7000系铝合金 (Al-Zn-Mg-Cu系) 具有低密度、高强度、高韧性等特点[1],在航空航天领域应用广泛。然而,由于其元素组成以及特定的微观组织结构特征,7000系合金容易发生点蚀、晶间腐蚀 (IGC) 和应力腐蚀开裂 (SCC) 等局部腐蚀[2]。通过合金化与调整热处理和时效制度,可以改善7000系铝合金的耐局部腐蚀性能。譬如,峰时效处理后,铝合金晶内存在大量弥散分布的η′相,这使得材料具有较高的强度,但是晶界上连续分布的η相会使材料的耐局部腐蚀性能变差,导致腐蚀沿晶间扩展。双级过时效工艺可以改变晶间η相的分布状态,使η相在晶间粗大断续分布,显著增强了铝合金的耐腐蚀能力,但以强度损失10%~15%为代价[3~5]。提高Zn和Mg含量可进一步提升7000系铝合金强度,但同样以牺牲耐蚀性能为代价。由此可见,强度与耐蚀性能之间的倒置关系在7000系合金中普遍存在。

解决铝合金强度与耐蚀性能倒置关系的一个思路是创新材料设计方法。合金化和热处理等传统方法制备的材料是一个均匀的块体,然而自然界中广泛存在的材料往往不是均匀的,而是具有梯度结构。经过几百万年甚至上亿年的进化,生物材料往往表现出多方面的优异性能,如强度和韧性的“完美”结合等。仅从材料科学的角度讲,生物材料实现人造材料无法达到的优异性能的原因之一是其多维结构的梯度化。螳螂虾的锤节以及蜘蛛的爪牙等是生物材料利用梯度结构获取优异性能的典型例子[6~8]。受自然界生物材料梯度化的启发,研究人员在结构材料的梯度化领域已经做了不少有益的尝试,如气相沉积[9]、自蔓延[10]、高温注入[11]、离子束掺杂[12]、表面渗氮[13]、增材制造[14]等技术已经被用以制备梯度结构材料。一些表面剧烈塑性变形技术如喷丸处理[15, 16]、超声喷丸处理[17]、滑动摩擦处理[18, 19]等表面处理技术可以将合金表层晶粒纳米化,而合金芯部组织结构不发生变化,从而获得从芯部到表层组织不断变化的纳米梯度结构材料[20]。人们已经利用多种表面机械处理技术提高铝合金的性能。通过表面机械处理技术在铝合金表面形成的表层纳米组织跟铝合金基体没有明显的界面分层,与传统的表面沉积技术相比更加稳定。表面机械处理技术在提升合金强度的同时,基体粗晶组织的存在还使其仍保留了良好的塑性,且合金的使用寿命可得到大幅度提升。Pandey等[21]研究了超声喷丸处理对7075铝合金腐蚀行为的影响。研究发现超声喷丸处理过的样品具有比未处理样更高的腐蚀电位和更低的电流密度,耐腐蚀性能的提升得益于超声喷丸处理后粗大析出相的细化、表层区域残余应力的引入以及表面更加致密均匀的钝化膜形成。遗憾的是,Pandey等[21]的研究中没有涉及7075铝合金的晶间腐蚀行为。相比于电化学腐蚀信息,晶间腐蚀性能对7000系铝合金更为关键,这是因为航空铝合金的应力腐蚀开裂行为往往与晶间腐蚀密切相关。Huo等[18]研究了经滑动摩擦处理 (SFT) 的7075铝合金,发现其机械强度和耐晶间腐蚀能力都有所提升,机械强度增加的原因主要是晶粒细化,耐晶间腐蚀能力的提升得益于SFT造成的晶粒细化以及晶界析出相和无沉淀析出带的消失。本课题组[22]研究了超声喷丸冲击能量对7150铝合金腐蚀行为的影响,结果表明超声喷丸对7150铝合金的局部腐蚀行为具有双重作用:当冲击能量足够高时,7150的局部腐蚀被完全抑制;而当冲击能量较低时,7150铝合金的耐局部腐蚀的能力并没有增强,晶间腐蚀扩展反而被梯度纳米结构加速。Bao等[23]研究了二次喷丸处理对7075铝合金腐蚀行为的影响,二次喷丸处理后7075铝合金的局部腐蚀坑数量和深度都有所减少,耐局部腐蚀能力增强,裂纹扩展被有效抑制,耐应力腐蚀性能增强。这是因为经二次喷丸处理的7075铝合金表面粗糙度有所下降,且具有更高的残余应力。

本文以国产7075铝合金棒材为研究对象,探究了超声喷丸处理对7075铝合金显微组织和硬度的影响,同时结合其晶间腐蚀行为以及不同深度的电化学腐蚀信息,讨论了超声喷丸处理对7075铝合金棒材的强化机制与腐蚀机理。

