超级奥氏体不锈钢中均含有很高Mo,可提高不锈钢的抗点蚀、抗晶间腐蚀能力,但是Mo在热加工过程中又极易形成析出相,降低耐蚀性。已有研究表明,低温时效有利于促进Cr向晶界的聚集,若不形成碳化物有利于耐蚀性的提高,即合理的热处理工艺,超奥钢充分的固溶处理有利于使析出相回溶提高耐蚀性,但是低温时效是否会促使Cr、Mo的晶界再分配,这方面在超奥钢中的研究却很少。硼微合金化也可抑制析出相的析出、提高耐蚀性[10-14],为此本文选取Mo较高的系列奥氏体不锈钢316L、904L、S31254、S31254-B,对其固溶处理后试样进行低温时效处理,分析其耐蚀性能,以便研究Mo、B对材料钝化膜结构和耐蚀性能的影响,为苛刻环境使用的超奥钢提供指导。

1 实验方法

实验材料为太原钢铁集团有限公司生产的材质为316L、904L、S31254、S31254-B高Mo超级奥氏体不锈钢热轧钢板,主要化学成分 (质量分数,%) 见表1所示。

表1 4种不锈钢的化学成分

Table 1

| Sample | C | Si | Mn | P | S | Cr | Ni | Mo | Cu | N | B |

|---|---|---|---|---|---|---|---|---|---|---|---|

| S31254-B | 0.014 | 0.84 | 0.98 | 0.012 | 0.001 | 20.23 | 18.05 | 6.23 | 0.85 | 0.242 | 0.004 |

| S31254 | 0.012 | 0.61 | 0.93 | 0.010 | 0.002 | 20.17 | 18.15 | 6.03 | 0.72 | 0.212 | --- |

| 904L | 0.011 | 0.52 | 1.29 | 0.018 | 0.001 | 20.10 | 24.31 | 4.42 | 1.42 | 0.06 | --- |

| 316L | 0.015 | 0.54 | 1.74 | 0.042 | 0.002 | 16.30 | 10.31 | 2.45 | --- | --- | --- |

用线切割机截取试样,尺寸为15 mm×15 mm× 3 mm。热处理前在试样外表面涂抹抗氧化液,防止高温氧化,随后将试样置于KSL-1200X箱式炉中,温度调至1220 ℃固溶处理,保温1 h后淬水冷却;部分固溶处理后试样再进行410 ℃低温时效处理,保温3 h后淬水冷却。热处理后的试样背面焊接导线,用亚克力粉和硬化剂对试样进行冷镶嵌,最后在试样周围涂装一圈硅胶密封,干燥备用。

试样依次采用180、240、400、600、800、1000、1500、2000、3000目SiC砂纸磨平,机械抛光至表面呈镜面,抛光后用蒸馏水冲洗,再用无水乙醇洗净吹干。采用王水化学浸蚀剂,显示出显微组织。利用Vega 3 XMV型扫描电子显微镜 (SEM) 观察显微组织。采用UltimMax170能谱分析仪 (EDS) 分析试样时效处理区晶界区的元素分布。

模拟试样在室温常压下Cl-环境中的腐蚀,使用CS350电化学工作站及配套的CorrTest测试软件对实验数据进行采集。实验介质为10% (质量分数) NaCl溶液,以饱和甘汞电极作为参比电极,铂电极作为对电极,平板腐蚀电解池作为腐蚀实验装置,工作面积为1 cm2。实验前先将试样在溶液中浸泡60 min,测定稳态开路电位,待开路电位稳定后,自开路电位-200 mV以0.5 mV/s的速率进行动电位极化曲线测试,以便分析极化曲线的特征值。使用幅值为10 mV的正弦波作为扰动信号,测试频率范围为105~10-2 Hz,从高频向低频扫描,进行电化学阻抗谱测试,Zview软件进行数据分析,以便分析样品表面钝化膜的电化学行为。每组实验做3组平行实验。用无水乙醇以及丙酮擦净试样表面,观察腐蚀形貌。

2 结果与讨论

2.1 显微组织分析

4种不锈钢在1220 ℃固溶处理1 h水淬后所得固溶态的显微组织如图1所示,均是单一奥氏体组织,均存在大量孪晶,未见明显析出相,316L不锈钢晶粒尺寸相对较小,约在100~150 μm,孪晶最多,904L不锈钢晶粒尺寸、S31254和S31254-B不锈钢晶粒尺寸略微大些,约200 μm左右。

