随着海洋强国战略的实施,近几年我国海工基础设施建设发展迅速。在这些海工基础设施中,大部分设施都使用钢结构和钢筋混凝土结构。然而,由于海洋恶劣的服役环境,许多钢筋混凝土结构在氯盐长期作用下发生腐蚀而引发结构过早失效,带来了一系列的经济、安全、环境等问题[1]。造成海洋混凝土结构失效的主要因素之一就是钢筋锈蚀[2~5]。在正常情况下,钢筋在混凝土高碱体系中表面生成了较为致密的钝化膜,可以在一定程度上阻止腐蚀的发生。但是,在混凝土的制作过程和外部环境中存在大量的Cl-去钝化剂,当Cl-浓度达到一定的临界值时,则会对钢筋表面的钝化膜造成严重破坏,从而引发钢筋锈蚀,导致钢筋混凝土结构失效[6]。由于不锈钢钢筋表面的钝化膜更为致密,且具有优异的耐氯盐侵蚀性能,使用不锈钢钢筋替代普通碳素钢筋是解决钢筋腐蚀、延长混凝土结构服役寿命的重要手段[7]。2304双相不锈钢钢筋由于其优异的耐蚀性能、较低的全寿命周期成本,成为了应用最为广泛的混凝土结构用不锈钢钢筋之一。但针对2304双相不锈钢钢筋的电化学腐蚀行为研究较少,2304双相不锈钢钢筋相对于其他不锈钢钢筋及普通钢筋在海洋环境下的长期性能,如钢筋钝化与脱钝行为、耐氯盐侵蚀性等,还缺乏系统的对比研究。

本工作采用电化学测试技术研究2304奥氏体-铁素体型双相不锈钢钢筋、304奥氏体不锈钢钢筋、HRB400普通碳素钢筋的钝化行为与耐氯盐侵蚀性能,对比分析奥氏体-铁素体型双相不锈钢钢筋与普通碳素钢筋、奥氏体不锈钢钢筋的耐蚀性能,明确2304双相不锈钢钢筋的耐蚀机理,以期为2304双相不锈钢钢筋的工程应用提供一些指导。

1 实验方法

以2304双相不锈钢钢筋、304不锈钢钢筋、HRB400普通钢筋为研究对象,切割成Φ2 cm×2 cm,并以一端为工作面,另一端焊接铜导线,采用环氧树脂边缘密封,固化后将钢筋用40#、100#、360#、600#、1000#、2000#砂纸逐级打磨,并用乙醇和去离子水冲洗并吹干待用。钢筋的主要成分如表1所示。混凝土孔隙模拟液为饱和氢氧化钙溶液(pH ≈ 12.5)。

表1 3种实验用钢筋的主要化学成分 (mass fraction / %)

Table 1

| Material | C | Si | Mn | P | S | N | Cr | Ni | Mo | Cu | Fe |

|---|---|---|---|---|---|---|---|---|---|---|---|

| HRB400 | 0.25 | 0.80 | 1.60 | 0.045 | 0.045 | - | - | - | - | - | Bal. |

| 304 stainless steel | 0.07 | 1.00 | 2.00 | 0.045 | 0.015 | 0.11 | 17.5-19.5 | 8.0-10.5 | - | - | Bal. |

| 2304 duplex stainless steel | 0.03 | 1.00 | 2.00 | 0.035 | 0.015 | 0.05-0.20 | 22.0-24.0 | 3.5-5.5 | 0.10-0.60 | 0.10-0.60 | Bal. |

采用PARSTAT2273电化学工作站进行电化学测试。采用三电极体系,以饱和甘汞为参比电极,钛网为辅助电极,钢筋为工作电极。电化学阻抗谱(EIS)测试的正弦信号频率范围为105~10-2 Hz,振幅为± 10 mV,数据采用ZSimp Win软件进行合理的等效电路拟合分析。动电位极化曲线测试范围为-0.3~1.2 V(相对开路电位(OCP)),扫描速率为3 mV/s,测试数据用CVIEW软件拟合分析。Mott-Schottky曲线测试电压范围为-0.3~0.6 V(相对参比电极电位),扰动信号为10 mV,频率为1 kHz,扫速为50 mV/s,延迟时间设定为2 s。

