近年来,碳钢板凭借自身强度高、硬度大的特点被广泛应用,但是碳钢极易与环境成分发生反应,从而因腐蚀导致大量经济损失和引发安全问题[1, 2]。有机硅改性的丙烯酸树脂涂层在碳钢板防腐方面的应用日益突出[3, 4],其中阳离子型有机硅氧烷改性的丙烯酸 (SMCWA) 乳液一方面经济环保,另一方面改善了传统丙烯酸树脂涂层在耐水性、耐候性和耐热性等方面的不足[5~8]。SMCWA乳液与碳钢板基底能够形成Si-O-Me键,提高与金属基底的结合,从而提高金属耐腐蚀性能,而且其能够自交联,使有机的膜层变得更加致密、疏水和耐腐蚀[9~13]。改性水性丙烯酸树脂涂层应用于碳钢板的防腐方面,环保经济、防腐性能较好,因此对其研究越来越深入,应用也更加广泛[14, 15]。目前,国外对可聚合胺基硅烷改性丙烯酸乳液的报道较少,国内的有关改性丙烯酸阴离子乳液的报道较多[16],对于可聚合胺基硅烷改性阳离子型丙烯酸乳液的研究处于成长阶段。改性乳液聚合采用半连续的聚合方法,先将一部分单体、乳化剂和引发剂加入到反应容器中,再将剩余的单体和引发剂滴加到反应器中。与其他聚合方法相比,该操作更加简单,由于采用滴加的方式,对反应过程能够更好的控制[17~20]。Chen等[21]通过半连续种子乳液聚合成功制备了二乙烯基硅烷改性的自交联聚丙烯酸酯胶乳。乳液具有良好的力学稳定性和化学稳定性,分散体呈蓝色、半透明,粒径小。制备的聚丙烯酸酯胶体膜具有突出的热稳定性和疏水性。Su等[5]通过可逆加成-断裂转移聚合开发了一种新的阳离子丙烯酸酯改性环氧树脂乳液,用于水性喷墨。该乳液兼具聚丙烯酸酯和环氧树脂的优点,具有高电势和高水接触角。该乳液成功地用于喷墨印刷的帆布涂层,这项工作将为喷墨印刷行业新型阳离子乳液的开发做出贡献。有机硅改性的阳离子丙烯酸乳液和环氧树脂对碳钢板耐腐蚀性能都有很大的提升[22~24]。本研究使用半连续乳液聚合法成功制备了绿色无污染的SMCWA乳液,其乳胶粒子表面的多胺基赋予了乳液优异的兼容性和稳定性。根据SMCWA乳液乳胶粒表面胺基能够固化环氧的原理,向其中加入少量环氧树脂,与乳胶粒表面的胺基反应,进一步增强了涂层的耐腐蚀性能。将SMCWA乳液与环氧树脂复配后,在碳钢板上制备了复合防腐涂层,同时兼具两者优点,其耐CuSO4点滴能力、附着力和耐腐蚀性能都得到提高。在此基础上,乳液成功进行了中试,并在卷钢基材上获得了实际应用。

1 实验方法

本实验首先通过计算确定实验药品的用量,然后将20% (质量分数,全文同) 的打底水,40%的自制的可聚合氨基硅烷功能单体 (DGO-M),3.3%乳化剂十六烷基三甲基氯化铵 (CTAC) 水溶液和30%甲甲酯 (MMA) 与丙烯酸丁酯 (BA) 混合溶液 (质量比2∶1) 加入到四口烧瓶中。75 ℃搅拌5 min,加入3.3%引发剂偶氮二异丁脒盐酸盐 (V50) 总量的30%的用量,将剩余的所有单体混合加入到带有机械搅拌的滴定漏斗中混合,再加入之前乳化剂用量的二分之一的用量,高速搅拌,同样把剩余的V50倒入到另一个恒压漏斗中。从看到出现蓝光开始,10 min后,开始滴加漏斗中的单体和引发剂,使他们同时在3.5 h滴加完成。75 ℃继续反应90 min,然后自然冷却降温、过滤,制得SMCWA乳液。

