1 实验方法

本文所用试样为X65管线钢,化学成分 (质量分数,%) 为:C 0.03,Si 0.17,Mn 1.51,P 0.02,Ni 0.17,Cu 0.04,Mo 0.16,Nb 0.06,Al 0.02,Ti 0.01,Fe余量。将10 mm×10 mm×3 mm尺寸的试样用铜导线焊接,再用环氧树脂密封,只保留10 mm×10 mm工作面。依次用400#、800#、1000#、2000#的SiC砂纸对试样的每个工作面进行打磨,再用无水乙醇清洗,干燥。使用前在紫外灯下照射试样30 min灭菌。

所用培养基用青岛小麦岛附近天然陈化海水配置,成分 (g/L) 为:K2HPO4 0.5,MgSO4·7H2O 0.5,NaNO3 0.5,(NH4)2SO4 0.5,CaCl2 0.2,柠檬酸铁铵10。全培养基用于IOB培养与计数,细菌计数采用最大可能数法 (MPN)。

为减小培养基成分对腐蚀的影响,用陈化海水将培养基稀释20倍,得到实验用腐蚀介质。培养基与腐蚀介质均用2 mol/L的NaOH调节pH至8.1±0.1,并用高压蒸汽灭菌锅高温121 ℃下灭菌20 min。实验前,向灭菌后的培养基中接种铁氧化菌,在恒温培养箱 (30 ℃) 中培养5 d,按1∶100体积比接种到腐蚀体系中进行实验,实验温度用恒温水浴锅控制在(25±1) ℃。

电化学测试采用三电极体系,工作电极为X65钢,辅助电极为钛基底贵金属氧化物电极,参比电极为饱和甘汞电极 (SCE)。采用Gamry Reference 600工作站进行相关电化学测试。在测试前1 h断开极化电位,等待体系开路电位 (OCP) 稳定后进行测试。测试参数:在开路电位下施加电压扰动信号幅值10 mV,扫描频率范围为105~10-2 Hz。

浸泡7 d后,从腐蚀体系中取出试样,用5 mL注射器吸取灭菌冷却后的磷酸盐pH缓冲溶液,轻轻冲洗表面3次以除去剩余的培养基和浮游细菌,放入5%戊二醛固定液中固定2 h,依次用10%、30%、50%、70%、90%、95%无水乙醇脱水10 min,再放入100%无水乙醇中脱水20 min,用于扫描电子显微镜 (SEM,ZEISS-Gemini 300) 观察。

用蒸馏水清洗干净待测试样表面,用无水乙醇浸泡3分钟以出去表面残余的水,干燥后用于表面拉曼测试 (Thermo Fisher Scientific-DXR Microscope)。

用蒸馏水冲洗掉表面残留溶液,然后用除锈液 (20 g六次甲基四胺溶于1 L 1∶1 (V/V) 的盐酸中) 浸泡3 min,取出后再用蒸馏水冲洗干净,放入无水乙醇中浸泡5 min后干燥,用于激光共聚焦显微镜 (Keyence- VK-X200) 观察。

2 结果与讨论

2.1 IOB生长情况

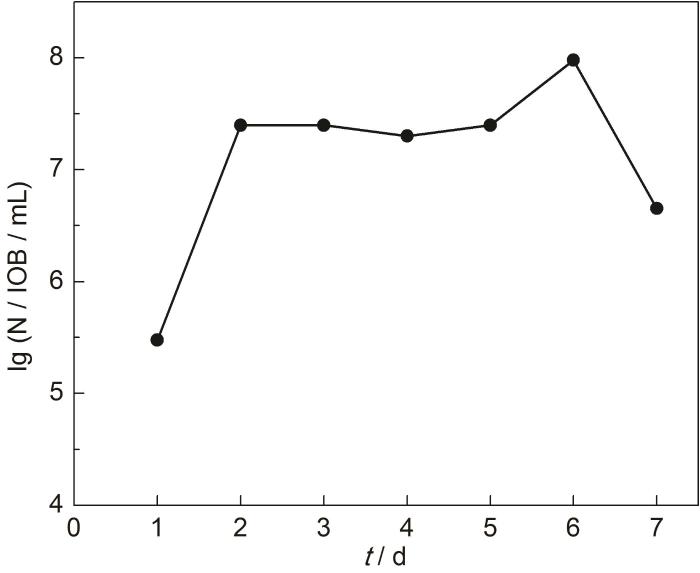

IOB在pH为8.1的海水中生长曲线如图1所示。看出,1~2 d时IOB迅速生长,为对数生长期,之后进入稳定期,数量较为稳定。6 d后由于营养物质消耗,数量有所减少。

