为航空飞机提供能源动力的燃气涡轮发动机不仅需要在高温、高压环境中长时服役,发动机叶片等热端部件有时更要承受高盐、高湿、复杂应力以及高速气流冲蚀等严苛工况,因此,叶片上直接与恶劣环境接触的热障涂层陶瓷层材料需要严格选择。氧化钇稳定氧化锆 (YSZ) 陶瓷因具有熔点高、热导率低、化学稳定性好等特点,是目前热障涂层陶瓷层应用的主流材料[5,6]。ZrO2有3种晶型结构,分别为立方 (cubic,c) 相,四方 (tetragonal,t) 相和单斜 (monoclinic,m) 相,其中t相ZrO2在1443~2643 K之间稳定存在,而m相ZrO2在1443 K以下稳定存在。在ZrO2内添加稳定剂Y2O3使ZrO2内生成氧缺陷,可以使t相ZrO2在室温稳定存在[7,8]。当固溶于ZrO2晶格内的Y2O3发生反应导致Y3+浓度下降时,t相ZrO2会发生失稳反应转变至m相,并且这一相变过程通常还伴随着3.5%的体积膨胀并导致陶瓷层内微裂纹萌生[9]。YSZ陶瓷层的稳定性至关重要,一旦陶瓷层出现剥落失效,涂层隔热能力将大幅下降,叶片在高温燃气的直接接触下容易熔融变形,并对发动机的安全运行造成危害。早在热障涂层应用前,YSZ一直是生物医药领域的重要材料,在牙用材料或人造关节材料的研究应用中技术更为领先[10,11]。研究[12]表明,在标准的水蒸气杀菌消毒过程中,YSZ表面出现不断水解腐蚀粗糙化至粉化,最后丧失力学性能的现象,表明YSZ陶瓷无法长时稳定在水相环境中使用。而长期服役在海洋附近的机组,涡轮叶片上热障涂层势必也会受到环境中饱和水蒸气的腐蚀。Cao等[13]分析了热障涂层在潮湿环境下的腐蚀现象,结果表明,在水热老化10 d后,YSZ陶瓷层表面发生粉化现象,YSZ晶粒被严重球化,晶面与棱被严重溶解,晶粒间出现裂纹。Wang等[14]研究表明,纳米氧化锆热障涂层在水热腐蚀24 h后,陶瓷层内出现较大裂纹,陶瓷层与粘结层结合强度降低70%。

除水蒸气腐蚀环境对热障涂层的退化影响外,气流冲蚀或部件间磨损位置会对热障涂层的服役寿命产生一定的影响。虽然热障涂层面层陶瓷具有较高的硬度和耐磨性,但在磨损-腐蚀的耦合作用下,热障涂层的防护性能将大幅退化[15]。Stachowiak等[16]研究了YSZ陶瓷在高温环境下的摩擦磨损行为。结果表明,随着温度的升高,YSZ陶瓷的摩擦系数逐渐变大,同时耐磨性能下降。Liu等[17]研究了YSZ陶瓷在水环境下的磨损行为,结果表明水改变了YSZ陶瓷的磨损机制,由磨粒磨损与表面断裂转变为微犁削。在实际情况中,飞机在飞行-停靠期间,发动机实际是处于高温-低温水汽循环交变的环境,热障涂层既要遭受高温氧化和低温水热老化腐蚀,还要承受服役过程中发生的摩擦损耗。目前对热障涂层的摩擦磨损性能研究较少,尚无有关热障涂层在水热老化环境下的磨损机理研究报道,而在高温-水热腐蚀环境下的摩擦磨损研究更是空白,水热老化过程对热障涂层摩擦磨损性能的影响机制亟需探明。

本文采用大气等离子喷涂在单晶合金N5上制备NiCrAlY粘结层,并在粘结层上制备8YSZ陶瓷层,对热障涂层在高温环境、水热环境以及高温-水热交变环境腐蚀后的摩擦磨损行为进行了对比研究,通过分析其磨损形貌、磨损机制以及硬度变化规律,探究水热腐蚀老化对热障涂层的摩擦磨损性能的影响机理。

1 实验方法

热障涂层采用N5单晶高温合金作为基体,以NiCrAlY为粘结层,陶瓷层则采用质量分数为8%的Y2O3-ZrO2。N5单晶合金的名义成分 (质量分数,%) 为:Al 6.2,Cr 7.0,Co 7.5,W 5.0,Ta 6.5,Mo 1.5,Re 3.0,Ni 余量。NiCrAlY为粘结层的名义成分 (质量分数,%) 为:Cr 22,Al 10,Y 1.0,Fe≤0.20,O≤0.05,N ≤0.020,Ni余量。