先将钢筋浸泡在混凝土孔隙模拟液中进行钝化,模拟钢筋混凝土养护阶段,再加入不同质量浓度的NaCl,测试不同NaCl浓度下钢筋的OCP、EIS,分析不同钢筋的耐氯盐侵蚀性能,并且测试动电位极化曲线分析3种钢筋在临界Cl-浓度下的耐蚀性能,通过Mott-Schottky曲线分析其钝化膜在含氯混凝土环境中的表面半导体特性。

2 结果与讨论

2.1 钝化行为分析

图1为2304双相不锈钢钢筋、304不锈钢钢筋及HRB400普通钢筋浸泡在混凝土孔隙模拟液中的OCP随时间变化曲线图。3种钢筋的OCP均随浸泡时间的延长先急剧增大,到30 h后缓慢增长并趋于稳定,在混凝土孔隙模拟液中浸泡240 h后,HRB400普通钢筋、304不锈钢钢筋、2304双相不锈钢钢筋的OCP基本稳定,依次为-138、-129、-142 mV vs. SCE。

图1

图1

3种钢筋在混凝土孔隙模拟液中的OCP随时间变化图

Fig.1

OCP of three types of reinforcement in concrete pore simulant as a function of time

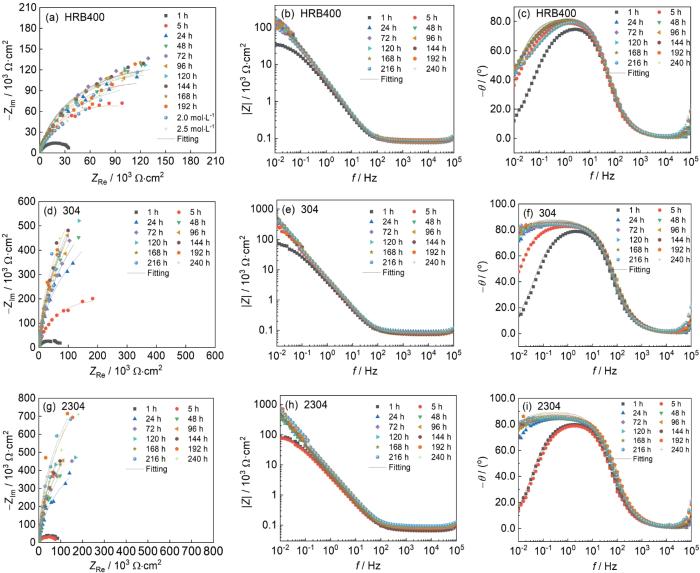

图2为3种钢筋在混凝土孔隙模拟液中浸泡不同时间后的EIS。由图可见,随着浸泡时间的延长,3种钢筋的容抗弧半径、低频阻抗模值、相位角峰宽均逐渐增大,最大相位角向低频方向移动。另外,HRB400普通钢筋、304不锈钢钢筋在5 h内钝化膜生长较快,之后钝化膜生长速率减缓;2304双相不锈钢钢筋在1~5 h未发生钝化反应,5~24 h钝化膜快速生长,后期钝化膜趋于稳定。在钝化240 h后,2304双相不锈钢钢筋的容抗弧半径和低频阻抗模值均大于304不锈钢钢筋,HRB400普通钢筋最小。

图2

图2

3种钢筋在混凝土孔隙模拟液不同浸泡时间下的EIS

Fig.2

Nyquist (a, d, g), impedance module (b, e, h) and phase angle (c, f, i) plots of HRB400 common steel bar (a-c), 304 stainless steel bar (d-f) and 2304 duplex stainless steel bar (g-i) in concrete pore simulant with different immersion time