1 实验方法

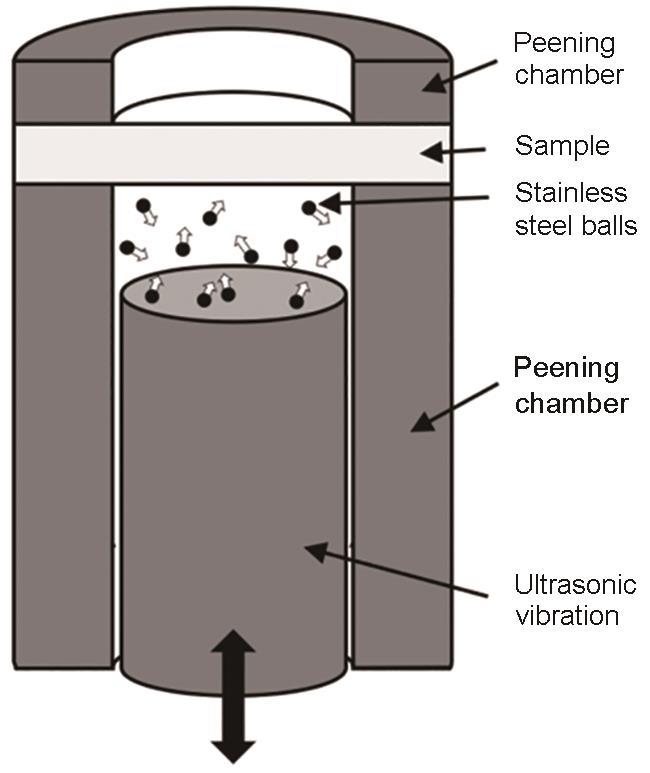

实验材料为7075-T6铝合金棒材 (恒瑞铝业),其成分 (质量分数,%) 为:Zn 5.5,Mg 2.3,Cu 1.9,Si 0.4,Fe 0.5,Mn 0.3,Cr 0.2,Zr 0.2,其他0.15,Al余量。采用线切割机加工成直径30 mm、厚度5 mm的圆形样品,之后依次用400#、600#、1000#、1500#的砂纸进行打磨,最后超声清洗。超声喷丸装置示意图如图1所示,对所得样品在不锈钢制圆柱形腔室进行超声喷丸处理。所用喷丸材质为304不锈钢,振子以20 kHz的频率振动,带动喷丸高速撞击样品,使样品表面产生剧烈的塑性变形。超声喷丸处理的能量会影响样品塑性变形层的厚度,而冲击的能量又主要受喷丸直径、冲击距离、超声振幅和冲击时间的影响。本研究中选用喷丸直径为3 mm,超声振幅为60 μm,冲击时间是8 min。选取不同的冲击距离 (15、25、40和60 mm) 探究了冲击能量对7075铝合金硬化层厚度的影响,并将冲击距离为15 mm的高能喷丸样用于后续电化学腐蚀和晶间腐蚀测试。

图 1

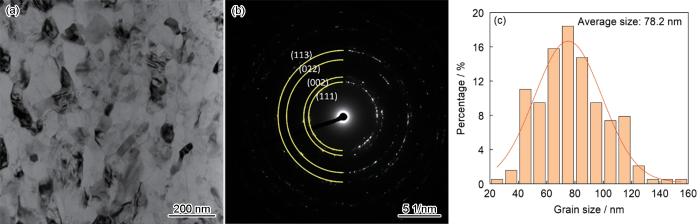

将喷丸处理后的样品进行切割,使用环氧树脂封装,并露出样品截面,依次用400#、600#、1000#、1500#、2000#的砂纸进行打磨,0.5 μm Al2O3抛光,超声清洗备用。采用凯勒试剂 (0.5% HF+l.5% HCl+2.5% HNO3+95.5% H2O) 侵蚀以在Axiolab5型光学显微镜下观察其金相组织。利用CuKα 辐射的TD-3500型X射线衍射仪 (XRD) 以2.4°/min的2θ扫描速率获得样品的XRD结果,对比喷丸前后样品表层相组成的变化。采用聚焦离子束-电子束双束系统 (FEI Scios) 制备厚度小于200 nm的薄膜,采用透射电子显微镜 (TEM, JEM-3200FS) 和选区电子衍射 (SAED) 技术分别获取表层纳米晶的形貌与衍射信息。

选用HM101显微硬度仪测试距喷丸面不同深度的硬度值。每个深度处选取5个位置测量硬度并求平均值,为避免应变强化的影响,不同点位间的距离超过压痕对角线距离的5倍,所用载荷为20 g,加载时间为10 s。

选用CHI 660电化学工作站测试样品在室温下的开路电位-时间曲线 (OCP)、电化学阻抗谱 (EIS) 和极化曲线。将电化学工作站连接到三电极体系,工作电极为7075铝合金试样,对电极为Pt片,参比电极是Ag/AgCl电极,工作电极接触到电解质溶液的面积是1 cm2。根据需要,采用千分尺辅助打磨7075铝合金喷丸样品至一定厚度,最终以Al2O3镜面抛光收尾,研究喷丸样不同深度区域的电化学腐蚀行为。分别采用0.1 mol/L Na2SO4+20 mmol/L NaCl溶液 (为了得到明显的点蚀电位) 以及3.5% NaCl溶液为电化学腐蚀测试溶液。静置20 min等待体系稳定,然后进行开路电位-时间曲线测试,测试时间为1200 s。待OCP稳定后,进行EIS测试,选用频率范围为105~1 Hz,施加的电位扰动为±5 mV。使用ZView软件对EIS结果进行拟合。随后,进行极化曲线测试,扫描速率为0.3 mV/s。所有的电化学测试均在Faraday电笼中进行。

