5A02铝合金是一种Al-Mg系防锈铝合金,具有优异的可塑性和焊接特性,被广泛应用于船舶、建筑、汽车制造等多个领域[1~3]。尽管铝合金表面自然生成的Al2O3薄膜能有效防止基体进一步氧化腐蚀,但在海南热带滨海大气环境中,铝合金会面临多种严酷环境因素的影响,包括潮湿的气候、盐雾和霉菌等,这些因素使其腐蚀行为变得更加复杂。棘孢曲霉(Aspergillus aculeatus)作为一种常见的曲霉属(Aspergillus sp.)典型的丝状真菌,约占真菌的12%,在海南地区的滨海大气环境中广泛分布。棘孢曲霉能产生多种类型并且具有不同活性的次生代谢产物[4~7],这些代谢产物增加了铝合金表面微生物的附着、生长和腐蚀风险。因此,尽管Al2O3氧化膜在一定程度上能够抵御常规氧化腐蚀,但其在防止微生物侵蚀方面的效果受到挑战。

在复杂的环境中,微生物是影响金属材料腐蚀的重要因素之一。铝合金在微生物存在下的腐蚀行为取决于微生物的类型,有些微生物抑制腐蚀过程,而另一些则促进腐蚀[8~13]。Chen等[14]研究表明在低辐射条件下,真菌的存活率仅为24.8%,但其生长速度较快,单位真菌代谢产生的有机酸含量较高,有机酸的积累被认为是5A06铝合金在低辐射下腐蚀严重的主要原因。Jirón-Lazos等[15]研究表明黑曲霉的存在会产生侵蚀性环境,真菌孢子粘附在金属表面后会引起差异曝气腐蚀单元过程,从而引起局部腐蚀。Guan等[16]研究表明,硫酸盐还原菌(SRB)可以加速5052铝合金的均匀和局部腐蚀,形成生物膜导致表面改性。相反,Shen等[17]研究显示,枯草芽孢杆菌能显著降低铝合金在微生物存在下的腐蚀速率。然而,对于棘孢曲霉这类曲霉属的微生物,尤其是其在海南滨海大气环境中对铝合金腐蚀行为的影响,目前尚缺乏全面系统的研究。棘孢曲霉产生的次生代谢产物结构独特且多具生物活性,因此深入研究其在铝合金腐蚀过程中的作用机制对于实施有效的微生物防护措施至关重要。

本研究旨在探讨棘孢曲霉在海南滨海大气环境中对5A02铝合金的腐蚀行为。通过对5A02铝合金腐蚀形貌的观察分析不同阶段棘孢曲霉在材料表面的生长特点及其对试样的腐蚀程度,结合EDS和XPS分析腐蚀产物的成分,利用电化学工作站及扫描Kelvin探针(SKP)对铝合金表面不同时间棘孢曲霉作用下的腐蚀电位进行分析,揭示棘孢曲霉对5A02铝合金的腐蚀机理。研究成果将为海南滨海大气环境中铝合金的微生物腐蚀防护提供新的思路和方法,推动相关领域的研究与应用。

1 材料与方法

1.1 试样准备

实验选用材料为5A02铝合金,具体化学成分(质量比,%)为:Si 0.0597、Cu 0.0019、Mg 2.5603、Mn 0.2140、Cr 0.1601、Ti 0.0095、Fe 0.1932、Al余量。试样的尺寸为10 mm × 10 mm × 3 mm,将其表面用砂纸打磨至2000#,清洗后用酒精浸泡24 h,放置无菌操作台正反两面各灭菌30 min。

1.2 棘孢曲霉分离纯化与培养

将棘孢曲霉从海南滨海大气环境暴露3个月后的PCB样品中分离出来,采用稀释法分离得到棘孢曲霉单菌落。分离培养基使用马铃薯葡萄糖琼脂(PDA,马铃薯浸粉200 g/L,葡萄糖20 g/L,琼脂20 g/L),重复琼脂平板法3次,得到纯分离物。将纯化后菌落的基因序列放在NCBI网站中进行检索,取Blast结果排序最高的菌株作对比菌株进行基因序列比对。实验菌株在PDA培养基上培养3 d,培养温度为30 ℃。

1.3 孢子悬浮液的配置

在无菌操作箱中用移液枪吸取9 mL灭菌后的PDB培养基(马铃薯浸粉5 g/L、葡萄糖15 g/L、蛋白胨10 g/L、NaCl 5 g/L)置于带有棘孢曲霉的培养皿里,用枪头在霉菌表面轻轻刮蹭,吸取培养基中混有菌丝及孢子的菌液至离心管内,在涡旋混合器中涡旋混合1 min,然后过滤去除菌丝得到孢子悬浮液,用无菌水对孢子悬浮液进行浓度稀释,通过光学显微镜(Zeiss,Lab A1)观察孢子并使用血球计数板进行计数,使最终孢子悬浮液的浓度约为105个/ L。

1.4 棘孢曲霉代谢酸分析

将5 mL、浓度为1 × 105的孢子悬浮液加入40 mL去离子水的锥形瓶中,在30 ℃下培养,进行pH和代谢酸测定,测试周期分别为1、3、5、7、10和14 d。每个周期在代谢酸鉴定之前使用Mettler toledo型电子pH对菌液进行pH测试,待pH稳定后用Millipore水系膜(PES材质)过滤有菌组的菌液,作为测试溶液,吸取5 mL置于离心管中,使用高效液相色谱仪进行代谢酸鉴定。

