT实验原位SEM观察及EDS分析结果

Fig.4

In-situ SEM observation and EDS analysis of A type of 718 alloy strips during SSRT experiment in high-temperature and high-pressure water environment, showing the presence of cracks at different strains (a-c) and compositions of (Nb, Ti)C (d) in Fig.4a2 and TiN (e) in Fig.4a3 precipitation phases

图5

图5

高温高压水环境镍基718合金B种带材SSRT实验原位SEM观察及EDS分析结果

Fig.5

In-situ SEM observation and EDS analysis of B type of 718 alloy strips during SSRT experiment in high-temperature and high-pressure water environment, showing the presence of cracks at different strains (a-c) and compositions of (Nb, Ti)C (d) in Fig.5a2 and TiN (e) in Fig.5a3 precipitation phases

表4 两种带材裂纹信息统计

Table 4

| Materials | Strain | Crack density #cracks/mm2 | Crack length per unit area / μm·mm-2 |

|---|---|---|---|

| Strip A | 10% | 7 | 44 |

| 15% | 48 | 356 | |

| Strip B | 10% | 33 | 253 |

| 15% | 145 | 1314 |

图6

图6

高温高压水环境中两种镍基718合金带材SSRT实验典型断口形貌

Fig.6

Typical fracture morphologies of A type (a) and B type (b) of 718 alloy strips after SSRT experiment in high-temperature and high-pressure water environment

综上,断口形貌的结果不能比较两种带材的SCC敏感性,但从不同应变下裂纹长度和密度的统计结果知,带材A的SCC敏感性小于带材B。

3 分析与讨论

3.1 裂纹萌生特征分析

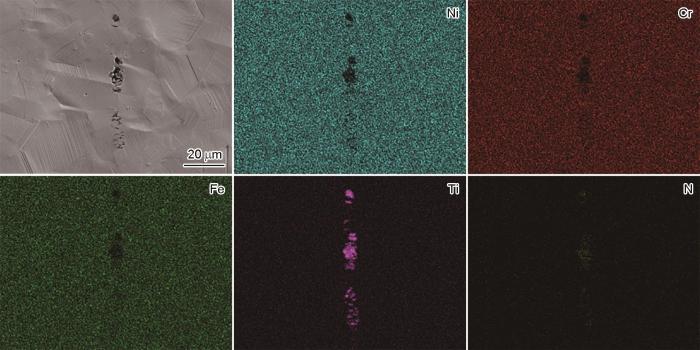

图7

图7

320 ℃下氮气环境中10%应变后镍基718合金B种带材表面TiN析出相SEM观察及能谱分析

Fig.7

SEM observation and EDS analysis of TiN phase on the surface of B type of 718 alloy strips after 10% strain during SSRT test in nitrogen environment at 320 ℃

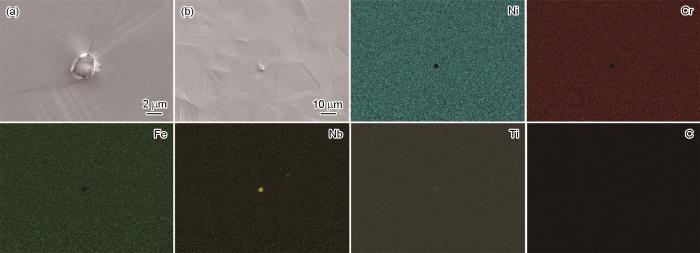

图8

图8

320 ℃下氮气环境中10%应变后镍基718合金B种带材表面(Nb,Ti)C析出相SEM观察及EDS分析

Fig.8

SEM observation (a) and EDS analysis (b) of (Nb,Ti)C phase on the surface of B type of 718 alloy strips after 10% strain during SSRT test in nitrogen environment at 320 ℃

表5 两种带材裂纹特征信息统计

Table 5

| Materials | Characteristics of original organizational structure | Crack density at different positions | ||

|---|---|---|---|---|

| Density of precipitated phases #cracks/mm2 | Strain | Crack density at grain boundaries / #cracks·mm-2 | Crack density at precipitated phases / #cracks·mm-2 | |

| Strip A | 130 | 10% | 3 | 4 |

| 15% | 40 | 8 | ||

| Strip B | 363 | 10% | 21 | 12 |

| 15% | 120 | 45 | ||

对比两种带材的裂纹特征信息,在10%和15%应变下,带材B的晶界和析出相处裂纹密度均大于带材A。对两种带材原始组织结构中析出相的密度进行统计,结果表明带材A中析出相密度为130个/mm2,带材B中析出相密度为363个/mm2。因此,带材B中析出相密度大于带材A,这是带材B的SCC敏感性大于带材A的原因之一。

