国内外学者就钛合金的应力腐蚀行为展开了大量研究。如Liu等[4]考察了Ti-6Al-4V在2 ℃、0.1 MPa和20 MPa在3.5% (质量分数) NaCl溶液中的应力腐蚀行为,结果表明在模拟2000 m深海环境中,高的静水压力会促进Ti的溶解,并且使其形成的氧化膜比空气中形成的氧化膜保护能力更差。王海杰等[5]研究了TC4、TC18等钛合金在35 ℃、3.5%NaCl溶液中的腐蚀行为,研究表明此环境中钛合金耐腐蚀性能较好。Cao等[6]研究表明,Ti3Al的析出提高了Ti-8Al-1Mo-1V应力腐蚀敏感性,在860 ℃条件下进行热等静压处理可提高钛合金在0.1 mol/L NaCl溶液中的的耐应力腐蚀能力。薛希豪等[7]通过恒位移试验研究了等轴棒材、网篮锻材在35 ℃、3.5%NaCl溶液中的应力腐蚀性能,结果表明等轴棒材耐应力腐蚀性能优于网篮锻件。综上所述,只有高压的海水环境中钛合金出现钝化膜性能变差的结论,大多35 ℃的海水或NaCl溶液中的研究结果均认为钛合金具有较好耐腐蚀性能。可见,温度对钛合金应力腐蚀性能的相关研究不多,尤其35 ℃以下更是鲜有报道。因而导致装备设计和应用选材困难,限制了钛合金在海洋工程装备上的应用[8]。

钛合金应用于海洋装备及船舶上,首先要考虑其不同海水环境适应性,尤其是承力结构件。因此,研究海洋环境因素对钛合金的应力腐蚀行为的影响规律,对于钛合金在海洋装备中的应用起着十分重要的作用。不同海域不同季节海水环境温度变化最明显,如我国南海海水最高温度约35 ℃左右,我国黄海海水温度冬季最低可达到5 ℃左右。钛合金耐腐蚀主要因为其表面极易形成钝化膜,而温度对钝化膜的形成有重要影响[9]。因此,本项目欲通过在实验室控制海水温度模拟不同海域、季节海水环境,开展一系列应力腐蚀实验,结合电化学、表面分析等手段,探讨温度对Ti80合金应力腐蚀行为的影响,希望可以为钛合金在海洋环境中应用积累基础数据。

1 实验方法

1.1 实验材料

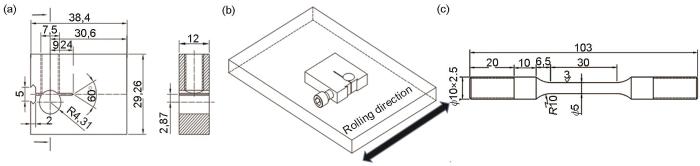

本实验所用材料为Ti80合金双态组织轧制板材,主要化学成分 (质量分数,%):C 0.05, N 0.05, H 0.02,O 0.15,Al 6.03,Mo 0.99,Si 0.15,Nb 2.74,Fe 0.19,Zr 1.95,微量V,Ti余量。根据试样参照GB/T 15970.6选用预裂纹恒位移加载试样 (WOL型),加载螺栓和销钉选用与试样相同的材料。试样尺寸如图1a所示,样品取样方式如图1b所示。慢应变速率拉伸试验样品取样垂直于轧制方向。按图1c所示尺寸加工,标距段表面打磨至光滑,用无水乙醇清洗烘干。电化学测试样品尺寸为10 mm×10 mm×10 mm,背部用铜导线引出,非工作面用环氧树脂密封。用400#~2000#砂纸逐级打磨至表面光亮无明显划痕,无水乙醇清洗后吹干备用。所用海水来自青岛海域天然海水。

图1

图1

试样尺寸和取向图及慢应变速率拉伸样品形状及尺寸

Fig.1

Specimen dimension drawing (a) and sampling direction (b), shape and size of sample used in slow strain rate tensile test (c)