使用DK7720型电火花线切割机将N5单晶合金块体切割成30 mm×20 mm×5 mm的方形试样,之后依次用粒度为120#,200#,400#的砂纸打磨去除表面氧化层,随后将样品放入超声清洗器中,用无水乙醇清洗5 min,去除表面污渍。之后对样品进行粗化处理,即采用箱式喷砂机,以刚玉砂为喷料,对基体表面进行喷砂,增大喷涂过程中熔滴与基体的接触面积。采用大气等离子喷涂 (APS) 技术制备粘结层和陶瓷层。喷涂参数如下表1所示。制备的NiCrAlY粘结层厚度为50~60 μm,陶瓷层厚度为250~300 μm。

表1 大气等离子喷涂参数

Table 1

| Coating | Argon / L·min-1 | Helium / L·min-1 | Spray distance / mm | Gun speed / mm·s-1 | Gun interval / mm | I / A | Powder feed rate / g·min-1 |

|---|---|---|---|---|---|---|---|

| BC | 100 | 30 | 100 | V400 | 100 | 850 | 20 |

| TC | 80 | 50 | 80 | V500 | 80 | 900 | 20 |

为探究水热老化以及高温氧化-低温水热老化对热障涂层摩擦磨损性能的影响,设计了两组实验组及一组对照组。在摩擦磨损试验前先对涂层进行腐蚀处理。对照组为热障涂层在高温环境下腐蚀,记为H组;实验组一为涂层在低温水热老化环境下腐蚀,记为W组,而实验组二为涂层在高温氧化-低温水热老化循环交变的环境下腐蚀,记为A组。高温氧化腐蚀实验采用河南中苑实验电炉厂制造的ZY-XB14高温氧化炉,氧化温度为1150 ℃。低温水热老化腐蚀实验在高压釜内进行。将样品放入50 mL的高压釜中,加入25 mL的去离子水,拧紧釜盖后将高压釜放入WGL-65B电热鼓风干燥箱,干燥箱温度设定为180 ℃。已有研究表明[18],3Y-TZP (3%Y2O3-t-ZrO2,摩尔分数) 在134 ℃水热腐蚀20 h相当于在室温下腐蚀1 a。因此,为更好模拟飞机在实际服役过程中飞行时间短停靠时间长的特点,设计A组为依次经过20 h低温水热老化及20 h高温氧化为一个循环;H组为经过20 h高温氧化为一个循环;W组为经过20 h低温水热老化为一个循环。3组试样在各腐蚀环境经10个循环后,将样品取出并对热障涂层面层进行摩擦磨损实验。

使用MFT-5000型摩擦磨损试验机来测试实验组与对照组的摩擦磨损性能。摩擦用压头为直径9.525 mm的白色Al2O3对磨球,摩擦频率为2 Hz,加载压力为10 N,实验时间为60 min,测试温度选择室温,一个试样进行3次摩擦磨损试验,结果数据取其平均值。磨损率W可依照下式进行计算:

式中,W为磨损率,mm3·N-1·m-1,V为磨损体积,mm3,F为载荷,N,S为滑动行程,m。

采用Smartlab型X射线衍射仪 (XRD) 分析热障涂层腐蚀前后的物相结构,采用配有INCA XMAX型能谱分析仪 (EDS) 的Inspect F50场发射扫描电子显微镜 (SEM) 观察涂层的截面、磨损面形貌,采用带有OXFORD NordlysMax型电子背散射衍射功能 (EBSD) 的JEOL JSM-7800F型扫描电子显微镜观察陶瓷层内的物相分布。

2 实验结果

2.1 原始态8YSZ涂层的微观结构

图1

图1

APS制备的原始态热障涂层的表面与截面微观形貌图

Fig.1

Surface (a) and cross-sectional (b) morphologies of the as-deposited TBC by APS

2.2 腐蚀结果

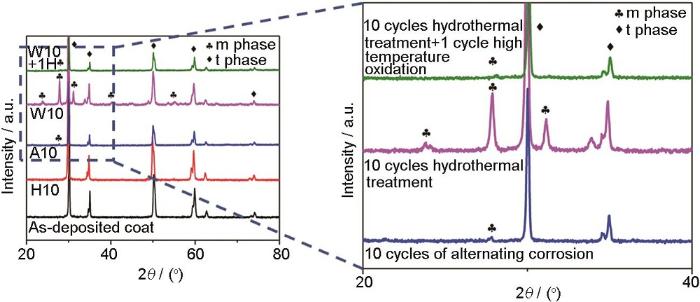

2.2.1 3种不同环境腐蚀后涂层的物相组成

图2

图2

YSZ陶瓷层在不同环境下交替腐蚀10次后的XRD谱图

Fig.2

XRD patterns of the ceramic top coating after alternating corrosion for 10 cycles under different conditions

