众所周知,热处理工艺可以消除SLM工艺中的残余应力,同时降低微观组织的各向异性和不均匀性[9];有效地控制第二相析出,从而调节合金的综合性能[10]。(FeNiCrMn)(100-x)Co x 进行退火处理后,σ相的析出提高了合金的硬度和屈服强度,降低了拉伸伸长率[11]。通过调控热处理后的微观组织,有助于提高合金力学性能,也很大程度地影响合金的其它性能,比如耐腐蚀性能。SLM 316L合金950℃热处理后消除了熔池边界(MPB)和高密度位错,保留了纳米夹杂物和蜂窝亚结构的优点,提高了耐腐蚀性能[12]。温度增加到1100℃,显著降低了合金低角晶界密度,增加了偏析和再沉淀,耐腐蚀性能下降。SLM制造15-5 PH不锈钢经过900℃时效处理后,形成细小的富Cu沉淀物,提高了耐腐蚀性能[13]。微观组织中析出相对耐腐蚀性能的影响至关重要。

一般认为,合金中的Cu可以提高其耐腐蚀性。Xi等[14]研究表明,随着Cu含量的增加,316 L不锈钢在NaCl溶液中的耐腐蚀性也随之增强。Wu等[15]研究了含Cu耐候钢在模拟海洋环境中的耐腐蚀性。结果表明,Cu的加入提高了自腐蚀电位,减缓了阳极溶解速率。腐蚀产物中形成了CuFeO2,Cu2O和CuO的富Cu层,增强了对基体的保护作用,降低了腐蚀速率。Xu等[16]研究了含Cu低碳钢在模拟地下水溶液中的腐蚀行为,由于Cu2+溶解在钢表面再次富集,形成抑制阳极反应的保护性腐蚀产物膜,从而提高合金耐腐蚀性。含Cu合金在盐溶液中的腐蚀机制已被广泛的讨论,但其在碱性溶液中的腐蚀机制文献报道较少,仍需要进一步分析和研究。本文以SLM制备的低成本含铜Fe-Mn-Cr-Ni MEA为对象,结合X射线衍射(XRD)、扫描电子显微镜(SEM)和能谱仪(EDS)分析,研究相结构、微观组织和形貌的变化。通过在1 mol/L NaOH溶液中电化学测试,包括电化学阻抗谱(EIS)和动电位极化,研究了打印态和经不同时效温度处理后MEA下的耐腐蚀性能。并利用X射线光电子能谱(XPS)技术测定了钝化膜的组成。探讨了微观组织演变对腐蚀行为的影响,为含Cu合金在碱性介质下的应用提供理论参考。

1 实验方法

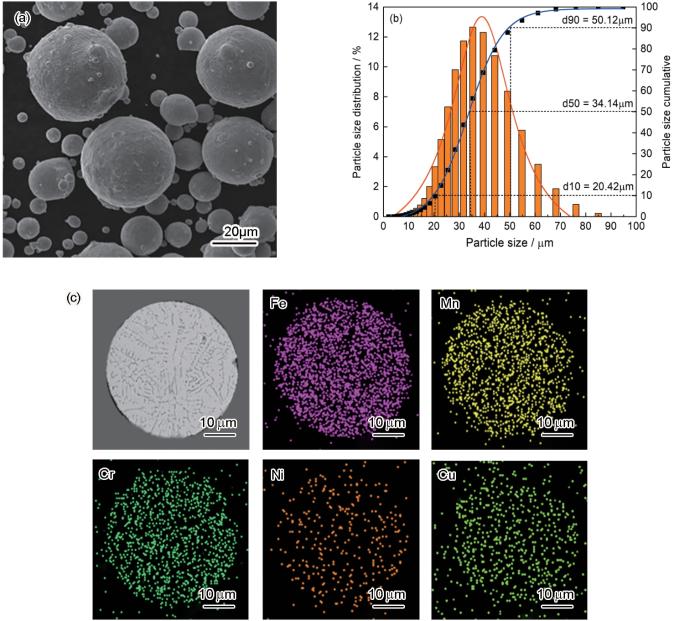

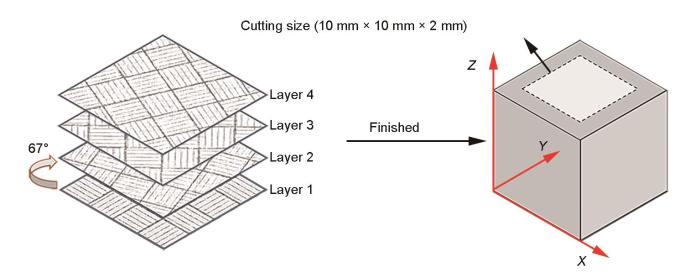

实验所用中熵合金粉末采用气雾法制备,合金粉末成分(质量分数,%)为:20Mn、14Cr、11Ni、4Cu、0.1C,其余为Fe。图1为中熵合金粉末的微观形貌和粒径分布图,由图可知,粉末颗粒球形度较高,颗粒直径呈正态分布,大小主要分布在15~53 μm,粉末截面的元素分布图表明合金粉末内部元素分布均匀。本次研究采用的SLM试样由HB-150型金属3D打印机制备,打印机配有500W Yb光纤激光器,激光光斑直径为75 μm。打印过程中在Ar保护气中进行(氧含量< 0.01%)。如图2显示了扫描策略和加工坐标图,所有打印样品采用棋盘式激光扫描策略,每层旋转角度为67°,层层加工成形。在SLM样品XOY平面,采用线切割电火花加工,用于电化学测试。根据Archimede排水法,选取高质量样品的工艺参数如下:激光功率175 W,扫描速率640 mm/s,扫描距离70 μm,层厚60 μm。

图1

图1

中熵合金粉末的微观形貌和粒径分布图

Fig.1

Medium entropy alloy powder: (a) powder morphology, (b) distribution of powder size, (c) etched cross-section and compositional analysis

图2

图2

试样扫描策略和切割位置示意图

Fig.2

Schematic diagram of the scanning strategy and cutting position of the specimen

为了研究时效处理后的微观组织和腐蚀性能。首先,将SLM试样放入真空热处理炉(SA2-16-14TP)中,加热温度为200、300、500和700℃,加热时间为60 min。之后,样品随着真空热处理炉冷却至室温。原始打印态的样品被命名为UT。温度为200、300、500和700℃时效处理的试样分别命名为AT-200、AT-300、AT-500和AT-700。

