近年来,Mg及镁合金在作为可降解生物医用材料方面,因为其密度低、强度高、刚性好,且有与其骨组织相近的弹性模量、良好的生物相容性、促成骨性等特点受到了越来越多的关注[1~5]。目前,限制其临床应用的主要原因就是Mg及镁合金耐腐蚀性能相对较差,在体内降解速率过快,在人体骨骼组织恢复完全之前,Mg及镁合金却已经降解完全。由于降解过快容易产生更多的气泡和碱性环境,细胞生长会受到一定的影响,并且,由于降解速率过快,人体内含有大量Mg2+无法及时排出体外,使人体会产生许多疾病,从而延缓了人体骨组织的恢复。延缓镁合金降解速率,降解过程产生的Mg2+是对人体有利的。因此,提高耐蚀性依然是镁合金研究的重要方面[6~8]。提高镁合金耐蚀性能,除了采用合金化方法,还可以采用表面改性的方法来进一步提高合金耐蚀性能[9~11]。研究表明,在镁合金表面制备生物活性涂层,不仅具有良好的生物相容性,促进骨骼组织发育,而且有利于降低合金在人体的降解速率。目前,可降解镁合金常采用的表面涂层有Ca-P涂层、Sr-P涂层和微弧氧化涂层等[12~16]。沈喜训等[17]研究表明,Ca-P涂层使得AZ31镁合金具有优良的耐腐蚀性能。姜舒婷等[18]通过在Mg-Zn-Zr合金制备Ca-P涂层,发现相比于Mg-Zn-Zr原始试样的耐蚀性有明显提高,含有Ca-P涂层的合金在Hank's溶液中的腐蚀电流密度降低了很多。陈军修[19]研究表明,Sr-P涂层能够明显提高合金的耐蚀性能。Sr作为对人体非常有益的微量元素之一,且含Sr的涂层具有良好的生物相容性、促成骨性,且效果发挥稳定,因此,对于人体骨骼组织恢复有很大的作用[20,21]。李梅等[22]研究表明含Sr-Ca-P涂层镁合金ZK60具有良好的促成骨细胞黏附、增殖和成骨分化作用。

制备涂层能够有效地提高Mg-Zn-Zr-Gd合金的耐蚀性能,减小合金的腐蚀速率,且涂层具有环保,操作简单,成本低,制作周期短等优点。本文所用基体材料是在脉冲磁场下凝固的Mg-Zn-Zr-Gd合金,脉冲磁场具有成本低、环保、细化晶粒等优点。经过本课题组前期的研究结果,脉冲磁场处理能显著提高合金力学性能,但是没对其耐蚀性能展开研究;并且,目前少有研究将涂层应用到脉冲磁场处理之后的镁合金基体上。因此,通过结合脉冲磁场处理和涂层制备的方法,有可能既解决生物镁合金的力学性能不佳又能解决耐蚀性能差的问题。本文提出了在脉冲磁场处理Mg-Zn-Zr-Gd合金的基础上,进一步研究Ca-P和Sr-P涂层对Mg-Zn-Zr-Gd合金耐蚀性的影响,并分析涂层对脉冲磁场处理后Mg-Zn-Zr-Gd合金降解性能的作用机理,对改善生物医用镁合金的耐蚀性能具有重要意义。

1 实验方法

本文选择将经过脉冲磁场处理后的铸态Mg-6Zn-0.5Zr-1Gd合金用线切割加工出ϕ8×3 mm的试样,试样用砂纸打磨至2000#后用酒精清洗干净,再用吹风机吹干备用。实验试样包含基体对照组 (无脉冲磁场处理的M1、有脉冲磁场处理的M9)、Ca-P涂层实验组 (Ca-P-M1、Ca-P-M9) 和Sr-P涂层实验组 (Sr-P-M1、Sr-P-M9)。

将用Ca(NO3)2替代NaNO3,从而形成含Ca的饱和溶液,促进了更多的钙磷盐沉积。将试样先在0.1 mol/L KF溶液中浸泡24 h,然后再在含84 g/L Ca(NO3)2、15 g/L Ca(H2PO4)2·H2O、20 mL/L H2O2的溶液中浸泡24 h,调节溶液的温度均为20 ℃,试样涂层制备完成后用酒精清洗并自然风干。

首先配置0.1 mol/L Sr(NO3)2和0.06 mol/L NH4H2PO4的混合溶液,并使用4%稀HNO3调节溶液pH为3.0,同时调节溶液温度为80 ℃,最后将试样置于溶液中浸泡14 min,试样涂层制备完成后用酒精清洗并自然风干。

将ϕ8×3 mm的试样用硅橡胶封装成电极用于电化学测试。电化学实验使用CHI604E电化学工作站,在Hank's溶液中进行。首先测试开路电位,时间30 min,接着进行电化学阻抗测试,调节频率范围至105~10-1 Hz,最后测试动电位极化曲线,以开路电位为基准,极化曲线的起始电位为+0.3 V,终止电位为-0.3 V,扫描速率0.005 V/s。

将带有不同涂层的试样和未制备涂层的试样分别在Hank's溶液中浸泡,研究合金的腐蚀行为。调节初始Hank's溶液的pH为7.40,设置浸泡温度为37 ℃。每隔24 h用PHS-3C型电子pH计测定一次浸泡提取液的pH值并记录,并且更换新的Hank's溶液。浸泡7 d后,将试样取出,并且使用铬酸 (200 g/L铬酸和10 g/L AgNO3) 清洗样品表面的腐蚀产物。

利用亚克力树脂固定试样,然后将试样用砂纸打磨至2000#后进行抛光,观察涂层横截面;利用扫描电镜 (SEM,SU1510) 对合金涂层的微观结构进行观察,同时结合自带的能谱仪EDS分析合金涂层的元素成分;利用X射线衍射分析 (XRD,D8ADVANCE-A25) 分析合金涂层的相组成,合金降解性能通过长期浸泡实验和电化学性能测试来进行表征。