2.2.2 腐蚀后涂层微观截面形貌

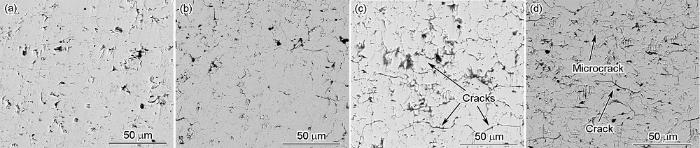

图3为不同环境下交替腐蚀10次后YSZ陶瓷层的微观截面形貌图。图3a为原始态涂层截面形貌图,可以看出原始态涂层结合较好,无明显裂纹。图3b为高温腐蚀10循环后H组陶瓷层的截面形貌图,高温处理后H组截面形貌与原始态涂层相差不大,仅有极少量裂纹产生。图3c和d分别为腐蚀10循环后A组与W组陶瓷层截面形貌图。可以看出,在腐蚀作用下,A组与W组陶瓷层内都有尺寸在50 μm左右的较大的裂纹产生,而对于W组,还生成了许多10 μm左右的微裂纹,产生差异的原因为A组生成的m相含量较少,不足以产生大量微裂纹,并且即便微裂纹产生,也容易在高温的烧结作用下愈合。由截面形貌图可以看出,热障涂层在水热环境下腐蚀最为严重,而在高温环境下腐蚀程度最轻。

图3

图3

YSZ陶瓷层在不同环境下交替腐蚀10次后的微观截面形貌图

Fig.3

Cross-sectional morphologies of the as-deposited coating (a), and the samples H (b), A (c) and W (d) after alternating corrosion for 10 cycles

2.2.3 腐蚀后涂层的相分布

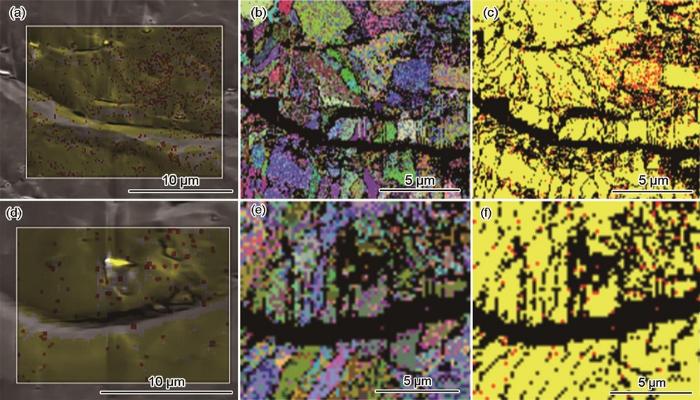

图4为热障涂层YSZ陶瓷层在不同环境下交替腐蚀10次后的EBSD图。由于高温处理会使水热腐蚀老化生成的m相转变回t相,因此为更好观察m相在A组陶瓷层内的生成情况,A组选取的是第10循环水热腐蚀老化后且高温氧化前的试样进行EBSD测试。图4a与图4d实线区域选取在陶瓷层内中部,红色区域代表m相,黄色区域代表t相。由图可以看出,在陶瓷层内部已有m相生成,表明水蒸气可以透过YSZ层表面并进入涂层内部。A组的m相较少,而W组的m相较多,这与XRD结果相一致。图4b和e为W组与A组的Euler图,图中不同取向的晶粒显示出不同的颜色。结合图4c和f的m相分布图,可以看出,对于W组与A组,水热腐蚀老化生成的m相主要分布在晶界处。对于水热腐蚀老化来说,m相的生成并不一定会产生裂纹,但一旦在某一处内m相生成过多,YSZ陶瓷层无法承受m相生成产生的体积膨胀及带来的应力集中,就会通过产生裂纹的方式来释放能量,因此,在裂纹的周围常伴有m相。从以上结果可以看出,水热腐蚀老化的结果为使涂层内部t相ZrO2转变为m相ZrO2,同时生成裂纹,使涂层致密性与结合强度下降。

图4

图4

YSZ陶瓷层在不同环境下交替腐蚀10次后表面的EBSD图

Fig.4

EBSD hierarchical images (a, d), Euler images (b, e) and phase distribution images (c, f) of the samples W (a-c) and A (d-f) after alternating corrosion for 10 cycles