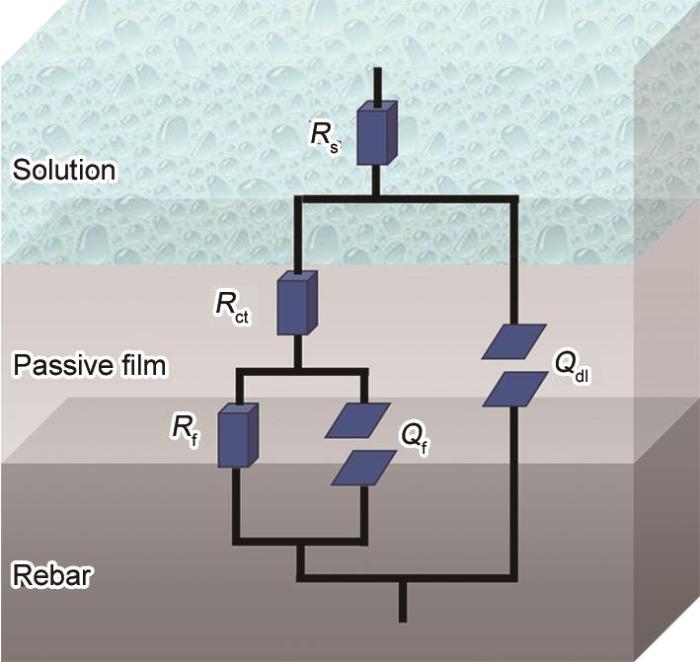

图3

3种钢筋在混凝土孔隙模拟液中浸泡不同时间的EIS拟合结果如图4所示,HRB400普通钢筋的Rct和Rf相较于304不锈钢钢筋和2304双相不锈钢钢筋来说增长较慢,且在混凝土孔隙模拟液中浸泡240 h后,钝化膜膜层电阻达到0.82 MΩ·cm2。304不锈钢钢筋在1~5 h内Rct和Rf增长较快,120 h后趋于稳定,浸泡240 h后钝化膜膜层电阻达到3.19 MΩ·cm2。2304双相不锈钢钢筋Rct和Rf与304不锈钢钢筋增长趋势相似,在浸泡240 h钝化膜膜层电阻为3.97 MΩ·cm2。这表明,2304双相不锈钢钢筋的钝化膜耐蚀性能优于304不锈钢钢筋,优于HRB400普通钢筋。

图4

图4

3种钢筋EIS拟合结果

Fig.4

Fitting results of EIS of three kinds of steel bars: (a) Rct with immersion time, (b) Rf with immersion time

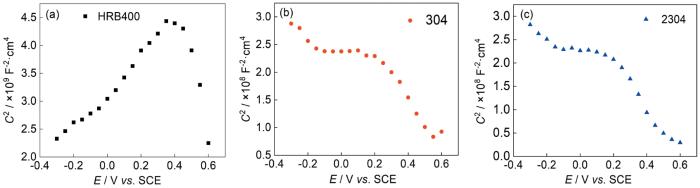

钢筋表面钝化膜具有半导体特性,但与本征半导体不同,钝化膜层通常表现为重掺杂、高度简并的半导体性质[10]。根据电子能带理论,当氧化物导带的电子数量大于价带中的空穴数量时,氧化物表现为n型半导体,反之为p型半导体,钝化膜的半导体特性可用Mott-Schottky关系式来描述[11]。根据点缺陷模型,钢筋表面钝化膜中含有各种高浓度的点缺陷,p型半导体钝化膜的主要点缺陷是阳离子空位,为电子受主;n型半导体钝化膜的主要点缺陷是氧空位/阳离子间隙,为电子施主[12,13]。氯离子等侵蚀性离子正是借助这些缺陷进入钢筋钝化膜表面空位,从而劣化钝化膜耐蚀性能。因此,钢筋钝化膜的点缺陷密度越小,氯离子等侵蚀性离子就越难吸附进入表面空位,阳极的反应也就越难进行,其钝化膜的耐腐蚀性能也就越优异[10]。

