钢筋混凝土是一种应用极其广泛的建筑结构材料,钢筋锈蚀会引发的混凝土结构的破坏,进而缩短钢筋混凝土的服役寿命。因此,钢筋的锈蚀是钢筋混凝土结构耐久性降低的首要原因。而在含氯盐环境下服役时,[Cl-]/[OH-]浓度比值高于临界值会引起钢筋锈蚀,造成钢筋混凝土结构破坏[1]。因此,高氯盐环境下,Cl-侵蚀引发的钢筋锈蚀极为普遍。如何降低钢筋表面Cl-的浓度进而降低其对钢筋锈蚀的影响,成为高氯盐环境下混凝土耐久性的关键。

铝酸钙(C3A)由铝氧四面体和钙氧八面体组成,离子间距d = 0.76 nm,通过中心的Ca2+配位连接,其中铝离子有两种配位方式,即四配位和六配位,因此铝氧四面体会发生变形。铝离子的活性较大,作为配位中心的Ca2+连接性不强,从而导致C3A活性较高,OH-易进入晶体内部导致C3A水化速度较高[2, 3]。C3A在水化过程中,可形成具有层状结构的C4AH19、C4AH13或C2AH8化合物[4],这类层状化合物是由带正电荷的钙铝主层板和存在于夹层空间里的OH-阴离子和水分子组成的Ca-Al-OH-LDHs[5,6]。Ca-Al-OH-LDHs主层板Ca、Al以2∶1组合,Ca2+半径(0.10 nm)高于Mg2+(0.072 nm),使其表面效应较Mg-Al-LDH高,更有利于提高离子交换速率,增大其交换容量。而层间的OH-可与CO

硅溶胶涂层与混凝土组成相近,硅溶胶涂层应用于钢筋可提高钢筋与混凝土的粘结强度,同时通过在硅溶胶涂层中引入C3A,其水化形成的层状结构增加涂层的致密性,形成的钙基LDHs可对氯离子进行吸附,有效抑制侵蚀性离子对钢筋的侵蚀。

本文以水玻璃为前驱体,在涂层制备中引入C3A填料,研究了C3A不同添加量对涂层防护性能的影响。采用X射线衍射仪、红外线光谱分析仪、扫描电镜、离子色谱仪分析以及电化学测量对C3A和其水化物的结构形貌及离子交换能力、涂层的结构形貌及防腐蚀性能进行表征。以获得对钢筋防护性能优良的硅溶胶涂层。

1 实验方法

采用扫描电镜(FESEM,JSM-6510)表征C3A(C3A,99%,5000目)形貌,用X射线衍射仪(XRD, D8 Advance)表征样品组成结构,用单色Cu Kα辐射,在15 kV、20 mA下扫描速率为2.4(2θ) (o)/min,扫描范围为10°~40°。用红外线光谱分析仪(FT-IR,PerkinElmer)分析C3A样品组成,扫描范围4000~400 cm-1。

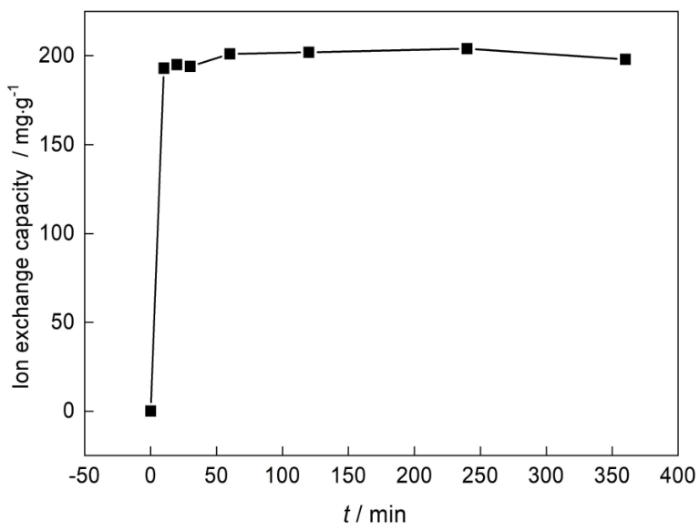

将C3A 0.2 g与100 mL的含0.01 mol/L NaCl的饱和Ca(OH)2溶液进行离子交换,密封搅拌,在设定的时间分别取出样品,取离心后的上清液利用离子色谱测定液体中Cl-浓度,根据实验前后Cl-浓度的差值计算出单位质量的C3A对Cl-的交换容量,计算公式如下:

式中:qe为离子交换量,C0为交换溶液的钠离子初始浓度,CE为交换溶液的Na+平衡后的浓度,m为用于交换的C3A的质量,V为用于交换的溶液体积。

并根据不同时间的交换容量绘制C3A对Cl-的交换容量动力学曲线。

用5 cm × 7 cm的Q235钢板替代钢筋,用400#~1500#砂纸逐级打磨样品,用石油醚、丙酮清洗除油,并依次用酒精、去离子水超声清洗,然后通过酸洗除去氧化物后用去离子水冲洗掉表面残留的酸,放入磷化液(Zn(NO3)2 56 g/L,Mn(NO3)2 20 g/L,Mn(H2PO4)2·2H2O 24 g/L,C6H8O7·H2O 2 g/L)中70℃磷化15 min,磷化完成后去离子水冲洗吹干表面备用。

分别将0.2、0.5和0.8 g的C3A粉末分散在3.5 mL水中超声分散30 min,为了增加涂层的致密性,也有助于减少Na+的析出[9],引入纳米氧化锌粉末0.5 g,并在3.5 mL水中超声分散30 min。取10 mL的水玻璃(SiO2含量27.5%,Na2O含量8.78%,模数3.23),按(氧化锌、C3A)顺序在磁力搅拌下将各分散好的填料逐滴加入到水玻璃中,持续搅拌3 h,超声分散30 min,制备出C3A改性硅溶胶涂料。取0.7 mL涂料均匀的刷涂在5 cm × 7 cm的磷化板上,室温固化24 h,真空干燥箱120℃干燥2 h。所得涂层厚度约为20 μm。未添加C3A填料的对比涂层样品记为Blank,引入不同C3A填料的涂层分别记为0.2 g、0.5 g和0.8 g。

采用电化学工作站(Interface1000型)对涂层样品进行电化学测量,溶液为3.5% (质量分数)NaCl的饱和Ca(OH)2液(pH = 12.6)。采用三电极体系,涂层样品为工作电极,暴露面积为7 cm2,饱和甘汞电极为参比电极,铂网作为对电极。测试前,将样品浸泡在溶液中30 min获得稳定的开路电位,随后进行电化学阻抗谱(EIS)测量和极化曲线测量。EIS测量的频率范围为105~10-2 Hz,正弦扰动幅值为10 mV;动电位极化扫描范围为-100~+100 mV (vs. OCP),扫描速率0.1667 mV /s。用Cview软件进行最小二乘法拟合动电位极化测试结果,用Zsimpwin软件结合等效电路对电化学阻抗谱数据进行拟合解析。

