FAC为物理和化学相互耦合的结果,其主要受流体动力学因素、环境因素及材料因素的影响[5~7]。当流体流经奇形管道区域时,会产生局部湍流,造成流体流动形态剧烈变化,加剧流动加速腐蚀的影响[8]。环境因素主要包括流体温度、pH值及溶解氧量等[9~11]。研究表明,对于单相流,FAC速率在140 °C左右出现峰值[12];随着pH值和溶解氧浓度的增加,FAC速率会显著降低[13]。此外,高湍流局部区域显著影响腐蚀产物向主流区的传质速率,易造成各管路系统频繁失效。然而,管道中的湍流参数,如流速、湍动能、湍流强度等很难通过实验进行准确测量。且目前各商业预测软件因需要大量现场数据进行优化与修正而无法被广泛推广和应用,所以深入研究各个影响因素,尤其是湍流参数与FAC速率的关系至关重要。

本工作结合实验和数值模拟,基于自设计FAC实验台获得弯管段FAC速率分布,对比模拟弯管段的流体动力学参数特征,揭示了弯管段FAC速率与湍流参数的相关性。

1 实验方法

实验工作电极由20#碳钢制成,单个电极暴露面积为3.14 mm×3.14 mm。实验前,用不同粒度的碳化硅砂纸逐级打磨电极,然后在抛光机中抛光,再依次用去离子水和丙酮进行超声清洗,去除电极表面残留杂质。利用NaOH溶液和去离子水配制测试液,根据压水堆核电站 (PWR) 二回路水化学方法,溶液pH为9.3 (25 °C)。在配置好的溶液中鼓吹N2同时开启加热装置,去除溶液中溶解氧的影响。

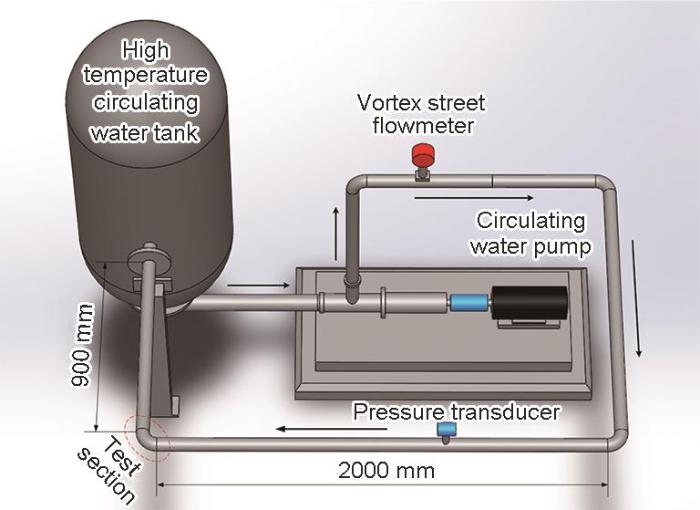

图1

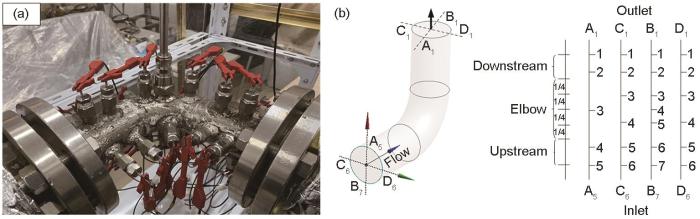

在Metrohm Autolab电化学工作站上,使用三电极系统进行电化学测量。如图2所示,弯管实验段共26个阵列电极,其中24个为工作电极,弯管肘部下侧为辅助电极;肘部上侧为参比电极,不同电极与管道间采用绝缘材料隔离。从弯管实验段出口至入口分别标记为B1~B7、A1~A5;两侧各分布6个测点,分别为C1~C6、D1~D6。其中,C3与C4之间为Ag/AgCl参比电极,D3与D4之间为辅助电极。电化学阻抗谱图频率范围为105~10-1 Hz,正弦电压激励信号幅值为10 mV。

图2

图2

实验段阵列电极安装及测点分布示意图

Fig.2

Schematic diagram of array electrode installation (a) and measuring point distribution (b) in test section

