微弧氧化 (MAO) 又称等离子体氧化[10],可通过电弧放电产生瞬时高温烧结得到陶瓷化涂层。该涂层具有高耐腐蚀性、耐高温冲击性、高耐磨性和优异的电绝缘性[11,12]。但是微弧氧化过程中可变参数太多,可造成涂层不致密,大量裂纹、局部烧损、内部应力集中和孔洞尺寸过大等现象[13],且MAO涂层自身表面存在着“火山状”孔洞,可成为腐蚀介质的堆积点,这些都牵制着镁合金耐腐蚀性的突破性提升[14,15]。重要的是,影响镁合金MAO涂层耐腐蚀性的主要因素有涂层形貌、结构和组成,陶瓷相的结构和数量,缺陷的数量和分布等[12,16,17],以上都可因为镁合金微弧氧化电解液组成的变化而变化[18,19]。因此,可通过调节MAO电解液组成有效地改善MAO涂层的耐蚀性[20]。

此外,可对MAO涂层表面“火山状”孔洞或缺陷进行封闭处理,进一步提升涂层耐蚀性。层状双羟基金属氧化物 (LDHs) 是一种经济环保的化学转化膜,被广泛研究用于减轻金属,特别是Al或镁合金的腐蚀[21]。LDHs可用通式[M1-x2+Mx3+(OH)2][A n-] x/n ·mH2O表示,其中M 2+和M 3+分别为二价和三价金属阳离子,A n-为n价的层间阴离子[22,23]。二价金属离子包括Fe2+、Mg2+和Zn2+,三价金属离子包括Al3+、Cr3+、La3+和Y3+等[21]。国内外学者[24,25]通过在MAO涂层上再制备LDHs涂层,取得了较为明显的耐蚀性提升效果。王彪等[26]在AZ91表面制备了具有结构封闭和耐腐蚀性能良好的MAO/LDHs涂层,有效地填补镁合金微弧氧化后产生的涂层缺陷。将MAO涂层和LDHs结合形成的复合涂层,不仅对基体起到多重保护作用,还具有与基体良好的结合能力,使得材料的耐腐蚀性能得到稳定的提升。当涂层受到Cl-的侵蚀时,LDHs薄膜表面由于A n- (如NO

本文首先在铝酸盐/硅酸盐体系 (AS)、铝酸盐/磷酸盐体系 (AP)、硅酸盐/磷酸盐体系 (SP) 和铝酸盐/磷酸盐/硅酸盐体系 (APS) 的微弧氧化电解液中对Mg-Gd-Y-Zn-Mn合金进行微弧氧化,得到了不同表面形貌、相结构、相数量和成分分布等的MAO涂层。然后,采用原位生长的方法在MAO表面成功制备了MAO/MgAlLa-LDHs复合涂层。通过对MAO涂层和MAO/MgAlLa-LDHs复合涂层的形貌、结构及成分的表征分析和对其耐腐蚀性能的评估,提出了不同电解液体系制备的MAO涂层对MgAlLa-LDHs原位生长和对MAO/MgAlLa-LDHs复合涂层性能的影响规律。

1 实验方法

本实验所用材料为Mg-Gd-Y-Zn-Mn合金,其化学成分 (质量分数,%) 为:Y 4.33±0.1,Gd 7.91±0.1,Zn 1.51±0.1,Mn 0.81±0.1,余量Mg。将镁稀土合金材料切割为尺寸规格15 mm×15 mm×5 mm和20 mm×20 mm×5 mm的试样,在试样一侧中间开直径约2 mm圆孔并攻丝,并将试样用400#、600#、800#、1000#和1500#砂纸依次垂直上一次划痕打磨;将端口螺纹直径为2 mm的铜导线拧入试样侧面孔内,再用生胶带缠绕基体和导线的交接部分以防止电解液进入基体内部,得到的预处理试样暂存在真空干燥皿中为后续微弧氧化做准备。

配制不同体系的微弧氧化电解液,如AS、AP、SP和APS,具体成分见表1。将预处理的试样与微弧氧化设备正极连接,不锈钢板连接负极,将试样完全浸入5 L电解液中,进行微弧氧化表面处理。其中,微弧氧化为恒压模式,设置电压为380 V,脉宽为300 μs,频率为500 Hz,氧化时间为5 min,且冷却装置控制电解液为 (12±4) ℃。微弧氧化后,将试样移出,用去离子水冲洗,热空气吹干,得到的微弧氧化涂层分别标记为MAO-AS、MAO-AP、MAO-SP和MAO-APS试样。

表1 不同微弧氧化电解液具体成分 (g/L)

Table 1

| Electrolyte system | NaAlO2 | Na3PO4 | Na2SiO3 | NaOH |

|---|---|---|---|---|

| AS | 6 | 0 | 6 | 2 |

| AP | 6 | 6 | 0 | 2 |

| PS | 0 | 6 | 6 | 2 |

| APS | 4 | 4 | 4 | 2 |

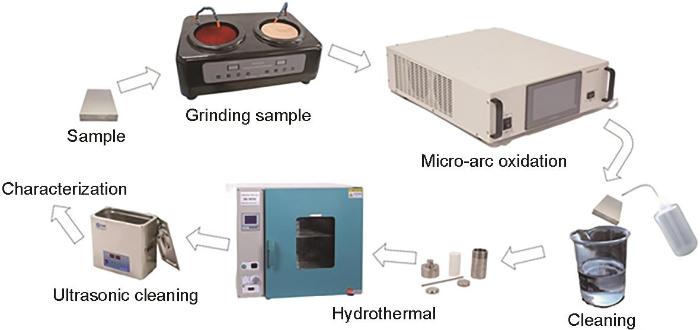

配制LDHs原位生长溶液,具体成分 (mol/L) 为:La (NO3)3 0.02,NaNO3 0.1、Al (NO3)3 0.05,溶液pH 10.72。将原位生长溶液移入聚四氟乙烯内胆中,然后分别将MAO-AS、MAO-AP、MAO-SP和MAO-APS样品也置入盛满生长溶液内胆中,使用配套的高温高压将内胆密封,置入电热恒温鼓风干燥箱。干燥箱参数设定为:温度140 ℃,保温时间12 h。待干燥箱温度降至室温后,将样品取出,去离子水冲洗,再用酒精超声清洗5 min,热空气吹干,得到MAO-AS/MgAlLa-LDHs、MAO-AP/MgAlLa-LDHs、MAO-SP/MgAlLa-LDHs和MAO-APS/MgAlLa-LDHs复合涂层试样,分别标记为MAO-AS-L、MAO-AP-L、MAO-SP-L和MAO-APS-L试样。复合涂层的制备流程如图1所示。

