在油气开采过程中,由于地层疏松和加砂压裂开采方式,地层中的砂砾会随流体进入集输管线,发生严重的冲刷腐蚀,进而引起管线的减薄甚至穿孔,导致严重的安全事故和经济损失。据相关数据统计,冲刷腐蚀引起的腐蚀穿孔占我国集输管线腐蚀穿孔事故的80%[1~6]。据雅克拉凝析气田的相关数据统计,站场内的管线在投产3年中发生了28次腐蚀穿孔事故[7]。同时,当前国内的油气田开发大多进入高含水期,回注水和沉积物中会携带大量的硫酸盐还原菌 (SRB),我国区域所处纬度适宜SRB菌群生长。研究者们研究表明,SRB腐蚀是危害最大的微生物腐蚀[8~17]。在中国新疆的一条X52钢输油管道,因SRB在管道沉积物下的大量繁殖导致管道腐蚀失效发生爆管泄漏。所以研究集输管线的冲刷腐蚀和SRB腐蚀非常重要。

1 实验方法

选取现场常用的集输管线钢L360作为实验材料,其化学成分(质量分数,%)为:C 0.25,Si 0.32,P 0.025,S 0.015,Ti、V、Nb<0.1,Fe余量。

数值模拟中选用ANSYS 2020R1中的Fluent进行计算流体动力学 (CFD) 模拟。模拟主要分为3部分:预处理 (实验管道的几何数据:管径Φ60 mm×5 mm,实际长度L=200 mm;管道两端分别设为inlet、outlet,壁面设为工作面wall,用Mesh功能对管段模型划分网格,再用Smooth Transition边界层模型,划分后生成网格总数为233477个);求解 (选用Standard类型的k-ε模型、入口处边界条件设为velocity-inlet,设置入口流速;出口处边界条件设为pressure-outlet,出口压力为0 Pa;壁面类型设置为固定无滑移壁面);后处理 (求解方法及控制均采用默认值,残差曲线各量精度均取0.0001,设置完成后点击初始化,进行迭代求解)。

采用自制的环路测试系统模拟集输管线冲刷腐蚀实验。实验装置由变频清水泵、测试管段、水箱和橡胶软管等组成。清水泵为实验介质的循环流动提供动力,通过变频器控制泵控制流速。测试管段由内径50 mm的PC管制成,在测试段安装工作电极、辅助电极和参比电极。实验介质采用模拟地层水:SRB菌液=3∶1的溶液 (模拟地层水成分:KCl 0.54 g/L、NaCl 17.24 g/L、NaHCO3 3.98 g/L、Na2SO4 0.37 g/L、MgCl2 0.5 g/L、CaCl2 0.43 g/L;SRB培养基[21]:乳酸钠4 mL/L,酵母粉1 g/L,抗坏血酸0.1 g/L,七水合硫酸镁0.2 g/L,磷酸氢二钾0.01 g/L,六水合硫酸亚铁铵0.2 g/L,氯化钠10 g/L),实验流速根据CFD模拟结果设定为1.5 m/s,实验温度为35 °C。

将工作电极用环氧树脂封装后分别用400#、800#、1200#和1500#砂纸逐级打磨,使用前用N2吹干。试样1 (未预膜试样) 直接放入模拟地层水+SRB菌的混合腐蚀溶液中进行后续电化学实验;试样2 (SRB预膜试样) 在SRB菌液中浸泡1 d后(膜厚大约8μm) 再放入腐蚀溶液中进行电化学测试(开路电位 (OCP)、电化学阻抗谱 (EIS) 和极化)。采用ZEISS EV0 MA15扫描电子显微镜 (SEM) 表征不同腐蚀产物膜的表面形貌和元素组成。

通过绝迹稀释法中的3次重复法测试不同时刻溶液中SRB的浓度 (每一组设置10个装有9 mL API RP-38液体培养基的10 mL西林瓶,编号为1~10,分别对应不同的稀释等级。后一瓶分别对前一瓶的试样稀释10倍,每组做3次平行实验)。