碳钢板防腐涂层用7 μm线棒涂覆之前,碳钢板基底表面预处理过程为:擦去碳钢板表面多余的油脂,再将碳钢板的裁剪处打磨光滑,以免损伤线棒和涂覆不均匀。用无水乙醇再擦拭一遍碳钢板表面,放入到配置好的20 g/L的脱脂剂中,45 ℃,超声5 min。取出用清水荡洗多次,再用乙醇冲洗去除表面的水分,放入80 ℃的烘箱中烘干备用。

用滴管取上述适量的用水稀释相同固含的SMCWA乳液/环氧树脂复合乳液,配比分别为10/0、9/1、9.25/0.75、9.5/0.5和9.75/0.25,分别滴加到固定在涂布器预先处理好的碳钢板上。用7 μm的线棒双手压住匀速进行辊涂,迅速放入到230 ℃的烘箱中80 s,用镊子取出,即获得碳钢板复合乳液涂层,供后续测试使用。

使用ZS90型激光纳米粒度仪对用去离子水将SMCWA乳液稀释成固含量100倍的溶液进行Zeta电位和粒径及其分布的测定,温度为25 ℃。使用IRAffinity-1S型Fourier红外光谱仪 (FT-IR) 对上述制备好的涂层的结构进行表征和分析。使用JSM6490型扫描电子显微镜 (SEM) 观察碳钢板表面乳液膜层和复合防腐乳液膜层的成膜结果。

将接触角仪器里的水滴到所需测试的膜层上,再利用计算机软件分析计算出接触角的数据。据GB/T9286-1998进行实验所需碳钢板表面树脂膜层材料的附着力测试。配置CuSO4点滴所需的溶液 (100 g) :50 g CuSO4,45.2 g H2O,3.5 g NaCl,1.3 mL的0.1 mol/L HCl。用滴管吸取配置好的测试溶液滴到涂有膜层的碳钢板上,观察碳钢板表面出现红点时的时间,每个碳钢板上不同位置测试4组,取平均时间作为最终点滴数据。一般碳钢板表面从滴下液滴到出现红点的时间越长,表示碳钢板表面膜层的防腐性能越好。

利用CHI660E型电化学工作站,以碳钢板为工作电极,甘汞电极作为参比电极,铂丝电极作为辅助电极进行电化学测试分析。采用YWX/Q型盐雾箱进行中性盐雾实验,温度 (35±2) ºC,NaCl浓度 (50±5) g/L,pH 6.5~7.2之间。

