冰区航行时,船舶用钢不仅受到腐蚀的影响,更多时候是腐蚀与磨损的耦合作用,在此交互作用下,材料的表面反应层特性易发生改变,从而使得腐蚀行为更加复杂。一般来说摩擦可改变材料表面反应层特性从而直接影响材料的腐蚀性能[11~13]。王东胜等[14]和石亮[15]通过改变Cl-浓度、施加不同电位等方法对船舶用钢FH36的腐蚀磨损交互作用进行分析。结果表明,FH36的腐蚀倾向随Cl-浓度增加而增大。磨蚀条件下,腐蚀与磨损相互促进且腐蚀引起的磨损占据主导。低盐度模拟海水中,FH36的磨损机制主要为磨粒磨损伴随腐蚀磨损。阴极保护电位下,FH36钢的磨损机理均以磨粒磨损为主。当前,对更多型号船舶用钢的腐蚀磨损交互作用分析仍旧欠缺,需开展相关研究并对不同船舶用钢的耐磨耐蚀性能进行对比。然而,目前针对船舶用钢在极地环境下腐蚀磨损交互机制的研究仍然不足,特别是对不同类型船舶用钢的耐腐蚀与耐磨损性能的定量对比研究更为欠缺。

本研究选取了3种船舶用钢作为研究对象,分别是EH40、FH40、921A。通过力学-电化学相结合的实验方法,模拟了船舶用钢在人工海水环境中的腐蚀磨损行为。使用白光干涉仪、SEM、XRD、XPS、维氏硬度计等测试手段对材料磨损区域进行微观形貌表征、表面成分鉴定、硬度检测等表征。旨在深入探讨腐蚀和磨损在海洋环境下对船舶用钢性能影响的内在联系,为船舶用钢的选材、设计和维护提供科学依据。

1 实验方法

1.1 样品制备

本实验采用的3种船舶用高强钢牌号为EH40、FH40、921A,3种材料的化学成分组成如表1所示。钢材均加工成10 mm × 10 mm × 3 mm的块状样品。样品背面与铜导线连接并用环氧树脂密封,裸露面积为1 cm2。依次使用80、400、800、1500、3000目水磨砂纸打磨样品,无水乙醇超声10 min后冷风吹干作为电化学与摩擦实验样品备用。硬度测试、XRD表征、微观形貌表征所使用的样品在打磨至3000目后,使用1 μm金刚石膏抛光至镜面备用。

表1 EH40、FH40、921A钢的化学成分 (mass fraction / %)

Table 1

| Steel | Mn | Mo | Ni | Si | C | Cr | Nb |

|---|---|---|---|---|---|---|---|

| EH40 | 1.5 | - | 0.70 | 0.20 | 0.055 | 0.14 | 0.02 |

| FH40 | 1.56 | 0.061 | 0.31 | 0.15 | 0.053 | 0.16 | 0.038 |

| 921A | 0.5 | 0.26 | 2.85 | 0.35 | 0.09 | 0.98 | - |

1.2 摩擦磨损实验

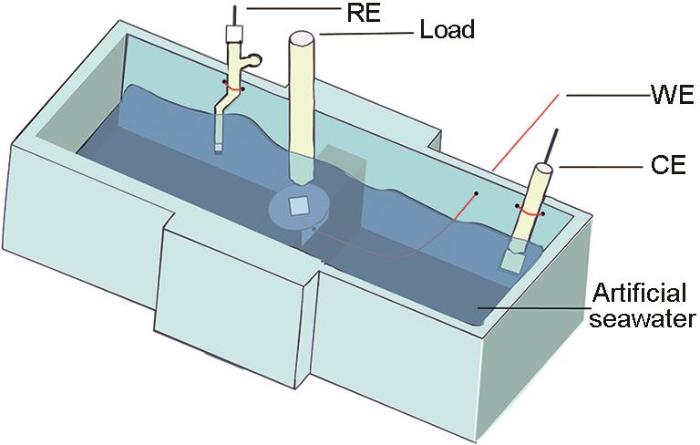

实验在多功能摩擦磨损实验机(Bruker,UMT-3 Tribolab型)上开展。Gamry电化学工作站的型号为Interface 100E。将聚四氟乙烯模具(图1)固定在摩擦磨损实验机的实验平台。摩擦副为直径8 mm的SiC球,摩擦行程为7 mm,施加载荷为20 N,摩擦频率1 Hz。实验采用三电极体系,试样为工作电极(WE),20 mm × 20 mm × 0.1 mm的铂片为对电极(CE),饱和甘汞电极(SCE)作为参比电极(RE)。电解液为采用ASTM D1141-98(2003)标准配置的人工模拟海水(g/L):NaCl 24.35、MgCl2 5.20、NaSO4 4.09、CaCl2 1.16、KCl 0.695、NaHCO3 0.201、KBr 0.101、H2BO3 0.027、SrCl2 0.025、NaF 0.003。

图1

图1

多功能摩擦磨损实验机上模具安装示意图

Fig.1

Schematic diagram of mold installation on multifunctional friction and wear testing machine