2 结果与分析

2.1 CFD模拟

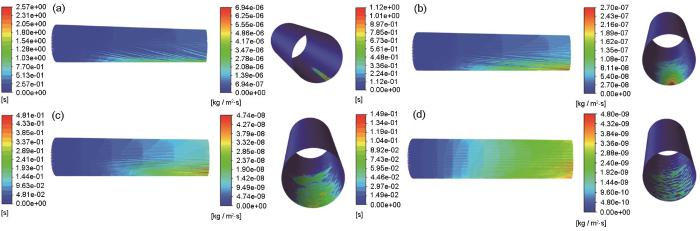

图1是腐蚀介质以0.6、1、1.5和2 m/s (颗粒0.3 mm,0.15%,Total Flow Rate为0.011 kg/s) 流动时CFD模拟得到的管道内壁腐蚀区域预测云图和固体粒子运动轨迹线图。由固体粒子运动轨迹线图可知:在重力作用影响下,固体粒子出现在管道底部的概率大于管道顶部,且越靠近出口处沉积现象越明显,因此在腐蚀预测云图中管道底部腐蚀较顶部严重、管道出口处腐蚀较入口处严重;因流体速度越大携带能力越强,随着入口流速的增加,粒子在底部的沉积现象变弱,其在管内的分布更均匀。结合腐蚀速率预测云图可知,粒子浓度越大的位置,冲刷腐蚀速率越大。

图1

图1

不同入口流速的粒子迹线图和腐蚀预测云图

Fig.1

Particle traces and corrosion area at different inlet velocities: (a) 0.6 m/s, (b) 1 m/s, (c) 1.5 m/s, (d) 2 m/s

在流体速度小于1.5 m/s时,腐蚀区域面积扩大,局部腐蚀程度减小;因介质流速超过1.5 m/s时,流速增大使固体颗粒被携出测试管段的倾向增大,减少了其与壁面发生碰撞的几率,使整体腐蚀速率变小。因此,后续电化学测试选取1.5 m/s的流速。

2.2 OCP

图2为35 ℃下L360钢试样在有无SRB预膜情况下的OCP随时间变化曲线。由图可知,未预膜试样OCP随冲刷时间延长产生负移,4 h后电位基本达到稳定,未预膜试样OCP负移是由于流体的冲刷作用导致腐蚀溶液中的SRB不能很好的吸附在金属表面形成具有保护性的膜层,在流体冲刷作用下金属发生腐蚀;4 h后随着腐蚀位点的形成,为SRB在金属表面的附着创造了条件,试样表面形成的腐蚀产物膜和微生物膜减弱了碳钢表面的传质过程,OCP逐渐达到稳定。与初始相比,流体冲刷8 h后试样OCP负移约50 mV。预膜试样因预先在SRB菌液中已形成较为均匀的膜层,使试样有较好抵挡流体冲刷的能力;其OCP在测试时间内较为稳定。