1.5 棘孢曲霉腐蚀实验

设置实验组与对照组,实验组为有菌体系(含有棘孢曲霉的PDB培养基),对照组为无菌体系,即纯的PDB培养基。用双面胶将灭菌后的5A02铝合金样品底部与培养皿连接,将稀释过的浓度为1 × 105的孢子悬浮液吸取0.4 mL滴到样品表面,用相同方法吸取同等量纯的PDB培养基滴到无菌试样表面作为对照,用滤菌膜将培养皿封口,放置到温度为30 ℃、相对湿度为90%的霉菌培养箱中进行恒温实验,分别于1、3、7和14 d取样对试样进行测试分析。

1.6 腐蚀形貌及表面成分分析

采用Keyence VK-200型显微共聚焦系统进行宏观形貌分析,测试时间为1、3、7和14 d,放大倍率为400倍。使用FEI Quanta 250型扫描电子显微镜(SEM)分析材料的表面微观形貌,使用DEAX型能谱仪(EDS)进行能谱分析,SEM倍率为1000倍和4000倍,EDS分为点测和面扫两种方式。测试时间为1、3、7和14 d。采用Thermo Scientific ESCALAB 250Xi型X射线光电子能谱仪(XPS)对腐蚀14 d后的5A02铝合金试样表面成分进行分析。测试使用Al Kα射线源(1486.6 eV),束斑直径为500 μm。通过全谱扫描和高分辨谱扫描获取表面元素组成及化学态信息,并利用Avantage软件对数据进行分峰拟合分析。利用Princeton M370型微扫描电化学工作站SKP模式,对试样表面电位进行深入的分析。设备探针与样品表面之间的间距为(100 ± 2) μm,频率设置为80 Hz,振幅设置为30 μm。测试前先对测试区域进行平齐处理,然后采集高度数据,再将高度数据载入工作站中进行SKP模式扫描。采用扫描模式为“Scan Step Scan”。对样品进行全谱扫描后,对Al 2p进行窄区扫描,使用Avantage软件进行分峰处理,测试对象为5A02铝合金,测试时间为14 d。

2 结果与讨论

2.1 代谢酸分析

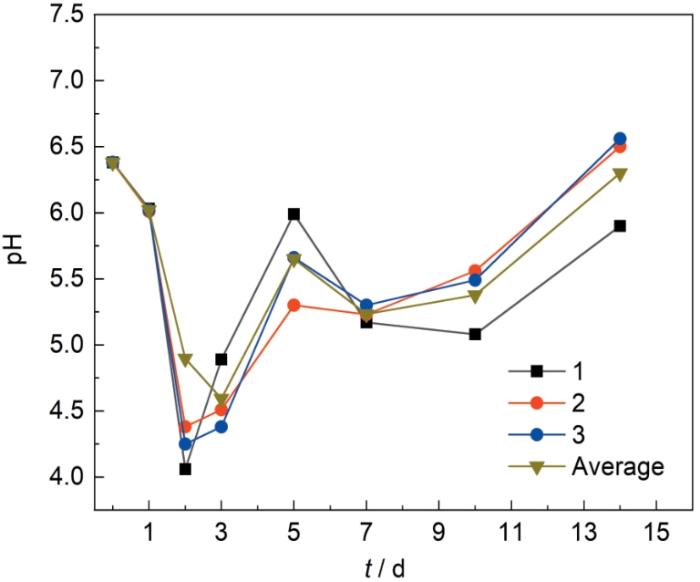

海南滨海大气环境采集的棘孢曲霉在30 ℃条件下培养14 d,图1显示了液体培养基棘孢曲霉的pH值变化趋势。可以看出,含棘孢曲霉的菌液pH值随着浸泡时间的延长呈现出前期快速降低,中期快速升高,后期pH略微升高的趋势。从开始到3 d后菌液pH值显著降低,这是由于棘孢曲霉利用碳源(葡萄糖、蛋白胨)进行生长代谢过程中不断产出有机酸[18,19];后期pH升高一方面是由于细胞膜的渗透性受周边环境pH值的影响,影响霉菌对营养物质的吸收及代谢物的排泄,导致自身新陈代谢速度降低,产出的有机酸大大减少[20],另一方面由于养分不足,菌体产生蛋白酶水解培养基中的蛋白质,导致氨基氮含量增加,同时大量霉菌死亡,细胞自溶,造成pH值升高[21]。

图1

图1

液体培养基棘孢曲霉的pH值变化

Fig.1

Changes of pH value of Aspergillus aculeatus in liquid medium

表1 液体培养基棘孢曲霉的有机酸浓度

Table 1

| Time d | pH | Oxalic acid mg/mL | Tartaric acid mg/mL | Malic acid mg/mL | Lactic acid mg/mL | Acetic acid mg/mL | Citric acid mg/mL |