图1

涂层的晶体结构通过Rigaku D/Max 2500 X型X射线衍射仪 (XRD) 进行测定,测试使用Cu Kα1射线 (λ=0.154 nm),管电压及管电流分别为40 kV和40 mA,测试范围2θ = 5°~80°,掠射角为2°。涂层的化学成分与La化学状态通过ESCALAB 250Xi型X射线光电子能谱分析仪 (XPS) 进行分析 (Al Kα射线,1486.6 eV) 。涂层的表面结构、形貌和化学组成可用JSM-7800F场发射扫描电子显微镜 (FESEM) 和能谱仪 (EDS) 来观察分析,SEM的加速电压为20 kV且样品喷金处理以保证导电性。样品的Fourier变换红外光谱 (FT-IR,Nicolet iS5) 测试范围为4000~400 cm-1。

为研究涂层的耐蚀性,用电化学测试系统 (Princeton PARSTAT 4000 A) 测试了样品在3.5% (质量分数) NaCl溶液中的动电位极化曲线和电化学阻抗谱 (EIS),测试采用传统的三电极体系,由饱和甘汞参比电极 (SCE)、Pt箔为对电极、样品为工作电极组成,测试面积为1 cm2,极化曲线扫描速率为2 mV/s,扫描范围为-0.5~0.5 V (相对于开路电位),EIS测量频率范围为105~10-2 Hz,测试前先将试样的背面用砂纸磨光,增加测试夹具与试样的导电性,减小误差。析氢测试通过将样品浸没在室温下 (25 ℃) 的3.5% (质量分数) NaCl溶液中进行。析氢装置是一个连接到刻度为50 mL滴定管的倒置漏斗中,每隔固定的时间记录H2的析出。

2 结果与讨论

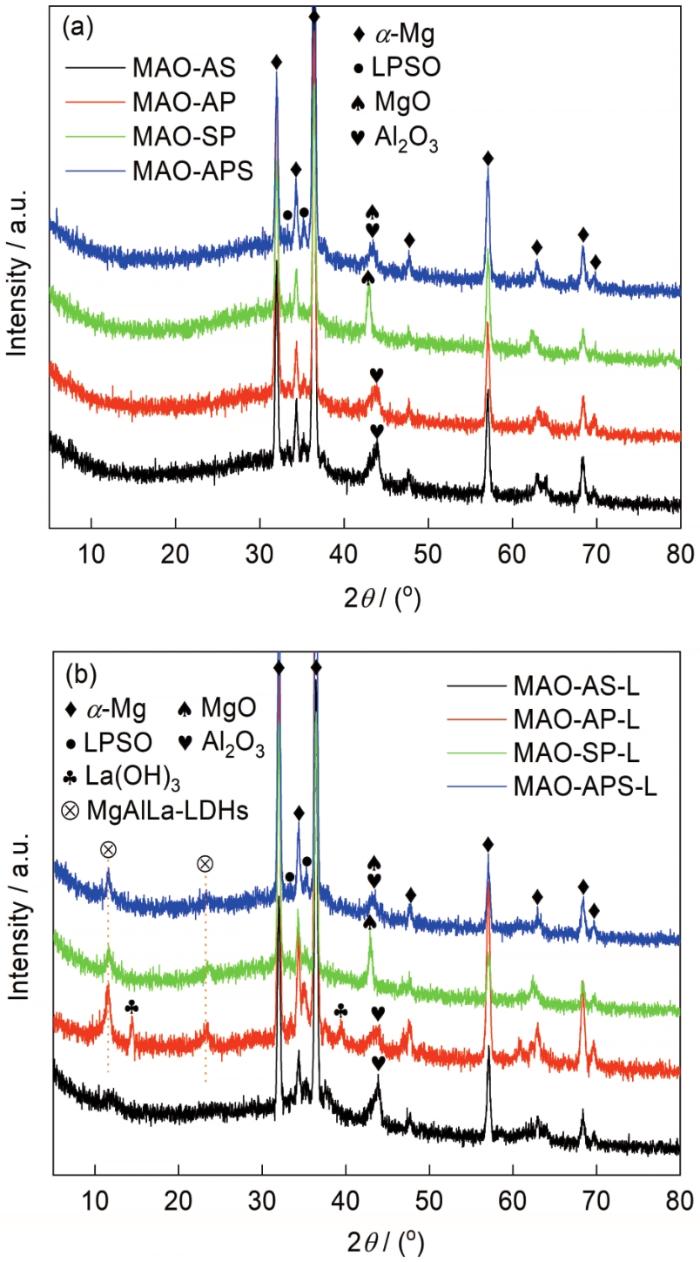

图2表示不同MAO涂层和MAO/MgAlLa-LDHs复合涂层的XRD谱。可以看出,MAO涂层和MAO/MgAlLa-LDHs复合涂层在32.19°,34.40°,36.62°,47.83°,57.37°,63.06°,67.30°,68.62°,69.98°,72.48°和77.81°附近均出现了衍射峰,分别对应着α-Mg的(100),(002),(101),(102),(110),(103),(200),(112),(201),(004) 和 (202) 的晶面[32]。另外,在2θ约为34.02°和35.42°处显示的衍射峰与镁合金中的LPSO相有关[33];据前期工作报道[34],这可增加MAO涂层密度。图2a中MAO-AP涂层在2θ≈43.05°处检测出尖锐的晶体MgO衍射峰,MAO-SP涂层在2θ≈44.05°处出现了晶体Al2O3的衍射峰,而MAO-APS涂层在2θ≈43.59°出现的衍射峰可能是MgO和Al2O3的衍射峰叠加[34]。对照图2b,MAO-SP-L、MAO-AP-L和MAO-APS-L涂层在11.32°和23.22°处都出现了衍射峰,这属于LDHs的特征衍射峰,对应 (003) 和 (006) 晶面,表明LDHs在MAO表面的成功制备[35]。然而,MAO-AS-L涂层仅在2θ ≈ 11.66°处出现了衍射峰波动,表明MAO-AS涂层表面的LDHs结晶度不强。

图2

图2

不同MAO涂层及对应的MAO/MgAlLa-LDHs复合涂层的XRD谱

Fig.2

XRD patterns of MAO coatings (a) and MAO/MgAlLa-LDHs composite coatings (b)