图1

图1

4种不锈钢1220 ℃固溶处理后显微组织

Fig.1

Micrographs of the solution-treated sample of 316L (a), 904L (b), S31254 (c), S31254-B (d) stainless steel

4种不锈钢在1220 ℃固溶处理后并于410 ℃低温时效处理3 h水淬后所得的显微组织如图2所示,均是单一奥氏体组织,仍然存在大量孪晶,较固溶态相比仍然晶界非常清晰,没有看到析出相的存在,晶粒尺寸与固溶组织接近,没有发生太多的变化。

图2

图2

4种不锈钢固溶并410 ℃低温时效处理后显微组织

Fig.2

Micrographs of the aging-treated sample of 316L (a), 904L (b), S31254 (c), S31254-B (d) stainless steel

S31254-B不锈钢经410 ℃低温时效处理后晶界区域能谱分析如图3所示,Cr、Mo等元素在晶界并没有聚集现象,即没有析出相的形成。

图3

图3

S31254-B不锈钢经410 ℃低温时效处理后晶界区域能谱分析

Fig.3

EDS of grain boundary region of S31254-B stainless steel after low temperature aging at 410 ℃

2.2 耐蚀性能分析

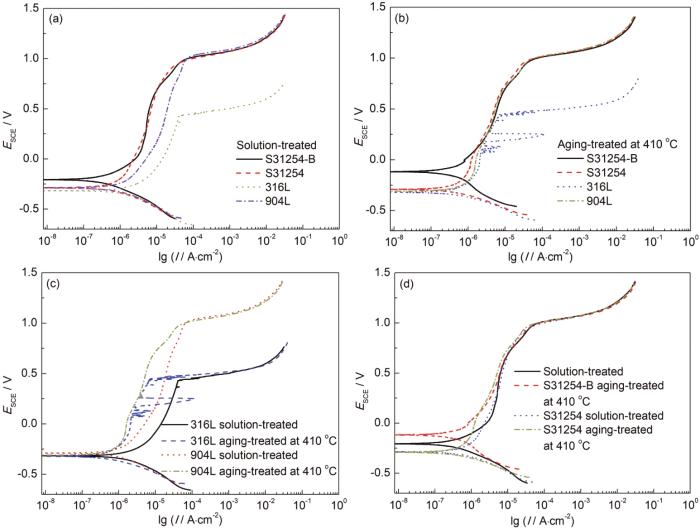

图4

图4

4种不锈钢在10%NaCl溶液中的极化曲线

Fig.4

Potentiodynamic polarization curves of solution-treated sample of 316L, 904L, S31254, S31254-B stainless steel (a), aging-treated at 410 ℃ sample of 316L, 904L, S31254, S31254-B stainless steel (b), solution-treated and aging-treated at 410 ℃ sample of 316L, 904 stainless steel (c), solution-treated and aging-treated at 410 ℃ sample of 31254-B, S31254 stainless steel (d) in 10%NaCl solution