|---|---|---|---|---|---|---|---|

| 1 | 6.03 | 3234.8 | 18.6 | 21.3 | 8.1 | 25.4 | 14.9 |

| 3 | 4.38 | 3571.9 | 19.5 | 23.7 | 2.5 | 31.5 | 1.8 |

| 5 | 4.89 | 4560.0 | 20.7 | 30.2 | 4.3 | 25.4 | 2.3 |

| 7 | 5.99 | 5003.1 | 21.2 | 31.2 | 0.8 | 18.7 | 2.9 |

| 10 | 5.23 | 6074.3 | 24.7 | 38.1 | 1.3 | 4.5 | 1.1 |

| 14 | 5.56 | 6223.9 | 35.2 | 67.5 | 0.4 | 2.9 | 0.1 |

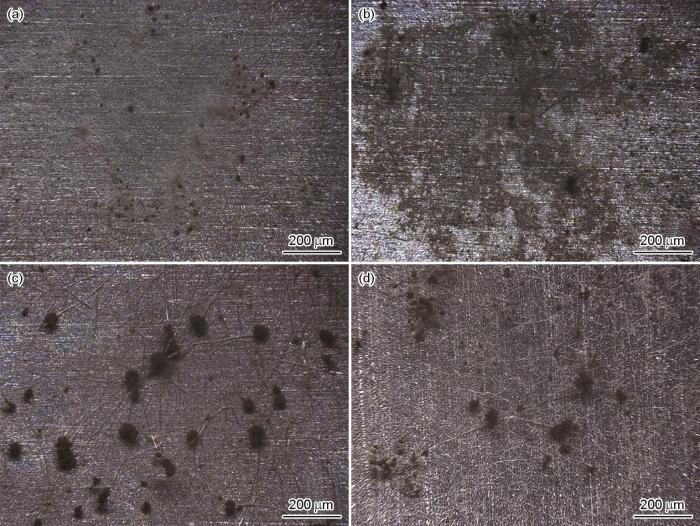

2.2 宏观形貌

图2为在5A02铝合金试样表面喷涂纯PDB培养基的无菌组在不同暴露时间下的宏观形貌。初期部分培养基生成有机物颗粒聚集随机分布在材料表面,随着实验时间的增加,白色有机物团颜色加深,出现结块现象,PDB培养基逐渐失去水分,开始出现裂纹且越来越多,暴露14 d后样品表面结块区域发生腐蚀,腐蚀区域较四周颜色偏黄。

图2

图2

无菌组在不同暴露时间后的5A02铝合金表面宏观形貌

Fig.2

Macroscopic morphologies of 5A02 Al-alloy surface in aseptic group after 1 d (a), 3 d (b), 7 d (c) and 14 d (d) exposure time

图3是经过稀释后的孢子浓度为1 × 105 /mL的棘孢曲霉悬浮液喷涂在5A02铝合金试样上的宏观形貌。1 d后棘孢曲霉孢子开始吸收水分与营养物质生成菌丝,且在溶液的交界处出现棘孢曲霉孢子堆积的现象;3 d后棘孢曲霉不断生长繁殖生成菌丝体,棘孢曲霉不断长大,逐渐生成分生孢子散布在5A02铝合金表面;7 d后在5A02铝合金表面观察到更粗、更大且脉络清晰的菌丝体,到14 d随着菌丝水分的流失,菌丝紧密贴附在5A02铝合金表面。

图3

图3

有菌组在不同暴露时间后的5A02铝合金表面宏观形貌

Fig.3

Macroscopic morphologies of 5A02 Al-alloy surface in bacteria-containing group after 1 d (a), 3 d (b), 7 d (c) and 14 d (d) exposure time

图4

图4

暴露14 d试样除锈后表面共聚焦形貌

Fig.4

Confocal morphologies of the surface of the sample after 14 d of exposure after rust removal: (a) sterility, (b) bacterium