所有样品都通过标准的金相制样方法获取,包括逐级机械研磨和抛光,然后用FeCl3溶液(10 g FeCl3 + 30 mL HCl + 120 mL H2O)进行腐蚀。通过使用带有Cu Kα辐射的XRD (X'Pert3 Power)对不同处理态的样品进行物相分析,扫描速率为5°/min,扫描范围为30°~100°。采用TESCAN MIRA3场发射扫描电子显微镜(FESEM)、Oxford X-Max型EDS对试样进行微观组织和化学成分表征。此外,使用Thermo Scientific K-Alpha型XPS表征了样品浸泡7 d的氧化膜成分,采用C 1s峰结合能284.6 eV进行峰位校正,之后使用Thermo Avantage软件拟合所有XPS峰,分析各元素价态。

采用CHI760型电化学工作站对不同时效温度样品进行电化学测试,包括开路电位(OCP)测量、EIS分析和动电位极化测试,使用常规三电极系统,测试在室温(25 ± 1℃)、1 mol/L NaOH溶液中进行。工作电极为方形片状试样,工作面积为1 cm2。试样工作面用SiC砂纸打磨至2000#,然后用2.5 μm金刚石膏抛光,最后无水乙醇进行清洗,热风吹干。对比电极和参比电极分别为铂片和饱和甘汞电极(SCE)。首先,将样品浸入1 mol/L NaOH溶液中1800 s,以获得稳定的OCP。然后再进行EIS和动态电位极化测试。EIS的扫描频率范围为105~10-2 Hz,振幅为5 mV。动电位极化实验的扫描速率为1 mV/s,电位范围为-1 VSCE~0.7 VSCE,随后用ZSimpWin软件拟合实验数据。为了数据再现性,电化学测试至少重复3次。

2 结果与讨论

2.1 微观结构表征

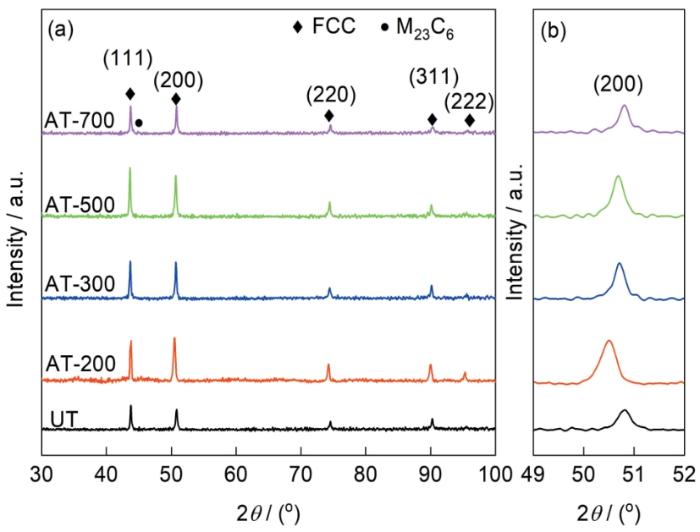

图3

图3

时效处理后SLM-MEA的XRD谱和(200)放大图

Fig.3

XRD patterns of SLM MEA after aging treatments (a) and enlarged pattern of (200) (b)

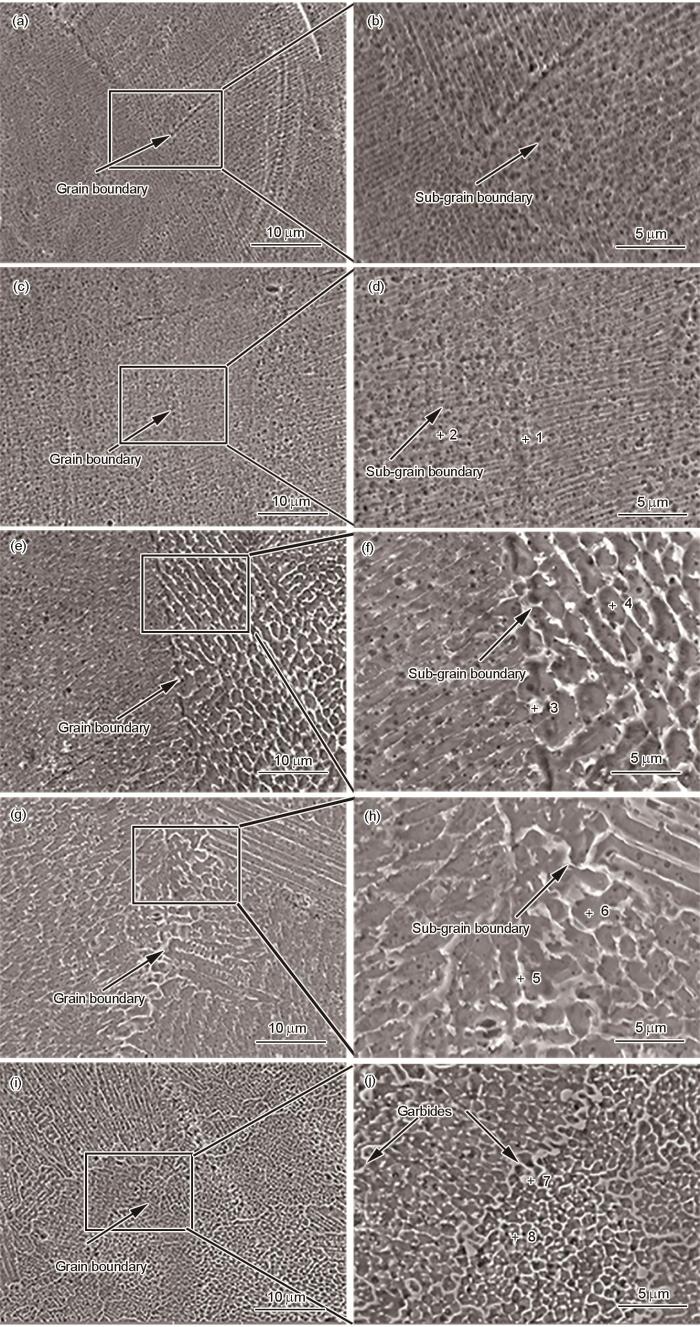

如图4和表1,时效处理使富Cu析出相的位置沿晶界处向胞状亚晶内部转移。UT为典型的胞状亚晶微观结构,这种结构的形成可能与Bernard Marangoni驱动的不稳定性(BMI)和粒子积累结构形成(PAS)机制有关[18]。经过200℃时效后,晶界与亚晶界处有少量富Cu相析出(图4d,点1)。值得注意地是,AT-300的晶界与亚晶界处出现明显的富Cu相亮色颗粒(图4e和f,点3)。如图4g和h,AT-500晶界处亮色颗粒为少量的富Cr碳化物(图4h,点6)和富Cu相。时效温度升至700℃,晶界出现了连续的富Cr碳化物(图4j, 点7)。AT-700部分亚晶界消失,胞状亚晶中出现明亮的富Cu相(图4j,点8)。