2.3 摩擦磨损分析

2.3.1 划痕尺寸

图5为不同环境下交替腐蚀10次后YSZ陶瓷层的磨痕照片。可以看出,在常温摩擦磨损实验后,3组样品的划痕尺寸呈现较大差异。从整体来看,H组的划痕形状较不规则,而A组与W组的划痕形状较为规整。通过Nano Measure软件可以测得不同腐蚀环境下YSZ陶瓷层的划痕参数。H组的平均划痕宽度为0.841 mm,深度为0.0189 mm,A组的平均划痕宽度为1.172 mm,深度为0.0363 mm,W组的平均划痕宽度为1.489 mm,深度为0.0587 mm,可以看出,W组的划痕宽度与深度远大于A组与H组,而A组的划痕宽度与深度略大于H组。从质量损失来看,H组在磨损后质量几乎没有损失,A组磨损后平均质量损失为0.25 mg,而W组在磨损后平均质量损失最大,为0.64 mg。经

图5

图5

不同试验环境下交替腐蚀10次后YSZ陶瓷层的磨痕形貌

Fig.5

Macro-morphologies of wear scars on the ceramic top coating of the samples H (a), A (b) and W (c) after alternating corrosion for 10 cycles

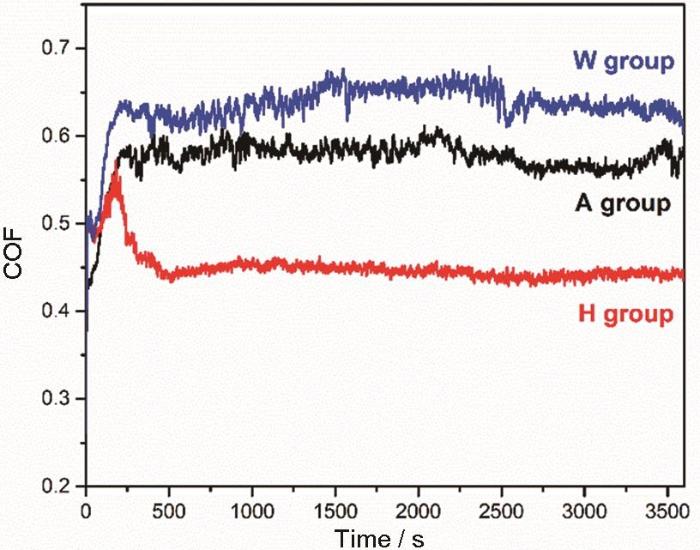

图6

图6

不同试验环境下腐蚀10循环后YSZ陶瓷层的摩擦系数曲线

Fig.6

Coefficient of friction curves of the ceramic top coatings after corrosion at different atmosphere for 10 cycles

2.3.2 磨损形貌

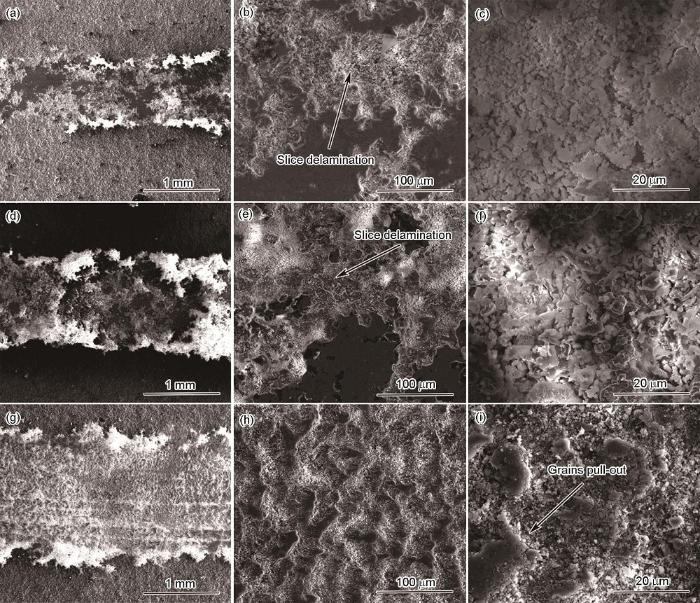

图7a,d和g分别为高温环境、交互环境以及水热环境下的摩擦磨损形貌图,图中白色部分为摩屑。由图7a和b可以看出,H组的磨损形貌主要由光滑的磨损面与表面剥落坑组成,这是较为经典的YSZ陶瓷摩擦磨损形貌,与Li的研究结果一致[19]。由图7d和e可以看出,A组的磨损形貌与H组相似,也由光滑磨损面与剥落坑组成,但与H组不同的是,A组剥落坑的数量远大于H组,且仅有较少的光滑磨损面存在。对于W组,其磨损面呈现出类似波浪花样的形貌 (图7g和h),图中较为光滑的凸起部分为磨损的片层。H组、A组与W组间摩屑的形貌也不相同,由图7c、f和i中的摩屑形貌图也可以看出,H组与A组的摩屑尺寸较大,平均尺寸为5 μm,且呈片状或大颗粒状,而W组的摩屑尺寸较小,平均尺寸为1 μm,且呈粒状。