3.2 析出相对镍基718合金SCC的影响

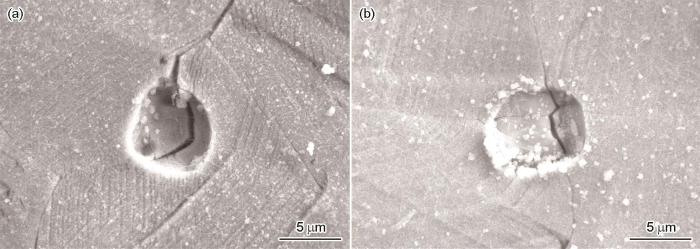

图9

图9

带材A在拉断以及带材B在应变10%时(Nb, Ti)C析出相SEM像

Fig.9

SEM images of (Nb, Ti)C precipitates for fractured strip A (a) and strip B with 10% strain (b)

图10

图10

带材B表面(Nb, Ti)C析出相SEM观察及EDS分析

Fig.10

SEM observation and EDS analysis of (Nb, Ti)C precipitates on the surface of strip B

4 结论

(1) 核电用标准热处理工艺的镍基718合金在除氧模拟核电一回路水环境中以晶界开裂为主,氧化物后的(Nb, Ti)C与TiN在应力的作用下也发生开裂。

(2) 在SSRT实验过程中,随着应变的增加,晶界和(Nb, Ti)C析出相处的裂纹沿着晶界扩展,TiN析出相处的裂纹存在向晶界扩展的趋势。因此,(Nb, Ti)C与TiN会降低镍基718合金的抗SCC性能。

参考文献

Irradiation assisted stress corrosion cracking of commercial and advanced alloys for light water reactor core internals

[J].Thirteen alloys including high- and low-strength nickel-base alloys, austenitic stainless steels, and ferritic alloys were irradiated using 2 MeV protons to a damage level of 2.5 dpa at 360 degrees C and assessed for their susceptibility to irradiation assisted stress corrosion cracking (IASCC) in both BWR normal water chemistry (NWC) and PWR primary water. Cracking susceptibility was highest for high strength nickel-base alloys, followed by the low strength nickel-base alloys and then the low strength iron-base alloys. Cracking in the nickel-based alloys was worst in normal water chemistry, which was reversed for the iron-based alloys. In general, cracking correlated with the degree of microstructure changes, though no single feature could be linked to cracking. IGSCC occurred in both the unirradiated and irradiated conditions in high strength nickel-base alloys with susceptibility being considerably higher following irradiation. In all cases, slip was planar, and the degree of slip localization correlated with the probability of IG crack initiation. Low strength nickel-base alloys showed the same dependence on environment as high strength alloys but were considerably less susceptible to IASCC initiation. Among the low strength iron-base alloys, alloy 800 was most susceptible to IASCC initiation in both BWR NWC and PWR primary water, which also correlated with grain boundary chromium depletion and silicon segregation. Across all alloys, cracking correlated with both the degree of localized deformation and the hardness in the irradiated condition. The agreement is expected as increased hardening also correlates with localized deformation, which is likely a necessary, though insufficient condition for cracking. (C) 2018 Elsevier B.V.

Investigations on Inconel 718 irradiated with 800 MeV protons

[J].

Radiation-induced phase instabilities and their effects on hardening and solute segregation in precipitation-strengthened alloy 718

[J].

The influence of dissolved hydrogen on nickel alloy SCC: a window to fundamental insight

[A].

Stress corrosion cracking of stainless steels and nickel alloys in high-temperature water

[J].

The roles of thermal mechanical treatment and δ phase in the stress corrosion cracking of alloy 718 in primary water

[J].

Effects of precipitation on the stress corrosion crack initiation of alloy 718 in simulated pressurized water reactor primary environment

[J].

Deformability of austenitic stainless steels and Ni-base alloys in the core of a boiling and a pressurized water reactor

[A].

Measurement of the deformability of austenitic stainless steels and nickel-base alloys in light water reactor cores

[A].

Analysis of stress corrosion cracking in alloy 718 following commercial reactor exposure

[J].

Study of the effect of hydrogen charging on the tensile properties and microstructure of four variant heat treatments of nickel alloy 718

[J].

Chemical and microstructural aspects of creep crack growth in inconel 718 alloy

[A].

Kinetic measurements of oxygen dissolution into niobium substrates: in situ X-ray photoelectron spectroscopy studies

[J].

High temperature oxidation of Nb, NbC and Ni3Nb and oxygen enhanced crack growth

[J]

Effects of heat-treatment on the extent of chromium depletion and caustic corrosion resistance of alloy 690

[J].