海洋生物污损是指在海水中人工结构上的有害生物附着物,海洋环境中污损生物种类繁多[1],海洋生物污损从微生物附着到生物膜形成,再到微生物沉降及大型生物定居、生长,整个过程十分复杂[2]。海洋生物污损能够对海洋与人类活动产生诸多不利影响:首先,在经济方面,微生物附着会造成船体表面侵蚀,一方面增加维护成本,另一方面粗糙的船体致使船舶航行阻力增加,降低船舶最大速度和船舶操纵性[3];其次,从环境和生态方面,生物污损导致更多的燃料消耗和温室气体排放[4],另外,附着在船身的生物体随船舶行进,被携带到远离其栖息地的海域,成为影响当地生态系统的生物入侵者[5];再次,从安全方面,污损生物分泌的生物酸会导致金属腐蚀、混凝土变质等,进而影响船舶、海洋仪器设施等的正常运行,增加安全事故隐患。

自然界中许多动植物即使长时间静置在水中,依然具有抵御海洋生物污损能力,如某些生物凭借其特殊的表皮微结构具有抗污性,而某些生物则通过产生特殊的化学物质击退污物等。这些动植物本身具有的天然抗粘附机制为仿生防污技术的发展奠定了基础,高效且绿色环保的仿生防污理念应运而生。本文在生物表面微结构研究的基础上,对仿生微结构复刻与表面润湿性调控两种水下仿生防生物污损技术进行梳理。

1 生物表面微结构研究与仿生表面复制

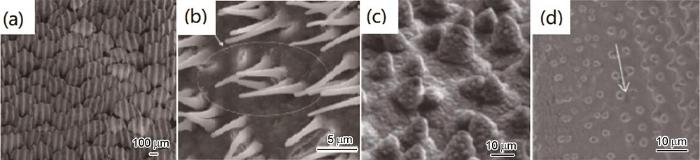

多种海洋动物皮肤以及植物叶片具有特殊的微观结构,进而表现出优异的抑制生物污垢附着的能力。研究表明[7],鲨鱼表皮覆盖有齿状微/纳米级鳞片,鳞片上的沟槽与凸起交替排列,紧凑有序,前后相邻的鳞片在边缘部位发生重叠 (如图1a),鲨鱼表皮的这种结构可以有效抑制微观生物硅藻和贻贝足丝的附着。海蟹壳表面微结构的研究表明[8],蟹壳上分布着细小的尖刺,其平均长度为4 μm,间距约为6.5 μm (如图1b所示),这种结构使得海蟹即使长时间浸泡在海水中,其表面仍然能够保持干净无污垢。针对荷叶和水稻叶的研究指出[9],两种植物叶片具有类似的层次结构,且表面均被蜡质微乳突覆盖 (如图1c和d),该结构有助于形成超疏水界面,即便荷叶和稻叶从污泥中长出,仍可“出淤泥而不染”。经证实,“鲨鱼皮效应”、“荷叶效应”及“稻叶效应”等不依赖于抗生素或毒性杀生剂的释放,其防污机理取决于生物表面的微观结构,由此,生物表皮微结构复制为绿色防污技术开发带来灵感。

图1

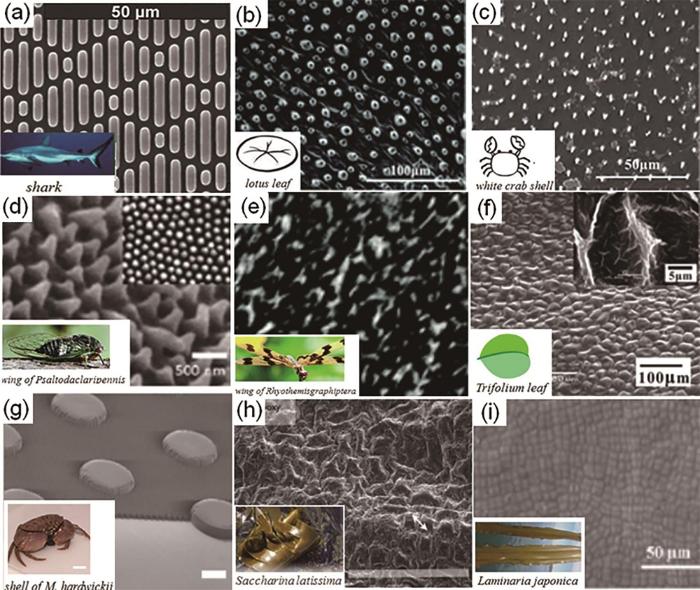

采用聚合物如聚二甲基硅氧烷 (PDMS) 作为模具可以进行微纳米结构的复制,PDMS模具复刻法是重建生物表面微结构常见且有效的方法,它具有灵活、成本低、易于操作等优点,可实现各种材料的微图案化[10,11]。Schumacher等[12]采用PDMS模具复刻技术成功复制了鲨鱼皮肤,研究指出,该仿生微形貌的纵横比与其防污效果具有显著的相关性,控制好纵横比可以有效降低孢子沉降率。Chen等[13]利用PDMS技术复制了天然荷叶与蟹壳表面,研究表明,这种“桥”和“气垫”结构有利于抑制硅藻沉降,梭菌粘附率降低约73%。随后,Gangadoo等[14]证实,采用PDMS技术复制的蝉与蜻蜓翅膀表面微结构能够有效减少脱氧核糖核酸、蛋白质和碳水化合物的吸附。