为研究材料在模拟海水中的腐蚀磨损行为,设计并进行3个系列的实验。(1) 开路电位(OCP)下的磨蚀:在不施加外加电位的条件下对试样进行腐蚀磨损,摩擦时间为3600 s,实验中监测摩擦系数(COF)的变化。(2) 动电位极化测试:样片浸入电解液后监测其OCP变化,待OCP值相对稳定后进行动电位极化测试,以1 mV/s的扫描速率,扫描范围相对于(OCP±0.3) V,测量静态与磨蚀状态下的极化曲线。(3) 为了获得纯摩擦对材料造成的体积损失量,在阴极保护电位下进行摩擦实验[16]:选择对试样施加-1 V的恒电位,极化时间为5400 s,包括摩擦前900 s,摩擦时3600 s,摩擦结束后900 s。实验过程中持续监测样品表面电流密度以及COF值的变化。

1.3 其他表征

将抛光后的样品在体积分数为4%的硝酸酒精中侵蚀10 s。利用配备Oxford Xplore 30的能谱分析仪(EDS)的Sigma 300扫描电镜(SEM)观察试样的微观组织特征,同样的设备用于分析摩擦实验后的磨痕微观形貌。使用HV-1000STA型显微维氏硬度计检测材料的硬度,遵循ISO 6507-2标准,实验负荷为20 N,保荷时间为10 s。使用Rigaku SmartLab SE型X射线衍射仪(XRD)分析材料物相组成,靶材为Cu靶,扫描速率为2.5(°)/min,扫描范围为25°~90°。使用Contour GT-X3白光干涉仪观察不同条件下摩擦后的磨痕轮廓,将磨痕轮廓的横截面积与磨痕长度相乘获得磨损体积。Scientific K-Alpha型X射线光电子能谱(XPS)用于分析磨蚀样品表面Fe化学成分与价态,激发源为Al Kα射线(hv = 1486.6 eV),扫描步长为0.1 eV,通过能量为50 eV,使用Avantage软件对光谱进行分峰拟合,数据通过无定形碳的C 1s峰(284.8 eV)进行峰位校正。

1.4 腐蚀磨损交互作用量化方法

其中,VT指材料总损失量,通过腐蚀磨损后的磨痕轨迹获得。VW指材料在没有腐蚀影响下,纯磨损的体积损失量,通过阴极保护下样品的磨痕轨迹获得。VC为材料在没有磨损情况下的纯腐蚀损失量。VS是指腐蚀和磨损互相影响,交互作用造成的材料损失量,可具体分为腐蚀引起的磨损增量ΔVW和磨损引起的腐蚀增量ΔVC。当ΔVW或ΔVC为负值时,表示磨损和腐蚀是对立的;而当ΔVW和ΔVC都为正值时,表示两者相互促进[14]。由Faraday定律,纯腐蚀损失量与磨损引起的腐蚀增量可由式(

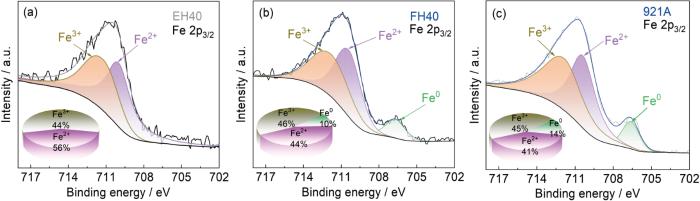

其中,I为静态下材料表面的腐蚀电流密度(A),Ir为动态与静态过程下的电流密度差(A),t为摩擦实验中的摩擦时间(3600 s)。M为测试金属的相对分子质量,可通过合金元素相对含量进行计算。n为测试过程中参与氧化反应的电荷转移数(由XPS分析可知3种材料的Fe2+与Fe3+含量之比均接近1∶1,因此计算中取2.5)。Faraday常数F为96500 C/mol。ρ为测试金属的密度。再通过各材料磨损区域的面积占总面积的比例,可进一步计算得到磨损区域内的纯腐蚀损失量与磨损引起的腐蚀增量[20]。最后将获得的各分量重新代入式(

2 结果与讨论

2.1 微观组织与显微硬度

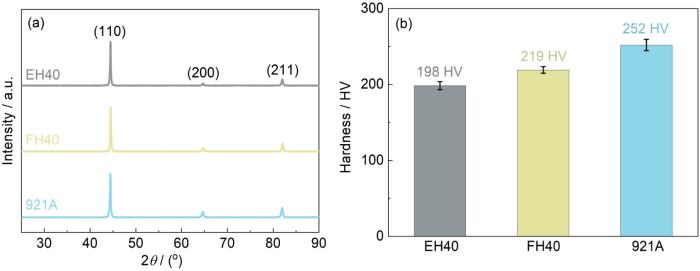

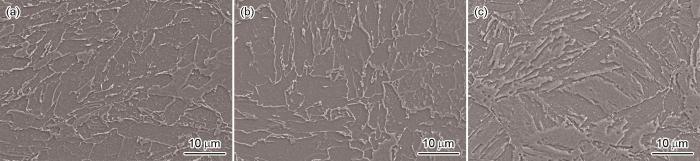

EH40、FH40、921A钢的XRD图谱(图2a)对应标准α-Fe的(110)、(200)、(211)三强峰且(110)晶面呈现较高的衍射强度[21,22]。这表明试验钢的主要相结构均为体心立方BCC相[23]。而可能存在的面心立方FCC相(奥氏体)以及碳化物相等,由于含量低于XRD物相检出最低限度(5%左右),未能检测出[20,24]。由图2b可知,3种钢中,921A钢的维氏硬度最大,达到252 HV,EH40钢仅为198 HV,FH40的硬度介于二者之间,与EH40钢较接近。如图3所示,EH40与FH40钢的显微组织均主要为铁素体基体,同时分布少量珠光体以及粒状贝氏体。921A钢的组织主要由马氏体组成,同时铁素体与粒状碳化物分布均匀。

