研究者[16~18]研究了加工工艺对镁合金腐蚀性能的影响,并解释了部分机理。Zhang等[19]通过失重、电化学阻抗谱(EIS)和动态电位极化测量研究了热挤压对AZ91镁合金腐蚀行为的影响。挤压态合金的耐蚀性较铸造态合金低,这是由于位错、孪晶和晶界密度的增加促进了AZ91镁合金的阳极溶解,β相的重排加快了阴极过程。但也有研究表明,采用挤压和等道角挤压一体化工艺可以提高镁合金强度,同时降低镁合金的腐蚀速率[20]。这与镁合金的晶粒细化有关,也与Zn和Zr溶质在微观结构中的重新分布有关。Oktay和ürgen[21]研究了金属间化合物的尺寸和分布对不同加工方法制备的镁合金腐蚀行为的影响。虽然关于工艺对镁合金腐蚀性能影响的研究较多,但关于择优取向作用的研究较少。择优取向对改善镁合金的力学性能有重要作用[22~25],其对镁合金耐蚀性的影响有待进一步验证。

本文采用失重、电化学阻抗谱(EIS)和动态电位极化测试等方法研究了ZM5镁合金轧制前后的腐蚀行为。通过第一性原理计算,研究了择优取向的作用。通过实验和计算说明了择优取向对镁合金腐蚀行为的影响,以期为工艺优化提供有效依据。

1 实验方法

实验用铸态ZM5镁合金成分(质量分数,%)为:Al 8.61,Zn 0.53,Mn 0.18,其余为Mg。实验采用铸态和轧态ZM5镁合金。铸锭的轧制温度为450℃,轧制比为8%。金相试样和电化学试样尺寸为10 mm × 10 mm× 5 mm,浸泡实验尺寸为20 mm × 20 mm × 5 mm。实验前用150~2000#耐水砂纸依次打磨,抛光至表面光亮如镜,接着用无水乙醇清洗、吹干待用。

利用Phenom XL扫描电子显微镜(SEM)对铸态和轧态ZM5镁合金的显微组织进行观察。采用Ultima IV型X射线衍射仪(XRD)对样品进行XRD分析,范围为20°~90°,Cu靶,电流30 mA,电压40 kV。使用硬度计(HVS-5Z)进行显微硬度测量。通过施加50 g的负载,加载时间为10 s测量铸态和轧态ZM5镁合金的硬度。

浸泡实验前,利用数字天平(BSM-120.4)对上述处理好的样品进行称重(精度0.0001 g)。实验溶液采用3.5%(质量分数)NaCl,溶液体积与样品面积之比控制在40∶1。浸泡试样在浴温为25 ± 1℃的实验溶液中浸泡168 h,之后用铬酸盐溶液(200 g/L CrO3 + 10 g/L AgNO3)浸泡5~10 min,去除腐蚀产物。最后用去离子水清洗试样,冷风吹干后再次称重。利用失重法计算Mg合金的腐蚀速率。为保证良好的重现性,每次测量的平行试样为5个。

采用与失重测试相同的溶液和试样,倒置滴定管置于试样上方,滴定管末端装有漏斗,将产生的氢气气泡输送到滴定管[25]中,通过读取滴管中测试溶液液体的高度确定反应析氢量的动力学变化。

采用电化学工作站(P4000)研究了铸态和轧制态ZM5镁合金在3.5%NaCl溶液中的腐蚀电化学(EIS)行为。采用三电极系统,以Mg合金为工作电极,饱和甘汞电极(SCE)为参比电极,铂电极为辅助电极。测量前,通过开路电位(OCP)使样品工作电极稳定10 min左右。采用交流电压扰动和频率范围的方法,对EIS参数进行了设置。交流电压扰动和频率范围分别为10 mV和105~10-2 Hz。采用ZSimpWin数据分析软件对EIS数据进行拟合。动态电位曲线测量开始于-300 mV(vs. OCP),阳极电流密度快速增加时终止,扫描速率设置为0.5 mV·s-1。

