一般来说,页岩气水力压裂作业、油气田注水作业及海底管道油气输送过程中均存在不同程度的MIC[3]。MIC通常是指由微生物或其自身分泌的活性代谢物而导致的金属劣化行为[5,6],其已成为诱发油气田井下及地面集输系统设备、管柱和管道腐蚀失效的主要因素之一。造成MIC的细菌主要有SRB、铜绿假单胞杆菌(PAE)、铁氧化细菌(IOB)、产甲烷杆菌(Methanogens)以及腐生菌(TGB)等[7,8],其中SRB引起的细菌腐蚀占50%以上且最为严重。2006年,普拉德霍湾的海底输油管道由于腐蚀失效发生大面积海上溢油事故,不仅遭受严重的经济损失,还对生态环境造成了严重破坏,据调查显示该管线腐蚀与MIC直接相关[9]。

一般来说,油田开采阶段的压裂液及地下深层油藏等均为油气田管道中腐蚀性微生物的来源[10]。腐蚀性微生物易在管道表面定殖形成复杂的微生物群落,进而发展为生物膜。有研究[11]表明,腐蚀性微生物群落的形成加速了成品油管道的内腐蚀,并且形成矿物沉淀的沉积区腐蚀最为严重。因此,对于油气钢管道的MIC来说,生物膜的形成以及矿物(如FeS、FeCl2及FeCO3等)的沉积都是MIC发生所必不可少的过程。SRB等腐蚀性微生物自身代谢过程中会产生粘附性较强的胞外聚合物(EPS)等有机副产物,这些物质附着在油气田管道表面,进而促进金属表面生物膜的形成[12]。另外,SRB代谢可产生具有半导体性质的特征性腐蚀产物FeS,其可以作为SRB从金属中直接获取电子的介体,从而加速金属的腐蚀[13]。吴堂清等[14]指出SRB使X80钢的腐蚀形式由非均匀腐蚀转变为局部腐蚀,金属/细菌间的直接电子转移和SRB腐蚀代谢产物可能是促进局部腐蚀的主要原因。

由MIC造成的管道穿孔失效不可避免[15],但利用科学的腐蚀防护方法比全部更换管线更加经济可行[16]。在控制油气管道MIC方面,添加杀菌剂与缓蚀剂是一种常用且较为有效的方法[17,18]。2,2-二溴-3-次氮基丙酰胺(DBNPA)不仅具有杀菌力强、广谱抗菌、极强的灭藻及除垢等功能,还具有缓蚀能力且易降解的特点,是一种环保型杀菌剂[19]。鼠李糖脂(RL)是一种典型的阴离子型生物表面活性剂,是一类同时具有亲水性和疏水性的两亲性化学物质,能够显著降低油水界面张力[20],另外其具有的典型的生物活性可以激活地层本源微生物,从而起到协同采油的作用[21]。Unsal等[22]研究表明,当在SRB体系中仅加入150 mg/L的DBNPA时,腐蚀速率仅降低38.7%,由此可见单独使用150 mg/L的DBNPA的杀菌能力有限。Li等[16]向SRB体系中加入1000 mg/L RL时,腐蚀速率降低了72.2%,具有较好的腐蚀防护效果。RL具有优良的缓蚀性能且兼备环境友好性的特点,但其产量较低,成本较高,不利于大规模推广使用[23]。

因此,基于DBNPA的抗菌性能以及RL的天然活性剂性能,本研究旨在探究DBNPA与RL的协同作用在减少DBNPA和RL使用量的同时提高MIC抑制效率,为油气管道的绿色科学防腐提供一定的参考。

1 实验方法

1.1 菌株培养

菌株采用从中国南海碳钢锈层中分离出的SRB菌株 Desulfovibrio bizertensis SY-1[24](NCBI:PRJNA790473)。菌株在70 mL改良的PGC培养基[25]中活化,并在体积为100 mL的厌氧瓶中30℃下培养3~5 d。初始pH值利用0.1 mol/L的NaOH溶液或盐酸溶液调节至7.2 ± 0.2。为了保证无氧环境,每个装有改良PGC培养基[26]的厌氧瓶在灭菌前都要向厌氧瓶中通入氮气进行除氧操作,并在高温灭菌锅(LDZX-75L)中高温灭菌(121℃,20 min)。冷却后,过滤(0.22 µm,MF Millipore)添加L-半胱氨酸(5 mL 4%(w/v))溶液以去除厌氧瓶中残留的氧气。另外,DBNPA与RL也通过滤膜(0.22 µm,MF Millipore)过滤添加。

1.2 微生物生理代谢测定

本实验生理代谢因子测定包括pH及溶液吸光度。采用分光光度法(OD)在600 nm处测定吸光度,使用pH计(METTLER TOLEDO S220-B)测定体系pH。

细菌计数分为浮游细菌及固着细菌计数两部分。对于浮游细菌的计数采用光学显微镜(OLYMPUS DP80)和Auvon Helber细菌计数板进行。在进行固着细菌计数时,首先取出试样并用pH为7.4的磷酸盐水溶液(PBS)冲洗以去除表面附着的浮游细菌,用一次性无菌手术刀片刮取试样表面的生物膜,而后将其一并置于5 mL PBS溶液中涡漩1 min,之后在光学显微镜下进行细菌计数[27]。

1.3 电化学测试

电化学测试中使用的金属试样是X80管线钢,尺寸为1.0 cm × 1.0 cm × 0.3 cm,其化学成分[28](质量分数,%)为:C 0.07,Mn 1.82,Ni 0.17,Nb 0.056,N 0.004,Si 0.19,Al 0.028,Cr 0.026,S 0.023,Fe为余量。对钢试样进行打磨(400到2000粒度),在无水乙醇中超声清洗并用高纯氮气干燥。实验前将试片在紫外灯下照射30 min以灭菌。

电化学测试采用三电极体系,工作电极为制备好的X80管线钢,工作面积为1 cm2。饱和甘汞电极和铂片电极(1.0 cm × 1.0 cm)分别为参比电极和对电极,溶液为添加不同浓度DBNPA和RL的PGC培养基。使用CHI 760电化学工作站进行电化学实验的测定,包括开路电位(OCP)和动电位极化曲线的测量。Tafel曲线测量的扫描速率为0.167 mV/s[29],扫描电位范围为-500~ +500 mV vs. OCP。每组实验进行3个平行样品的测量以保证实验数据的准确性。