生物表面微结构的复刻不仅限于单一PDMS模具法,还可以将PDMS技术与其它工艺协同。Liu等[15]将PDMS模具复刻技术与火焰处理相结合,制备了具有鲨鱼皮肤表面形态与荷叶层次化微纳结构的双仿生表面,该表面的接触角高达160°,具有自清洁、防污、减阻等性能。Wan等[16]将PDMS模具复制法与PSPMA分子刷修饰相结合,获得的仿生三叶草表面可以有效抑制微藻的沉降。Brzozowska等[8]采用两性离子聚合物刷对PDMS复制技术得到的仿生海蟹外壳表面进行改性后,至少六个星期能够抑制生物污损。Chapman等[17]在PDMS复制过程中加入溴化呋喃酮,使得大型藻类仿生表面的防污效果提高40%。Zhao等[18]采用层层自组装法在PDMS复制海带表面构建了聚电解质多层膜,有效阻碍了梭状芽胞杆菌的粘附。图2为采用单一PDMS技术或将PDMS技术与其它工艺结合,进行仿生微结构复刻的代表性研究。

图2

此外,Sun等[19]利用皮秒激光技术在不锈钢表面得到了具有微纳米级的仿生粗糙分层结构,该表面可以使微生物平均附着面积比降低近50%。由此看出,生物表面微结构的复刻是一种绿色、可行且有效的水下仿生防污技术。

2 基于润湿性调控的仿生表面设计

针对自然界生物体的防污机理研究发现,多种生物表皮具有特殊的润湿性。润湿可以被定义为液体与固体表面保持接触的能力,早在1805年Young[20]就指出,液滴在固体表面的形状由接触角θ决定,根据Young方程:

接触角θ取决于液体表面张力γl、固体表面能γs以及固/液界面能γsl。以空气中的水滴为例,对应4种表面润湿性分别为:超亲水性 (θ<10°)、亲水性 (θ<90°)、疏水性 (θ>90°)、超疏水性 (θ>150°)。对于水下油滴,可以进一步定义为水下亲油性与水下疏油性等。由于润湿性与生物粘附之间存在一定的相关性,由此,控制生物污垢附着的策略除了对仿生表面微结构复刻外,还可以对材料进行基于润湿性调控的仿生微结构设计,以此提高材料的防污性能。

2.1 亲水性表面

一些海洋生物如海洋鱼类和珊瑚几乎从不受到海洋污损生物的污染,其直接原因是鱼类或珊瑚的表面亲水且光滑。来自于贻贝表面的灵感,基于开花树微纳结构对硅藻抑制作用的研究证实[21],亲水性基团因其能够在材料表面形成稳定的强水合表面,故而可以有效阻碍蛋白质、藻类/细菌等的粘附。受此启发,研究人员开发了一系列亲水性表面用以抵抗海洋生物的附着。

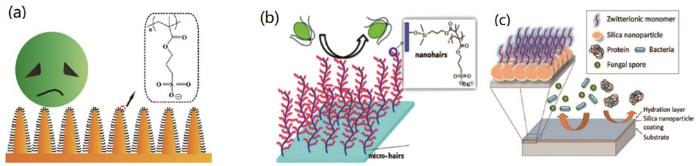

聚电解质刷通过在材料表面构建一个只有几纳米厚的涂层,凭借“刷子”的物理屏障作用抵抗海洋污损生物在材料表面的粘附。研究表明,单一聚电解质刷或在聚电解质刷表面接枝与改性是实现海洋仿生防污的有效手段,如Wan等[16]采用SI-ATRP法将亲水性聚电解质刷 (PSPMA) 接枝到仿生三叶草结构表面 (如图3a),仿生表面微观结构和化学成分均能有效提高其海洋防污性能。受软珊瑚表面防污性能启发,Bing等[22]制备了石墨烯-硅氧烷弹性体 (GSE) 复合材料,该材料通过物理作用 (如珊瑚触手的摆动) 有效抵抗了革兰氏阴性菌及阳性菌的粘附活性。为研究微藻/孢子与“毛状”覆盖仿生表面之间的关系,Wan等[23]采用原子转移自由基聚合法 (SI-ATRP) 将PSPMA接枝到天然毛皮上 (图3b),通过一系列微藻/游动孢子室内静态和动态沉降实验可见,长且密度高的纤维表面可以有效抵抗微藻/孢子的沉降。

图3

此外,研究人员在探索中发现,红细胞的非致血栓潜能归因于两性离子磷脂,受此启发,多种两性离子聚合物被开发并应用于海洋防污领域。两性离子聚合物通常由主链和带有正负电荷基团的侧链组成,通过物理相互作用或化学键合的方式接枝固定到材料表面,对于两性离子聚合物的防污机理,Liu等[24]通过分子模拟得出,碳主链长度和侧两性离子基团的性质对防污性能具有显著影响。Song等[25]认为,由于两性离子聚合物的净电荷几乎为零,且相反的电荷分布均匀,因此不会通过静电作用与带电蛋白质或微生物进行吸附。Li等[26]指出,两性离子聚合物的离子溶剂化提供了致密的水合层,因此可以利用物理阻隔作用防止蛋白质吸附。Higaki等[27]通过藤壶幼虫和贻贝幼虫附着期的沉降实验证实,两性离子聚 (羧基甜菜碱) 刷和聚 (磺酸甜菜碱) 刷对大型生物和微生物附着进行了有效的阻止。Knowles等[28]将两性聚磺酸甜菜碱功能化二氧化硅NPs自旋包覆在金基体表面,形成了亲水涂层 (如图3c),该涂层可以有效对抗蛋白质、细菌和真菌孢子的粘附,同时该粒子功能化涂层能够应用于各种基体表面。