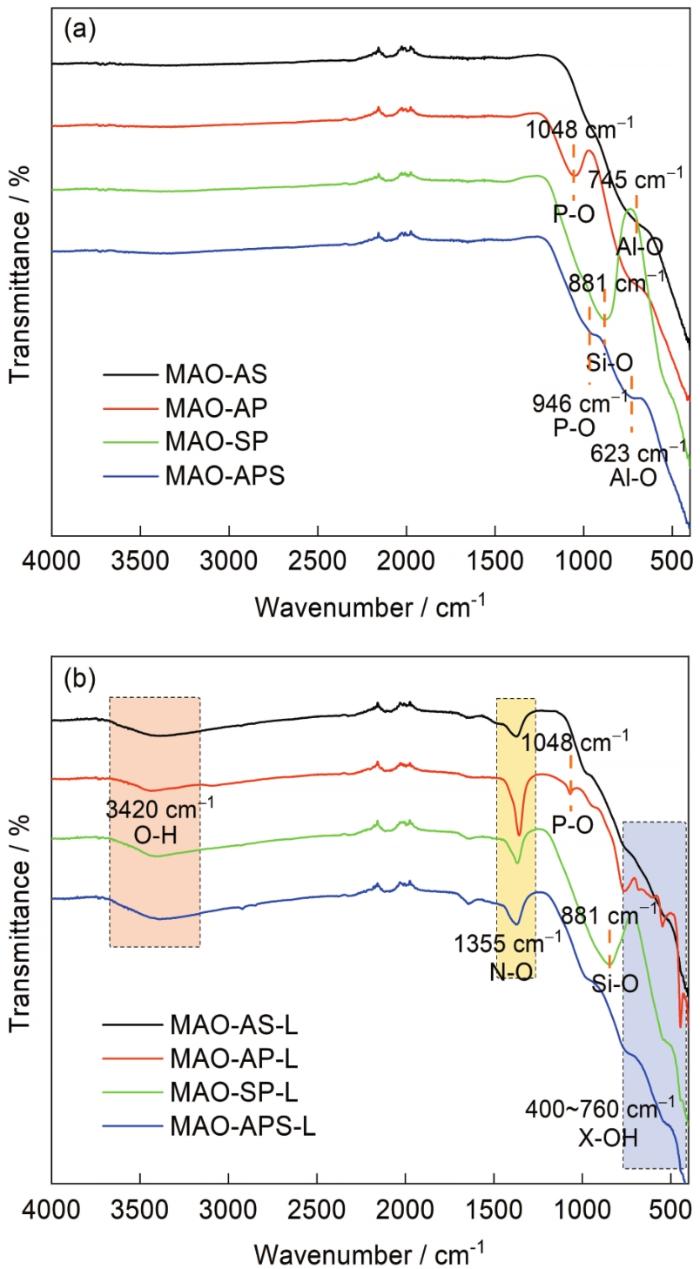

为了进一步分析,对不同涂层的官能团组成进行FT-IR测试,所得结果见图3。图3a中,MAO-AP涂层在1048 cm-1处出现了明显的吸收峰,而MAO-APS涂层在946 cm-1处出现了吸收峰,这都可归因于P-O的伸缩振动[36]。MAO-SP涂层在881 cm-1处出现明显的吸收峰,对应于Si-O的伸缩振动[37]。此外,MAO-AS涂层在745 cm-1处出现了微弱的吸收峰,可归因于Al-O的振动[38]。相似的,MAO-APS涂层在623 cm-1处的微弱吸收峰也与Al-O的振动有关。经过表明LDHs原位生长后,图3b显示4种LDHs涂层均出现了以3420 cm-1为中心的较宽的吸收峰,这对应于水或羟基中的O-H化学键的伸缩振动,可能与LDHs中的层间水分子或LDHs层板金属羟基有关[39]。MAO-AP-L、MAO-SP-L和MAO-APS-L涂层在低波数带 (400~760 cm-1) 出现X-OH吸收峰,其X代表Al、Mg和La,表明这3种MAO/LDHs复合涂层成功制备[40],与XRD结果一致。此外,这3种MAO/LDHs复合涂层均在1355 cm-1处出现了明锐的吸收峰,归因于NO

图3

图3

不同MAO涂层及对应的MAO/MgAlLa-LDHs复合涂层的FT-IR光谱

Fig.3

FT-IR spectra of MAO coatings (a) and MAO/MgAlLa-LDHs composite coatings (b)

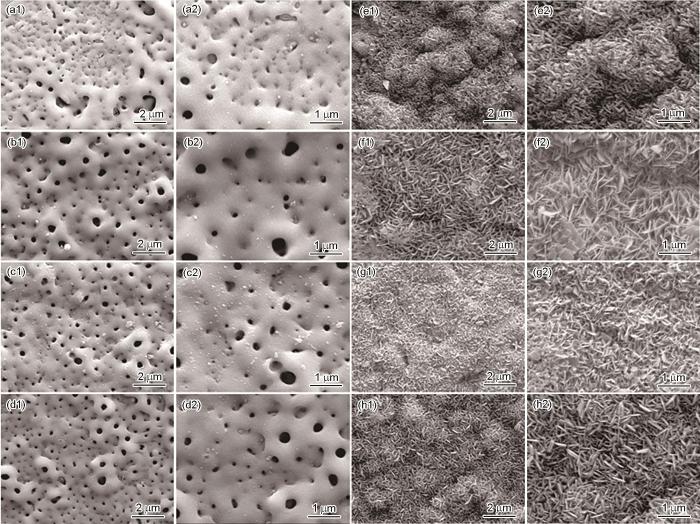

图4和表2为MAO和MAO/LDHs复合涂层的表面形貌和EDS。能够发现4种电解液体系制备的MAO涂层表面都具有多孔状的“火山口”形貌特征,这与微弧氧化的机理有直接关系。当基体表面氧化涂层被高电压击穿后,形成的放电通道中产生瞬时的高温高压。基体和电解液在这种环境下发生一系列复杂的物理化学反应,再通过电解液的快速冷却从而逐渐形成微孔结构。然而,图4a2~d2显示这4种MAO涂层在微观形貌上也具有一定的差异:MAO-AS涂层表面凹凸不平,微孔大小各异、分布不均,存在微小的细孔但局部孔洞仍然粗大、不规则;MAO-AP涂层表面“火山口”特征较为明显且孔洞连续交叠,分布较为密集,但局部仍然存在表面凹陷、微孔分布不均的特征;MAO-SP涂层表面“火山口”直径范围约为0~1 μm,但局部表面凹陷且有些许白色颗粒附着表面;MAO-APS涂层表面“火山口”微孔无破损,大多数孔洞交叠连贯且分布密集均匀,多为纳米尺寸。这有利于阻碍基体和环境介质的接触,提升基体耐腐蚀性能。表2中的EDS数据显示MAO涂层主要成分为MgO,且不同MAO电解液体系的添加盐均参与了成膜反应,可能分别得到了MgAl2O4、Mg3(PO4)2或Mg2SiO4陶瓷相[42]。此外,4种MAO涂层表面原位生长了LDHs后的形貌显示:MAO-AP-L、MAO-SP-L和MAO-ASP-L涂层表面存在着经典的LDHs纳米片结构,即垂直于基体表面生长的“血小板”状结构[41],平面尺寸远大于厚度;而MAO-AS-L涂层表面围绕“火山口”处分布着混乱、无方向的团簇条状结构,这可能是LDHs未完全生长导致的,与XRD结果相符。图4e1~h1和e2~h2显示MAO-AP-L纳米片分布均匀,尺寸大,但少量被沉淀物覆盖,这与XRD中出现的La(OH)3衍射峰有关;MAO-SP-L纳米片分布密集,尺寸细小,与MAO-ASP-L纳米片结构相似。表2中的EDS数据也显示MAO-AP-L、MAO-SP-L和MAO-ASP-L涂层中,Al和O的含量增加,且存在着La和N,这可能与MgAlLa-LDHs的存在有关,且层间阴离子为NO