1.4 腐蚀失重实验

其中vcorr、Δm、

1.5 腐蚀形貌观察和腐蚀产物分析

将腐蚀后的X80试片取出后置于2.5%(v/v)的戊二醛溶液中固定2 h,浸泡结束后用25%、50%、60%、70%、80%、90%和100%浓度的乙醇(v/v)逐级脱水10 min,脱水结束后干燥喷金,以确保样品具有较强的导电性。采用FEI Quanta 250型扫描电子显微镜(SEM)在5~20 V的加速电压下,对试片表面锈层的形貌进行观察。利用3D共聚焦激光扫描显微镜(CLSM,Lext OLS5000)测量X80试片去除腐蚀产物后表面腐蚀坑的深度。

试片腐蚀结束后用高纯氮气吹干。采用X射线衍射仪(XRD,D/max-Ultima IV)研究锈层的晶体结构,从而对腐蚀产物的类型进行表征。采用X射线光电子能谱(XPS, K-Alpha)分析腐蚀后试片表面腐蚀产物元素价态。

2 实验结果

2.1 SRB生理代谢过程

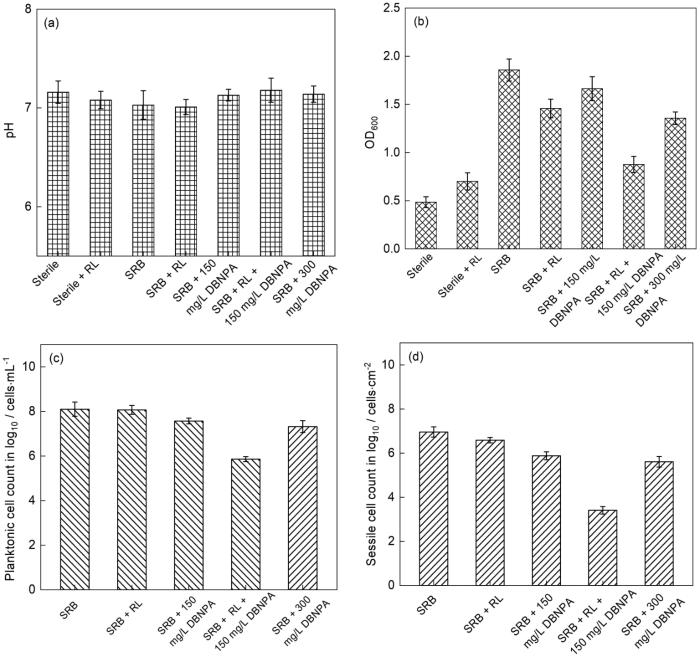

为探究DBNPA及RL对SRB生长和生理代谢的影响,分别测定了溶液中pH、OD600、浮游细菌及固着细菌浓度,结果如图1所示。在各体系中加入RL和DBNPA腐蚀浸泡15 d后的pH如图1a所示,各体系的pH均维持近中性的环境,Dou等[32]也提出SRB的硫酸盐还原过程通常不会引起质子浓度的净变化。图1b是各体系腐蚀浸泡15 d后的OD600值,其间接反映浮游SRB细胞浓度[26],同时其变化也受SRB代谢产生的FeS量的影响。当体系中仅含有SRB时,OD600值最高,可能是由于SRB的生长及代谢产生大量的FeS。随着DBNPA浓度的提高,OD600值降低,推测可能是由于DBNPA抑制了SRB的生长代谢所致。当体系中含有150 mg/L DBNPA和 500 mg/L RL复配时,其OD600值均低于仅含DBNPA的体系,说明复配体系极大地抑制了SRB的生长及生理代谢过程。

图1

图1

X80试片在不同溶液体系中浸泡15 d后的pH、OD600、浮游细菌及固着细菌计数

Fig.1

pH (a), OD600 (b), planktonic bacteria (c) and sessile bacteria (d) counts of X80 coupons after immersion in different media for 15 d

如图1c所示,当体系中含有150 mg/L DBNPA和500 mg/L RL时,与SRB体系相比,浮游细菌的数量减少了2个对数,为7.2 × 105 cells/mL。如图1d所示,腐蚀浸泡15 d后,SRB体系固着细菌的数量为9.2 × 106 cells/cm2,含有150和300 mg/L DBNPA的体系固着细菌数量分别为7.3 × 105和4.1 × 105 cells/cm2;含有150 mg/L DBNPA和500 mg/L RL复配的体系固着细菌的数量为2.6 × 103 cells/cm2,与SRB体系相比减少了3个对数,与仅含DBNPA体系相比减少了2个对数,说明150 mg/L DBNPA与500 mg/L RL的复配可有效抑制SRB的生长,能够减少DBNPA用量且提高杀菌效率。

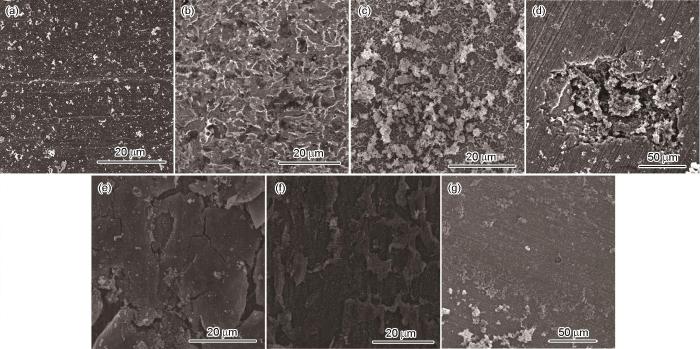

2.2 腐蚀形貌

图2为X80试片在不同体系中腐蚀浸泡15 d后的腐蚀形貌。在无菌培养基中,试片表面的腐蚀产物量较少,没有形成明显的腐蚀坑及腐蚀裂纹,推测可能是金属表面吸附了培养基中的大分子有机物等形成了产物层,在一定程度上阻碍了溶液中的腐蚀性离子向金属表面的扩散[33],从而抑制了X80管线钢的腐蚀;当在无菌体系中添加RL后,钢片表面呈现纹状腐蚀形貌。如图2c所示,在含SRB的体系中,试片表面附着有大量的细菌,腐蚀产物较为疏松并在试片表面大量积累[22]。如图2d所示,当体系中仅含有500 mg/L RL时,X80试片表面出现了直径较大的腐蚀坑。如图2g所示,当150 mg/L DBNPA与500 mg/L RL复配时,试片表面的细菌和腐蚀产物数量均减少,没有明显的塌陷式腐蚀坑。