根据ASTM G110-92标准,在57 g/L NaCl+10 mL/L HCl (37%) 溶液中进行晶间腐蚀测试。室温下,将样品浸入溶液中分别浸泡6 h,之后用凯勒试剂侵蚀样品截面,以观察喷丸面和未处理面的晶间腐蚀形貌差异。

2 实验结果

2.1 金相组织

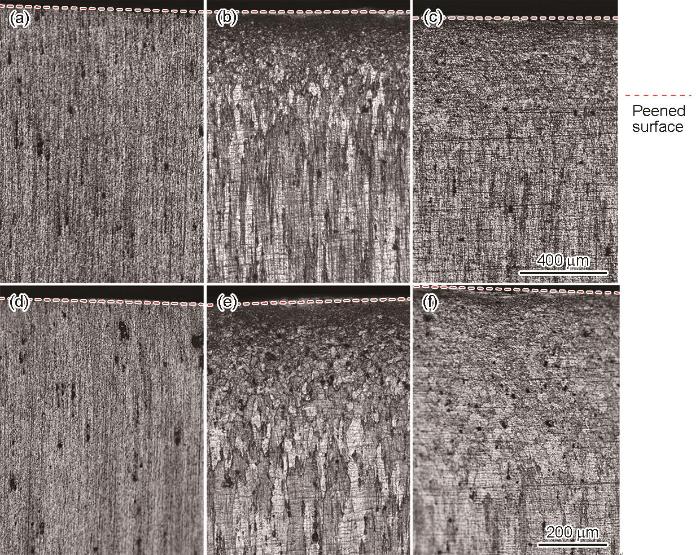

图2

图2

不同冲击距离的超声喷丸7075铝合金截面金相图片

Fig.2

Cross-sectional metallographic graphs of USSPed 7075 Al-alloy with 40 mm (a, d), 25 mm (b, e) and 15 mm (c, f) impact distances

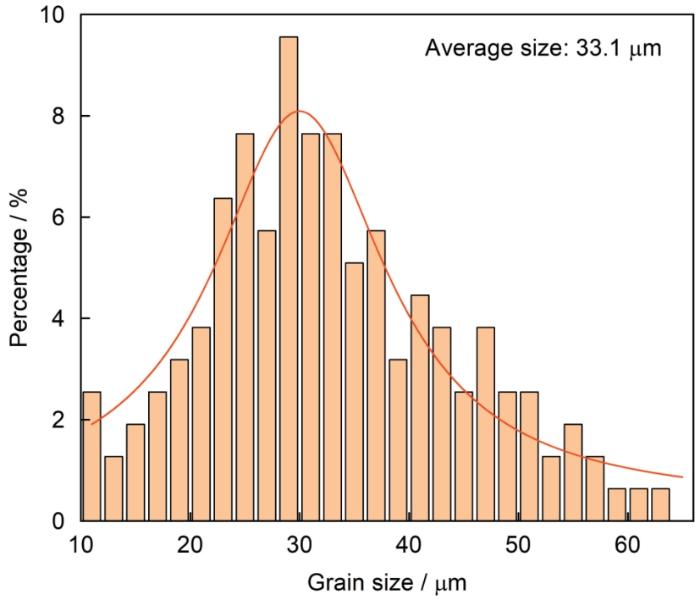

图3

2.2 XRD

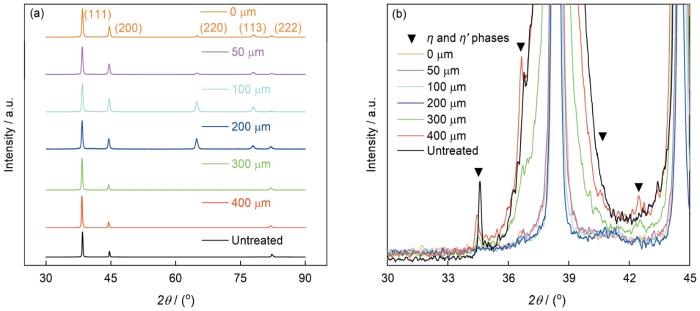

图4给出了7075铝合金在超声喷丸处理前后的XRD结果。为了研究喷丸样在不同深度处的相组成变化,对冲击距离为15 mm的7075铝合金喷丸样分别打磨0、50、100、200、300和400 μm深度,然后进行XRD测试。可以看出,7075铝合金未处理样XRD结果显示出明显的棒材择优取向面(111),且未有(220)面和(311)面的峰出现。喷丸处理后的样品表面XRD结果与铝的计算结果接近,原因是超声喷丸处理后表层的粗大纤维状晶粒破碎并细化为纳米等轴晶。另外,若未处理样中的粗大析出相细化至尺寸过小,或是其回溶进基体,距喷丸表面越近时,代表η相和η′相(MgZn2)的衍射峰强度会逐渐降低,直至消失,如图4b。结合图5 TEM结果,未在表层观察到破碎后弥散分布的细小析出相,这表明在超声喷丸处理后,7075铝合金表层的时效析出强化相出现了回溶。