图2

图2

EH40、FH40、921A钢的XRD图谱和维氏硬度

Fig.2

XRD patterns (a) and Vickers hardness values (b) of EH40, FH40 and 921A steels

图3

图3

EH40,FH40和921A钢的微观形貌

Fig.3

Microstructures of EH40 steel (a), FH40 steel (b), 921A steel (c)

2.2 开路电位下的腐蚀磨损

图4为利用光学轮廓仪获得的EH40、FH40、921A钢在OCP下腐蚀磨损后磨痕的平面及三维形貌。可以看出磨痕都比较均匀,呈现中间深,两边浅的形状。其中,EH40钢的磨痕最宽最深,范围最大,921A钢的磨痕轮廓最窄。

图4

图4

OCP下磨蚀后磨痕的平面及三维形貌

Fig.4

2D and 3D morphologies of the wear marks of EH40 steel (a), FH40 steel (b) and 921A steel (c) after abrasion at OCP

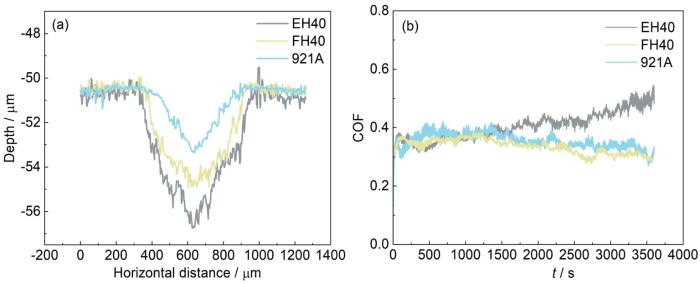

图5分别为根据3D轮廓绘制出的磨痕截面图像(图5a)以及3种钢的摩擦系数曲线(图5b)。摩擦系数是表征钢材和碳化硅磨球在模拟海水中摩擦特性的重要特征,金属材料的摩擦系数主要受表面粗糙度和表面润滑的影响[25]。在开路条件下,3种钢的平均摩擦系数分别为0.40、0.34、0.36。结合磨痕长度,计算得到的3种钢的损失体积分别为16.23 × 10-3、12.19 × 10-3和5.02 × 10-3 mm-3。EH40钢的体积损失最大,这与其材质相对较软,摩擦系数最高且呈现增大趋势有着紧密联系。同时,FH40与921A钢的摩擦系数曲线后期呈下降趋势,这可能是因为其生成的腐蚀产物具有一定的润滑作用[26]。COF值能反映出材料表面摩擦力、切向力的趋势,但其与磨损体积不一定呈线性关系[27,28]。921A钢的COF值与FH40钢接近,但磨损体积显著降低,这是由于其具有较高的表面硬度与剪切强度,在较大的切向力作用下仍能维持良好的抗机械磨损能力,同时,921A钢中的马氏体结构能够在受力时产生塑性变形而不易断裂,接触区域始终较小,没有大量碎屑产生,使其处于更轻度的磨损阶段[29~31]。

图5

图5

OCP下磨蚀后磨痕的截面图及摩擦时的COF曲线

Fig.5

Cross-sectional views of the wear marks of EH40, FH40 and 921A steels after abrasion at OCP (a) and COF curves during friction (b)