表2 4种不锈钢极化曲线特征值

Table 2

| Heat treatment | Icorr / 107 A·cm-2 | Ecorr / VSCE | Epit / VSCE |

|---|---|---|---|

| Solution-treated of 316L stainless steel | 1.058 | -0.330 | 0.431 |

| Aging-treated at 410 ℃ of 316Lstainless steel | 1.183 | -0.320 | 0.450 |

| Solution-treated of 904L stainless steel | 0.833 | -0.304 | 1.014 |

| Aging-treated at 410 ℃ of 904L stainless steel | 0.877 | -0.319 | 1.028 |

| Solution-treated of S31254 stainless steel | 0.910 | -0.300 | 1.092 |

| Aging-treated at 410 ℃ of S31254 stainless steel | 1.024 | -0.298 | 1.096 |

| Solution-treated of S31254-B stainless steel | 0.617 | -0.212 | 1.125 |

| Aging-treated at 410 ℃ of S31254-B stainless steel | 0.536 | -0.111 | 1.232 |

4种不锈钢的动电位极化曲线具有相同的趋势,均存在明显的钝化区,说明其腐蚀机理基本相同。极化曲线特征值中,自腐蚀电位Ecorr排序:410 ℃低温时效态>固溶态,固溶态S31254-B>S31254>904L>316L,410 ℃低温时效态S31254-B>S31254>904L>316L;点蚀电位Epit排序:410 ℃低温时效态>固溶态,固溶态S31254-B>S31254>904L>316L,410 ℃低温时效态S31254-B>S31254>904L>316L。点蚀电位Epit是电流密度开始随电位增大而快速增大的起始电位,是评价材料点蚀敏感性的重要指标,一般认为点蚀电位越正,材料的耐点蚀性能越好[15]。4种不锈钢的耐点蚀性排序:410 ℃低温时效态>固溶态,S31254-B>S31254>904L>316L。这是由于不锈钢在低温时效处理过程中,由于温度很低,难以形成Cr23C6类型的析出相,但是会使得Cr等在晶界富集,从而提高晶界的抗腐蚀性能[16,17];固溶态基体组织中也没有析出相,同样也具有较好的耐点蚀性能,但是就其晶界来讲,较低温时效处理试样的耐点蚀性能略差。对于316L和904L不锈钢进行对比,Mo含量增加,有利于形成稳定钝化膜,耐蚀性得到提高[15]。对S31254和S31254-B不锈钢进行对比,微量合金元素B的加入可以提高材料的耐点蚀性能,这是由于B可以使得基体组织中的第二相快速溶解并且抑制析出相的生成,从而使得材料获得更稳定且致密的钝化膜[16,17]。

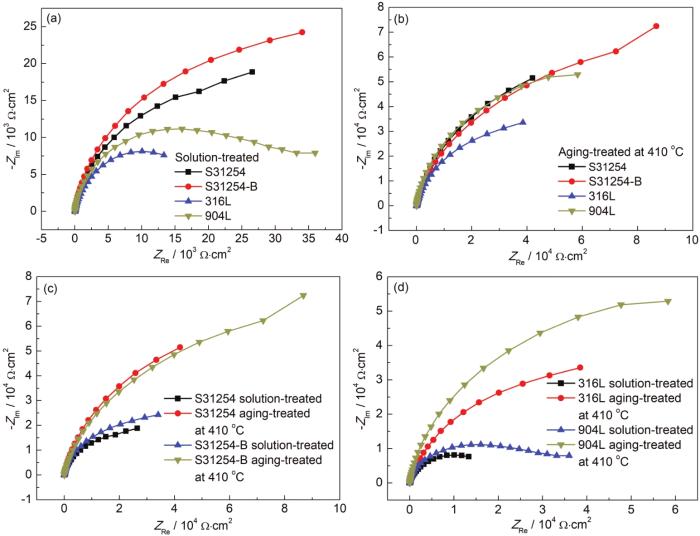

图5

图5

4种不锈钢在10%NaCl溶液中电化学阻抗谱

Fig.5

Impedance spectroscopy of solution-treated sample of 316L, 904L, S31254, S31254-B stainless stain (a), aging-treated at 410 ℃ sample of 316L, 904L, S31254, S31254-B (b), solution-treated and aging-treated at 410 ℃ sample of 31254-B, S31254 (c) and solution-treated and aging-treated at 410 ℃ sample of 316L, 904 stainless steel (d) in 10%NaCl solution

2.3 表面腐蚀形貌分析

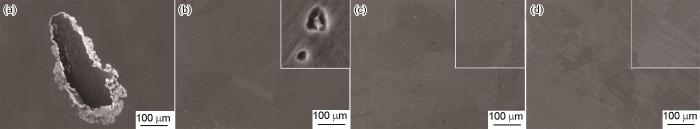

4种不锈钢在1220 ℃固溶处理1 h水淬后试样经电化学腐蚀后的腐蚀形貌如图6所示。316L不锈钢腐蚀坑数量较多,尺寸较大,904L不锈钢有极少量腐蚀坑,S31254不锈钢和S31254-B不锈钢未见明显腐蚀坑。

图6

图6

4种不锈钢固溶处理后动电位极化后表面形貌

Fig.6

Surface corrosion morphologies of the solution-treated sample of 316L (a), 904L (b), S31254 (c), S31254-B (d) stainless steel after potentiodynamic polarization

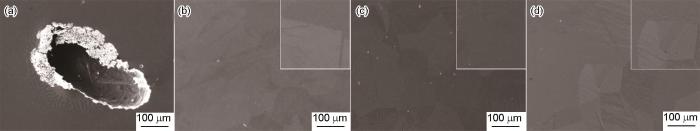

4种不锈钢在1220 ℃固溶处理1 h水淬后并410 ℃低温时效处理3 h水淬后试样经电化学腐蚀后的表面腐蚀形貌如图7所示。316L不锈钢表面点蚀坑数量较多,尺寸较大,其余3种钢未见明显腐蚀坑,但是904L不锈钢有一些非常微小的孔洞,而S31254不锈钢表面非常干净。