2 结果与讨论

2.1 SMCWA乳液的粒径和Zeta电位

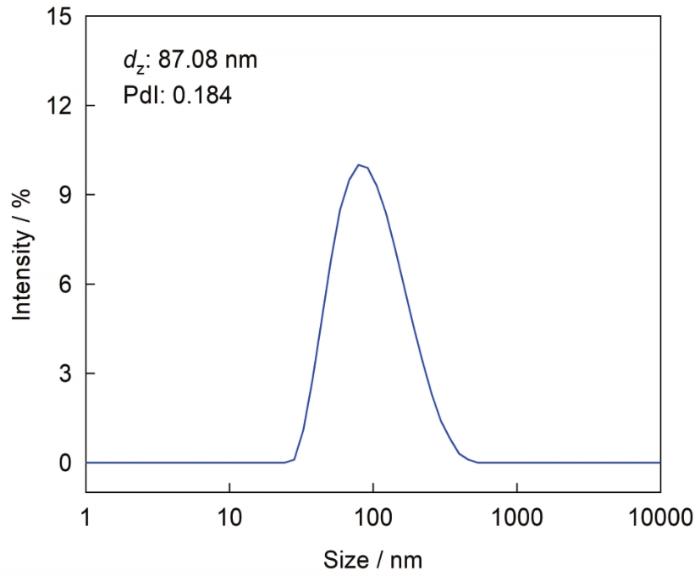

图1

图1

SMCWA 乳液中乳胶粒子的粒径大小和分布

Fig.1

Size and distribution of latex particles in SMCWA emulsion

图2

图2

SMCWA乳液中乳胶粒子的Zeta电位

Fig.2

Zeta potential of latex particles in SMCWA emulsion

2.2 SMCWA乳液与环氧树脂复合涂层的防腐性能

利用上述成功制备的SMCWA乳液作为主要成膜物质,再根据乳液中乳胶粒子表面的胺基能够固化环氧树脂的原理,使乳液与环氧树脂进行复配,在低碳钢板表面制备耐腐蚀性能优异的复合涂层。对制备的涂层进行表征分析,以此来检验复合涂层的耐腐蚀性能。

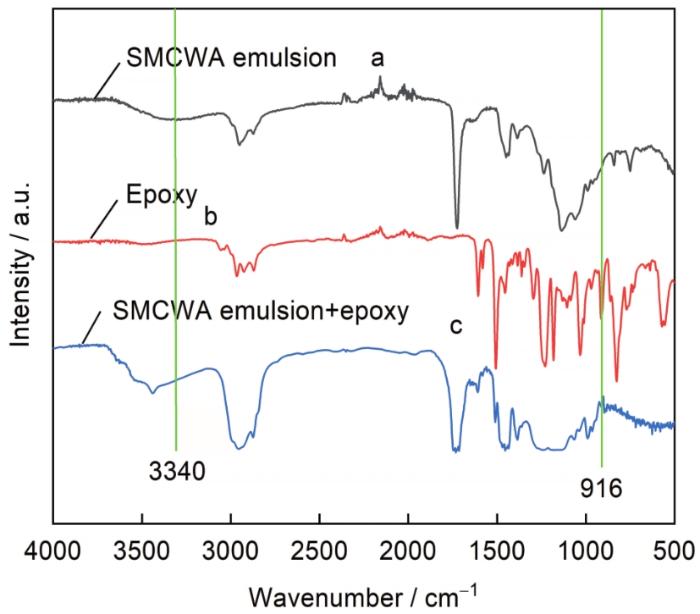

2.2.1 FT-IR分析

制备的SMCWA乳液中含有许多胺基,可以与环氧树脂发生反应,固化环氧,使SMCWA乳液与环氧树脂在金属防腐方面的优点结合起来,达到增强碳钢板上防腐复合涂层耐腐蚀能力的目的。固化前的SMCWA乳液、环氧树脂和固化后的复合涂层的红外光谱如图3所示。可以观察SMCWA乳液a的红外图谱在3340 cm-1处有一个-OH和N-H共存的一个特征峰,这是SMCWA乳液能够固化环氧树脂的关键。从红外谱图c可以看到,固化后在3340 cm-1只剩下了-OH特征吸收峰,并且在916 cm-1处b图中的环氧基消失了,说明乳液中的胺基与环氧树脂反应,起到了环氧树脂固化剂的作用。

图3

图3

SMCWA乳液与环氧树脂固化前后的红外光谱图

Fig.3

FT-IR spectra of SMCWA emulsion and epoxy resin before and after curing

2.2.2 SEM结果

将不同比例的乳液/环氧树脂涂覆在碳钢板上制备复合涂层,利用SEM观察膜层的成膜情况,结果见图4。可以观察到,不同比例的乳液/环氧树脂制得的复合涂层成膜都是完整没有缺陷的,都均匀的涂覆在碳钢板表面。这说明乳液/环氧树脂复合后能够很好地相互作用,形成致密的复合涂层,对碳钢板的耐腐蚀性能防护发挥着关键的作用。