利用Fluent对90°弯管进行数值模拟,入口直管段长为2000 mm,出口直管长为900 mm,与实验管道尺寸一致。采用Realizable k-ε (RKE) 湍流模型求解Navier-Stokes方程,velocity-inlet为入口边界条件,弯管段入口流速分别为1、2、3和4 m/s;出口边界条件设定为pressure-outlet。

2 结果讨论与分析

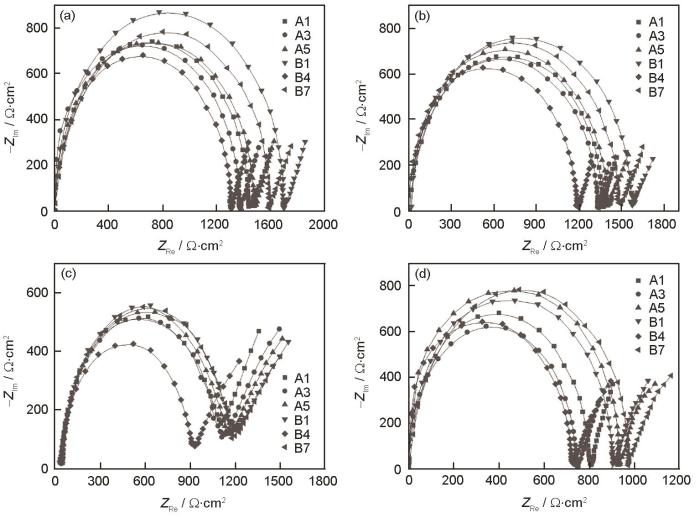

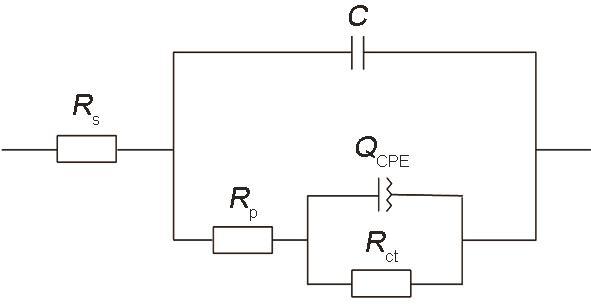

图3为不同流速下典型位置阵列工作电极 (A1,A3,A5,B1,B4和B7) 的Nyquist图。不同流速下的阻抗谱均由高频区的电容性半圆和低频区的扩散容抗弧组成。电容性半圆归因于界面电荷转移反应,体现了工作电极样品在FAC过程中的溶解行为,电容性半圆形的直径大小代表电荷转移电阻的大小;扩散容抗弧偏离标准半圆现象归因于电极表面的“弥散效应”[15]。由图可知,不同流速下工作电极的Nyquist图在高频区容抗弧半径沿流动方向均先减小后增大。随着流速的增大,对应工作电极的容抗弧半径逐渐减小,表明电荷传递电阻也逐渐减小。此外,在不同流速下,最小容抗弧半径均位于B4电极处,即弯管实验段外弯最外侧位置。

图3

图3

不同流速条件下弯管段典型阵列电极Nyquist图

Fig.3

Nyquist plots of typical array electrodes in elbow section at 1 m/s (a), 2 m/s (b), 3 m/s (c) and 4 m/s (d)

图4

图5

图5

不同流速下弯管实验段阵列工作电极的电荷传递电阻和腐蚀电流密度

Fig.5

Charge transfer resistance (a) and corrosion current density (b) of array working electrode in elbow test section at different flow rates