图4

图4

7075铝合金棒材在超声喷丸处理前后的XRD

Fig.4

XRD patterns of 7075 Al-alloy before and after USSP treatment (0, 50, 100, 200, 300 and 400 μm are the subsequent polishing depths of USSPed samples)

图5

图5

超声喷丸处理后7075铝合金棒材表层约5 μm处的TEM结果

Fig.5

TEM images of the USSPed 7075 Al-alloy at ~5 μm to surface: (a) bright field TEM, (b) corresponding selected area electron diffraction, (c) statistical results of grain size

2.3 TEM

2.4 硬度测试

图6显示了超声喷丸处理后7075铝合金的显微硬度在深度方向上的变化趋势。该试样的冲击距离为15 mm,最表层的显微硬度值约为203 HV,且随着深度的增加硬度逐渐降低。在深度约为1200 μm处,硬度降至168 HV左右,即7075铝合金基体的硬度。因此,该喷丸试样的表层硬化深度约为1200 μm。7075铝合金表层的喷丸强化机制将在讨论部分进行探讨。

图6

图6

超声喷丸处理后7075铝合金棒材的硬度-深度曲线

Fig.6

Hardness-depth profile of 7075 Al-alloy rod after USSP treatment

2.5 电化学腐蚀测试

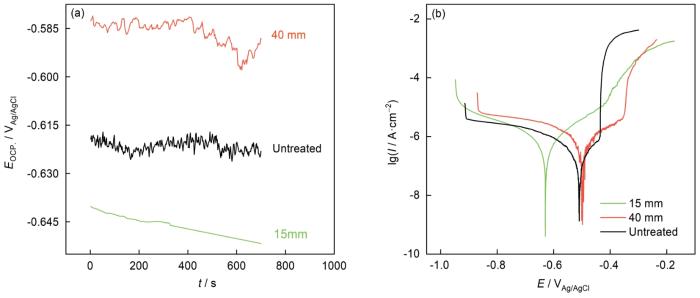

对7075铝合金棒材未处理样、冲击距离40与15 mm的喷丸样进行开路电位与极化曲线测试,结果如图7所示。为了获得明显的点蚀电位,采用0.1 mol/L Na2SO4+20 mmol/L NaCl溶液为腐蚀电介质[24, 25]。随着冲击距离的减少,冲击能量增加,7075铝合金的开路电位先正移后负移,同时自腐蚀电位变化趋势跟开路电位也相符合,这主要与超声喷丸处理引起的表层元素偏析有关[26]。相比于未处理样,喷丸样的点蚀电位都变得更正,说明7075铝合金耐点蚀诱发的能力得到了增强。然而,7075铝合金棒材在超声喷丸处理后的自腐蚀电流密度增大至未处理样的4倍以上,这是由于超声喷丸过程中不可避免地引入了外来杂质的缘故[27]。作者所在课题组在前期研究中确定外来杂质主要是非晶态的富含铁氧的混合物[28],且随着喷丸能量的提升,在样品表层引入的杂质含量越多。由表1可见,冲击距离为40 mm的7075铝合金喷丸样能量较小,引入的杂质较少,故相比于冲击距离为15 mm的喷丸样 (-0.42 VAg/AgCl),其点蚀电位更正 (-0.35 VAg/AgCl)。

图7

图7

未处理样和不同冲击距离7075铝合金喷丸样在0.1 mol/L Na2SO4+20 mmol/L NaCl溶液中的开路电位-时间曲线与极化曲线

Fig.7

Open circuit potential-time curves (a) and polarization curves (b) of the untreated and peened 7075 Al-alloy with different impact distances in 0.1 mol/L Na2SO4+20 mmol/L NaCl