图7

图7

4种不锈钢固溶并410 ℃时效后动电位极化后表面形貌

Fig.7

Surface corrosion morphologies of the aging-treated sample of 316L (a), 904L (b), S31254 (c), S31254-B (d) stainless steel after potentiodynamic polarization

2.4 对比分析

4种不锈钢分别经过1220 ℃固溶处理1 h,410 ℃低温时效处理3 h,这两种不同的热处理工艺。410 ℃低温时效态试样的自腐蚀电位、点蚀电位、容抗弧半径均高于固溶态试样,即低温时效态耐蚀性明显高于固溶态。

3 结论

(1) 316L、904L、S31254、S31254-B 4种高钼超级奥氏体不锈钢固溶后显微组织为单一奥氏体组织,且孪晶数量很多,经410 ℃低温时效处理后,有利于改善耐蚀性,晶界仍无析出相的析出。

(2) 316L、904L、S31254、S31254-B 4种高钼超级奥氏体不锈钢耐10%NaCl溶液腐蚀的顺序:316L<904L<S31254<S31254-B。

(3) 在奥氏体不锈钢中,增加Mo含量、加入微量B,均可促使奥氏体不锈钢表面形成富Cr、Mo氧化物,且钝化膜更加致密,耐点蚀性提高。微量合金元素B还可以抑制析出相的生成,从而使得材料具有更稳定、致密的钝化膜,提高了不锈钢材料整体的耐点蚀性能。

参考文献

Experience in effective application of metallic materials for construction of FGD systems

[R].

High specialty stainless steels and nickel alloys for FGD dampers

[R].

RETRACTED: Future sustainable water desalination technologies for the Saudi Arabia: A review

[J].

Selection of engineering material of distillation of seallater with low temperature and multi-effect function

[J].

低温多效海水淡化工程材料的选用

[J].

Analyses and protection of seawater cooling system in offshore oil platform

[J].

某石油平台海水冷却系统腐蚀分析与防护方法

[J].

Pitting corrosion of several super stainless steels in a simulated water environment of low temperature multi effect desalination unit

[J].

几种超级不锈钢在模拟低温多效海水淡化环境中的点蚀行为研究

[J].

Corrosion behavior of several metal materials in blast furnace gas condensates

[J].

几种金属材料在高炉煤气管道冷凝液中的电化学腐蚀行为

[J].

Electrochemical studies of 254SMO stainless steel in comparison with 316L stainless steel and Hastelloy C276 in phosphoric acid media in absence and presence of chloride ions

[J].

Effects of Mo addition and austenitizing temperature on hardenability of low alloy B-added steels

[J].

A grain boundary characterization study of boron segregation and carbide precipitation in alloy 304 austenitic stainless steel

[J].

Comparison of SCC behavior of 304L stainless steels with and without boron addition in acidic chloride environment

[J].

Effects of boron on microstructure and metastable pitting corrosion behavior of Super304H austenitic stainless steel

[J].

Effect of Ni and B on the hot workability of high Mo austenitic stainless steels

[J].

Microstructural evolution and pitting corrosion behavior of friction stir welded joint of high nitrogen stainless steel

[J].

Intergranular corrosion behavior of low-chromium ferritic stainless steel without Cr-carbide precipitation after aging

[J].

Corrosion resistance and passivation behavior of B-containing S31254 stainless steel in a low pH medium

[J].

Corrosion behavior of 904L austenitic stainless steel in hydrofluoric acid

[J].

Influence of pH on the passivation behavior of 254SMO stainless steel in 3.5%NaCl solution

[J].

Electrochemical characterisation of a martensitic stainless steel in a neutral chloride solution

[J].

Characterization of passive film on 2205 duplex stainless steel in sodium thiosulphate solution

[J].

Influence of pH on the passivation behaviour of 904L stainless steel bipolar plates for proton exchange membrane fuel cells

[J].

Corrosion behavior of four corrosion-resistant alloys in ultra-supercritical boiler flue gas condensate

[J].

4种耐蚀合金在超超临界锅炉烟气冷凝液中的腐蚀行为研究

[J].

Pitting Behavior of two stainless steels in simulated heavy water reactor primary solution and 3.5%NaCl solution

[J].

两种不锈钢在模拟重水堆一回路溶液和

Effect of sensitization treatment on electrochemical corrosion and pitting corrosion properties of 00Cr21NiMn5Mo2N stainless steel

[J].

敏化处理对00Cr21NiMn5Mo2N节镍型双相不锈钢堆焊层电化学腐蚀与点蚀性能的影响

[J].