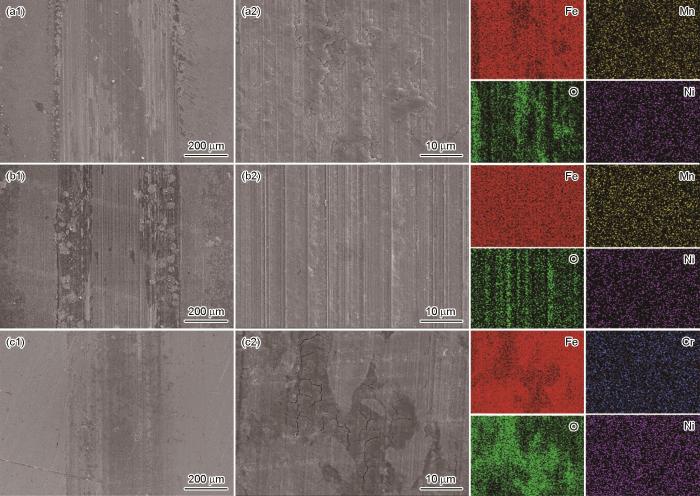

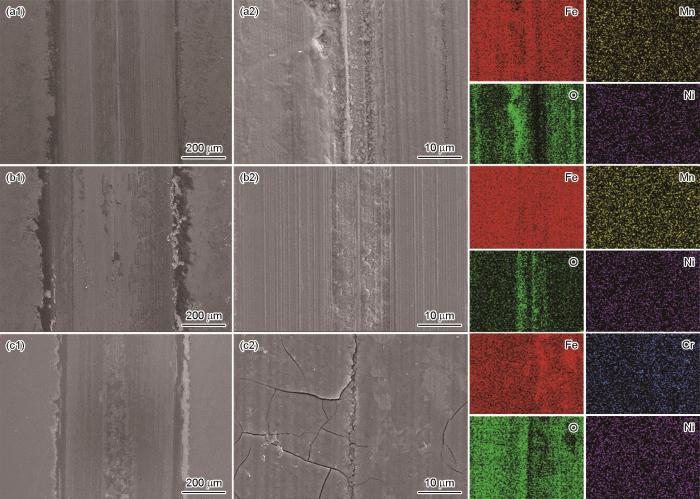

图6显示了EH40、FH40、921A钢在OCP下的磨蚀表面SEM形貌和对应的EDS图像。磨痕宽度由大到小分别为EH40、FH40、921A,与轮廓仪结果一致。在EH40钢表面观察到沿着滑动方向的磨粒磨损迹象,如图6a,这主要由脱落的氧化物颗粒所引起的微切削作用而形成[32]。进一步在磨痕表面观察到由磨粒磨损形成的犁沟。同时,磨痕中部的犁沟表面,覆盖着由磨屑、腐蚀产物等构成的摩擦膜,摩擦膜往往呈现出减磨润滑作用,给予材料一定的保护[25,33]。EDS成分分析表明摩擦膜主要由铁的氧化物组成。FH40钢的摩擦膜集中分布在磨痕两侧且存在剥落迹象,说明其难以稳定存在。磨痕中间几乎没有摩擦膜形成,如图6b所示,呈现明显的凹凸犁沟状,表明磨粒磨损程度加剧。EDS结果表明,犁沟中的氧含量较低,只存在少量因摩擦氧化脱落的磨屑。在921A钢磨蚀表面也存在磨粒磨损迹象,同时观察到较连续摩擦膜,占磨痕面积比例较高。摩擦膜中存在微小裂纹,且有垂直于滑动方向扩展的迹象,如图6c所示。EDS结果表明,磨痕中的氧含量主要来源于摩擦膜。

图6

图6

OCP下磨蚀表面的SEM形貌和对应的EDS图像

Fig.6

SEM surface morphologies and corresponding EDS element mappings for EH40 steel (a), FH40 steel (b) and 921A steel (c) after abrasion at OCP

2.3 电化学控制下的腐蚀磨损

2.3.1 动电位极化测试

图7为3种钢在静态、磨蚀状态下的动电位极化曲线以及其对应的自腐蚀电流密度与腐蚀电位图。静态条件下,使用Tafel外推法获得EH40、FH40和921A钢的自腐蚀电流密度分别为15.1、13.3以及8.29 µA/cm2。相较而言,摩擦状态下,3种钢的腐蚀电位均发生不同程度正向移动,同时极化曲线向电流密度增大的方向偏移明显[34],此时的电流密度分别为62.3、38.2以及12.8 µA/cm2。3种材料的自腐蚀电流密度均增大,这说明摩擦磨损改变了材料的腐蚀倾向,加速了它们的腐蚀。结合图7c,不论在静态还是动态条件下,921A钢的腐蚀电位均最高,腐蚀电流密度最小且增幅最小,这说明921A钢展现出最优的耐蚀性能并且摩擦对其腐蚀的影响最小。EH40与FH40钢在静态下的腐蚀速率接近,施加载荷后,摩擦对EH40钢造成的腐蚀增速最明显。

图7

图7

3种钢在静态和摩擦状态下的动电位极化曲线,以及腐蚀电位与自腐蚀电流密度图

Fig.7

Potentiodynamic polarization curves of EH40, FH40 and 921A steels under static (a) and frictional (b) conditions, and histograms of the corrosion potentials and self-corrosion current densities (c)

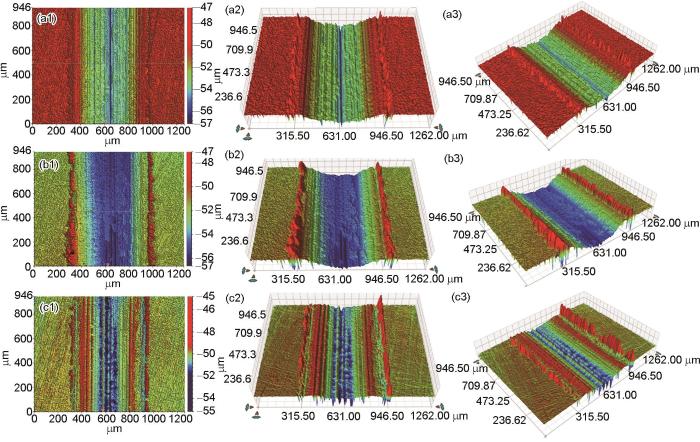

2.3.2 阴极保护下的摩擦实验

图8为利用光学轮廓仪获得的EH40、FH40、921A钢在阴极保护电位下磨损后磨痕的平面及三维形貌。部分磨屑均堆积在磨痕两边。921A钢的磨痕最浅,几乎与未摩擦区域处于同一平面。FH40与EH40钢的磨痕宽度接近,均为520 µm左右,FH40钢的磨痕深度较均匀,约为4 µm。EH40钢的磨痕最深处在磨损区域的中部,达到6 µm,说明此条件下该区域磨损最为严重,其余部分深度约为4 µm。

图8

图8

阴极保护电位下摩擦后磨痕的平面及三维形貌

Fig.8

2D and 3D morphologies of the wear marks of EH40 steel (a), FH40 steel (b) and 921A steel (c) after friction under cathodic protection potentials