图5为3种钢筋在混凝土孔隙模拟液中钝化240 h后的Mott-Schottky曲线。由图可见,外加电位在-0.3~0.4 V范围时,HRB400普通钢筋钝化膜的C-2-E关系呈M-S特性,Mott-Schottky曲线斜率为正值,显示n型半导体性质。304不锈钢钢筋和2304双相不锈钢钢筋表面钝化膜在外加电压范围内Mott-Schottky曲线斜率为负值,表现为p型半导体行为。HRB400普通钢筋表面钝化膜成分主要为FeO、Fe2O3、FeOOH[14],304不锈钢钢筋表面钝化膜主要成分除了Fe的氧化物还含有Cr、Ni的氧化物[7],而2304双相不锈钢钢筋在此基础上富含Mo的氧化物[15]。研究表明,Fe的氧化物具有n型半导体性质,Cr、Ni、Mo的氧化物具有p型半导体性质[16,17],这与M-S曲线的结果是一致的。根据氧化物的等电点理论[18~20],以Cr、Ni、Mo的氧化物为主的p型半导体表面带负电荷,对Cl-具有较强的排斥作用,故304不锈钢钢筋与2304双相不锈钢钢筋对Cl-具有较强的排斥作用,耐蚀性能更强。根据Mott-Schottky关系式计算3种钢筋的载流子密度和平带电位(Efb),结果如表2所示,ND为施主密度,NA为受主密度。在混凝土孔隙模拟液中浸泡240 h后,HRB400普通钢筋载流子密度为2.76 × 1021 cm-3,304不锈钢钢筋载流子密度为1.07 × 1021 cm-3,2304双相不锈钢钢筋的载流子密度为8.63 × 1020 cm-3。这表明,HRB400普通钢筋钝化膜缺陷最多,耐蚀性能最差,304不锈钢钢筋耐蚀性能比HRB400普通钢筋较为优异。而2304双相不锈钢钢筋由于Cr,Ni,特别是Mo耐蚀元素的存在[21],钝化膜更加致密,表面点缺陷密度最少,耐蚀性能最好。

图5

图5

3种钢筋在混凝土孔隙模拟中钝化10 d后的Mott-Schottky曲线图

Fig.5

Mott-Schottky curves for HRB400 ordinary steel bar (a), 304 stainless steel bar (b) and 2304 duplex stainless steel bar (c) after passivation in concrete pore simulation for 10 d