然而,同亲水性聚合物刷一样,两性离子聚合物的机械性能较弱,容易损坏,这限制了它们在海洋环境中的应用。一些研究试图将两性离子聚合物与其它材料复合来解决这一问题。如Jin等[29]的研究中,将甲基丙烯酸羧甜菜碱 (CBMA) 和2-甲基丙烯酰氧乙基磷酰胆碱 (MPC) 加入到聚甲基丙烯酸甲酯 (PMMA) 中,获得了优异的防污性能及力学性能。Wang等[30]将两性离子水凝胶与市售超级胶结合,制备了一种持久耐用的两性离子防污涂层,该涂层在水中浸泡90 d后,即便在恶劣条件下 (如缓冲剪切、水冲洗、刮刀和砂纸磨损) 仍能保持优异的防污性能。蔺存国课题组[31,32]将Ag、Bi5O7I等与两性离子含氟聚合物协同,制备出几种新型复合物,研究表明,基于Bi5O7I的光催化作用、Bi3+和Ag+的释放以及两性离子聚合物形成的水合层等共同作用,材料抗硅藻沉降性能得到提高。他们一系列研究还表明,对具有低表面能、且在水中呈现良好细胞稳定性的PDMS进行改性也是获得亲水性仿生结构与防污性能的有效途径。比如,采用磺基甜菜碱硅烷和聚乙烯醇 (PVA) 火焰处理对PDMS改性可以获得亲水性表面,与未改性PDMS相比,该亲水表面的硅藻粘附力最大可降低99.0%[33];基于PVP合成的亲水性聚合物对PDMS的改性表明[34,35],形成的具有较强物理化学稳定性的高亲水性聚合物能够降低金黄色葡萄球菌和硅藻粘附力约97%,同时该材料在现场试验中至少4个月保持了良好的抗生物污染性能;将两性离子酯和辣椒素共聚物接枝到PDMS结构上[36],利用两性离子酯和辣椒素分子的共同作用可以有效抵抗海洋生物附着,研究证实,与未接枝PDMS相比,改性后的蛋白质粘附力降低88.5%,细菌粘附力降低99.0%,硅藻粘附力降低99.5%,藤壶粘附力降低72.4%,黄海试验进一步证实,该材料至少在261 d内保持了优异的抗生物污染能力。另外,该课题组合成了具有超亲水性能的PGHPA-PDF-MF复合材料[38],该材料凭借其官能团、三维多孔结构和超亲水表面的协同作用,表现出优异的抑制藻类和贻贝粘附特性和有效的抗藻类生长行为 (近88%的细胞死亡率)。

2.2 低表面能/超疏水表面

式中,θW为粗糙表面的Wenzel接触角,θr为光滑表面的Young接触角,r为粗糙因子,代表实际固/液界面的接触面积与几何接触面积之比;θCB为多孔表面的Cassie-Baxter接触角,f为液体与固体的接触面积分数。由此看出,Wenzel模型强调粗糙度对接触角的影响,Cassie-Baxter模型则偏重于对多孔非均质表面的描述。他们认为,在粗糙的固体表面,由于表面张力的存在,液滴并不会完全浸润固体表面,而是悬浮于粗糙表面之上,形成固/液/气三相的复合界面,因此,除了粗糙度以外,固体表面自由能是影响材料润湿性的另一关键因素[40]。根据Wenzel模型,固体表面若想实现疏水性,水滴的表征接触角应大于90°,结合Young方程,这需要固体表面自由能足够低,正如Aishwarya等[41]的研究所证实的,固体表面粗糙度与表面能成反比,即粗糙度越大,表面能越低。低表面能可以使固体不容易被液滴润湿,进而实现材料的超疏水性[42]。

受“荷叶效应”启发,具有低表面能的材料一方面可以利用水的剪切应力或船舶外部触发器的机械力清除掉污损生物,另一方面材料表面的疏水性可以降低船舶在航行过程中的阻力,减少燃料消耗及CO2排放。水滴界面接触角大于150°的表面称为超疏水表面,水在超疏水表面形成珠状,水珠滚动能够去除材料表面污染物,因此低表面能/超疏水材料具有防污性能和自清洁效果。

(1) 有机硅材料

自1961年硅烷偶联剂应用于船舶以来,人们发现由硅树脂制成的涂料可以有效防止藤壶附着。典型的有机硅防污材料—PDMS弹性体具有低表面能和低弹性模量,它可以为生物体提供相对较小的粘接强度,致使海洋生物只能微弱的粘附在基质表面,通过水剪切力便可轻易去除。然而,PDMS弹性体具有机械稳定性差、与基材附着力弱的缺点,而且其防污效果只有在船速高于15节时才能达到,在静态条件下,防污性能较差[43]。

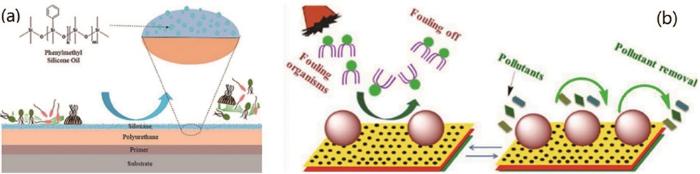

为了改善其应用性能,Webster小组[44]尝试将PDMS与更硬的聚氨酯 (PU) 混合,制备的PDMS/PU复合材料附着力明显增强 (图4a),且可有效降低大型藻类、藤壶和贻贝的粘附。此外,研究证实,向PDMS基材料添加适量微/纳米尺寸的无机填料不仅可以保持材料的疏水性能,还能够有效增强PDMS基材料的力学性能,如Selim小组[45]制备的PDMS/纳米磁铁矿自清洁复合材料具有良好的动态不粘性能,能够有效防止硅藻和细菌的附着 (图4b);向有机硅中加入0.5%纳米ZnO后,得到了防污性能较好的超疏水纳米复合材料[46],且可满足海洋环境下的长期使用;该小组还研究了基于CuO2纳米立方体与PDMS协同的纳米复合材料[47],当CuO2含量仅为0.1%时,材料具有疏水性能和有效的防污性能,然而当CuO2含量超过5%后,颗粒聚集导致表面粗糙度提高,防污性能下降;该小组对TiO2-SiO2核-壳纳米棒[48]、MnO2纳米棒[49]、碳化硅纳米线[50]等协同PDMS的研究均得到与CuO2类似的结果。