1.2 慢应变速率拉伸实验

慢应变速率拉伸实验 (SSRT) 在慢应变速率拉伸机 (YYF-100) 上进行。应变速率选择1×10-6 s-1,即拉伸速率为0.0018 mm/min。加上海水槽、温度控制仪并在试样平行长度段标记好样品标距,分别在空气中和不同温度海水中进行SSRT实验。实验结束后,用超声波仪器清洗断口。测量断后标距长度,然后在场发射扫描电子显微镜 (ULTRA 55,SEM) 下观察断口微观形貌,测量断面最小面积。然后通过计算断面收缩率损失系数Iψ 和断后伸长率损失系数Iδ 作为应力腐蚀开裂 (SCC) 的敏感性指标[10]。表达式如下:

其中,ψ是腐蚀环境下的断面收缩率,ψ0是空气环境下断面收缩率,δ是腐蚀环境下的断后伸长率,δ0是空气环境下的断后伸长率。

1.3 恒位移应力腐蚀实验

样品的预制裂纹完成之后,用无水乙醇进行超声波清洗。实验K1值取100 MPa·m0.5,根据GB/T 15970.6计算样品所需加载的恒定位移。一边加载,一边用游标卡尺测量样品张开位移达到目标值即可。

实验环境为5、15、25和35 ℃的海水,溶解氧均控制在4.5~5 mg/L。所用的仪器为低温精密试验柜和恒温水浴锅,实验周期30 d,每隔5 d换一次海水,测量样品裂纹长度,计算平均扩展速率,当裂纹扩展平均速率低于10-9 m/s时,认为裂纹已经停止扩展[12]。取出样品、卸载螺钉、沿裂纹拉断并用超声波仪器清洗断口。在HIROX三维视频显微镜 (KH-3000 V) 和扫描电子显微镜 (SEM,ULTRA 55) 下测量断口裂纹扩展长度、观察断口微观形貌。并根据

式中,a为加载中心到裂纹尖端的距离,w为样品宽度。最后按照

电化学测试采用三电极体系,钛合金样品为工作电极,饱和甘汞电极 (SCE) 为参比电极,铂铌丝为辅助电极,青岛海域天然海水为电解质液。通过向海水中通N2的方式控制溶解氧浓度,采用低温试验槽和恒温水浴锅来控制温度。利用电化学工作站PARSTAT 2723进行电化学测试,为去除样品表面钝化膜,首先对试样进行恒电位极化5 min,电位值为-1 V (vs SCE)。然后将其浸泡在不同温度海水中重新成膜。开始测量开路电位 (OCP),待电位稳定后,进行自腐蚀状态下的电化学阻抗谱测量,频率范围:105~10-2 Hz,扰动电压为10 mV。莫特-肖特基曲线扫描范围-1~2 V,频率为100 Hz,扫描速率为50 mV/s。

2 结果与讨论

2.1 慢应变速率拉伸实验结果

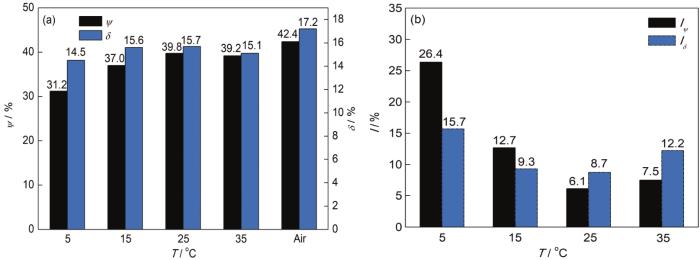

图2是钛合金在不同环境中的应力-应变曲线。可见,不同曲线的弹性阶段基本重合,与空气环境相比,不同温度海水中样品的断裂应变出现不同程度的减小;且5 ℃海水中断裂应变最小,表明低温环境中韧性下降比较明显。图3是钛合金样品不同温度海水中断面收缩率、断后伸长率以及损失系数柱状图。由图3a可以看到,随着温度的降低,样品的断面收缩率和断后伸长率逐渐减小,表明样品的塑性变形能力逐渐变差。由图3b可知,随着温度的降低,断面收缩率和断后伸长率损失系数逐渐减增大。损失系数越小,说明样品的应力腐蚀破裂的敏感性越小,反之,则表明应力腐蚀敏感性较大。可以看到5 ℃低温海水环境中样品SCC敏感性指数明显最大,其中断面收缩率损失系数是35 ℃时3倍多,断后伸长率损失系数也比其他温度条件下的值增大25%~50%,这表明5 ℃低温海水环境有着更明显的应力腐蚀敏感性。