图2

图2

X80试片在不同溶液体系中浸泡15 d后的腐蚀形貌

Fig.2

Corrosion morphologies of X80 coupons after immersion in sterile (a), sterile + 500 mg/L RL (b), SRB (c), SRB + 500 mg/L RL (d), SRB + 150 mg/L DBNPA (e), SRB + 300 mg/L DBNPA (f), SRB + 150 mg/L DBNPA + 500 mg/L RL (g) media for 15 d

2.3 腐蚀速率与腐蚀坑

图3为X80试片在不同体系中浸泡15 d后的腐蚀速率。X80试片在SRB体系中浸泡15 d后的腐蚀速率为22.63 ± 2.70 μm/a。当向体系中加入150 mg/L DBNPA时,腐蚀速率与SRB体系相比降低了20.2%,为18.05 ± 0.96 μm/a。当体系中含有300 mg/L DBNPA时,腐蚀速率为16.74 ± 0.39 μm/a,与SRB体系相比降低了26%。将150 mg/L DBNPA和500 mg/L RL进行复配时,腐蚀速率为5.02 ± 0.78 μm/a,与SRB体系相比降低了77.8%,显著抑制了X80试片的腐蚀(p = 0.009)。然而,当SRB体系中含有500 mg/L RL时,腐蚀速率也相对较低,推测可能是由于RL在X80试片表面形成了一层保护层[16],但由图2可知,此时易形成面积较大的塌陷式腐蚀坑,腐蚀防护效果仍然欠佳。因此,150 mg/L DBNPA与500 mg/L RL进行复配时,可显著降低X80管线钢的腐蚀速率。

图3

图3

X80试片在不同溶液体系中浸泡15 d的腐蚀速率

Fig.3

Corrosion rates of X80 coupons during immersion in different media for 15 d

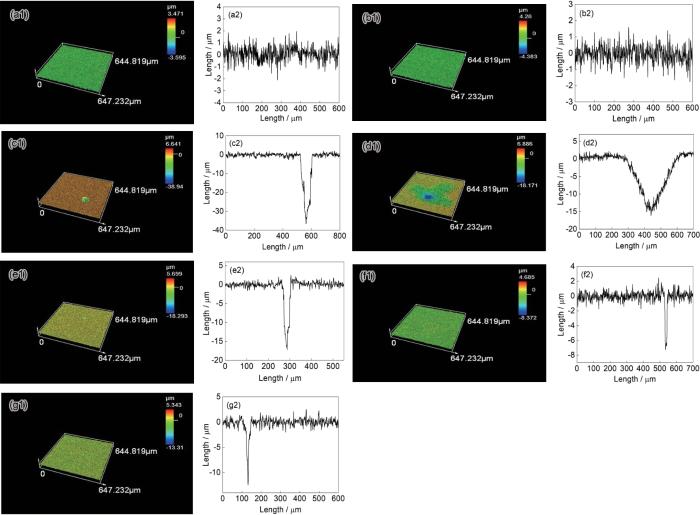

图4为X80试片在不同体系中浸泡15 d后的最大腐蚀坑深度。由图4可知,当体系中仅含SRB时,最大腐蚀坑深度可达38.94 μm,平均腐蚀坑深度为37.31 ± 2.17 μm。随着DBNPA浓度的增加,腐蚀坑深度减小。当SRB体系中含有500 mg/L RL时,最大腐蚀坑深度减小,但是腐蚀坑直径明显增大,与图2d中出现直径较大的腐蚀坑一致。将150 mg/L DBNPA和500 mg/L RL进行复配时,最大腐蚀坑深度为8.372 μm,平均腐蚀坑深度为7.73 ± 0.50 μm,X80试片表面没有出现大的腐蚀坑,这与图2g一致。因此,150 mg/L DBNPA与500 mg/L RL的复配使得试片的腐蚀坑深度明显减小,显著抑制了由SRB引起的点蚀。

图4

图4

X80试片在不同溶液体系中浸泡15 d后的最大腐蚀坑深度

Fig.4

Maximum depths of corrosion pits of X80 coupons immersed in different media for 15 d: (a1, a2) sterile, (b1, b2) sterile + 500 mg/L RL, (c1, c2) SRB + 500 mg/L RL, (d1, d2) SRB + 500 mg/L RL, (e1, e2) SRB + 150 mg/L DBNPA, (f1, f2) SRB + 150 mg/L DBNPA + 500 mg/L RL, (g1, g2) SRB + 300 mg/L RL

