目前,研究人员主要采用时效热处理等方式来提高7xxx铝合金的强度和耐蚀性。其中,T6峰时效热处理是当前提高7系铝合金强度的重要途径,时效过程中析出的细小η′(MgZn2)相可通过阻碍位错运动,进而提高强度。然而,经过T6峰时效处理后,η′相沿着晶界呈链状分布,在晶界处形成了电化学活性较高的区域,由于η′相与铝基体之间存在较大的电化学差,易形成微电池效应,进而导致点蚀和晶间腐蚀的发生[8]。经T7过时效处理后,可使7xxx铝合金中粒径细小的亚稳态η′相转变为尺寸较大的稳定η相,此时晶界析出相变得分散和不连续,从而减少晶界腐蚀程度,进而提高7xxx铝合金耐蚀性。然而,T7处理所需时间较长,这使得析出相尺寸增大,而较大的析出相往往分布不均匀,容易形成应力集中区域,这些区域在外力作用下易发生塑性变形,导致材料强度降低[9,10]。因此,传统热处理方法并不能同时提高强度和耐蚀性。

循环强化工艺(CS)是一种无需时效热处理方式,该工艺既能提高7075铝合金强度,又能大幅度提高耐蚀性[11]。在室温下对7075铝合金施加交变载荷,使其内部产生许多空位和位错,并形成原子团簇。这些原子团簇会对位错产生阻碍作用,同时也会降低铝合金基体的电位差,达到提高强度和耐蚀性的目的。Sun等[12]通过CS工艺对AA7075铝合金进行处理后,其强度从375 MPa提升至525 MPa。AA2024铝合金经循环强化后,相比于峰时效,其强度提高了约5.3%,自腐蚀电位提高了约11.6%[11]。Zhang等[13]对不可热处理强化的AA5083铝合金进行循环强化处理后,其强度相比于固溶态提高了约20%,自腐蚀电位相比于初始状态提高约10%。因此,无论是可热处理强化还是不可热处理强化的铝合金,CS工艺均能提高其强度和耐蚀性。此外,由于CS工艺在室温下进行,这既节约了传统时效所耗费的时间,又降低了能源消耗。因此,CS工艺是提高7xxx铝合金强度和耐蚀性的有效途径。

本文选取AA7075铝合金为研究对象,对其进行CS工艺处理,研究CS工艺对该合金力学性能和耐蚀性的影响,并与传统T6工艺对比。利用扫描电镜(SEM)观察经过晶间腐蚀与盐雾腐蚀后的T6试样和CS试样的表面形貌,同时结合X射线光电子能谱(XPS)检测其腐蚀产物。使用透射电镜(TEM)分析其微观结构,以揭示CS工艺引入的原子团簇与T6工艺析出的η′相对AA7075铝合金力学性能和耐蚀性的影响机理。

1 实验方法

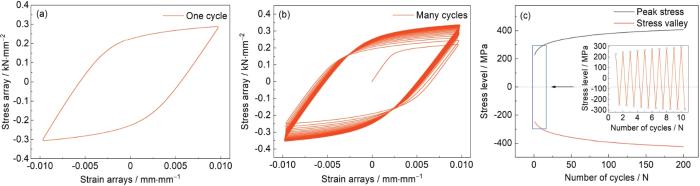

选用AA7075铝合金轧制板材,其化学成分(质量分数,%)为:Zn 5.41,Mg 2.31,Cu 1.61,Cr 0.20,Fe 0.14,Si 0.10,Mn 0.01,Ti 0.02,Al余量。使用电火花切割机沿板材轧制方向加工,试样几何形状如图1a所示。T6工艺为470 ℃下固溶1 h后淬火(水淬,WQ),随后在120 ℃下时效24 h,最后再空气冷却(AQ),如图1b所示。CS工艺为470 ℃下固溶1 h后淬火,随后在室温下使用MTS高频疲劳试验机以低周疲劳(LCF)模式进行循环处理,如图1c所示,其滞回线和循环次数-应力如图2a~c所示。其中CS参数为:加载频率f为0.2 Hz,应力比R为-1,应变量δ为0.8%,循环次数N为100次;随后应变量δ为0.9%,循环次数N为50次;最后应变量δ为1.0%,循环次数N为10次。使用MTS-322液压伺服疲劳试验机进行力学拉伸试验,拉伸速率为2 mm/min。