图9分别为3种钢在阴极保护状态下进行摩擦实验的电流密度变化曲线(图9a)、磨痕截面图(图9b)以及摩擦系数曲线(图9c)。测试电位为-1 V (vs. SCE)时,样品表面电流密度均恒为负值,说明样品处于阴极保护状态下不发生腐蚀,该电位下材料最终的体积损失均由机械磨损造成[35~37],通过计算该电位下的体积损失即可获得材料的纯机械磨损量。摩擦过程中,样品表面电流密度均瞬间出现明显的负向增长,这是由于该阶段溶液中的溶解氧增多,新鲜金属基底因摩擦不断暴露在溶液中,反应面积增大促进氧的吸收,从而阴极电流增加[14,18]。同时,由于摩擦造成的氧还原反应面积增大,使得摩擦结束后的电流密度比摩擦前更负。结合磨痕长度,计算得到的EH40、FH40、921A钢的损失体积分别为10.61 × 10-3、9.77 × 10-3、1.79 × 10-3 mm-3。921A钢继续表现出优良的耐纯摩擦性能,FH40钢在该条件下的磨损体积与EH40钢接近。阴极保护状态下,3种钢材的平均摩擦系数分别为0.48、0.52、0.39。通过与OCP下的实验结果比较可见,3种材料的摩擦系数均有不同程度的增加,这是因为纯机械状态下,对摩副之间缺少腐蚀产物的润滑作用[26,38]。FH40钢的COF增幅最大,这与其仍然具有较高的体积损失量相符。同时,921A与FH40钢的COF均呈现出随时间推移逐渐增大的趋势,这是因为随摩擦进行,暴露出更多较硬的粗糙基底,而EH40钢的COF随摩擦进行迅速达到动态平衡,在均值附近有规律波动。

图9

图9

3种钢在阴极保护电位下摩擦时电流密度变化,磨痕轮廓及摩擦系数

Fig.9

Changes of the current densities of EH40, FH40, and 921A steels during friction under cathodic protection potentials (a), and cross-sectional contours of the wear marks (b) and coefficients of friction (c)

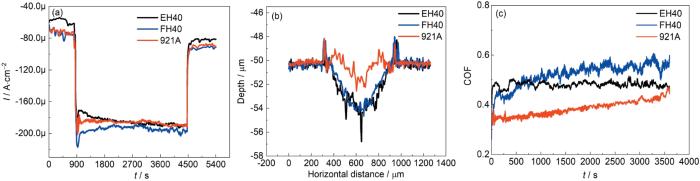

图10为EH40、FH40和921A钢在纯摩擦条件下的磨损表面SEM形貌及相应的EDS图像。与OCP下的磨蚀形貌相比,磨痕内部由于腐蚀产物的减少显得更加清洁,尤其在EH40和FH40钢中表现较为明显。此外,由于磨损最先发生于磨痕中部,3种钢在该区域磨损均最严重且呈现出与摩擦方向一致的线性特征。

图10

图10

3种钢在阴极保护状态下磨痕表面的SEM形貌和对应的EDS图像

Fig.10

SEM surface morphologies and corresponding EDS element mappings of the wear marks for EH40 steel (a), FH40 steel (b) and 921A steel (c) after friction under cathodic protection conditions

2.4 磨蚀表面磨痕的XPS分析

图11为EH40、FH40、921A钢在OCP下磨损后磨痕表面Fe 2p3/2的高分辨光谱与反卷积分析结果。通过与文献对比,确定Fe的价态[38~40]。根据自旋轨道分裂原理,EH40钢曲线被拟合成两个峰,709.9 eV与711.1 eV处的峰分别对应于Fe2+和Fe3+;FH40和921A钢曲线被拟合成3个峰,其中单质Fe的峰位对应于706.6 eV,Fe2+的峰位对应于710.3 eV,Fe3+的峰位对应于711.8 eV。同时,分别对3种钢的Fe 2p3/2光谱进行半定量分析,如图所示,EH40钢的光谱中没有观察到单质Fe的峰,说明在磨蚀状态下,其表面不存在未被氧化的Fe,这与其在该状态下具有较高的腐蚀速率有很大关系。摩擦过程中,暴露的金属表面首先氧化为Fe2+,随后可能进一步氧化为更加稳定的Fe3+。3种钢中,Fe2+含量均较高,与Fe3+含量之比接近1∶1,EH40中Fe2+含量甚至高于Fe3+。这是由于摩擦的持续进行,Fe3+的还原与Fe2+氧化同时发生,且钢材在摩擦中不断有基底露出,使得Fe2+的生成速率始终较高[41~44],同时,滑动造成的温度升高会部分降低溶液中溶解氧的含量[45],对Fe2+的进一步氧化起到抑制作用。

图11

图11

3种钢材在OCP下磨损后磨痕表面Fe 2p3/2的高分辨光谱与反卷积分析结果

Fig.11

XPS high-resolution spectra and deconvolution analysis results of Fe 2p3/2 on the wear mark surfaces of EH40 steel (a), FH40 steel (b) and 921A steel (c) after abrasion under OCP

2.5 腐蚀磨损交互作用分析

综上所述,EH40、FH40、921A钢在模拟海水中的腐蚀磨损过程中,并不简单发生独立的腐蚀或磨损,磨损对腐蚀起到加速作用。为进一步明确腐蚀磨损过程中腐蚀与磨损的交互作用细节,现进行进一步分析。