本工作的密度泛函理论(DFT)模拟采用第一性原理方法,通过维也纳从头计算软件包(VASP)从头算模拟包[26]进行。具有平面波基矢投影缀加波方法(PAW)[27,28]在计算总能量和电子性质方面具有较高的精度和效率,被用于描述价电子与离子核之间的相互作用,以获得高精度的结构稳定性和电子性质结果。选择交换相关泛函作为Perdew、Burke和Ernzerhof (PBE)参数化的广义梯度近似(GGA)[29,30]。在几何优化过程中,采用8 × 8 × 5 Monkhorst-Pack k点网格进行布里渊区采样,平面波截止动能为450 eV。采用平板模型对金属表面进行模拟。板间真空层为1.2 nm,相邻层间相互作用可以忽略。平板模型有4层。模型的固定片层是低表面的原子层,用来模拟体相。上表面是完全放松的。当原子间力最大值小于0.01 eV/nm时,弛豫结束,最大收敛周期为100。电子功函数定义为真空能级和费米能级之间的差值。

2 结果与讨论

2.1 微观形貌分析

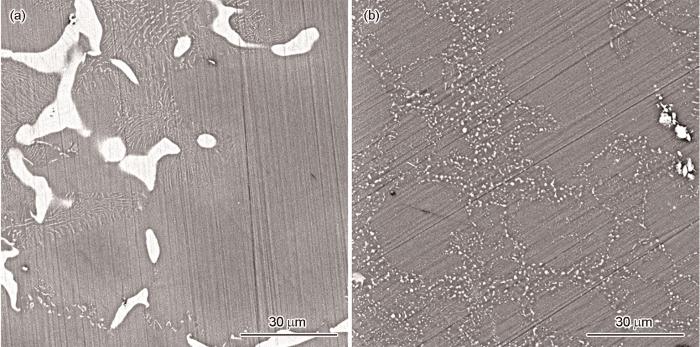

图1

图1

ZM5镁合金轧制前后的形貌

Fig.1

Morphology of ZM5 Mg-alloy before (a) and after (b) the rolling process

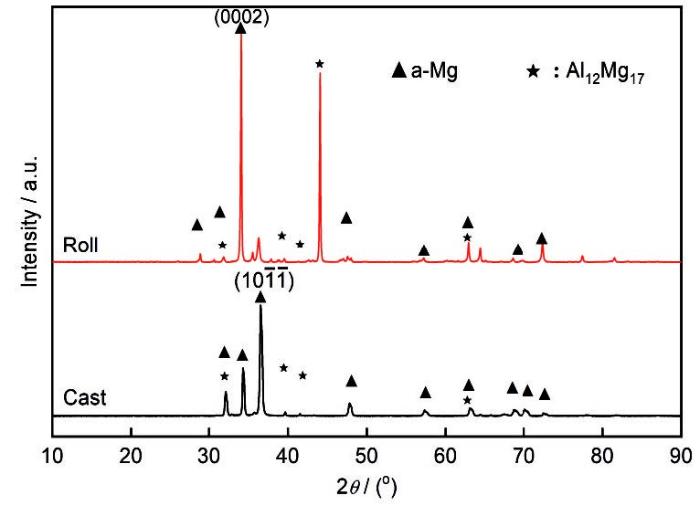

2.2 XRD分析

铸态和轧制态ZM5镁合金的XRD谱如图2所示。由图可见,铸锭与轧制后的ZM5镁合金在结晶学取向上存在差异。轧制后的ZM5镁合金出现了较高的(0002)取向峰,表明动态再结晶优先服从(0002)取向,轧制后的ZM5镁合金出现了(

图2

2.3 显微硬度分析

为了比较轧制前后ZM5镁合金显微硬度的变化,对铸态和轧制态的ZM5镁合金进行了硬度的测试。铸态和轧制态ZM5镁合金的显微硬度分别为58.9和81.6。可见,轧制后ZM5镁合金的硬度明显高于铸态ZM5镁合金的硬度。轧制后,ZM5镁合金的显微硬度提高了38.5%,说明轧制后ZM5镁合金的力学性能有了很大的提高。