图4

图4

不同涂层的表面SEM形貌

Fig.4

SEM morphologies of MAO-AS (a1, a2), MAO-AP (b1, b2), MAO-SP (c1, c2), MAO-APS (d1, d2), MAO-AS-L (e1, e2), MAO-AP-L (f1, f2), MAO-SP-L (g1, g2) and MAO-APS-L (h1, h2) coatings

表2 MAO和对应的MAO/LDHs复合涂层的EDS分析结果 (atomic fraction / %)

Table 2

| Coating | Mg | O | Al | La | P | Si | Gd | Y | N |

|---|---|---|---|---|---|---|---|---|---|

| MAO-AS | 39.9 | 45.9 | 7.8 | 0 | 0 | 4.6 | 1.2 | 0.6 | 0 |

| MAO-AP | 37.5 | 48.7 | 7.6 | 0 | 4.3 | 0 | 1.3 | 0.6 | 0 |

| MAO-PS | 39.6 | 48.6 | 0 | 0 | 4.3 | 5.2 | 1.5 | 0.8 | 0 |

| MAO-APS | 35.6 | 47.0 | 7.3 | 0 | 4.1 | 4.1 | 1.2 | 0.7 | 0 |

| MAO-AS-L | 38.4 | 48.4 | 8.0 | 0 | 0 | 3.8 | 0.8 | 0.4 | 0.2 |

| MAO-AP-L | 32.9 | 51.7 | 8.2 | 1.5 | 3.4 | 0 | 0.8 | 0.3 | 1.2 |

| MAO-PS-L | 33.8 | 52.9 | 0 | 1.8 | 3.5 | 4.4 | 0.9 | 0.5 | 1.2 |

| MAO-APS-L | 31.8 | 49.8 | 8.0 | 1.5 | 3.1 | 3.6 | 0.8 | 0.4 | 1.0 |

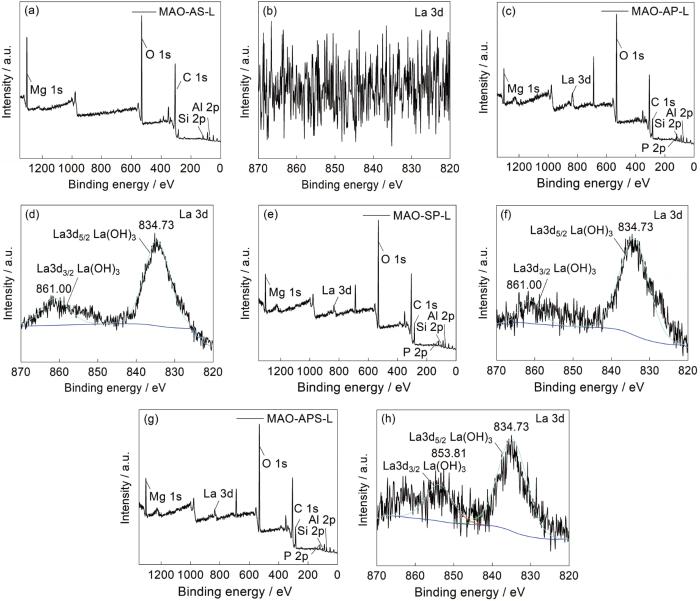

进一步通过灵敏的XPS探测技术定性验证分析了不同MAO/LDHs复合涂层中La3+是否成功被引入到LDHs的层间结构当中。图5为不同MAO/LDHs涂层的XPS元素总谱图和对应的La 3d高分辨图谱。图5b显示MAO-AS-L涂层的La 3d分峰图信号微弱无明显的特征峰,同时在图5a中也未检测出对应的La 3d峰的存在,表明MAO-AS-L涂层表面不存在MgAlLa-LDHs。然而,在MAO-AP-L、MAO-PS-L和MAO-APS-L涂层的XPS元素总谱图 (图5c、e和g) 均存在La 3d峰,与之相对应的在图5d中的834.73和861.00 eV,图5f中的834.08 和861.08 eV和图5h中的834.77和853.81 eV分别对应La(OH)3的La 3d5/2和La 3d3/2的两个价态峰[43],表明MgAlLa-LDHs在MAO-AP、MAO-PS和MAO-APS涂层上成功原位生长。

图5

图5

不同MAO/LDHs复合涂层的XPS谱

Fig.5

XPS spectra of MAO-AS-L (a, b), MAO-AP-L (c, d), MAO-PS-L (e, f) and MAO-APS-L (g, h) composite coatings