图2

图2

Ti80钛合金在大气和不同温度海水中的应力-应变曲线

Fig.2

Stress-strain curves of Ti80 Ti-alloy in atmospheric environment and seawater at different temperatures

图3

图3

Ti80钛合金断面收缩率,断后伸长率以及损伤系数与温度的关系

Fig.3

Reduction of area, elongation after the break (a), and damage coefficients (b) of Ti80 Ti-alloy under different conditions

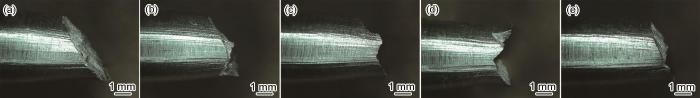

图4为钛合金在不同温度海水和空气环境中样品的宏观断口形貌。可见,随着海水温度降低,样品的断口附近的颈缩特征逐渐变得不明显,表明温度较低,韧性较差。5 ℃低温环境下样品与主轴呈现近似45°倾斜角,颈缩程度最小,塑性变形能力最差。这和前面分析应力-应变曲线时得出结论一致。

图4

图4

Ti80钛合金在不同条件下的宏观断口形貌

Fig.4

Photos of macroscopic fractures of Ti80 Ti-alloy in seawater at 5 ℃ (a), 15 ℃ (b), 25 ℃ (c) and 35 ℃ (d), and atmospheric environment (e)

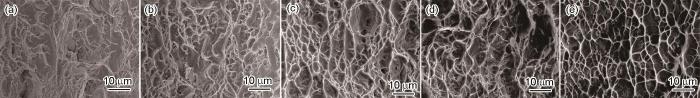

图5是钛合金SSRT拉伸断口的微观形貌。可见,5 ℃条件下的断口形貌有大量小型韧窝特征,其中包围着明显的河流状花样解理特征,这表明样品有着一定的应力腐蚀破裂倾向。在15 ℃环境下,断口表现为明显较浅、较大的韧窝包围着小的准解理平面形貌。25 ℃海水环境下断口呈现明显较深的典型韧窝特征,随着温度继续升高,断口处韧窝越来越密集,空气环境下断口呈现密集的韧窝特征。上述结果表明钛合金在温度较低海水环境中塑性变形能力明显变差。

图5

图5

Ti80钛合金样品在不同条件下的微观断口形貌

Fig.5

Microfracture morphologies of Ti80 Ti-alloy in seawater at 5 ℃ (a), 15 ℃ (b), 25 ℃ (c) and 35 ℃ (d), and atmospheric environment (e)

2.2 恒位移实验结果

图6

图6

Ti80钛合金恒位移样品宏观断口形貌

Fig.6

Macroscopic fracture morphologies of Ti80 Ti-alloy after constant displacement tests in seawater at 5 ℃ (a), 15 ℃ (b), 25 ℃ (c) and 35 ℃ (d)

表1 Ti80钛合金样品应力腐蚀开裂数据

Table 1

| T / ℃ | Crack length mm | K1SCC MPa·m0.5 | Crack growth rate m·s-1 |

|---|---|---|---|

| 5 | 6.993 | 56.37 | 2.310×10-9 |

| 15 | 4.616 | 64.63 | 1.526×10-9 |

| 25 | 3.968 | 66.84 | 1.312×10-9 |

| 35 | 3.395 | 75.69 | 1.123×10-9 |

表2 不同温度下Ti80钛合金阻抗拟合分析结果

Table 2

| T / ℃ | Rs / Ω·cm2 | Q1 / Ω-1·cm-2·sn | n1 | R1 / Ω·cm2 | Q2 / Ω-1·cm-2·sn | n2 | R2 / Ω·cm2 |