表2 3种钢筋生成钝化膜的载流子密度和平带电位

Table 2

| Rebar | ND / NA | Efb |

|---|---|---|

| HRB400 | 2.76 × 1021 | -0.693 |

| 304 stainless steel | 1.07 × 1021 | 0.685 |

| 2304 duplex stainless steel | 8.63 × 1020 | 0.541 |

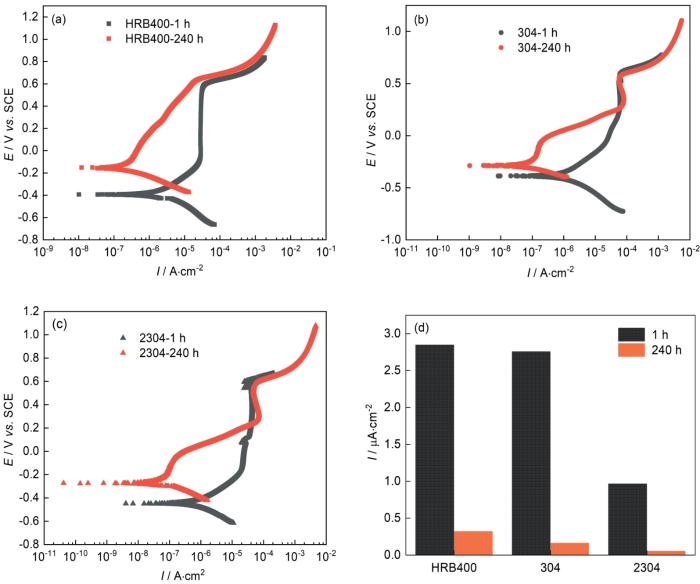

图6为3种钢筋在混凝土孔隙模拟液中浸泡1和240 h后进行动电位极化曲线测试结果及其拟合结果。由图可见,在浸泡240 h后,HRB400普通钢筋腐蚀电流密度从2.84 μA/cm2降低至0.32 μA/cm2,304不锈钢钢筋的腐蚀电流密度从2.76 μA/cm2降低至0.16 μA/cm2,2304双相不锈钢钢筋的腐蚀电流密度从0.97 μA/cm2降低至为0.05 μA/cm2。这表明,经过在混凝土孔隙模拟液中浸泡后,3种钢筋均发生钝化,且表面钝化膜缺陷减少,使得腐蚀电流密度降低。

图6

图6

3种钢筋在混凝土孔隙模拟液中浸泡1和240 h后的动电位极化曲线及腐蚀电流密度

Fig.6

Plots of dynamic potential polarization curves for HRB400 ordinary steel bar (a), 304 stainless steel bar (b) and 2304 duplex stainless steel bar (c) after immersion in concrete pore simulation solution for 1 and 240 and corrosion current density (d)

2.2 耐氯盐侵蚀性能分析

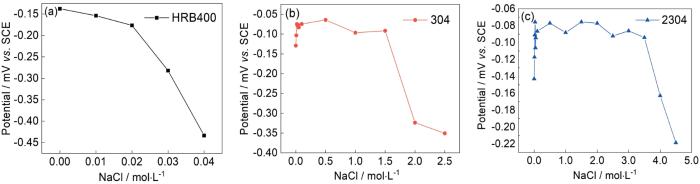

为了模拟钢筋混凝土的实际服役状况,先将3种钢筋浸泡在混凝土孔隙模拟液中进行钝化以模拟其养护阶段,之后再添加NaCl研究其耐氯盐侵蚀性能。图7为3种钢筋钝化后的OCP随NaCl浓度的变化规律,所有试样在进行OCP测试前均在含氯混凝土模拟液中浸泡了1 d。由图可见,随着NaCl的不断添加,3种钢筋的OCP均出现不同程度的下降,且均在某一值发生急剧变化:当NaCl浓度为0.03 mol/L时,HRB400普通钢筋的OCP显著降低至-282 mV,当NaCl浓度为2.0 mol/L时,304不锈钢钢筋的OCP显著降低至-324 mV,当NaCl浓度为4.0 mol/L时,2304双相不锈钢钢筋的OCP降低至-163 mV。

图7

图7

3种钢筋在不同含氯混凝土孔隙模拟液中的OCP随NaCl浓度变化

Fig.7

OCP of HRB400 ordinary steel bar (a), 304 stainless steel bar (b) and 2304 duplex stainless steel bar (c) in different chloride containing concrete pore simulants with NaCl concentration

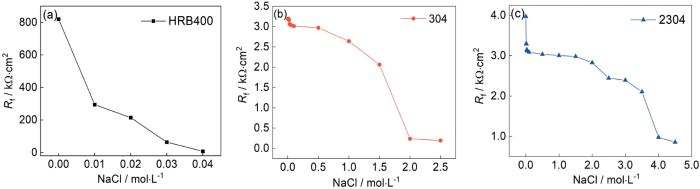

图8为3种钢筋在不同NaCl浓度下进行EIS测试结果。由图可见,随着NaCl浓度的增大,3种钢筋的容抗弧半径、低频阻抗模值和相位角峰宽逐渐减小。HRB400普通钢筋在0.02~0.03 mol/L NaCl浓度范围内,304不锈钢钢筋在1.5~2 mol/L NaCl浓度范围内,2304双相不锈钢钢筋在3.5~4 mol/L NaCl浓度范围内的容抗弧半径、低频阻抗模值和相位角峰宽均发生了显著减小。这表明在此NaCl浓度范围内3种钢筋表面钝化膜均产生了较大缺陷,这与OCP的结果是一致的。