表2 在0.01%NaCl薄液膜下试样表面蚀坑参数

Table 2

| Area | Horizon / μm | Vertical / μm |

|---|---|---|

| ab | 125.356 | 4.393 |

| cd | 513.086 | 10.139 |

2.3 微观形貌观测及成分测定

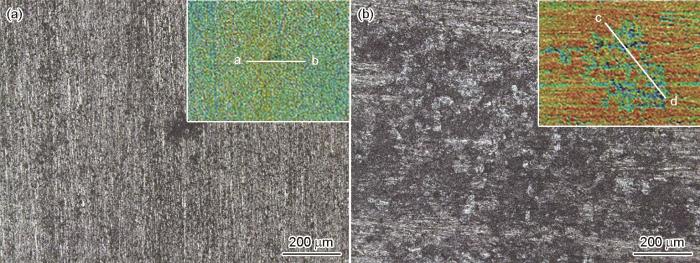

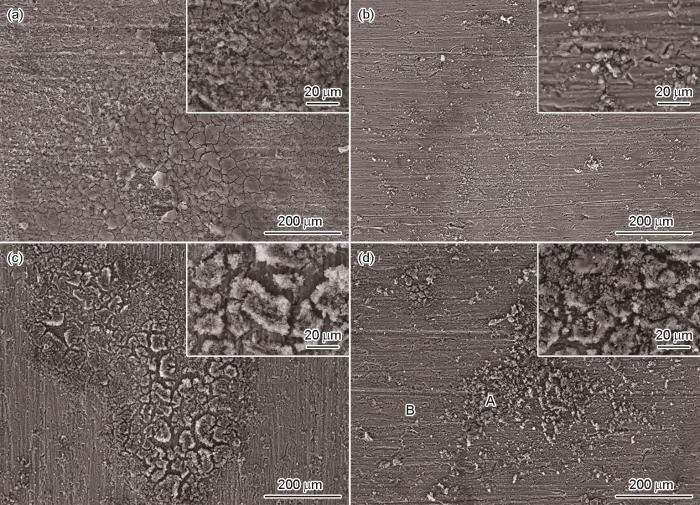

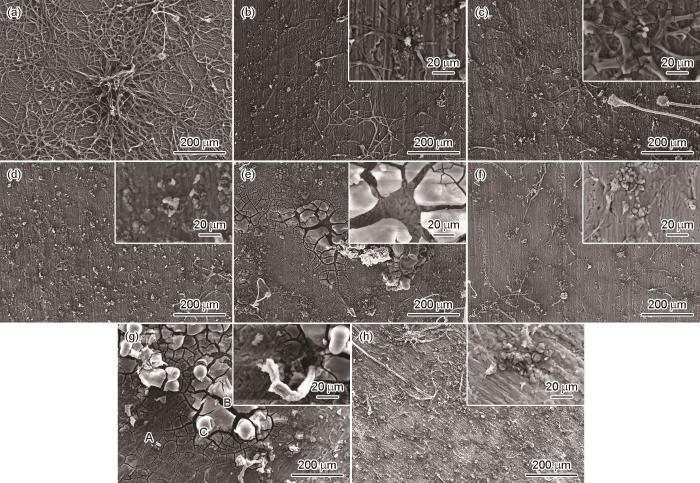

图5为无菌组5A02铝合金试样表面的微观形貌。初期部分培养基沉积生成有机物颗粒呈片状聚集随机分布在材料表面,部分颗粒嵌入基体缺陷处,随着时间延长,出现结块现象,培养基逐渐失去水分,导致结块出现裂纹和龟裂状产物,伴随着层片结构逐步细化,团絮状腐蚀产物开始在表面生成,形成分层,该层腐蚀产物极为疏松且存在明显的裂纹。

图5

图5

无菌组在不同暴露时间后的5A02铝合金表面微观形貌

Fig.5

Surface morphologies of 5A02 Al-alloy in sterile group after 1 d (a), 3 d (b), 7 d (c) and 14 d (d) exposure time

表3为14 d后无菌组5A02铝合金表面的元素含量。通过能谱扫描可以看出B区域的Al含量远高于其他元素,确定为铝基体。A区域试样表层O、C含量要高于基体,可能为培养基结块和铝的腐蚀产物。

表3 无菌试样表面EDS元素含量 (mass fraction / %)

Table 3

| Position | Al | Cl | O | C | Na | Mg | Total |

|---|---|---|---|---|---|---|---|

| A | 59.68 | 0.84 | 20.85 | 17.03 | - | 1.6 | 100 |

| B | 85.45 | - | 6.20 | 6.30 | - | 2.05 | 100 |

图6为有菌组5A02铝合金试样表面的微观形貌。图6a和b所示,暴露1 d后棘孢曲霉生成大量菌丝覆盖到材料表面,在菌液与5A02铝合金交界处少量孢子定殖到材料表面,发生腐蚀。图6c和d所示,3 d后可以观察到菌丝发育比较完全,菌丝顶端形成大量孢子分散到四周,且在中心区域观察到菌丝与基体表面紧密贴合并且开始出现裂纹,菌丝断裂处有腐蚀产物聚集。图6e和f所示,7 d后铝合金基体表面形成了一层薄薄的、相对致密的腐蚀产物,呈现出不规则片状分布和龟裂状态,随时间延长腐蚀产物逐渐堆积成块状,且内部产生了较深的裂纹,同时棘孢曲霉菌丝连同菌丝顶端孢子囊由于水分流失发生裂解。图6g和h所示,14 d后腐蚀产物上出现表面光滑的球状物体,同时观察到棘孢曲霉通过裂纹将菌丝延伸到腐蚀产物层,加速了铝合金的腐蚀。与最终周期的无菌样品相比,接种棘孢曲霉的样品的表面粗糙度更高,并且含有更多的腐蚀产物,这些腐蚀产物与微生物活性分泌物相互混合。

图6

图6

有菌组在不同暴露时间后的5A02铝合金表面微观形貌

Fig.6

Surface morphologies of 5A02 Al-alloy after 1 d (a, b), 3 d (c, d), 7 d (e, f) and 14 d (g, h) exposure time in the bacterial group

表4为14 d后有菌组5A02铝合金表面的元素含量。从EDS结果得出A区域主要由Al、O、C组成,说明Al基体表层被一层产物膜覆盖,通过与无菌组基体成分比较,碳含量明显升高,说明A区域为PDB培养基析出的有机物。区域B主要由Al、Cl、O、C组成,相较于A区,B区的Al和C明显降低,O和Cl明显升高;A区O主要来源于培养基,含量为8.66%,B区氧含量为24.09%,明显高于A区,说明B区O主要来源于Al的腐蚀产物,同时可以看到该区的Cl含量很高,达31.32%,表明B区的主要腐蚀产物由铝的氧化物和氯化物共同构成。区域C以Al、O为主,说明该区的主要腐蚀产物为铝的氧化物。

表4 有菌组试样表面EDS元素含量 (mass fraction / %)