图4

(2) 有机氟材料

有机氟是另一类低表面能材料,与PDMS相比,有机氟聚合物以低表面能、高化学稳定性著称,它与水的接触角高达114°。最初,聚四氟乙烯 (PTFE) 被认为是一种很好的脱污材料,但后来发现它溶解度低、结晶度高、附着力弱,且很容易遭到损坏,因此,对PTFE的研究逐渐转向了含氟聚合物的研究。如Krishnan团队[51]研究了氟化梳状液晶嵌段共聚物,认为含氟共聚物针对孢子的防污性能更好,但对硅藻反而更差,这说明特定生物与材料表面之间的相互作用尤为重要。据Martinelli等[52]报道,主链是聚苯乙烯和PDMS,侧链是聚乙二醇和氟碳链的嵌段共聚物的广谱防污能力优异。为避免较长的氟碳侧链对海洋环境的影响,进一步提高防污稳定性,Wooley等[53]利用超支化含氟聚合物合成的三元共聚物对蛋白质吸附的阻力增加60%。此外,Galli等[54]合成的以甲基丙烯酸酯为主链,聚硅氧烷为侧链,PEG/氟烷基为单体的共聚物可以有效阻止孢子的沉降。

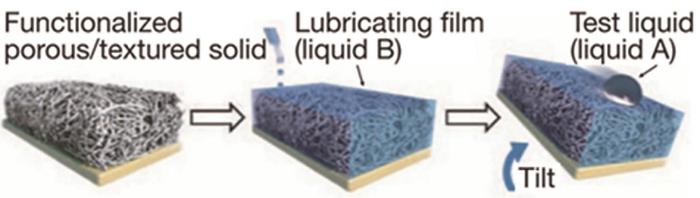

2.3 光滑液体注入多孔表面

图5

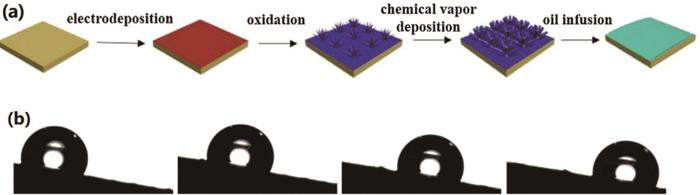

Epstein等[56]的研究指出,向多孔PTFE中注入全氟液体形成SLIPS,在一周内可以阻止铜绿假单胞菌定植高达99.6%,即便在极端和紫外线暴露环境下,潜入水中的SLIPS仍然是稳定的,表面几乎没有细胞毒性。此外,通过表面沉积、刻蚀技术等制备多孔纳米结构基质,随后进行功能化处理,可以进一步实现其与注入油相的化学性质的匹配,如蔺存国团队[57]采用电沉积、氧化、化学气相沉积等一系列工艺在CuZn金属表面形成纳米级Cu(OH)2束簇结构后,经过十二硫醇表面改性,超疏水性和稳定性得到提高,随后向其表面注入油相形成SLIPS (图6),测试结果表明,该表面在外部机械损伤下仍然具有良好的超疏水性和自愈效果,并能够有效抑制生物侵蚀。

图6

由于SLIPS主要依靠油相层抵抗生物污垢,油相渗漏将会导致SLIPS防污性能的下降,据报道[58],SLIPS的稳定性可以通过油相损失量、接触角滞后、水和乙醇液滴在表面的滑动角来表征,均匀的纳米结构比层状结构表现出更好的剪切耐受性和疏水性。2018年,Ware等[59]首次量化了防污所需的油相剂量,研究指出,注入0.9 μL·cm-2硅油,细菌抑制率高达99%,在海水中浸泡两周后,硅油含量降至0.04 μL·cm-2,对细菌的抑制率降到约80%。Wang等[60]构建了一种注入全氟聚醚 (PFPE) 的纳米结构,用以解决海洋光学仪器的生物污染问题,研究表明,在静态环境中浸泡10 d,SLIPS细菌覆盖率仅为1.56%。然而,在振动环境下,SLIPS的水接触角滞后急剧增加,这表明SLIPS的稳定性需要进一步研究与提高。

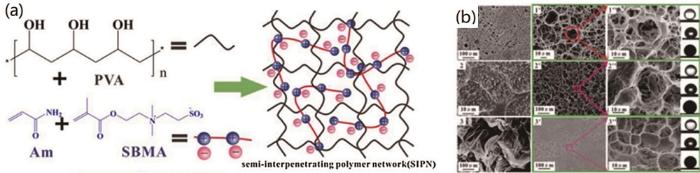

2.4 水下超疏油表面

构建水下超疏油表面可以削弱生物污垢与材料的接触,进而实现材料的抗生物污损性能。Zhou等[61]制备了基于PVA的水下超疏油材料,形成了特殊的半交互式聚合物网络结构 (SIPN,图7),将该材料涂于钢板上置于南海浸泡6周后,未出现明显的生物污染现象,证实了该材料的抗生物污损能力。Su等[62]采用溶液铸造法将MPS-SiO2/PNIPAM复合纳米粒子与ER混合,制备了水下超疏油涂层,该涂层能够在腐蚀性溶液中保护基体,防止细菌附着和生物膜形成。Chen等[63]通过亲水聚合物链修饰分级微凝胶MHMS的自组装,成功制备了一种水下超疏油水凝胶涂层,基于单体的三维有序结构,该涂层具有良好防生物污损性能、耐酸稳定性和耐碱性,该材料的研发为船用防污涂层的制备提供了思路。