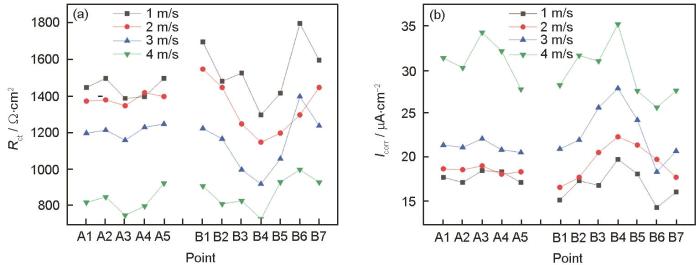

根据Stern-Geary方程[15],得出对应位置处的腐蚀电流密度,如图5b所示。由图可知,随着流速的增加,腐蚀电流密度的分布形态无明显变化,沿流动方向肘部腐蚀电流密度明显高于其它位置。表1为不同流速下典型位置阵列工作电极的电荷转移电阻和腐蚀电流密度的具体数值。由表可知,在弯管实验段,外弯侧和内弯侧的腐蚀电流密度最大值分别位于B4 (对应于弯管最外侧) 与A3 (对应于弯管最内侧)。流速的增加能够显著增大弯管段阵列电极的腐蚀电流密度,这是因为金属基体和氧化物界面的可溶性含铁组分 (包括Fe2+、FeOH+、HFeO

表1 不同流速下典型位置阵列工作电极的电荷转移电阻和腐蚀电流密度

Table 1

| Position | Rct / Ω·cm2 | Icorr / μA·cm-2 | |||||||

|---|---|---|---|---|---|---|---|---|---|

| 1 | 2 | 3 | 4 | 1 | 2 | 3 | 4 | ||

| A1 | 1450 | 1375 | 1200 | 820 | 17.72 | 18.68 | 21.41 | 31.33 | |

| A3 | 1390 | 1350 | 1161 | 750 | 18.48 | 19.03 | 22.12 | 34.25 | |

| A5 | 1500 | 1400 | 1250 | 925 | 17.12 | 18.35 | 20.55 | 27.77 | |

| B1 | 1700 | 1550 | 1226 | 910 | 15.11 | 16.57 | 20.96 | 28.23 | |

| B4 | 1300 | 1150 | 922 | 730 | 19.76 | 22.34 | 27.87 | 35.19 | |

| B7 | 1600 | 1450 | 1240 | 930 | 16.05 | 17.72 | 20.72 | 27.62 | |

3 实验数据与数值模拟结果比较

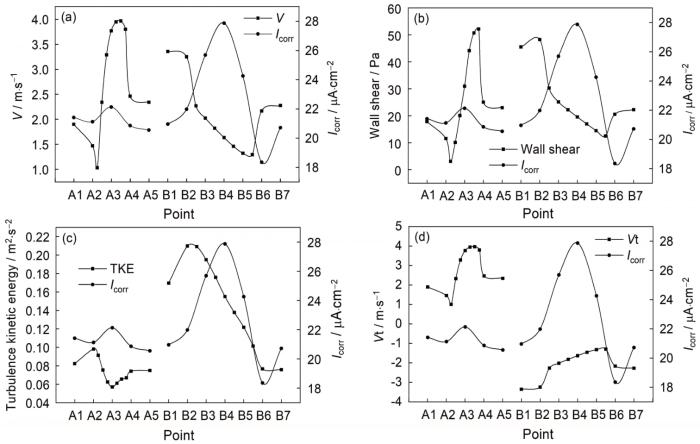

由实验结果可知,当流速大于3 m/s时,阵列工作电极腐蚀电流密度明显增加,故选取入口速度为3 m/s实验段的流体动力学参数与腐蚀结果进行分析。图5a~d为腐蚀电流密度与各流体动力学参数对比。从图中可知,弯管段腐蚀电流密度与流速、剪切应力、湍动能以及轴向速率仅呈现局部相关,所以上述四个流体动力学参数不能作为反映弯管段流动加速腐蚀速率大小的“指示参数”。

图6

图6

各流体动力学参数与腐蚀电流密度比较

Fig.6

Comparison of velocity (a), wall shear (b), turbulence kinetic energy (c), axial local velocity (d) and corrosion current density

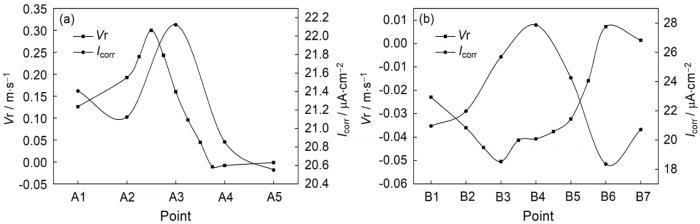

图7

图7

径向局部速度与腐蚀电流密度的比较

Fig.7

Comparison of radial local velocity and corrosion current density between intrados (a) and extrados (b)