|---|---|---|---|---|---|---|---|

| 5 | 11.67 | 2.486×10-5 | 0.9147 | 537.1 | 2.404×10-5 | 0.4501 | 2.654×105 |

| 15 | 9.186 | 1.924×10-5 | 0.9358 | 9115 | 4.763×10-6 | 0.8038 | 4.326×105 |

| 25 | 7.340 | 2.220×10-5 | 0.9183 | 4325 | 8.843×10-7 | 0.9561 | 2.115×106 |

| 35 | 6.234 | 2.051×10-5 | 0.9421 | 1689 | 2.264×10-6 | 0.9639 | 2.465×106 |

测量样品裂纹扩展长度,根据

恒位移应力腐蚀样品裂纹尖端断口微观形貌如图7所示,右边是局部放大图。15、25和35 ℃海水环境条件下,局部主要呈现较为密集的韧窝状特征。5 ℃海水环境中钛合金样品裂纹微观断口表面凹凸不平,韧窝特征明显较浅,且局部位置出现了撕裂岭准解理形貌。结合K1SCC值以及宏观形貌结果,可以认为随着温度的降低,钛合金的韧塑性变差,这与慢应变速率实验结果一致。

图7

图7

Ti80钛合金样品恒位移实验后微观断口形貌

Fig.7

Macroscopic fracture morphologies of Ti80 Ti-alloy samples after constant displacement tests in seawater at 5 ℃ (a, b), 15 ℃ (c, d), 25 ℃ (e, f) and 35 ℃ (g, h)

2.3 电化学测试结果

图8a,b是钛合金在不同温度的海水中的Nyquist图和Bode图。一定程度上Nyquist图中容抗弧越大,材料耐腐蚀性能越好,Bode图高频区反应钛合金与腐蚀溶液界面之间的腐蚀特性,中低频区则反应钛合金界面特性,阻抗幅值越大,耐蚀性能越好[13,14]。由图8c可知,钛合金的容抗弧随着温度降低逐渐减小。观察图8b表明,25 ℃和35 ℃温度环境下钛合金样品的阻抗模值|Z|、相位角θ随频率的变化趋势大致相同。lg|Z|-lgf曲线图中低频区表现为一段斜率接近-1的直线,phase-lgf曲线在中低频区呈现出相位角很宽的平台,表明此种环境下的钛合金有很强的耐蚀性[15]。5和15 ℃温度环境下钛合金样品的lg|Z|-lgf曲线图中低频区的斜率偏离-1,phase-lgf曲线在中低频区出现了明显的相位角θ峰,不再有较宽平台出现。综上所述,低温海水环境中钛合金表面钝化膜防护性能下降。

图8

图8

Ti80钛合金在不同温度海水中的电化学阻抗谱及等效电路图

Fig.8

Nyquist (a) and Bode (b) plots and equivalent circuit model (c) of Ti80 Ti-alloy in seawater at different temperatures

图8c为等效电路图,拟合结果见表2。其中Rs是溶液电阻,Q和n为常相位角元件两个参数,Q是常相位角元件 (CPE),n是弥散指数 (0<n<1),n=1时为纯电容元件。用常相位角元件代替纯电容,主要是体系处于非理想状态,试样表面存在弥散效应。n值样品表面粗糙度有关,n越大,试样表面钝化膜保护能力越好[16]。一般也认为钛合金的钝化膜是分层存在的,分为疏松的外层和致密的内层[17]。所以Q1、R1和Q2、R2分别表示钛合金外部疏松层和内部致密层的电容和电阻。通过表2拟合结果可以知道钝化膜外层电阻R1远小于内层电阻R2,表明Ti80合金耐腐蚀性能主要取决于钝化膜内部致密层,疏松多孔层对合金耐蚀性贡献较小[18]。表中5 ℃海水环境中钛合金样品的R2和n值明显小于其它温度海水环境中的值,说明5 ℃低温海水环境中钛合金钝化膜电阻较小,自修复能力较差,因此钝化膜保护性能最差。

材料的表面钝化膜通常为半导体,其电子性能可以用Mott-schottky分析进行评价[19]。因此金属-电解质界面的电荷分部状态也可以通过钝化膜的空间电荷电容CSC和电极电位E的函数来 (5) (6) 描述[20]。式中CSC为空间电荷电容;εr为钝化膜的相对介电常数 (TiO2钝化膜为60[21]);ε0是真空介电常数 (8.854×10-14 F/cm);e为电荷电量 (1.602×10-19 C);Nd和Na分别为施主和受主载流子浓度;A为试样与介质真实接触面积1 cm2;Efb为平带电位;k为Boltzmann常数 (1.38×10-23 J/K);T为热力学温度,室温下kT/e约为25 mV,一般忽略不计。