表2 EH40、FH40、921A钢磨蚀后的各体积损失分量

Table 2

| Steel | E / V | VT / 10-3 mm-3 | VW / 10-3 mm-3 | VC / 10-3 mm-3 | ΔVW / 10-3 mm-3 | ΔVC / 10-3 mm-3 |

|---|---|---|---|---|---|---|

| EH40 | 16.230 | 10.614 | 0.072 | 5.318 | 0.226 | |

| FH40 | OCP | 12.194 | 9.769 | 0.058 | 2.257 | 0.110 |

| 921A | 5.018 | 1.790 | 0.033 | 3.178 | 0.017 |

图12

图12

3种钢磨蚀后各体积损失分量占比柱状图

Fig.12

Bar charts of the proportions of each volume loss component for EH40 steel, FH40 steel and 921A steel after abrasion

由表2可知,腐蚀磨损的各个分量均为正值,说明腐蚀与磨损是相互促进的。EH40钢的各体积损失分量均最大,同时,除腐蚀引起的摩擦增量外,921A钢的其余各分量在3种钢中均最小,进一步说明其耐磨蚀性能最好。同时,结合图12看出,3种钢中VC与ΔVC对总体积损失的贡献都十分有限。Vc占总体积损失最高的是921A钢,仅为0.7%,ΔVC占总体积损失最高的是EH40钢,也仅为1.4%。但是,由腐蚀引发的磨损增量不可忽视,921A钢中的ΔVW所占比例高达63.3%,占据主导地位,FH40钢中的ΔVW为32.8%,EH40钢中ΔVW为18.5%。这说明虽然腐蚀对体积损失带来的直接影响微乎其微,但其间接引起的摩擦增量巨大,而在材料的服役过程中,磨损与腐蚀基本上是同时作用密不可分的。另外,纯摩擦分量在EH40与FH40钢中占据最大比例。因此,总的来说,在磨蚀过程中,纯机械磨损与腐蚀引发的摩擦增量共同控制了3种钢的材料损耗过程。

3 结论

(1) EH40、FH40、921A钢的主要物相组成均为α-Fe,EH40与FH40钢的显微组织主要为铁素体,921A钢主要为马氏体。其中921A钢维氏硬度最高,达到252 HV,EH40和FH40钢分别为198和219 HV。

(2) OCP下的磨蚀状态中,3种钢均发生磨粒磨损,生成主要成分为Fe氧化物的摩擦膜。其中,EH40与FH40钢生成的摩擦膜分别集中在磨痕中间与两边。921A钢的磨痕宽度最窄,同时其生成的摩擦膜占磨痕面积比最大,存在微裂纹,垂直于磨痕方向扩展。921A钢体积损失最小,其次分别是FH40和EH40钢。

(3) 阴极保护下的纯摩擦状态中,3种钢仍然发生磨粒磨损且平均摩擦系数均较OCP条件下升高。因缺少腐蚀影响,磨损体积都有不同程度下降,921A钢继续表现出最好的耐磨性。而该条件下的FH40钢磨损体积与EH40钢接近,这是因为其生成的保护性摩擦膜仍主要分布在磨痕边缘,但此时磨痕中部磨损最为剧烈。

(4) 腐蚀与磨损存在明显交互作用,本研究中,二者之间相互促进。磨蚀条件下,纯摩擦分量Vw均占据很大比例,尤其是FH40钢中,Vw高达80.1%,同时,腐蚀引起的摩擦增量ΔVW占比也很高,在921A钢中,这一比例为63.3%,腐蚀对摩擦带来的影响须引起重视。3种材料中的Vw与ΔVW分量相加都超过98%,共同主导了材料的体积损失。

综上所述,3种钢表现出不同的耐磨耐蚀能力。921A钢由于高硬度的马氏体结构,在OCP和阴极保护条件下均表现出最佳的耐磨损性,其摩擦膜覆盖率高且磨痕窄,体积损失最小,同时其静态与摩擦状态下的耐蚀性均最好;EH40和FH40钢的耐磨耐蚀性略逊于921A钢,其中FH40钢优于EH40钢,尤其在磨蚀条件下;纯摩擦条件下,FH40与EH40钢磨损量接近。未来可针对更多典型船舶用钢,通过施加不同载荷、不同电位进行研究,以期对船舶用钢的腐蚀磨损交互作用机理探索得更加全面。

参考文献

Polar offshore engineering equipment: development status and key technologies

[J].

极地海洋工程装备的应用现状及关键技术分析

[J].极地海洋工程装备是我国参与北极海洋油气开发的主要平台与实力象征。我国极地海洋工程装备设计建造与配套能力难以得到认可,这与造船大国地位不匹配,迫切需要寻求解决方法。本文分析了我国对极地海洋工程装备的发展需求,梳理了极地海洋工程装备的应用现状,提炼极地海洋工程装备的关键技术,总结我国极地海洋工程装备存在的问题。最后,本文提出成立“北极海上油气勘探开发共性关键技术研发及应用创新”专项,设立“极地海洋油气工程技术国际研发中心”,成立“中俄北极能源合资公司”等发展建议。围绕北极开发能力与环境保护能力的协调发展,本文研究为我国发展极地海洋工程装备提供参考,为我国跻身俄罗斯北极油气开发业务提供指导。

Research progress in tribology of materials in polar marine environment

[J].

极地海洋环境服役材料的摩擦学研究进展

[J].