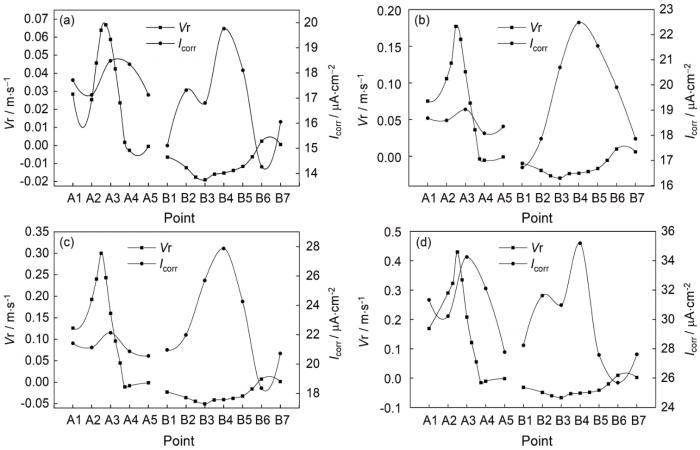

为进一步验证径向局部速度分量的有效性,我们将不同流速 (1、2、3和4 m/s) 下,弯管实验段不同测点的腐蚀电流密度和径向局部速度分量进行比较,如图8所示。由图可知,在不同流速下,实验段不同阵列工作电极腐蚀电流密度的变化趋势与径向局部速度分量变化趋势吻合良好,这证明了Vr与FAC速率具有明显的相关性。

图8

图8

不同流速下径向局部速度与腐蚀电流密度的比较

Fig.8

Comparison of radial local velocity and corrosion current density at 1 m/s (a), 2 m/s (b), 3 m/s (c) and 4 m/s (d)

4 径向局部速度分量与腐蚀电流密度的关系

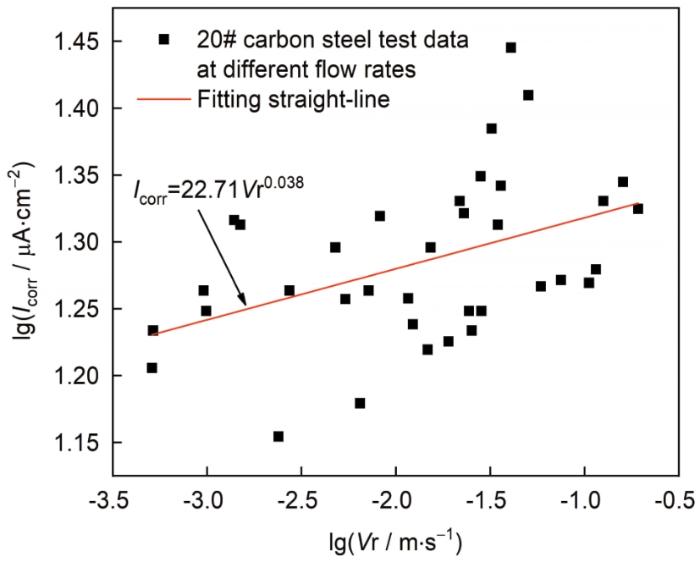

为确定Vr和腐蚀电流密度的关系,逐点选取基于实验的腐蚀电流密度值和基于数值模拟结果的Vr值,并将计算为负值的Vr取其绝对值。图9给出了基于Vr与腐蚀电流密度同取对数的最小二乘法直线拟合,Vr与腐蚀电流密度的经验方程可表示为:

图9

图9

弯管实验段不同流速的腐蚀电流密度和Vr的拟合关系

Fig.9

Fitting relationship between corrosion current density and Vr at different flow rates in elbow test section

由于本研究对给水系统的管道进行了分析,因此本经验方程 (1) 只适用于入口流速为1~4 m/s,常温下的pH为9.3,溶液中溶解氧在0.1 μg/kg以下的工况。