对于n型半导体来说:

对于p型半导体来说:

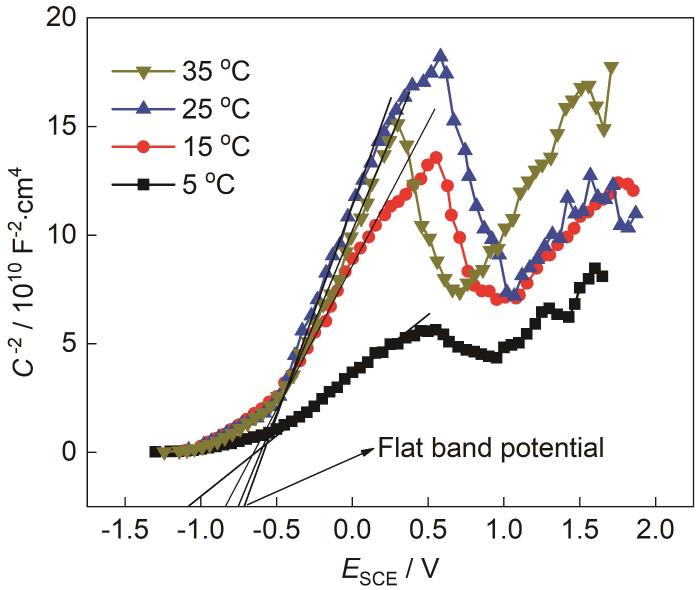

图9是不同温度海水中钛合金的莫特肖特基曲线。低电位区斜率可表示半导体材料的特性[22,23]。图中钛合金低电位区的斜率都为正值,表明不同温度海水环境中样品表面生成的钝化膜均为n型半导体,表明主要载流子为间隙Ti离子和氧空位[24]。选取低电位线性区对试样半导体特性进行分析,根据Mott-Schottky方程计算载流子密度值Nd和平带电位Efb,Nd可以通过1/C2-E曲线的斜率2/(eεrε0kA2) 计算,平带电位Efb可以通过1/C2=0求得。图10是钛合金在不同温度海水环境中生成钝化膜的Nd和Efb。可知35 ℃、25 ℃、15 ℃海水环境中钛合金样品的载流子密度Nd在1.39×1019~1.75×1019 cm-3之间,5 ℃海水环境中钛合金样品的Nd=4.72×1019 cm-3,相比之下Nd增大2倍之多。表明5 ℃海水环境中,钛合金样品表面钝化膜的载流子密度最大。载流子密度越大,意味着钝化膜的缺陷越多,施主密度的升高会促进电子的转移,进而促进钝化膜的溶解反应,从而降低了钝化膜的保护能力[25]。Efb也随着温度的降低逐渐负移,进一步表明钝化膜的保护能力逐渐降低。

图9

图9

Ti80钛合金Mott-schottky基曲线

Fig.9

Mott-schottky curves of Ti80 Ti-alloy in seawater at different temperatures

图10

图10

在不同温度海水中Ti80钛合金表面形成的钝化膜的Efb和Nd

Fig.10

Efb and Nd of passive films formed on Ti80 Ti-alloy during immersion in seawater at different temperatures

根据以上分析可知,通常情况下,钝化膜完整的钛合金在海水环境中不发生明显腐蚀,没有明显应力腐蚀敏感性。但是对于钝化膜遭到破坏的活化体系以及微裂纹、缝隙等闭塞结构,低温和低氧不利于金属钝化,使局部无膜区产生腐蚀。