2 结果与分析

2.1 铸态Mg-Zn-Zr-Gd合金的显微组织形貌

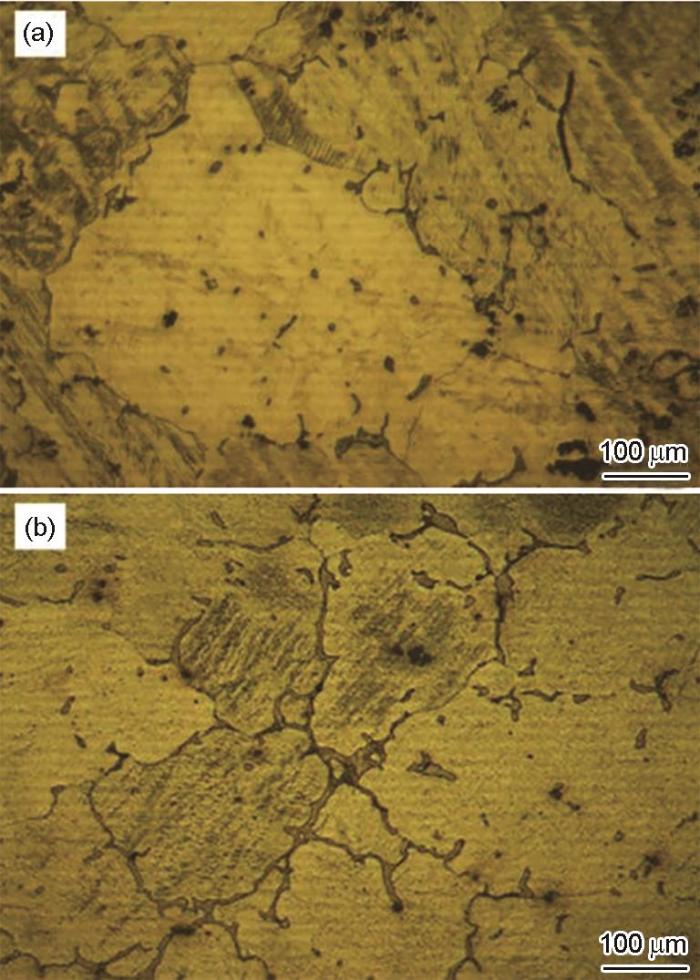

图1

图1

未经及经过脉冲磁场处理合金的铸态形貌

Fig.1

Original microstructure of alloy of untreated (a) and pulsed magnetic field treatment (b)

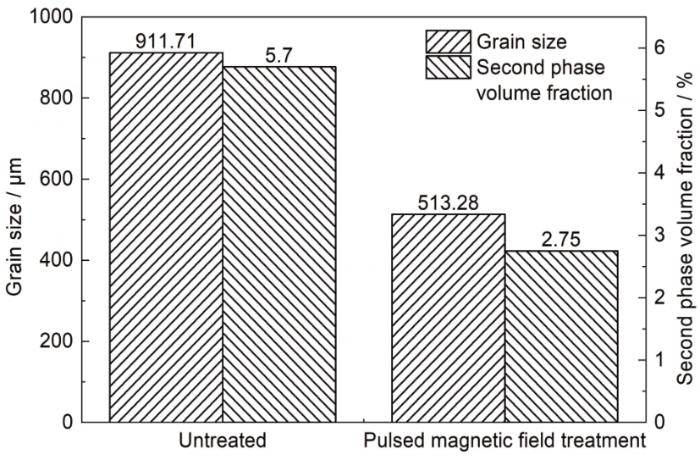

图2

图2

不同处理方式对合金的晶粒尺寸和第二相体积分数的影响

Fig.2

Effects of different treatment methods on the grain size and volume fraction of the second phase of the alloy

2.2 涂层表征与分析

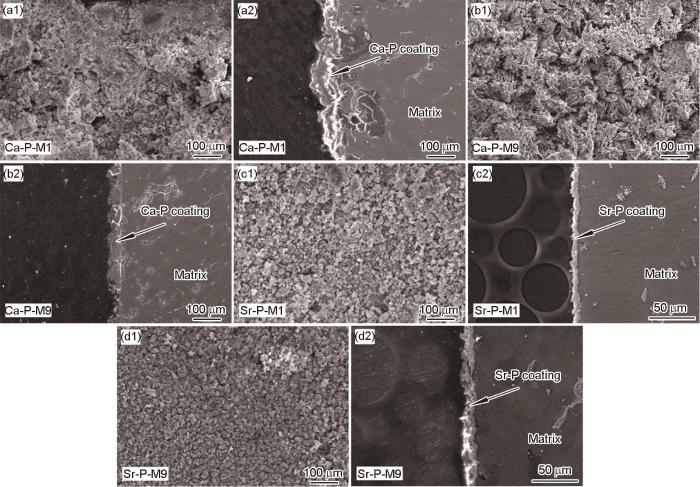

图3为不同基体试样表面不同化学涂层的横纵截面形貌。可以看出,Ca-P涂层厚度不均匀,约为20~50 μm (图3a2、b2)。根据其表面形貌可以观察到,涂层由大量的棒状颗粒组成,棒状颗粒的分布不均匀且较为疏松;含Ca-P涂层的M9试样 (图3b1、b2) 与M1试样 (图3a1、a2) 相比,M9试样涂层厚度更均匀。如图3c2、d2所示,Sr-P涂层的厚度约为8~15 μm,相比于Ca-P涂层,其厚度较薄,从图3c1、d1可以观察到有许多不规则的结晶状颗粒分布在基体表面,且Sr-P涂层的致密性明显好于Ca-P涂层;制备了Sr-P涂层的M9试样 (图3d1、d2) 与M1试样 (图3c1、c2) 相比,M9试样的涂层更厚且分布更均匀。