图4

图4

不同时效处理后的SLM-MEA微观结构

Fig.4

Microstructure of SLM MEA after different aging treatments: (a, b) UT, (c, d) AT-200, (e, f) AT-300, (g, h) AT-500, (i, j) AT-700

表1 图 4中标记点的化学成分 (mass fraction / %)

Table 1

| Sample | Spectrum point | Fe | Mn | Cr | Ni | Cu | C |

|---|---|---|---|---|---|---|---|

| AT-200 | 1 | 46.90 | 20.81 | 11.92 | 10.04 | 6.47 | 3.86 |

| 2 | 47.55 | 21.18 | 12.31 | 10.52 | 4.92 | 3.52 | |

| AT-300 | 3 | 40.16 | 21.19 | 11.96 | 11.44 | 11.77 | 3.47 |

| 4 | 46.50 | 19.72 | 13.32 | 11.09 | 4.74 | 4.57 | |

| AT-500 | 5 | 42.01 | 19.67 | 11.87 | 12.08 | 9.49 | 4.89 |

| 6 | 46.51 | 20.20 | 13.90 | 10.81 | 5.09 | 4.17 | |

| AT-700 | 7 | 46.93 | 17.24 | 18.47 | 9.27 | 4.95 | 3.14 |

| 8 | 36.15 | 17.96 | 23.91 | 8.45 | 11.08 | 2.45 |

2.2 电化学研究

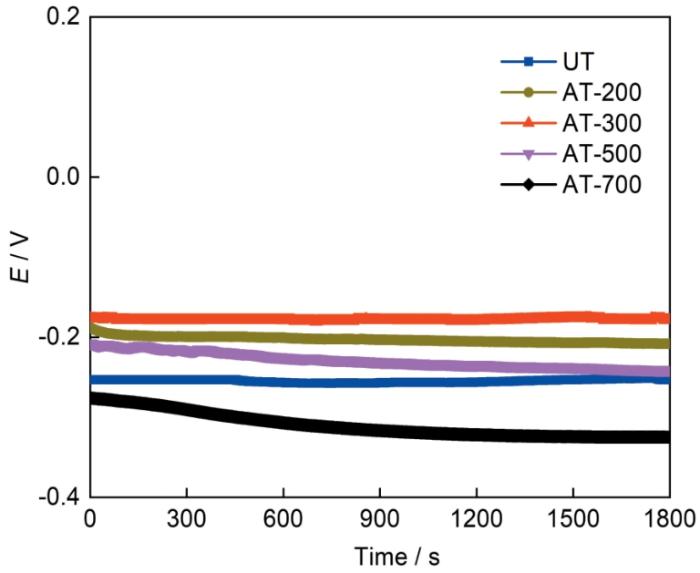

通过OCP、极化曲线和EIS测试,研究了不同处理态样品在25℃的1 mol/L NaOH溶液中的腐蚀行为。图5为不同时效态样品的OCP,可以看出,AT-300腐蚀电位高于其他样品,说明AT-300电化学阳极活性较低。

图5

图5

不同时效态样品在1 mol/L NaOH溶液中的开路电位

Fig 5

OCP of samples with different aging states in 1 mol/L NaOH solution

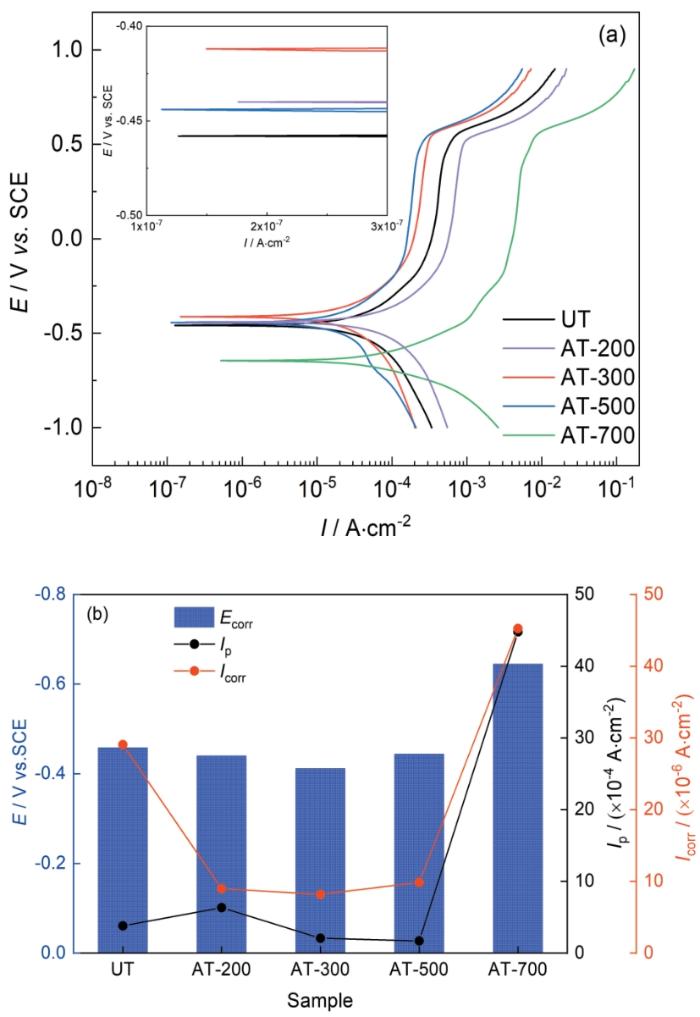

图6a为不同时效处理温度样品的极化曲线,样品都出现了钝化行为。图6b为不同时效样品的相对参数图,包括腐蚀电位(Ecorr)、维钝电流密度(Ip)和腐蚀电流密度(Icorr)。可以看出,Ecorr随温度升高呈先降低再上升趋势,其中AT-300表现出最高的Ecorr,为-0.412 VSCE。Wang等[19]认为,Ecorr具有显著的阳极位移,这是由材料良好的自发钝化能力造成的。基于该分析,AT-300比其它样品具有更强的自钝化能力。Ip的数值能反映材料的溶解速率,其数值越小,腐蚀速率越小[20]。Ip的变化趋势不显著,AT-300的Ip较小,腐蚀速率较慢。Icorr描述了钝化膜对腐蚀环境的耐受性,并作为钝化膜耐腐蚀性的标准[21]。Icorr与腐蚀电位变化趋势相同,AT-300的Icorr最小,为8.20 × 10-6 A·cm-2。