海水环境中样品在应力和海水中Cl-、Br-等离子的协同作用下,钛合金裂纹尖端钝化膜被破坏,使裂纹尖端钛合金基体暴露在腐蚀介质中,促进钛合金尖端基体腐蚀溶解,使得裂纹向内部扩展。除了外加应力之外,膜致应力对裂纹的扩展也起到了重要作用,在裂纹尖端附近,膜致应力强度因子越大,应力腐蚀裂纹越容易形核和扩展[26]。海水环境温度较高时,离子迁移速率较快,生成钝化膜载流子浓度小、钝化膜的缺陷少、自修复能力较好、膜致应力较小、所以重新生成钝化膜后可有效减缓裂纹扩展。然而在5 ℃低温海水环境中生成钝化膜杂质、缺陷较多,位错容易在此堆积,造成钝化膜局部应力集中,膜致应力增大。因此在外加应力和膜致应力共同作用下,尖端裂纹加速形核和扩展,从而导致尖端钝化膜难以修复,裂纹扩展速度加快。

3 结论

(1) 常压、溶解氧含量为4.5~5 mg/L海水环境下,随温度减小,应力腐蚀开裂敏感性指数增大,临界应力强度因子K1SCC减小,表明钛合金抗应力腐蚀开裂性能下降。

(2) 在5 ℃海水环境中,钛合金SSRT拉伸断口局部出现河流花样准解理特征,恒位移应力腐蚀断口局部出现撕裂岭准解理特征,应力腐蚀开裂倾向明显较其它温度条件下增大。

(3) 5 ℃海水环境下生成的钝化膜缺陷较多,电阻较小,自修复能力较差,因此裂尖处钛合金表面受应力作用撕裂开的新鲜表面更加难以修复,阳极溶解明显,使裂纹扩展速度加快。

(4) 可以通过适当的热处理来改善钛合金组织,减少气体含量,消除残余应力,提高材料塑性、冲击韧性、和耐腐蚀性来降低钛合金低温应力腐蚀倾向性。

参考文献

Requirement and development analysis of warship equipment materials system

[J].

舰船装备材料体系需求与发展分析

[J].

Applications of titanium alloys in warship building

[J].

钛合金在舰船上的应用

[J].

Review on research progress of marine titanium alloy equipment materials and preparation technology

[J].

船用钛合金装备材料及制备技术研究进展评述

[J].

A primary study of the effect of hydrostatic pressure on stress corrosion cracking of Ti-6Al-4V alloy in 3.5% NaCl solution

[J].

Corrosion behavior of three titanium alloys in 3.5%NaCl solution

[J].

钛合金在3.5%NaCl溶液中的腐蚀行为

[J].

Effects of microtexture and Ti3Al (α2) precipitates on stress-corrosion cracking properties of a Ti-8Al-1Mo-1V alloy

[J].

Effect of microstructure on stress corrosion cracking property of TC18 alloy

[J].

显微组织对TC18合金应力腐蚀性能的影响

[J].

Service performance of titanium alloy in marine environment

[J].

海洋环境下钛合金主要服役性能研究

[J].

Influence of temperature on the electrochemical property of passive film formed on X80 pipeline steel

[J].

温度对X80管线钢钝化膜电化学性能的影响

[J].

Influence of applied potential on the stress corrosion behavior of X90 pipeline steel and its weld joint in simulated solution of near neutral soil environment