图1

图1

7075铝合金试样的加工尺寸与T6、CS工艺参数

Fig.1

Machining dimensions of 7075 Al-alloy specimens (a), process parameters of T6 (b) and CS (c) heat treatments

图2

图2

7075铝合金的一次或多次循环强化滞回线与循环-应力图

Fig.2

One or more cycle-enhanced hysteresis lines and cycle-stress diagrams for 7075 Al-alloy: (a) one cycle, (b) many cycles, (c) cycle-stress level chart

用100 g/L的NaOH溶液对试样进行5 min的碱洗,随后浸入1.4 g/mL的HNO3溶液中1 min进行酸洗,最后再水洗并晾干。将57 g NaCl溶解在990 mL水中,然后加入30% (质量分数)的H2O2溶液。将该溶液保持在恒温30 ℃,用于晶间腐蚀实验。腐蚀时间为6、12、24和48 h。腐蚀完毕后,将试样沿主变形方向切开,进行打磨抛光,随后在金相显微镜下观察截面的晶间腐蚀深度,并观察腐蚀形貌。

将样品置于JJ-60精密型盐水喷雾试验箱中,进行中性盐雾实验,实验参数为:pH值为7.1,NaCl溶液浓度为50 g/L,喷雾压力为98 kPa,实验温度为35 ℃,试样与垂直方向成20°,腐蚀时间为7 d。

用ESCALAB 250Xi型X射线光电子能谱仪进行XPS测试,激发源为单色化Al Kα射线,检测面积为5 mm × 5 mm。XPS检测参数:功率为150 W (电压为15 kV,电流为10 mA),全谱通能为160 eV,步长为1.0 eV;窄谱通能为40 eV,步长为0.1 eV。

用CHI760e型电化学工作站对试样进行电化学测试,采用三电极体系,试样为工作电极,工作电极的暴露面积为1 cm2,饱和甘汞电极(SCE)为参比电极,铂电极为对电极,在室温下采用3.5% (质量分数) NaCl溶液进行极化曲线测试,扫描范围为-1.2~-0.3 V,扫描速率为0.5 mV/s。电化学阻抗谱(EIS)测试频率范围为105~10-2 Hz,扫描速率为0.01 mV/s,最后使用Zview软件对阻抗数据进行拟合。

对试样腐蚀后的区域取样,先用酒精冲洗较大的杂质,再用超声波清洗仪清洗300 s (超声波清洗剂为酒精,频率为40 Hz)后快速风干,用SU3500型扫描电子显微镜观察微观组织形貌,扫描电镜工作模式为二次电子,工作电压为25 kV。

用砂纸将试样打磨至约100 μm,冲裁成直径为3 mm的圆片,然后在Struers TenuPol-5型双喷电解减薄仪上进行电解双喷,电解液采用1∶3 (体积分数)的硝酸-甲醇溶液。采用液氮冷却,双喷温度约为-20 ℃,双喷电压为20 V,电流为50~70 mA。用FEI Tecnai F20型透射电镜(TEM)表征微观结构特征,透射电镜实验加速电压为200 kV。

2 结果与分析

2.1 力学性能和析出相形貌

对固溶后7075铝合金试样进行不同应变量和循环次数的循环强化,以确定最佳循环强化工艺参数。由图2c与图3a,b可知,随着循环次数增加,7075铝合金在同一应变量下抗拉强度略有提高,但延伸率下降明显;随着应变量增加,7075铝合金在同一循环次数下强度和延伸率表现出相同规律。然而,在高应变量条件下,试样经多次循环容易发生弯曲甚至断裂失效,但在低应变量下强化效果并不显著。因此,经多次实验探索,通过在低应变量下多次循环以增强其强度,使其适应在高应变量下的循环,随后在高应变量下少量循环进一步提高强度,从而获得较好的强化效果,如图3c所示。由表1可知,经过0.8% (N = 100) + 0.9% (N = 50) + 1.0% (N = 10)循环后,其强度达到540 MPa,延伸率为6.9%,此参数为CS工艺最佳参数,后续实验均在此参数下进行。