2 结果与讨论

2.1 C3A的离子交换与结构表征

2.1.1 C3A对Cl-的交换量随时间的变化

图1

图1

C3A对Cl-的交换容量随时间的变化

Fig.1

The variational of anion exchange capacity of C3A to chloride ions with time

2.1.2 离子交换前后C3A的表征

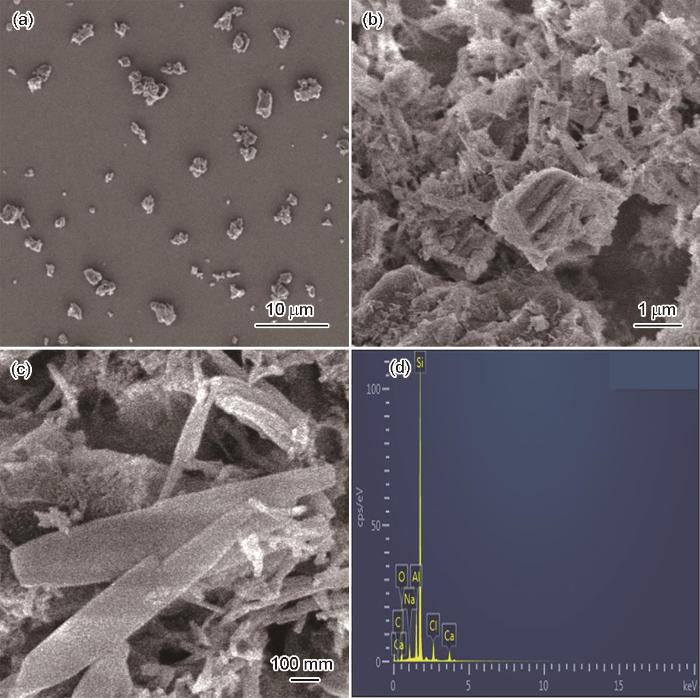

图2

图2

C3A离子交换前后SEM形貌和交换后C3A的EDS分析

Fig.2

SEM morphologies of C3A before (a) and after (b, c) ion exchange, and EDS results of the exchanged C3A sample (d)

图3

图4为C3A进行离子交换前后的XRD图,对应标准PDF卡78-1532,原样中在31.8°、34.8°、36.4°、44.6°、47.3°有Ca3(Al(OH)6)2的特征峰。交换后的样品在11.2°、31.14°处出现了Ca2Al(OH)6Cl(H2O)2层状结构所特有的特征峰[14](Ca-Al-Cl-LDH,pdf:78-1219)。交换后的样品中在31.8°、36.4°、44.6°附近仍有衍射峰,为交换后的产物部分为未交换的Ca-LDH,部分发生离子交换生成Ca-Al-Cl-LDH[15]。C3A水化产物中形成层状结构LDHs[16],带正电的中间层状结构单元{Ca2(Al(OH)6)2}+为了平衡由于Al3+置换的Ca2+导致的电荷变化,大部分游离的Cl-从含0.01 mol/L的饱和Ca(OH)2溶液中被吸附到层状结构中{Ca2(Al(OH)6)2}+中。

图4

图4

C3A离子交换前后的XRD

Fig.4

XRD patterns of C3A Sample before and after ion exchange

2.2 C3A改性硅溶胶涂层

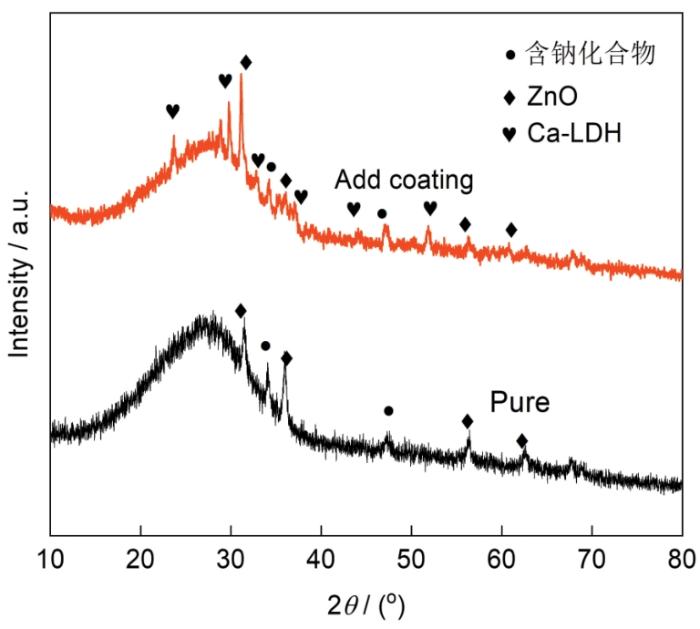

图5

图5

添加C3A涂层与未添加涂层的XRD谱

Fig.5

XRD patterns of silica sol coating with and without C3A added

图6

图6

添加C3A前后涂层截面SEM图

Fig.6

SEM morphologies of cross-section of the coating before (a) and after (b) adding C3A