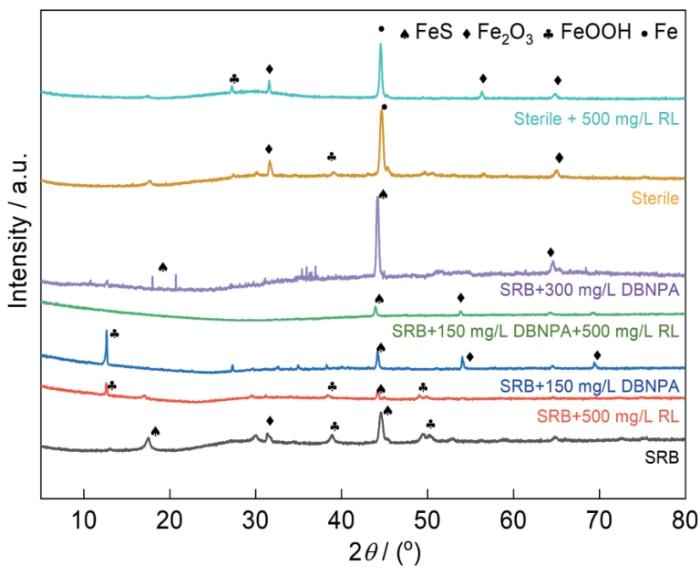

2.4 腐蚀产物组成

图5

图5

X80试片在不同溶液体系中浸泡15 d后表面XRD图谱

Fig.5

XRD patterns of X80 coupons after 15 d immersion in different media

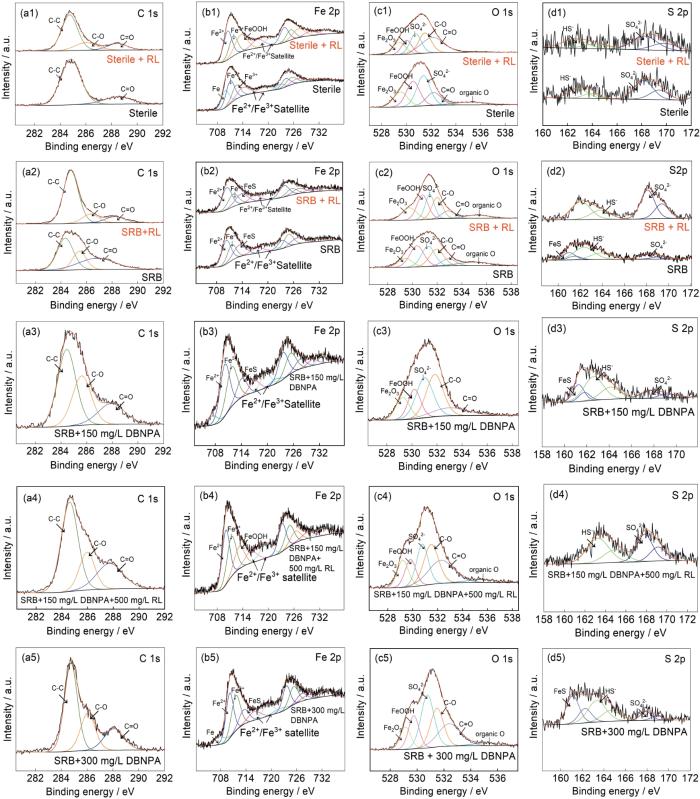

利用XPS方法对腐蚀产物的元素价态进行分析如图6所示,对C 1s、O 1s、Fe 2p和S 2p光谱的拟合参数以及腐蚀产物组成的相对质量占比进行了分析,如表1所示。无菌培养基中X80试片表面检测出腐蚀产物主要由Fe和O组成,这可能是由于试片表面吸附了培养基中的大分子有机物形成了产物层,从而抑制了金属的进一步腐蚀,这与SEM的分析相符合。如表1所示,含SRB的体系中试片表面的有机C含量更高,这可能是由于SRB在生长代谢过程中产生大量的胞外聚合物。在SRB体系中,S 2p在162.34和168.04 eV附近分别为HS-和SO

图6

图6

X80试片在不同溶液体系中浸泡15 d后腐蚀产物的XPS图谱

Fig.6

XPS fine peaks of C 1s (a), Fe 2p (b), O 1s (c), and S 2p (d) of corrosion products formed on X80 coupons after immersion in different media for 15 d

表1 依据XPS拟合得到的浸泡后X80试片表面腐蚀产物各元素含量 (atomic fraction / %)

Table 1

| Conditions | C 1s | Fe 2p | O 1s | N 1s | S 2p |

|---|---|---|---|---|---|

| Sterile | 42.78 | 8.40 | 46.24 | 1.36 | 1.22 |

| Sterile + 500 mg/L RL | 37.82 | 13.12 | 46.62 | 1.39 | 1.05 |

| SRB | 54.32 | 3.94 | 34.18 | 5.69 | 1.87 |

| SRB + 500 mg/L RL | 54.08 | 3.60 | 34.93 | 3.86 | 3.53 |

| SRB +150 mg/L DBNPA | 54.29 | 5.33 | 32.86 | 6.77 | 2.75 |

| SRB + 150 mg/L DBNPA+500 mg/L RL | 52.38 | 6.44 | 32.35 | 6.13 | 2.71 |

| SRB + 300 mg/L DBNPA | 46.86 | 7.17 | 36.47 | 6.85 | 2.64 |

2.5 电化学测定

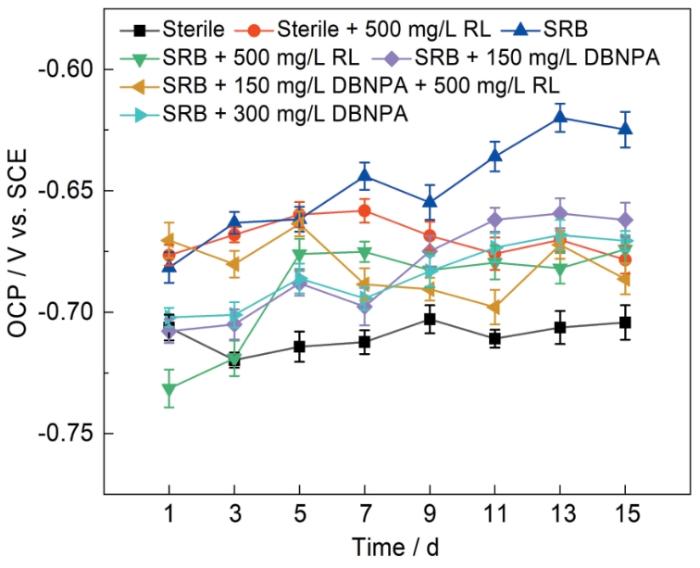

图7显示了X80试片在各体系中浸泡15 d后开路电位的变化情况。如图7所示,X80试片在无菌体系中的OCP值变化不大,基本维持在-0.72 V vs. SCE左右。与无菌体系相比,当体系中存在SRB时,X80试片的OCP值正移,这可能是由于有机物的附着及生物膜的形成所致[25]。当在SRB体系中加入150 mg/L DBNPA或者500 mg/L RL时,DBNPA抑制了体系中SRB的生长,X80管线钢的OCP值均负于仅含SRB体系。X80试片在含有150 mg/L DBNPA和500 mg/L RL的SRB体系中腐蚀浸泡15 d后,其OCP值与只含DBNPA的体系相比发生负移,推测此时可能抑制了试片表面SRB生物膜的形成和发展。