表1 未处理样和不同冲击距离7075铝合金喷丸样的极化曲线参数

Table 1

| Sample | Ecorr / VAg/AgCl | Icorr / 10-7 A·cm-2 | Epit / VAg/AgCl |

|---|---|---|---|

| Untreated | -0.51 | 1.64 | -0.44 |

| USSP_15 mm | -0.63 | 6.55 | -0.42 |

| USSP_40 mm | -0.49 | 6.92 | -0.35 |

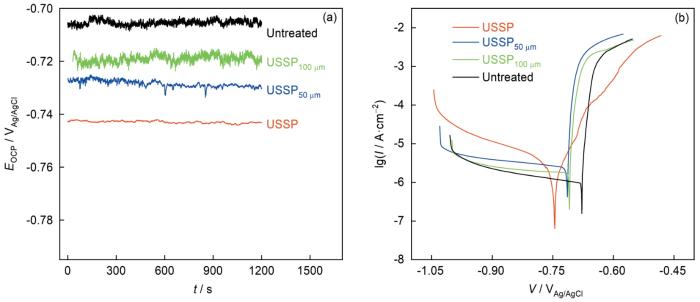

为进一步研究外来污染以及表层组织改变对7075铝合金电化学腐蚀性能的影响,将超声喷丸处理样品从表面打磨至不同的深度 (0、50、100 μm),再分别进行开路电位、极化曲线以及EIS测试,腐蚀测试溶液为室温下的3.5% NaCl溶液。测得的开路电位-时间曲线和极化曲线如图8所示。与未处理区域相比,喷丸样表面具有更负的开路电位,随着更接近基体部分,开路电位逐渐正移。此外,从极化曲线中得到的自腐蚀电位的趋势与开路电位的趋势较为吻合。因此,若在喷丸处理后的表面出现了局部腐蚀,表层与次表层/基体之间会产生电偶作用,喷丸样的表面充当阳极,对合金基体提供阳极保护。从表2结果可知,相比于喷丸样表面 (1.6×10-7 A·cm-2),抛光去除50 和100 μm表层的样品的腐蚀速率均出现大幅度下降,这充分说明了外来杂质污染对喷丸样腐蚀行为的影响。相比于抛光去除50和100 μm表层的喷丸样品,7075未处理样的自腐蚀电流密度最小,这证明喷丸引起的组织变化加速了7075铝合金棒材在3.5% NaCl溶液中的腐蚀。

图8

图8

7075铝合金未处理样和喷丸样在3.5%NaCl溶液中的开路电位-时间曲线和极化曲线

Fig.8

Open circuit potential-time curves (a) and polarization curves (b) of the untreated and peened 7075 Al-alloy (with surface being polished off 0, 50, 100 μm) in 3.5%NaCl solution

表2 7075铝合金棒材未处理样和喷丸样在3.5%NaCl溶液中极化曲线的参数

Table 2

| Sample | Ecorr / V | Icorr / 10-6 A·cm-2 |

|---|---|---|

| USSP_0 μm | -0.75 | 3.83 |

| USSP_50 μm | -0.71 | 2.36 |

| USSP_100 μm | -0.70 | 1.72 |

| Untreated | -0.68 | 0.97 |

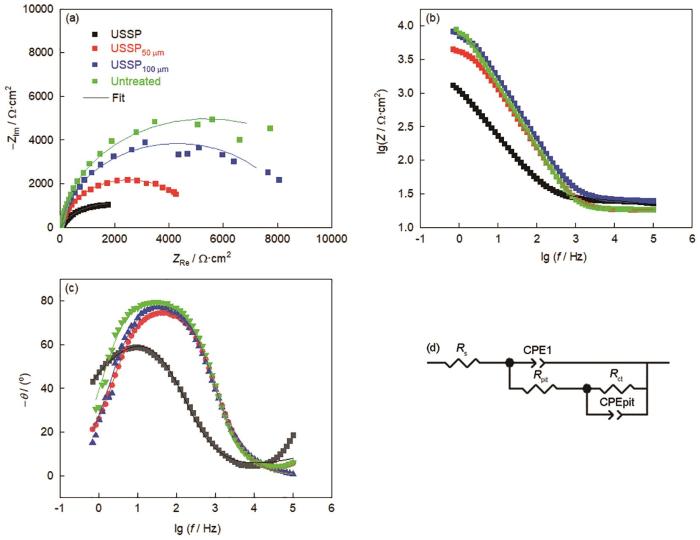

图9

图9

7075铝合金未处理样和喷丸样在3.5%NaCl溶液中的EIS结果

Fig.9

Nyquist plot (a) and Bode plots (b, c) and equivalent circuit model (d) of the untreated and peened 7075 Al-alloy (without and with surface being polished off 0, 50, 100 μm)

表3 图9中EIS的拟合结果

Table 3

| Sample | Rs Ω·cm2 | Y1 Ω-1·cm-2·S n | α1 | Rpit Ω·cm2 | Rct Ω·cm2 | Ypit Ω-1·cm-2·S n | αpit |