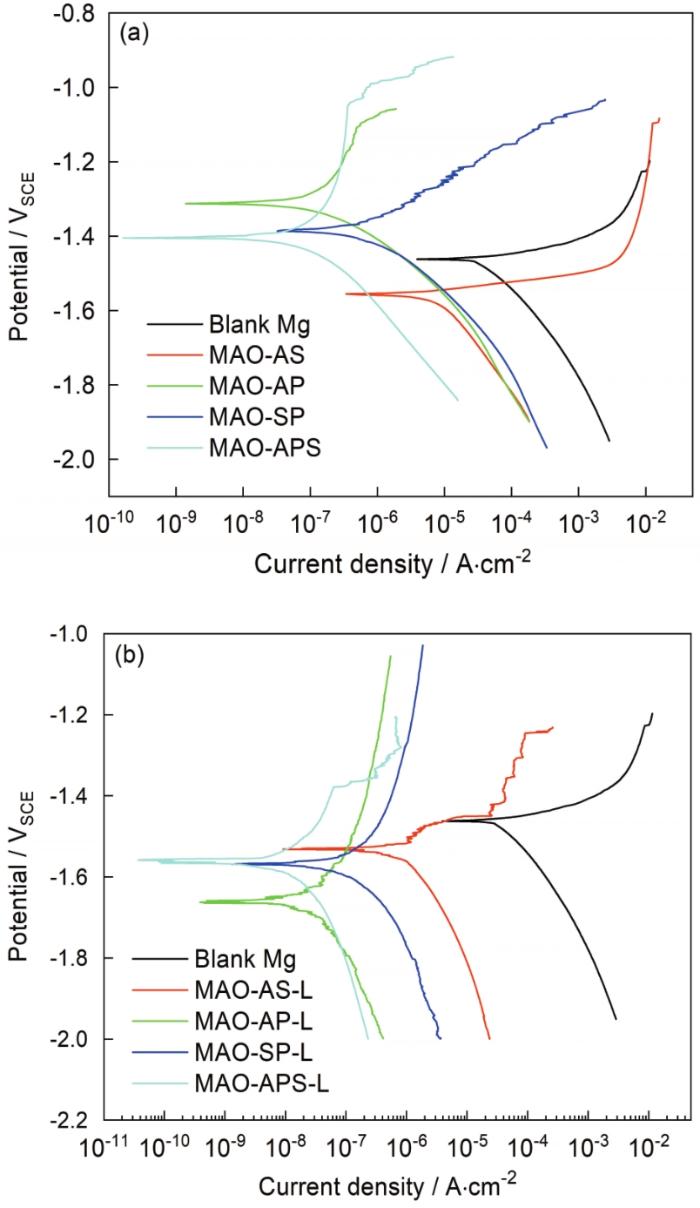

进一步通过电化学测试的方法对涂层的耐腐蚀性能进行了评估。图6展示了在3.5% NaCl溶液中测量的镁合金基体、MAO涂层和MAO/LDHs复合涂层的动电位极化曲线,其电位 (Ecorr) 和电流密度 (Icorr) 的拟合计算结果见表3。通常,Icorr越小,腐蚀过程越慢,这意味着耐腐蚀性越好[44]。表3显示镁合金基体的Icorr最大,为4.34×10-5 A cm-2,其腐蚀速率较大,表明镁合金基体作为结构材料必须进行表面处理,以提高耐腐蚀性,延长使用寿命。图6和表3显示在镁合金基体制备MAO涂层和MAO/LDHs复合涂层后,耐蚀性都有所提升,但提高的效果不同。在4种MAO涂层中,MAO-APS涂层的耐腐蚀性最好,其Icorr为4.83×10-8 A cm-2,比镁基体提升了约3个数量级。而MAO-AS涂层的Icorr为7.15×10-6 A·cm-2,耐蚀性提升不到一个数量级。原位生长LDHs后,涂层的耐蚀性也相应地进一步提高。MAO-APS-L涂层耐蚀性最优,其Icorr为9.14×10-9 A·cm-2,比镁基体提升了约3个数量级;MAO-AP-L和MAO-SP-L涂层在耐腐蚀性方面相似,对应的Icorr分别为2.39×10-8和8.47×10-8 A·cm-2,而MAO-AS涂层耐腐蚀性较差,其Icorr为1.05×10-6 A·cm-2。

图6

图6

在3.5% NaCl溶液中测量的镁合金基体、MAO涂层和MAO/LDHs复合涂层的动电位极化曲线

Fig.6

Potentiodynamic polarization curves of Mg alloy substrate, MAO coatings (a) and MAO/LDHs composite coatings (b) in 3.5%NaCl solution

表3 图6中动电位极化曲线的Ecorr和Icorr的拟合计算结果

Table 3

| Sample | Ecorr / VSCE | Icorr / A·cm-2 |

|---|---|---|

| Blank Mg | -1.469 | 4.34×10-5 |

| MAO-AS | -1.562 | 7.15×10-6 |

| MAO-AP | -1.298 | 1.22×10-7 |

| MAO-SP | -1.401 | 6.55×10-7 |

| MAO-APS | -1.404 | 4.83×10-8 |

| MAO-AS-L | -1.538 | 1.05×10-6 |

| MAO-AP-L | -1.664 | 2.39×10-8 |

| MAO-SP-L | -1.569 | 8.47×10-8 |

| MAO-APS-L | -1.559 | 9.14×10-9 |

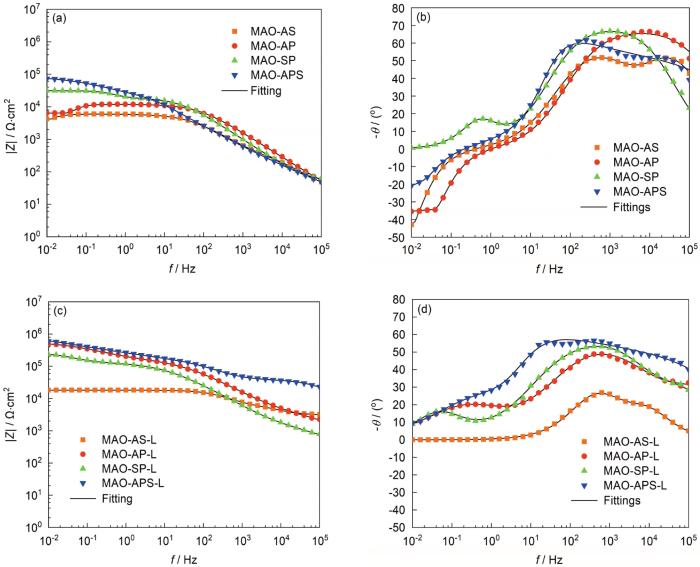

为了分析不同涂层表面的电化学特性,进行了EIS测试。在测试之前,进行了30 min的开路电位 (OCP) 测试来稳定样品的表面电荷状态[39]。图7为MAO涂层和MAO/LDHs复合涂层的Bode图。通常10-2 Hz的低频电阻|Z|0.01对应于涂层的整体电阻,可判断耐蚀性差异[45]。因此,通过对比图7a和c中10-2 Hz对应的阻抗模值,可见4种MAO涂层中MAO-APS涂层耐蚀性最优,同样的4种MAO/LDHs复合涂层中MAO-APS-L涂层耐蚀性也最优。有趣的是,MAO-AP和MAO-AS在图7a中的低频处阻抗模值和图7b中的低频处相位角出现拐点,这可能与电感有关。对于镁合金的电化学阻抗来说,电感的产生是比较常见的,它受到腐蚀产物在基体界面吸附和脱附的影响。

图7

图7

不同涂层在3.5% NaCl溶液中测得的Bode图

Fig.7

Impedance module (a, c) and phase angle (b, d) plots of MAO coatings (a, b) and MAO/LDHs composite coatings (c, d) in 3.5% NaCl solution