图7

2.5 两亲性表面

两亲性是指同一种材料同时具有亲水性和亲油性。近年来,两亲性共聚物的抗蛋白性能得到了研究者们的广泛关注,该材料是受血管内壁表面结构的微相分离而设计和启发的,其防污机理来源于血管内壁凸凹不平的表面可以有效防止蛋白质黏附和血栓凝结[64]。含有亲水/亲油性段的两亲性共聚物由于相分离而形成的具有微纳尺寸的不均匀表面能够有效减少生物污物附着[65],其中聚乙二醇 (PEG) 以其对蛋白质吸附的抵挡以及对海洋污染生物粘附的抵抗而闻名[66]。PEG是一种中性亲水聚合物,通常作为两亲共聚物的亲水段。2004年,Wooley等[67]首次报道了由亲油性超支化氟聚合物和亲水性PEG组成的两亲性聚合物在海洋防污中的应用,研究指出,两亲性聚合物中PEG的比例对防污性能有较大影响。此外,混合亲/疏水表面凭借其在水中呈亲水性,而在空气中为疏水性的特殊性质,实现了材料一方面在水中可以抵抗蛋白质、藻类/细菌等的粘附,另一方面在空气中能够轻松除污的目的,如Galhenage等[68]一步合成了PEG修饰PDMS/PU两亲材料,该材料中的亲水与疏水组分聚在一起,分布在水/材料界面附近,使材料具有优异的广谱防污性能。

由于亲/疏水之间的相互作用难以找到平衡,因此制备多组分两亲性材料面临着一定的挑战,嵌段共聚物可以有效克服这些限制,它们的结构能够保证纳米尺寸的疏水和亲水结构域的形成[69],然而,表面活性嵌段共聚物的制备通常限于克级,目前很难将这些材料从实验室研究扩大到商业化产品。

3 展望

海洋物种千差万别,仿生防海洋污损材料面临着广谱防污性能和长效防污的巨大挑战。对于海洋生物污垢,具有亲水性、超疏水性、水下超疏油性和两亲性材料表现出优异的防污性能,仿生防生物污损材料的物理化学、机械强度和表面形貌之间的协同效应对持续防污至关重要,后续应探索污垢与界面润湿性之间的深层关系;此外,材料表面性能在自然海洋环境中也可能发生变化,因此需要唤醒材料对外界环境变化的自我反应,加强材料科学、生物科学及海洋科学交叉融合的研究,促进海洋防污技术的可持续发展和成功开发。

参考文献

Combat biofouling with microscopic ridge-like surface morphology: a bioinspired study

[J].

The progress on antifouling organic coating: From biocide to biomimetic surface

[J].The advancement in material science and engineering technology has led to the development of antifouling (AF) coatings which are cheaper, durable, less toxic, and safe to the environment. The use of AF coatings containing tributyltin compounds was prohibited at the beginning of 2003, this necessitated the development of environmentally friendly coatings. The fouling release coating (FRC) lacks biocides and has low surface energy, low elastic modulus with smooth surface properties, hence a better release effect to fouling organisms. Several functional coatings have been recently developed based on fouling release (FR) technology to combat the effects of biofouling. Here, we provide a brief overview of innovative technologies and recent developments based on FRCs, including silicone, modified fluorinated polymer, cross-linked coatings, amphiphilic copolymer coating, hydrogel coatings, and biomimetic coatings. We also highlight the key issues and shortcomings of innovative technologies based on FRCs. This may give new insights into the future development of marine AF coatings.

Marine paints: the particular case of antifouling paints

[J].

Economic impact of biofouling on a naval surface ship

[J].In the present study, the overall economic impact of hull fouling on a mid-sized naval surface ship (Arleigh Burke-class destroyer DDG-51) has been analyzed. A range of costs associated with hull fouling was examined, including expenditures for fuel, hull coatings, hull coating application and removal, and hull cleaning. The results indicate that the primary cost associated with fouling is due to increased fuel consumption attributable to increased frictional drag. The costs related to hull cleaning and painting are much lower than the fuel costs. The overall cost associated with hull fouling for the Navy's present coating, cleaning, and fouling level is estimated to be $56M per year for the entire DDG-51 class or $1B over 15 years. The results of this study provide guidance as to the amount of money that can be reasonably spent for research, development, acquisition, and implementation of new technologies or management strategies to combat hull fouling.

Progress in biomimetic leverages for marine antifouling using nanocomposite coatings

[J].

Recent developments and practical feasibility of polymer-based antifouling coatings

[J].

Study on biomimetic preparation of shell surface microstructure for ship antifouling

[J].

Biomimicking micropatterned surfaces and their effect on marine biofouling

[J].When synthetic materials are submerged in marine environments, dissolved matter and marine organisms attach to their surfaces by a process known as marine fouling. This phenomenon may lead to diminished material performance with detrimental consequences. Bioinspired surface patterning and chemical surface modifications present promising approaches to the design of novel functional surfaces that can prevent biofouling phenomena. In this study, we report the synergistic effects of surface patterns, inspired by the marine decapod crab Myomenippe hardwickii in combination with chemical surface modifications toward suppressing marine fouling. M. hardwickii is known to maintain a relatively clean carapace although the species occurs in biofouling communities of tropical shallow subtidal coastal waters. Following the surface analysis of selected specimens, we designed hierarchical surface microtopographies that replicate the critical features observed on the crustacean surface. The micropatterned surfaces were modified with zwitterionic polymer brushes or with layer-by-layer deposited polyelectrolyte multilayers to enhance their antifouling and/or fouling-release potential. Chemically modified and unmodified micropatterned surfaces were subjected to extensive fouling tests, including laboratory assays against barnacle settlement and algae adhesion, and field static immersion tests. The results show a statistically significant reduction in settlement on the micropatterned surfaces as well as a synergistic effect when the microtopographies are combined with grafted polymer chains.