图3

图3

经T6处理以及不同参数下CS处理的7075铝合金应力-应变曲线以及强度和延伸率柱状图

Fig.3

Stress-strain curves of 7075 Al-alloy treated by T6 process and CS processes with different number of cycles (a), different strain (b) and different strain and number of times (c), and histograms of strength and elongation (d)

表1 T6以及最佳参数下CS处理的7075铝合金力学性能数据

Table 1

| Process | Tensile strength / MPa | Yield strength / MPa | Elongation / % |

|---|---|---|---|

| T6 | 616 | 533 | 5.3 |

| CS (optimized) | 540 | 416 | 6.9 |

| Solution | 371 | 164 | 11.5 |

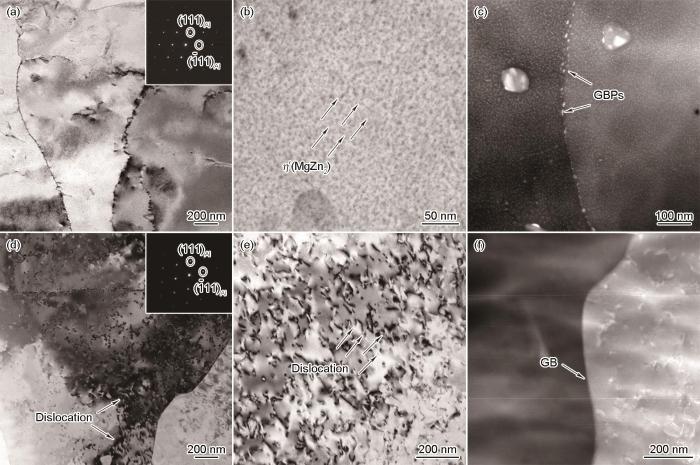

图4

图4

T6、CS处理的7075铝合金的TEM图像

Fig.4

TEM images (a, d), intracrystalline images (b, e) and HAADF-STEM images of grain boundaries (c, f) for 7075 Al-alloy treated by T6 (a-c) and CS (d-f) processes, respectively

图5

图5

T6、CS处理的7075铝合金的晶内HRTEM图像

Fig.5

Intragranular HRTEM images (a, d), IFFT images (b, e) and FFT images (c, f) of 7075 Al-alloy treated by T6 (a-c) and CS (d-f) processes, respectively

2.2 耐蚀性能

2.2.1 极化曲线与阻抗分析

将经过T6和CS处理的7075铝合金试样置于3.5%NaCl溶液中进行Tafel极化曲线测试,其结果如图6a所示。随着电极电位的增加,T6和CS试样的阴极极化曲线中电流密度均先缓慢减小后急剧下降。随后,因试样在活性溶解区时会因电化学反应而导致基体开始发生溶解,电流密度随着电极电位升高急剧上升。铝合金在活性溶解区外的溶解速率降低,因而其电流密度随着电极电位的增加而缓慢上升。其中,T6试样在阳极极化时存在明显的点蚀击穿电位(Epit),表明此时铝合金表面的氧化膜因腐蚀而发生破裂;而CS试样未出现明显的点蚀击穿电位,说明在NaCl溶液环境中CS试样很难发生点蚀现象,表现为整体均匀的腐蚀。由表3可知,CS试样比T6试样具有更高的自腐蚀电位(Ecorr),较高的自腐蚀电位表明7075铝合金在NaCl溶液环境中更难发生腐蚀反应。因此,CS试样比T6试样具有更好的耐蚀性。电化学阻抗谱(EIS)如图6b所示,其中,Rs代表溶液电阻,Rct代表界面转移电阻,CPE代表常相位元件。由图6b可知,T6试样和CS试样的Nyquist图均表现为半圆弧形,通常阻抗谱的半径越大,表明合金耐蚀性越好[14]。同时由表2可知,CS试样的阻抗值高于T6试样,表明其发生电化学腐蚀的难度更高。因此,相比于T6工艺,7075铝合金经过CS处理后拥有更好的耐蚀性能,这与极化曲线测试结果一致。