图3

图3

脉冲磁场处理合金的不同涂层的微观组织

Fig.3

Microstructures of different coatings of the pulsed magnetic field treatment alloy Ca-P-M1 (a1, a2), Ca-P-M9 (b1, b2), Sr-P-M1 (c1, c2) and Sr-P-M9 (d1, d2)

表1 图3中标定区域A和B的EDS分析结果 (atomic fraction / %)

Table 1

| Element | Region A | Region B |

|---|---|---|

| Mg | 0.25 | 0.73 |

| Zn | 0.66 | 1.97 |

| P | 45.12 | 51.34 |

| Ca | 51.79 | - |

| Sr | - | 44.75 |

| Zr | 2.18 | 0.92 |

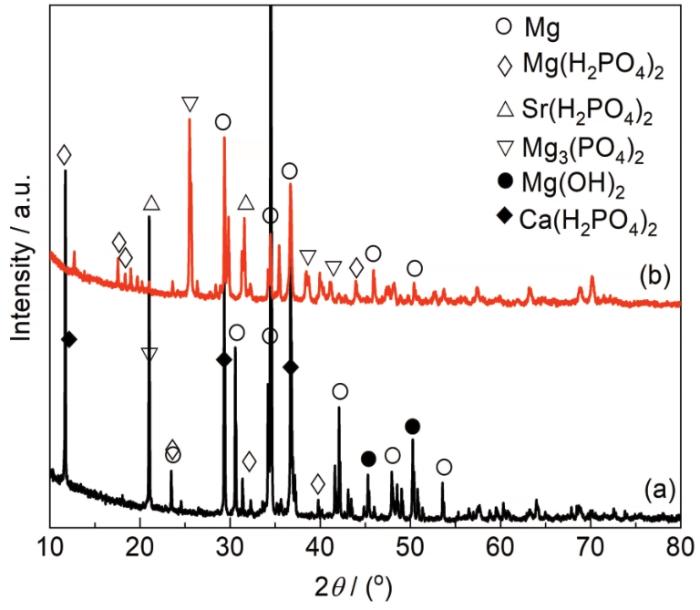

图4为两种涂层的XRD图谱,对涂层成分进一步分析可知,Ca-P涂层主要组分为Mg、Ca(H2PO4)2和Mg(H2PO4)2,Sr-P涂层主要组分为Mg、Sr(H2PO4)2、Mg(H2PO4)2和Mg(PO4)2。

图4

2.3 电化学实验分析

2.3.1 动电位极化曲线分析

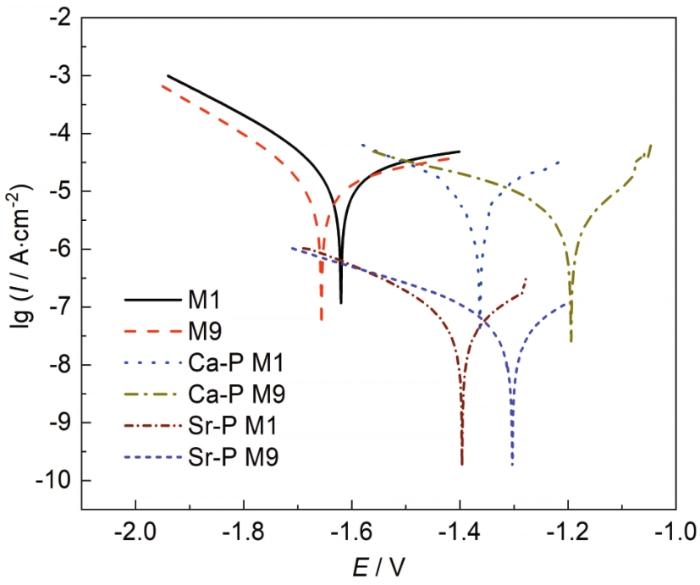

图5为不含涂层的对照组 (未经脉冲磁场处理的M1试样及经过脉冲磁场处理的M9试样) 和两种不同涂层分别在两组不同对照试样表面沉积后试样的动电位极化曲线,腐蚀液为Hank's溶液,表2是动电位极化曲线的Tafel拟合结果。由该结果可知,与对照组相比,两种涂层均提高了试样的耐蚀性能。M9试样表面无论是否有涂层的沉积,其腐蚀电流密度均低于相对应同等条件下的M1试样的测试结果;结合涂层横截表面形貌图可知 (图3),M9试样涂层厚度比M1试样都更均匀,由此可以说明,M9试样的耐蚀性均能高于M1。通过对比两组基体表面的Sr-P涂层和Ca-P涂层的腐蚀电流密度可知,两组试样表面Sr-P涂层的腐蚀电流密度密度分别为1.45×10-8和1.09×10-8 A/cm2,远小于其对应试样表面Ca-P涂层的腐蚀电流密度密度 (分别为2.35×10-6和9.24×10-7 A/cm2);且Sr-P涂层的致密性明显好于Ca-P涂层,Ca-P涂层较为疏松,因此,说明Sr-P涂层的耐蚀性能比Ca-P涂层更好。