图2

2.3 EIS

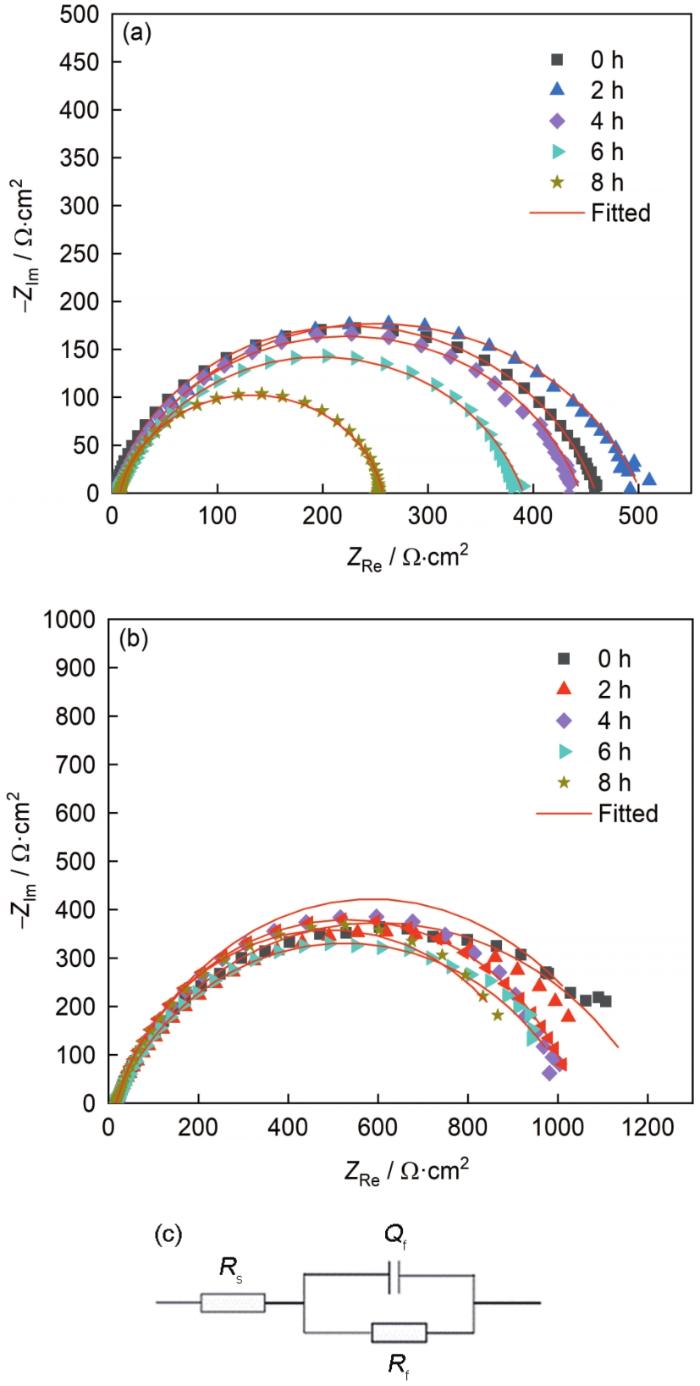

未预膜试样在环路内不同时间的EIS如图3a所示。由图可知,未预膜试样Nyquist图是近半圆的圆弧,随着时间延长,阻抗弧半径呈现先增大后减小的趋势。4 h前,随着腐蚀的进行,金属表面逐渐形成具有一定保护能力的产物膜,使其腐蚀速率减小;4 h后,阻抗逐渐减小;表明随着时间的延长,金属腐蚀加重,这与OCP测试结果一致。预膜试样在环路内不同时间的EIS如图3b所示。由图可知,随着流动时间延长,阻抗弧半径有所减小,腐蚀速率增大。与未预膜组相比,预膜后电极的交流阻抗值大于未预膜的整体交流阻抗值。这表明SRB预膜后的工作电极在流体冲刷作用下的腐蚀速率小于未预膜的工作电极,生物膜对金属的保护作用大于微生物导致的腐蚀作用。

图3

图3

试样不同时间的电化学阻抗谱图及等效电路模型图

Fig.3

EIS of samples at different test time without (a) and with (b) SRB pre-film, and equivalent circuit (c)

用图3c所示等效电路图对EIS进行拟合,Qf为与腐蚀产物层电容相关的恒相位元件;Rf为腐蚀产物层的电阻,相应的拟合参数见表1。可知,未预膜试样随冲刷时间延长,Rf先增大后减小,试样腐蚀4 h时,膜层电阻达到最大,表明此时金属表面形成的腐蚀产物膜使其腐蚀速率降低;Rf值在4 h后迅速减小,说明长时间的冲刷破坏了金属表面的混合膜,腐蚀速率增大,这与上述Nyquist图结果一致。预膜试样因表面已生成的生物膜和腐蚀产物膜,在实验室时间内阻抗谱的减小并不明显,且预膜试样的阻抗值均大于同时间内未预膜试样的阻抗值,表明在实验条件下预膜时所形成的混合膜对基体具有一定的保护性能;同时随着实验介质流动时间的增加,Qf先缓慢增大后迅速增大;n值在不断波动。n值不断波动的情况说明在冲刷过程中微生物膜在不断被破坏和修复,SRB形成的微生物膜层耐流体冲刷。