Table 4

| Position | Al | Cl | O | C | Na | Mg | Total |

|---|---|---|---|---|---|---|---|

| A | 51.21 | 0.32 | 8.66 | 38.13 | 0.53 | 1.15 | 100.00 |

| B | 28.77 | 31.21 | 24.09 | 15.12 | 0.49 | 0.32 | 100.00 |

| C | 32.14 | 3.73 | 57.58 | 4.28 | 1.58 | 0.69 | 100.00 |

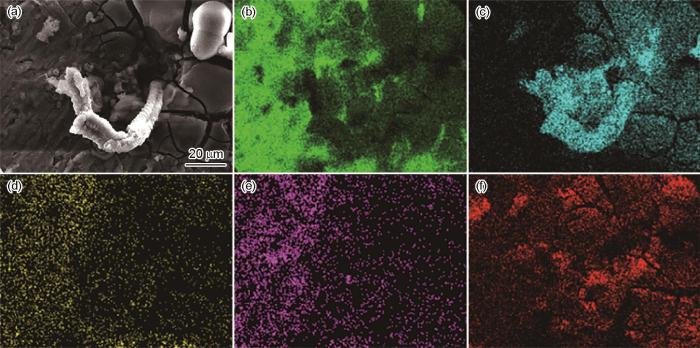

通过对有菌组A区域与无菌组B区域作比较可以看出,菌组A区域O含量低于无菌组B区域,表明无菌组B区域存在腐蚀产物。进一步比较以上5个区域看出无菌组B区与有菌组A、B、C区域均含有Cl,并且随着Cl含量的增加,结块现象越严重,说明Cl是本次实验影响腐蚀结果的主要因素之一。图7为霉菌腐蚀后的5A02铝合金样品表面的能谱面扫描元素分布图,可以看出右侧结块区域Cl、O含量要高于左侧区域,且菌丝处Cl-含量很高。一定浓度的Cl-对铝合金的均匀腐蚀使霉菌迅速附着,其菌丝结构可以从周围环境中吸收Cl-以维持细胞内的离子平衡,棘孢曲霉在生长代谢过程中释放酸性有机物改变材料表面pH,协同Cl-加快铝合金的腐蚀[25~28]。

图7

图7

霉菌腐蚀后的5A02铝合金样品表面的能谱面扫描元素分布图

Fig.7

EDS mapping of 5A02 Al-alloy sample surface after mold degradation: (a) SEM, (b) Al, (c) Cl, (d) Na, (e) C, (f) O

2.4 腐蚀产物XPS测定

利用XPS对5A02铝合金的腐蚀产物进行了分析。图8为经过14 d棘孢曲霉腐蚀后的5A02铝合金样品表面全谱与元素的高分辨图谱,总体谱图显示了Al 2p、O 1s和C 2p的特征峰位。为了更深入的探究可能存在的腐蚀产物,进一步对各个元素的高分辨图谱做了细致的分峰处理。

图8

图8

霉菌腐蚀后的5A02铝合金样品表面的XPS谱图

Fig.8

XPS full spectrum and high-resolution spectra of elements on the surface of 5A02 Al-alloy samples after mold degradation: (a) full spectrum, (b) Al 2p spectrum, (c) C 1s spectrum, (d) O 1s spectrum

Al 2p谱图主要在74.2 eV处出现1个峰,对应于样品表面的AlO(OH),另外在74.6 eV处的峰对应于样品表面的Al2O3,在72.9 eV处的峰对应于样品表面的Al。在O 1s谱图中,531.1 eV处的峰对应于Al2O3,531.5处的峰对应于AlO(OH),结合Al 2p谱图可以推断出铝合金表面腐蚀产物主要由AlO(OH)和Al2O3组成,除此之外,在529.8 eV处的峰对应于MgO,532.5 eV处的峰对应于C=O基团,对应于C 1s的XPS光谱。C 1s谱图显示位于284,284.8和287.8 eV的峰分别对应于C-H,C-C和C=O基团,可能来源于培养基以及棘孢曲霉代谢物。