图5

图5

不同涂层的动电位极化曲线

Fig.5

Curve of dynamic potential polarization (pulse) of different coating

表2 动电位极化曲线的Tafel拟合结果

Table 2

| Sample | Ecorr / V vs SCE | Icorr / A·cm-2 |

|---|---|---|

| M1 | -1.70 | 4.25×10-6 |

| M9 | -1.68 | 3.42×10-6 |

| Ca-P-M1 | -1.28 | 2.35×10-6 |

| Ca-P-M9 | -1.26 | 9.24×10-7 |

| Sr-P-M1 | -1.49 | 1.45×10-8 |

| Sr-P-M9 | -1.41 | 1.09×10-8 |

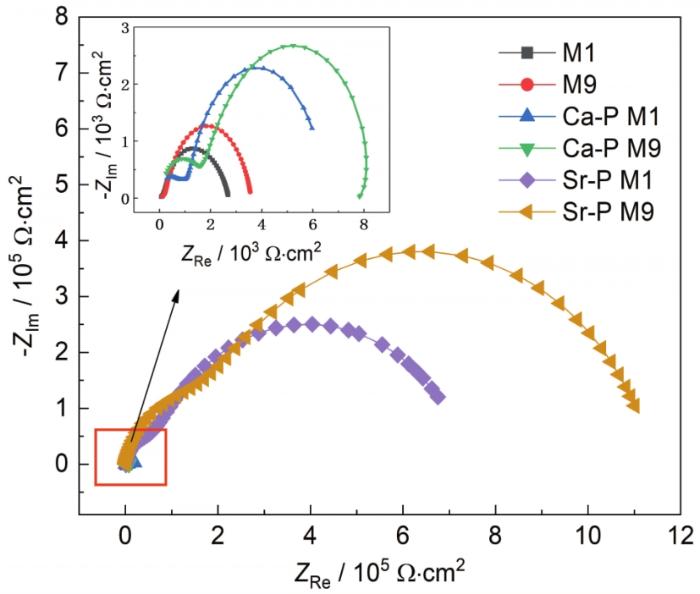

2.3.2 阻抗谱曲线分析

电化学阻抗谱曲线可以反应合金的降解过程和机理,阻抗谱曲线常表现为容抗弧,没有涂层的对照组和Sr-P涂层的曲线是一段容抗弧,而Ca-P涂层的曲线是一段容抗弧加一段感抗弧。合金的耐蚀性能通过容抗弧的半径大小反映出来,容抗弧的半径越大,合金的耐蚀性能越好。

图6为不同基体试样及其表面不同化学涂层试样的阻抗谱曲线。由图可见,有脉冲磁场处理的基体试样M9的曲线半径比无脉冲磁场处理的基体试样M1的曲线半径大,结合基体表面形貌可知,基体试样M9晶粒细小,第二相分布更均匀,从而使得耐蚀性能有所提高;而M9试样表面制备不同化学涂层后,其曲线半径均比相对应同等条件下M1试样表面制备的涂层试样曲率半径大,结合涂层横截表面形貌可知,含涂层的M9试样与M1试样相比,M9试样涂层厚度都更均匀,由此说明,含涂层M9试样耐蚀性能有所提高。同时,对比基体和不同种类的涂层样品还可以看出,Ca-P涂层和Sr-P涂层的曲线半径明显大于无涂层的对照组,说明两种涂层均提高了合金试样的耐蚀性能;Sr-P涂层的曲线半径远大于Ca-P涂层,说明Sr-P涂层的耐蚀性能较Ca-P涂层更好,这是由于Sr-P涂层的致密性明显好于Ca-P涂层,Ca-P涂层较为疏松。

图6

图6

脉冲磁场处理试样的阻抗谱曲线

Fig.6

Impedance spectral curve of the pulsed magnetic field processing specimen

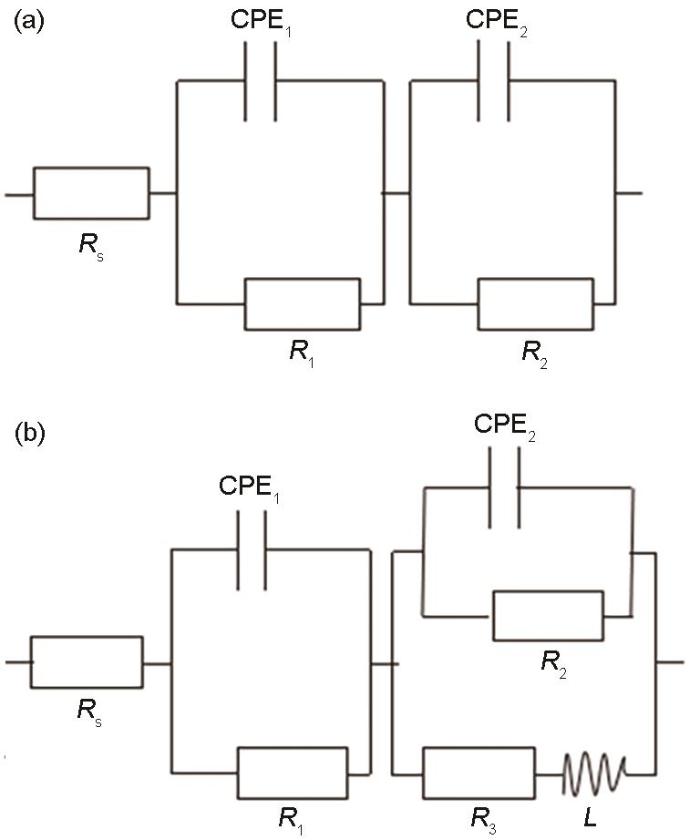

图7为EIS曲线拟合的等效电路图。Sr-P涂层的拟合电路:R1为膜层电阻,与Sr-P涂层的保护效果有关,CPE1为常相位角元素,代表膜层的电容;R2代表电荷转移电阻,CPE2代表了镁合金基体和溶液之间的双电层电容,Rs代表溶液电阻。Ca-P涂层的等效电路前面部分的物理意义与上述相同。另外,R3和L表示阻抗谱中的感抗部分,即样品表面有氢气析出。