图7

图7

不同添加量涂层样品的极化曲线

Fig.7

Polarization curves of coating samples with different dosage of C3A

表1 不同添加量涂层的极化曲线拟合数据

Table 1

| Additive / g | Ecorr / V vs SCE | I0 / A·cm-2 |

|---|---|---|

| Blank | -0.64 | 1.09 × 10-6 |

| 0.2 g | -0.550 | 4.4 × 10-9 |

| 0.5 g | -0.375 | 3.08 × 10-10 |

| 0.8 g | -0.579 | 5.24 × 10-9 |

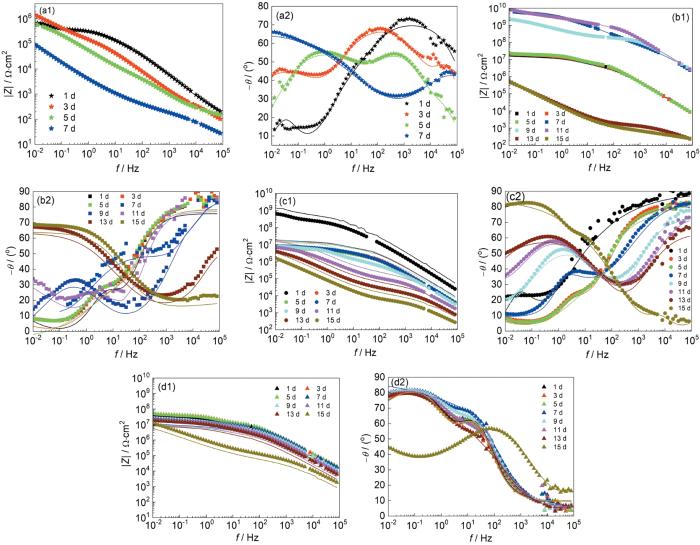

图8a2~d2表示的是不同C3A添加量样品的相角图,可以观察到涂层样品在高频处的相角值接近80°,相角高频处响应与涂层的阻隔性能有关,高频相角越接近90°,涂层越接近纯电容,相角值越大涂层阻隔性能越好,低频响应则与涂层和基板基体界面发生的腐蚀过程有关。当添加量为0.8 g时涂层的响应在中低频,表明电解质进入到涂层内部接触到金属界面发生了电荷转移过程,产生了低频响应,同时存在0.01 Hz到0.1 Hz产生的与扩散过程对应的响应。随着浸泡时间的增加,电荷转移产生的响应由低频逐渐向高频转移。而0.2g和0.5 g样品在浸泡开始并没有产生低频响应,代表涂层有着良好的阻隔性能,随着浸泡时间的增加,0.2 g样品在第7 d开始出现明显低频响应,随着浸泡时间的进一步增加,第13 d时0.2 g样品涂层的高频响应几乎消失,涂层的阻隔性能迅速下降,模值的变化也说明了这一点。对于添加量为0.5 g的样品来说,第9 d开始出现低频相角,但是此时高频处仍有响应。表明此时涂层相对完好有一定的阻隔性能。直到浸泡时间达到15 d时,涂层的高频相角消失。综合来看当添加量为0.5 g时涂层的阻隔性能,耐腐蚀能力最好。通过EIS的测量结果来看,C3A改性涂层有效地的提高了涂层的耐蚀性,显著地的提高了涂层对金属基体的保护性能,起到了隔绝侵蚀性离子的作用。通过|Z|0.01 Hz的阻抗模量大小值来比较样品的耐蚀性[18],添加量为0.5 g涂层的阻抗模量值最大,比添加量为0.8 g的样品高2个数量级,这表明在添加量一定时,C3A的添加可以提高涂层的耐蚀性。