图6

图6

T6、CS处理的7075铝合金极化曲线与阻抗图

Fig.6

Polarization curves (a) and impedance diagrams (b) of 7075 Al-alloy treated with T6 and CS

表2 T6、CS处理的7075铝合金极化曲线与阻抗测试结果

Table 2

| Process | Ecorr vs.SCE / V | Icorr / μA·cm-2 | Rct / Ω·cm2 |

|---|---|---|---|

| T6 | -0.87 | 0.47 | 1.61 × 103 |

| CS | -0.69 | 0.57 | 5.69 × 103 |

2.2.2 腐蚀产物

将T6和CS试样置于3.5% NaCl溶液中浸泡腐蚀7 d,随后对试样表面因腐蚀所产生的腐蚀产物进行XPS分析,其结果如图7所示。T6和CS试样的Al 2p窄谱均由3组峰组成,其结合能分别为75.7、74.5和73.9 eV[15,16],对应的物质分别为AlCl3、Al2O3和Al(OH)3。由于Al2O3为铝合金氧化膜的主要成分,不是腐蚀过程中形成的腐蚀产物,因此腐蚀产物主要为AlCl3、Al(OH)3[17]。7075铝合金表面的氧化膜并非完整,总存在一些有缺陷的区域[18],在含有腐蚀性离子的溶液中(如Cl-),腐蚀性离子会进入氧化膜,使得铝合金基体发生溶解。此时,铝基体作为阳极发生氧化反应生成Al3+,第二相作为阴极发生还原反应,从而破坏铝合金表面的氧化膜。其化学反应式如下:

图7

图7

T6、CS处理的7075铝合金试样在3.5%NaCl溶液中浸泡7 d后的XPS图谱

Fig.7

XPS fine spectra of Al 2p3/2 (a, b) and Zn 2p3/2 (c, d) of T6 (a, c) and CS (b, d) treated 7075 Al-alloy specimens after 7 d immersion in 3.5%NaCl solution