图7

图7

Ca-P和Sr-P涂层的等效电路图

Fig.7

Equivalent circuit diagrams of Ca-P (a) and Sr-P (b) coating

表3是以上阻抗曲线的电路拟合结果,其中,由膜层电阻R1的数值大小可以判断出耐蚀性能的差异,R1值越大表明耐蚀性能越好。比较无涂层的基体对照组和两种涂层的膜层电阻R1可以看出,基体试样中,M9的R1值大于M1,M9表面制备的涂层试样的R1值也大于对应的M1表面的涂层试样,表明M9的耐蚀性能比M1更好,且基体耐蚀性能越好,其表面制备的涂层的耐蚀性能也越好;对比基体、Sr-P和Ca-P涂层的R1值之间的关系分别为:Sr-P涂层>Ca-P涂层>基体,说明Sr-P涂层起到的提高基体耐蚀性能的效果为最佳,Ca-P涂层其次,该结果与上文阻抗谱图的分析结果一致。

表3 脉冲磁场处理试样阻抗曲线的电路拟合结果

Table 3

| Sample | Rs / Ω·cm2 | Q-Yo | Q-n | R1 / Ω·cm2 | Q-Yo | Q-n | R2 / Ω·cm2 | R3 / Ω·cm2 | L |

|---|---|---|---|---|---|---|---|---|---|

| M1 | 34.23 | 3.551×10-5 | 0.456 | 1.368×102 | 1.226×105 | 0.749 | 4.007×103 | 6.929×103 | 29.03 |

| M9 | 32.23 | 7.492×10-6 | 0.827 | 3.555×103 | 6.077×105 | 0.374 | 2.287×102 | 1.173×102 | 5.018 |

| Ca-P-M1 | 10.66 | 7.238×10-7 | 0.900 | 5.307×103 | 2.736×107 | 0.681 | 1.165×1014 | 1.177×103 | 2.570×103 |

| Ca-P-M9 | 1.007×10-7 | 9.538×10-7 | 0.799 | 7.803×103 | 2.531×108 | 0.837 | 1.619×103 | 1.450×107 | 32.09 |

| Sr-P-M1 | 1.929×10-4 | 7.737×10-9 | 0.951 | 4.876×104 | 6.082×108 | 0.794 | 6.948×105 | - | - |

| Sr-P-M9 | 7.064×10-5 | 2.819×10-8 | 0.891 | 1.613×105 | 1.289×107 | 0.829 | 9.811×105 | - | - |

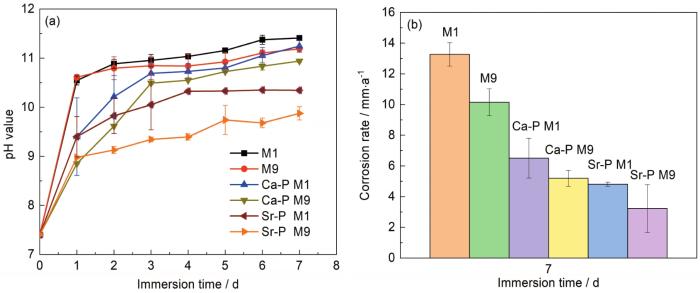

2.4 浸泡实验

图8a为不同基体试样及其表面不同化学涂层试样在Hank's溶液中浸泡7 d的pH值变化折线图。对pH变化曲线分析可知,基体M1试样pH最高值已经靠近11.5左右,基体M9试样pH值整体趋势要比M1小,pH最高值达11左右;Ca-P涂层整体pH值要比无涂层对照组试样都要低,还可以看出M9试样表面的Ca-P涂层试样在前期pH值要明显低于M1试样表面的Ca-P涂层试样,后期其pH值稳定在10.7左右;对于Sr-P涂层来说,相比于对照组和Ca-P涂层,其pH值都是最低的,浸泡后期,M1试样表面的Sr-P涂层试样的pH值稳定在10.2左右,M9试样表面的Sr-P涂层试样的pH值稳定在9.5左右。

图8

图8

六组脉冲试样在Hank's溶液中浸泡7 d后pH变化及腐蚀速率曲线

Fig.8

Variation of the pH of the solution (a) and corrosion rate (b) of pulsed specimens soaked in Hank's solution for 7 d

图8b为不同基体试样及其表面不同化学涂层试样浸泡7天后的平均腐蚀速率。基体M9试样的降解速率低于基体M1试样,表明M9的耐蚀性优于M1,且对于两组基体表面制备的涂层而言,M9表面的涂层的降解速率低于M1表面的涂层试样,且含涂层的M9试样涂层厚度均高于相应的M1试样;Sr-P涂层试样的降解速率小于Ca-P涂层试样的降解速率,小于无涂层对照组试样,结合涂层横截表面腐蚀形貌可知,Ca-P涂层的表面沉积物比较粗大,疏松,溶液容易与涂层内部接触,Sr-P涂层的腐蚀产物组织较细,可以增加涂层的致密性,因此,Sr-P涂层的耐蚀性能优于Ca-P涂层,优于对照组。