图7

图7

X80试片在不同溶液体系中浸泡15 d后的开路电位

Fig.7

Open circuit potentials of X80 coupons after 15 d immersion in various media

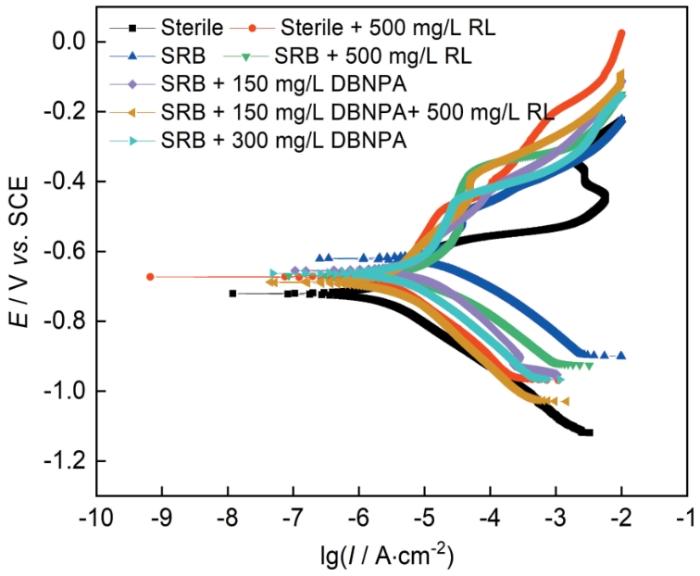

图8为X80管线钢在不同的溶液环境中浸泡15 d后动电位极化曲线图。SRB体系的X80管线钢的Ecorr比无菌体系更正,当在SRB体系中加入150 mg/L DBNPA和500 mg/L RL后,体系的Ecorr与SRB相比发生负移。表2为动电位极化曲线的拟合参数。与无菌体系相比,SRB体系中X80管线钢的βc减小,βa增大,Icorr为17.6µA/cm2,远大于无菌体系(2.1 µA/cm2),说明SRB的存在加速了X80试片的腐蚀。当SRB体系加入150和300 mg/L DBNPA浓度时,Icorr腐蚀电流密度分别降低为6.8和6.3 µA/cm2,说明DBNPA可抑制SRB对试片的腐蚀。将150 mg/L DBNPA和500 mg/L RL复配时,腐蚀电流密度为2.7µA/cm2,与SRB体系相比降低了84.7%,因而二者的复配显著抑制了SRB的腐蚀,这与腐蚀失重的分析结果一致。

图8

图8

X80试片在各种溶液体系中浸泡15 d后的动电位极化曲线

Fig.8

Potentiodynamic polarization curves of X80 coupons after 15 d immersion in various media

表2 X80试片在不同溶液体系中的动电位极化曲线的拟合参数

Table 2

| Parameter | Ecorr / mV vs. SCE | Icorr / µA·cm-2 | βa / mV·dec-1 | βc / mV·dec-1 |

|---|---|---|---|---|

| Sterile | -721 | 2.1 | 158.3 | -126.2 |

| Sterile + 500 mg/L RL | -673 | 3.3 | 277.3 | -135.5 |

| SRB | -621 | 17.6 | 350.6 | -105.7 |

| SRB + 500 mg/L RL | -669 | 8.9 | 208.4 | -108.7 |

| SRB + 150 mg/L DBNPA | -655 | 6.8 | 190.0 | -146.6 |

| SRB + 150 mg/L DBNPA + 500 mg/L RL | -688 | 2.7 | 194.4 | -148.6 |

| SRB + 300 mg/L DBNPA | -663 | 6.3 | 311.4 | -131.4 |

3 讨论

当体系中仅存在SRB时,X80试片浸泡15 d的腐蚀速率为22.63 ± 2.70 µm/a,与无菌体系(4.08 ± 0.53 µm/a)相比极大地加速了X80管线钢的腐蚀(p = 0.007)。当向SRB体系中加入DBNPA时,DBNPA的加入抑制了SRB的生长代谢,腐蚀速率有所降低。向SRB体系中加入500 mg/L RL时,腐蚀速率为5.85 ± 0.45 µm/a,与SRB体系相比降低了74.1%,但由SEM图像及点蚀坑的测量可知,在含有RL的SRB菌液中浸泡的试片表面出现了直径较大的腐蚀坑,腐蚀防护效果欠佳。当将150 mg/L DBNPA与500 mg/L RL复配时,腐蚀速率与SRB体系相比降低了77.8% (p = 0.009),与添加500 mg/L RL的体系相比,没有出现凹陷式的深坑,腐蚀坑直径较小且较浅。同时,将150 mg/L DBNPA与500 mg/L RL复配时,体系腐蚀电流密度为2.7µA/cm2,与无菌体系中的腐蚀电流密度(2.1µA/cm2)相差不大,这说明二者的复配对抑制SRB的腐蚀极为有效[22]。

本实验对腐蚀速率测定发现,仅含有500 mg/L RL的体系中金属的腐蚀速率较低,但对表面腐蚀坑深测量发现,此时金属表面出现了直径较大的凹陷式深坑。对原因进行探究分析,推测可能是由于RL在金属表面形成的保护膜[16]抑制了SRB的附着,但随着浸泡时间的延长,大量SRB在溶液中增殖。然而,溶液中碳源等营养物质有限,大量增殖的SRB处于相对寡营养的环境体系,SRB为获取电子而彼此相连[37]以对覆盖RL保护膜的金属进行攻击,大量SRB的“合作”式攻击提高了电子获取效率,促进了X80试片表面的局部腐蚀,从而在试片表面形成了直径较大的凹陷式深坑。因此,体系中仅含有500 mg/L RL无法有效抑制SRB的生长,其在金属表面形成的保护膜虽然可以起到一定程度保护的作用,但难以阻止SRB为获取钢样中电子而进行的“组团”式攻击,以致在X80管线钢表面出现塌陷式深坑,促进了钢样的局部腐蚀,从而使得仅含有500 mg/L RL时腐蚀防护效果欠佳。