Fluid drag reduction and efficient self-cleaning with rice leaf and butterfly wing bioinspired surfaces

[J].Researchers are continually inspired by living nature to solve complex challenges. For example, unique surface characteristics of rice leaves and butterfly wings combine the shark skin (anisotropic flow leading to low drag) and lotus leaf (superhydrophobic and self-cleaning) effects, producing the so-called rice and butterfly wing effect. In this paper, we present an overview of rice leaf and butterfly wing fluid drag and self-cleaning studies. In addition, we examine two other promising aquatic surfaces in nature known for such properties, including fish scales and shark skin. Morphology, drag, self-cleaning, contact angle, and contact angle hysteresis data are presented to understand the role of wettability, viscosity, and velocity. Liquid repellent coatings are utilized to recreate or combine various effects. Discussion is provided along with conceptual models describing the role of surface structures related to low drag, self-cleaning, and antifouling properties. Modeling provides design guidance when developing novel low drag and self-cleaning surfaces for applications in the medical, marine, and industrial fields.

Micro and nanofabrication methods to control cell-substrate interactions and cell behavior: a review from the tissue engineering perspective

[J].Cell-substrate interactions play a crucial role in the design of better biomaterials and integration of implants with the tissues. Adhesion is the binding process of the cells to the substrate through interactions between the surface molecules of the cell membrane and the substrate. There are several factors that affect cell adhesion including substrate surface chemistry, topography, and stiffness. These factors physically and chemically guide and influence the adhesion strength, spreading, shape and fate of the cell. Recently, technological advances enabled us to precisely engineer the geometry and chemistry of substrate surfaces enabling the control of the interaction cells with the substrate. Some of the most commonly used surface engineering methods for eliciting the desired cellular responses on biomaterials are photolithography, electron beam lithography, microcontact printing, and microfluidics. These methods allow production of nano- and micron level substrate features that can control cell adhesion, migration, differentiation, shape of the cells and the nuclei as well as measurement of the forces involved in such activities. This review aims to summarize the current techniques and associate these techniques with cellular responses in order to emphasize the effect of chemistry, dimensions, density and design of surface patterns on cell-substrate interactions. We conclude with future projections in the field of cell-substrate interactions in the hope of providing an outlook for the future studies.

Biomimetic surface coatings for marine antifouling: natural antifoulants, synthetic polymers and surface microtopography

[J].

Species-specific engineered antifouling topographies: correlations between the settlement of algal zoospores and barnacle cyprids

[J].Novel, non-toxic antifouling technologies are focused on the manipulation of surface topography to deter settlement of the dispersal stages of fouling organisms. This study investigated the effect of the aspect ratio (feature height/feature width) of topographical features engineered in polydimethylsiloxane, on the settlement of cyprids of Balanus amphitrite and zoospores of Ulva linza. The correlation of relative aspect ratios to antifouling efficacy was proven to be significant. An increase in aspect ratio resulted in an increase of fouling deterrence for both zoospores and cyprids. The spore density of Ulva was reduced 42% with each unit increase in aspect ratio of the Ulva-specific Sharklet AF topography. Similarly, the number of settled cyprids was reduced 45% with each unit increase in aspect ratio. The newly described barnacle-specific Sharklet AF topography (40 microm feature height, aspect ratio of 2) reduced cyprid settled by 97%. Techniques have been developed to superimpose the smaller Ulva-specific topographies onto the barnacle-specific surfaces into a hierarchical structure to repel both organisms simultaneously. The results for spore settlement on first-generation hierarchical surfaces provide insight for the efficacious design of such structures when targeting multiple settling species.

Designing environmentally benign modified silica resin coatings with biomimetic textures for antibiofouling

[J].

Biomimetics for early stage biofouling prevention: templates from insect cuticles

[J].

A new method for producing “Lotus Effect” on a biomimetic shark skin

[J].

Grafting polymer brushes on biomimetic structural surfaces for anti-algae fouling and foul release

[J].

Bioinspired synthetic macroalgae: examples from nature for antifouling applications

[J].

Layer-by-layer-assembled antifouling films with surface microtopography inspired by Laminaria japonica

[J].

Anti-biofouling superhydrophobic surface fabricated by picosecond laser texturing of stainless steel

[J].

The mussel-inspired micro-nano structure for antifouling: a flowering tree

[J].

Bio-inspired non-bactericidal coating used for antibiofouling

[J].

Multiscale hairy surfaces for nearly perfect marine antibiofouling

[J].

Molecular simulations and understanding of antifouling zwitterionic polymer brushes

[J].

Engineering and application perspectives on designing an antimicrobial surface

[J].

Superhydrophilicity and strong salt-affinity: Zwitterionic polymer grafted surfaces with significant potentials particularly in biological systems

[J].

Versatile inhibition of marine organism settlement by zwitterionic polymer brushes

[J].

Silica nanoparticles functionalized with zwitterionic sulfobetaine siloxane for application as a versatile antifouling coating system

[J].

Incorporation of carboxybetaine methacrylate into poly (methyl methacrylate) to prevent multi-species biofilm formation

[J].

Superdurable coating fabricated from a double-sided tape with long term “zero” bacterial adhesion

[J].

Surface plasma Ag-decorated Bi5O7I microspheres uniformly distributed on a zwitterionic fluorinated polymer with superfunctional antifouling property

[J].