图6

图6

不同时效态样品的动电势极化曲线及Ecorr,Ip和Icorr

Fig.6

Dynamic potential polarization curves (a) and relative parameters (b) of samples under different aging states

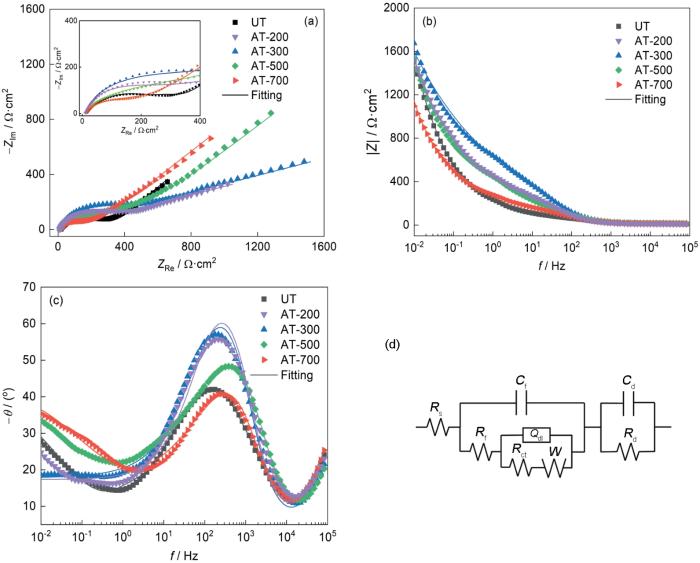

此外,图7a~c为所有样品在1 mol/L NaOH溶液中的Nyquist图和Bode图。在Nyquist图中只能看到一个电容回路,这表明溶液的腐蚀过程受电荷转移过程的动力学控制[22]。Nyquist图的半弧直径越大,钝化膜的耐蚀性越高,可见AT-300样品耐蚀性优于其他试样。Bode图中,利用|Z|和频率的关系(图7b),用0.01 Hz对应的|Z|值来表征合金的极化电阻(Rp)[23]。在相角(θ)与频率的关系图中(图7c),相角曲线的宽度和高度分别代表试样的腐蚀倾向和表面稳定性[24]。Bode图中的结果进一步证明了AT-300具有最好的耐蚀性能。在1 mol/L NaOH溶液中的等效电路如图7d所示,其中,Rs表示溶液电阻,Rf表示外层界面电阻,Rct表示电荷转移电阻,W表示由扩散过程引起的Warburg阻抗。有限扩散层环电路(Cd和Rd)表明了腐蚀行为的复杂性[25]。Cf表示钝化膜的电容,Qdl是一种双层电容的恒定相角元件(CPE),用于表示双层电容和更好地拟合EIS数据。n2是恒定相位角元件Qdl的指数。根据等效电路,样品的EIS数据都拟合良好,详细数据如表2。图表中Rs相差不大,说明样品的实验环境几乎相同。表中Rct明显高于Rf,说明腐蚀保护主要由内层提供,而耐腐蚀性的差异是由样品电荷转移电阻引起的。在比较耐腐蚀性时可用整个电路的极化电阻Rp的计算公式[22]:

显然易见,AT-300的Rp大于其它试样,这与|Z|-f图的结果一致,说明AT-300电极越难极化和腐蚀。

图7

图7

不同时效态样品在1 mol/L NaOH溶液中电化学阻抗谱和拟合电路

Fig.7

Nyquist (a), impedance module (b) and phase angle (c) plots of samples with different aging states in 1 mol/L NaOH solution and equivalent circuit (d)

表2 等效电路中参数的拟合值

Table 2

| Sample | Rs Ω·cm2 | Cf Ω-1·cm-2·s n | Rf Ω·cm2 | Qdl Ω-1·cm-2·s n | n2 | Rct Ω·cm2 | W Ω-1·cm-2·s n | Cd Ω-1·cm-2·s n | Rt Ω·cm2 |

|---|---|---|---|---|---|---|---|---|---|

| UT | 33.86 | 7.831 × 10-6 | 16.12 | 1.418 × 10-4 | 0.7028 | 3.494 × 102 | 7.720 × 10-3 | 3.347 × 10-5 | 4.014 × 102 |

| AT-200 | 24.20 | 6.228 × 10-6 | 14.22 | 1.515 × 10-4 | 0.6061 | 6.725 × 102 | 2.998 × 10-3 | 2.721 × 10-5 | 7.472 × 102 |

| AT-300 | 27.45 | 6.167 × 10-6 | 24.38 | 1.076 × 10-5 | 0.4278 | 7.650 × 102 | 3.461 × 10-3 | 2.594 × 10-5 | 7.912 × 102 |

| AT-500 | 49.35 | 6.280 × 10-6 | 18.06 | 5.290 × 10-5 | 0.4244 | 6.699 × 102 | 2.636 × 10-3 | 2.958 × 10-5 | 6.957 × 102 |

| AT-700 | 58.14 | 8.544 × 10-6 | 14.15 | 6.381 × 10-4 | 0.4211 | 2.911 × 102 | 3.243 × 10-3 | 4.999 × 10-5 | 3.447 × 102 |

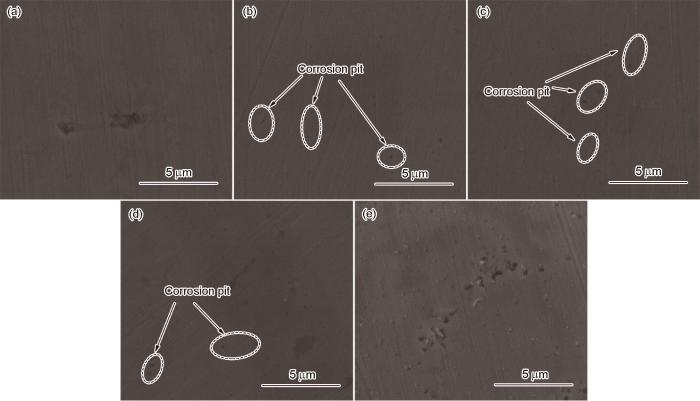

2.3 腐蚀表面形态

图8

图8

不同时效态样品在1 mol/L NaOH溶液中电化学腐蚀形貌

Fig.8

Electrochemical surface morphologies of samples with different aging states in 1 mol/L NaOH solution: (a) UT, (b) AT-200, (c) AT-300, (d) AT-500, (e) AT-700