图8

图8

3种钢筋在不同含氯混凝土孔隙模拟液中的EIS

Fig.8

Nyquist (a, d, g), impedance module (b, e, h) and phase angle (c, f, i) plots of HRB400 common steel bar (a-c), 304 stainless steel bar (d-f) and 2304 duplex stainless steel bar (g-i) in different chloride containing concrete pore simulants

图9

图9

3种钢筋在不同含氯混凝土孔隙模拟液中的EIS拟合结果随NaCl浓度变化

Fig.9

Plots of Rf versus NaCl concentration for the EIS fitting results for HRB400 plain steel bar (a), 304 stainless steel bar (b) and 2304 duplex stainless steel bar (c) in different chloride containing concrete pore simulants

在分析了3种钢筋在不含氯的混凝土孔隙模拟液中表面钝化膜半导体特性的基础上,研究其在Cl-作用下的钝化膜半导体特性。图10为3种钢筋钝化后在4.5 mol/L NaCl溶液中浸泡的M-S曲线测试结果图。对比图中3种钢筋钝化后的M-S结果可知,3种钢筋的钝化膜结构由于Cl-的侵蚀均发生了变化。除304不锈钢钢筋外,HRB400普通钢筋和2304双相不锈钢钢筋均在施加电位范围内呈现4个区域,对曲线进行拟合,如表3所示,在每一个区域内,2304双相不锈钢钢筋的施主密度和受主密度都小于304不锈钢钢筋,小于HRB400普通钢筋,这表明,在Cl-的侵蚀下,2304双相不锈钢钢筋钝化膜表面破坏最小,具有优异的耐氯盐侵蚀性能。

图10

图10

3种钢筋在含4.5 mol/L NaCl混凝土孔隙模拟液中的Mott-Schottky曲线图

Fig.10

Mott-Schottky curves of HRB400 plain steel bar (a), 304 stainless steel bar (b) and 2304 duplex stainless steel bar (c) in concrete pore simulation solution containing 4.5 mol/L NaCl

表3 3种钢筋在含4.5 mol/L NaCl的混凝土孔隙模拟液中表面钝化膜的载流子密度

Table 3

| Rebar | ND1 | NA1 | ND2 | NA2 |

|---|---|---|---|---|

| HRB400 | 8.41 × 1021 | 8.98 × 1021 | 5.24 × 1021 | 9.72 × 1021 |

| 304 stainless steel | 3.15 × 1021 | 2.94 × 1021 | - | 3.07 × 1021 |

| 2304 duplex stainless steel | 2.45 × 1021 | 8.62 × 1020 | 3.08 × 1021 | 2.07 × 1021 |

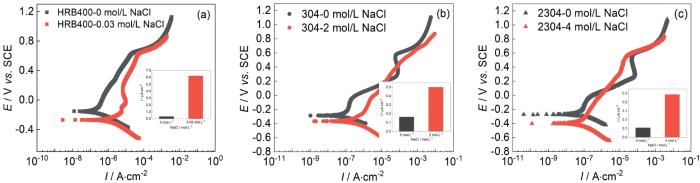

图11为3种钢筋在不同含氯混凝土孔隙模拟液中的动电位极化曲线图及拟合结果。由图可见,在未添加NaCl时,HRB400普通钢筋、304不锈钢钢筋、2304双相不锈钢钢筋的自腐蚀电流密度分别为0.32、0.16和0.05 μA/cm2,而在0.03 mol/L NaCl浓度下,HRB400普通钢筋的自腐蚀电流密度为6.22 μA/cm2;在2.0 mol/L NaCl浓度下304不锈钢钢筋的自腐蚀电流密度为0.50 μA/cm2;在4.0 mol/L NaCl浓度下2304双相不锈钢钢筋自腐蚀电流密度为0.24 μA/cm2。可以看出,即使在高盐浓度下,2304双相不锈钢钢筋仍具有较低的腐蚀电流密度,表现出优异的耐氯盐侵蚀性能。