表1 试样的电化学阻抗拟合值

Table 1

| Sample | t / h | Rf / Ω·cm2 | Qf / 10-3 F·cm2 | n |

|---|---|---|---|---|

| Without SRB pre-film | 0 | 455.30 | 3.618 | 0.900 |

| 2 | 453.60 | 3.706 | 0.905 | |

| 4 | 694.20 | 4.397 | 0.541 | |

| 6 | 448.20 | 3.675 | 0.900 | |

| 8 | 391.80 | 5.077 | 0.837 | |

| With SRB pre-film | 0 | 1214.00 | 6.435 | 0.906 |

| 2 | 1113.00 | 6.541 | 0.912 | |

| 4 | 1192.00 | 6.696 | 0.908 | |

| 6 | 1193.00 | 6.727 | 0.911 | |

| 8 | 1064.00 | 7.645 | 0.907 |

2.4 动电位极化

图4为有无进行预膜处理的试样在冲刷8 h后的极化曲线。由图可知,预膜试样的阴极反应斜率低于未预膜试样,表明预膜试样表面的混合膜对阴极反应具有一定的抑制作用,同时预膜试样的阳极区腐蚀速率要缓于未预膜试样,表明预膜试样的腐蚀程度要小于未预膜试样,这与EIS测试结果一致。

图4

通过拟合结果数据可得:未预膜试样阳极Tafel系数Ba为91.15 mV、阴极Tafel系数Bc为-94.45 mV、自然腐蚀电位Ecorr为-0.658 V、腐蚀电流密度I0为6.94×10-5 A/cm2、腐蚀速率为0.814 mm/a。预膜试样阳极Tafel系数Ba为415.75 mV、阴极Tafel系数Bc为-134.32 mV、自然腐蚀电位Ecorr为-0.835 V、腐蚀电流密度I0为3.20×10-5 A/cm2、腐蚀速率为0.727 mm/a。两组试样的自然腐蚀电位都较实验开始时减小,说明在热力学上L360的腐蚀趋势逐渐增强。

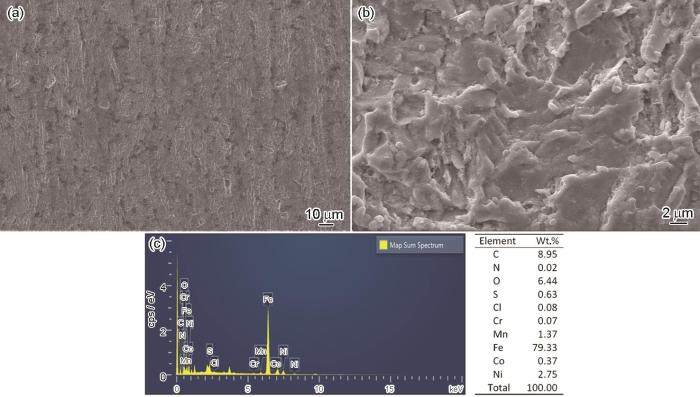

2.5 微观形貌

图5为未预膜试样冲刷8 h后的表面腐蚀形貌。可以看出,电极表面附着了较多疏松粗糙的腐蚀产物和生物膜,放大后可清晰地看到膜层不致密,因此不具有较好的保护作用,表明试样在流体冲刷作用下遭受了较为严重的腐蚀。通过EDS扫描可知,C和O的含量较高。由此可见,腐蚀产物膜和生物膜中存在有机物,其主要来源是SRB细胞,SRB胞外聚合物等。同时Fe、S和P含量较高,说明主要腐蚀产物可能为有机物和FeS混合物以及少量的磷化物。

图5

图5

未预膜试样表面腐蚀形貌和EDS

Fig.5

Surface corrosion morphology (a, b) and EDS result (c) of sample without pre-film treatment

图6为预膜试样冲刷8 h后的表面腐蚀形貌。可以看出,工作电极表面覆盖着较为光滑的腐蚀产物和生物膜的混合膜层,放大后可清晰地看到呈短棒状的SRB,且膜层致密、破坏程度小。预膜试样的腐蚀产物膜较未预膜试样腐蚀产物膜致密,较为致密的腐蚀产物膜降低了试样的腐蚀程度。通过EDS扫描可知,C和O的含量较高,由此可见,腐蚀产物膜和生物膜中存在有机物,其主要来源是SRB细胞,SRB胞外聚合物等。同时Fe、S和P含量较高,说明主要腐蚀产物可能为有机物和FeS混合物以及少量的磷化物。但预膜组S的质量含量 (1.50%) 大于未预膜的 (0.63%),说明预膜组的工作电极发生SRB腐蚀的程度更大。

图6

图6

预膜试样表面腐蚀形貌和EDS

Fig.6

Surface corrosion morphology (a, b) and EDS result (c) of sample with pre-film treatment