图1

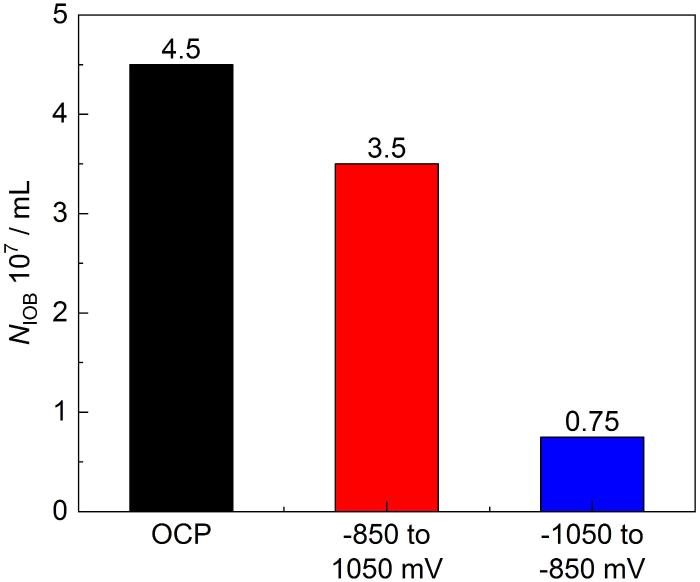

图2为3 d时不同电位条件下溶液中IOB数量。可以看到,随着初始电位的负移,IOB数量有所减少。-850转-1050 mV极化下IOB数量相差不大,说明-850 mV极化对IOB的抑制效果较弱,IOB仍能在电极表面附着并形成生物膜。而-1050 mV转-850 mV极化明显抑制了IOB的数量。

图2

图2

不同阴极电位下3 d时溶液中IOB数量

Fig.2

Amount of IOB in the solution after 3 d at different cathodic potentials

2.2 表面形貌与成分分析

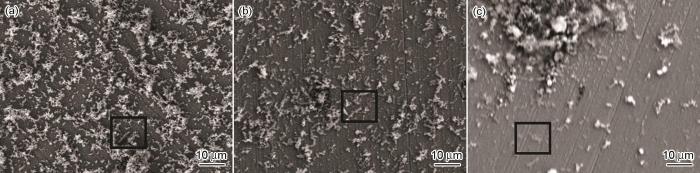

图3为开路电位和-850 mV转-1050 mV、-1050 mV转-850 mV两种组合极化电位下,X65钢浸泡7 d时的表面形貌图。可以看到,3种条件下腐蚀产物都未完全覆盖试样表面。在开路电位条件下,试样表面十分杂乱,附着有细菌和大量疏松的腐蚀产物。-850 mV转-1050 mV条件下,腐蚀产物虽然有所减少,但仍能观察到较明显的点蚀痕迹。-1050 mV转-850 mV条件下,试样表面附着的腐蚀产物较少且致密,没有发现明显的杆状细菌。这可能是由于-850 mV极化对IOB的抑制较小,前3 d时IOB在试样表面附着并形成生物膜。后4 d施加的-1050 mV极化不能完全去除已形成的生物膜,同时,大量的腐蚀产物造成电极表面电位分布不均,更减弱了阴极极化的抑菌效果。先施加-1050 mV极化时,不仅抑制了IOB的附着,还大量杀死了处于对数生长期的细菌,抑制了体系中IOB数量的增长,大大减轻了IOB造成的腐蚀;再施加-850 mV极化,由于体系中IOB数量较少,对腐蚀的促进不明显。

图3

图3

不同组合电位下浸泡7 d后X65钢表面形貌图

Fig.3

Surface morphologies of X65 steel after immersion for 7 d under different combined potentials: (a) OCP, (b) -850 mV to -1050 mV polarization, (c) -1050 mV to -850 mV polarization