Study on corrosion behavior of marine EH40 steel by polar cryogenic microorganisms

[J].

极地低温微生物对船用EH40钢的腐蚀行为研究

[J].

Erosion-wear resistance of DH32 steel under ice load in simulated polar ice-breaking environment

[J].

DH32船用钢板在模拟极地破冰环境中的冰载荷冲蚀磨损性能研究

[J].

Research progress on ultra-low temperature steels: a review on their composition, microstructure, and mechanical properties

[J].

A review on the advance of low-temperature toughness in pipeline steels

[J].

Corrosion behaviour of welded low-carbon steel in the Arctic marine environment

[J].

Pigmented Pseudoalteromonas piscicida exhibited dual effects on steel corrosion: Inhibition of uniform corrosion and induction of pitting corrosion

[J].

Influence of non-metallic inclusions on corrosive properties of polar steel

[J].

Current status and trends of low-temperature steel used in polar regions

[J].

Tribocorrosion behaviour of a biomedical Ti-25Nb-3Mo-3Zr-2Sn alloy in ringer's solution

[J].

Tribocorrosion behavior of Ti-30Zr alloy for dental implants

[J].

Corrosion-wear interaction behavior of TC4 titanium alloy in simulated seawater

[J].

TC4钛合金在模拟海水中腐蚀-磨损交互行为研究

[J].

Tribocorrosion behavior of FH36 steel in simulated seawater with different salinity

[J].

FH36钢在不同盐度模拟海水中的摩擦腐蚀行为研究

[J].

Mechanism of wear and corrosion properties and protection of FH36 steel used in shipbuilding

[D].

船用FH36钢的磨损腐蚀机制及防护研究

[D].

Methods of measuring wear-corrosion synergism

[J].

Influence of temperature on the corrosion and tribocorrosion behaviour of High-Strength Low-Alloy steels used in offshore applications

[J].

Influence of load and electrode potential on the tribocorrosion behavior of Ti-6Al-3Nb-2Zr-1Mo alloy in seawater

[J].

载荷和电位对Ti-6Al-3Nb-2Zr-1Mo合金在海水中腐蚀磨损行为的影响

[J].

Tribocorrosion study of martensitic and austenitic stainless steels in 0.01 M NaCl solution

[J].

Microstructure and properties of steel for ship fabricated by wire-arc addtitive manufacturing

[D].

电弧熔丝增材制造船用钢组织性能研究

[D].

Effect of high-pressure quenching on pure-iron martensite transformation and its strengthening mechanism

[J].

Research on shape and properties control of CMT arc additive remanufacturing 921A steel

[D].

CMT电弧增材再制造921A钢形性调控研究

[D].

High pressure martensitic transformation study of IF steel

[D].

IF钢的高压马氏体相变研究

[D].

Corrosion fatigue mechanism and corrosion fatigue life prediction of microalloyed 780 MPa high-strength marine engineering steel

[D].

微合金化780 MPa高强度海工钢腐蚀疲劳机理与寿命预测研究

[D].

Study of the corrosion and tribocorrosion behavior of Ti-Zr-Nb-Ta multi-principal element alloys

[D].

Ti-Zr-Nb-Ta系多主元合金腐蚀与磨蚀行为研究

[D].

Microstructure and tribocorrosion properties of Cr-W-Mo-V coating fabricated via laser hot-wire cladding

[J].

热丝激光熔覆Cr-W-Mo-V钢涂层组织与腐蚀磨损性能

[J].随着海洋油气资源的开发,钻采装备面临腐蚀与磨损的耦合损伤。开发耐磨耐蚀涂层材料及制备技术是海洋装备安全、 可靠运行的保障。利用热丝激光熔覆技术在 20 钢基材表面制备 Cr-W-Mo-V 钢涂层,通过光学显微镜(OM)、X 射线衍射仪 (XRD)、扫描电子显微镜(SEM)等分析涂层的显微组织和相组成,采用往复电化学腐蚀摩擦磨损试验仪分析涂层的干摩擦、 电化学腐蚀及在 3.5 wt.% NaCl 溶液中的腐蚀磨损行为。制备的涂层组织均匀、致密,无裂纹、气孔等缺陷,主要由碳化物、 马氏体和残余奥氏体组成,显微组织主要为柱状晶和胞状晶。涂层的平均硬度约为 780 HV<sub>0.1</sub>,约是基材硬度的 6.5 倍,自腐蚀电位为?0.386 V,自腐蚀电流密度为 3.45×10<sup>?6</sup> A / cm<sup>2</sup> ,具有优异的耐蚀性。在 3.5 wt.% NaCl 溶液中,随摩擦载荷的增大, 涂层的开路电位下降,摩擦因数下降,腐蚀电流密度增大,摩擦对腐蚀有明显促进作用。随外加电位增加,涂层腐蚀电流密度增大,摩擦因数降低。热丝激光熔覆技术制备的 Cr-W-Mo-V 钢涂层结构致密、组织均匀,具有优异的腐蚀磨损性能,可用于海洋油气钻采装备在腐蚀磨损苛刻环境下零部件的表面改性。

Critical length scale controls adhesive wear mechanisms

[J].The adhesive wear process remains one of the least understood areas of mechanics. While it has long been established that adhesive wear is a direct result of contacting surface asperities, an agreed upon understanding of how contacting asperities lead to wear debris particle has remained elusive. This has restricted adhesive wear prediction to empirical models with limited transferability. Here we show that discrepant observations and predictions of two distinct adhesive wear mechanisms can be reconciled into a unified framework. Using atomistic simulations with model interatomic potentials, we reveal a transition in the asperity wear mechanism when contact junctions fall below a critical length scale. A simple analytic model is formulated to predict the transition in both the simulation results and experiments. This new understanding may help expand use of computer modelling to explore adhesive wear processes and to advance physics-based wear laws without empirical coefficients.