图8

图8

不同添加量涂层的Bode图

Fig.8

Bode diagram with different addition amounts: (a1, a2) no coating added, (b1, b2) adding 0.2 g C3A coating, (c1, c2)adding 0.5 g C3A coating, (d1, d2) adding 0.8 g C3A coating

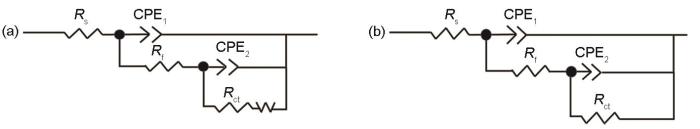

图9给出了对应的等效电路,常用于硅酸盐涂层的阻抗谱[19]。根据拟合数据对膜电阻和电荷转移电阻随时间的变化得到了图10,拟合结果如表2所示。等效电路中Rf和Rct分别为涂层膜电阻和电荷转移电阻,W代表warburg阻抗。由于电容的非理想性用恒相元件CPE代替,其中CPE1和CPE2分别代表涂层的电容和基板/涂层界面的电容[20],Warburg阻抗反映界面的扩散过程。随着浸泡时间增加发生扩散等效电路(图9a)。由图10可见,浸泡第1 d时,0.2 g、0.5 g样品的膜电阻大于108 Ω·cm2,相对于0.8 g样品高一个数量级,相对于未添加样品涂层膜电阻高4个数量级,说明C3A的添加对于涂层阻隔性能有着显著的提升。随着浸泡时间的增加,涂层的膜电阻呈下降趋势。浸泡7 d后0.5 g样品的膜电阻仍保持在107 Ω·cm2,涂层有着良好的阻隔性能[21]。而0.2 g样品在浸泡到第5 d时膜电阻接近107 Ω·cm2,第7 d小于107 Ω·cm2,对应相角图中0.5 g样品在第7 d开始出现低频响应。从图10b数据可以看出,添加C3A后的样品电荷转移电阻均比空白样品大3个数量级,浸泡7 d后引入C3A的涂层电荷转移电阻均高于107 Ω·cm2。从几种样品的Rct随时间的变化来看,还可以发现一个特征,即,随着C3A添加量的增加,Rct随时间下降幅度较小,可能是因为C3A的添加可以有效地吸纳了进入涂层的Cl-[22],同时提高基体表面的pH值,这可以降低[Cl-]/[OH-]比,延缓氯离子对基体腐蚀的作用。

图9

图9

不同添加量的涂层等效电路

Fig.9

Equivalent circuit for coatings with additives blank and 0.8 g sample (a), 0.2 g and 0.5 g sample (b)

图10

图10

涂层Rf及Rct随时间变化图

Fig.10

Changes in Rf (a) and Rct (b) of the coating over time

表2 不同添加量的涂层的拟合值

Table 2

| Sample | Time d | CPE1 nΩ-1·S n ·cm-2 | Freq1 | Rf Ω·cm2 | CPE2 nΩ-1·S n ·cm-2 | Freq2 | Rct Ω·cm2 | W |

|---|---|---|---|---|---|---|---|---|

| 0.2 g | 1 | 7.09 × 10-10 | 0.9104 | 2.58 × 108 | 1.261 × 10-7 | 0.6532 | 5.09 × 108 | / |

| 3 | 8.808 × 10-9 | 0.8503 | 5.82 × 107 | 8.504 × 10-10 | 0.9116 | 4.75 × 107 | / | |

| 5 | 6.661 × 10-10 | 0.9178 | 2.30 × 107 | 1.269 × 10-8 | 0.6442 | 2.48 × 107 | / | |

| 7 | 6.17 × 10-11 | 0.6312 | 1.22 × 107 | 4.929 × 10-11 | 0.6564 | 1.53 × 107 | / | |

| 9 | 1.708 × 10-11 | 0.9001 | 5.05 × 106 | 6.351 × 10-9 | 0.515 | 1.24 × 107 | / | |