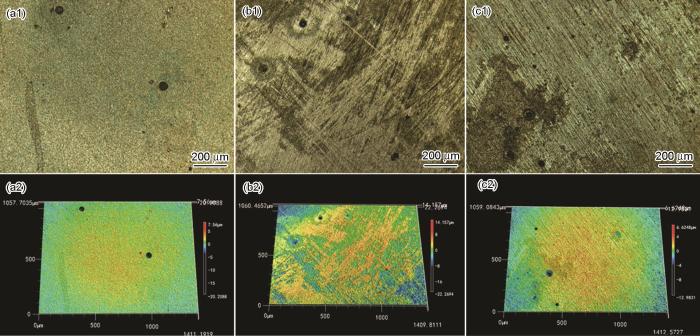

去除腐蚀产物后,利用激光共聚焦显微镜观察试样基底,如图4所示。可以看到,3种条件下,试样表面都出现了明显的蚀坑。阴极极化的施加使蚀坑深度明显减少。-1050 mV转-850 mV条件下,试样基底表面较为光滑,还能看到打磨的痕迹,坑深也显著低于-850 mV转-1050 mV。说明两组组合电位极化对IOB腐蚀都有一定抑制作用,而-1050 mV转-850 mV极化保护效果优于-850 mV转-1050 mV,与SEM观察结果相符。

图4

图4

不同阴极电位下极化7 d后去除试样表面腐蚀产物后基底形貌

Fig.4

Surface morphologies of X65 steel after removing corrosion products formed during polarization for 7 d at diff-erent cathodic potentials: (a) OCP, (b) -850 to -1050 mV, (c) -1050 to -850 mV

表1 X65钢在不同阴极电位下极化7 d后去除腐蚀产物的激光共聚焦显微镜测量数据

Table 1

| Condition | Npit / 1/mm2 | davg / μm | dmax / μm | Davg / μm |

|---|---|---|---|---|

| OCP | 45.25 | -1.56 | -12.85 | 24.92 |

| -850 to -1050 mV | 27.50 | -1.47 | -8.82 | 21.07 |

| -1050 to -850 mV | 11.75 | -1.48 | -4.77 | 20.47 |

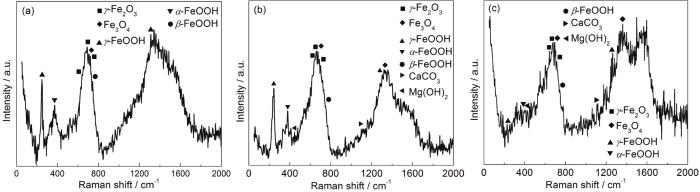

图5

图5

不同阴极电位下极化7 d后X65钢表面Raman谱图

Fig.5

Raman spectra of X65 steel after polarization for 7 d at different cathodic potentials: (a) OCP, (b) -850 to -1050 mV, (c) -1050 to -850 mV

2.3 电化学特征

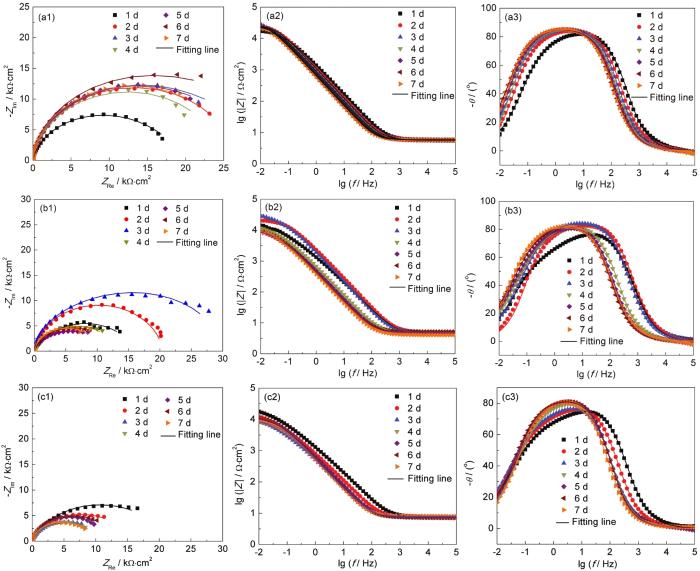

图6

图6

不同阴极电位下极化不同时间后X65钢的电化学阻抗图

Fig.6

EIS of X65 steel after polarization for different time under different cathodic polarization potentials: (a1~a3) OCP, (b1~b3) -850 to -1050 mV, (c1~c3) -1050 to -850 mV