Three-dimensional flower-like shaped Bi5O7I particles incorporation zwitterionic fluorinated polymers with synergistic hydration-photocatalytic for enhanced marine antifouling performance

[J].

A facile hydrophilic modification strategy initiated by flame treatment of silicone coatings for marine antifouling application

[J].

Direct formation of amphiphilic crosslinked networks based on PVP as a marine anti-biofouling coating

[J].

Slime-resistant marine anti-biofouling coating with PVP-based copolymer in PDMS matrix

[J].

A switchable zwitterionic ester and capsaicin copolymer for multifunctional marine antibiofouling coating

[J].

A hybrid sponge with guanidine and phytic acid enriched surface for integration of antibiofouling and uranium uptake from seawater

[J].

Resistance of solid surfaces to wetting by water

[J].

Wettability of porous surfaces

[J].

Characterization and distribution of water-repellent, self-cleaning plant surfaces

[J].

Surface energy calculation using Hamaker’s constant for polymer/silane hydrophobic thin films

[J].Understanding the behavior of a surface is important for various applications. Non-wettable surfaces inspired from lotus leaf phenomenon was described by Wenzel and Cassie Baxter theories. Hydrophobic surface can be obtained by enhancing surface roughness which is inversely proportional to the surface energy. The determination of Hamaker's constant is necessary for the calculation of surface energy. Here in this work surface roughness and energy of various silane and polymer blend were calculated using Hamaker's constant which implies hydrophobicity. (C) 2019 Elsevier B.V.

Recent progress in durable and self-healing super-nonwettable fabrics

[J].

Zwitterionic siloxane-polyurethane fouling-release coatings

[J].

Effects of pigmentation on siloxane-polyurethane coatings and their performance as fouling-release marine coatings

[J].

Eco-friendly design of superhydrophobic nano-magnetite/silicone composites for marine foul-release paints

[J].

Silicone/ZnO nanorod composite coating as a marine antifouling surface

[J].The effects of ZnO nanorod (NR) filler distribution and the nano-structured surface on the superhydrophobicity and fouling-release (FR) of silicone nanocoatings were investigated. Incorporation of 0.5 wt% ZnO NR fillers resulted in increasing the non-wettability characteristics and surface roughness and reducing the surface free energy were observed. Thus, an outstanding superhydrophobic nanocomposite coaling model was fabricated with stable surface properties, surface innerness toward fouling adhesion, economic savings and prolonging longevity for marine applications. A polydimethylsiloxane/ZnO NR composite was prepared via in-situ technique. ZnO NRs were 30-40 nm wide and 0.5-1 mu m long single-crystals with wurtzite structure grown in (0001) direction. Studying the influences of incorporation of different nanofiller concentrations on the surface and FR features was inevitable to achieve surface roughness with minimized free energy. Surface features were considered via water contact angles (WCAs), free energy calculations and atomic force microscopy. Mechanical characteristics were evaluated as a durability factor. Chosen micro-organisms were employed to investigate the nanocomposites FR and biological characteristics. A tough field trial was performed on the nanocomposites which were immersed (for 6 months) in marine water of a tropical region. The most favorable FR properties with maximum WCA (158 degrees) and minimum free energy (11.25 mN/m) were shown for 0.5 wt% NRs as an excellent distributed surface.

Smart photo-induced silicone/TiO2 nanocomposites with dominant [110] exposed surfaces for self-cleaning foul-release coatings of ship hulls

[J].

Recent progress in marine foul-release polymeric nanocomposite coatings

[J].

Superhydrophobic coating of silicone/β-MnO2 nanorod composite for marine antifouling

[J].

Superhydrophobic silicone/SiC nanowire composite as a fouling release coating material

[J].

Comparison of the fouling release properties of hydrophobic fluorinated and hydrophilic PEGylated block copolymer surfaces: attachment strength of the diatom navicula and the green alga ulva

[J].

Amphiphilic block copolymer/poly (dimethylsiloxane) (PDMS) blends and nanocomposites for improved fouling-release

[J].Amphiphilic diblock copolymers, Sz6 and Sz12, consisting of a poly(dimethylsiloxane) block (average degree of polymerisation = 132) and a PEGylated-fluoroalkyl modified polystyrene block (Sz, average degree of polymerisation = 6, 12) were prepared by atom transfer radical polymerization (ATRP). Coatings were obtained from blends of either block copolymer (1-10 wt%) with a poly(dimethylsiloxane) (PDMS) matrix. The coating surface presented a simultaneous hydrophobic and lipophobic character, owing to the strong surface segregation of the lowest surface energy fluoroalkyl chains of the block copolymer. Surface chemical composition and wettability of the films were affected by exposure to water. Block copolymer Sz6 was also blended with PDMS and a 0.1 wt% amount of multiwall carbon nanotubes (CNT). The excellent fouling-release (FR) properties of these new coatings against the macroalga Ulva linza essentially resulted from the inclusion of the amphiphilic block copolymer, while the addition of CNT did not appear to improve the FR properties.

Hyperbranched fluoropolymer-polydimethylsiloxane-poly (ethylene glycol) cross-Linked terpolymer networks designed for marine and biomedical applications: heterogeneous nontoxic antibiofouling surfaces

[J].

Copolymer films containing amphiphilic side chains of well-defined fluoroalkyl-segment length with biofouling-release potential

[J].

Bioinspired self-repairing slippery surfaces with pressure-stable omniphobicity

[J].