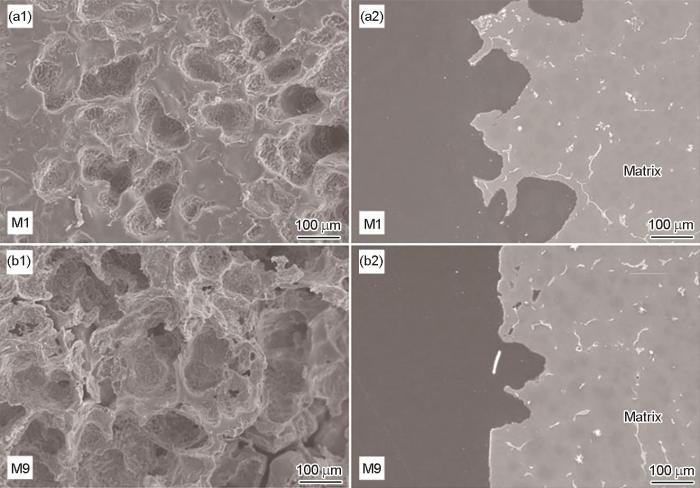

2.5 腐蚀结果分析

图9为不含涂层的对照组基体试样 (未经脉冲磁场处理的M1试样及经过脉冲磁场处理的M9试样) 浸泡7 d后的腐蚀形貌。可以观察到合金表面均发生严重的点蚀坑,基体M1试样点蚀坑深度约200 μm,基体M9试样约120 μm,且基体M9试样产生的点蚀坑数量更少深度更浅。由于未处理的合金晶粒比较粗大,晶界更少,所以更容易发生腐蚀,且未处理时基体M1试样点蚀坑数量更多深度更深,随着浸泡时间的延长,点蚀现象会加剧,导致合金的腐蚀速率加快,使得基体M1试样合金的耐腐蚀性能下降。脉冲磁场处理能够细化晶粒和第二相,使第二相分布较均匀,晶粒尺寸减小,第二相体积分数增大,虽然,第二相与基体会产生电偶腐蚀,使得耐蚀性能下降,但是,另一方面,晶界越多,越能阻碍溶液的浸润[23]。同时,第二相沿晶界分布为连续网络状,围绕着α-Mg基体,成为α-Mg基体的屏障,所以不容易发生腐蚀[24,25]。此外,经过脉冲磁场处理后,Gd在镁基体中分布更均匀,随着腐蚀的进行,Gd3+会替代Mg2+进入Mg(OH)2腐蚀产物层,腐蚀产物层中的Gd3+使得正电荷数增多,减缓了Cl-对Mg(OH)2腐蚀产物层的渗透作用,提高了合金的耐蚀性能[26]。因此,基体M9试样的耐蚀性要优于M1试样。

图9

图9

不同基体表面在Hank's溶液中浸泡7 d后的腐蚀形貌

Fig.9

Corrosion morphologies (a1, b1) and cross-sectional morphologies (a2, b2) of M1 (a1, a2) and M9 (b1, b2) matrix surfaces in Hank's solution for 7 d

图10

图10

不同基体表面的不同涂层在Hank's溶液中浸泡7 d后腐蚀形貌

Fig.10

Corrosion surface morphologies (a1-d1) and cross-sectional morphologies (a2-d2) of Ca-P-M1 (a1, a2), Ca-P-M9 (b1, b2), Sr-P-M1 (c1, c2) and Sr-P-M9 (d1, d2) coatings on different matrix surfaces in Hank's solution for 7 d

对于Sr-P涂层,由于涂层较薄,难免会有些不均匀的地方,当发生腐蚀后,Mg2+、Zn2+和Gd3+等溶于溶液后,这些阳离子会与溶液中的OH-、PO43-等阴离子反应形成Zn3(PO4)2、Ca3(PO4)2、Mg(OH)2和Gd(OH)3[26]。从Sr-P涂层腐蚀形貌图可以看出 (图10c1、d1),Sr-P涂层的腐蚀产物组织较细,其表面沉积的腐蚀产物可以增加涂层的致密性,从而提高了合金的耐蚀性能。同时Sr-P涂层有许多不规则的结晶状颗粒分布在基体表面,结晶状颗粒互锁在一起的,因此,整个涂层可以牢固地固定在基体上,所以Sr-P涂层没有发生明显的破坏 (图10c2、d2),也说明了Sr-P涂层具有良好的保护效果。

对于同种涂层有无脉冲磁场处理试样,如果基体本身的耐蚀性能相对较差,而其涂层的保护效果也会相对较差,由于基体的耐蚀性能提高,其表面制备的涂层试样的耐蚀性能也相应提高,表明相同涂层之间的的耐蚀性能差异与基体的耐蚀性能有关[28,29]。首先同种Ca-P涂层M9和M1试样相比,含Ca-P涂层的M9试样 (图1b2) 与M1试样 (图1a2) 相比,M9试样涂层厚度更均匀,且由于无涂层M9集体试样的耐蚀性能要高于M1试样,因此,M9试样表面的Ca-P涂层腐蚀程度相对低于M1试样表面的Ca-P涂层,且通过电化学实验、浸泡实验等结果也说明M9表面的Ca-P涂层试样耐蚀性能较好一些。对于同种Sr-P涂层M9和M1试样相比,M9试样表面Sr-P涂层的致密性更高 (图10c1、d1),同时M9表面的Sr-P涂层比M1表面的Sr-P涂层更厚,因此,M9表面的Sr-P涂层试样耐蚀性能较好。

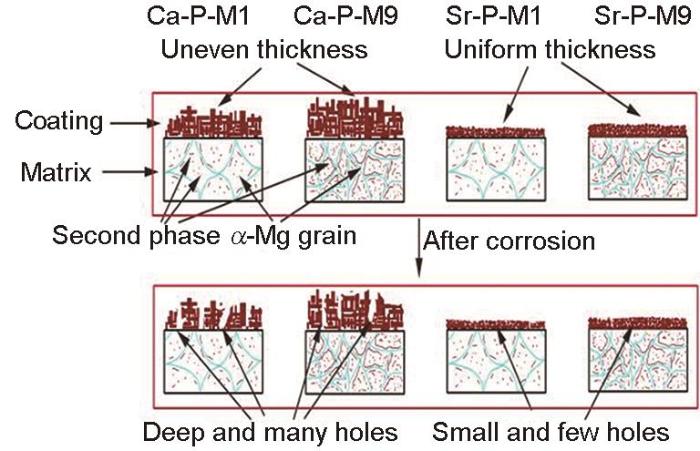

图11不同基体表面的不同涂层腐蚀示意图。Ca-P涂层表面沉积物为较粗大的棒状颗粒,厚度不均匀,在浸泡过程中,Ca-P涂层与基体的结合力较弱,孔洞比较多,涂层容易脱落,溶液易于渗入涂层内部,所以Ca-P涂层保护效果不如Sr-P涂层。Sr-P涂层沉积物致密性比较好,厚度均匀,溶液不容易渗入涂层内部,且表面沉积的腐蚀产物使涂层更加致密,所以耐蚀性能优于Ca-P涂层。对于同种涂层有无脉冲磁场处理试样,M9试样涂层厚度均高于M1试样,且无涂层M9基体试样耐蚀性能比M1基体试样好,因此,同种涂层M9试样耐蚀性能均优于M1试样。