|---|---|---|---|---|---|---|---|

| USSP_0 μm | 2.21 | 3.43×10-8 | 0.98 | 22.37 | 3.05×103 | 1.97×10-4 | 0.75 |

| USSP_50 μm | 17.36 | 1.29×10-6 | 0.99 | 18.31 | 5.04×103 | 1.84×10-5 | 0.89 |

| USSP_100 μm | 18.34 | 1.94×10-6 | 0.97 | 25.93 | 8.75×103 | 1.23×10-5 | 0.93 |

| Untreated | 27.01 | 1.11×10-7 | 0.95 | 25.85 | 1.08×104 | 1.27×10-5 | 0.92 |

2.6 晶间腐蚀测试

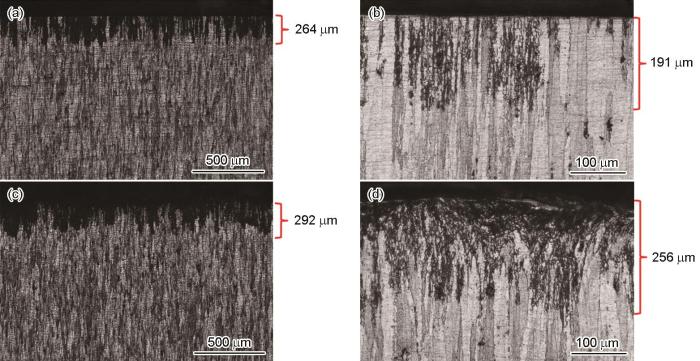

晶间腐蚀测试后7075铝合金的截面腐蚀形貌如图10所示。在浸泡6 h后的未处理样 (图10a) 和喷丸样 (图10b) 中都观察到了剧烈的晶间腐蚀,且喷丸样的晶间腐蚀深度更深,从264 μm增加到292 μm。需要说明的是,6 h浸泡后合金的晶间腐蚀过于严重,表层已经形成了轻微的剥落腐蚀。为了更清楚地揭示喷丸处理对7075耐晶间腐蚀能力的影响,增加了浸泡2 h的实验组,此时样品表面都已有晶间腐蚀出现,但未形成剥落腐蚀,如图10b和d所示。可见,浸泡2 h后,喷丸样的平均晶间腐蚀深度为256 μm,而未处理样的平均晶间腐蚀深度为191 μm,且出现晶间腐蚀的区域面积更少。图10所示的结果充分说明,经超声喷丸处理之后,7075铝合金棒材的耐晶间腐蚀能力降低。

图10

图10

7075铝合金在晶间腐蚀测试后的截面光镜形貌

Fig.10

Cross-sectional optical micrographs of 7075 Al- alloys after IGC test: (a) 6 h and (b) 2 h immersion of the untreated sample, (c) 6 h and (d) 2 h immersion of the peened sample

3 讨论

3.1 表层强化机制

经超声喷丸处理后,7075铝合金棒材引入了多重强化机制,如细晶强化、加工硬化等,并在几种机制的协同影响下才最终决定了材料的强度。晶粒细化后的合金强度遵从Hall-Petch关系:

式中,σ为材料的强度,d为晶粒的尺寸,σ0为与材料相关的强度常数,k为常数,在超声喷丸处理后,表层区域的微米级晶粒破碎、细化,变为纳米等轴晶,即d减小,从而提高材料的强度。同时,喷丸处理在表层区域引入了高密度的位错缺陷,起到了加工硬化的作用。

众所周知,常规7075铝合金的高强度主要来源于时效析出强化效应。然而,XRD结果显示,喷丸处理过程中7075铝合金的强化析出相出现了回溶。超声喷丸处理后析出相的溶解可归因于Gibbs-Thomson效应[29]:

如

3.2 腐蚀机理

IGC实验表明,超声喷丸处理后7075铝合金耐晶间腐蚀能力下降。这一结果与文献中超声喷丸7150[30]和7075铝合金[31]的结果不一致。本课题组[22]研究表明,超声喷丸处理造成的表层晶粒细化对于晶间腐蚀有双重作用:对于未处理样,其晶粒呈纤维状,被腐蚀后会出现较大直径的点蚀坑,喷丸处理后,由于表层纳米等轴晶的存在,其点蚀发生时间会比未处理样更慢,但是由于其点蚀坑直径更小,因此腐蚀产物容易堆积在腐蚀坑处,使得点蚀坑更加闭塞,一旦形成局部腐蚀,其扩展速率反而会被梯度纳米结构加速。超声喷丸处理时的能量会影响晶间腐蚀能力[22],高能喷丸处理可以全面抑制合金晶间腐蚀,而低能喷丸样的晶间腐蚀反而进一步加剧,会发展成为更深的针状点蚀坑。因此,超声喷丸处理后的7075铝合金耐晶间腐蚀能力下降可能是由于: (1) 超声喷丸处理所用能量不够。由于“双刃剑”作用的存在,喷丸能量较低时7075铝合金晶间腐蚀能力较弱,所以在使用超声喷丸处理调控7075铝合金的耐晶间腐蚀能力时,要注意选取合适的喷丸处理参数。(2) 超声喷丸处理过程中7075铝合金微观组织结构的改变不同于其他铝合金,未起到改善耐晶间腐蚀能力的作用。由于成分的不同,喷丸处理后晶内或晶界析出相以及晶界无沉淀析出带的行为也会有差异[32],若表层细晶层的晶界析出相以及晶界无沉淀析出带未有明显减少,喷丸处理将无法起到改善耐晶间腐蚀能力的作用。

4 结论

(1) 通过超声喷丸处理技术,在7075铝合金棒材粗晶样品上成功制备了表层晶粒尺寸约为78.2 nm的梯度纳米结构,且超声喷丸处理后,原本存在的时效析出强化相 (η和η′相) 回溶到铝基体中。

(2) 超声喷丸处理后,7075铝合金棒材的表层硬度由168 HV增加至203 HV,提升了约20%。表层硬度改变是细晶强化、加工硬化与析出相回溶软化效应互相竞争的结果。

(3) 超声喷丸处理后7075铝合金棒材的耐点蚀萌生能力增强,但其腐蚀速率增加,耐晶间腐蚀能力减弱。

参考文献

Nanoparticle promoted solution treatment by reducing segregation in AA7034

[J].

Microstructure, corrosion behaviour and thermal stability of AA 7150 after ultrasonic shot peening

[J].

Investigation of mechanical and corrosion properties of an Al-Zn-Mg-Cu alloy under various ageing conditions and interface analysis of η′ precipitate

[J].