[J].Pipe is the main mode of transportation of oil and gas contemporary, and its security and reliability has an important influence on the smooth development of regional economy and even the security situation. For decades, quite a number of researches have been mainly focusing on various factors on the stress corrosion cracking (SCC) of both high and middle strength pipeline steels in soil or underground water conditions, but the division of the sensitive potential ranges which determines the different SCC mechanisms was rarely reported. Soil environmental stress corrosion cracking (SCC) of pipeline steel in the process of service operation is one of the biggest security hidden dangers. The external environment SCC of pipeline steel mainly includes two modes, high pH SCC and close to neutral pH SCC. Between them, the high pH SCC occurred mainly in CO32-/HCO3- under the coating of liquid, the mechanism of cracking is widely regarded as membrane rupture, crack tip anodic dissolution mechanism; near neutral pH SCC occurred mainly in the coating containing low concentration of HCO3- resident fluid or groundwater environment. Due to pipe in the process of serving for a long time, pipeline external coating damage and strip defects are common, under the joint action of the applied potential and soil medium, SCC will generally occur in nearly neutral pH environment, which lead to a serious risk in nearly neutral pH SCC. As a new generation of high strength pipeline steel, the X90 steel probes into its SCC sensitivity at different applied potentials in a certain pH environment is of great significance. In this work, the SCC behavior as well as its mechanism of X90 pipeline steel and its weld joint in an simulated solution of the near neutral soil environment (NS4 solution) were studied by slow strain rate tensile tests (SSRT), potentiodynamic polarization tests and SEM observation of fracture surfaces. The results showed that both the as received X90 pipeline steel and its weld joint have obvious SCC susceptibilities, which initiated and extended in transgranular cracking mode under different applied potentials. Within the potential ranges from OCP to -1000 mV, the SCC mechanism of both X90 steel and its weld joint microstructures are a combined mechanisms of anodic dissolution (AD) and hydrogen embrittlement (HE), i.e. the AD+HE mechanism. The SCC susceptibility is apparent under the OCP due to a strong AD effect. At -800 mV, the SCC susceptibility comes to a minimum due to AD and HE being weaker, and it presents the highest SCC susceptibility at -900 mV because the HE effect was greatly enhanced. The SCC susceptibility of the weld organization is higher than that of the base metal, which may be related to organization phase transformation in the welds and metallurgical reaction.

外加电位对X90钢及其焊缝在近中性土壤模拟溶液中应力腐蚀行为的影响

[J].采用慢应变速率拉伸(SSRT)实验、动电位极化技术和SEM观察等方法,研究了X90钢基体和焊缝在近中性土壤模拟溶液中不同阴极保护电位下的应力腐蚀行为。结果表明,X90管线钢及其焊缝组织在近中性土壤模拟溶液中均具有一定的应力腐蚀敏感性,裂纹扩展为穿晶腐蚀裂纹;应力腐蚀开裂(SCC)的裂纹萌生与扩展与外加保护电位有关。在开路电位(OCP)~-1000 mV的电位范围内,X90钢的SCC机制均为阳极溶解(AD)+氢脆(HE)的混合机制;在OCP下,由于AD作用较强,SCC敏感性较明显;在-800 mV下,由于AD和HE作用均较弱,导致SCC敏感性最低;而在-900 mV时,由于HE作用明显增强,具有最高的SCC敏感性;在相同电位条件下,焊缝的SCC敏感性高于母材。

The sensitivity of welded steel joint to stress corrosion in wet H2S medium

[J]. J.

15MnVN与16MnR钢焊接接头在湿H2S介质中应力腐蚀破裂敏感性的研究

[J].

Research on influence of marine atmosphere on stress corrosion of TA15 titanium alloy

[J].

海洋大气对TA15钛合金应力腐蚀影响研究

[J].

Properties of passive film formed on CP titanium, Ti-6Al-4V and Ti-13.4Al-29Nb alloys in simulated human body conditions

[J].

Galvanic corrosion of TB5 titanium alloy of anodic oxidation film

[J].

TB5钛合金脉冲阳极氧化膜电偶腐蚀性能研究

[J].

Research on electrochemical corrosion of Ti-Ta alloy in nitric acid

[J].

Ti-Ta合金在硝酸中电化学腐蚀研究

[J].

Preparation and corrosion resistance of Nb2N coating on TC4 Ti-alloy

[J].

Nb2 N涂层制备及其耐腐蚀性能研究

[J].

Effect of Ru on corrosion behavior of Ti-6Al-4V alloy and its mechanism

[J].

Ru对Ti-6Al-4V合金腐蚀行为的影响及机理研究

[J].

In vitro corrosion resistance of Ta2N nanocrystalline coating in simulated body fluids