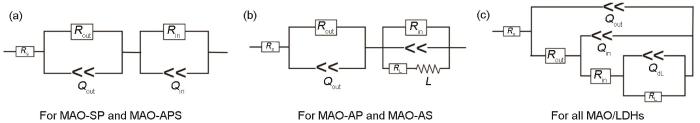

考虑到涂层的非均匀性和复杂性,采用恒相元件 (CPE) 来代替理想的电容,定义式为[46]:

式中,Q与理想电容有关,j为虚数单位,w为角频率,n为指数 (0<n≤1)。图8给出了不同涂层的EIS等效电路图,其中Rs、Rout、Rin和Rct分别代表测试溶液电阻、多孔层电阻、致密层电阻和电荷转移电阻,Qout、Qin和Qdl分别代表多孔层电容、致密层电容和双电层电容,RL和L分别表示电感电阻和电感。所有拟合的分量值如表4所示,所有样本的拟合误差卡方值都很小,可以忽略。通常使用Rout、Rin和Rct之和来代表涂层的整体电阻。同样发现,4种MAO涂层中MAO-APS涂层耐蚀性最佳,且4种MAO/LDHs复合涂层中MAO-APS-L涂层耐蚀性也最优异,其中MAO-APS-L涂层的Rct值可达5.9×105 Ω·cm2。

图8

图8

用于拟合EIS数据的等效电路

Fig.8

Equivalent circuits used for fitting EIS data: (a) MAO-SP, MAO-APS, (b) MAO-AP, MAO-AS, (c) all MAO/LDHs composite coatings

表4 图7中EIS数据的等效电路拟合结果

Table 4

| Sample | Rout Ω·cm2 | Qout S·s n ·cm-2 | nout | Rinn Ω·cm2 | Qinn S·s n ·cm-2 | ninn | Rct Ω·cm2 | Cdl S·s n ·cm-2 | ndl | χ2 |

|---|---|---|---|---|---|---|---|---|---|---|

| MAO-AS | 1.23×102 | 6.9×10-7 | 0.9 | 5.9×103 | 2.6×10-6 | 0.7 | - | - | - | 2.9×10-4 |

| MAO-AP | 8.3×102 | 9.1×10-7 | 1.0 | 6.7×103 | 4.8×10-7 | 0.9 | - | - | - | 2.4×10-4 |

| MAO-SP | 1.3×104 | 3.1×10-5 | 0.8 | 2.2×104 | 9.2×10-7 | 0.8 | - | - | - | 1.1×10-4 |

| MAO-APS | 1.3×104 | 4.0×10-6 | 0.9 | 8.6×104 | 1.8×10-5 | 0.6 | - | - | - | 8.1×10-4 |

| MAO-AS-L | 3.3×103 | 7.4×10-9 | 1.0 | 7.4×103 | 3.8×10-8 | 1.0 | 1.3×104 | 3.1×10-7 | 1.0 | 1.4×10-4 |

| MAO-AP-L | 3.9×104 | 1.1×10-9 | 0.8 | 1.2×104 | 3.3×10-6 | 0.8 | 4.2×105 | 3.3×10-6 | 0.5 | 3.3×10-4 |

| MAO-SP-L | 1.4×104 | 1.1×10-7 | 0.7 | 7.4×105 | 3.5×10-7 | 0.7 | 1.6×105 | 2.5×10-5 | 0.7 | 1.9×10-4 |

| MAO-APS-L | 4.1×104 | 5.2×10-8 | 0.7 | 8.5×104 | 1.4×10-7 | 0.7 | 5.9×105 | 3.7×10-6 | 0.6 | 3.3×10-4 |

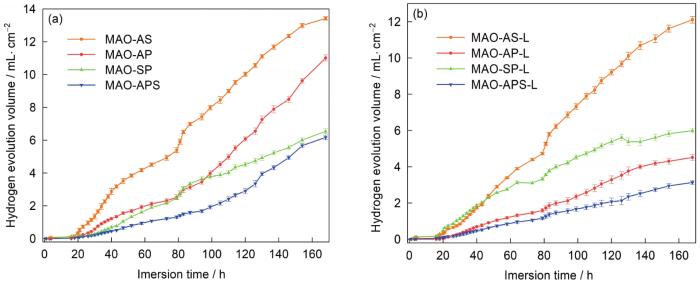

由于Cl-腐蚀镁合金基体时会有H2产生,所以可通过相同浸泡时间对应的析氢量来判断涂层对镁合金基底的保护性能[47]。图9为所有涂层在不同浸泡腐蚀时间下的单位面积析氢体积。结果表明,MAO-APS-L涂层的耐腐蚀性最好,浸泡168 h的H2析出量仅3.13 mL·cm-2,而MAO-AS涂层的耐腐蚀性最差,浸泡168 h的H2析出量为13.42 mL·cm-2。此外,生长LDHs后的复合涂层与MAO涂层相比,析氢量均有所下降,表明耐蚀性确实有所提升。因此,根据所有涂层析氢量的结果分析,其耐腐蚀性由好到差为:MAO-APS-L>MAO-AP-L>MAO-SP-L>MAO-APS>MAO-SP>MAO-AP>MAO-AS-L>MAO-AS,这与电化学测试结果相符合。

图9

图9

不同涂层在3.5% NaCl溶液中浸泡的析氢数据

Fig.9

Hydrogen evolution data of MAO coatings (a) and MAO/LDHs composite coatings (b) during immersion in 3.5% NaCl solution

3 结论

(1) XRD、SEM、EDS和XPS对涂层的结构、形貌和成分的分析结果表明,不同电解液体系的MAO涂层在相结构、相的数量、元素分布和孔洞尺寸等存在着差异,从而影响后续MgAlLa-LDHs的原位生长。其中,MAO-AP-L、MAO-SP-L和MAO-ASP-L涂层表面成功生长了MgAlLa-LDHs纳米片,而MAO-AS-L涂层未有LDHs纳米片结构。

(2) 电化学测试和浸泡析氢的结果表明,所有涂层的耐蚀性顺序为:MAO-APS-L>MAO-AP-L>MAO-SP-L>MAO-APS>MAO-SP>MAO-AP>MAO-AS-L>MAO-AS,其中MAO-APS-L涂层具有最为优异的耐蚀性,电流密度Icorr为9.14×10-9 A·cm-2,阻抗Rct值可达5.9×105 Ω·cm2。

参考文献

Effect of Al on the microstructure, corrosion behavior and mechanical properties of Mg-4Li

[J].This paper aims to investigate microstructure, corrosion behavior and mechanical properties of Mg-4Li and Mg-4Li-3Al.

Enhanced corrosion resistance of Mg alloy ZK60 after processing by integrated extrusion and equal channel angular pressing

[J].

Effect of selective oxidation on corrosion behavior of Mg-Gd-Y-Zn-Zr alloy

[J].