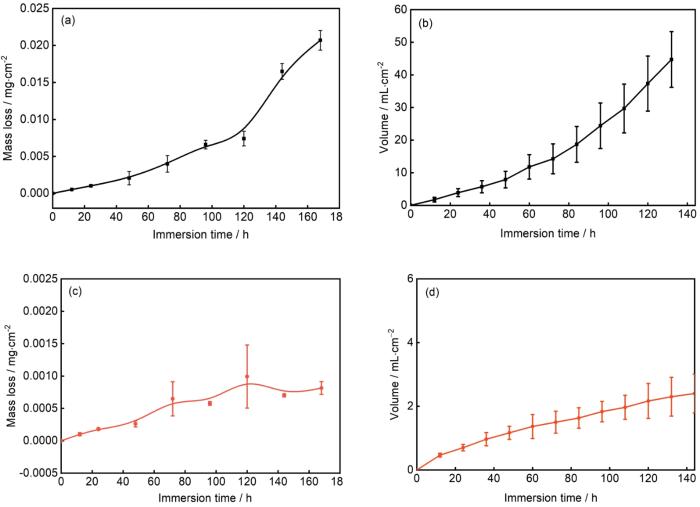

2.4 失重和析氢反应分析

为了研究轧制后ZM5镁合金的耐蚀性,对轧制前后的镁合金进行了挂片腐蚀失重试验和析氢反应试验。铸轧前后ZM5镁合金在3.5%NaCl溶液浸泡过程中的失重和析氢体积的相关数据如图3所示。可见两种状态的样品在前12 h的失重有相同的趋势。之后,轧制ZM5镁合金试样的失重与浸泡时间基本呈线性关系,而铸态ZM5镁合金的腐蚀在12 h到120 h之间呈近似指数函数增长,120 h后变为幂律函数,铸态ZM5镁合金比轧制态ZM5镁合金腐蚀更严重。

图3

图3

铸态和轧制态ZM5镁合金在3.5%NaCl浸泡过程中的失重和析氢体积的变化

Fig.3

Mass loss (a, c) and the dependence of hydrogen evolution volume (b, d) of the cast (a, b) and rolled (c, d) ZM5 Mg- alloy during immersion in 3.5%NaCl solution

铸轧ZM5镁合金析氢体积的变化与失重测量数据的变化是相同的。铸态ZM5镁合金的析氢体积增长比轧制态ZM5镁合金的析氢体积增长更严重,呈近似指数函数增长。轧制态ZM5镁合金析氢体积随浸泡时间呈近似线性关系,并与X轴接近,变化较小。

失重和析氢结果均表明,轧态ZM5镁合金的耐腐蚀性能优于铸态ZM5镁合金。为了进一步分析ZM5镁合金的腐蚀行为,对其动电位极化曲线和EIS。

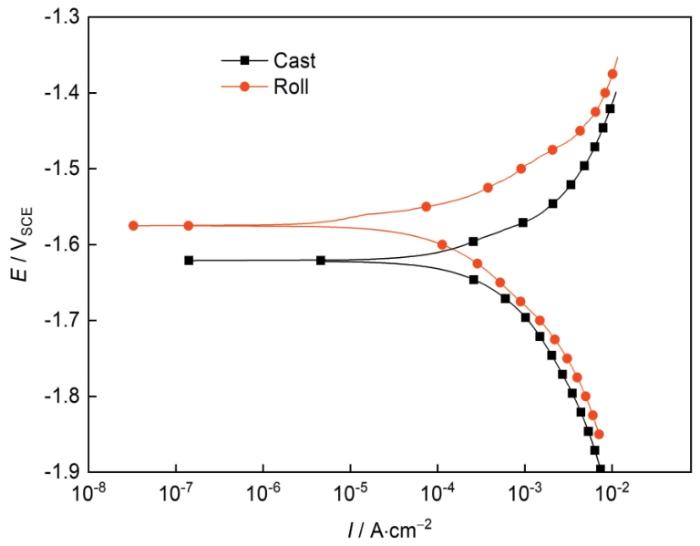

2.5 极化曲线分析

ZM5镁合金轧制前后的极化曲线如图4所示。从极化曲线的形状看,铸态和轧制态ZM5镁合金的形状相似,阳极均表现出活性溶解的状态。相比铸态,轧制态ZM5镁合金的极化曲线整体往左上进行了移动,轧制态表现出较好的耐蚀性。通过对极化曲线的腐蚀电位、腐蚀电流密度和Tafel斜率进行拟合,其结果如表1所示,可以看出,铸态ZM5镁合金的腐蚀电位低于轧制态,说明铸态ZM5镁合金腐蚀倾向高于轧制态ZM5镁合金。从腐蚀电流密度可以看出,铸态ZM5镁合金腐蚀电流密度明显高于轧制态,说明ZM5镁合金轧制后耐蚀性明显增强。通过对极化曲线的拟合,铸态和轧态试样的具体参数如表1。且轧制试样的腐蚀电位明显高于铸造试样。两种试样的耐蚀性下降趋势对应于:轧制>铸件。