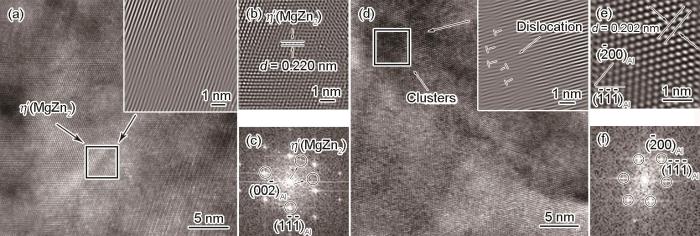

2.2.3 晶间腐蚀

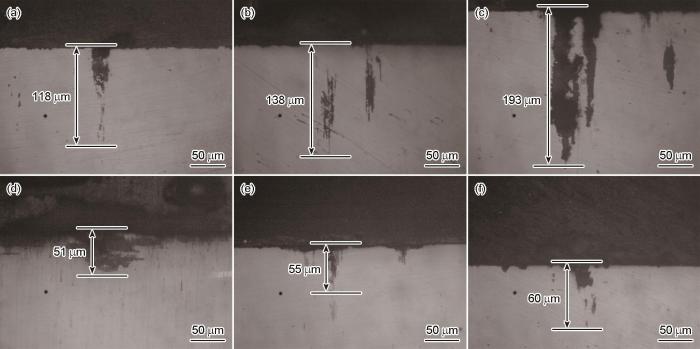

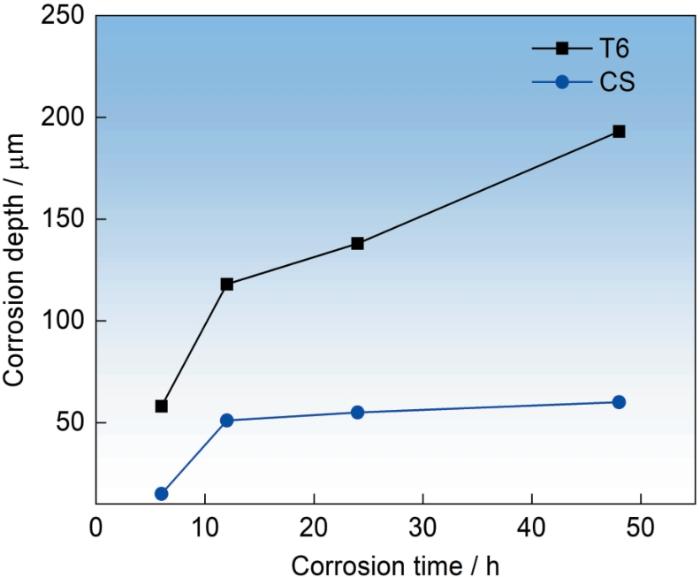

7075铝合金的晶间腐蚀主要发生在晶粒边界,导致晶粒之间结合力减弱,最终可能使7075铝合金发生脆性断裂[23]。由图8可知,T6试样的腐蚀深度达到58 μm,而CS试样的腐蚀深度仅为15 μm;同时,相较于CS试样,T6试样腐蚀后表面产生的微裂纹更为密集。因此,相比于T6试样,经过CS处理后的7075铝合金具有更低的晶间腐蚀敏感性。将晶间腐蚀的时间延长至12、24和48 h,其腐蚀深度如图9和图10所示。T6试样经长时间腐蚀后,其腐蚀深度从118 μm增加至193 μm。而CS试样的腐蚀深度仅从51 μm增加至60 μm,其腐蚀深度增量明显小于T6试样。因此,经过长时间晶间腐蚀后,CS试样仍然比T6试样具有更好的抗晶间腐蚀能力。

图8

图8

T6、CS处理的7075铝合金晶间腐蚀6 h后的表面及截面形貌

Fig.8

Cross-sectional (a, b) and surface (c, d) morphologies of T6 (a, c) and CS (b, d) treated 7075 Al-alloy after intergranular corrosion for 6 h

图9

图9

T6、CS处理的7075铝合金经12、24和48 h晶间腐蚀后的截面形貌

Fig.9

Cross-sectional morphologies of T6 (a-c) and CS (d-f) treated 7075 Al-alloy after intergranular corrosion for 12 h (a, d), 24 h (b, e) and 48 h (c, f)

图10

图10

T6、CS处理的7075铝合金的腐蚀时间-腐蚀深度曲线

Fig.10

Corrosion depths of 7075 Al-alloy treated by T6 and CS after corrosion for different time

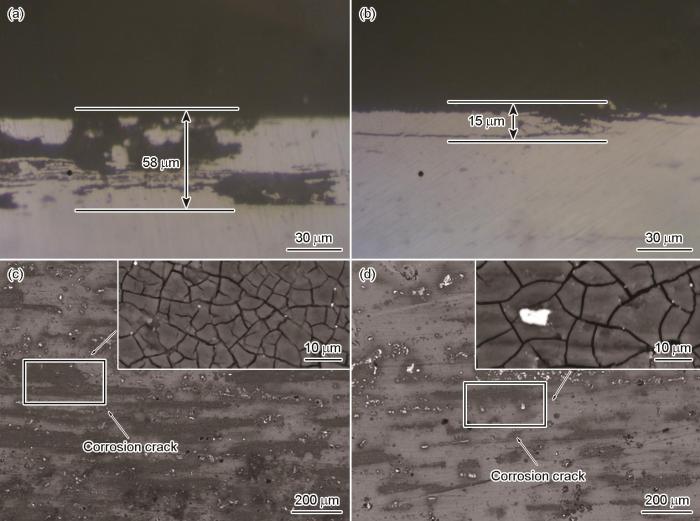

2.2.4 盐雾腐蚀

图11

图11

T6、CS处理的7075铝合金试样经盐雾腐蚀后表面貌

Fig.11

Surface morphologies of T6 (a-c) and CS (d-f) treated 7075 Al-alloy specimens after salt spray test