图11

图11

3种钢筋在不同含氯混凝土孔隙模拟液中的动电位极化曲线图及腐蚀电流密度

Fig.11

Plots of dynamic potential polarization curves and corrosion current density for HRB400 plain steel bar (a), 304 stainless steel bar (b) and 2304 duplex stainless steel bar (c) in different chloride containing concrete pore simulation liquids

3 结论

(1) 3种钢筋在混凝土模拟孔隙液中浸泡5 d后均完成钝化,2304双相不锈钢钢筋钝化后表面钝化膜耐蚀性能最好。

(2) HRB400普通钢筋、304不锈钢钢筋和2304双相不锈钢钢筋的临界Cl-浓度范围分别为0.02~0.03、1.5~2.0和3.5~4.0 mol/L。

(3) 耐氯盐侵蚀性能提升的原因是钢筋表面钝化膜表面点缺陷密度的减少以及不锈钢中Cr、Ni、Mo等耐蚀元素形成的钝化膜对Cl-排斥作用的增强。

参考文献

Marine corrosion and protection: Current status and prospect

[J].

海洋腐蚀防护的现状与未来

[J].

Reinforcement corrosion in concrete structures, its monitoring and service life prediction-a review

[J].

Electrochemical behaviour of steel rebars in concrete: influence of environmental factors and cement chemistry

[J].

Critical chloride content in reinforced concrete-A review

[J].

Chloride-induced corrosion resistance of high-strength stainless steels in simulated alkaline and carbonated concrete pore solutions

[J].

Probability analysis on service life prediction of reinforced concrete structures

[J].

基于概率分析的钢筋混凝土结构服役寿命预测研究

[J].采用Monte Carlo法建立了钢筋混凝土结构耐久性失效的概率模型,研究了钢筋混凝土结构服役寿命概率分布。结果表明,Monte Carlo模拟次数为10000次时,既节约计算资源又满足计算精度。采用概率方法 (p<sub>fmax</sub>=5%和10%) 计算的结构服役寿命比用确定方法计算的服役寿命短,确定性模型低估了Cl<sup>-</sup>侵蚀引起的耐久性失效。对水灰比、混凝土保护层厚度、粉煤灰掺量、表面Cl<sup>-</sup>浓度、临界Cl<sup>-</sup>浓度参数化分析结果表明,保护层厚度对服役寿命影响最为显著;同时,服役寿命长的结构,其安全储备期也较长,一般安全储备期在5~10 a之间。本文提出的服役寿命预测模型为钢筋混凝土结构的修复、健康监测提供了理论依据。

Critical chloride concentration of stainless steels in simulated concrete pore solutions

[J].

不锈钢钢筋的临界氯离子浓度

[J].

Study on natural passivation and depassivation behavior of stainless steel in simulated concrete pore solution

[D].

模拟混凝土孔隙液中不锈钢自然钝化及脱钝行为研究

[D].

Equivalent circuits fitting of electrochemical impedance spectroscopy for corrosion of reinforcing steel in concrete

[J].

等效电路拟合钢筋锈蚀行为的电化学阻抗谱研究

[J].

A correlation study of corrosion resistance and semiconductor properties for the electrochemically modified passive film of stainless steel

[J].

不锈钢钝化膜耐蚀性与半导体特性的关联研究

[J].

The point defect model for the passive state

[J].

A point defect model for anodic passive films: I. Film growth kinetics

[J].