图4

图4

ZM5镁合金轧制前后在3.5%NaCl中的极化曲线

Fig.4

Polarization curves of ZM5 Mg-alloy before and after rolling in 3.5%NaCl solution

表1 极化曲线拟合数据

Table 1

| Sample | Ecorr V (vs. SCE) | Icorr A·cm-2 | Tafel slope V·dec-1 |

|---|---|---|---|

| Cast | -1.621 | 5.091 × 10-4 | βa = 0.06336 βb = -0.14123 |

| Roll | -1.575 | 1.362 × 10-4 | βa = 0.15772 βb = -0.1508 |

2.6 阻抗分析

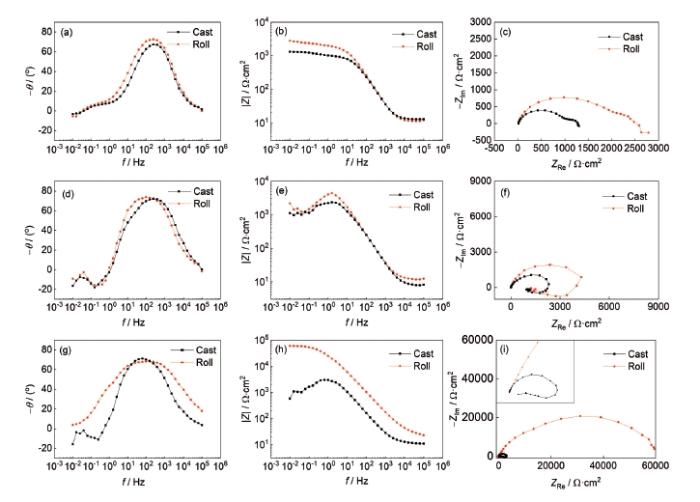

铸态和轧态ZM5镁合金在不同浸泡时间后的EIS如图5所示。从阻抗的形状来看,在浸入初始阶段,两种合金的阻抗谱都由两个电容组成。当浸泡时间延长到12 h时,两种合金的阻抗谱在高频范围内表现为电容环路,在低频范围内表现为电感环路,可能是由于随着浸泡的进行,表面生成腐蚀产物,腐蚀产物的弥散效应导致低频形成感抗弧。在浸泡后期,铸态ZM5镁合金与轧态ZM5镁合金有明显的差异。铸态ZM5镁合金的阻抗谱在高频区仍表现为电容环路,在低频区表现为电感环路,这可能是铸态ZM5镁合金表面仍存在腐蚀产物,而轧制态表面腐蚀产物可能脱落未出现弥散效应。在所有浸泡周期内,轧制合金的低频阻抗模值大于铸造合金的低频阻抗模值,轧制态表现出耐蚀性比铸态好。

图5

图5

铸轧ZM5镁合金在3.5%NaCl溶液中浸泡不同时间的EIS图

Fig.5

Phase angle (a, d, g), impedance module (b, e, h) and Nyquist (c, f, i) plots of the cast and rolled ZM5 Mg-alloy during 0.5 h (a-c), 12 h (d-f) and 168 h (g-i) immersion time in 3.5%NaCl solution

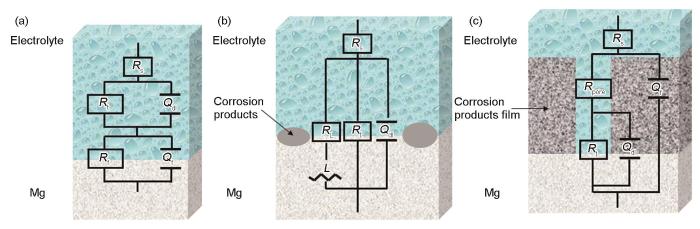

图6

图6

铸轧合金不同浸泡时间的EIS等效电路

Fig.6

Equivalent circuits of the cast and rolled alloy for different immersion periods

图7为ZM5镁合金轧制前后在3.5% NaCl溶液中浸泡不同时间的Rp值。可以看出,不同浸泡周期下,铸态的Rp值均小于轧制态的Rp值,说明整个浸泡过程中轧制合金的腐蚀速率低于铸造合金,这与极化曲线和失重测量结果一致。