图4

图4

不同比例SMCWA乳液/环氧树脂复合涂层的SEM图

Fig.4

SEM images of composite coatings with SMCWA emulsion/epoxy ratios of 10/0 (a), 9/1 (b), 9.25/0.75 (c) and 9.5/0.5 (d)

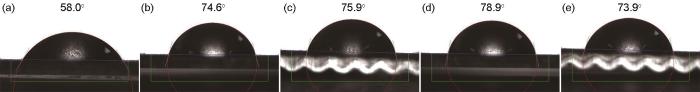

2.2.3 水接触角测试

对不同比例的乳液/环氧树脂复合涂层进行水接触角测试,并与空白乳液涂层进行对比,结果如图5。从图中的水接触角数据对比分析可以得到,与环氧树脂作用后所制备的复合涂层均比空白乳液涂层的水接触角的数值有所提高,说明环氧树脂的加入使复合涂层的疏水性能获得了增强。乳液中乳胶粒子表面的胺基与环氧树脂反应,使环氧树脂固化,变得更加耐水的侵蚀,使水更难通过复合涂层侵蚀碳钢板基底,达到提高其耐腐蚀性能的目的。

图5

图5

不同比例SMCWA乳液/环氧树脂复合涂层的水接触角图

Fig.5

Water contact angle diagrams of composite coatings with SMCWA emulsion/epoxy ratios of 10/0 (a), 9/1 (b), 9.25/0.75 (c), 9.5/0.5 (d) and 9.75/0.25 (e)

2.2.4 CuSO4点滴测试

SMCWA乳液/环氧树脂配比分别为10/0、9/1、9.25/0.75、9.5/0.5和9.75/0.25时,制备的复合涂层耐CuSO4点滴的时间分别为180、230、248、296和226 s。加入环氧树脂后,制备的复合涂层耐CuSO4点滴的时间都要优于空白乳液涂层,这是因为环氧树脂和SMCWA乳液共同作用以后,复合涂层兼具了SMCWA乳液和环氧树脂两者的优点,使得腐蚀介质更难到达碳钢板基底,对其造成腐蚀,使复合涂层耐腐蚀能力得到增强。

2.2.5 附着力测试

图6是不同比例SMCWA乳液/环氧树脂复合涂层的附着力测试结果图。所制备的涂层均没有脱落,并且切割边缘光滑清晰均匀,表明环氧树脂的加入没有对涂层产生破坏。所制备的涂层与碳钢板金属基底的结合均表现良好,涂层附着力测试结果都达到了最高的0级。

图6

图6

不同比例SMCWA乳液/环氧树脂复合涂层的附着力图

Fig.6

Adhesion charts of composite coatings with SMCWA emulsion/epoxy ratios of 10/0 (a), 9/1 (b), 9.25/0.75 (c), 9.5/0.5 (d) and 9.75/0.25 (e)

2.2.6 电化学测试分析

图7

图7

不同比例SMCWA乳液/环氧树脂复合涂层的EIS图

Fig.7

Bode (a, b) and Nyquist (c) diagrams of composite coatings with different SMCWA emulsion/epoxy ratios

使用图8等效电路进行拟合,研究复合涂层在3.5%NaCl溶液中的腐蚀行为 (浸泡1 h,腐蚀电压稳定后进行EIS测试),得到的数据如表1。其中,Rc为膜层电阻,Rct为电荷转移电阻,阻值越大,电荷转移越困难,腐蚀行为越不易进行。n为弥散系数,CPEc是与膜层相关的常相位角元件,通常来讲n值越接近于1,膜层越接近理性模型,CPEc越小,膜层越致密,防腐性能越好。通过比较表中的数据可以得到,SMCWA乳液/环氧树脂复合涂层相比于空白乳液涂层阻抗值都获得了增强。当SMCWA乳液与环氧树脂的配比为9.5/0.5时,此时碳钢板上的复合涂层Rct最大,为42008 Ω·cm2,比空白乳液涂层提高了4倍多。CPEc的值为3.5246×10-8 Ω·cm-2·s-n,也是几个配比中最小的,证明膜层更加致密疏水。弥散系数n1值为0.92514,相比于其他比例复合涂层的数值,更接近于1,碳钢板基底上的涂层更加致密光滑,更接近于理性涂层。综合以上的数据,都表明涂层的耐腐蚀性能变得更加优异。