| 11 | 1.609 × 10-9 | 0.5924 | 2.30 × 106 | 1.165 × 10-5 | 0.7087 | 4.70 × 106 | 8.794 × 1012 | |

| 13 | 2.384 × 10-6 | 0.6437 | 1673 | 1.21 × 10-5 | 0.7477 | 51690 | 1.097 × 10-17 | |

| 15 | 3.184 × 10-6 | 0.6451 | 557.5 | 1.336 × 10-5 | 0.7367 | 4.97 × 104 | 3.428 × 10-16 | |

| 0.5 g | 1 | 7.425 × 10-10 | 0.9411 | 2.88 × 108 | 1.594 × 10-10 | 0.9308 | 6.68 × 108 | / |

| 3 | 8.501 × 10-10 | 0.8917 | 1.07 × 108 | 7.441 × 10-10 | 0.8 | 9.76 × 107 | / | |

| 5 | 9.217 × 10-10 | 0.888 | 4.09 × 107 | 2.038 × 10-8 | 0.5538 | 9.45 × 107 | / | |

| 7 | 5.738 × 10-8 | 0.8 | 3.62 × 107 | 7.538 × 10-10 | 0.9059 | 2.11 × 107 | / | |

| 9 | 8.977 × 10-10 | 0.9089 | 1.21 × 107 | 5 × 10-8 | 0.8 | 1.65 × 107 | / | |

| 11 | 4.398 × 10-9 | 0.8347 | 1.95 × 106 | 1.1 × 10-7 | 0.6623 | 1.62 × 107 | 1.723 × 10-6 | |

| 13 | 1.967 × 10-8 | 0.7934 | 39710 | 4.309 × 10-7 | 0.6747 | 1.45 × 107 | 4.38 × 10-8 | |

| 15 | 1.117 × 10-7 | 0.7301 | 12310 | 1.55 × 10-6 | 0.682 | 1.34 × 107 | 1 × 1020 | |

| 0.8 g | 1 | 7.439 × 10-10 | 0.9105 | 5.95 × 106 | 2.162 × 10-8 | 0.5973 | 4.37 × 108 | 7.5 × 10-7 |

| 3 | 6.956 × 10-10 | 0.9135 | 4.11 × 106 | 1.811 × 10-8 | 0.6073 | 1.50 × 107 | 7.5 × 10-7 | |

| 5 | 1.331 × 10-8 | 0.8284 | 3.75 × 106 | 8.562 × 10-10 | 0.9078 | 1.60 × 107 | 4.679 × 10-7 | |

| 7 | 5.368 × 10-8 | 0.254 | 2.63 × 106 | 1.466 × 10-9 | 0.8532 | 1.30 × 107 | 4.804 × 10-7 | |

| 9 | 6.631 × 10-9 | 0.9209 | 1.17 × 106 | 2.861 × 10-7 | 0.518 | 9.51 × 106 | 1.385 × 10-5 | |

| 11 | 1.173 × 10-9 | 0.9292 | 1.02 × 106 | 5.268 × 10-8 | 0.4379 | 8.86 × 106 | 3.668 × 10-5 | |

| 13 | 1.823 × 10-9 | 0.9241 | 882300 | 4.362 × 10-8 | 0.5515 | 6.27 × 106 | 1.855 × 10-6 | |

| 15 | 1.999 × 10-8 | 0.8314 | 41920 | 4.995 × 10-7 | 0.6229 | 1.20 × 106 | 3.526 × 10-7 |

3 结论

通过对离子交换前后的C3A进行了分析,并将C3A引入到以水玻璃为前驱体的硅基无机溶胶-凝胶涂层中,通过扫描电镜观察C3A及涂层截面形貌,采用XRD和红外对C3A及涂层成分进行物相分析,并对不同添加量C3A改性的涂层性能进行研究,利用电化学测量来评估涂层的耐蚀性能。得到以下结论:

(1) C3A在含0.01 mol/L NaCl的饱和Ca(OH)2溶液中可以形成层状双金属氢氧化物Ca-LDHs,对Cl-进行交换生成Ca2Al(OH)6Cl(H2O)2。

(2) C3A在涂层制备中可以水化形成片层状结构Ca-LDHs,这种片层状结构在含Cl-的环境中可有效固定周围游离的Cl-,当混凝土在含Cl-的环境中服役时,涂层中的C3A水化产物可以吸附到达钢筋表面的Cl-,延缓Cl-对钢筋腐蚀的促进作用。同时,C3A的引入显著提升了涂层的阻隔性能。

参考文献

Probability model of corrosion initiation time of steel in concrete structure in chloride environment

[J].

Tricalcium aluminate hydration: microstructural observations by in-situ electron microscopy

[J].

Tricalcium aluminate hydration: microstructural observations by in-situ electron microscopy

[J].

Chloride binding behaviors and early age hydration of tricalcium aluminate in chloride-containing solutions

[J].

Friedel’s salt, Ca2Al(OH)6(Cl,OH)·2H2O: its solid solutions and their role in chloride binding

[J].

The role of sodium and sulfate sources on the rheology and hydration of C3A polymorphs

[J].

Molecular dynamics modeling of chloride binding to the surfaces of calcium hydroxide, hydrated calcium aluminate, and calcium silicate phases

[J].

Astrocyte responses to complement peptide C3a are highly context-dependent

[J].Astrocytes perform a range of homeostatic and regulatory tasks that are critical for normal functioning of the central nervous system. In response to an injury or disease, astrocytes undergo a pronounced transformation into a reactive state that involves changes in the expression of many genes and dramatically changes astrocyte morphology and functions. This astrocyte reactivity is highly dependent on the initiating insult and pathological context. C3a is a peptide generated by the proteolytic cleavage of the third complement component. C3a has been shown to exert neuroprotective effects, stimulate neural plasticity and promote astrocyte survival but can also contribute to synapse loss, Alzheimer’s disease type neurodegeneration and blood–brain barrier dysfunction. To test the hypothesis that C3a elicits differential effects on astrocytes depending on their reactivity state, we measured the expression of Gfap, Nes, C3ar1, C3, Ngf, Tnf and Il1b in primary mouse cortical astrocytes after chemical ischemia, after exposure to lipopolysaccharide (LPS) as well as in control naïve astrocytes. We found that C3a down-regulated the expression of Gfap, C3 and Nes in astrocytes after ischemia. Further, C3a increased the expression of Tnf and Il1b in naive astrocytes and the expression of Nes in astrocytes exposed to LPS but did not affect the expression of C3ar1 or Ngf. Jointly, these results provide the first evidence that the complement peptide C3a modulates the responses of astrocytes in a highly context-dependent manner.

Low cost fabrication of anti-corrosive coatings on metal surfaces

[J].

低成本制备铁基金属表面防腐蚀无机涂层

[J].

Binding capability of chloride ions in mortar and paste with ground granulated blast furnace slag

[J].

磨细矿渣净浆和砂浆结合外渗氯离子的性能

[J].

Role of calcium ion on chloride binding in hydrated C3A pastes blended with CaCO3 and CaSO4·2H2O

[J].

CaCO3和CaSO4·2H2O共同作用下Ca2+对C3A水化浆体固化氯离子性能的影响

[J].

The effects of silica fume on C3A hydration

[J].

Determining cement composition by Fourier transform infrared spectroscopy

[J].

Immobilization remediation of Cr-contaminated soils by hydrocalumite and the relevant risk assessment

[J].

水化氯铝酸钙对土壤铬的钝化修复及风险评估

[J].