5 结论

通过对90°弯管进行流动加速腐蚀实验和数值模拟,研究了流速对弯管段FAC速率的影响。使用阵列电极技术对碳钢弯管段不同位置进行了电化学测量,实验结果表明,不同的流速下,内弯侧和外弯侧腐蚀电流密度均呈先增大后减小趋势,且弯管段的最大腐蚀电流密度位于弯管最外侧,与火力发电厂及核电站事故特征符合良好。随着流速的增加,弯管实验段工作电极电荷传递电阻减小,腐蚀电流密度增大,且当流速大于3 m/s时,FAC速率显著增加,这与流速加快溶解产物的有效传质过程有关。此外,通过数值模拟获得不同流速下流体动力学参数 (流速、剪切应力、湍动能、轴向速率及径向速率) 与腐蚀电流密度的相关性,发现沿着弯管径向局部速度分量与腐蚀电流密度变化趋势吻合较好,这与90°弯头二次流的演化密切相关。基于最小二乘拟合结果可以得出:Icorr=22.71Vr0.038。该结果可用于20#碳钢弯管段壁厚减薄原因的验证及管道设计的修改,有助于减少FAC事故的发生,提高电厂相关系统运行的安全性。

参考文献

Research on the mechanism of flow accelerated corrosion and its countermeasures of water-steam system in power station

[D].

电站汽水系统流动加速腐蚀机理及对策研究

[D].

A novel model for predicting flow accelerated corrosion rate in reducer

[J].

一种预测异径管流动加速腐蚀速率的新模型

[J].通过将稳态传质模型和一维电偶腐蚀模型耦合,提出了预测异径管流动加速腐蚀速率的新模型。该模型先由稳态传质模型得到异径管近壁面处的自腐蚀电流密度分布和速度极值点处的自腐蚀电位,而后将极值点处自腐蚀电位代入到一维电偶腐蚀模型中,计算该壁面处的电偶腐蚀电流密度。应用此新模型对某一异径管流动加速腐蚀速率进行计算,发现异径管大端的腐蚀电流密度比小端腐蚀电流密度大两个数量级,据此可以解释台湾某核电站蒸汽冷凝水管线统计得出异径管大端出现最大减薄量的现象。与壁面剪切应力理论和稳态传质理论计算流动加速腐蚀速率分布相比,该模型的计算结果更贴近实际情况。

Influence of chromium on the flow-accelerated corrosion behavior of low alloy steels in 3.5% NaCl solution

[J].

Numerical simulation and experimental study on erosion-corrosion of square elbow based on orthogonal test

[J].

基于正交实验的90°弯管冲刷腐蚀数值模拟及实验研究

[J].采用正交试验和数值模拟相结合的方法,研究了90°弯管在液固两相流条件下,管径 (A)、入口流速 (B)、液体流向 (C)、砂粒直径 (D) 和砂粒质量流量 (E) 5个因素对弯管冲刷腐蚀行为的影响程度大小。结果表明:不同因素对弯管冲刷腐蚀影响的顺序为B>A>E>C>D。当B为5 m/s、A为30 mm、E为0.03 kg/s、C液体流向为水平竖直向上、D为500 μm时,冲蚀速率达到最大,冲蚀速率较大的区域集中在弯管轴向角度60°到90°之间,径向角度180°附近,即位于弯管外侧靠近出口处,实验结果也验证了此种工况下弯管外侧出口处的腐蚀速率更高,同时最优因素水平试验结果也表明:降低入口流速和增大管径能大幅度降低冲蚀速率。

Enhancement of corrosion resistance in carbon steels using nickel-phosphorous/titanium dioxide nanocomposite coatings under high-temperature flowing water

[J].

Effect of applied stress and medium flow on corrosion behavior of carbon steel in H2S/CO2 coexisting environment

[J].

H2S/CO2共存环境中施加应力与介质流动对碳钢腐蚀行为的影响

[J].采用带有磁力驱动轴的高温高压腐蚀测试釜,通过失重法研究了施加应力与介质流动对20#钢和L245NS钢在H<sub>2</sub>S/CO<sub>2</sub>共存环境中腐蚀行为的影响。采用SEM和XRD表征手段分析了浸泡腐蚀后四点弯曲试样表面的微观形貌及腐蚀产物的组成。结果表明:在H<sub>2</sub>S/CO<sub>2</sub>共存环境中的各实验条件下,20#钢的平均腐蚀速率均高于L245NS钢的。当施加应力和液态介质流动时,两种材料的腐蚀速率均增大;应力对腐蚀速率的影响更显著。推测腐蚀机理为:H<sub>2</sub>S在腐蚀过程中起主导作用,生成了具有保护性的FeS腐蚀产物膜。应力会导致腐蚀产物膜存在大量微观通道,促进了腐蚀过程的进行;流体流动加速了金属溶解和腐蚀性物质的扩散,表现出最大的腐蚀速率。

Research progress on flow-accelerated corrosion of power plant and contermeasures

[J].