Correlations between intergranular stress corrosion cracking, grain-boundary microchemistry, and grain-boundary electrochemistry for Al-Zn-Mg-Cu alloys

[J].

Effect of heat treatment on strength, exfoliation corrosion and electrochemical behavior of 7085 aluminum alloy

[J].

Textured fluorapatite bonded to calcium sulphate strengthen stomatopod raptorial appendages

[J].Stomatopods are shallow-water crustaceans that employ powerful dactyl appendages to hunt their prey. Deployed at high velocities, these hammer-like clubs or spear-like devices are able to inflict substantial impact forces. Here we demonstrate that dactyl impact surfaces consist of a finely-tuned mineral gradient, with fluorapatite substituting amorphous apatite towards the outer surface. Raman spectroscopy measurements show that calcium sulphate, previously not reported in mechanically active biotools, is co-localized with fluorapatite. Ab initio computations suggest that fluorapatite/calcium sulphate interfaces provide binding stability and promote the disordered-to-ordered transition of fluorapatite. Nanomechanical measurements show that fluorapatite crystalline orientation correlates with an anisotropic stiffness response and indicate significant differences in the fracture tolerance between the two types of appendages. Our findings shed new light on the crystallochemical and microstructural strategies allowing these intriguing biotools to optimize impact forces, providing physicochemical information that could be translated towards the synthesis of impact-resistant functional materials and coatings.

The stomatopod dactyl club: a formidable damage-tolerant biological hammer

[J].Nature has evolved efficient strategies to synthesize complex mineralized structures that exhibit exceptional damage tolerance. One such example is found in the hypermineralized hammer-like dactyl clubs of the stomatopods, a group of highly aggressive marine crustaceans. The dactyl clubs from one species, Odontodactylus scyllarus, exhibit an impressive set of characteristics adapted for surviving high-velocity impacts on the heavily mineralized prey on which they feed. Consisting of a multiphase composite of oriented crystalline hydroxyapatite and amorphous calcium phosphate and carbonate, in conjunction with a highly expanded helicoidal organization of the fibrillar chitinous organic matrix, these structures display several effective lines of defense against catastrophic failure during repetitive high-energy loading events.

Functional gradients and heterogeneities in biological materials: Design principles, functions, and bioinspired applications

[J].

Corrosion resistance of multilayer and gradient coatings deposited by PVD and CVD techniques

[J].

Self-propagating high-temperature synthesis of gradient transitional layer between ceramics and metal

[J].

陶瓷与多种梯度过渡层的自蔓延高温合成

[J].

Gradients in elastic modulus for improved contact-damage resistance. Part I: The silicon nitride-oxynitride glass system

[J].

Ion beam doping of silicon nanowires

[J].We demonstrate n- and p-type field-effect transistors based on Si nanowires (SiNWs) implanted with P and B at fluences as high as 10(15) cm (-2). Contrary to what would happen in bulk Si for similar fluences, in SiNWs this only induces a limited amount of amorphization and structural disorder, as shown by electrical transport and Raman measurements. We demonstrate that a fully crystalline structure can be recovered by thermal annealing at 800 degrees C. For not-annealed, as-implanted NWs, we correlate the onset of amorphization with an increase of phonon confinement in the NW core. This is ion-dependent and detectable for P-implantation only. Hysteresis is observed following both P and B implantation.

Nitriding iron at lower temperatures

[J].The microstructure in the surface layer of a pure iron plate was refined at the nanometer scale by means of a surface mechanical attrition treatment that generates repetitive severe plastic deformation of the surface layer. The subsequent nitriding kinetics of the treated iron with the nanostructured surface layer were greatly enhanced, so that the nitriding temperature could be as low as 300 degrees C, which is much lower than conventional nitriding temperatures (above 500 degrees C). This enhanced processing method demonstrates the technological significance of nanomaterials in improving traditional processing techniques and provides a new approach for selective surface reactions in solids.

Additive manufacturing of biologically-inspired materials

[J].Additive manufacturing (AM) technologies offer an attractive pathway towards the fabrication of functional materials featuring complex heterogeneous architectures inspired by biological systems. In this paper, recent research on the use of AM approaches to program the local chemical composition, structure and properties of biologically-inspired materials is reviewed. A variety of structural motifs found in biological composites have been successfully emulated in synthetic systems using inkjet-based, direct-writing, stereolithography and slip casting technologies. The replication in synthetic systems of design principles underlying such structural motifs has enabled the fabrication of lightweight cellular materials, strong and tough composites, soft robots and autonomously shaping structures with unprecedented properties and functionalities. Pushing the current limits of AM technologies in future research should bring us closer to the manufacturing capabilities of living organisms, opening the way for the digital fabrication of advanced materials with superior performance, lower environmental impact and new functionalities.

Effect of shot peening and plasma electrolytic oxidation on the intergranular corrosion behavior of 7A85 aluminum alloy

[J].

Review of shot peening processes to obtain nanocrystalline surfaces in metal alloys

[J].

Ultrasonic shot peening

[J].

Simultaneously enhanced mechanical strength and inter-granular corrosion resistance in high strength 7075 Al alloy

[J].

The origin of surface microstructure evolution in sliding friction

[J].