2.3 腐蚀机理模型

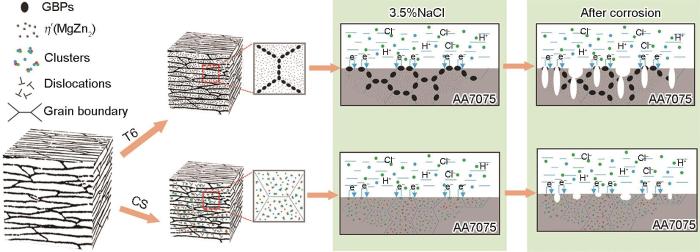

7075铝合金在NaCl溶液中会发生多种形式的腐蚀,主要包括点蚀、晶间腐蚀和应力腐蚀开裂等。其腐蚀机理通常认为是电化学腐蚀,即由于金属间化合物与铝基体之间的电位差,二者形成了原电池结构,导致铝基体作为阳极发生腐蚀溶解[26,27]。T6和CS工艺的腐蚀机理模型如图12所示。T6峰时效使得铝合金内部晶界处的η′相容易与铝基体发生电化学反应,导致严重的腐蚀[28]。相比之下,CS工艺使得铝合金内部产生原子团簇,而非η′相析出。一方面,η′相主要由Mg和Zn元素组成,而原子团簇可能包含Al、Mg和Zn等多种元素,不同元素的电化学电位不同[29],并且η′相与铝基体的电位差大于原子团簇与铝基体的电位差,电位差越大,通常更容易发生电化学腐蚀[30];另一方面,η′相具有特定的晶体结构,而原子团簇是无序结构,其结构差异也会影响它们的电化学行为[31]。通常η′相比原子团簇的电化学活性更高,更容易形成腐蚀微电池,导致局部腐蚀。因此,相比于T6时效析出的η′相,经CS工艺诱导产生的原子团簇具有更好的耐蚀性能。

图12

图12

T6、CS处理的7075铝合金的腐蚀机理模型

Fig.12

Schematic diagrams of corrosion mechanism of T6 and CS treated 7075 Al-alloy

3 结论

(1) 7075铝合金在CS处理时,通过多次循环和增加循环应变量使其内部产生大量原子团簇和位错。这些原子团簇、位错等晶格缺陷在变形过程中能显著阻碍位错运动,从而提高7075铝合金抗拉强度。

(2) CS工艺能提高7075铝合金的自腐蚀电位,进而提高其耐蚀性。CS试样经6 h晶间腐蚀后,其腐蚀深度为15 μm,明显低于T6试样。此外,长时间腐蚀下,CS试样腐蚀深度的增量为9 μm,低于T6试样。中性盐雾腐蚀环境中,CS试样中点蚀坑的数量及尺寸均低于T6试样。

(3) 相比于T6试样,CS试样未在晶界处析出易被腐蚀的η′相,而是通过微变形在铝合金内部形成原子团簇。原子团簇比T6态的η′相的电化学活性更低,这降低了析出相与基体的电位差,进而提高7075铝合金的耐蚀性。

参考文献

A review on the research of the 7xxx series high strength aluminum alloys as structural material in China

[J].

我国7xxx系高强铝合金及其研究进展

[J].

Research progress of hot crack in fusion welding of advanced aeronautical materials

[J].The high fusion welding hot cracking sensibility of the next-generation alloy is the key technological difficulty that hinders its widely application in the aeronautic and astronautic industry. A critical review of the fusion welding hot cracking from the perspective of basic mechanism and the experimental research of typical materials was presented in this article. The fusion welding hot cracking phenomena include solidification cracking (occurs within the fusion zone) and liquidation cracking (occurs at the interface between fusion zone and partial melting zone). The formation factors of the fusion welding hot cracking include alloying composition, welding thermal cycle and thermal stress. Based on the comprehensive understanding of the formation mechanism of the fusion welding hot cracking, the relative research progress in the field of aluminum alloys, magnesium alloys, advanced high strength steel and nickel alloys was summarized. The establishment of the quantitative criterion that involves the effects of complicated multi-component and the morphology of the dendrite on the cracking sensibility is the key development direction. Optimizing the alloying composition of the base metal or filler metal, adding nucleanting agent or auxiliary facilities are the practical method for restraining the fusion welding hot cracking. Conducting the research on the mechanism and restraining method of the fusion welding hot cracking helps to solve the difficulty of the next generation alloys processing, which can realize their application in the field of aeronautic and astronautic industry.