The role of long‐period stacking ordered phase on the discharge and electrochemical behaviors of magnesium anode Mg‐Zn‐Y for the primary Mg‐air battery

[J].

In vitro degradation and antibacterial property of a copper-containing micro-arc oxidation coating on Mg-2Zn-1Gd-0.5Zr alloy

[J].

Microstructure and corrosion resistance of medical degradable Mg-2Y-1Zn-xZr alloy

[J].

医用可降解Mg-2Y-1Zn-xZr合金微观组织和耐蚀性能研究

[J].为了提高医用可降解Mg-2Y-1Zn合金耐腐蚀性能,添加了不同含量的Zr (0,0.2%,0.4%和0.6%,质量分数),并通过XRD、OM、SEM、EDS、析氢和电化学实验等方法研究了Zr含量对合金显微组织和腐蚀行为的影响。结果表明:Mg-2Y-1Zn主要由α-Mg与Mg<sub>3</sub>Y<sub>2</sub>Zn<sub>3</sub>相组成,适量Zr (≤0.4%) 的加入没有改变第二相的类型。Zr可以有效细化合金晶粒,优化组织结构,降低腐蚀电流密度,提升合金耐腐蚀性,并使之趋于均匀腐蚀。但当Zr含量达到0.6%时,多余的Zr会析出形成富Zr区,促进电偶腐蚀的发生,使合金耐蚀性有所下降。析氢结果表明,Mg-2Y-1Zn-0.4Zr合金耐腐蚀性最佳。

Effect of Zr addition on microstructure and corrosion behavior of Mg-3Zn-1Y alloys

[J].

Zr含量对Mg-3Zn-1Y合金显微组织和腐蚀行为的影响

[J].

Review of recent developments in the field of magnesium corrosion

[J].

Research Progress of Corrosion Inhibitor for Mg-alloy

[J].

镁合金缓蚀剂研究进展

[J].镁化学性质活泼,在水溶液环境中腐蚀速度较快,很大程度上制约了镁合金的大规模应用。缓蚀剂是目前腐蚀与防护领域应用最广泛的一种技术,具备高效、成本低等特点,可在工业应用中大幅度提高镁合金的耐蚀性能。本文依据缓蚀剂的化学组成进行分类,概述无机、有机缓蚀剂以及复配缓蚀剂的研究进展,通过总结缓蚀机理对镁合金缓蚀剂未来的研究方向提出了展望。

Introduction to plasma electrolytic oxidation—an overview of the process and applications

[J].Plasma electrolytic oxidation (PEO), also called micro-arc oxidation (MAO), is an innovative method in producing oxide-ceramic coatings on metals, such as aluminum, titanium, magnesium, zirconium, etc. The process is characterized by discharges, which develop in a strong electric field, in a system consisting of the substrate, the oxide layer, a gas envelope, and the electrolyte. The electric breakdown in this system establishes a plasma state, in which, under anodic polarization, the substrate material is locally converted to a compound consisting of the substrate material itself (including alloying elements) and oxygen in addition to the electrolyte components. The review presents the process kinetics according to the existing models of the discharge phenomena, as well as the influence of the process parameters on the process, and thus, on the resulting coating properties, e.g., morphology and composition.

Active protection of Mg alloy by composite PEO coating loaded with corrosion inhibitors

[J].

Plasma electrolytic oxidation of magnesium and its alloys: Mechanism, properties and applications

[J].

Micro-defects in Micro-arc Oxidation Coatings on Mg-alloys

[J].

镁合金微弧氧化膜中微缺陷问题研究进展

[J].针对镁合金的微弧氧化膜,对微缺陷的形成及其影响因素、微缺陷对微弧氧化膜性能及应用的影响、微缺陷的识别技术、后处理手段进行了总结与分析。最后,提出了镁合金微弧氧化膜及其他金属防护层中微缺陷问题的未来研究方向和思路。

Formation mechanism of oxide layer on AZ31 Mg alloy subjected to micro-arc oxidation considering surface roughness

[J].

Characterization of pitting corrosion behavior of AZ91 Mg-alloy without and with MAO coating

[J].

AZ91镁合金和MAO涂层的点蚀行为研究

[J].采用循环极化曲线研究了AZ91镁合金及其表面微弧氧化 (MAO) 涂层在3.5%NaCl溶液中的点蚀行为。采用光学显微镜和扫描电镜观察循环极化不同阶段的点蚀形貌,探讨了点蚀在AZ91镁合金和MAO涂层上的萌生和扩展机制。结果表明,合金上点蚀倾向于在α-Mg相上萌生,而涂层上点蚀在多孔结构和裂纹处萌生,合金和涂层上点蚀的初始形态均为开口的“火山口”形貌。合金上点蚀坑中沉积一层腐蚀产物层对点蚀产生一定钝化效果,导致了点蚀在合金上横向扩展。而涂层上点蚀造成涂层的剥离和腐蚀产物的溶解,无法对点蚀形成钝化效果,导致点蚀在涂层上向纵深扩展。点蚀在循环极化过程中持续扩展的微观形貌验证了合金和涂层的循环极化曲线上出现正的滞后环,而不同的点蚀扩展现象也验证了涂层上较大的滞后环面积。

Influence of second phase on corrosion performance and formation mechanism of PEO coating on AZ91 Mg alloy

[J].

Effect of ultrasonic rolling pretreatment on corrosion resistance of micro-arc oxidation coating of Mg-alloy

[J].

镁合金表面超声滚压预处理对微弧氧化膜耐蚀性能的影响

[J].

Plasma electrolytic oxidation coatings on Mg alloy with addition of SiO2 particles

[J].

Plasma electrolytic oxidation of AZ31 and AZ91 magnesium alloys: Comparison of coatings formation mechanism

[J].

The influence of additives on the stability behavior of electrolyte, discharges and PEO films characteristics

[J].

Layered double hydroxides (LDHs) as functional materials for the corrosion protection of aluminum alloys: A review

[J].

Layered double hydroxide films: synthesis, properties and applications

[J].

Research progress on anti-corrosion coatings of layered double hydroxides

[J].

层状双金属氢氧化物防腐蚀涂层材料的研究进展

[J].层状双金属氢氧化物 (LDHs) 作为一种重要的无机纳米容器型材料,具有离子交换性、结构可调控、热稳定性良好等优势,近年来已发展成为防腐蚀涂层领域的研究热点。本文系统总结了近年来该领域的相关研究成果,阐述了LDHs材料的防腐蚀机理和影响LDHs防腐蚀性能的因素,总结了几类主流LDHs防腐蚀涂层的研究进展,分析了其在应用过程中存在的问题并提出具有可行性的解决途径。同时,重点对LDHs防腐蚀涂层在多功能化和复合化方面的相关进展进行了总结和展望。

PEO/Mg-Zn-Al LDH composite coating on Mg alloy as a Zn/Mg Ion-release platform with multifunctions: enhanced corrosion resistance, osteogenic, and antibacterial activities

[J].