图8

图8

SMCWA乳液/环氧树脂复合涂层EIS拟合等效电路图

Fig.8

Equivalent circuit diagram for fitting of EIS of SMCWA emulsion/epoxy composite coating

表1 不同比例SMCWA乳液/环氧树脂复合涂层的EIS拟合结果

Table 1

| SMCWA emulsion / Epoxy ratio | Rs / Ω·cm2 | Rc / Ω·cm2 | CPEc / Ω·cm-2·s-n | n1 | Rct / Ω·cm2 | CPEdl / Ω·cm-2·s-n | n2 |

|---|---|---|---|---|---|---|---|

| 10/0 | 26.18 | 700 | 1.098×10-6 | 0.69480 | 9221 | 7.667×10-5 | 0.62230 |

| 9/1 | 22.41 | 2434 | 7.0823×10-8 | 0.83892 | 21284 | 1.1987×10-5 | 0.70538 |

| 9.25/0.75 | 24.71 | 5900 | 6.7149×10-8 | 0.86988 | 34876 | 1.1078×10-5 | 0.80804 |

| 9.5/0.5 | 22.63 | 9680 | 3.5246×10-8 | 0.92514 | 42008 | 1.6133×10-6 | 0.90489 |

| 9.75/0.25 | 26.12 | 2279 | 2.603×10-7 | 0.81547 | 19261 | 3.8761×10-5 | 0.65058 |

图9

图9

不同比例SMCWA乳液/环氧树脂复合涂层的Tafel极化曲线

Fig.9

Tafel polarization curves of composite coatings with different SMCWA emulsion/epoxy ratios