先进航空材料焊接过程热裂纹研究进展

[J].

Research on corrosion damage evolution of aluminum alloy for aviation

[J].

Development and applications of aluminum alloys for aerospace industry

[J].

Study on corrosion damage distribution and failure law of naval aircraft structure

[J].

飞机结构腐蚀损伤分布及失效规律研究

[J].

Comprehensive analysis of mechanical properties, wear, and corrosion behavior of AA7075-T6 alloy subjected to cryogenic treatment for aviation and defense applications

[J].

Fatigue and corrosion behavior of in-service AA7075 aircraft component after thermo-mechanical and retrogression and re-aging treatments

[J].

Comparison of mechanical properties and corrosion behaviors of 7075 aluminum alloy at various aging systems

[J].

不同时效制度7075铝合金力学性能及腐蚀性能综合比较研究

[J].

Role of T7 heat treating on the dimensional stability of automotive A319 Al alloys

[R].

Effects of different heat treatments on mechanical properties and corrosion resistance of Al-7.95Zn-1.84Mg-0.65Cu aluminum alloy

[J].

不同热处理对Al-7.95Zn-1.84Mg-0.65Cu合金力学性能和耐腐蚀性能的影响

[J].

Tailoring precipitate distribution in 2024 aluminum alloy for improving strength and corrosion resistance

[J].For the traditional peak-aged (PA) AA2024 alloy, the formation of large S-phase precipitates within the grains, wide precipitate-free zones (PFZs) near the grain boundaries (GBs), and continuous distribution of grain boundary precipitates (GBPs) can be observed. As a result, the PA alloy exhibits relatively high strength but poor corrosion resistance. However, with the application of cyclic plasticity treatment, high-density 1-2 nm clusters form within the matrix, and no PFZs form near GBs. In this study, this treatment yields the optimal balance between strength-elongation characteristics and corrosion resistance. By combining cyclic plasticity and ageing heat treatment with different heating rates, the nanoscale clusters play a crucial role as heterogeneous nucleation sites, resulting in the formation of finer and higher number density of S precipitates within the matrix. Additionally, the presence of these clusters reduces the formation of GBPs and minimizes the width of PFZs. Consequently, compared to the traditional PA sample, this approach achieves a significantly higher yield strength (increased by 46 %) and ultimate tensile strength (increased by 18 %), along with superior corrosion resistance. Although the influence of ageing heat treatment with different rates on mechanical properties is not significant, it notably affects the formation of GBPs and corrosion resistance. Specifically, a slower heating rate leads to an increase in the spacing between adjacent GBPs, resulting in improved corrosion resistance. In summary, cyclic strengthening, as a novel method for alloy strengthening, when combined with ageing heat treatment, modulates the distribution of S precipitates within the matrix and GBs. This optimization maximizes the effects of precipitation strengthening and breaks the inverse relationship between strength and corrosion resistance.

Precipitation strengthening of aluminum alloys by room-temperature cyclic plasticity

[J].High-strength aluminum alloys are important for lightweighting vehicles and are extensively used in aircraft and, increasingly, in automobiles. The highest-strength aluminum alloys require a series of high-temperature "bakes" (120° to 200°C) to form a high number density of nanoparticles by solid-state precipitation. We found that a controlled, room-temperature cyclic deformation is sufficient to continuously inject vacancies into the material and to mediate the dynamic precipitation of a very fine (1- to 2-nanometer) distribution of solute clusters. This results in better material strength and elongation properties relative to traditional thermal treatments, despite a much shorter processing time. The microstructures formed are much more uniform than those characteristic of traditional thermal treatments and do not exhibit precipitate-free zones. These alloys are therefore likely to be more resistant to damage.Copyright © 2019 The Authors, some rights reserved; exclusive licensee American Association for the Advancement of Science. No claim to original U.S. Government Works.

Enhancing the strength and sensitization resistance of 5xxx alloys via nanoscale clustering induced by room-temperature cyclic plasticity

[J].