2.6 SRB数量分析

表2 不同实验时间下SRB数量

Table 2

| t / h | Ct1 / cell·mL-1 | Ct2 / cell·mL-1 | Ct3 / cell·mL-1 |

|---|---|---|---|

| 0 | 2500000 | 2500000 | 2500000 |

| 4 | 2600000 | 2500000 | 2600000 |

| 8 | 2300000 | 2500000 | 2400000 |

| 12 | 2200000 | 2200000 | 2500000 |

| 24 | 2200000 | 2100000 | 2100000 |

| Scour 0 h | 2400000 | 2200000 | 2200000 |

| Scour 8 h | 2200000 | 2200000 | 2100000 |

图7

图7

绝迹稀释法测试SRB数量

Fig.7

Number of SRB tested by extinction dilution method: (a) scour 0 h, (b) scour 8 h

2.7 SRB流体作用下的腐蚀机理

分析SRB腐蚀的阴极反应,目前国内外最新的SRB腐蚀机理是生物阴极催化硫酸盐还原机理(BCSR)[16],具体反应如下式:

氧化反应

还原反应

通过以上分析,在流体冲刷不足以破坏微生物膜时,SRB生物膜下的阴极反应即为

3 结论

(1) 由CFD模拟可知,管道不同位置处的砂粒分布和对管道的腐蚀情况有所差异,其中管道底部腐蚀最严重、管道顶部轻微腐蚀,管道出口处腐蚀程度大于管道入口处,且砂粒对于管道的冲刷与其腐蚀速率的大小呈正相关。

(2) 随着实验时间的延长,未预膜试样的OCP负移,阻抗弧半径逐渐变小,说明腐蚀逐渐加剧;试样表面预先形成SRB膜的试样,OCP和阻抗弧半径并未发生明显减小趋势。

(3) 当金属表面未形成生物膜时,主要以冲刷腐蚀为主;而金属表面形成了生物膜后,由于金属表面附着的致密SRB生物膜对试样产生一定程度的保护,使其均匀腐蚀程度降低,但膜下会发生SRB腐蚀。

参考文献

Understanding the influences of pre-corrosion on the erosion-corrosion performance of pipeline steel

[J].

A systematic erosion-corrosion study of two stainless steels in marine conditions via experimental design

[J].

Erosion-corrosion of stainless steel at different locations of a 90° elbow

[J].

Electrochemical corrosion behavior of X-65 steel in the simulated oil-sand slurry. II: Synergism of erosion and corrosion

[J].

Erosion-corrosion at different locations of X65 carbon steel elbow

[J].

Slurry erosion-corrosion of 90° AISI 1018 steel elbow in saturated potash brine containing abrasive silica particles

[J].

Research progress of the erosion-corrosion in oil and gas production and transmission process

[J].

油气生产与输送过程中冲刷腐蚀的研究进展

[J].

Chemical and physical characterization of produced waters from conventional and unconventional fossil fuel resources

[J].Characterization of produced waters (PWs) is an initial step for determining potential beneficial uses such as irrigation and surface water discharge at some sites. A meta-analysis of characteristics of five PW sources [i.e. shale gas (SGPWs), conventional natural gas (NGPWs), conventional oil (OPWs), coal-bed methane (CBMPWs), tight gas sands (TGSPWs)] was conducted from peer-reviewed literature, government or industry documents, book chapters, internet sources, analytical records from industry, and analyses of PW samples. This meta-analysis assembled a large dataset to extract information of interest such as differences and similarities in constituent and constituent concentrations across these sources of PWs. The PW data analyzed were comprised of 377 coal-bed methane, 165 oilfield, 137 tight gas sand, 4000 natural gas, and 541 shale gas records. Majority of SGPWs, NGPWs, OPWs, and TGSPWs contain chloride concentrations ranging from saline (>30000 mg L(-1)) to hypersaline (>40000 mg L(-1)), while most CBMPWs were fresh (<5000 mg L(-1)). For inorganic constituents, most SGPW and NGPW iron concentrations exceeded the numeric criterion for irrigation and surface water discharge, while OPW and CBMPW iron concentrations were less than the criterion. Approximately one-fourth of the PW samples in this database are fresh and likely need minimal treatment for metal and metalloid constituents prior to use, while some PWs are brackish (5000-30000 mg Cl(-) L(-1)) to saline containing metals and metalloids that may require considerable treatment. Other PWs are hypersaline and produce a considerable waste stream from reverse osmosis; remediation of these waters may not be feasible. After renovation, fresh to saline PWs may be used for irrigation and replenishing surface waters.Copyright © 2011 Elsevier Ltd. All rights reserved.