图7

图7

不同环境下交替腐蚀10次后陶瓷层表面的磨损形貌

Fig.7

Worn surfaces of the ceramic top coatings of the samples H (a-c), A (d-f) and W (g-i) after alternating corrosion for 10 cycles

3 分析与讨论

由上述实验结果可知,在3种腐蚀环境中,W组的腐蚀程度最严重,热障涂层的耐磨性能下降最大。下面将结合上述分析结果,讨论热障涂层在水热老化以及高温氧化-低温水热老化交变环境下的腐蚀破坏机理以及水热腐蚀老化对热障涂层的摩擦磨损机制的影响。

3.1 水热腐蚀老化以及高温氧化-低温水热老化的腐蚀破坏机理

水热腐蚀老化的本质为ZrO2由t相至m相转变,而对于t相ZrO2在室温的稳定存在,稳定剂Y2O3起到了重要的作用。Y2O3稳定t相的过程Y2O3固溶至ZrO2晶格后,2个Y3+替代2个Zr4+产生一个氧空位,而生成的氧空位带正电荷,可以吸引周围的O2-向其靠拢同时拉大与Zr4+的距离,引发晶格畸变,形成特殊的晶胞结构,这种结构对周围的ZrO2有一定的束缚作用,可以阻碍ZrO2的相变并使其在t相稳定下来[20]。

而t相至m相的转变,伴随着3.5%的体积膨胀,而大量的相转变带来的体积膨胀过程中容易有大量裂纹产生,因此可以在W组中观察到数量众多的裂纹。

有研究表明[9],当ZrO2内发生t相至m相的转变时,晶粒体积的膨胀会产生使陶瓷裂纹缩小的应力,并阻止裂纹扩展,从而使陶瓷增韧,并对YSZ的摩擦磨损性能起到正面效果,但这一过程是存在阈值的[23],一旦m相含量过大,就会从增韧效果转变为破坏效果,最直观的体现就在于涂层内较大裂纹的产生 (如图3d所示)。而对于A组的样品而言,虽然经历了较多的循环,但也仅有极少m相生成,并且对涂层起到了破坏作用而不是增韧作用,这很可能是涂层的特殊相变状态引起的。在XRD结果中,高温使m相ZrO2重新转变为t相,表明OH-占据氧空位形成的质子缺陷 (OH)O无法在高温中稳定存在。Wang[24]的研究结果表明,在高温环境下,OH-很可能会以某种形式脱离ZrO2晶格,使晶格内氧空位浓度回复到正常值,m相会重新转变为t相稳定下来。因此,在交变环境下,YSZ涂层将一直处于t→m→t→m的反复相变过程中。A组的反复相变的机理可由图8表示,当热障涂层进行水热老化处理后,YSZ层内t相转变为m相,带来3.5%的体积增大;而又进行高温处理后,原本转变为m相的晶粒重新转变为t相,体积缩小7%,在此过程中t相→m相和m相→t相的转变所带来的体积变化是不可逆的[25],而随着循环次数的增加,反复相变所带来的的体积变化越来越大,裂纹也逐渐生成,因此可以在极少m相产生的情况下对涂层起到破坏或不是增韧效果。

图8

图8

H组试样反复相变示意图

Fig.8

Schematic representations of phase transition of H group of samples (a) as-deposited coating; (b) water penetration in the ceramic top coating, the phase transformation of some YSZ grains from t-phase to m-phase happened, resulting in the volume expansion of the grains; (c) the m-phase transfomed to t-phase at high temperature and then the volume of the grains decreased. During this process, the accumulation of irreversible volume change induced the initiation of cracks