Characterisation of passive film on HRB400 steel rebar in curing stage of concrete

[J].The standard curing time of concrete is 28 days in order to guarantee the strength of the concrete. It is well known that a stable passive film can be formed on the surface of steel rebar in the alkaline pore fluid during the concrete curing stage, long before the steel rebar will be influenced by chloride ingress or concrete carbonation in the future. However, there is no consensus on the time conditions for the pre-passivation of the steel bars in the open literature. In this study, the growth process and characteristic evolution of the passive film formed on HRB400 steel rebar in a Ca(OH)2 saturated solution, which aims to simulate the medium in concrete pores during curing period, were studied by a series of electrochemical tests (open-circle potential (OCP), electrochemical impedance spectroscopy (EIS), potentiodynamic polarization curve (PDC)) and XPS. Results show that it will take 5 days to form a stable passive film on the surface of HRB400 steel rebar, and the passive film has a two-layered structure. In the initial stage of passivation, on the HRB400 steel surface a thin film mainly composed of Fe(II) products firstly formed, then on top of which, a film mainly composed of Fe(III) products would further form.

混凝土养护期间HRB400钢筋钝化行为研究

[J].为了研究HRB400钢筋在模拟养护阶段混凝土孔隙液中表面钝化膜的生长过程,采用3种电化学测试技术(开路电位、电化学阻抗谱、动电位极化曲线)研究钢筋表面钝化膜的性能随着浸泡时间的变化特征,此外通过XPS对稳定钝化膜的成分与结构进行分析。结果表明,同传统钢筋材料一样,HRB400钢筋在模拟混凝土养护条件的溶液中展现出良好的耐蚀性能,浸泡5 d后便能够生成稳定钝化膜。XPS分析发现钢筋钝化膜为双层结构,内层以二价铁离子化合物为主,外层主要由三价铁离子化合物组成。

Mo effect on natural passivation and corrosion behavior of duplex stainless steels in alkaline media

[J].The role of Mo in the natural passivation behavior and pitting corrosion resistance of duplex stainless steels (DSSs) in alkaline medium was investigated by X-ray photoelectron spectroscopy and electrochemical analyses as a function of immersion time. It is shown that the Mo participated directly in the formation process of natural passive film, which affected the chemical distribution and thickness of the film by modifying the contents of other species (e.g. Cr oxide). With the increasing of prepassivation time, the oxidized Cr species were gradually enriched in the passive film, and the corrosion resistance of DSSs in alkaline solution containing Cl− was enhanced. Mo greatly improved the pitting corrosion resistance and the tolerance to Cl− attack of the passive film formed on DSS surface by inhibiting the initiation and growth of pitting.

Investigation of the passivity and chloride-induced behavior of new corrosion-resistant steel rebar in concrete

[D].

新型耐蚀钢筋在混凝土环境中的钝化及氯盐侵蚀行为研究

[D].

The research of semiconducting properties of the passive film formed on 304 stainless steel in seawater

[D].

304不锈钢钝化膜在海水介质中的半导体特性研究

[D].

Mechanism of anion adsorption at the ferric and chromic oxide/water interfaces

[J].

Analysis of Cl- corrosion resistance of high Mo super austenitic stainless steels

[J].

高Mo超级奥氏体不锈钢耐Cl-腐蚀性能分析

[J].对比分析了不同Mo含量的316L、904L、S31254和S31254-B奥氏体不锈钢在10%NaCl溶液中的腐蚀行为,及其固溶处理、低温时效处理对其耐蚀性的影响;利用扫描电子显微镜、电化学极化曲线和电化学阻抗谱对4种不锈钢的显微组织、耐蚀性和表面腐蚀形貌进行了分析。结果表明:4种不锈钢在10%NaCl溶液中有不同的耐蚀性能,耐蚀性排序为:低温时效态>固溶态,S31254-B>S31254>904L>316L。Mo含量的提高、微量合金元素B加入奥氏体、低温时效处理均有利于提升材料的耐蚀性能。B促使表面形成富Cr、Mo氧化物的钝化膜,提升钝化层的致密化,减缓晶界处贫Cr、贫Mo区,提高耐蚀性。