Complement C3a receptor inactivation attenuates retinal degeneration induced by oxidative damage

[J].Retinal degeneration causes vision loss and threatens the health of elderly individuals worldwide. Evidence indicates that the activation of the complement system is associated with retinal degeneration. However, the mechanism of complement signaling in retinal degeneration needs to be further studied. In this study, we show that the expression of C3 and C3a receptor (C3ar1) is positively associated with the inflammatory response and retinal degeneration. Genetic deletion of C3 and pharmacological inhibition of C3ar1 resulted in the alleviation of neuroinflammation, prevention of photoreceptor cell apoptosis and restoration of visual function. RNA sequencing (RNA-seq) identified a C3ar1-dependent network shown to regulate microglial activation and astrocyte gliosis formation. Mechanistically, we found that STAT3 functioned downstream of the C3-C3ar1 pathway and that the C3ar1-STAT3 pathway functionally mediated the immune response and photoreceptor cell degeneration in response to oxidative stress. These findings reveal an important role of C3ar1 in oxidative-induced retinal degeneration and suggest that intervention of the C3ar1 pathway may alleviate retinal degeneration.

In situ nano-scale observation of C3A dissolution in water

[J].

Regulations on the hydration, morphology, and sulfate-attack resistivity of C3A with micro/nano-silica particles

[J].

One-step synthesis of superhydrophobic polyaniline capsules and its effect on corrosion resistance of organic coatings

[J].

超疏水聚苯胺胶囊的一步可控合成及其对有机涂层防腐性能的影响

[J].通过乳液聚合法,控制表面活性剂十二烷基苯磺酸钠 (SDBS) 的添加量,一步合成了具有超疏水性质、空心球形貌的聚苯胺胶囊,该微纳米空腔结构可实现缓蚀剂等物质的包覆功能。结果表明,不同表面活性剂添加量下的产物形貌均为空心球状,并且可实现水接触角由67°提升到152°的超疏水。将超疏水胶囊掺入涂层,在3.5%NaCl溶液中浸泡14 d后,低频阻抗模值为2.69×10<sup>10</sup>,与添加亲水性聚苯胺的环氧树脂涂层及不添加填料的环氧树脂涂层相比,涂层电阻超过一个数量级以上。其原因为粉末的超疏水性,增大了腐蚀介质在涂层中扩散阻力,同时由于长链烷基的掺杂,改善了聚苯胺粉末在环氧树脂中的相容性,提高了涂层致密性及耐蚀性。

Effect of nano-silica on the corrosion behavior of silicate conversion coatings on hot-dip galvanized steel

[J].

Silica-based hybrid coatings for corrosion protection of carbon steel. Part I: effect of pretreatment with phosphoric acid

[J].

Corrosion resistance of three zinc-rich epoxy coatings

[J].

环氧富锌涂层防腐蚀性能研究

[J].制备了添加纳米SO<sub>2</sub>材料的纳米复合环氧富锌涂层,通过测试金属Zn含量、拉开法附着力、浸泡实验、盐雾实验和电化学阻抗谱实验,并与两种未添加纳米材料的环氧富锌涂层防腐蚀性能进行对比研究,结果表明,纳米复合环氧富锌涂层具有良好的附着力和内聚力,前期可以作为有机屏蔽层,中期阴极保护作用温和,持续时间长,后期Zn的反应产物又可以提供涂层良好的屏蔽,耐腐蚀性能显著,而未添加纳米材料的两种富锌涂层由于起泡和锈蚀而失效。

Research progress on anti-corrosion coatings of layered double hydroxides

[J].

层状双金属氢氧化物防腐蚀涂层材料的研究进展

[J].层状双金属氢氧化物 (LDHs) 作为一种重要的无机纳米容器型材料,具有离子交换性、结构可调控、热稳定性良好等优势,近年来已发展成为防腐蚀涂层领域的研究热点。本文系统总结了近年来该领域的相关研究成果,阐述了LDHs材料的防腐蚀机理和影响LDHs防腐蚀性能的因素,总结了几类主流LDHs防腐蚀涂层的研究进展,分析了其在应用过程中存在的问题并提出具有可行性的解决途径。同时,重点对LDHs防腐蚀涂层在多功能化和复合化方面的相关进展进行了总结和展望。