3.2 在不同腐蚀环境下热障涂层的磨损机制

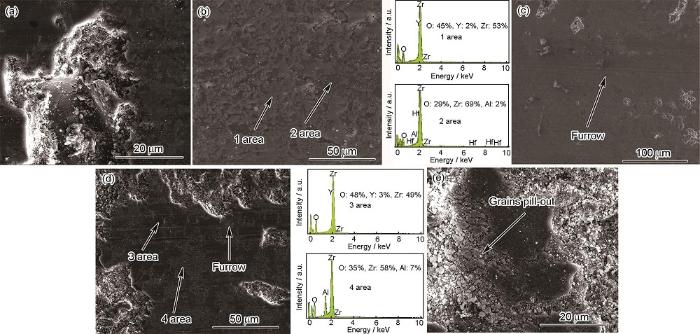

图9为热障涂层在不同环境下交替腐蚀10次后的表面磨损形貌图。如图9a所示,H组磨损表面有剥落坑的存在,剥落坑的形成是由于本课题热障涂层采用的是大气等离子喷涂技术制备的,导致YSZ陶瓷层内呈片层状结构,且片层与片层间呈机械结合,结合强度较弱,且涂层表面为类sin函数似的起伏状,因此,热障涂层在Al2O3对磨球滑动所产生的的剪切应力作用下,裂纹容易沿着扁平片层的边界萌生并扩展[26],涂层表面的起伏处和片层间结合相对较差的地方就容易发生断裂并被Al2O3对磨球拔出刮除形成剥落坑,而对于片层间结合相对较好的地方,片层无法断裂拔出,表面就会不断被对磨球磨平而形成光滑磨损面。因此,对于高温组,磨损面上的剥落坑表明涂层的磨损机制为脆性断裂引起的片层剥离,而脆性断裂是硬质陶瓷磨损过程中较为普遍的磨损形式[27]。由图9b可以看出,H组磨损面上出现衬度不一样的区域,与灰白色1区域相比,灰黑色的2区域内EDS结果显示有少量Al存在,表明YSZ涂层在磨损过程中与Al2O3对磨球发生了物质交换,与对磨球间发生了粘着磨损。由图9c所示,在光滑磨损面上有数道宽度为10 μm的犁沟存在,表明涂层在摩擦时刮除的颗粒与磨损面间又发生了二次摩擦,并在摩擦副的挤压下形成犁沟,磨损面内发生了磨粒磨损。可以看出,H组的磨损机制较为典型,与较多高硬度的陶瓷材料磨损机制相似,以脆性断裂引起片层剥落为主,并有少量的磨粒磨损与粘着磨损。如图9d所示,灰黑色3区域与灰白色4区域的EDS结果表明,A组的磨损面上也存在与对磨球发生物质交换的区域,磨损过程中发生粘着磨损;磨损面内有犁沟存在,磨损过程中发生了磨粒磨损;磨损面上有较多剥落坑存在,表明磨损面上发生了脆性断裂。A组的磨损机制与H组相同,以脆性断裂为主,磨粒磨损与粘着磨损为辅。图9e为水热组表面磨损形貌图,由图可以看出,不同于高温组与交变组片层断裂并被Al2O3对磨球拔起刮除的形式,图9e展现了水热组磨损过程中片层内晶粒剥离的过程,即在摩擦副滑动摩擦下,片层内发生微断裂并被直接分解为细小颗粒,随后细小颗粒被Al2O3对磨球带走,形成摩屑,并以此形式不断损耗片层。由此可以看出,水热组的磨损机制为微断裂引起的晶粒剥离。

图9

图9

不同环境下交替腐蚀10次后陶瓷层的磨损形貌

Fig.9

Worn surfaces of the ceramic top coating of the samples H (a-c), A (d) and W (e) after alternating corrosion for 10 cycles

3.3 水热腐蚀老化对热障涂层摩擦磨损机制的影响

在水热腐蚀老化过程中,氧空位的存在是保持t相ZrO2稳定存在的关键。文献[20,21]研究表明,晶界处是氧空位主要聚集存在的场所。同时,带负电的OH-在扩散过程中易被具有正电荷的晶界吸引,所以对于晶粒而言,当水热腐蚀老化发生时,晶粒晶界处将是腐蚀最为严重的地方。因此,由图4f的EBSD相分布图可以看出,在腐蚀开始时,红色区域所代表的m相主要分布在晶界周围,而随着腐蚀时间的延长,如图4c所示,m相才逐渐在晶粒内部生成,也就是说,水热老化的过程是由晶粒晶界逐渐向晶粒内部腐蚀。腐蚀最先发生在晶界处,意味着晶粒与晶粒间的结合将很容易受到破坏。而表面的晶粒所受约束较少,一旦发生腐蚀,晶粒将很容易处于不稳定状态。对于W组而言,水热腐蚀时间较长,水蒸气可以完全渗透进片层内部,并在片层内晶粒晶界处腐蚀。Cao等[13]研究表明,水热腐蚀10 d后,YSZ晶粒间出现沿晶裂纹,晶粒内则出现穿晶裂纹。晶界处的沿晶裂纹将大大降低晶粒间结合强度,因此,在磨损过程中的损耗倾向于如图9d所示的直接从片层上刮除晶粒而不是将片层拔起脱离的形式,使磨损形貌呈现出类似波浪花样的形貌。同时,由于晶粒间的结合已被水热老化严重破坏,摩擦副刮去晶粒仅需要较小的能量,因此在摩擦磨损实验中W组显示出最大的磨损率,其大小是A组的2.1倍,H组的5.4倍。