Research progress on sulfate-reducing bacteria induced corrosion of steels

[J].

硫酸盐还原菌对钢材腐蚀行为的研究进展

[J].

Corrosion products associated with attached bacteria at an oil field water injection plant

[J].Attached populations of corrosion enhancing sulfate-reducing bacteria (SRB) and organic acid-producing bacteria (APB) were measured on steel plugs at an oil field water injection plant near Wainwright, Alberta. The sample plugs were colonized to ca. 106 SRB/cm2. Counts for APB ranged from 102 to 10/cm2. Scanning electron microscopic examination of the sample plugs revealed an uneven distribution of surface corrosion deposits. A thin iron sulfide layer covered most of the exposed areas. Thicker sulfur-enriched deposits occurred randomly. The bulk of the thicker deposits were smooth, whereas peripheral regions exhibited a porous texture. The elemental composition of the different regions was the same; however, bacterial cells were concentrated in the porous areas and were not found in the thinner deposits. In transmission electron microscopic thin sections cut perpendicularly through corrosion deposits, bacterial cells were found mineralized in successive stages by iron sulfides. The corrosion deposit matrix also generated strong Cl peaks in energy dispersive X-ray spectra. This entrainment of bacterial cells within a corrosion deposit matrix is consistent with the concept of bacterial enhancement of corrosion by removal of reducing power from iron sulfides galvanically coupled to the steel surface. Key words: microbial corrosion, iron sulfide, cathodic hydrogen, electron microscopy.

Stress corrosion cracking of X100 pipeline steel in acid soil medium with SRB

[J].

SRB作用下X100管线钢在酸性土壤环境中的应力腐蚀开裂行为

[J].采用慢应变速率拉神 (SSRT) 实验和SEM研究了SRB对X100管线钢在典型的酸性土壤 (鹰潭土壤模拟溶液) 中应力腐蚀开裂行为的影响。结果表明,X100钢母材和焊缝在无菌的鹰潭土壤模拟溶液中的SCC敏感性高于有菌时的,X100钢母材和焊缝在无菌和有菌酸性土壤中的断裂模式均为穿晶SCC断裂,说明SRB的存在抑制了X100钢的脆变,导致X100钢的SCC敏感性降低,这可能是由于SRB能在X100钢表面快速生长繁殖并形成生物膜,该生物膜随时间的增加会不断的堆积并变得致密,一定程度上阻隔了腐蚀性Cl<sup>-</sup>进入钢基体表面,致使X100钢的SCC敏感性减小。

Stress corrosion cracking behavior of 2205 duplex stainless steel in 3.5%NaCl solution with sulfate reducing bacteria

[J].

硫酸盐还原菌作用下2205双相不锈钢在3.5%NaCl溶液中应力腐蚀开裂行为研究

[J].采用动电位极化技术、慢应变速率拉伸实验 (SSRT) 以及扫描电子显微镜 (SEM) 等方法研究了硫酸盐还原菌 (SRB) 新陈代谢对2205双相不锈钢 (DSS) 在3.5% (质量分数) NaCl溶液中的应力腐蚀开裂 (SCC) 行为的影响。结果表明,与无菌溶液中相比,SRB的存在促进了2205DSS的阳极溶解过程,诱发了点蚀,为SCC萌生提供了裂纹源。2205DSS的SCC敏感性与SRB活性浓度呈正相关,在稳定生长期SRB活性浓度最大,此时2205DSS的SCC敏感性最大。2205DSS在含SRB的3.5%NaCl溶液中发生的SCC机理为阳极溶解和氢脆混合控制机制。SRB作用下,2205DSS中铁素体相表现为穿晶解理特征,奥氏体相表现为韧性撕裂的特征,铁素体相具有更高的SCC敏感性。

Microbial metabolisms in a 2.5-km-deep ecosystem created by hydraulic fracturing in shales