表2 不同比例SMCWA乳液/环氧树脂复合涂层的腐蚀参数

Table 2

| SMCWA emulsion/epoxy ratio | Ecorr / V | Icorr / 10-7 A·cm-2 |

|---|---|---|

| 10/0 | -0.588 | 19.78 |

| 9/1 | -0.572 | 13.88 |

| 9.25/0.75 | -0.569 | 10.38 |

| 9.5/0.5 | -0.527 | 5.926 |

| 9.75/0.25 | -0.573 | 14.78 |

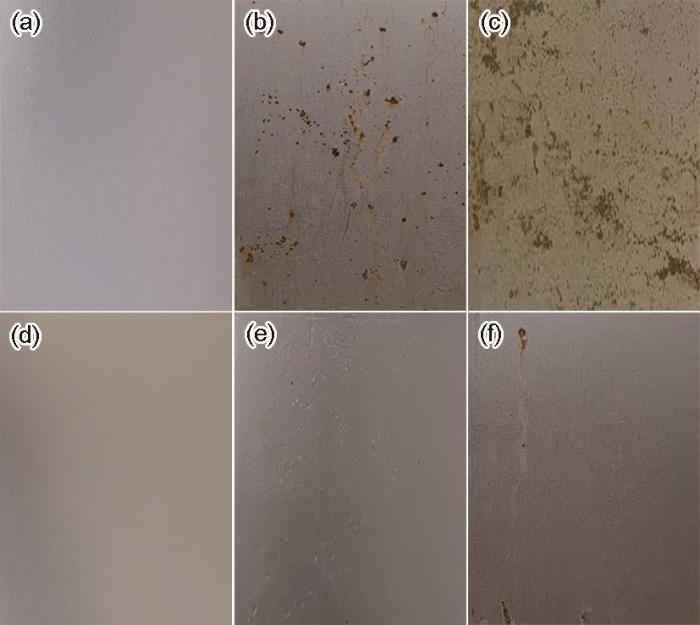

2.2.7 中性盐雾实验

从图10的中性盐雾实验结果可以看出,空白乳液涂层在8 h时已经出现了腐蚀,24 h时,出现了较多的腐蚀产物。相对于空白乳液涂层,SMCWA乳液/环氧树脂为9.5/0.5的复合涂层在8 h时,没有被腐蚀,对碳钢板基底保护优异;24 h时,只是出现了很小的腐蚀点。由此可见,复合涂层对碳钢板表现出了优异的耐腐蚀性能。

图10

图10

空白以及SMCWA乳液/环氧树脂比例为9.5/0.5的涂层中性盐雾实验不同时间后的表面形貌

Fig.10

Surface morphologies of SMCWA emulsion coating (a-c) and SMCWA emulsion /epoxy composite coating with the ratio of 9.5/0.5 (d-f) after neutral salt spray test for 0 h (a, d), 8 h (b, e) and 24 h (c, f)

3 结论

(1) 通过粒径和Zeta电位数据分析可以得出,实验成功合成了纳米粒径、带有正电荷和稳定的有机硅氧烷改性的阳离子型丙烯酸乳液。SEM、附着力测试以及水接触角测试表明制备的复合涂层均匀无缺陷,与碳钢板基底结合良好,并且疏水性能获得提高。

(2) CuSO4点滴实验和电化学测试表明涂层的致密性得到增强,耐腐蚀性能获得显著提升。其中,SMCWA乳液与环氧树脂配比为9.5/0.5时,点滴时间达到296 s,阻抗值比空白乳液涂层提高4倍多,腐蚀电流密度下降一个数量级。

(3) SMCWA乳液/环氧树脂为9.5/0.5的复合涂层中性盐雾实验表现优异,对碳钢板基材耐腐蚀防护能力强,已在实际工业中获得应用。

参考文献

Novel water-based coatings of acrylic-polyurethane reinforced with mixed metal pigment for oil and gas pipelines protection

[J].

Corrosion and protection of metals

[J].During the last few decades, an enormous effort has been made to understand corrosionphenomena and their mechanisms, and to elucidate the causes that dramatically influence the servicelifetime of metal materials [...]

Property modification of a silicone acrylic pressure-sensitive adhesive with oligomeric silicone urethane methacrylate

[J].

Synthesis of novel waterborne silicone modified acrylic sealant and its corrosion resistance in Fe-based amorphous coatings

[J].

Synthesis of water-based cationic polyacrylate copolymer emulsion by RAFT polymerization and its application as an inkjet printing agent

[J].In this work, the authors used reversible addition-fragmentation transfer (RAFT) polymerization to develop a new cationic acrylate modified epoxy resin emulsion for water-borne inkjet which have the advantages of both polyacrylate and epoxy resin. The emulsion was successfully used in the canvas coating for inkjet printing. This paper aims to contribute to the development of novel cationic emulsions for inkjet printing industry.

Molecular design and copolymerization to enhance the anti-corrosion performance of waterborne acrylic coatings

[J].

A multi-functional coating based on acrylic copolymer modified with PDMS through copolymerization

[J].

A type of silicone modified styrene-acrylate latex for weatherable coatings with improved mechanical strength and anticorrosive properties

[J].

Insight into the anti-corrosion performance of electrodeposited silane/nano-CeO2 film on carbon steel

[J].