图11

图11

不同基体表面的不同涂层腐蚀示意图

Fig.11

Schematic diagram of corrosion of different coatings on different matrix surfaces

3 结论

(1) 脉冲磁场处理能够细化晶粒和第二相,使基体第二相分布较均匀,晶粒尺寸减小,第二相体积分数增大,虽然,第二相与基体会产生电偶腐蚀,使得耐蚀性能下降,但是,另一方面,晶界越多,越能阻碍溶液的浸润;同时,第二相沿晶界分布为连续网络状,围绕着α-Mg基体,成为α-Mg基体的屏障,所以不容易发生腐蚀,因此,经过脉冲磁场处理的基体试样的耐蚀性能比未处理的基体试样更好。

(2) 经过脉冲磁场处理基体表面含Ca-P涂层或Sr-P涂层试样的耐蚀性能均比其相应未处理基体表面含Ca-P涂层或Sr-P涂层试样的耐蚀性能更好,基体耐蚀性能越好,其表面制备的涂层耐蚀性能也越好,说明相同涂层之间的耐蚀性能差异与基体的耐蚀性能联系紧密。

(3) Ca-P涂层主要成分为Mg、Ca(H2PO4)2和Mg(H2PO4)2,Sr-P涂层主要成分为Mg、Sr(H2PO4)2、Mg(H2PO4)2和Mg(PO4)2。Ca-P涂层由大量粗大的棒状颗粒组成,棒状颗粒分布不均匀且较为疏松,涂层厚度不均匀,在浸泡过程中易于脱落,导致其耐蚀性能较差;Sr-P涂层由许多细小的结晶状颗粒组成,且结晶状颗粒互锁在一起的,所以整个涂层可以牢固地固定在基体上,涂层厚度均匀。Sr-P涂层腐蚀产物能够增加涂层的致密性,并稳定涂层,从而阻碍了合金基体进一步被腐蚀,明显提高合金的耐蚀性能。因此,Sr-P涂层和Ca-P涂层都提高了合金试样的耐蚀性能,且Sr-P涂层的耐蚀性能优于Ca-P涂层,优于无涂层Mg-Zn-Zr-Gd合金。

参考文献

Current research status and prospect of Mg-Zn-Zr series bio-magnesium alloys

[J].

Mg-Zn-Zr系生物镁合金研究现状及展望

[J].

Application and development of magnesium alloy in biomedicine

[J].

镁合金在生物医学上的应用与发展

[J].

A review on casting magnesium alloys: modification of commercial alloys and development of new alloys

[J].The research and development status of casting magnesium alloys including the commercial casting alloys and the new types casting alloys are reviewed, with more attention to microstructure and mechanical properties of modified-AZ91, AM60 and WE43 alloys with various additions, and new types of low cost casting alloys and high strength casting alloys. The modification and/or refinement of Mg2Si phase in Mg-Al-Si based casting alloys by various additions are discussed and new purifying technologies for casting magnesium alloys are introduced to improve the performance. The modified AZ81 alloy with reduced impurities is found to have the tensile strength of 280 ± 6 MPa and elongation of 16% ± 0.7%. The fatigue strength of AZ91D alloy could be obviously improved by addition of Ce and Nd. The Mg-16Gd-2Ag-0.3Zr alloy exhibits very high tensile and yield strengths (UTS: 423 MPa and YS: 328 MPa); however, its elongation still needs to be improved.

On the room temperature deformation mechanisms of a Mg-Y-Zn alloy with long-period-stacking-ordered structures

[J].

Research progress on biodegradable medical magnesium-based materials

[J].

可降解医用镁基金属生物材料的研究进展

[J].

Research progress of microarc oxidation for corrosion prevention of Mg-alloys

[J].

微弧氧化及其在镁合金腐蚀防护领域的研究进展

[J].简要综述了微弧氧化 (MAO) 及其火花放电机理研究的发展历程。重点根据近年来MAO在镁合金腐蚀防护领域的研究结果,详细综述了电源特性、工作模式、电参数、电解液、后处理、前处理等MAO工艺的进展情况,并指出了今后的发展趋势。同时,也提出了MAO技术在镁合金表面防护领域研究所存在的问题和建议。

Novel magnesium alloys developed for biomedical application: a review

[J].There is an increasing interest in the development of magnesium alloys both for industrial and biomedical applications. Industrial interest in magnesium alloys is based on strong demand of weight reduction of transportation vehicles for better fuel efficiency, so higher strength, and better ductility and corrosion resistance are required. Nevertheless, biomedical magnesium alloys require appropriate mechanical properties, suitable degradation rate in physiological environment, and what is most important, biosafety to human body. Rather than simply apply commercial magnesium alloys to biomedical field, new alloys should be designed from the point of view of nutriology and toxicology. This article provides a review of state-of-the-art of magnesium alloy implants and devices for orthopedic, cardiovascular and tissue engineering applications. Advances in new alloy design, novel structure design and surface modification are overviewed. The factors that influence the corrosion behavior of magnesium alloys are discussed and the strategy in the future development of biomedical magnesium alloys is proposed.

Research progress of corrosion resistance of degradable medical magnesium alloys

[J].

可降解医用镁合金耐腐蚀性能研究进展

[J].

Enhanced mechanical and corrosion properties of NZ20K alloy by double extrusion and aging processes for biomedical applications

[J].

Advances in functionalized polymer coatings on biodegradable magnesium alloys-A review

[J].

Current status of surface treatment for magnesium alloy

[J].