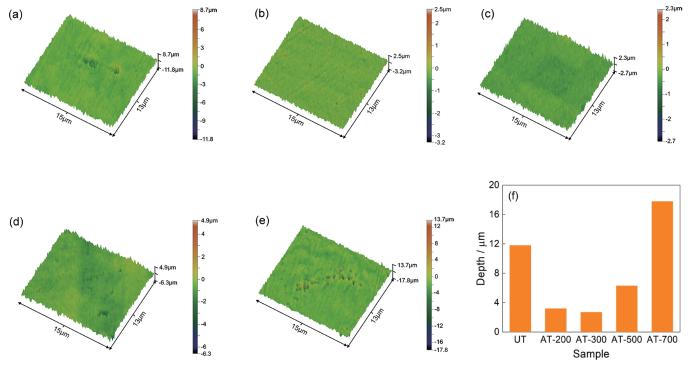

图9

图9

不同时效态样品的电化学腐蚀形貌3D图和腐蚀深度图

Fig.9

3D electrochemical corrosion morphologies (a-e) and corresponding corrosion depth (f) of UT (a), AT-200 (b), AT-300 (c), AT-500 (d) and AT-700 (e)

2.4 钝化膜特性

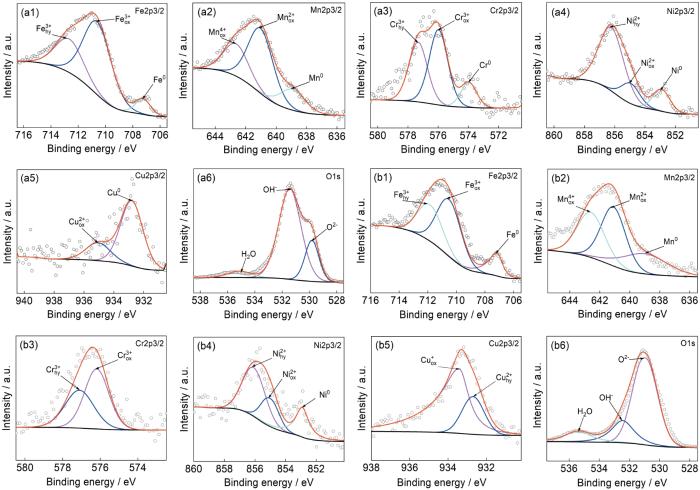

图10为UT和AT-300样品在1 mol/L NaOH溶液中浸泡7 d后形成钝化膜的XPS谱。根据相关文献分析[26],图10a1和b1为Fe 2p3/2光谱,分解为3个峰,分别对应金属Fe0, Feox3+和Fehy3+。图10a2和b2中,Mn 2p3/2光谱中对应有3个峰,分别为 Mn0, Mnox2+和Mnox4+。图10a3显示了UT样品中Cr 2p3/2电离分为3组峰,Cr(OH)3, Cr2O3和金属Cr0。图10b3显示了AT-300样品的Cr 2p3/2电离分为两组峰,Cr(OH)3和Cr2O3。相关文献表明,Cr 2p3/2电离出金属Cr0峰会降低UT试样耐腐蚀性能[22]。图10a4和b4中的Ni 2p3/2 光谱分为3种峰,分别为Ni0,Niox2+和Nihy2+。图10a5和b5显示了Cu 2p3/2具有2个组成峰的光谱,分别为Cuox2+和Cuhy2+。图10a6和b6为O 1s的电离,主要包括3种成分,金属氧化物形式的O2-、金属氢氧化物形式的OH-和水分子。

图10

图10

UT和AT-300在1 mol/L NaOH 溶液中浸泡7 d后钝化膜的XPS谱

Fig.10

XPS spectra of passive film formed after 7 d of immersion in 1 mol/L NaOH solution: (a1-a6) UT, (b1-b6) AT-300

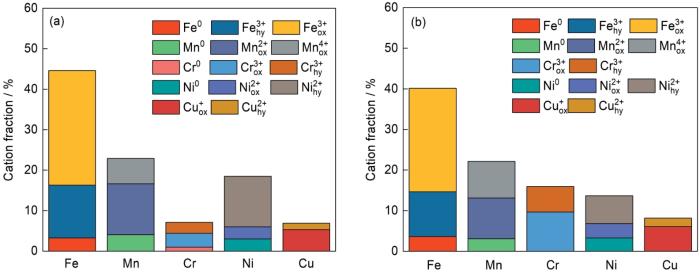

基于XPS检测结果,对钝化膜的成分进行半定量分析,各元素离子比例(Cx )的计算公式[27]:

式中,Ix 为各元素的峰面积;Sx 为原子的灵敏度因子。UT和AT-300各元素离子比例计算结果如图11所示,通过对比看出,AT-300的Ni离子含量少于UT。这是Ni(OH)2在碱性溶液中的溶解度较低,在钝化膜击破过程中少量的Ni2+可能会溶解,大部分Ni2+会在金属表面积聚[28]。AT-300的Cr离子含量高于UT,钝化膜中Cr和Ni都具有保护基体的作用,但Cr相比Ni对基体的保护作用更强。由Ni2O和Ni(OH)组成的钝化膜,其保护性比由Cr2O3和Cr(OH)3构成的保护层低10倍,由Cr2O3组成的层具有较少的缺陷[29]。具有更高Cr离子含量的钝化膜更具有保护性[30]。根据图11离子含量图,计算出UT和AT-300钝化膜中Cr+Ni/Fe+Mn阳离子比值,结果表明AT-300的值高于UT,约为UT的1.2倍,说明AT-300具有优异的耐腐蚀性能。

图11

图11

UT和AT-300在1 mol/L NaOH 溶液中浸泡7 d钝化膜中的阳离子含量

Fig.11

Cation content (atomic fraction) in passive film of UT (a) and AT-300 (b) formed by immersion in 1 mol/L NaOH solution for 7 d

2.5 电极过程

在这项研究中,AT-300具有最佳的耐腐蚀性能,这与富Cu相有密切关系。钝化膜在形成和溶解过程中经历4个阶段:(1)从MEA表面浸出离子到钝化膜;(2)液相传质过程,离子向电极表面附近的液层迁移;(3)电子转移过程,离子在电极和溶液界面上得失电子生成产物;(4)新相生成过程,反应物生成新相,如气体,可溶性产物等。在电极过程,阳极中由金属(M)本身和环境成分(O2, H2O)形成致密的氧化膜[31]:

在

根据Fe-H2O体系的电位-pH图,在腐蚀初期样品表面产生的

其中,

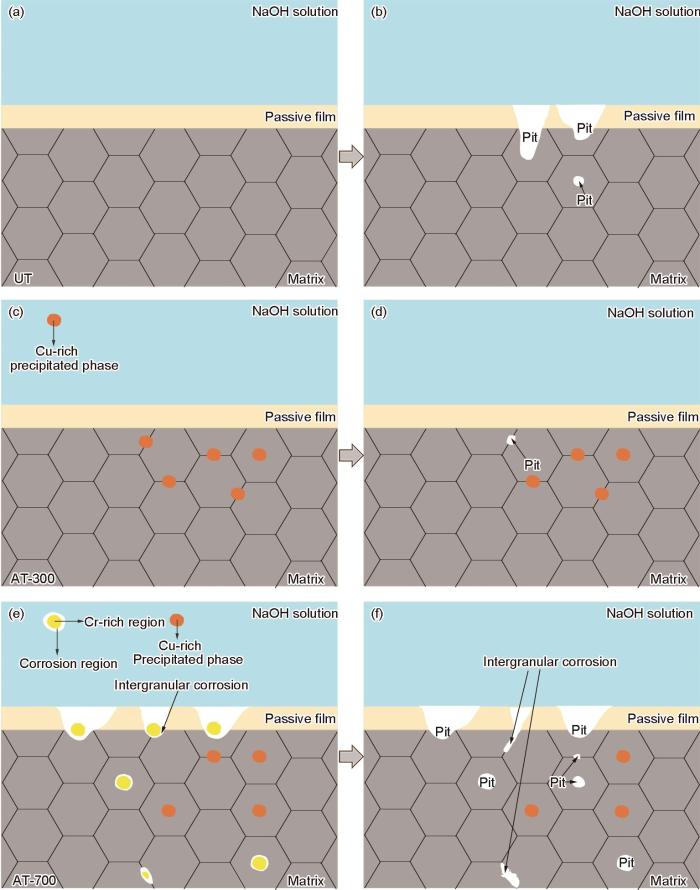

2.6 腐蚀过程

图12

图12

UT,AT-300和AT-700样品在1 mol/L NaOH溶液中的腐蚀行为示意图

Fig.12

Schematic illustration showing the corrosion processes in 1 mol/L NaOH solution: (a, b) UT; (c, d) AT-300, (e, f) AT-700

3 结论

(1) 打印态MEA为典型的胞状亚晶微观组织。经时效处理后,基体组织中出现富Cu析出相和富Cr碳化物。SLM-MEA经300℃时效处理后,富Cu析出相在晶界析出。随着时效温度的升高,富Cu析出相位置由晶界处向胞状亚晶内部转移,富Cr碳化物则发生粗化。

(2) 相比于其它时效态样品,AT-300具有最优异的耐蚀性能。与原始态试样相比,AT-300的腐蚀电流密度下降了37.37%,极化电阻提高了2倍。

(3) AT-300钝化膜中Cr+Ni/Fe+Mn阳离子比值约为UT的1.2倍,较高的Cr + Ni离子含量的AT-300具有更好的耐腐蚀性能。AT-300晶界处的Cu颗粒脱落后蚀坑表面的Fe发生再钝化,使钝性恢复,同时提高了钝化膜中的阳离子比值。

参考文献

A hybrid prediction frame for HEAs based on empirical knowledge and machine learning

[J].

High entropy alloys: A focused review of mechanical properties and deformation mechanisms

[J].The high-entropy alloy (HEA) concept was based on the idea that high mixing entropy can promote formation of stable single-phase microstructures. During the past 15 years, various alloy systems have been explored to identify HEA systems with improved property combinations, leading to an extraordinary growth of this field. In the large pool of alloys with varying characteristics, the first single-phase HEA with good tensile properties, the equiatomic CrMnFeCoNi alloy has become the benchmark material, and it forms the basis of much of our current fundamental understanding of HEA mechanical behavior. As the field is evolving to the more broadly defined complex concentrated alloys (CCAs) and the available data in the literature increase exponentially, a fundamental question remains unchanged: how special are these new materials? In the first part of this review, select mechanical properties of HEAs and CCAs are compared with those of conventional engineering alloys. This task is difficult because of the limited tensile data available for HEAs and CCAs. Additionally, the wider suite of mechanical properties needed to assess structural materials is woefully lacking. Nonetheless, our evaluations have not revealed many HEAs or CCAs with properties far exceeding those of conventional engineering alloys, although specific alloys can show notable enhancements in specific properties. Consequently, it is reasonable to first approach the understanding of HEAs and CCAs through the assessment of how the well-established deformation mechanisms in conventional alloys operate or are modified in the presence of the high local complexity of the HEAs and CCAs. The second part of the paper provides a detailed review of the deformation mechanisms of HEAs with the FCC and BCC structures. For the former, we chose the CrMnFeCoNi (Cantor) alloy because it is the alloy on which the most rigorous and thorough investigations have been performed and, for the latter, we chose the TiZrHfNbTa (Senkov) alloy because this is one of the few refractory HEAs that exhibits any tensile ductility at room temperature. As expected, our review shows that the fundamental deformation mechanisms in these systems, and their dependence on basic physical properties, are broadly similar to those of conventional FCC and BCC metals. The third part of this review examines the theoretical and modeling efforts to date that seek to provide either qualitative or quantitative understanding of the mechanical performance of FCC and BCC HEAs. Since experiments reveal no fundamentally new mechanisms of deformation, this section starts with an overview of modeling perspectives and fundamental considerations. The review then turns to the evolution of modeling and predictions as compared to recent experiments, highlighting both successes and limitations. Finally, in spite of some significant successes, important directions for further theory development are discussed. Overall, while the individual deformation mechanisms or properties of the HEAs and CCAs are not, by and large, "special" relative to conventional alloys, the present HEA rush remains valuable because the compositional freedom that comes from the multi-element space will allow exploration of whether multiple mechanisms can oper ate sequentially or simultaneously, which may yet lead to the creation of new alloys with a spectrum of mechanical properties that are significantly superior to those of current engineering alloys. (C) 2019 Acta Materialia Inc. Published by Elsevier Ltd.