本文中热障涂层采用的是APS喷涂制备的,原始态涂层内就存在一定量的缺陷,这些缺陷和片层与片层间的间隙为水蒸气的渗透提供了快速通道,同时也是水蒸气腐蚀的场所。A组的腐蚀程度较轻,水汽难以渗透至片层内部,水热老化主要发生在涂层的固有缺陷处与片层间隙处。在反复相变作用下,虽然产生的m相较少,但也能生成一定数量的裂纹。在这些裂纹中,尺寸较小的裂纹会在高温的烧结作用下愈合,仅留下尺寸较大的裂纹,而这些尺寸较大的裂纹将大大降低片层间结合力以及片层内断裂所需要的能量。因此,A组的片层更容易在摩擦磨损中被剥离形成剥落坑,进而相对于H组表现出更大的摩擦系数与磨损率。对于A组与H组,磨损面上都存在着较多的剥落坑,有研究结果表明,陶瓷在干摩擦条件下磨损后,摩屑会回填至坑内形成保护层,而这层保护层可以抵抗摩擦副进一步的磨损,因此,交互组与高温组相较于水热组都表现出较小的划痕尺寸与磨损率。

4 结论

本文研究了热障涂层在高温氧化环境、低温水热老化环境以及低温水热老化-高温氧化交变环境腐蚀后的摩擦磨损行为,得到如下结论:

(1) 热障涂层在低温水热老化环境下腐蚀后,其陶瓷层内ZrO2会发生t相至m相的转变,并生成大量的微裂纹。水热腐蚀老化诱发生成的m相将优先在晶粒晶界处生成,而伴随m相生成所产生的裂纹将降低晶粒与晶粒间的结合强度,使YSZ片层在摩擦副作用下容易被分解为小颗粒并被刮除,导致涂层耐磨性能下降。

(2) 高温处理会使水热腐蚀老化诱发生成的m相还原为t相,所以热障涂层在低温水热老化-高温氧化交变环境下,将会持续处于t相与m相的反复相变过程,而在ZrO2反复相变过程中积累不可逆的体积变化将会导致陶瓷层内的裂纹萌生。因此热障涂层在低温水热老化-高温氧化交变环境下,即便仅生成少量的m相,也可以生成大量的裂纹。

(3) 热障涂层在高温氧化环境及低温水热老化-高温氧化交变环境腐蚀10循环后,其磨损机制为脆性断裂导致的片层剥离,并伴有粘着磨损与磨粒磨损;热障涂层在低温水热老化环境腐蚀10循环后,其磨损机制为微断裂引起的晶粒剥离。

参考文献

Thermal barrier coatings for gas-turbine engine applications

[J].Hundreds of different types of coatings are used to protect a variety of structural engineering materials from corrosion, wear, and erosion, and to provide lubrication and thermal insulation. Of all these, thermal barrier coatings (TBCs) have the most complex structure and must operate in the most demanding high-temperature environment of aircraft and industrial gas-turbine engines. TBCs, which comprise metal and ceramic multilayers, insulate turbine and combustor engine components from the hot gas stream, and improve the durability and energy efficiency of these engines. Improvements in TBCs will require a better understanding of the complex changes in their structure and properties that occur under operating conditions that lead to their failure. The structure, properties, and failure mechanisms of TBCs are herein reviewed, together with a discussion of current limitations and future opportunities.

Effect of spraying ceramic powder pore structure on thermophysical properties of plasma-sprayed thermal barrier coatings

[J].

Mechanisms controlling the durability of thermal barrier coatings

[J].

Application of thermal barrier coatings on aero-engines of high thrust-to-weight ratio

[J].

高推重比发动机热障涂层应用现状分析

[J].

Synthesis and characterization of nanostructured t′-YSZ spherical feedstocks for atmospheric plasma spraying

[J].

Recent advances in the thermal barrier coatings for extreme environments

[J].

The zirconia-yttria system

[J].

Low temperature degradation -aging- of zirconia: a critical review of the relevant aspects in dentistry

[J].This review presents a critical survey of all experimental data about the low temperature degradation of zirconia (often referred to as "aging") due to the tetragonal-to-monoclinic transformation, which have been collected at temperatures of interest for dental application (room temperature to about 100 degrees C). It is shown that the main factors affecting the aging phenomenon are (i) the stabilizer type and content, (ii) the residual stress and (iii) the grain size. It is also shown that extrapolating the low temperature degradation rate from accelerated aging tests can lead to unacceptable conclusions about the lifetime of the zirconia-based components. Finally, based on the experimental evidence, a set of engineering guidelines for the use of zirconia in restorative and prosthetic dentistry is proposed.Copyright 2010 Academy of Dental Materials. Published by Elsevier Ltd. All rights reserved.

Zirconia as a sliding material: histologic, laboratory, and clinical data

[J].

The tetragonal-monoclinic transformation in zirconia: lessons learned and future trends

[J].

Low-temperature degradation of zirconia and implications for biomedical implants

[J].

Degradation of zirconia in moisture

[J].