镁合金表面处理技术的研究进展

[J].介绍了国内外镁合金表面处理的最新研究进展,其中包括化学转化、自组装单分子膜、阳极氧化、电镀与化学镀、液相沉积与溶胶凝胶涂层、气相沉积、喷涂、激光熔覆合金技术等,并对镁合金表面处理的发展趋势作了展望。

Development of corrosion and wear resistant micro-arc oxidation coating on a magnesium alloy

[J].

A new environment-friendly anodizing process for magnesium alloys

[J].

镁合金环保型阳极氧化工艺研究

[J].

Effect of Ca/P ratio on the structural and corrosion properties of biomimetic Ca-P coatings on ZK60 magnesium alloy

[J].

Controlling initial biodegradation of magnesium by a biocompatible strontium phosphate conversion coating

[J].A simple strontium phosphate (SrP) conversion coating process was developed to protect magnesium (Mg) from the initial degradation post-implantation. The coating morphology, deposition rate and resultant phases are all dependent on the processing temperature, which determines the protective ability for Mg in minimum essential medium (MEM). Coatings produced at 80 °C are primarily made up of strontium apatite (SrAp) with a granular surface, a high degree of crystallinity and the highest protective ability, which arises from retarding anodic dissolution of Mg in MEM. Following 14 days' immersion in MEM, the SrAp coating maintained its integrity with only a small fraction of the surface corroded. The post-degradation effect of uncoated Mg and Mg coated at 40 and 80 °C on the proliferation and differentiation of human mesenchymal stem cells was also studied, revealing that the SrP coatings are biocompatible and permit proliferation to a level similar to that of pure Mg. The present study suggests that the SrP conversion coating is a promising option for controlling the early rapid degradation rate, and hence hydrogen gas evolution, of Mg implants without adverse effects on surrounding cells and tissues.Copyright © 2013 Acta Materialia Inc. Published by Elsevier Ltd. All rights reserved.

Effect of KH-550 content on structure and properties of a Micro-arc oxidation coating on Mg-alloy AZ31B

[J].

KH-550对AZ31B镁合金表面微弧氧化膜结构及性能的影响

[J].通过微弧氧化 (MAO) 的方法在Na<sub>2</sub>SiO<sub>3</sub>-KOH-NaF电解质溶液中处理AZ31B镁合金,利用SEM、XRD和电化学等表征手段,研究了硅烷偶联剂KH550对MAO膜结构及性能的影响。结果表明,KH-550浓度在0~20 mL/L范围内增加时,MAO膜表面微孔尺寸和粗糙度先减小后增大,膜层厚度和耐蚀性能先增加后降低;引入KH-550后并未改变MAO膜的物相结构。分析认为KH-550通过硅烷醇的吸附和化学作用,增加了阳极表面薄弱区域离子移动的阻力,抑制镁合金在MAO过程的弧光放电,从而提高了膜层的生长效率,细化并均匀化微孔,改善了MAO膜的耐蚀能力。

Fabrication of Ca-P coating on AZ31 magnesium by electrochemical-assisted chemical conversion and evaluation of its corrosion resistance

[J].

镁合金表面Ca-P涂层的电化学辅助化学转化法制备及其耐蚀性研究

[J].

Fabrication of Ca-P coating of Mg-Zn-Zr alloy and corrosion resistance

[J].

Mg-Zn-Zr表面Ca-P涂层的制备及其降解性能研究

[J].

Study on properties and surface modification of biodegradable Mg-2Zn-xRE (Gd, Nd, Y)- 0.5Zr alloys

[D].

生物可降解Mg-2Zn-xRE (Gd、Nd、Y)- 0.5Zr合金性能及其表面改性研究

[D].

In vivo study of strontium-doped calcium phosphate cement for biological properties

[J].

掺锶磷酸钙骨水泥材料生物学性能的动物实验

[J].

Bioactivity and corrosion properties of gelatin-containing and strontium-doped calcium phosphate composite coating

[J].

Effects of SrCaP-coated Mg alloy ZK60 on preosteoblast functions in mice

[J].

含SrCaP涂层镁合金ZK60对小鼠前成骨细胞功能的影响

[J].

Effect of minor content of Gd on the mechanical and degradable properties of as-cast Mg-2Zn-xGd-0.5Zr alloys

[J].RE-containing Mg alloys used as biodegradable medical implants exhibit good promising application due to their good mechanical properties and degradation resistance. In this work, effect of Gd on the microstructure, mechanical properties and biodegradation of as-cast Mg-2Zn-xGd-0.5Zr alloys was investigated. The results showed that there were mainly α-Mg, I-phase, W-phase and MgZn2 phase in Mg-Zn-Gd-Zr alloys. With increase of the Gd content, the strength of the alloys was enhanced due to the second phase strengthening and grain refinement. The degradation resistance of Mg-2Zn-0.5Zr alloy was increased by adding 0.5-1% Gd due to the uniformly distributed second phases which acted as a barrier to prevent the pitting corrosion. However, increasing Gd content to 2% reduced the degradation resistance of the alloy due to the galvanic corrosion between the matrix and the second phases. The good degradation resistance and mechanical properties of as-cast Mg-2Zn-1Gd-0.5Zr alloy makes it outstanding for biomaterial application.

Roles of β phase in the corrosion process of AZ91D magnesium alloy

[J].

Corrosion behaviour of bulk ultra-fine grained AZ91D magnesium alloy fabricated by equal-channel angular pressing

[J].

Structural and corrosion characterization of biodegradable Mg-RE (RE=Gd, Y, Nd) alloys

[J].

Comparative study on effects of different coatings on biodegradable and wear properties of Mg-2Zn-1Gd-0.5Zr alloy

[J].

Comparison study of different coatings on degradation performance and cell response of Mg-Sr alloy

[J].

Microstructure, mechanical properties, bio-corrosion properties and cytotoxicity of as-extruded Mg-Sr alloys

[J].