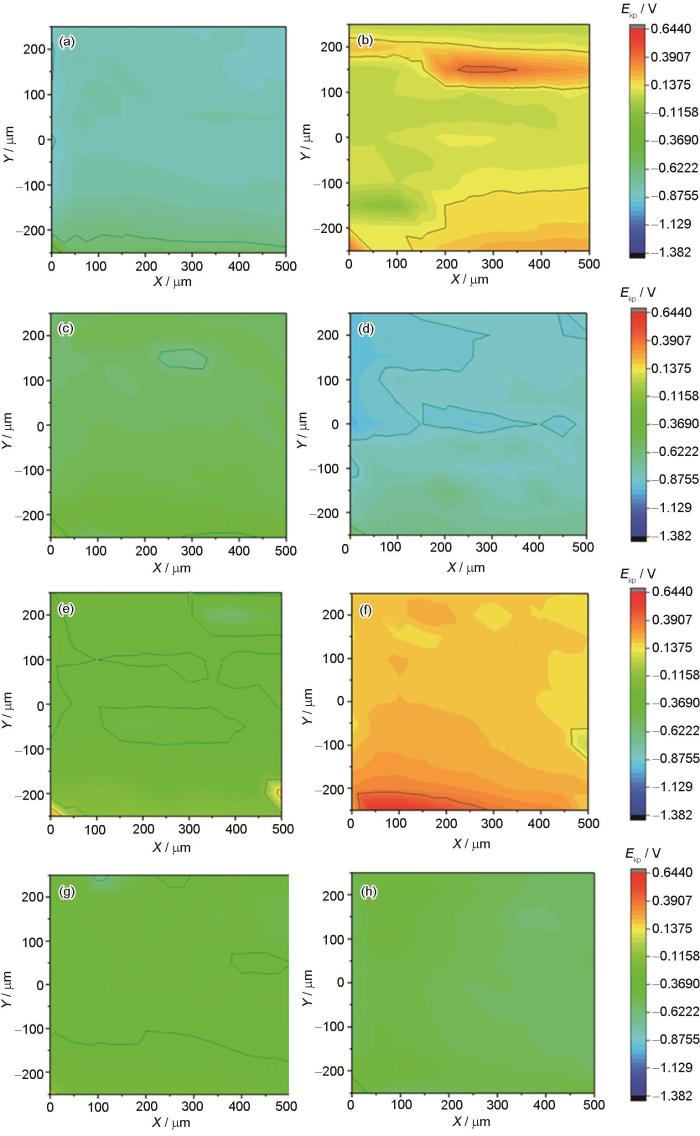

2.5 SKP测定

图9

图9

5A02铝合金试样暴露不同时间后表面SKP电位分布图

Fig.9

SKP potential distribution on the surface of 5A02 aluminum alloy sample after exposure test in bacteria group (a-d) and sterile group (e-h) for 1 d (a, e), 3 d (b, f), 7 d (c, g) and 14 d (d, h)

对有菌组样品表面SKP电位进行分析显示,随着腐蚀时间的增加,5A02铝合金表面电位出现先升高后降低的趋势,且在14 d后电位出现最负值。试验1~3 d,棘孢曲霉大量繁殖并堆积在试样表面,棘孢曲霉在其生长区域和周边裸露区域之间构成腐蚀电偶,并在代谢时分泌出大量的有机酸和无机酸,一定程度上加速了腐蚀过程的发生,使得表面电位逐渐升高。虽然在棘孢曲霉生物膜下Al基体会继续发生腐蚀,其表层电位会随着棘孢曲霉的生长而越来越正,但如图9f所示,在实验后期7~14 d,菌丝与基体紧密连接,导致局部腐蚀现象,所以探针可以检测到样品表面的实际电位信号,显示为越来越负。棘孢曲霉的生长活动加剧了局部腐蚀,进而导致整体腐蚀更加严重。

通过扫描Kelvin探针测到的电位

其中,F为Faraday常数,Wref为电极的功函数,φref/2为参比电极的半电池电位。振动探针用作参考电极,对于测量系统来说,Wref和φref/2的数值是恒定的。因此,φkp与φcorr呈正相关,可以反映样品在大气下的腐蚀情况。

其中,μ是电势分布的期望值,而σ是高斯分布的标准偏差,表示电势分布的分散程度。

表5 5A02铝合金样品表面Kelvin电势分布的高斯拟合参数

Table 5

| Aspergillus aculeatus | μ / V | σ2 | Sterile | μ / V | σ2 |

|---|---|---|---|---|---|

| a | -0.76880 | 1.309912 | e | -0.31640 | 0.873802 |

| b | 0.11045 | 0.120542 | f | 0.22938 | 0.1191912 |

| c | -0.75514 | 6.620632 | g | -0.39034 | 0.144492 |

| d | -0.82554 | 0.539902 | h | -0.50451 | 0.531992 |

2.6 腐蚀机理研究

棘孢曲霉对5A02铝合金的腐蚀过程可分为3个阶段。前期主要为化学腐蚀,如式(

有机酸的电离和水解(以草酸为例):

化学腐蚀:阳极:

阴极:

中期主要为氧浓差腐蚀,如式(

电化学腐蚀:阳极:

阴极:

后期主要为点蚀。随着暴露实验进行,棘孢曲霉逐渐干涸,样品表面逐渐显漏出来。部分棘孢曲霉孢子定殖蚀坑内部伴随着氯离子的富集与棘孢曲霉代谢产酸,使腐蚀沿着样品更深处发生。

3 结论

(1) 通过对5A02铝合金试样的宏观形貌、微观形貌进行观测,棘孢曲霉在5A02铝合金表面经历以下3个阶段:孢子萌发形成菌丝体、生成的分生孢子吸收营养物质形成菌丝、菌丝干涸与材料表面连接紧密。棘孢曲霉在生长代谢过程中可以分泌各种有机酸,以草酸为主,提高了5A02铝合金的腐蚀速率。

(2) 利用EDS和XPS对5A02铝合金的腐蚀产物成分进行分析,主要由AlO(OH)、Al2O3和MgO组成。对5A02铝合金样品表面进行伏打电位测定,结果表明有菌组的电位变化幅度更大且整体电位较无菌组更负,且有菌组电位随着时间的延长出现先升高后降低的趋势。

(3) 棘孢曲霉对5A02铝合金腐蚀的影响表现为:前期在棘孢曲霉与材料的交界处孢子嵌入到样品里,伴随着腐蚀产物的生成;中期在棘孢曲霉定殖的地方以及Cl-富集的地方出现干裂现象,且棘孢曲霉失去水分,出现裂解现象;后期腐蚀产物逐渐堆积成块状,且内部产生了较深的裂纹,棘孢曲霉菌丝通过腐蚀产物裂纹接触到铝合金基体,加速其腐蚀。

参考文献

Review of laser-arc hybrid welding process of aluminum alloys for new energy vehicles (Invited)

[J].

新能源汽车用铝合金激光-电弧复合焊接研究进展(特邀)

[J].

Corrosion resistance of marine aluminum alloy and its application on ships and warships

[J].

海洋铝合金的抗蚀性及其在舰船上的应用

[J].

Research progress and applications of conductive aluminum alloys used in transportation

[J].

交通运输用导电铝合金的应用现状及研究进展

[J].