图7

图7

ZM5镁合金轧制前后在3.5%NaCl溶液中浸泡不同时间的Rp值

Fig.7

Rp of ZM5 Mg-alloy before and after rolling during various immersion time in 3.5%NaCl solution

2.7 表面功函数分析

ZM5镁合金在NaCl溶液中的腐蚀阳极和阴极反应由方程(4)和(5)表示。

阳极:

阴极:

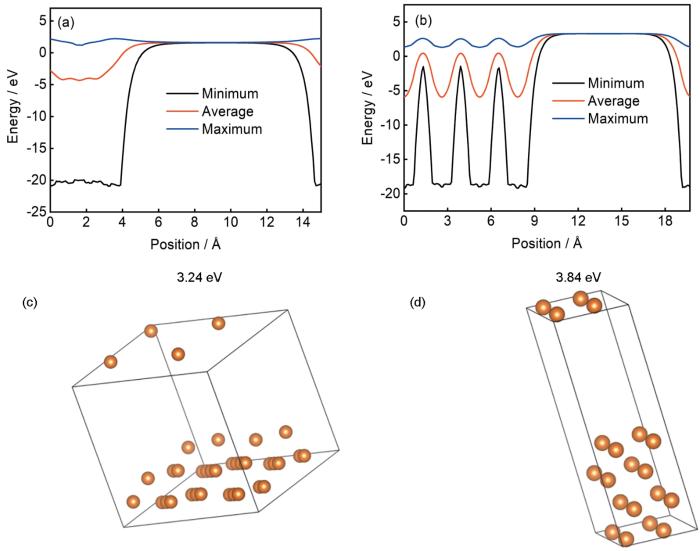

为了获得铸态和轧制态ZM5镁合金表面功函数,利用第一性原理对其表面功函数进行计算。图8为铸态和轧制态ZM5镁合金的表面功函数和局部电位模型。根据XRD等对铸态和轧制态微观结构的分析可知,铸态ZM5镁合金以(10

图8

图8

ZM5镁合金轧制前后的静电势能曲线和计算模型

Fig.8

The electrostatic energies and calculation models of the of ZM5 Mg-alloy before (a, c) and after rolling (b, d)

3 结论

(1) ZM5镁合金轧制后力学性能有所提高,微观组织观察表明,轧制工艺细化了ZM5镁合金的晶粒,并形成了择优取向。

(2) ZM5镁合金轧制后在3.5%NaCl溶液中腐蚀失重、析氢量明显下降,腐蚀电位、极化电阻显著上升,表明轧制工艺有效提升了ZM5镁合金的耐腐蚀性能。

(3) ZM5镁合金轧制后的择优取向是影响其耐腐蚀性能的重要因素。不同取向间功函数的差异是导致耐蚀性变化的原因,通过模拟计算表明,轧制后镁合金主要取向的电子功函数高于铸态,使其具有更好的耐蚀性。

参考文献

A high-specific-strength and corrosion-resistant magnesium alloy

[J].Ultra-lightweight alloys with high strength, ductility and corrosion resistance are desirable for applications in the automotive, aerospace, defence, biomedical, sporting and electronic goods sectors. Ductility and corrosion resistance are generally inversely correlated with strength, making it difficult to optimize all three simultaneously. Here we design an ultralow density (1.4 g cm(-3)) Mg-Li-based alloy that is strong, ductile, and more corrosion resistant than Mg-based alloys reported so far. The alloy is Li-rich and a solute nanostructure within a body-centred cubic matrix is achieved by a series of extrusion, heat-treatment and rolling processes. Corrosion resistance from the environment is believed to occur by a uniform lithium carbonate film in which surface coverage is much greater than in traditional hexagonal close-packed Mg-based alloys, explaining the superior corrosion resistance of the alloy.