Enhanced corrosion resistance of AZ31 Mg alloy by one-step formation of PEO/Mg-Al LDH composite coating

[J].

Fabrication and corrosion resistance of MAO-LDH composite coating on AZ91 Mg alloy

[J].

微弧氧化-水滑石复合涂层的制备及其在AZ91镁合金防腐蚀中的应用

[J].

“Smart” coatings for active corrosion protection based on multi-functional micro and nanocontainers

[J].

Effect of Ce on corrosion resistance of films of ZnAlCe-layered double hydroxides on Mg-alloy

[J].

Ce对镁合金表面ZnAlCe-LDHs薄膜耐腐蚀性能的影响机理研究

[J].利用一步水热法在AZ91D镁合金表面原位制备ZnAl-LDHs薄膜和ZnAlCe-LDHs薄膜,借助X射线衍射仪、扫描电镜、能谱仪和电化学阻抗谱等表征手段,研究Ce对镁合金表面ZnAlCe-LDHs薄膜形貌结构、化学组成及耐腐蚀性能的影响。结果表明,Ce离子加入不改变镁合金表面LDHs鸟巢网状形貌,但增加了薄膜的厚度以及纳米片的尺寸。EIS结果表明,ZnAlCe-LDHs薄膜与ZnAl-LDHs薄膜相比,自腐蚀电位正移0.05 V,腐蚀电流密度降低1~2个数量级,阻抗图中容抗弧半径明显增大,说明加入Ce离子可以增强镁合金的耐腐蚀性能。

Doublely-doped Mg-Al-Ce-V2O7 4- LDH composite film on magnesium alloy AZ31 for anticorrosion

[J].

Intercalation of Y in Mg-Al layered double hydroxide films on anodized AZ31 and Mg-Y alloys to influence corrosion protective performance

[J].

Microstructural characteristics of oxide layer formed by plasma electrolytic oxidation: Nanocrystalline and amorphous structures

[J].

Microstructure and mechanical properties of large-scale Mg-Gd-Y-Zn-Mn alloys prepared through semi-continuous casting

[J].Large-scale Mg-8Gd-4Y-1Zn-Mn (wt.%) alloy ingot with a diameter of 315 mm and a length of 2410 mm was prepared through semi-continuous casting. Chemical composition, microstructure and mechanical properties at different locations of the samples with as-cast, T4 and T6 heat-treated states, respectively, were investigated. No obvious macro segregation has been detected in the high-quality alloy ingot. The main eutectic structures at all different locations are composed of α-Mg, Mg3RE-type, Mg5RE-type and LPSO phases. At the edge of ingot, the unusual casting twins including $\text{ }\!\!\{\!\!\text{ 10}\bar{1}\text{2 }\!\!\}\!\!\text{ }$ extension twins and $\text{ }\!\!\{\!\!\text{ 10}\bar{1}\text{1 }\!\!\}\!\!\text{ }$ compression twins were observed due to the intensive internal stress. In T4 heat-treated alloy, the micro segregation was eliminated. The remained phases were α-Mg and LPSO phase. Combined with the remarkable age-hardening response, T6 samples exhibits improved mechanical properties at ambient temperature, which derives from the dense prismatic β' precipitates and profuse basal γ' precipitates.

Effect of Zn/ (Gd + Y) ratio on the microstructure evolution and mechanical properties of Mg-Gd-Y-Zn-Zr alloy

[J].

Effect of electrolyte systems on plasma electrolytic oxidation coatings characteristics on LPSO Mg-Gd-Y-Zn alloy

[J].

Active corrosion protection by a smart coating based on a MgAl-layered double hydroxide on a cerium-modified plasma electrolytic oxidation coating on Mg alloy AZ31

[J].

Enhancing the self-healing property by adding the synergetic corrosion inhibitors of Na3PO4 and 2-mercaptobenzothiazole into the coating of Mg alloy

[J].

Effect of particles addition to solution of plasma electrolytic oxidation (PEO) on the properties of PEO coatings formed on magnesium and its alloys: a review

[J].

Growth behaviour of low-energy plasma electrolytic oxidation coatings on a magnesium alloy

[J].

In situ growth of Mg-Zn-Al LDHs by ZIF-8 carrying Zn source and micro-arc oxidation integrated coating for corrosion and protection of magnesium alloys

[J].

One-step in situ synthesis of graphene oxide/MgAl-layered double hydroxide coating on a micro-arc oxidation coating for enhanced corrosion protection of magnesium alloys

[J].

A self-healing corrosion protection coating with graphene oxide carrying 8-hydroxyquinoline doped in layered double hydroxide on a micro-arc oxidation coating

[J].

Role of the electrolyte composition in establishing plasma discharges and coating growth process during a micro-arc oxidation

[J].

Synergistic effect of graphene oxide/ ternary Mg-Al-La layered double hydroxide for dual self-healing corrosion protection of micro-arc oxide coating of magnesium alloy

[J].

Evaluation of self-healing ability in protective coatings modified with combinations of layered double hydroxides and cerium molibdate nanocontainers filled with corrosion inhibitors

[J].

Interlayer intercalation and arrangement of 2-mercaptobenzothiazolate and 1, 2, 3-benzotriazolate anions in layered double hydroxides: in situ X-ray diffraction study

[J].

Development of metal-organic framework (MOF) decorated graphene oxide/MgAl-layered double hydroxide coating via microstructural optimization for anti-corrosion micro-arc oxidation coatings of magnesium alloy

[J].An efficient and simple in-situ growth strategy has been discovered for the preparation of highly reproducible and continuous symbiotic ZIF-8-based anticorrosion coating by using graphene oxide (GO)/MgAl-NO3 layered double hydroxides (G/LDHs) buffer layer as a new type of connecting carrier based on micro-arc oxide (MAO) coating of AZ31 magnesium alloy. The components of ZIF-8 were adsorbed and bounded to the surface of the G/LDHs buffer layer-modified substrates to promote the nucleation of ZIF-8, thus growing a phase-pure, uniform, and good symbiosis ZIF-8 membrane. ZIF-8 particles with different growth times compensate for the grain boundary defects of the G/LDHs coating precursor buffer layer to different degrees. The prepared ZIF-8-based coating has excellent stability and corrosion resistance. The results demonstrate that the G/LDHs buffer layer provides a new channel for the MOF-modified MAO substrate of AZ31 magnesium alloy. It also proves that it is feasible to build high-performance anticorrosive coatings with MOF materials.

Essential Readings in Magnesium Technology

[M].