Recent progress in high-entropy alloys

[J].

Effect of micro-alloying with Cr, N and Al on corrosion resistance of high manganese austenitic steel in acidic salt spray environment

[J].

微合金化对高锰奥氏体钢在酸性盐雾环境下的耐蚀性能影响研究

[J].

Additively manufactured high strength and ductility CrCoNi medium entropy alloy with hierarchical microstructure

[J].

Sensitive temperature and reason of rapid fatigue crack propagation in nickel-based superalloy

[J].Superalloys are widely used in aerospace industry owing to the excellent mechanical properties and microstructure stability at high temperatures. However, the recent developments in the aerospace industry have piled higher demands on superalloys, especially for damage tolerance at high temperatures. The fatigue crack growth rate (FCGR) is an important parameter that describes damage tolerance. Although several domestic studies on FCGR in superalloys have been reported, systematic understanding is still lacking and urgently required. Hence, this study investigated the phenomenon of sensitive temperature for rapid fatigue crack propagation in several nickel-based superalloys and reasons for its emergence by adopting a systematic program of experiments and simulations. The fatigue crack propagation behavior of FGH4096, FGH4097, and FGH4098 powder-metallurgy nickel-based superalloys, and GH4720Li and GH4738 wrought nickel-based superalloys were systematically investigated in a wide temperature range of 550-800oC using a fatigue crack propagation test. The fatigue crack propagation paths and crack microstructures after the fatigue crack propagation tests were observed. The results clearly demonstrated that the relationship between fatigue life and temperature is nonlinear. A sensitive temperature for rapid fatigue crack propagation for all investigated nickel-based superalloys was also observed, where the fatigue crack propagation rate markedly increased and fatigue life dramatically shortened. Microstructure evolution and mechanical property degradation at high temperatures were not found to be the major reasons behind the occurrence of sensitive temperature of rapid fatigue crack propagation. However, a comparison of fracture morphologies and fatigue crack propagation paths at different temperatures combined with the analysis of oxidation damage components revealed the high-temperature oxidation damage of grain boundary as the major reason for the occurrence of sensitive temperature. The contributions of fatigue damage and oxidation damage at different temperatures were compared using the classical linear superposition damage component model. The results showed that the contribution of oxidation damage increased markedly with increasing temperature. As a result, the fatigue life decreased dramatically at high temperatures and the fatigue propagation rates increased rapidly. Furthermore, the effect of O on the grain boundary strength in the Ni and NiCr system at different temperatures was investigated by molecular dynamics simulations. The grain boundary separation work decreased with increasing temperature and after which the value decreased dramaticalloy. It was concluded that the accumulation of O on the grain boundary resulted in a decrease in the grain boundary separation work and weakened the grain boundary.

镍基高温合金疲劳裂纹急速扩展敏感温度及成因

[J].

Corrosion behavior in molten salts at 850 ℃ and its effect on mechanical properties of Hastelloy X alloy fabricated by additive manufacturing

[J].

增材制造Hastelloy X合金在850℃混合硫酸盐中热腐蚀行为及其对力学性能的影响

[J].

Probing deformation mechanisms of a FeCoCrNi high-entropy alloy at 293 and 77 K using in situ neutron diffraction

[J].

Selective laser melting additive manufacturing of TiC/AlSi10Mg bulk-form nanocomposites with tailored microstructures and properties

[J].

Effect of heat treatments on corrosion behavior of 3Cr low carbon steel

[J].

两种热处理工艺对3Cr钢腐蚀行为影响及机理研究

[J].采用电化学测试、扫描Kelvin探针 (SKP)、原子力显微镜 (AFM) 和浸泡实验等手段研究了两种热处理条件下含3%Cr (质量分数) 的低碳钢在含Cl<sup>-</sup>环境中的腐蚀行为与机理,利用微区电化学等手段建立了显微组织与耐蚀性的相关性。结果表明:含3%Cr钢退火后得到单一铁素体组织,正火后得到铁素体+贝氏体组织。两种组织的差异是造成初期腐蚀形貌差异的根本原因,正火组织由于不同相间的电偶效应导致其耐蚀性较退火组织差。

Annealing effect on the phase stability and mechanical properties of (FeNiCrMn)(100- x) Cox high entropy alloys

[J].

Effect of subcritical-temperature heat treatment on corrosion of SLM SS316L with different process parameters

[J].

Effects of heat treatment on microstructure, mechanical and corrosion properties of 15-5 PH stainless steel parts built by selective laser melting process

[J].With recent advancements in additive manufacturing, Selective Laser Melting (SLM) is emerging as an unconventional manufacturing process of exceptional flexibility capable to fabricating any complex part without requiring expensive fixtures, tooling, mold or any other additional auxiliary with a very short lead time from design conceptualization to fabrication. Very few reports are available on the effect of heat treatment on mechanical and corrosion properties of SLM 15-5 Precipitation Hardening (PH) stainless steel. Herein, microstructural evolution and its correlation with various mechanical and corrosion properties of heat treated SLM 15-5 PH stainless steel are investigated to widen the application of SLM parts for industrial usages. Results show, standard aging condition (H900) increases yield strength, hardness and corrosion resistance through the formation of fine spherical epsilon-Cu-rich precipitates (similar to 15 nm), but makes the specimens brittle resulting in an increase in wear rate and a decrease in impact energy. Combined effects of coarsening of elliptical epsilon-Cu-rich precipitates and increase in reverted austenite phase in overaging (H1150) make the specimen ductile having relatively low yield strength, hardness, wear rate but high impact energy. Solution annealing was found to reduce anisotropy in mechanical properties through the homogenization of microstructure. Higher aging temperature and longer soaking time doesn't have significant impact on different mechanical properties but deteriorates the corrosion properties. Solution annealing before aging is recommended for the homogeneity in microstructure. Present findings can be used as a guideline to select proper post heat treatment for SLM 15-5 PH stainless steel to impart application oriented mechanical and corrosion properties.

Effect of copper addition on mechanical properties, corrosion resistance and antibacterial property of 316L stainless steel

[J].

Synergy of Cu and Sb to enhance the resistance of 3%Ni weathering steel to marine atmospheric corrosion

[J].

Effects of alloyed Cr and Cu on the corrosion behavior of low-alloy steel in a simulated groundwater solution

[J].

Effect of post-treatments on the fatigue behaviour of 316L stainless steel manufactured by laser powder bed fusion

[J].

Formation of metastable cellular microstructures in selective laser melted alloys

[J].