Unsal等[22]研究表明,DBNPA能够抑制SRB的生长代谢,从而抑制SRB的MIC。Wang等[19]证实DBNPA有效地抑制了金属表面腐蚀性微生物的附着,从而抑制油气行业设备管道中发生的MIC。刘宏芳等[38]从电化学角度分析发现,DBNPA通过改变阴极反应过程,阻碍了腐蚀性微生物和腐蚀产物在电极表面的吸附,抑制了碳钢的MIC。Ana等[39]也提出,DBNPA是一种中等亲电试剂,不会与细胞膜发生相互作用,但会干扰影响细胞代谢的关键成分,从而对其起到抑制作用。因此,在本实验中,DBNPA在杀菌混合物中的作用机理可能为阻碍SRB在X80试片表面的附着,抑制细菌的代谢,从而减缓金属材料发生MIC。

综上所述,DBNPA可以通过干扰影响SRB代谢的成分,从而有效抑制SRB的增殖,减缓金属MIC的腐蚀速率,抑制了金属表面的局部腐蚀;而RL能够在金属表面形成保护膜,阻碍微生物在金属表面的附着,抑制腐蚀性微生物生物膜的形成。本研究通过实验证明,150 mg/L DBNPA和500 mg/L RL杀菌混合物的防腐蚀性能均优于仅含DBNPA或RL的体系,DBNPA可以起到抑制SRB增殖的作用,RL可在金属表面形成阻隔膜,二者的协同作用可有效抑制X80试片的MIC。因而具有优良杀菌性能的DBNPA和环境友好的生物表面活性剂RL之间的协同作用可以有效实现金属材料腐蚀防护的目的。

4 结论

本文对150 mg/L DBNPA和500 mg/L RL的杀菌混合物抑制SRB的MIC机制进行了研究,结果表明,SRB的存在极大地加速了X80管线钢的腐蚀。在SRB体系中添加150 mg/L DBNPA与500 mg/L RL时,腐蚀速率降低了77.8%,X80管线钢表面固着细菌数量减少了3个数量级,点蚀坑深度明显降低,腐蚀电流密度降低了84.7%。因此,150 mg/L DBNPA与500 mg/L RL进行复配时,显著抑制了X80管线钢的MIC,杀菌性能优于仅含DBNPA或RL的体系,在减少DBNPA使用量的基础上,RL的复配使得DBNPA杀菌效率显著提高,这可为实际工况下杀菌剂的选择与使用提供一定的参考。

参考文献

Management and control of microbiologically influenced corrosion (MIC) in the oil and gas industry—Overview and a North Sea case study

[J].Microbiologically influenced corrosion (MIC) is the terminology applied where the actions of microorganisms influence the corrosion process. In literature, terms such as microbial corrosion, biocorrosion, microbially influenced/induced corrosion, and biodegradation are often applied. MIC research in the oil and gas industry has seen a revolution over the past decade, with the introduction of molecular microbiological methods: (MMM) as well as new industry standards and procedures of sampling biofilm and corrosion products from the process system. This review aims to capture the most important trends the oil and gas industry has seen regarding MIC research over the past decade. The paper starts out with an overview of where in the process stream MIC occurs - from the oil reservoir to the consumer. Both biotic and abiotic corrosion mechanisms are explained in the context of managing MIC using a structured corrosion management (CM) approach. The corrosion management approach employs the elements of a management system to ensure that essential corrosion control activities are carried out in an effective, sustainable, well-planned and properly executed manner. The 3-phase corrosion management approach covering of both biotic and abiotic internal corrosion mechanisms consists of 1) corrosion assessment, 2) corrosion mitigation and 3) corrosion monitoring. Each of the three phases are described in detail with links to recent field cases, methods, industry standards and sampling protocols. In order to manage the corrosion threat, operators commonly use models to support decision making. The models use qualitative, semi-quantitative or quantitative measures to help assess the rate of degradation caused by MIC. The paper reviews four existing models for MIC Threat Assessment and describe a new model that links the threat of MIC in the oil processing system located on an offshore platform with a Risk Based Inspection (RBI) approach. A recent field case highlights and explains the conflicting historic results obtained through serial dilution of culture media using the most probable number (MPN) method as compared to data obtained from corrosion monitoring and the quantitative polymerase chain reaction (qPCR) method. Results from qPCR application in the field case have changed the way MIC is monitored on the oil production facility in the North Sea. A number of high quality resources have been published as technical conference papers, books, educational videos and peer-reviewed scientific papers, and thus we end the review with an updated list of state-of-the-art resources for anyone desiring to become more familiar with the topic of MIC in the upstream oil and gas sector.Copyright © 2017 Elsevier B.V. All rights reserved.

Microbiologically assisted stress corrosion cracking in the presence of nitrate reducing bacteria

[J].

Gathering pipeline corrosion of oil and gas field and its anti-corrosion technologies

[J].

油气田地面管道内腐蚀现状及防腐技术研究进展

[J].

Internal corrosion risk and solution of offshore oilfield pipeline

[J].

海洋石油海底管道面临的内腐蚀风险及对策

[J].

Corrosion of antibacterial Cu-bearing 316L stainless steels in the presence of sulfate reducing bacteria

[J].

Effects of biogenic H2S on the microbiologically influenced corrosion of C1018 carbon steel by sulfate reducing Desulfovibrio vulgaris biofilm

[J].

Electrochemical behaviour of stainless steels in media containing iron-oxidizing bacteria (IOB) by corrosion process modeling

[J].

The corrosion of two aluminium sacrificial anode alloys in SRB-containing sea mud

[J].

Corrosion at Prudhoe Bay - A lesson on the line

[J].

Present situation and development trend of inhibiting microbial corrosion in oil field

[J].

抑制油田微生物腐蚀的现状与发展趋势

[J].

Investigating the effects of environment, corrosion degree, and distribution of corrosive microbial communities on service-life of refined oil pipelines

[J].

Progress on the corrosion mechanism of sulfate-reducing bacteria in marine environment on metal materials

[J].