Improving the anticorrosion characteristics of polymer coatings in the case of their modification with compositions based on organosilanes

[J].The effect of a series of organosilanes and their mixtures with corrosion inhibitors on the anticorrosion properties of polymer and paint coatings on steel, namely, on the adhesive characteristics of the coatings and corrosion behavior of the metal in the presence of coatings modified with organosilanes, corrosion inhibitors, and their mixtures, is studied. It is shown that mixtures of 1,2,3-benzotriazole (BTA) with vinyltrimethoxysilane (VTMS) or aminoethylaminopropyltrimethoxysilane—diaminosilane (DAS) inhibit the local dissolution and underfilm corrosion of carbon steel, and the potential of local depassivation shifts by 0.3–0.4 V. Here, compact polymer-like layers that are strongly bound to the metal surface are formed on the surface of steel. Corrosion and mechanical tests of the samples of pipe steels with different types of inhibiting compositions are conducted. The effect of the inhibitors on the crack growth under static loading in a model soil electrolyte (pH of 5.5) and on the crack resistance of steel under slow tension in an NS-4 model underfilm electrolyte (pH of 7.0) is evaluated. The tests are performed in media free from and containing hydrogen sulfide. It is shown that the best inhibiting properties are manifested by the mixtures of corrosion inhibitors with organosilanes. Comparative laboratory and bench tests for the adhesive strength, water resistance, and resistance to cathodic detachment of the adhesive junctions obtained upon applying the modified polymer and paint coatings onto the surface of steel are performed. It is found that introducing a mixture of organosilane and a corrosion inhibitor improves the adhesive properties of polymer and paint coatings.

Studies on synthesis and characterization of aqueous hybrid silicone-acrylic and acrylic-silicone dispersions and coatings. Part I

[J].The objective of the study was to investigate the effect of the method of synthesis on properties of aqueous hybrid silicone-acrylic (SIL-ACR) and acrylic-silicone (ACR-SIL) dispersions. SIL-ACR dispersions were obtained by emulsion polymerization of mixtures of acrylic and styrene monomers (butyl acrylate, styrene, acrylic acid and methacrylamide) of two different compositions in aqueous dispersions of silicone resins synthesized from mixtures of silicone monomers (octamethylcyclotetrasiloxane, vinyltriethoxysilane and methyltriethoxysilane) of two different compositions. ACR-SIL dispersions were obtained by emulsion polymerization of mixtures of the same silicone monomers in aqueous dispersions of acrylic/styrene copolymers synthesized from the same mixtures of acrylic and styrene monomers, so the compositions of ACR and SIL parts in corresponding ACR-SIL and SIL-ACR hybrid dispersions were the same. Examination of the properties of hybrid dispersions (particle size, particle structure, minimum film forming temperature, Tg of dispersion solids) as well as of corresponding coatings (contact angle, water resistance, water vapour permeability, impact resistance, elasticity) and films (tensile strength, elongation at break, % swell in toluene), revealed that they depended on the method of dispersion synthesis that led to different dispersion particle structures and on composition of ACR and SIL part. Generally, coatings produced from hybrid dispersions showed much better properties than coatings made from starting acrylic/styrene copolymer dispersions.

Synthesis and characterization of polyacrylate composite and its application in superhydrophobic coating based on silicone-modified Al2O3

[J].

Preparation and characterization of polyacrylate composite and its application in superhydrophobic coating based on silicone-modified ZnO

[J].

Development of a water-based acrylic paint with resistance to efflorescence and test method to determine the appearance of stains

[J].

Effect of water-based acrylic acid microcapsules on the properties of paint film for furniture surface

[J].In this paper, self-healing microcapsules with urea formaldehyde coated Nippon water-based acrylic acid were prepared, and the performance of water-based topcoat paint film added with self-healing microcapsules and the repair effect of microcapsules were investigated. The results show that when the content of microcapsules in water-based topcoat paint film on the surface of wood increased, the color difference and hardness rose gradually, the gloss and adhesion declined gradually, the impact resistance and tensile strength at break rose first and then declined. The 0.67:1 core-wall ratio microcapsules had a better micromorphology, and the water-based topcoat paint film with 0.67:1 microcapsules had a certain repair effect. The microcapsules were added to the water-based topcoat paint film to repair the coating to a certain extent, which provide technical reference for prolonging the service life of water-based topcoat paint film for the furniture surface.