Effect of grain ultra-refinement on microstructure, tensile property, and corrosion behavior of low alloy steel

[J].

Effect of plastic deformation processing on corrosion behavior of pure zinc in a leaching solution of soil at Tianjin

[J].

塑性变形加工对纯锌在天津土壤浸出液中腐蚀行为的影响

[J].由热挤压获得了不同变形加工量的工业纯锌棒材,通过电化学测试、浸泡加速腐蚀实验及金相表征研究了变形加工量对纯锌微观组织及腐蚀特性的影响。结果表明:铸造纯锌金相组织较为粗大,粗晶粒内部存在大量细小亚晶粒及铸造孪晶。随塑性变形加工量的增加,纯锌的初级晶粒会显著细化,亚晶粒会融合长大,孪晶显著减少直至消失。在土壤浸出液中纯锌的点蚀电位及钝化区间随变形量的增加而增大,腐蚀电流密度及维钝电流密度则呈减小趋势,塑性变形处理提升了纯锌的钝化膜电阻及腐蚀反应中的电荷转移电阻。纯锌的金相组织均匀性随塑性变形量的增加持续改善,进而显著提升了纯锌在土壤浸出液中的耐蚀能力。

Antibacterial durability and biocompatibility of antibacterial-passivated 316L stainless steel in simulated physiological environment

[J].

Corrosion behavior of CoCrNi medium-entropy alloy compared with 304 stainless steel in H2SO4 and NaOH solutions

[J].

Characterization of passive films on shape memory stainless steels

[J].

Microstructure evolution and corrosion behavior of the novel maraging stainless steel manufactured by selective laser melting

[J].

Corrosion of polypyrrole: kinetics of chemical and electrochemical processes in NaOH solutions

[J].

Influence of carbon on the corrosion behaviour of interstitial equiatomic CoCrFeMnNi high-entropy alloys in a chlorinated concrete solution

[J].

Corrosion resistance enhancement of CoCrFeMnNi high-entropy alloy fabricated by additive manufacturing

[J].

X‐ray photoelectron spectroscopic examinations of electrochemically formed passive layers on Ni‐Cr alloys

[J].

The anodic dissolution and passivation of NiCrFe alloys studied by ESCA

[J].

Comparison of corrosion resistance of CoCrFeMnNi high entropy alloys with pipeline steels in an artificial alkaline soil solution

[J].

CoCrFeMnNi高熵合金和管线钢在碱性土壤环境中的耐蚀性对比研究

[J].采用电化学技术、X射线光电子能谱、原子力显微镜测试和浸泡实验研究了有/无热处理的等原子比CoCrFeMnNi高熵合金和管线钢在碱性土壤模拟溶液中的耐蚀性差异。结果表明:高熵合金呈现出局部腐蚀特征,腐蚀形态为零星分布的针孔状点蚀,而X80和X100管线钢表面发生了全面腐蚀,并有大尺寸腐蚀坑存在。高熵合金热处理后在碱性土壤模拟溶液中形成的钝化膜结构致密稳定,含有较多Cr的氧化物和水以及更少的FeO,有利于其钝化膜的保护性;而管线钢钝化膜薄且含有缺陷,对基体的保护性较差。有/无热处理高熵合金的耐蚀性均优于X80和X100管线钢,且热处理可提升高熵合金的耐蚀性能。

Corrosion behavior of X80 pipeline steel in the presence of Brevibacterium halotolerans in Beijing soil

[J].

Corrosion behavior of Ti3AlC2 in NaOH and H2SO4

[J].

The corrosion behavior of a Ni0.91Cr0.04Cu0.05 anode for the electroreduction of Fe2O3 in molten NaOH

[J].

Corrosion behavior of typical grounding materials in artificial alkaline soil solution

[J].

典型接地材料在碱性土壤模拟液中的腐蚀行为研究

[J].通过电化学阻抗谱和极化曲线电化学测试技术研究了Q235钢、镀锌钢和纯铜在山东典型碱性土壤模拟液中的腐蚀电化学行为,利用金相显微镜和激光共聚焦显微镜 (CLSM) 对其极化后的表面腐蚀形貌进行了分析。结果表明,3种金属材料在该种碱性模拟环境下发生不同程度的腐蚀,其阳极过程都为金属的阳极溶解,而阴极过程为吸氧反应。Q235钢的耐腐蚀性最差,Q235钢和镀锌钢发生全面腐蚀,纯铜表面发生点蚀,3种金属的耐腐蚀程度为:纯铜>镀锌钢>Q235钢。

Copper corrosion inhibition by combined effect of inhibitor and passive film in alkaline solution

[J].

Electrochemical behaviour of passivation film formed on SLM-fabricated Hastelloy X superalloy surface in 10wt% NaNO3 solution

[J].

Mechanical properties and corrosion behavior of selective laser melted 316L stainless steel after different heat treatment processes

[J].Irregular grains, high interfacial stresses and anisotropic properties widely exist in 3D-printed metallic materials, and this paper investigated the effects of heat treatment on the microstructural, mechanical and corrosion properties of 316 L stainless steel fabricated by selective laser melting. Sub-grains and low-angle boundaries exist in the as-received selective laser melted (SLMed) 316 L stainless steel. After heat treatment at 1050 °C, the sub-grains and low-angle boundaries changed slightly, and the stress state and strength decreased to some extent due to the decrease of dislocation density. After heat treatment at 1200 °C, the grains became uniform, and the dislocation cells vanished, which led to a sharp decline in the hardness and strength. However, the ductility was improved after recrystallization heat treatment. The passive film thickness and corrosion potential of the SLMed 316 L stainless steel decreased after heat treatment, and the pitting potential also decreased due to the accelerated transition from metastable to steady-state pitting; this accelerated transition was caused by the presence of weak passive films at the enlarged pores after heat treatment, especially for an adequate solid solution treatment.

Effect of solution concentration on semiconducting properties of passive films formed on austenitic stainless steels

[J].

Correlation between microstructure and intergranular corrosion behavior of low delta-ferrite content AISI 316L aged in the range 550-700oC

[J].

Mechanism of post-heat treatment on intergranular corrosion behavior of SLM-316L stainless steel with different carbon content

[J].

后热处理对不同含碳量SLM-316L不锈钢晶间腐蚀行为的作用机制研究

[J].

Precipitation of M23C6 in austenitic steels Precipitation de carbures M23C6, dans les aciers austenitiquesAusscheidung von M23C6 in austenitischen stählen

[J].

Formation of M23C6-type precipitates and chromium-depleted zones in austenite stainless steel

[J].