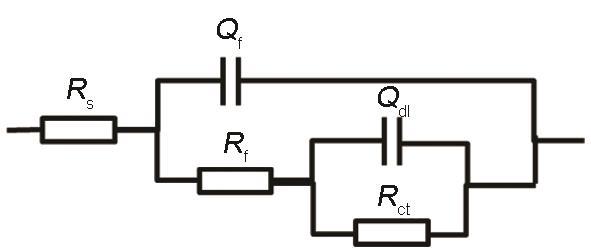

图7

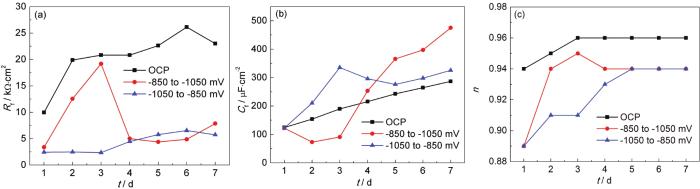

图8

图8

电化学阻抗谱拟合参数随时间变化曲线

Fig.8

Time dependences of fitting parameters of EIS: (a) Rf, (b) Cf ,

在图8b和c中,开路电位下,由于IOB在电极表面附着,生物膜面积不断增大,n和Cf不断增大。在-850转-1050 mV极化下,3 d后由于电位变负,电极表面生物膜被部分破坏,膜层变薄且不完整,Cf迅速增大,n减小。而在-1050转-850 mV极化下,3~5 d时由于电位变正,IOB受到的抑制减弱,生物膜逐渐变厚,Cf逐渐减小。但电化学测试结果不能表征试样的点蚀。

结合试样表面形貌和成分分析结果,在开路电位下,试样表面有细菌附着,腐蚀严重且有明显的坑蚀,产物成分主要为FeOOH、Fe2O3、Fe3O4,为粘附腐蚀产物的生物膜,生物膜的存在使Rf较大,但保护作用较弱。在极化条件下,特别是-1050转-850 mV极化下,试样表面细菌数量明显减少,产物膜中α-FeOOH明显含量下降,并有少量CaCO3和Mg(OH)2生成,说明生物膜的生长受到抑制,钙镁沉积层逐渐形成,由于钙镁沉积层未完全覆盖表面导致Rf小于开路电位条件下,但保护效果较好,抑制了点蚀的发生。

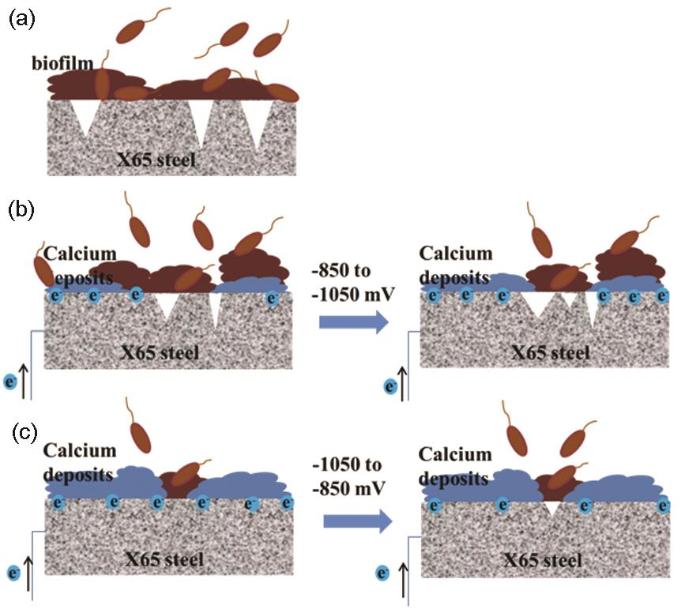

不同阴极电位下电极表面状态如图9所示。在开路电位下,IOB迅速在电极表面附着成膜,诱发点蚀[28]。在-850 mV转-1050 mV极化下,如图9b,-850 mV极化对IOB抑制效果较弱,生成的少量钙质沉积层也不能起到良好的保护作用,电极表面有点蚀发生。当电位负移后,-1050 mV部分破坏了已形成的生物膜,但并未完全去除,仍附着的IOB继续促进点蚀的发生[29,30]。而在图9c中,先施加的-1050 mV极化较好的抑制了IOB的生长与附着,电极表面只有少量IOB附着,生成的钙镁沉积层具有一定的保护作用。当电位正移后,溶液中的IOB数量较少,同时,已形成的钙镁沉积层阻碍了IOB与试样直接接触,所以试样腐蚀较轻。