Exfoliation corrosion of aluminum alloy AA7075 examined by electrochemical impedance spectroscopy

[J].

Investigation on the corrosion behavior of aluminum alloys 3A21 and 7A09 in chloride aqueous solution

[J].

Properties degradation and atmospheric corrosion mechanism of 6061 aluminum alloy in industrial and marine atmosphere environments

[J].

Microstructure, elevated-temperature mechanical properties and creep resistance of dispersoid-strengthened Al-Mn-Mg 3xxx alloys with varying Mg and Si contents

[J].

Characterization of 7A04 aluminum alloy corrosion under atmosphere with chloride ions using electrochemical techniques

[J].

Effect of trace Cl- and Cu2+ ions on corrosion behavior of 3A21 al-alloy in ethylene glycol coolant

[J].

痕量Cl-和Cu2+对3A21铝合金在乙二醇冷却液中腐蚀行为的影响

[J].针对3A21铝合金在乙二醇冷却液中的腐蚀问题,采用浸泡实验和表面分析技术系统研究了痕量Cl<sup>-</sup>和Cu<sup>2+</sup>对3A21铝合金在50 ℃乙二醇-水冷却液中腐蚀行为的影响。结果表明,Cl<sup>-</sup>引发了铝合金的点腐蚀,随着Cl<sup>-</sup>浓度增大,铝合金点蚀敏感性增大。Cu<sup>2+</sup>促进铝合金钝化膜的破裂,并与Al发生置换反应沉积在铝合金表面,电偶作用加速了铝合金的腐蚀。Cl<sup>-</sup>和Cu<sup>2+</sup>共存时,钝化膜破裂和电偶作用导致铝合金腐蚀加剧。

In situ and operando AFM and EIS studies of anodization of Al 6060: influence of intermetallic particles

[J].

Effect of aging time on precipitation of MgZn2 and microstructure and properties of 7075 aluminum alloy

[J].

Investigation of the effects of deformation aging applied to AA7075 aluminum alloy on mechanical and metallographic properties

[J].

Intergranular corrosion behavior of friction-stir welding joint for 20 mm thick plate of 7075 Al-alloy

[J].

7075厚板铝合金搅拌摩擦焊接头晶间腐蚀行为研究

[J].对20 mm厚7075铝合金搅拌摩擦焊 (FSW) 接头沿板厚方向进行分层晶间腐蚀行为研究。借助光学显微镜及扫描电子显微镜分析了接头组织、第二相成分及分布、腐蚀深度及接头各区腐蚀形貌。结果表明:焊缝中心区腐蚀程度最轻,热机影响区 (TMAZ) 次之,热影响区 (HAZ) 腐蚀程度最严重;沿板厚向下,焊核区 (NZ) 腐蚀程度逐渐变大,TMAZ腐蚀程度先变大后减小,HAZ腐蚀程度逐渐减小;接头沿板厚方向晶粒大小和第二相粒子尺寸及分布存在差异,是造成沿板厚方向各区不同晶间腐蚀程度的主要原因。

Property of electromagnetic welded joints of 5052 aluminum alloy and HC420LA high strength steel in salt fog corrosion

[J].

5052铝合金-HC420LA高强钢磁脉冲焊接接头盐雾腐蚀性能

[J].

Evaluation of AA 7075-T6 alloy's corrosion behavior using salt spray test

[A].

Corrosion mechanism of aluminum alloy materials under high corrosion conditions

[J].

高腐蚀条件下用铝合金材料腐蚀机理

[J].

Corrosion fatigue behavior of 7075 aluminum alloy in saline water environment at different temperatures

[J].

7075铝合金在不同温度盐水环境中的腐蚀疲劳行为

[J].

Revealing the evolution of microstructure, mechanical property and corrosion behavior of 7A46 aluminum alloy with different ageing treatment

[J].

Microstructural evolution in 7075 aluminum alloy during retrogression process: experimental and phase-field modeling

[J].

Focusing on the relationship between the precipitated phases and the pitting corrosion of ZL101A aluminum alloy

[J].

Effect of aging time on precipitation of MgZn2 and microstructure and properties of 7075 aluminum alloy

[J].