[J].Hydraulic fracturing is the industry standard for extracting hydrocarbons from shale formations. Attention has been paid to the economic benefits and environmental impacts of this process, yet the biogeochemical changes induced in the deep subsurface are poorly understood. Recent single-gene investigations revealed that halotolerant microbial communities were enriched after hydraulic fracturing. Here, the reconstruction of 31 unique genomes coupled to metabolite data from the Marcellus and Utica shales revealed that many of the persisting organisms play roles in methylamine cycling, ultimately supporting methanogenesis in the deep biosphere. Fermentation of injected chemical additives also sustains long-term microbial persistence, while thiosulfate reduction could produce sulfide, contributing to reservoir souring and infrastructure corrosion. Extensive links between viruses and microbial hosts demonstrate active viral predation, which may contribute to the release of labile cellular constituents into the extracellular environment. Our analyses show that hydraulic fracturing provides the organismal and chemical inputs for colonization and persistence in the deep terrestrial subsurface.

Identification of persistent sulfidogenic bacteria in shale gas produced waters

[J].Produced waters from hydraulically fractured shale formations give insight into the microbial ecology and biogeochemical conditions down-well. This study explores the potential for sulfide production by persistent microorganisms recovered from produced water samples collected from the Marcellus shale formation. Hydrogen sulfide is highly toxic and corrosive, and can lead to the formation of "sour gas" which is costly to refine. Furthermore, microbial colonization of hydraulically fractured shale could result in formation plugging and a reduction in well productivity. It is vital to assess the potential for sulfide production in persistent microbial taxa, especially when considering the trend of reusing produced waters as input fluids, potentially enriching for problematic microorganisms. Using most probable number (MPN) counts and 16S rRNA gene sequencing, multiple viable strains of bacteria were identified from stored produced waters, mostly belonging to the Genus, that were capable of growth via fermentation, and produced sulfide when supplied with thiosulfate. No sulfate-reducing bacteria (SRB) were detected through culturing, despite the detection of relatively low numbers of sulfate-reducing lineages by high-throughput 16S rRNA gene sequencing. These results demonstrate that sulfidogenic produced water populations remain viable for years post production and, if left unchecked, have the potential to lead to natural gas souring during shale gas extraction.Copyright © 2020 Cliffe, Nixon, Daly, Eden, Taylor, Boothman, Wilkins, Wrighton and Lloyd.

Characteristics of SRB biofilm and microbial corrosion of X80 pipeline steel

[J].

X80管线钢表面SRB生物膜特征及腐蚀行为

[J].

Anaerobic microbiologically influenced corrosion mechanisms interpreted using bioenergetics and bioelectrochemistry: A review

[J].Microbiologically influenced corrosion (MIC) is a major cause of corrosion damages, facility failures, and financial losses, making MIC an important research topic. Due to complex microbiological activities and a lack of deep understanding of the interactions between biofilms and metal surfaces, MIC occurrences and mechanisms are difficult to predict and interpret. Many theories and mechanisms have been proposed to explain MIC. In this review, the mechanisms of MIC are discussed using bioenergetics, microbial respiration types, and biofilm extracellular electron transfer (EET). Two main MIC types, namely EET-MIC and metabolite MIC (M-MIC), are discussed. This brief review provides a state of the art insight into MIC mechanisms and it helps the diagnosis and prediction of occurrences of MIC under anaerobic conditions in the oil and gas industry.

Case analysis of microbial corrosion in product oil pipeline

[J].

成品油输送管道微生物腐蚀案例分析

[J].

Effect of sand size and temperature on synergistic effect of erosion-corrosion for 20 steel in simulated oilfield produced fluid with sand

[J].

粒径和温度对20号钢冲刷腐蚀协同作用的影响

[J].

Experiments and CFD simulations of erosion of a 90° elbow in liquid-dominated liquid-solid and dispersed-bubble-solid flows

[J].

A new methodology for modelling erosion-corrosion regimes on real surfaces: Gliding down the galvanic series for a range of metal-corrosion systems

[J].

Toxicity of ZnO nanoparticles to Escherichia coli: mechanism and the influence of medium components

[J].

Effects of biogenic H2S on the microbiologically influenced corrosion of C1018 carbon steel by sulfate reducing Desulfovibrio vulgaris biofilm

[J].

Modification of D-W model for corrosion rate of shale gas pipeline under the synergistic corrosion of SRB and CO2

[J].The purpose of this paper is to develop an equation for the synergistic corrosion of SRB and CO2 based on the D-W model.