图9

图9

不同阴极电位下X65钢表面状态图

Fig.9

Surface state diagrams of X65 steel under different cathodic polarization potentials: (a) OCP, (b) -850 mV to -1050 mV, (c) -1050 mV to -850 mV

3 结论

(1) 两种组合电位阴极极化都对IOB腐蚀有抑制作用,X65钢表面仍有点蚀发生。

(2) 极化与开路电位条件下X65钢试样表面腐蚀产物种类基本相同,但极化条件下试样表面有CaCO3和Mg(OH)2生成。

(3) -1050 mV转-850 mV极化组合电位的保护效果要优于-850 mV转-1050 mV极化,这可能是由于前期施加-1050 mV极化可以有效抑制IOB的附着与生长,从而抑制了IOB腐蚀的发生。但后期施加的-1050 mV极化不能完全去除已形成的生物膜,不均匀的生物膜导致电极界面电位分布不均,IOB仍能在电极表面电位较正处生长,从而促进腐蚀。

参考文献

Study on constitutive relation and failure criteria of X65 pipeline steel

[J].

X65管线钢的本构关系及失效判据研究

[J].

Microbiologically influenced corrosion of pipeline steels

[J]. J.

管线钢的微生物腐蚀

[J].

Neutrophilic iron-oxidizing “Zetaproteobacteria” and mild steel corrosion in nearshore marine environments

[J].

In situ microbial community succession on mild steel in estuarine and marine environments: Exploring the role of iron-oxidizing bacteria

[J].

Corrosion behavior of carbon steel in the presence of sulfate reducing bacteria and iron oxidizing bacteria cultured in oilfield produced water

[J].

Study of biofilm influenced corrosion on cast iron pipes in reclaimed water

[J].

Mechanism of microbiologically influenced corrosion of X65 steel in seawater containing sulfate-reducing bacteria and iron-oxidizing bacteria

[J].

Isolation and characterization of novel iron-oxidizing bacteria that grow at circumneutral pH

[J].

Kinetics and product of ferrous iron oxygenation in aqueous systems

[J].

Characterization of a neutrophilic, chemolithoautotrophic Fe(II)-oxidizing β-proteobacterium from freshwater wetland sediments

[J].

Pitting corrosion of carbon steel caused by iron bacteria

[J].

Electrochemical behaviour of stainless steels in media containing iron-oxidizing bacteria (IOB) by corrosion process modeling

[J].

De-alloying of 316 stainless steel in the presence of a mixture of metal-oxidizing bacteria

[J].

Iron biomineralization by anaerobic neutrophilic iron-oxidizing bacteria

[J].

The corrosion behavior and mechanism of X65 steel induced by iron-oxidizing bacteria in the seawater environment

[J].

Corrosion of carbon steel C1010 in the presence of iron oxidizing bacteria Acidithiobacillus ferrooxidans

[J].

Corrosion behavior of L245 pipeline steel in shale gas fracturing produced water containing iron bacteria

[J]. J.

铁细菌对L245钢腐蚀行为的影响研究

[J].

Corrosion behavior of X80 pipeline steel in oil-field produced water containing iron oxidizing bacteria

[J].

铁氧化菌对X80管线钢腐蚀行为的影响

[J].

Cathodic protection of XL 52 steel under the influence of sulfate reducing bacteria

[J].

Influence of sulfate-reducing bacteria on the corrosion behavior of high strength steel EQ70 under cathodic polarization

[J].

Effects of SRB on cathodic protection of Q235 steel in soils

[J].

Surface conditions for microcosm development and proliferation of SRB on steel with cathodic corrosion protection

[J].

Effect of cathodic polarization on corrosion behavior of X65 steel in seawater containing iron-oxidizing bacteria

[J].

Research progress of corrosion of steels induced by iron oxidizing bacteria

[J]. J.

铁氧化菌引起的钢铁材料腐蚀研究进展

[J].

Electrochemical formation and transformation of corrosion products on carbon steel under cathodic protection in seawater

[J].

Influence of bacteria on film formation inhibiting corrosion

[J].

Research on corrosion behavior of Q235 steel in marine iron-oxidizing bacteria

[J].

Q235钢在海洋铁细菌作用下的腐蚀行为研究

[J].

Effect of cathodic polarization on microbial film in seawater environment

[J].

阴极极化对金属电极表面微生物膜的影响

[J].

Investigating electrochemical removal of bacterial biofilms from stainless steel substrates

[J].