Liquid-infused structured surfaces with exceptional anti-biofouling performance

[J].Bacteria primarily exist in robust, surface-associated communities known as biofilms, ubiquitous in both natural and anthropogenic environments. Mature biofilms resist a wide range of antimicrobial treatments and pose persistent pathogenic threats. Treatment of adherent biofilm is difficult, costly, and, in medical systems such as catheters or implants, frequently impossible. At the same time, strategies for biofilm prevention based on surface chemistry treatments or surface microstructure have been found to only transiently affect initial attachment. Here we report that Slippery Liquid-Infused Porous Surfaces (SLIPS) prevent 99.6% of Pseudomonas aeruginosa biofilm attachment over a 7-d period, as well as Staphylococcus aureus (97.2%) and Escherichia coli (96%), under both static and physiologically realistic flow conditions. In contrast, both polytetrafluoroethylene and a range of nanostructured superhydrophobic surfaces accumulate biofilm within hours. SLIPS show approximately 35 times the reduction of attached biofilm versus best case scenario, state-of-the-art PEGylated surface, and over a far longer timeframe. We screen for and exclude as a factor cytotoxicity of the SLIPS liquid, a fluorinated oil immobilized on a structured substrate. The inability of biofilm to firmly attach to the surface and its effective removal under mild flow conditions (about 1 cm/s) are a result of the unique, nonadhesive, "slippery" character of the smooth liquid interface, which does not degrade over the experimental timeframe. We show that SLIPS-based antibiofilm surfaces are stable in submerged, extreme pH, salinity, and UV environments. They are low-cost, passive, simple to manufacture, and can be formed on arbitrary surfaces. We anticipate that our findings will enable a broad range of antibiofilm solutions in the clinical, industrial, and consumer spaces.

Slippery liquid-infused porous surface fabricated on CuZn: a barrier to abiotic seawater corrosion and microbiologically induced corrosion

[J].

Hierarchical or not? Effect of the length scale and hierarchy of the surface roughness on omniphobicity of lubricant-infused substrates

[J].Lubricant-infused textured solid substrates are gaining remarkable interest as a new class of omni-repellent nonfouling materials and surface coatings. We investigated the effect of the length scale and hierarchy of the surface topography of the underlying substrates on their ability to retain the lubricant under high shear conditions, which is important for maintaining nonwetting properties under application-relevant conditions. By comparing the lubricant loss, contact angle hysteresis, and sliding angles for water and ethanol droplets on flat, microscale, nanoscale, and hierarchically textured surfaces subjected to various spinning rates (from 100 to 10,000 rpm), we show that lubricant-infused textured surfaces with uniform nanofeatures provide the most shear-tolerant liquid-repellent behavior, unlike lotus leaf-inspired superhydrophobic surfaces, which generally favor hierarchical structures for improved pressure stability and low contact angle hysteresis. On the basis of these findings, we present generalized, low-cost, and scalable methods to manufacture uniform or regionally patterned nanotextured coatings on arbitrary materials and complex shapes. After functionalization and lubrication, these coatings show robust, shear-tolerant omniphobic behavior, transparency, and nonfouling properties against highly contaminating media.

Marine antifouling behavior of lubricant-infused nanowrinkled polymeric surfaces

[J].

Fabrication of slippery lubricant-infused porous surface with high underwater transparency for the control of marine biofouling

[J].

Contribution of charges in polyvinyl alcohol networks to marine antifouling

[J].

Robust and underwater superoleophobic coating with excellent corrosion and biofouling resistance in harsh environments

[J].

Self-healing underwater superoleophobic and antibiofouling coatings based on the assembly of hierarchical microgel spheres

[J].Marine biofouling has been plaguing people for thousands of years. While various strategies have been developed for antifouling (including superoleophobic) coatings, none of these exhibits self-healing properties because the bestowal of a zoetic self-repairing function to lifeless artificial water/solid interfacial materials is usually confronted with tremendous challenges. Here, we present a self-repairing underwater superoleophobic and antibiofouling coating through the self-assembly of hydrophilic polymeric chain modified hierarchical microgel spheres. The obtained surface material not only has excellent underwater superoleophobicity but also has very good subaqueous antibiofouling properties. More importantly, this surface material can recover the oil- and biofouling-resistant properties once its surface is mechanically damaged, similar to the skins of some marine organisms such as sharks or whales. This approach is feasible and easily mass-produced and could open a pathway and possibility for the fabrication of other self-healing functional water/solid interfacial materials.

Synthesis of amphiphilic acrylate boron fluorinated polymers with antifouling behavior

[J].

Superhydrophilic and underwater superoleophobic nanofibrous membrane with hierarchical structured skin for effective oil-in-water emulsion separation

[J].

Study on the core-shell reversion of PSBMA-b-PLMA nanoparticles for the fabrication of antifouling coatings

[J].

Hyperbranched fluoropolymer and linear poly (ethylene glycol) based amphiphilic crosslinked networks as efficient antifouling coatings: an insight into the surface compositions, topographies, and morphologies

[J].

Poly (ethylene) glycol-modified, amphiphilic, siloxane-polyurethane coatings and their performance as fouling-release surfaces

[J].

Polymer-based marine antifouling and fouling release surfaces: strategies for synthesis and modification

[J].In marine industries, the accumulation of organic matter and marine organisms on ship hulls and instruments limits performance, requiring frequent maintenance and increasing fuel costs. Current coatings technology to combat this biofouling relies heavily on the use of toxic, biocide-containing paints. These pose a serious threat to marine ecosystems, affecting both target and nontarget organisms. Innovation in the design of polymers offers an excellent platform for the development of alternatives, but the creation of a broad-spectrum, nontoxic material still poses quite a hurdle for researchers. Surface chemistry, physical properties, durability, and attachment scheme have been shown to play a vital role in the construction of a successful coating. This review explores why these characteristics are important and how recent research accounts for them in the design and synthesis of new environmentally benign antifouling and fouling release materials.