Chemical constituents from marine-derived fungus Aspergillus insulicola

[J].

深海曲霉属真菌Aspergillus insulicola的化学成分研究

[J].

Research progress on the secondary metabolites and activities of endophytic fungi of genus Aspergillus and Trichoderma from mangroves

[J].

红树林来源曲霉属和木霉属内生真菌次生代谢产物及活性研究进展

[J].

Study on the diketopiperazines from the Lumnitzera littorea-derived fungus Aspergillus terreus HT-1

[J].

红榄李内生真菌Aspergillus terreus HT-1二酮哌嗪类次级代谢产物研究

[J].

Microbiologically influenced corrosion and mechanisms

[J].

微生物腐蚀及腐蚀机理研究进展

[J].

Laboratory investigation of microbiologically influenced corrosion of C1018 carbon steel by nitrate reducing bacterium Bacillus licheniformis

[J].

Effect of SRB on corrosion behavior of X70 pipeline steel in near-neutral pH solution

[J].

SRB对X70管线钢在近中性pH溶液中腐蚀行为的影响

[J].采用电化学阻抗、动电位极化及微观观察法,对比了有、无硫酸盐还原菌 (SRB) 的情况下X70管线钢在近中性pH溶液 (NS4) 中的腐蚀行为,研究了SRB生长周期对X70钢腐蚀行为的影响。结果表明:X70钢在无菌溶液中腐蚀速率随时间增加呈单一增大的趋势。SRB在NS4溶液中的生长周期分为对数繁殖期 (1~3 d),稳定生长期 (4~7 d) 和衰亡期 (7~14 d) 3个阶段。SRB对X70钢在NS4溶液中腐蚀速率的影响与其在溶液中生长规律有关:当SRB处于对数繁殖期和稳定期时,X70钢表面覆盖一层致密的生物膜,对钢起到了保护作用,此时X70钢的腐蚀速率比无菌条件下低;当SRB进入衰亡期,X70钢腐蚀的程度比无菌介质中严重,钢表面腐蚀产物逐渐增多,生物膜出现破裂,腐蚀速率增大。

Effect of iron bacteria on corrosion behavior of 20 carbon steel in circulation cooling system

[J].

循环冷却水含铁细菌对20碳钢管壁腐蚀行为的影响

[J].

Effect of iron bacteria on corrosion behavior of J55 steel

[J].

铁细菌对J55钢腐蚀行为的影响

[J].

Microbiological influenced corrosion attack by Bacillus Megaterium bacteria on Al-Cu alloy

[J].

Corrosion of carbon steel by sulphate reducing bacteria: Initial attachment and the role of ferrous ions

[J].

Microbial corrosion behavior and mechanism of 5A06 aluminum alloy under low dose proton radiation

[J].

Localized corrosion of aluminum alloy 6061 in the presence of Aspergillus niger

[J].

Interaction between sulfate-reducing bacteria and aluminum alloys—Corrosion mechanisms of 5052 and Al-Zn-In-Cd aluminum alloys

[J].Microbiologically influenced corrosion caused by sulfate-reducing bacteria (SRB) poses a serious threat to marine engineering facilities. This study focused on the interaction between the corrosion behavior of two aluminum alloys and SRB metabolic activity. SRB growth curve and sulfate variation with and with aluminum were performed to find the effect of two aluminum alloys on SRB metabolic activity. Corrosion of 5052 aluminum alloy and Al-Zn-In-Cd aluminum alloy with and without SRB were performed. The results showed that both the presence of 5052 and Al-Zn-In-Cd aluminum alloy promoted SRB metabolic activity, with the Al-Zn-In-Cd aluminum alloy having a smaller promotion effect compared with 5052 aluminum alloy. The electrochemical results suggested that the corrosion of the Al-Zn-In-Cd aluminum alloy was accelerated substantially by SRB. Moreover, SRB led to the transformation of Al-Zn-In-Cd aluminum alloy corrosion product from Al(OH)3 to Al2S3 and NaAlO2.

Study of pitting corrosion inhibition effect on aluminum alloy in seawater by biomineralized film

[J].

Aspergillus as a versatile cell factory for organic acid production

[J].

Microbial production of organic acids by endophytic fungi

[J].

Growth and synthesis of aflatoxin by Aspergillus parasiticus in the presence of sorbic acid

[J].Two media [basal (M) and enriched (M)] containing potassium sorbate (0-300 ppm as sorbic acid) were inoculated with spores (10 - 10/flask) of Aspergillus parasiticus and incubated for 5 days at 28 C. The greater the amount of sorbate added, the higher was the pH of the media after incubation and the smaller was the yield of mold mycelium. Intermediate amounts of sorbate sometimes resulted in greater accumulation of aflatoxin than when media were free of sorbate. Sorbate more effectively inhibited mold growth and aflatoxin production in medium M than M and when the small rather than the large inoculum was used. A second trial was done with 10 or 10 spores/flask of M (ca. 27 ml) and 10 spores/flask of M (ca. 27 ml) containing sorbate (200 ppm of sorbic acid). Cumulative data for mold growth. pH and content of aflatoxin in the medium showed that relative effects of different treatments changed during the incubation period. An index to measure the capacity of molds to synthesize aflatoxins was developed. Application of the index indicates that sorbate delayed mold growth but did not inhibit biosynthesis of aflatoxin. The ability to synthesize aflatoxin was greatest in the early stages of mold growth and then decreased linearly as mold growth progressed.