Effect of alloyed Sr on the microstructure and corrosion behavior of biodegradable Mg-Zn-Mn alloy in Hanks' solution

[J].

Designing a magnesium alloy with high strength and high formability

[J].Although magnesium alloys, as the lightest structural alloys, offer significant potential for automotive applications, their applications remain limited due to their poor formability at room temperature. Since the strategies used for improving formability usually result in a degradation of strength, there are no high strength magnesium alloys showing good formability. Here we report an alloy design concept that can simultaneously provide high strength and good formability. Such designed alloy when subjected to an appropriate processing technique shows a combination of strength and formability that surpasses those of the existing magnesium alloys reported so far. The alloy design concept used in the present study is based on the utilization of alloying elements that can induce precipitation, as well as maximize the segregation of other texture-controlling alloying elements. Such developed alloy is expected to broaden the application of Mg alloy sheets, which are now starting to gain acceptance by automotive industries.

Magnesium: Current and potential automotive applications

[J].

Strength and ductility with {

Based on their high specific strength and stiffness, magnesium alloys are attractive for lightweight applications in aerospace and transportation, where weight saving is crucial for the reduction of carbon dioxide emissions. Unfortunately, the ductility of magnesium alloys is usually limited. It is thought that one reason for the lack of ductility is that the development of {10 (1) over bar1}-{10 (1) over bar2} double twins (DTW) cause premature failure of magnesium alloys. Here we show with a magnesium alloy containing 4 wt% lithium, that the same impressively large compression failure strains can be achieved with DTWs as without. The DTWs form stably across the microstructure and continuously throughout straining, forming three-dimensional intra-granular networks, a potential strengthening mechanism. We rationalize that relatively easier <c+a> slip characteristic of this alloy plastically relaxed the localized stress concentrations that DTWs can generate. This result may provide key insight and an alternative perspective towards designing formable and strong magnesium alloys.

Enhanced ductility of a fine-grained Mg-Gd-Al-Zn magnesium alloy by hot extrusion

[J].

Bake-hardenable Mg-Al-Zn-Mn-Ca sheet alloy processed by twin-roll casting

[J].

Low-cycle fatigue characterization and texture induced ratcheting behaviour of forged AZ80 Mg alloys

[J].

Microstructure and mechanical properties of Mg-5Li-1Al sheets prepared by accumulative roll bonding

[J].Ultrafine-grain and high-strength Mg-5Li-1Al sheets were prepared by accumulative roll bonding (ARB) process. Evolution of microstructure and mechanical properties of ARB-processed Mg-5Li-1Al sheets was investigated.Results show that, during ARB process, the evolution of deformation mechanism of t Mg-5Li-1Al alloy is as follows: twinning deformation, shear deformation, forming macro shear zone, and finally dynamic recrystallization (DRX). The grain refining mechanism changes from twin DRX to rotation DRX. With the increase in ARB cycles, strength of the Mg-5Li-1Al sheets is enhanced, whilst elongation varies slightly. With the increase in rolling cycles, anisotropy of mechanical properties decreases. It is conclusive that strain hardening and grain refinement dominate the strengthening mechanism of Mg-5Li-1Al alloy.

Poisoning the corrosion of magnesium

[J].

Galvanic corrosion behavior for galvanic couple of AZ91D Mg-alloy/2002 Al-alloy in 0.5 mg/L NaCl solution

[J].

AZ91D镁合金和2002铝合金在0.5 mg/L NaCl溶液中的电偶腐蚀行为研究

[J].采用电化学方法和表面分析技术研究了AZ91D镁合金与2002铝合金在0.5 mg/L NaCl溶液中的电偶腐蚀行为。对于镁合金,耦合后始终为阳极,腐蚀电位正移,腐蚀速率增加,这可能归结为它们之间的电偶效应显著加速了其阴极过程。对于铝合金,耦合后始终为阴极,腐蚀电位也正移,腐蚀速率增加,这可能归结为它们之间的电偶效应抑制了其表面钝化膜的形成。随着浸泡时间的延长,它们之间的耦合电位先正移后逐渐负移,电偶电流密度先增加后减小,最后逐渐增加并达到相对稳定的状态。为汽车发动机材料的选择、设计及其电偶腐蚀的抑制提供基本理论依据。

Galvanic corrosion behavior of low alloy steel, stainless steel and Al-Mg alloy in simulated deep sea environment

[J].