WITHDRAWN: the effect of hydrothermal corrosion on the phase stability, microstructure and thermal cycling behavior of n-YSZ coating

[J].

Tribological properties of YSZ and YSZ/Ni-YSZ nanocomposite coatings prepared by electron beam physical vapour deposition

[J].

Unlubricated wear and friction of toughened zirconia ceramics at elevated temperatures

[J].

Friction and wear behavior of 3Y-TZP ceramics and their mechanisms

[J].

氧化锆陶瓷的摩擦磨损行为与机理

[J].

Hydrothermal degradation of a 3Y-TZP translucent dental ceramic: a comparison of numerical predictions with experimental data after 2 years of aging

[J].The purpose of the study was to assess the hydrothermal resistance of a translucent zirconia with two clinical relevant surface textures by means of accelerated tests (LTD) and to compare predicted monoclinic fractions with experimental values measured after two years aging at 37°C.Polished (P) and ground (G) specimens were subjected to hydrothermal degradation by exposure to water steam at different temperatures and pressures. The t-m phase transformation was quantified by grazing incidence X-ray diffraction (GIXDR). The elastic modulus and hardness before- and after LTD were determined by nanoindentation.G specimens presented a better resistance to hydrothermal degradation than P samples. Activation energies of 89 and 98kJ/mol and b coefficients of 2.0×10(-5) and 1.8×10(-6) were calculated for P and G samples respectively. The coefficients were subsequently used to predict transformed monoclinic fractions at 37°C. A good correlation was found between the predicted values and the experimental data obtained after aging at 37°C during 2 years. Hydrothermal degradation led to a significant decrease of the elastic moduli and hardness in both groups.The dependency of the t-m phase transformation rate on temperature must be determined to accurately predict the hydrothermal behavior of the zirconia ceramics at oral temperatures. The current prevailing assumption, that 5h aging at 134°C corresponds to 15-20 years at 37°C, will underestimate the transformed fraction of the translucent ceramic at 37°C. In this case, the mechanical surface treatment influences the ceramic's transformability. While mild grinding could potentially retard the hydrothermal transformation, polishing after occlusal adjustment is recommended to prevent wear of the antagonist teeth and maintain structural strength.Copyright © 2015 Academy of Dental Materials. Published by Elsevier Ltd. All rights reserved.

Plasma sprayed YSZ coatings deposited at different deposition temperatures, part 2: tribological performance

[J].

Progress on hydrothermal stability of dental zirconia ceramics

[J].In recent years, zirconia ceramic, as a preferential choice for teeth restorations, is used as fixed partial dentures and implants due to its excellent mechanical properties, favorable biocompatibility and aesthetic properties, thus significantly shortening the performance life and seriously damaging the reliabilities. However, zirconia ceramic easily occurs low temperature degradation (LTD) of t-m transformation in humid environments. This paper illustrated the characteristics, mechanism and kinetics of LTD, as well as the conventional characterization methods of LTD phenomena and new methods such as optical coherence tomography and focused ion beam. It is also shown the main factors affecting the aging phenomenon, and emphasized the inhibition methods of LTD. By developing materials system and improving processing technology to enhance the strength, fracture toughness of zirconia and to solve the LTD of zirconia, and to meet the needs of people for their health functionalization, zirconia ceramic will be widely applied in the dental restoration field.

齿科氧化锆陶瓷水热稳定性研究进展

[J].近年来, 齿科氧化锆陶瓷凭借高强韧性、良好生物相容性和美观自然色泽而成为牙齿临床修复的首选对象, 可用于修复、固定局部义齿和种植牙。然而, 在低温潮湿环境中氧化锆陶瓷易发生t-m相变老化, 服役寿命显著缩短, 严重影响其临床稳定性。本文综述了氧化锆陶瓷低温老化的特点、机制及其老化动力学规律, 并介绍了表征氧化锆低温老化现象的常规技术手段以及光学相干断层扫描、聚焦离子束等新方法; 总结了低温老化行为的主要影响因素以及抗老化措施, 具体可通过调整材料体系、改进加工方式等来增强氧化锆的韧性, 解决其存在的低温老化问题。随着齿科氧化锆陶瓷抗老化性能的提高以及健康功能化的未来需求, 其在齿科修复领域的应用将会越来越广泛。

Hydrothermal degradation mechanism of tetragonal zirconia

[J].

Water incorporation in tetragonal zirconia

[J].

Effect of hydrothermal treatment on tribological properties of alumina and zirconia based bioceramics

[J].

Failure mechanism of zirconia thermal barrier coating

[D].

氧化锆热障涂层失效机理研究

[D].

Microstructure and wear behaviour of powder and suspension hybrid Al2O3-YSZ coatings

[J].

The microstructural dependence of wear and indentation behaviour of some plasma-sprayed alumina coatings

[J].