On the debris-level origins of adhesive wear

[J].Every contacting surface inevitably experiences wear. Predicting the exact amount of material loss due to wear relies on empirical data and cannot be obtained from any physical model. Here, we analyze and quantify wear at the most fundamental level, i.e., wear debris particles. Our simulations show that the asperity junction size dictates the debris volume, revealing the origins of the long-standing hypothesized correlation between the wear volume and the real contact area. No correlation, however, is found between the debris volume and the normal applied force at the debris level. Alternatively, we show that the junction size controls the tangential force and sliding distance such that their product, i.e., the tangential work, is always proportional to the debris volume, with a proportionality constant of 1 over the junction shear strength. This study provides an estimation of the debris volume without any empirical factor, resulting in a wear coefficient of unity at the debris level. Discrepant microscopic and macroscopic wear observations and models are then contextualized on the basis of this understanding. This finding offers a way to characterize the wear volume in atomistic simulations and atomic force microscope wear experiments. It also provides a fundamental basis for predicting the wear coefficient for sliding rough contacts, given the statistics of junction clusters sizes.

Comparison of tribocorrosion behavior between 304 austenitic and 410 martensitic stainless steels in artificial seawater

[J].

Tribocorrosion behavior of typical austenitic, martensitic, and ferritic stainless steels in 3.5%NaCl solution

[J].Tribocorrosion behaviors of typical austenitic (ASTM 316), martensitic (ASTM S41500), and ferritic (ASTM S44660) stainless steels were investigated in a 3.5% NaCl solution under cathodic protection conditions, and variations in the microstructures and chemical compositions of worn surfaces were further analyzed. The results showed that the friction coefficient and wear rate of austenitic steels were lower than those of ferritic and martensitic steels in 3.5% NaCl solution with cathodic protection. Additionally, the tribocorrosion properties of ferritic steels were obviously unaffected by load. Wear mechanisms of the three typical stainless steels mainly included abrasive wear at lower loads and plastic deformation at a higher loads. Furthermore, in austenitic steels, variations in microstructure and chemical composition confirmed that a higher load was beneficial to the transformation of austenite to martensite; thus, the hardness and wear resistance were improved. Compared with austenitic steels, the phase compositions of martensitic and ferritic steel were more stable during sliding, and the surface hardness of martensitic steel increased due to the surface phase and microstructure transformations induced by sliding. In addition, the total damage to steel was mainly caused by mechanical wear and the interaction between corrosion and wear. Therefore, ASTM S44660 and 316 were suitable for high-load corrosion-wear environments and low-load corrosion-wear environments, respectively, providing guidance for material selection under practical conditions.

An advanced efficient model for adhesive wear in elastic-plastic spherical contact

[J].

Tribocorrosion response of the Ti6Al4V alloys commonly used in femoral stems

[J].

Corrosion and tribocorrosion behaviour of Ti6Al4V produced by selective laser melting and hot pressing in comparison with the commercial alloy

[J].

Corrosion and wear behavior of mooring chain steel in artificial seawater solution

[J].

人工海水溶液中系泊链钢的腐蚀磨损行为

[J].

Tribocorrosion behaviors of multilayer PVD DLC coated 304L stainless steel in seawater

[J].

Assessing the tribocorrosion performance of three different nickel-based superalloys

[J].

Tribocorrosion behaviour of AISI 304 stainless steel in 0.5 M NaCl solution

[J].

Research on microstructure modification and corrosion wear properties of 4Cr13 corrosion resistance plastic mold steel

[D].

4Cr13型耐蚀塑料模具钢组织均匀性调控与腐蚀磨损机理研究

[D].

Effect of Mn additions on the corrosion behaviour of TWIP Fe-Mn-Al-Si austenitic steel in chloride solution

[J].Corrosion of TWIP austenitic steels Fe-Mn-3AI-3Si was studied using polarization curves, EIS tests and XPS. Results indicated that increased concentrations of Mn were detrimental to its corrosion resistance. XPS study revealed that pseudo-protective oxide layer was composed of FeO, Fe2O3, FeOOH, Al2O3, MnO and MnO2. Enrichment of Mn oxides in the outermost oxide layer was found as Mn increased in the TWIP steel bulk along with a decrease in Fe oxides. The increased corrosion susceptibility exhibited with the concentration of Mn in the alloys was associated with the greater contribution of the less protective Mn oxide in the surface film.

Corrosion behavior of Fe-Cr-Si alloys in simulated PWR primary water environment

[J].

Tribocorrosion behavior of 410SS in artificial seawater: effect of applied potential

[J].

Corrosion wear characteristics of TC4, 316 stainless steel, and monel K500 in artificial seawater

[J].

Tribocorrosion of passive materials: a review on test procedures and standards

[J].

Tribocorrosion behavior of 2205 duplex stainless steel in sodium chloride and sodium sulfate environments

[J].

A review of the evidence on smoking bans and incidence of heart disease

[J].