Gradient nanostructured materials

[J].In this paper, research progresses on gradient nanostructured materials in recent years is briefly reviewed. It includes classification of gradient nanostructures, properties and processing techniques of the gradient nanostructured materials. Perspectives and challenges on scientific understanding and industrial applications of gradient nanostructured materials are addressed.

梯度纳米结构材料

[J].

Influence of ultrasonic shot peening on corrosion behavior of 7075 aluminum alloy

[J].

Localized corrosion behaviour of AA7150 after ultrasonic shot peening: Corrosion depth vs. impact energy

[J].

Surface characteristics and stress corrosion behavior of AA 7075-T6 aluminum alloys after different shot peening processes

[J].

Effect of trace chloride and temperature on electrochemical corrosion behavior of 7150-T76 Al alloy

[J].

微量Cl-和温度对7150-T76铝合金电化学腐蚀性能的影响

[J].利用开路电位、循环极化法和腐蚀形貌表征研究了微量Cl<sup>-</sup>与温度对7150-T76超高强度铝合金电化学腐蚀性能的影响。结果表明:低温低Cl<sup>-</sup>浓度的溶液中,铝合金主要发生点蚀;温度升高、Cl<sup>-</sup>浓度增大,晶间腐蚀的倾向逐渐变大。微量Cl<sup>-</sup>(20 mmol/L) 致使开路电位 (OCP) 显著负移;温度升高OCP逐渐降低,且在60~70 ℃温度范围内发生突变,表明腐蚀机理发生变化。还分析了循环极化曲线的各个电位和电流密度参数随Cl<sup>-</sup>浓度和温度的变化。点蚀转换电位E<sub>ptp</sub>的出现表明被侵蚀后的铝合金表面的钝化是分步进行的,E<sub>ptp</sub>随Cl<sup>-</sup>浓度的增大逐渐负移。自腐蚀电流密度随温度的升高先增大再减小,而自腐蚀电位逐渐负移,均可归因于高温溶液中溶解氧减少的缘故。此外,也论证了自腐蚀电位和再钝化电位的差值ΔE<sub>3</sub>(E<sub>corr</sub>-E<sub>rep</sub>) 作为评价局部腐蚀发展程度标准的局限性。

Link between pitting potentials and stress cracking corrosion susceptibility of 7150 Al Alloy with Different Ageing Processes

[J].

不同热处理7150铝合金的点蚀电位与应力腐蚀敏感性

[J].

Long distance chemical gradient induced by surface nanocrystallization

[J].Natural structures are wonderful examples of what can be done with a fairly limited selection of resources. Natural structures have this feature due to their complex architecture, gradient chemical compositions and microstructure. Inspired by nature, many attempts have been made to manufacture man-made materials with similar gradients (e.g. surface nanocrystallization by severe surface plastic deformation (S2PD)). Gradient microstructure of alloys manufactured by the S2PD techniques has been very well studied. However, the distribution of chemical compositions within the alloy after the S2PD treatment has rarely been explored. The current work found that by using S2PD combined with one-year long natural aging treatments, the microstructure and chemical composition of the Al-Zn-Mg-Cu alloy (7034 Al alloy) exhibited a new gradient distribution measured from the treated surface to the pristine interior. Zn (Cu) content on the surface layer increased from 10.2 (1.3) to 57.7 (5.9) wt.%, along with an Mg surface layer depletion after treatments. The thickness of the observed chemical gradient layer was surprisingly as thick as 45 vm. Also observed were the similar phenomena in other alloys after the same treatments. The findings provide potential improvements in bioinspired materials manufacturing, rare resource saving and surface functionalization. (C) 2018 Elsevier Ltd.

The effect of surface contamination on corrosion performance of ultrasonic shot peened 7150 Al alloy

[J].

Microstructure, corrosion behavior and hydrogen evolution of USSP processed AZ31 magnesium alloy with a surface layer containing amorphous Fe-rich composite

[J].

Gibbs-Thomson effects in phase transformations

[J].

Nanoscale corrosion investigation of surface nanocrystallized 7150 Al alloy in 3.5 wt% NaCl solution by using FIB-TEM techniques

[J].

Role of gradient nano-grained surface layer on corrosion behavior of aluminum 7075 alloy

[J].Gradient nano-grained structures have been a promising technique to evade the strength-ductility trade-off in metals and alloys. Therefore, in this work, the effect of surface mechanical attrition treatment (SMAT) on the microstructure and corrosion behavior of the high-strength aluminum alloy was investigated. SMAT was performed at room temperature and liquid-nitrogen (LN2) flow conditions to generate two distinctly different initial gradient microstructures. Potentiodynamic polarization, electrochemical impedance spectroscopy, and intergranular corrosion tests were performed. Surface film characterization of untreated and treated samples was performed using X-ray photoelectron spectroscopy and time of flight secondary ion mass spectroscopy techniques. Result reveals significant microstructural changes in SMAT processed samples such as the formation of precipitates and dissolution of inherent phases. In addition, a reduced anodic dissolution rate was observed with the SMAT processed samples. Furthermore, the surface film characterization revealed a thicker oxide film with Cu and SiO2 enrichment in SMAT samples.