低合金钢、不锈钢和铝镁合金在模拟深海环境中的电偶腐蚀行为研究

[J].采用宏观形貌对比、3D共聚焦测试、扫描电子显微镜等手段,研究了模拟3000 m深海环境中9XX低合金钢、316L不锈钢和5083-H116铝镁合金之间的电偶腐蚀行为。结果表明:在深海环境中,9XX低合金钢与316L不锈钢之间的电偶腐蚀倾向较大,腐蚀较为严重;5083铝镁合金与316L不锈钢之间电位差较大,但由于二者都形成了致密的保护膜,与316L不锈钢偶接的5083铝镁合金腐蚀较轻;316L不锈钢表面氧化保护膜的存在使其在深海环境中具有优良的耐腐蚀性。

Characterization of pitting corrosion behavior of AZ91 Mg-alloy without and with MAO coating

[J].

AZ91镁合金和MAO涂层的点蚀行为研究

[J].采用循环极化曲线研究了AZ91镁合金及其表面微弧氧化 (MAO) 涂层在3.5%NaCl溶液中的点蚀行为。采用光学显微镜和扫描电镜观察循环极化不同阶段的点蚀形貌,探讨了点蚀在AZ91镁合金和MAO涂层上的萌生和扩展机制。结果表明,合金上点蚀倾向于在α-Mg相上萌生,而涂层上点蚀在多孔结构和裂纹处萌生,合金和涂层上点蚀的初始形态均为开口的“火山口”形貌。合金上点蚀坑中沉积一层腐蚀产物层对点蚀产生一定钝化效果,导致了点蚀在合金上横向扩展。而涂层上点蚀造成涂层的剥离和腐蚀产物的溶解,无法对点蚀形成钝化效果,导致点蚀在涂层上向纵深扩展。点蚀在循环极化过程中持续扩展的微观形貌验证了合金和涂层的循环极化曲线上出现正的滞后环,而不同的点蚀扩展现象也验证了涂层上较大的滞后环面积。

Investigation of corrosion behavior of Mg-6Gd-3Y-0.4Zr alloy in Xisha atmospheric simulation solution

[J].

Corrosion behavior of AZ31 magnesium alloy in the chloride solution containing ammonium nitrate

[J].

Improvement of corrosion resistance and mechanical properties of a magnesium alloy using screw rolling

[J].

Mechanical and corrosion properties of Mg-Gd-Zn-Zr-Mn biodegradable alloy by hot extrusion

[J].

Laser rapid solidification improves corrosion behavior of Mg-Zn-Zr alloy

[J].

Corrosion of hot extrusion AZ91 magnesium alloy: I-relation between the microstructure and corrosion behavior

[J].

Enhanced corrosion resistance of Mg alloy ZK60 after processing by integrated extrusion and equal channel angular pressing

[J].

Corrosion behaviour of magnesium AZ31 sheet produced by twin roll casting

[J].

Grain refining of magnesium alloy AZ31 by rolling

[J].

Texture optimization on Mg sheets by preparing soft orientations of extension twinning for rolling

[J].

Orientation effects on acoustic emission during tensile deformation of hot rolled magnesium alloy AZ31

[J].

Strain path dependence of texture and property evolutions on rolled Mg-Li-Al-Zn alloy possessed of an asymmetric texture

[J].

Ab initio molecular dynamics for liquid metals

[J].

From ultrasoft pseudopotentials to the projector augmented-wave method

[J].

Self-interaction correction to density-functional approximations for many-electron systems

[J].

Ni Al(110)/Cr(110) interface: A density functional theory study

[J].

Galvanic corrosion of magnesium alloy AZ91D in contact with an aluminium alloy, steel and zinc

[J].

Effect of grain size and twins on corrosion behaviour of AZ31B magnesium alloy

[J].

Wettability, electron work function and corrosion behavior of CoCrFeMnNi high entropy alloy films

[J].

Influence of surface morphology on corrosion and electronic behavior

[J].

First principles calculations on the influence of solute elements and chlorine adsorption on the anodic corrosion behavior of Mg (0001) surface

[J].