海洋环境硫酸盐还原菌对金属材料腐蚀机理的研究进展

[J].硫酸盐还原菌 (SRB) 是一类广泛存在于自然环境中可以利用硫酸盐类物质作为呼吸代谢电子受体的厌氧类微生物,是造成金属腐蚀破坏和设备故障的主要原因之一,已经成为一个重要的研究课题。由于微生物活动的复杂性,生物膜内SRB与金属表面的相互作用缺乏深入的研究,其诱导腐蚀机理和腐蚀过程尚不清楚,难以进行有效的腐蚀预测。基于此,本文从SRB生物膜的呼吸代谢角度介绍了其诱导金属腐蚀的研究进展。介绍了SRB的生态特征和厌氧呼吸过程,重点综述了SRB腐蚀机理,包括阴极去极化、代谢产物腐蚀、浓差电池作用和胞外电子传递等理论,最后简要介绍了微生物腐蚀 (MIC) 研究的方法与技术手段。

Marine sulfate-reducing bacteria cause serious corrosion of iron under electroconductive biogenic mineral crust

[J].Iron (Fe(0) ) corrosion in anoxic environments (e.g. inside pipelines), a process entailing considerable economic costs, is largely influenced by microorganisms, in particular sulfate-reducing bacteria (SRB). The process is characterized by formation of black crusts and metal pitting. The mechanism is usually explained by the corrosiveness of formed H(2) S, and scavenge of 'cathodic' H(2) from chemical reaction of Fe(0) with H(2) O. Here we studied peculiar marine SRB that grew lithotrophically with metallic iron as the only electron donor. They degraded up to 72% of iron coupons (10 mm × 10 mm × 1 mm) within five months, which is a technologically highly relevant corrosion rate (0.7 mm Fe(0) year(-1) ), while conventional H(2) -scavenging control strains were not corrosive. The black, hard mineral crust (FeS, FeCO(3), Mg/CaCO(3) ) deposited on the corroding metal exhibited electrical conductivity (50 S m(-1) ). This was sufficient to explain the corrosion rate by electron flow from the metal (4Fe(0) → 4Fe(2+) + 8e(-) ) through semiconductive sulfides to the crust-colonizing cells reducing sulfate (8e(-) + SO(4) (2-) + 9H(+) → HS(-) + 4H(2) O). Hence, anaerobic microbial iron corrosion obviously bypasses H(2) rather than depends on it. SRB with such corrosive potential were revealed at naturally high numbers at a coastal marine sediment site. Iron coupons buried there were corroded and covered by the characteristic mineral crust. It is speculated that anaerobic biocorrosion is due to the promiscuous use of an ecophysiologically relevant catabolic trait for uptake of external electrons from abiotic or biotic sources in sediments.© 2012 Society for Applied Microbiology and Blackwell Publishing Ltd.

Microbiologically induced corrosion of X80 pipeline steel in an acid soil solution: (Ⅱ) corrosion morphology and corrosion product analysis

[J].

酸性土壤浸出液中X80钢微生物腐蚀研究: (Ⅱ)腐蚀形貌和产物分析

[J].利用X射线光电子能谱分析 (XPS) 和扫描电子显微镜 (SEM) 研究了X80管线钢在一种酸性土壤浸出液中硫酸盐还原菌 (SRB) 腐蚀的产物成分和形貌。结果表明,SRB没有改变样品表面腐蚀产物膜的结构,但其生理过程促进了S从氧化态向还原态的转变,并促进了S在腐蚀产物中的沉积;同时代谢产物磷化物也沉积在腐蚀产物中,改变了腐蚀产物的成分。SRB提高了管线钢局部腐蚀的敏感性,使得腐蚀形式从非均匀腐蚀向局部腐蚀转变。SRB代谢产物和细菌/金属间的直接电子转移可能是促进局部腐蚀萌生的主要原因。

Status and trend of microbiologically influenced corrosion and control technologies of pipelines in oil and gas field exploitation

[J].

油气田开采中管道微生物腐蚀防护技术研究现状与趋势

[J].

Rhamnolipid as an eco-friendly corrosion inhibitor for microbiologically influenced corrosion

[J].

A critical assessment of the efficacy of biocides used during the hydraulic fracturing process in shale natural gas wells

[J].

Control of microbial sulfide production with biocides and nitrate in oil reservoir simulating bioreactors

[J].Oil reservoir souring by the microbial reduction of sulfate to sulfide is unwanted, because it enhances corrosion of metal infrastructure used for oil production and processing. Reservoir souring can be prevented or remediated by the injection of nitrate or biocides, although injection of biocides into reservoirs is not commonly done. Whether combined application of these agents may give synergistic reservoir souring control is unknown. In order to address this we have used up flow sand packed bioreactors injected with 2 mM sulfate and volatile fatty acids (VFA, 3 mM each of acetate, propionate and butyrate) at a flow rate of 3 or 6 pore volumes (PV) per day. Pulsed injection of the biocides glutaraldehyde (Glut), benzalkonium chloride (BAG) and cocodiamine was used to control souring. Souring control was determined as the recovery time (RI) needed to re-establish an aqueous sulfide concentration of 0.8-1 mM (of the 1.7-2 mM before the pulse). Pulses were either for a long time (120 h) at low concentration (long-low) or for a short time (1 h) at high concentration (short high) The short high strategy gave better souring control with Glut, whereas the long-low strategy was better with cocodiamine. Continuous injection of 2 mM nitrate alone was not effective, because 3 mM VFA can fully reduce both 2 mM nitrate to nitrite and N-2 and, subsequently, 2 mM sulfate to sulfide. No synergy was observed for short high pulsed biocides and continuously injected nitrate. However, use of continuous nitrate and long-low pulsed biocide gave synergistic souring control with BAG and Glut, as indicated by increased RTs in the presence, as compared to the absence of nitrate. Increased production of nitrite, which increases the effectiveness of souring control by biocides, is the most likely cause for this synergy.