电厂机组流动加速腐蚀研究进展及防护措施

[J].

Mechanism of hydrodynamic process in flow corrosion behavior

[J].

流体动力学过程在流动腐蚀行为中的作用机制

[J].

Experimental study on flow-accelerated corrosion at elbow of carbon steel at different temperatures

[J].

碳钢弯管段在不同温度下流动加速腐蚀性能实验研究

[J].

Flow-accelerated corrosion in fossil and combined cycle/HRSG plants

[J].

Effect of dissolved oxygen and flow rate of seawater on film formation of B30 Cu-Ni alloy

[J].

溶解氧和流速对B30铜镍合金在海水中成膜的影响

[J].采用电化学以及表面观察的方法研究了海水的溶解氧和流速对于B30铜镍合金表面成膜的影响。结果表明,材料表面膜层的保护性随着海水中溶解氧浓度的提高而提高;在流速为0~2.0 m/s范围内,随着流速的增大,形成的膜层质量呈现先变好再变差的趋势;在流速为0.8 m/s左右时,形成的膜层最为致密完整。溶解氧通过影响其成膜的反应过程影响成膜质量;流速通过改变试样周围的溶解氧浓度以及产生一个冲刷作用来影响成膜,溶解氧浓度的提高有利于膜层的形成,海水的冲刷作用则会破坏形成的膜层。

Cause analysis on FAC failures of steam/water piping in secondary loop of PWR power plants and the countermeasures

[J].

核电站汽水管道流动加速腐蚀的影响因素分析及对策

[J].

Model of physico-chemical effect on flow accelerated corrosion in power plant

[J].

Design of specimen holders for flow accelerated corrosion experiments in molten lead with numerical evaluation of pressure losses

[J].

Influence of the thickness and roughness of polyaniline coatings on corrosion protection of AA7075 aluminum alloy

[J].

The corrosion behavior and mechanism of carbon steel induced by extracellular polymeric substances of iron-oxidizing bacteria

[J].

Erosion–corrosion at different locations of X65 carbon steel elbow

[J].

Investigation of corrosion behavior at elbow by array electrode and computational fluid dynamics simulation

[J].

Influence of flow velocity and temperature on flow accelerated corrosion rate at an elbow pipe

[J].Flow accelerated corrosion (FAC) is one of the important issues that must be considered for aging fossil and nuclear power plants. To understand the effect of thermal flow field on FAC, FAC rates at an elbow pipe were measured under different flow velocity and temperature conditions. The elbow WA section was made of stainless steel (diameter D = 49.5 mm) and FAC rates were measured using corrosion sensors made of carbon steel. The dissolved oxygen concentration was kept under 0.1 mu g/kg, and pH was nearly neutral (about 7.0) at room temperature. The mean cross-sectional velocity was changed from 0.39 to 5.74 m/s (Reynolds number, about 1.0e6). When the water temperature was about 150 degrees C, the FAC rate was smaller at the intrados of the elbow pipe than at other circumferential locations. This tendency continued downstream. The FAC rates at the elbow pipe were larger than those upstream and downstream from the elbow pipe and the FAC rates downstream from the elbow pipe decreased along the flow direction. FAC rates increased as flow velocity increased and their relationship was not linear. The ratios of the maximum FAC rate at the elbow to the FAC rate in the upstream straight pipe ranged from about 1.7 to 2.9. When temperature decreased to 100 degrees C, FAC rate at the intrados became the largest of the other circumferential sensors. When temperature decreased further to 50 degrees C, FAC rate also decreased, but the value was not negligible. The influence of flow velocity was negligibly small at 50 degrees C and remarkable at 100 degrees C and 150 degrees C. The combination effect of flow velocity and temperature was different from place to place and particularly strong at the elbow.

Effects of local velocity components on flow-accelerated corrosion at 90° elbow

[J].