[J].Due to its combination of outstanding characteristics, such as superior biocompatibility, excellent mechanical properties as well as good corrosion resistance, Ti-6Al-4V alloy has gained much attention as one of the most popular load-bearing biomedical metals in the area of orthopedic and dental. Unfortunately, Ti-6Al-4V alloy suffers from the localized corrosion damage in human body ?uids containing high chloride ion concentrations, which leads to the release of metal ions into the human body. The released ions (e.g., Al and V) are found to not only cause allergic and toxic reactions but also exhibit potential negative effects on osteoblast behavior. To improve the corrosion resistance of Ti-6Al-4V alloy in simulated body ?uids, a 40 μm thick Ta2N nanocrystalline coating with an average grain size of 12.8 nm was engineered onto a Ti-6Al-4V substrate using a double cathode glow discharge technique. The hardness and elastic modulus of the Ta2N coating were determined to be (32.1±1.6) GPa and (294.8±4.2) GPa, respectively, and the adhesion strength of the coating deposited on Ti-6Al-4V substrate was found to be 56 N. There is no evidence of crack formation within the coating under loads ranging from 0.49 N to 9.8 N, implying that the Ta2N nanocrystalline coating has a high contact damage resistance. Moreover, the corrosion resistance of the Ta2N nanocrystalline coating is significantly greater than that of Ti-6Al-4V alloy when tested in naturally aerated Ringer's solution at 37 ℃. This is due to that the passive film developed on the coating has superior compactness compared with that formed on the uncoated Ti-6Al-4V alloy. XPS analysis indicated that at a low polarized potential, the passive film consisted of TaOxNy, which would be converted to Ta2O5 at a higher polarized potential. The analysis of Mott-Schottky curves suggested that the passive film formed on the coating exhibits n-type semiconductor properties and, as such, the density and diffusivity of carrier for the coating was considerably lower than that for the uncoated Ti-6Al-4V alloy.

纳米晶Ta2N涂层在模拟人体环境中的耐蚀性能研究

[J].为了改善植入钛合金材料在人体环境中耐蚀性能,采用双阴极等离子反应溅射沉积方法,在医用Ti-6Al-4V钛合金表面制备了厚度为40 μm、平均晶粒尺寸为12.8 nm的Ta<sub>2</sub>N纳米晶涂层。采用纳米压入仪、Vikers压痕仪和划痕仪考察了Ta<sub>2</sub>N纳米晶涂层的硬度、弹性模量、韧性以及涂层与基体间的结合力。结果表明,Ta<sub>2</sub>N涂层的硬度和弹性模量分别为(32.1±1.6) GPa和(294.8±4.2) GPa,涂层与基体的结合力为56 N;在压入载荷为0.49~9.8 N下,Vikers压痕表面以及横断面均未观察到微裂纹,反映其具有较高的压痕韧性。采用动电位极化、电化学阻抗谱、恒电位极化和电容测量(Mott-Schottky)等多种电化学表征技术,对Ta<sub>2</sub>N涂层在Ringer's生理溶液中的电化学腐蚀行为进行了深入研究,并从钝化膜组成、致密性和半导体特性3个方面探讨了涂层的腐蚀防护机理。结果表明,在Ringer's生理溶液中,Ta<sub>2</sub>N涂层表面形成的钝化膜更加致密,其腐蚀抗力明显优于Ti-6Al-4V合金。XPS分析结果表明,在较低的极化电位下,Ta<sub>2</sub>N涂层的钝化膜主要由TaO<sub>x</sub>N<sub>y</sub>构成,随着外加极化电位的升高,其进一步氧化形成Ta<sub>2</sub>O<sub>5</sub>;电容测试结果表明,Ta<sub>2</sub>N涂层表面所生成的钝化膜具有n型半导体特征,其施主浓度和载流子扩散系数明显低于Ti-6Al-4V 合金表面生成的钝化膜。

Investigation on passivity of titanium under steady-state conditions in acidic solutions

[J].

Electrochemical activation of passivated pure titanium in artificial seawater

[J].

钝性纯Ti在人工海水中的电化学活化行为研究

[J].

Corrosion behavior and passive film characteristics formed on Ti, Ti3SiC2, and Ti4AlN3 in H2SO4 and HCl

[J].

Electrochemical and microstructural studies of tantalum and its oxide films for biomedical applications in endovascular surgery

[J].

Micro-EIS of anodic thin oxide films on titanium for capacitor applications

[J].

Effect of surface state on corrosion resistance of TC4 Ti-alloy

[J].

表面状态对TC4钛合金的耐蚀性影响

[J].

Corrosion behaviour of nanocrystalline 304 stainless steel prepared by equal channel angular pressing

[J].