Advances in signal regulation and detection strategies for autophagy in fungal cells

[J].

真菌细胞自噬的信号调节和检测策略研究进展

[J].

Correlation between organic acids accumulation and biosynthesis of avermectin

[J].

阿维菌素发酵过程有机酸积累规律与生物合成的关系

[J].

Research progress on mold corrosion of aluminum alloy

[J].

铝合金霉菌腐蚀研究进展

[J].

Advances in production of organic acid by rhizopus sp.integrated with in-situ product separation process

[J].

根霉菌反应分离耦合生产有机酸的研究进展

[J].

Effect of chloride ions on the corrosion behavior of carbon steel in an iron bacteria system

[J].Reclaimed water used as circulating cooling water can effectively relieve water stress, but the corrosion problem in it is very prominent. In particular, Cl and iron bacteria (IB) are important influencing factors of corrosion behavior in a circulating water environment, and both of them often coexist in circulating water systems, so it is crucial to study their synergistic effects. This paper investigated the effect of Cl on the corrosion behavior of carbon steel in the IB system by use of weight loss measurements, electro-chemistry and X-ray photoelectron spectroscopy (XPS). In the first 1-9 days of the experiment, the increase of Cl concentration led to an increase of corrosion rate and a decrease of anode potential and charge transfer resistance at the interface. The corrosion rate of the 4Cl condition reached 0.45 mm a in the 1st day, which was 1.47 and 1.15 times that of 3Cl and 1Cl, and its anode potential was 22.6% and 33.8% lower than that of 3Cl and 1Cl. This indicates that a higher concentration of Cl made the anodic reaction easier and the corrosion more severe. However, after 9 days, a decline in the corrosion rate was recorded at similarly high Cl concentrations. On the 15th day, the corrosion rates for 3Cl and 4Cl were 7.0% and 15.6% lower compared to the 1Cl condition. At this stage, the anode potential and film resistance had increased significantly, to become the dominant factors controlling the corrosion reaction. On the 15th day, the values of 1Cl, 3Cl and 4Cl were 1.2, 1.5 and 1.7 times higher than those of the 1st day, and the highest value of 1592.1 Ω cm was obtained for the 4Cl condition, which was 1.9 times higher than that of. In the early stage of corrosion, the surface of the carbon steel was enriched in Cl due to their high concentration, and the Cl could easily destroy the developing corrosion product film and promote the generation of Fe. At the same early stage, the growth of IB was enhanced, and the metabolism of IB was promoting local corrosion. However, in the later stage of corrosion, biofilms had an increasing effect on corrosion. A high concentration of Cl accelerated biofilm growth and densified the corrosion product layer which subsequently hindered the anodic reaction and thus inhibited corrosion.This journal is © The Royal Society of Chemistry.

Influence of NaCl concentration on microbiologically influenced corrosion of carbon steel by halophilic archaeon Natronorubrum tibetense

[J].

Corrosion behaviour of copper under the action of chlorine-containing thin liquid film and Aspergillus versicolor

[J].

铜在含氯薄液膜和杂色曲霉作用下的腐蚀行为

[J].

Application progress of corrosion protection for electronic and electrical equipment in coastal space launch sites

[J].

滨海发射场电子电气设备腐蚀防护应用进展

[J].

Fungal-induced atmospheric iron corrosion in an indoor environment

[J].

Effect of mold on corrosion behavior of immersion silver finished printed circuit board

[J].The corrosion behavior of Immersion Silver (ImAg) finished Printed Circuit Board (PCB) in mold environment was studied using Scanning Kelvin Probe (SKP) technology. The mold growth behavior was observed by using stereo microscope and SEM, and the corrosion product was analyzed by EDS. Based on the results of SEM and EDS, mold could grow on the surface of PCB-ImAg specimens under hygrothermal condition, Aspergillus niger shows higher activity and has a priority growth characteristics. The activity of mold is a promoter in the localized (pore) corrosion process and the leakage of copper of PCB-ImAg covered by mold. SKP results show that the PCB surface potential as a whole increases with time. And the colony region of PCB occurs preferentially corrosion as the anode; then the corrosion product area enlarges gradually. Although the corrosion reaction generates small amounts of toxic Ag<SUP>+</SUP>, which inhibits the growth and metabolism of the spores, this do not prevent the corrosion of PCB-ImAg caused by mold from occurrence. ImAg finished technology is unable to completely inhibit the growth of mold on PCB surface, which could not fully meet the requirement of PCB anti-mildew.

霉菌对化学浸银处理印制电路板腐蚀行为影响

[J].

A simple algorithm for fitting a Gaussian function [DSP tips and tricks]

[J].

QCM study of microbiological activity during long-term exposure to atmosphere—aluminium colonisation by Aspergillus Niger

[J].

Extracellular polymeric substances secreted by marine fungus Aspergillus terreus: Full characterization and detailed effects on aluminum alloy corrosion

[J].

Single-cell level investigation of microbiologically induced degradation of passive film of stainless steel via FIB-SEM/TEM and multi-mode AFM

[J].

The effect of a biofilm-forming bacterium Tenacibaculum mesophilum D-6 on the passive film of stainless steel in the marine environment

[J].

Study of the corrosion behavior of Aspergillus niger on 7075-T6 aluminum alloy in a high salinity environment

[J].

Adsorption and corrosion behaviour of Trichoderma harzianum for AZ31B magnesium alloy in artificial seawater

[J].