Effect of silane modified styrene-acrylic emulsion on the waterproof properties of flue gas desulfurization gypsum

[J].

Preparation and characterization of self-crosslinking acrylic emulsion with different fluorocarbon chain lengths

[J].Fluorine materials have received the keen attention of many researchers because of their water repellency and low surface free energy. The purpose of this paper is to prepare self-crosslinking fluorocarbon polyacrylate latexes containing different fluorocarbon chain lengths by semi-continuous seeded emulsion polymerization technology.

Thermal and mechanical properties of cationic starch-graft-poly (butyl acrylate-co-methyl methacrylate) latex film obtained by semi-continuous emulsion polymerization for adhesive application

[J].

Preparation and characterization of soap-free vinyl acetate/butyl acrylate copolymer latex

[J].The soap-free emulsion of vinyl acetate (VAc)/butyl acrylate (BA) copolymer was prepared by a semi-continuous and pre-emulsification polymerization method, using ammonium sulfate allyloxy nonylphenoxy poly(ethyleneoxy) (10) ether (DNS-86) as a reactive emulsifier. The effects of DNS-86 on the stability of the emulsion and the properties of the latex film were investigated. The infrared spectrum, thermal stability, glass transition temperature and micromorphology of latex were also studied. The results showed that the emulsion had the best stability and the conversion rate reached a maximum of 98.46% when the DNS-86 amount was 4 wt % of the total amount of monomers. Compared with the PVAc latex synthesized with octylphenol polyoxyethylene ether (10) (OP-10), the latex prepared with DNS-86 has higher thermal stability and ionic stability, whereas the latex film has better water resistance.

Modification of styrene-acrylic emulsion by organic UV absorber in synergy with fluorine and silicon monomers for weatherable coatings

[J].

Preparation and characterization of self-crosslinking acrylate emulsion modified by divinyl silane

[J].

Recent progress in silane coupling agent with its emerging applications

[J].

Research progress on anti-corrosion coatings of layered double hydroxides

[J].

层状双金属氢氧化物防腐蚀涂层材料的研究进展

[J].层状双金属氢氧化物 (LDHs) 作为一种重要的无机纳米容器型材料,具有离子交换性、结构可调控、热稳定性良好等优势,近年来已发展成为防腐蚀涂层领域的研究热点。本文系统总结了近年来该领域的相关研究成果,阐述了LDHs材料的防腐蚀机理和影响LDHs防腐蚀性能的因素,总结了几类主流LDHs防腐蚀涂层的研究进展,分析了其在应用过程中存在的问题并提出具有可行性的解决途径。同时,重点对LDHs防腐蚀涂层在多功能化和复合化方面的相关进展进行了总结和展望。

Effect of Ce on corrosion resistance of films of ZnAlCe-layered double hydroxides on Mg-alloy

[J].

Ce对镁合金表面ZnAlCe-LDHs薄膜耐腐蚀性能的影响机理研究

[J].利用一步水热法在AZ91D镁合金表面原位制备ZnAl-LDHs薄膜和ZnAlCe-LDHs薄膜,借助X射线衍射仪、扫描电镜、能谱仪和电化学阻抗谱等表征手段,研究Ce对镁合金表面ZnAlCe-LDHs薄膜形貌结构、化学组成及耐腐蚀性能的影响。结果表明,Ce离子加入不改变镁合金表面LDHs鸟巢网状形貌,但增加了薄膜的厚度以及纳米片的尺寸。EIS结果表明,ZnAlCe-LDHs薄膜与ZnAl-LDHs薄膜相比,自腐蚀电位正移0.05 V,腐蚀电流密度降低1~2个数量级,阻抗图中容抗弧半径明显增大,说明加入Ce离子可以增强镁合金的耐腐蚀性能。