Mitigating microbiologically influenced corrosion of an oilfield biofilm consortium on carbon steel in enriched hydrotest fluid using 2,2-dibromo-3-nitrilopropionamide (DBNPA) enhanced by a 14-mer peptide

[J].In the oil and gas industry, microbiologically influenced corrosion (MIC) is a major threat to hydrotest, a procedure which is required to certify whether a pipeline can be commissioned. Seawater is frequently used as a hydrotest fluid. In this biofilm prevention lab study, an oilfield biofilm consortium was grown in an enriched artificial seawater anaerobically at 37 °C for 60 days. The combination of 100 ppm (w/w) 2,2-dibromo-3-nitrilopropionamide (DBNPA) + 100 nM (180 ppb) Peptide A (a biofilm dispersal agent) led to extra SRB (sulfate reducing bacteria), APB (acid producing bacteria) and GHB (general heterotrophic bacteria) sessile cell count reductions of 0.9-log, 0.8-log and 0.6-log, respectively, compared with the outcome obtained by using 100 ppm DBNPA only. The Peptide A enhancement also led to extra reductions of 44 % in weight loss, 43 % in maximum pit depth, and 54 % in corrosion current density.

Rhamnolipid surfactants: An update on the general aspects of these remarkable biomolecules

[J].

Advances in optimization strategies for microbial high production of rhamnolipids

[J].

微生物合成鼠李糖脂的高产优化策略研究进展

[J].

D-Tyrosine enhancement of microbiocide mitigation of carbon steel corrosion by a sulfate reducing bacterium biofilm

[J].

Research progress in biosynthesis of Rhamnolipid biosurfactant

[J].

微生物合成鼠李糖脂生物表面活性剂的研究进展

[J].

Steel rust layers immersed in the South China Sea with a highly corrosive Desulfovibrio strain

[J].

Accelerated anaerobic corrosion of electroactive sulfate-reducing bacteria by electrochemical impedance spectroscopy and chronoamperometry

[J].

Interaction between sulfate-reducing bacteria and aluminum alloys—Corrosion mechanisms of 5052 and Al-Zn-In-Cd aluminum alloys

[J].Microbiologically influenced corrosion caused by sulfate-reducing bacteria (SRB) poses a serious threat to marine engineering facilities. This study focused on the interaction between the corrosion behavior of two aluminum alloys and SRB metabolic activity. SRB growth curve and sulfate variation with and with aluminum were performed to find the effect of two aluminum alloys on SRB metabolic activity. Corrosion of 5052 aluminum alloy and Al-Zn-In-Cd aluminum alloy with and without SRB were performed. The results showed that both the presence of 5052 and Al-Zn-In-Cd aluminum alloy promoted SRB metabolic activity, with the Al-Zn-In-Cd aluminum alloy having a smaller promotion effect compared with 5052 aluminum alloy. The electrochemical results suggested that the corrosion of the Al-Zn-In-Cd aluminum alloy was accelerated substantially by SRB. Moreover, SRB led to the transformation of Al-Zn-In-Cd aluminum alloy corrosion product from Al(OH)3 to Al2S3 and NaAlO2.

Effects of ferrous ion concentration on microbiologically influenced corrosion of carbon steel by sulfate reducing bacterium Desulfovibrio vulgaris

[J].Ferrous ion (Fe2+) in a sulfate reducing bacteria (SRB) culture medium is known to enhance microbiologically influenced corrosion (MIC) of carbon steel, but the underlining mechanism is controversial. This work showed that it was due to better sessile cell growth that was likely attributed to Fe2+ detoxification of H2S. Two hundred ppm (w/w) initial Fe2+ in the ATCC 1249 medium achieved a 4.7 times higher Desulfovibrio vulgaris sessile cell count and 5.0 times higher C1018 carbon steel weight loss, compared to 20 ppm. Linear polarization resistance, electrochemical impedance spectroscopy and potentiodynamic polarization measurements corroborated weight loss and pitting data trends.

Effect of sulfate-reducing bacteria from salt scale of water flooding pipeline on corrosion behavior of X80 steel

[J].

Two metabolic stages of SRB strain Desulfovibrio bizertensis affecting corrosion mechanism of carbon steel Q235

[J].

Corrosion inhibition and anti-bacterial efficacy of benzalkonium chloride in artificial CO2-saturated oilfield produced water

[J].

Biocorrosion caused by microbial biofilms is ubiquitous around us

[J].Biocorrosion first surfaced in the scientific literature when Richard H. Gaines associated corrosion with bacterial activities in 1910. It is also known as microbiologically influenced corrosion (MIC). In general, it covers two scenarios. One is that microbes cause corrosion directly, which usually means microbes secrete corrosive metabolites or microbes harvest electrons from a metal for respiration to produce energy. In the second scenario, microbes are behind the initiation or acceleration of corrosion caused by a pre-existing corrosive agent such as water and CO, by compromising the passive film (often a metal oxide film on a metal). MIC is caused by microbial biofilms. It is everywhere around us. This work dissects some notable examples with perspectives.© 2020 The Authors. Microbial Biotechnology published by Society for Applied Microbiology and John Wiley & Sons Ltd.

Influence of sulfate-reducing bacteria on the corrosion behavior of 5052 aluminum alloy

[J].

Raman spectroscopy of mackinawite FeS in anodic iron sulfide corrosion products

[J].

Oxidation and deprotonation of synthetic FeII-FeIII (oxy)hydroxycarbonate Green Rust: an X-ray photoelectron study

[J].

The influence of ionic strength, nutrients and pH on bacterial adhesion to metals

[J].

Study on corrosion mechanism of SRB in sea rust layer on Fe() and application of metabolic FeS

[D].

实海锈层SRB对Fe()腐蚀机理及其代谢FeS应用研究

[D].

An environmentally friendly bromine-based bactericide and its antibacterial and anticorrosion performance

[J].

环境友好型溴类杀菌剂的合成及其抗菌防腐蚀性能研究

[J].

A Multi-purpose approach to the mechanisms of action of two biocides (benzalkonium chloride and dibromonitrilopropionamide): discussion of Pseudomonas fluorescens’Viability and Death

[J].

Inhibiting action of biogenic surfactants in corrosive media

[J].

Rhamnolipids from Pseudomonas aeruginosa disperse the biofilms of sulfate-reducing bacteria

[J].